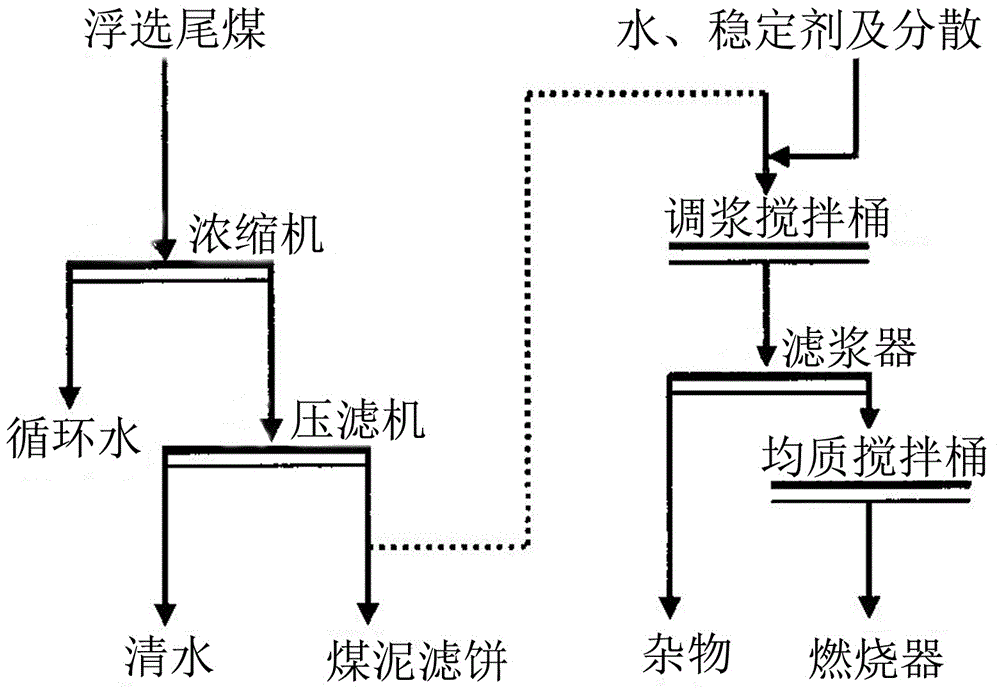

Process for directly preparing coal water slurry from underflow of concentrator of coal preparation plant

A technology of coal-water slurry and thickener, which is applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc., can solve problems such as difficulties, insufficient use of flocculant in the thickener, and land-occupying environment, so as to improve uniformity and stability High adaptability, strong adaptability of production process, and the effect of eliminating agglomeration and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Taking the thickener underflow of a certain coal preparation plant of Shenhua Group as an example to further describe the present invention:

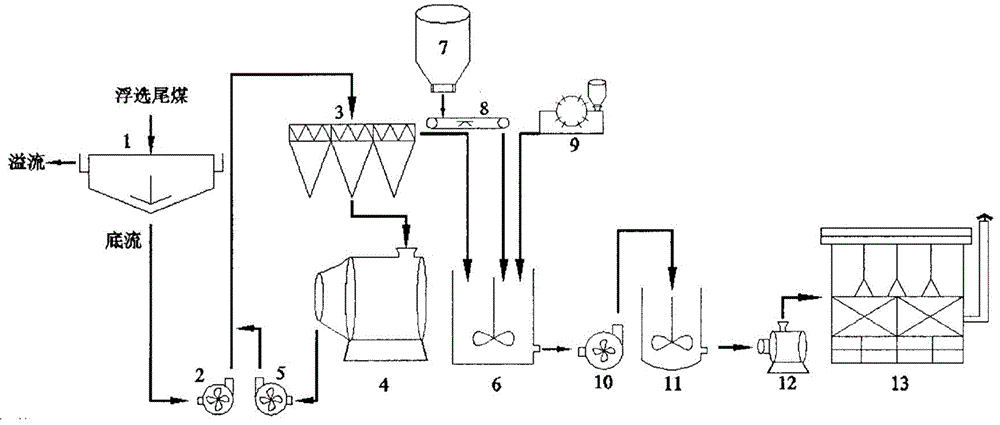

[0024] The flotation tailings of a coal preparation plant of Shenhua Group belong to low-ash slime, with an ash content of about 30% and a calorific value of 13.5MJ / kg. After the flotation tailings of the coal preparation plant are concentrated by the concentrator 1, the overflow is returned to the circulating water system of the coal preparation plant for use. 82% of the amount) is directly sent to the hydrocyclone group 3 through the slurry pump I2 for high-efficiency classification. After grading treatment, the qualified materials with a particle size of less than 75 μm in the hydrocyclone group 3 (accounting for about 82% of the total solids, assuming that the underflow of the concentrator is completely classified) enter the coal slurry mixing tank 6 directly from the overflow port, while the particle size is greater than Th...

Embodiment 2

[0030] Taking the thickener underflow of a coal preparation plant of Henan Energy and Chemical Industry Group as an example, the present invention is further described:

[0031] The flotation tailings of a coal preparation plant of Henan Energy and Chemical Industry Group belong to medium ash slime, with an ash content of about 40% and a calorific value of 12.1MJ / kg. After the flotation tailings of the coal preparation plant are concentrated by the thickener 1, the overflow is returned to the circulating water system of the coal preparation plant for use. 78% of the amount) is directly sent to the hydrocyclone group 3 through the slurry pump I2 for high-efficiency classification. After grading treatment, the qualified materials with a particle size of less than 75 μm in the hydrocyclone group 3 (accounting for about 78% of the total solids, assuming that the underflow of the concentrator is completely classified) enter the coal slurry mixing tank 6 directly from the overflow p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com