Patents

Literature

247 results about "Coal oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal oil is a shale oil obtained from the destructive distillation of cannel coal, mineral wax, or bituminous shale, once used widely for illumination. Chemically similar to the more refined, petroleum-derived kerosene, it consists mainly of several hydrocarbons of the alkane series, with 10 to 16 carbon atoms in each molecule, with a boiling point of 175°C to 325°C, higher than gasoline or the petroleum ethers, and lower than the oils.

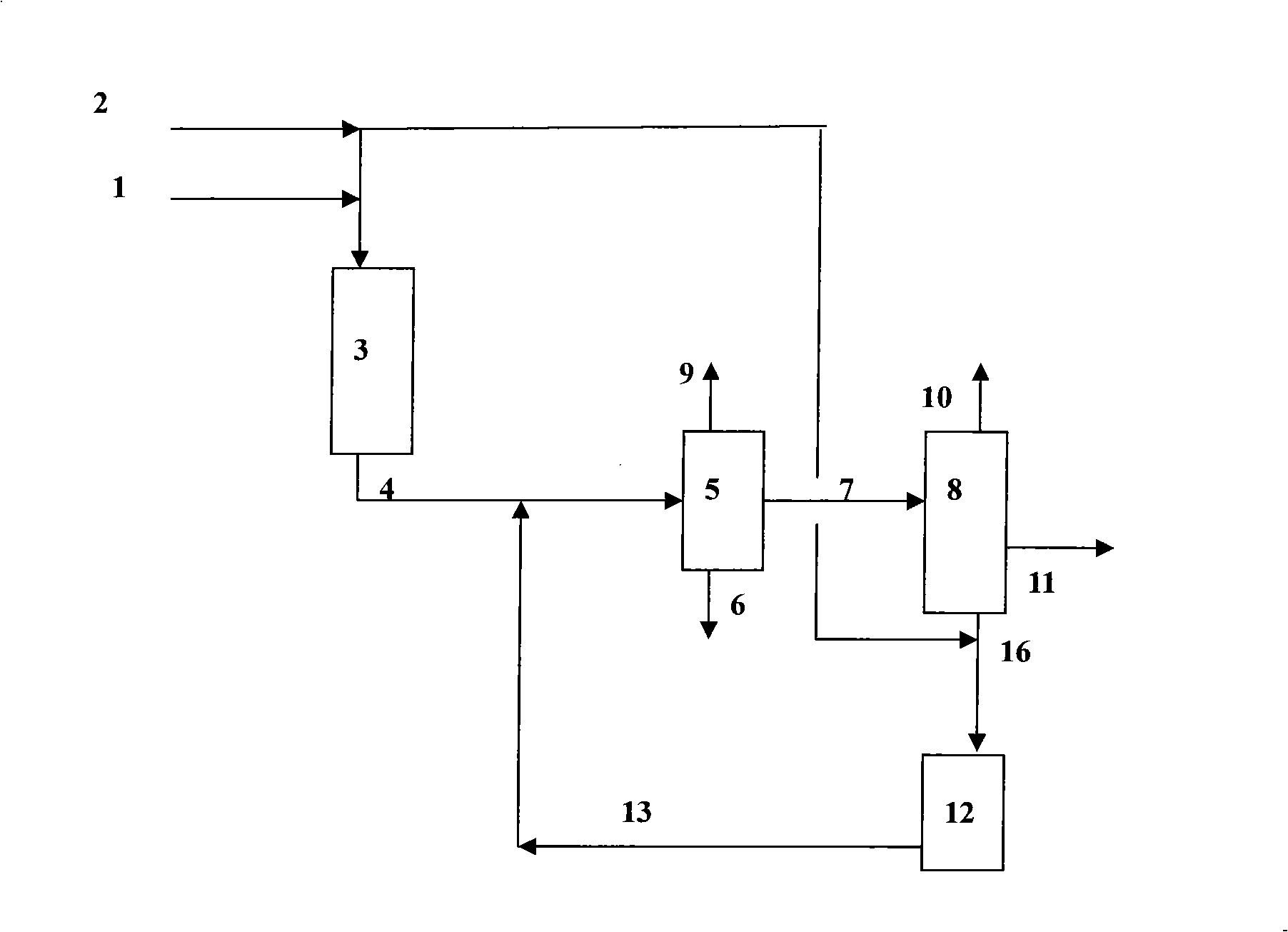

Coal tar whole fraction hydrotreatment process

ActiveCN1766058AImprove operating conditionsSimple processTreatment with hydrotreatment processesFixed bedGasoline

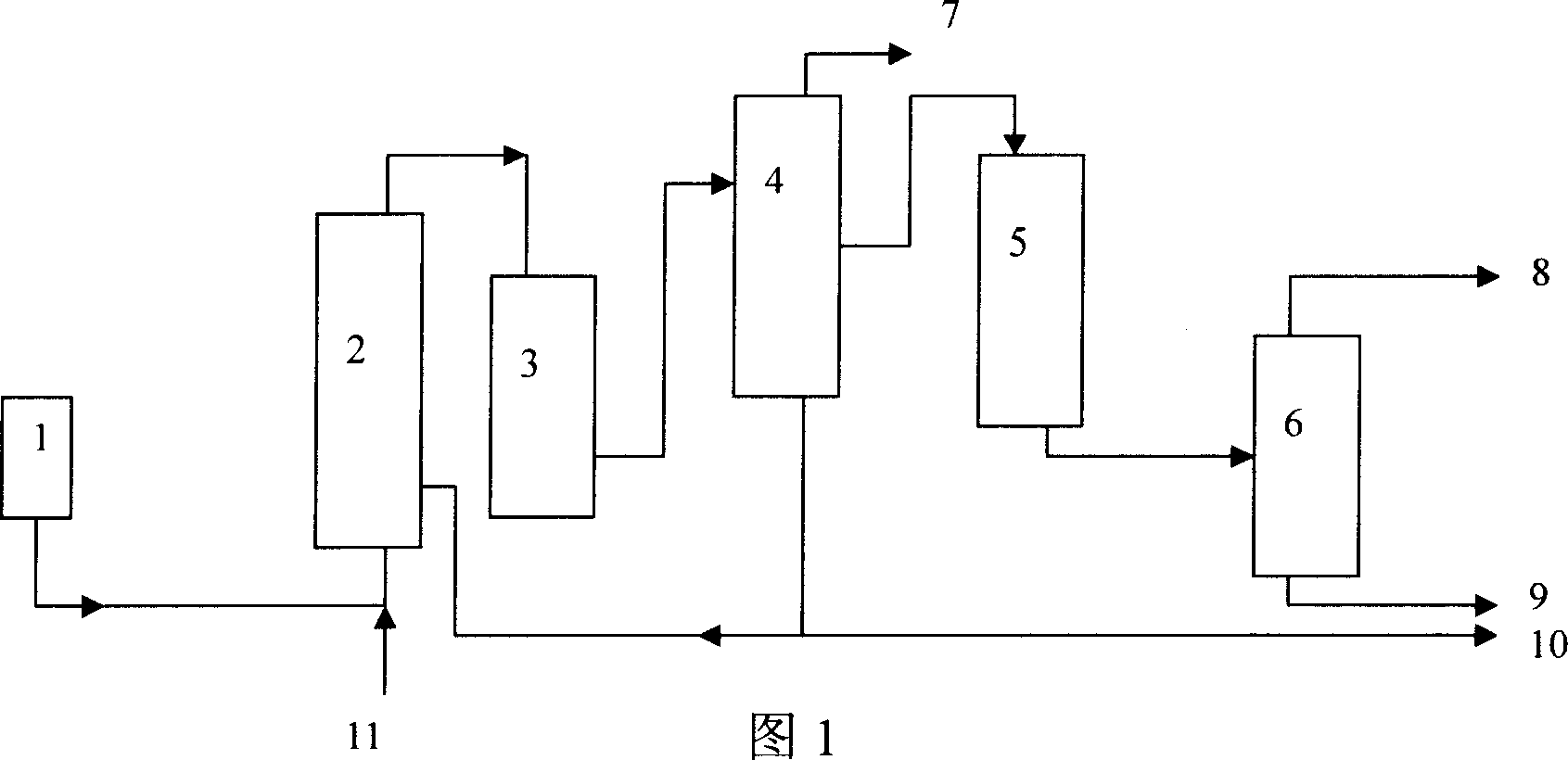

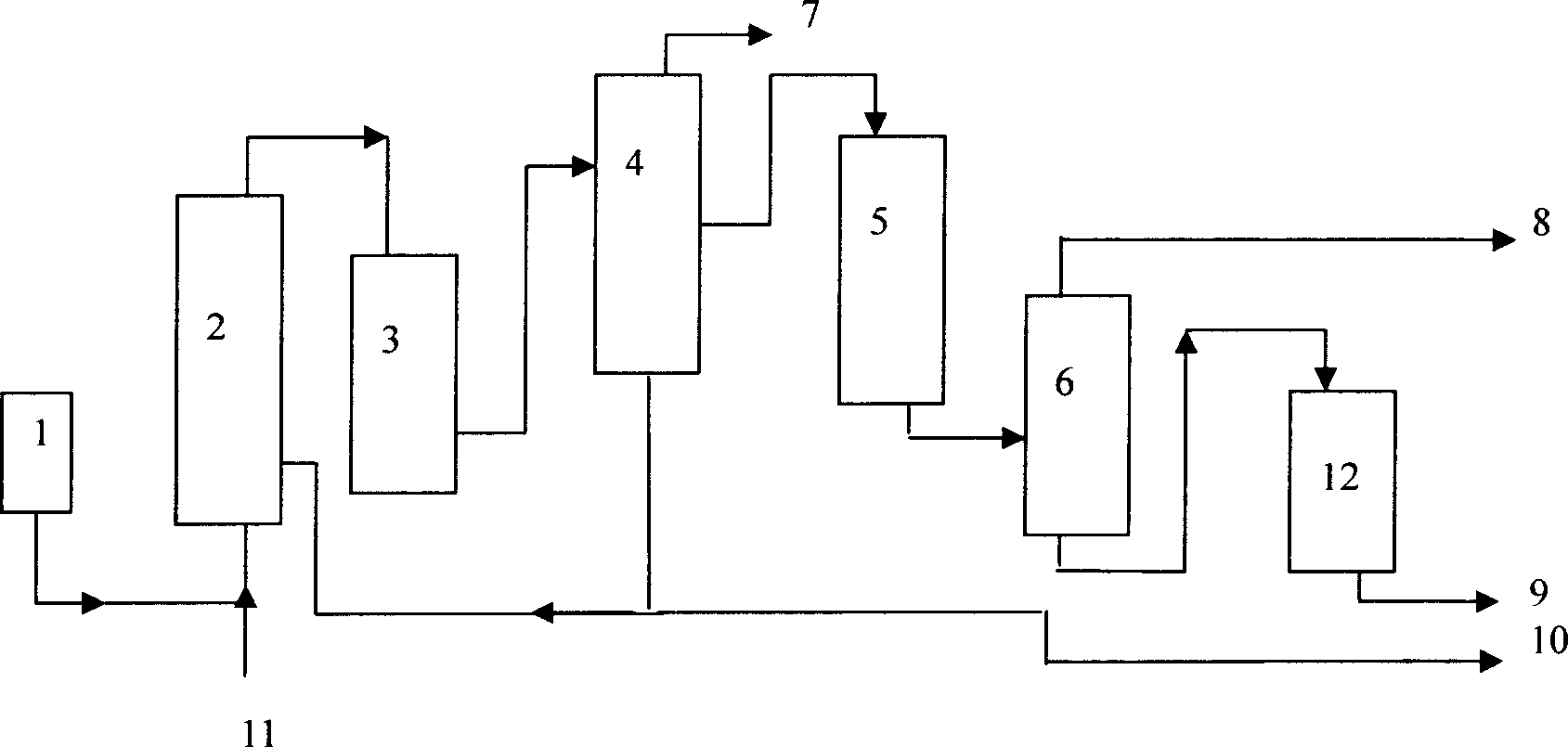

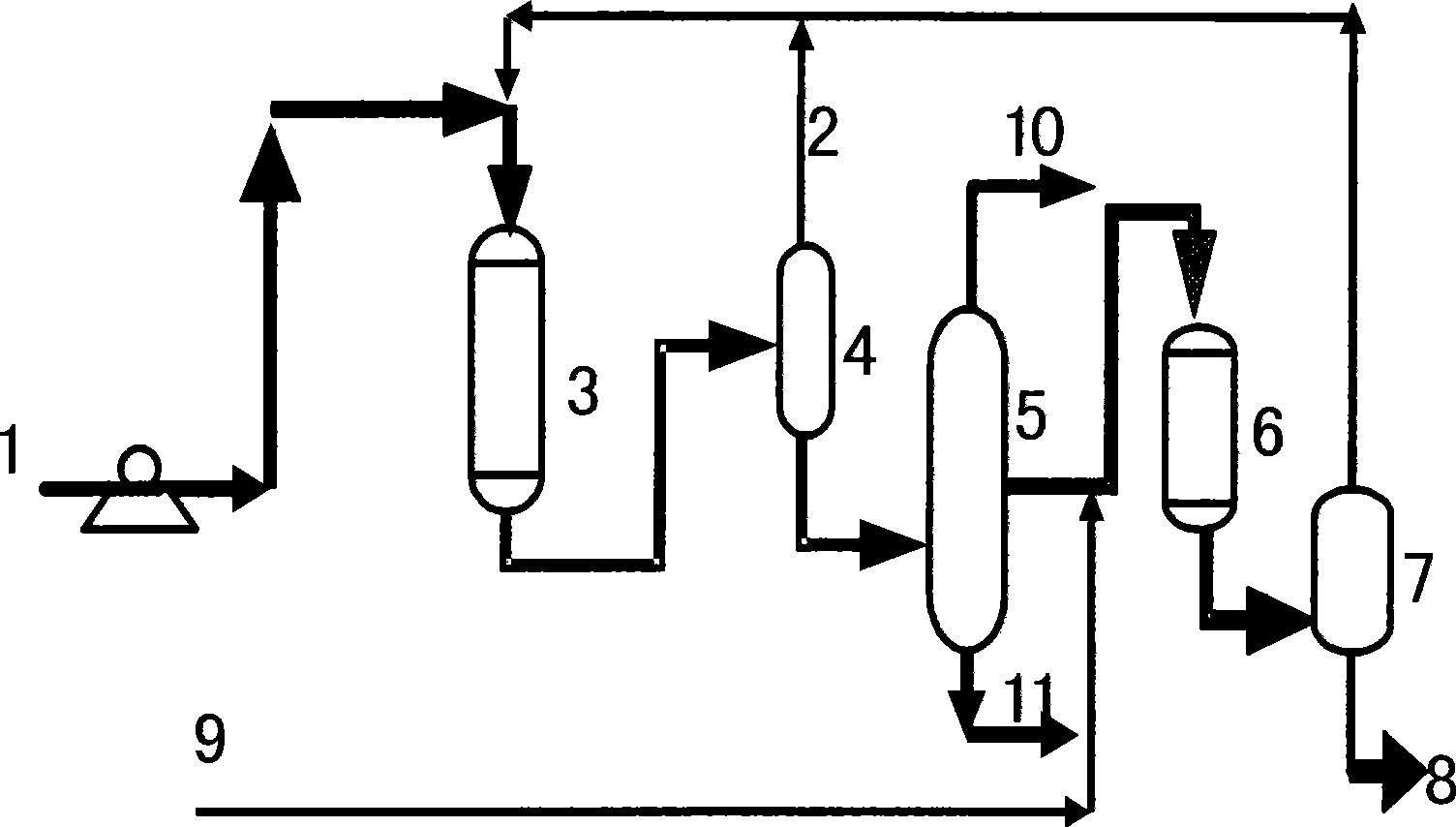

The invention discloses a hydrocracking treatment technique for coal tar total distillate, which comprises: first mixing with homogeneous catalyst, or adding impurity, gum, asphaltene and coal oil total distillate contained much oxygen element directly into suspended-bed hydrogenation device; cutting the stream with distilling plant to discharge water, distillate less than 370Deg that enters fixed bed reactor for hydrorefining reaction to cut gasolene less than 150Deg and diesel oil 150-370Deg, and tail oil less than 370Deg that recycles to said reactor and converts into light oil product. Compared with prior art, this invention is simple, but high conversion rate and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Coal slime flotation collector and preparation method thereof

The invention discloses a coal slime flotation collector and a preparation method thereof. The coal slime flotation collector comprises the following matters in percentage by weight: 20-50 percent of kerosene and / or light diesel oil, 1-5 percent of primary emulsion, 0.006-0.015 percent of auxiliary emulsion and the balance of water; wherein the primary emulsion is a mixture of polyoxyethylene sorbitan fatty acid ester and dehydrated sorbitol fatty acid ester, and the hydrophile-lipophile balance (HLB) value of the primary emulsion is within 12.8-14.3; the auxiliary emulsion is selected from the following (1) or (2), wherein the (1) is sodium dodecyl benzene sulfonate, and the (2) is a mixture obtained by mixing fatty alcohol polyoxyethylene ether sulfate and the sodium dodecyl benzene sulfonate according to the mass ratio of 1: 0.5-2. The coal slime flotation collector has good stability, simple preparation process and 40-60 percent of the oil-saving ratio on the premise of improving the float yield and the tail coal ash proportion. The collector is beneficial to saving the energy, reducing the emission and improving the economical benefit when being used for floating the coal slime.

Owner:SHANXI MEDICAL UNIV

Coal tar hydrocracking method

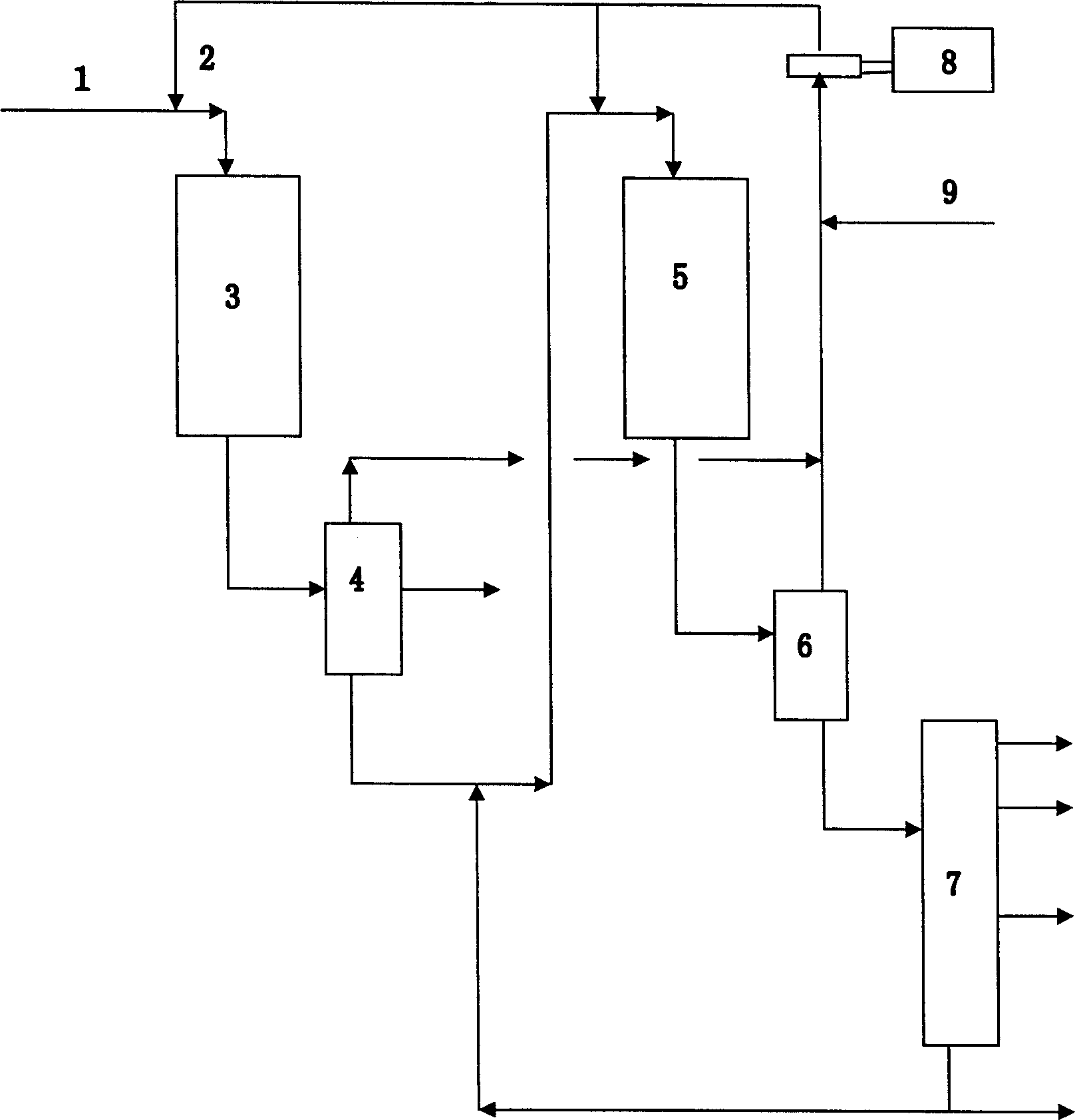

InactiveCN1876767AExtended service lifeImprove natureTreatment with hydrotreatment processesHigh pressureChemistry

The invention discloses the coal oil hydrocracking method. The method comprises the following steps: mixing the coal oil and hydrogen gas, adding them into hydrogenation reaction chamber, getting the generating oil, putting the generating oil into heat-high pressure separator, getting light-end products and water from upper logistics, putting lower logistics and hydrogen gas into hydrocracker reaction chamber, getting hydrocracking product, putting the product into high pressure separator, getting hydrogen gas to be used again, and putting the liquid into fractionating tower to get gas, petrol, diesel, light-end products and tail oil. The invention uses low grade coal oil to produce premium grade gasoline and diesel.

Owner:胜帮科技股份有限公司

Coking inhibitor and preparation method and application thereof

InactiveCN101037618AImprove performanceImprove hydrogen supply capacityTreatment apparatus corrosion/fouling inhibitionHydrocarbon mixturesBoiling point

The invention discloses a agglomerating inhibiting agent, preparing method and application thereof. The agglomerating inhibiting agent is selected from one or more hydrogenizating upgrading products of hydrocarbon mixture of coal oil, ethylene tar oil, catalytic crackingre cycle stock, catalytic crackingre slurry oil, catalytic crackingre heavy oil, catalytic crackingre extract oil and coking hydrowax, which contain 65-100 wt% of cyclane and arene, boilingpoint is 150 DEG C to 500 DEG C. The agglomerating inhibiting agent is used for preventing, slowing and removing agglomerating of apparatus and pipilines in process of petroleum refining and petrochemical processing.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

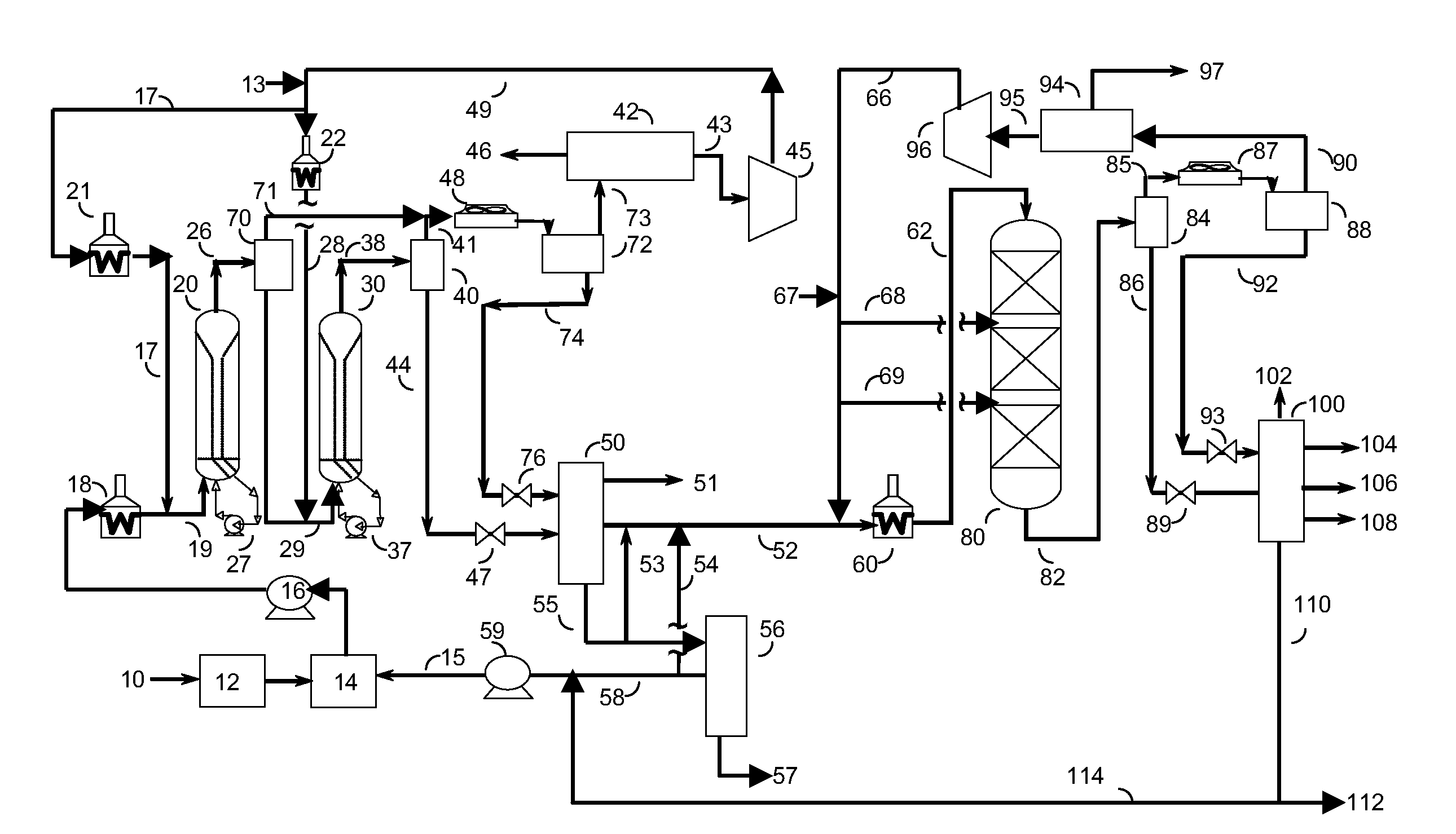

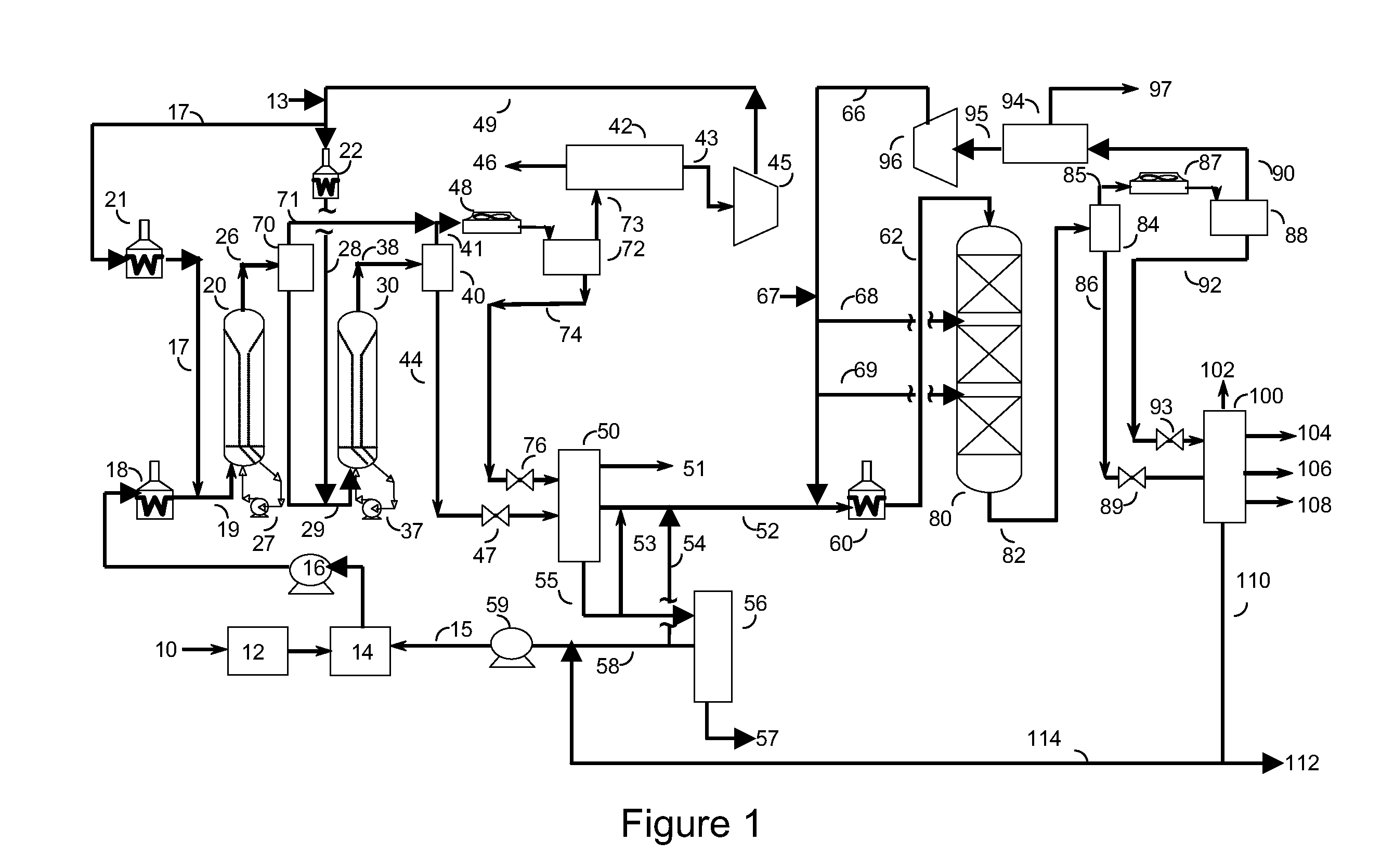

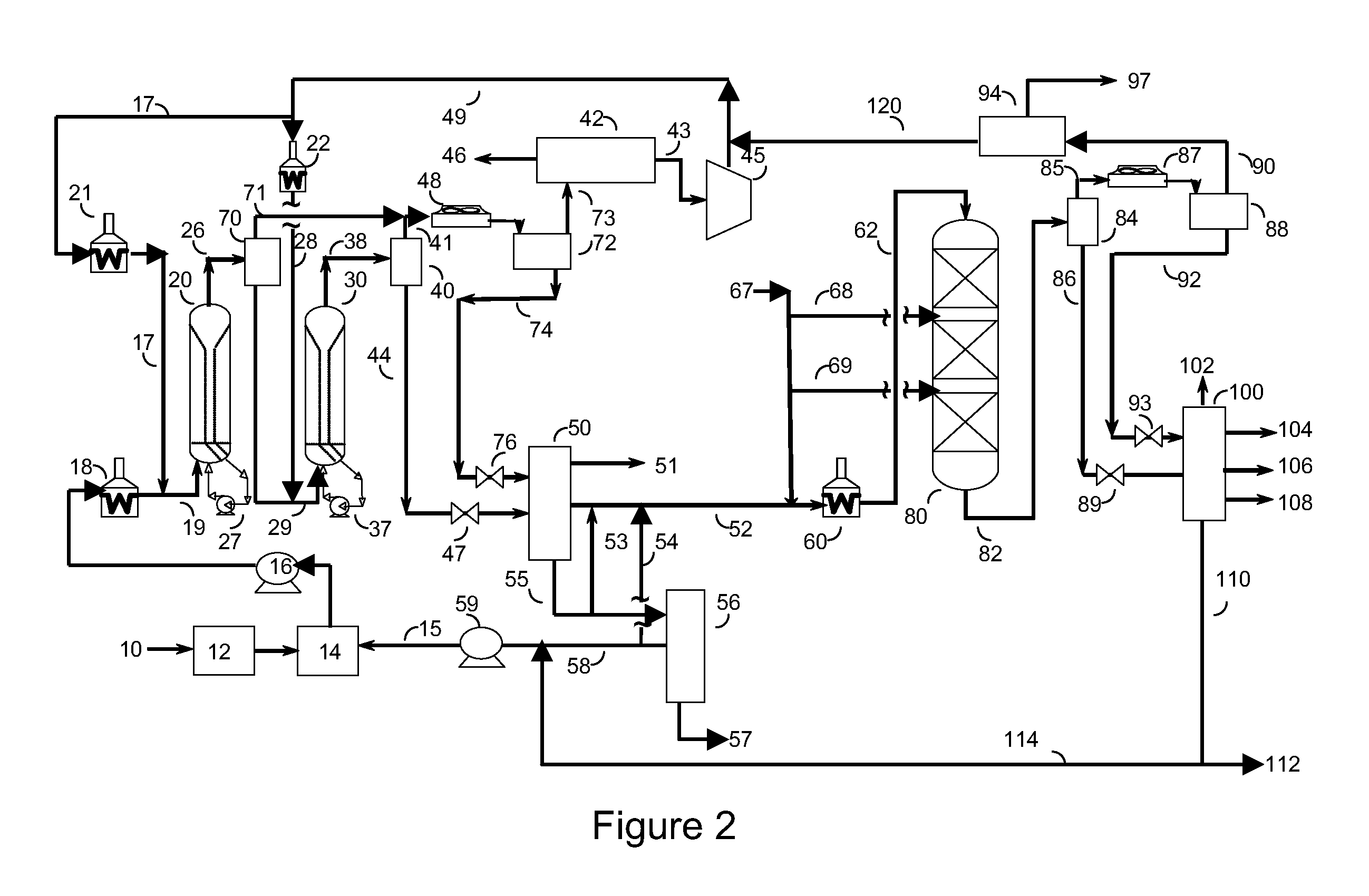

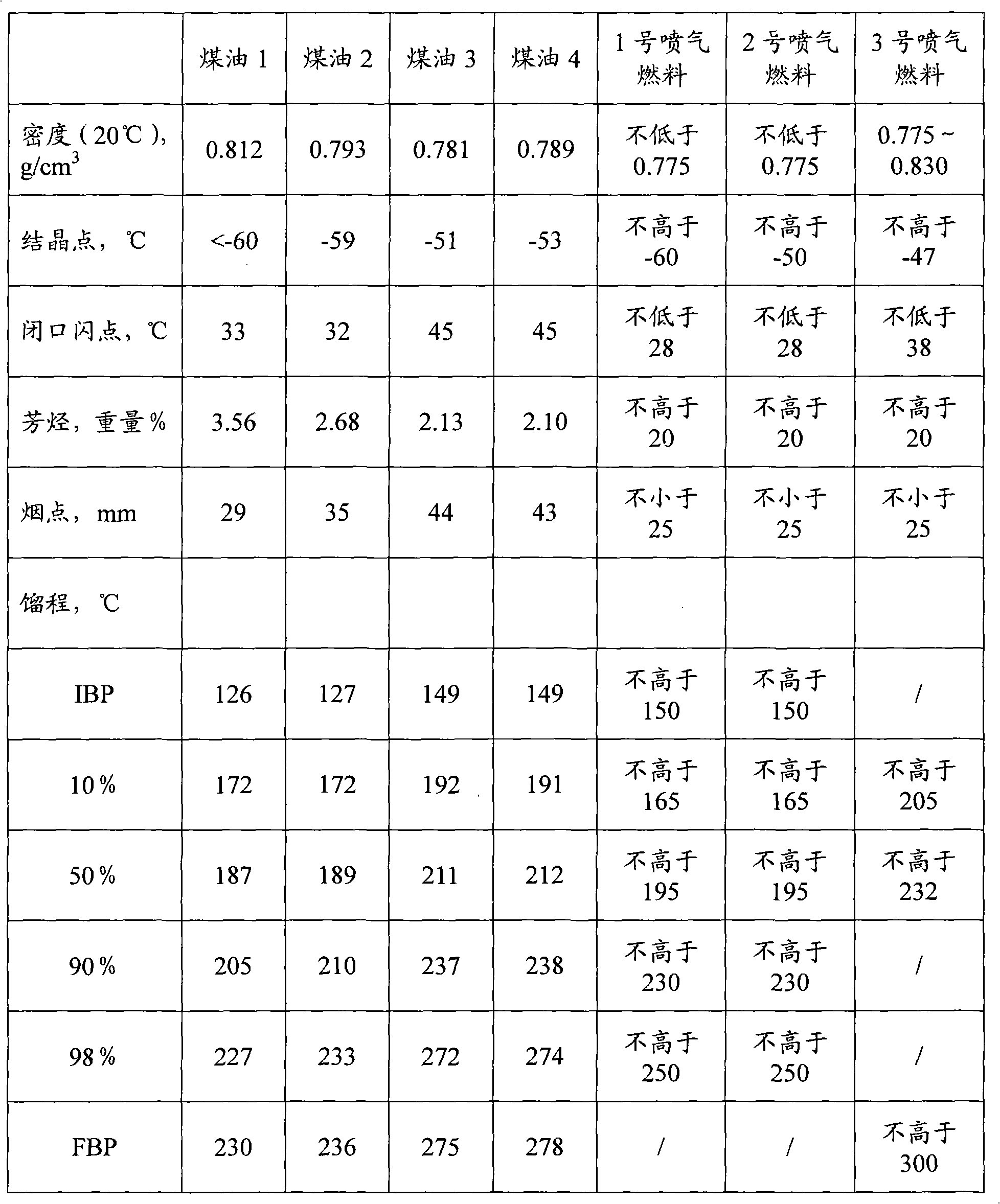

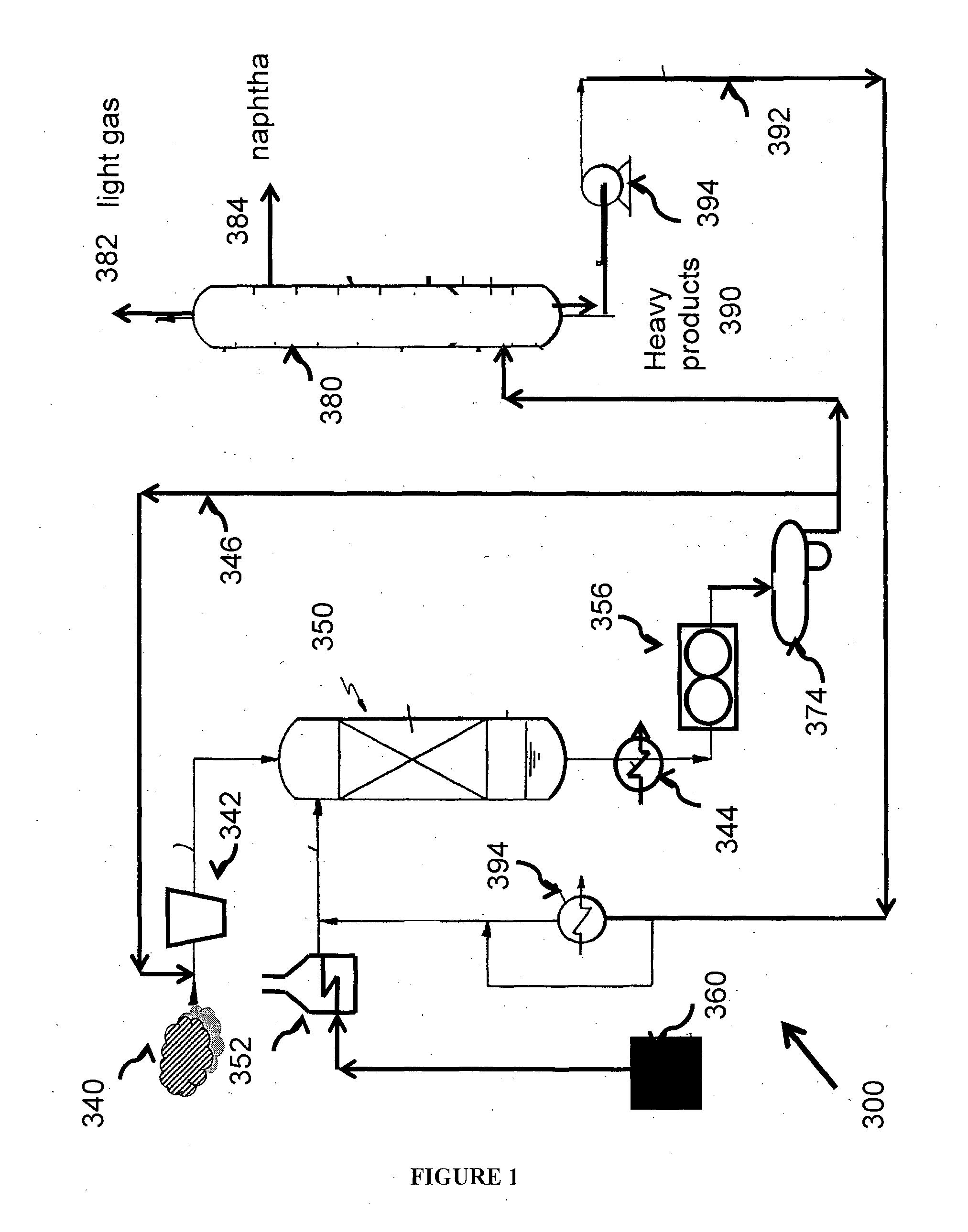

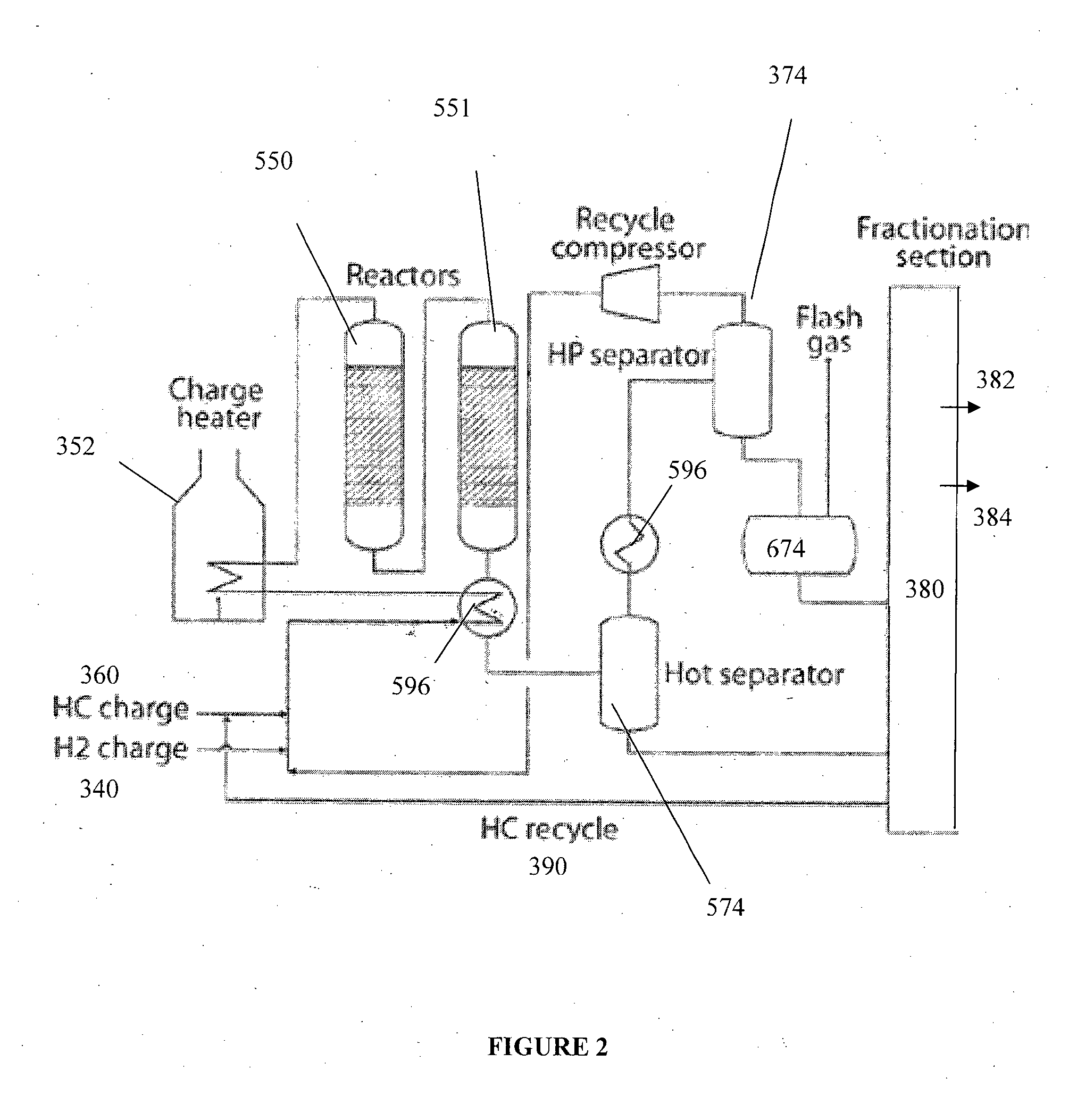

Coal conversion process and products, comprising two direct ebullated bed liquefaction stages and a fixed bed hydrocracking stage

ActiveUS20110230688A1High yieldEasy to transportWaste based fuelLiquid carbonaceous fuelsKeroseneFixed bed

A process for the conversion of coal into fuel bases comprises two successive direct liquefaction stages in ebullated bed reactors followed by a fixed bed hydrocracking stage. This process can produce excellent quality fuel bases (kerosene and diesel).

Owner:INST FR DU PETROLE

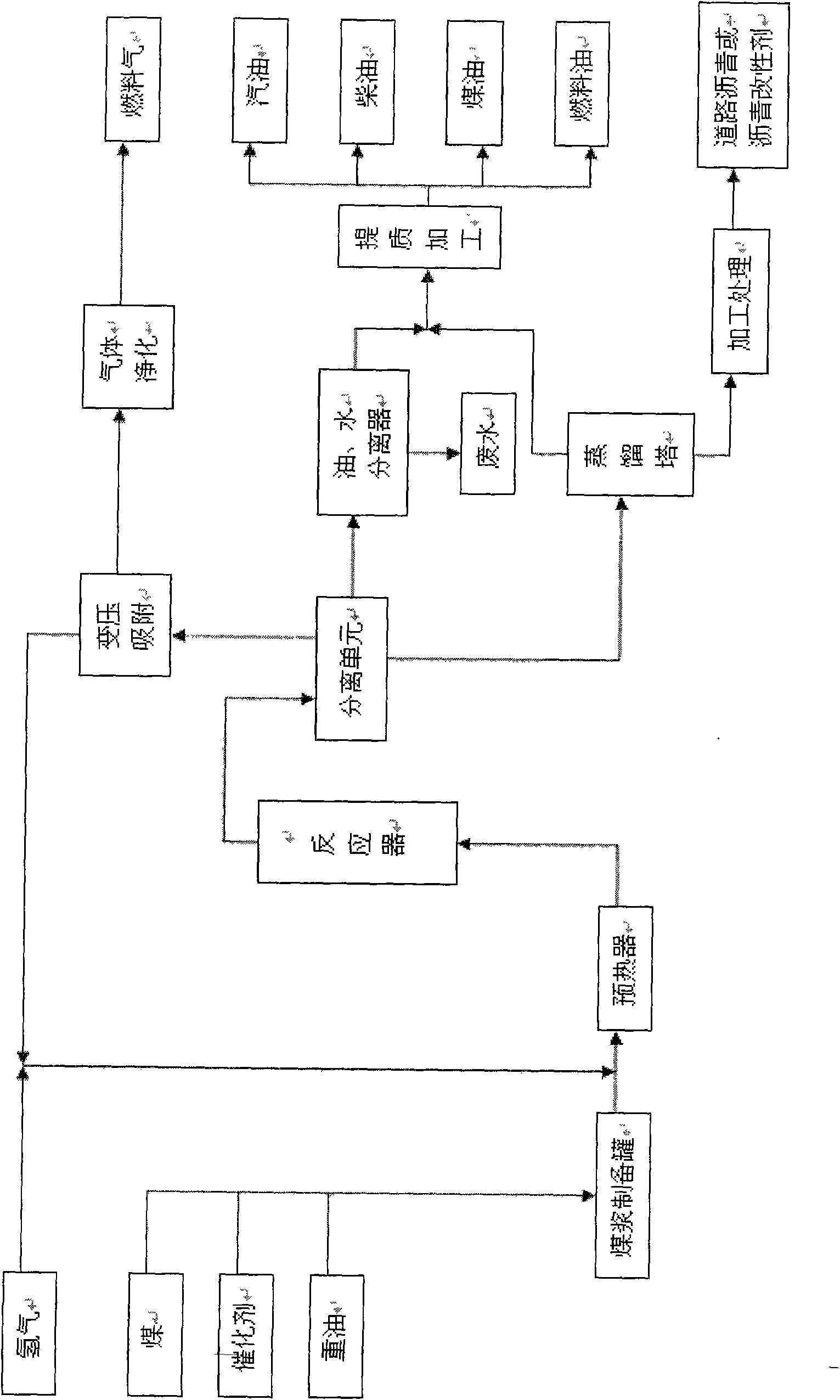

Method for simultaneously producing liquid fuel and asphalt paving materials by coprocessing coal and heavy oil

InactiveCN101649220AReduce investmentLow costHydrocarbon distillationGaseous fuelsKeroseneDistillation

The invention relates to a method for simultaneously producing liquid fuel and asphalt paving materials by coprocessing coal and heavy oil. The method comprises the following steps: mixing coal dust, catalyst and heavy oil to prepare pulp; preheating and entering a reactor to carry out reaction; separating reaction products to separate gaseous substance, light oil, water and heavy mixture; extracting hydrogen from the separated gaseous substance through pressure swing adsorption; returning the purified hydrogen to the reactor to be used circularly, and using the remaining gas as fuel after purification; carrying out oil-water separation on the separated light oil and water to obtain the light oil and the water; leading the heavy mixture into a distilling tower to obtain coarse oil and tower bottom product through distillation separation; mixing the coarse oil and the light oil to obtain liquid fuels of gasoline, kerosene, diesel fuel, fuel oil, and the like through upgrading process; and processing the tower bottom product to get the asphalt paving materials. The invention has the advantage that under the moderate process condition, the liquid fuel and asphalt paving materials canbe produced simultaneously.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

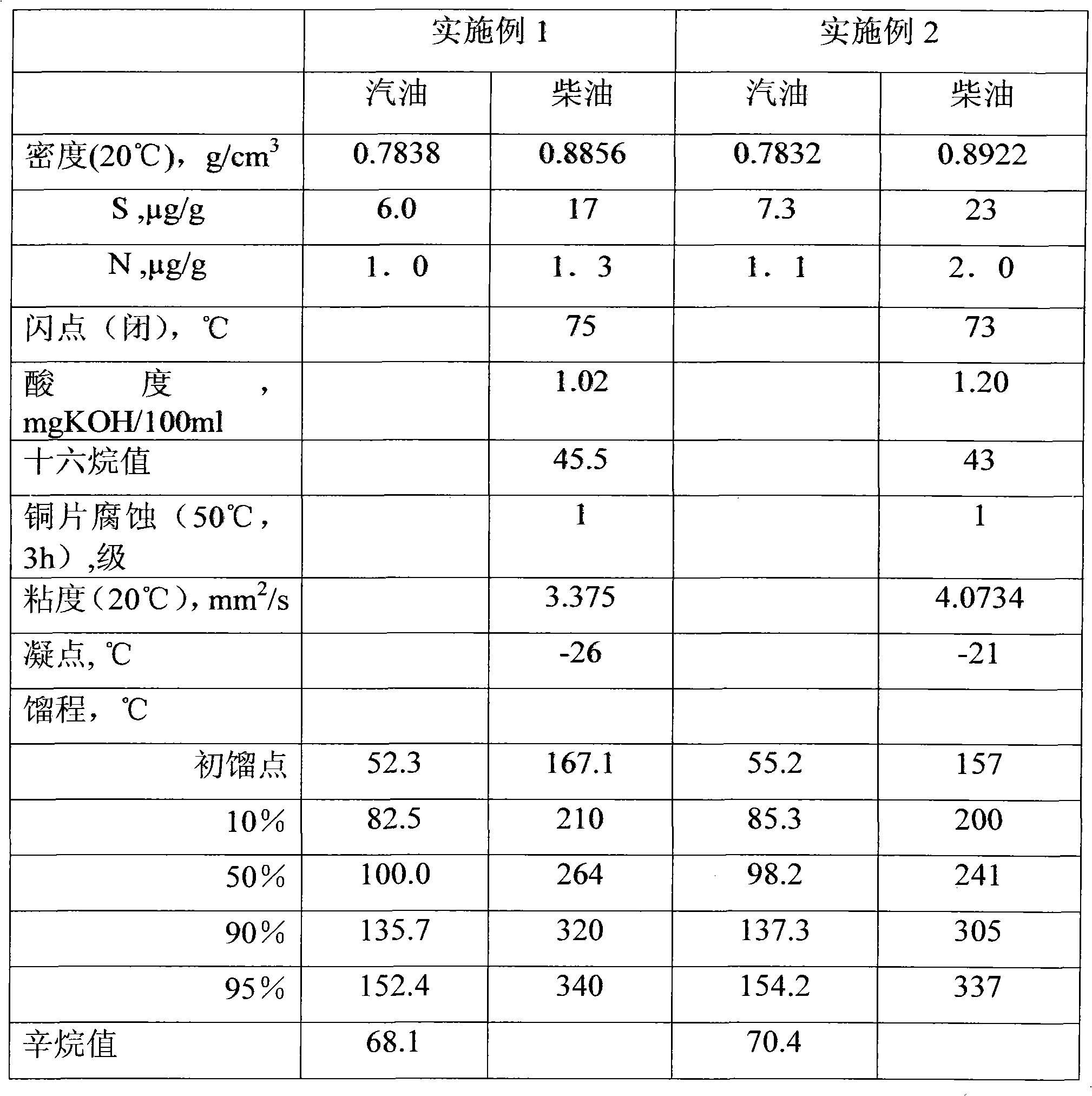

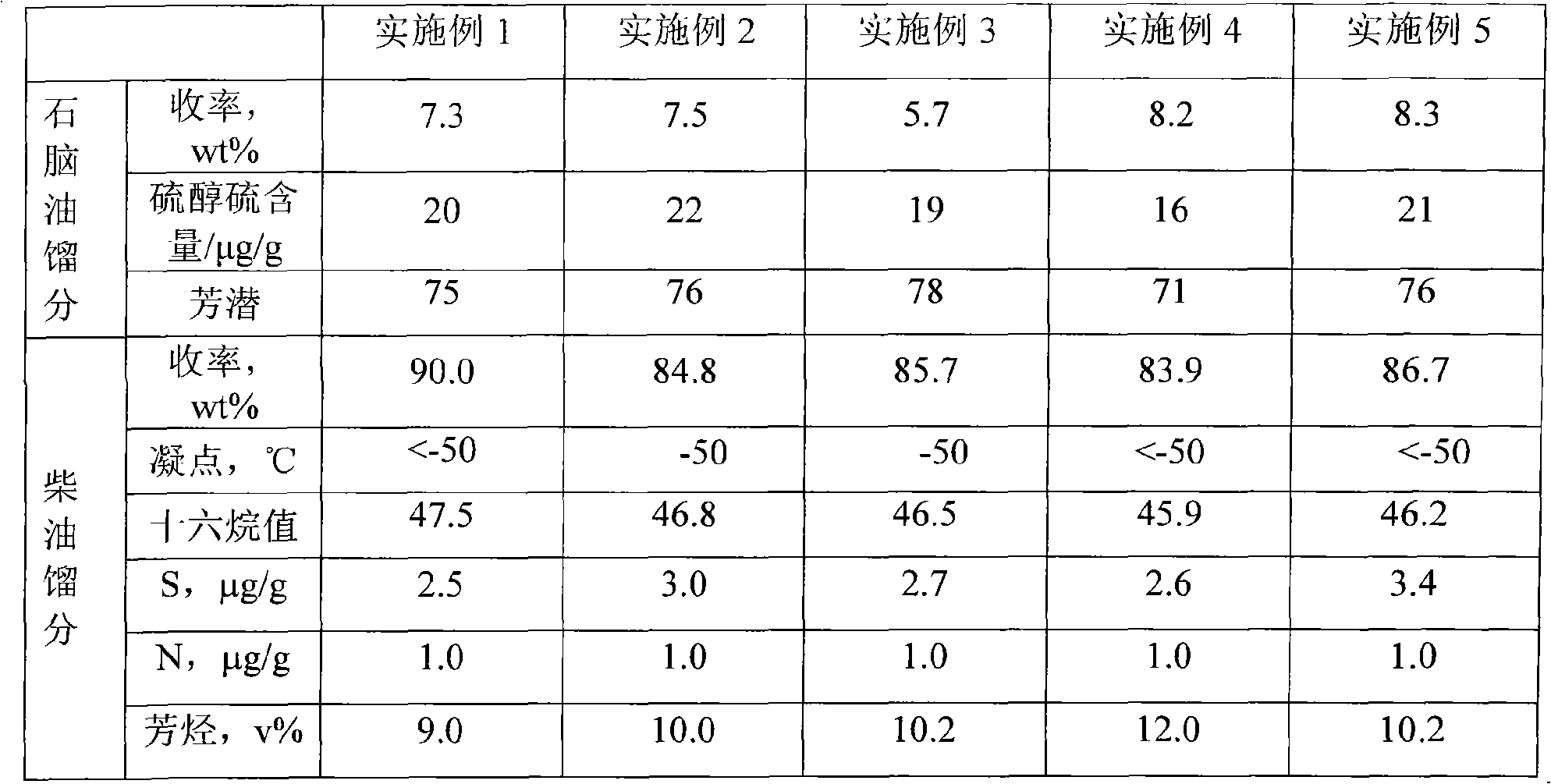

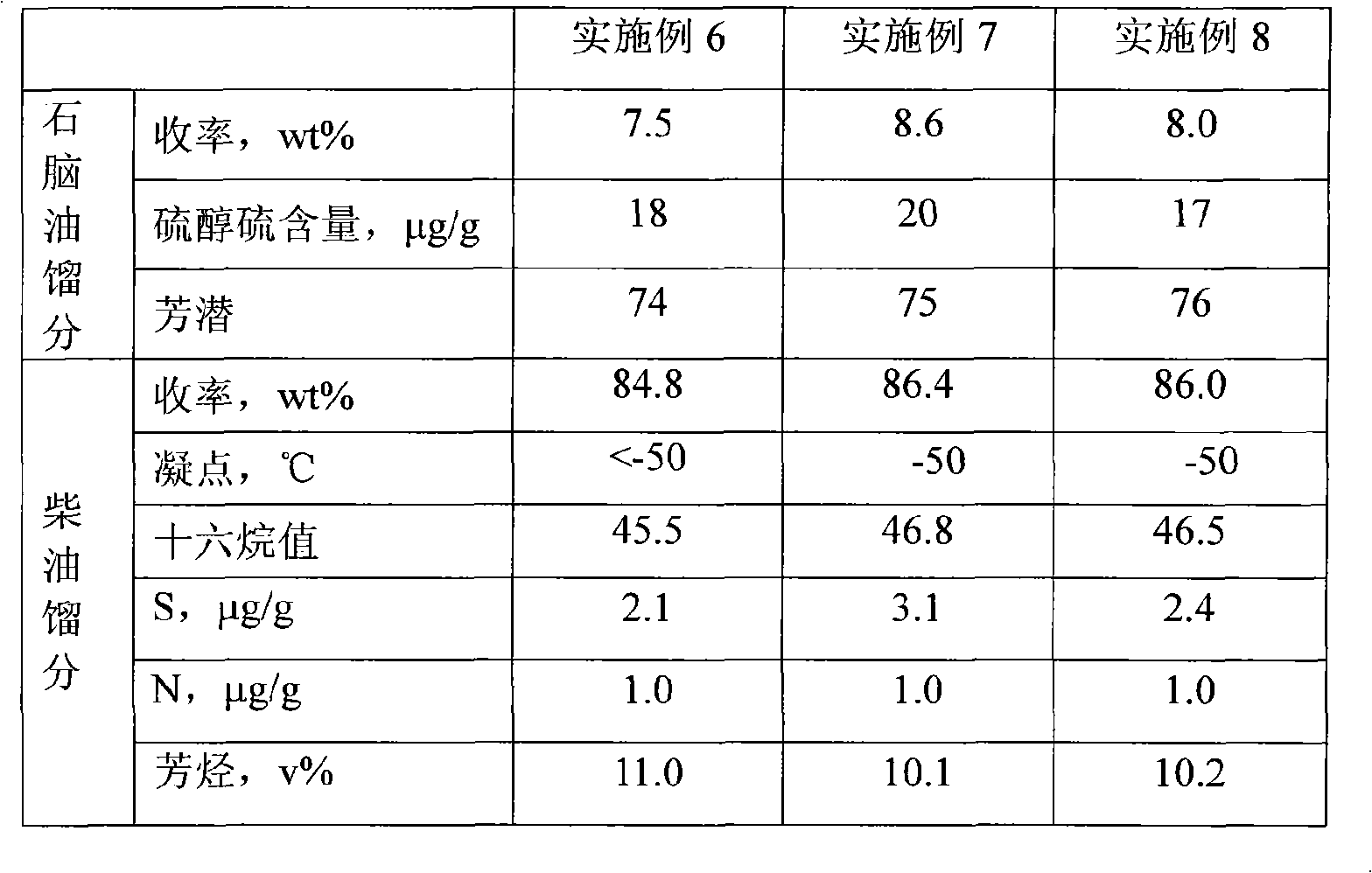

Process for greatly preparing hihg-quality diesel oil or jet fuel from liquefied coil oil

A process for preparing high-quality diesel oil or jet fuel from liquefied coal oil with the highest output includes filtering, stable hydrogenation to obtain diesel oil fraction and tail oil fraction, modifying them by deep hydrogenation, separating its product to obtain gas, naphtha fraction, diesel oil fraction, jet fuel, and tail oil fraction, and cyclic use of hydrogen-enriched gas. Its advantages are high output rate of diesel oil (more than 70 wt.%), low contents of S and N, low density and high hexadecane number.

Owner:CHINA PETROLEUM & CHEM CORP +1

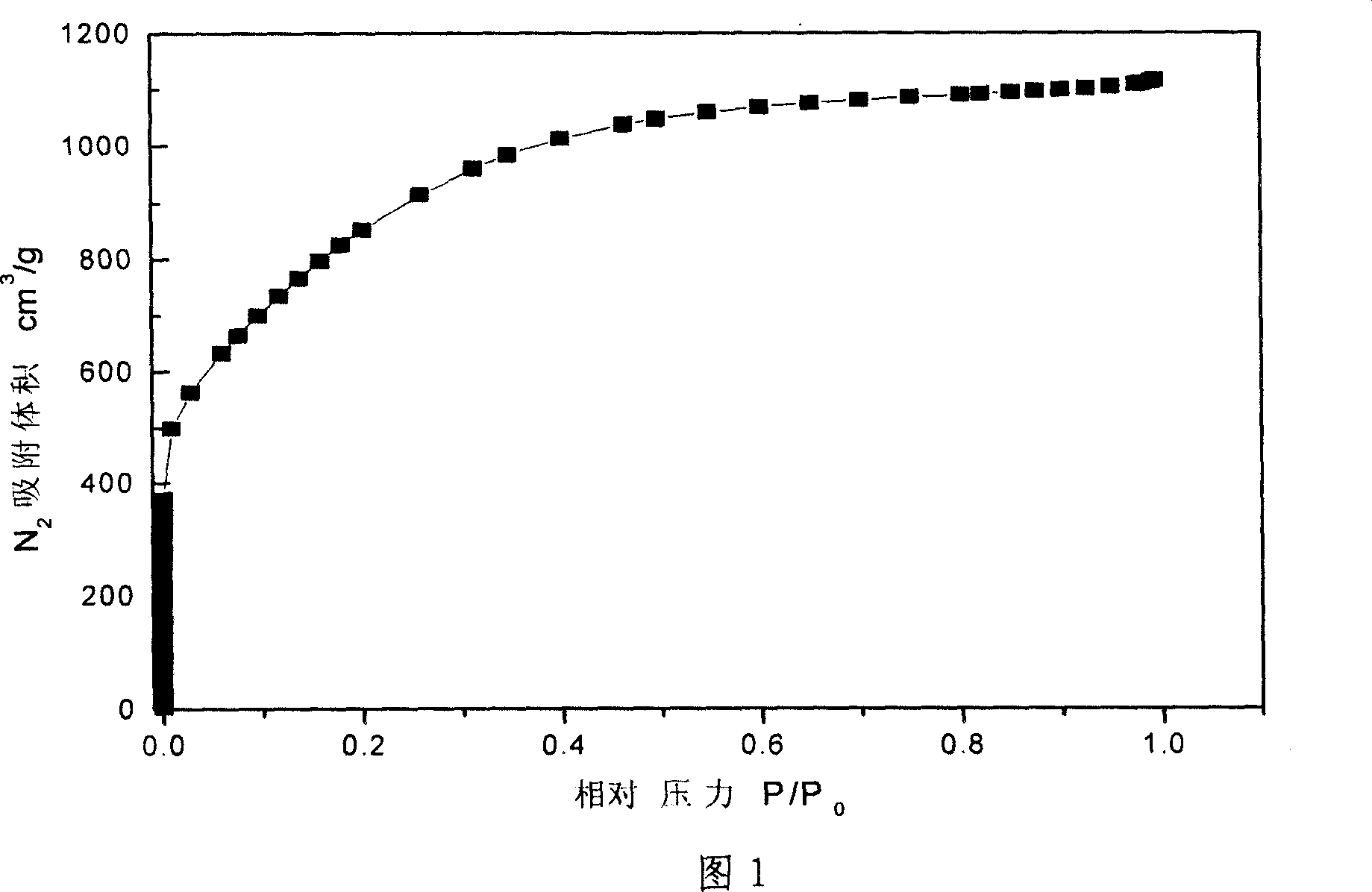

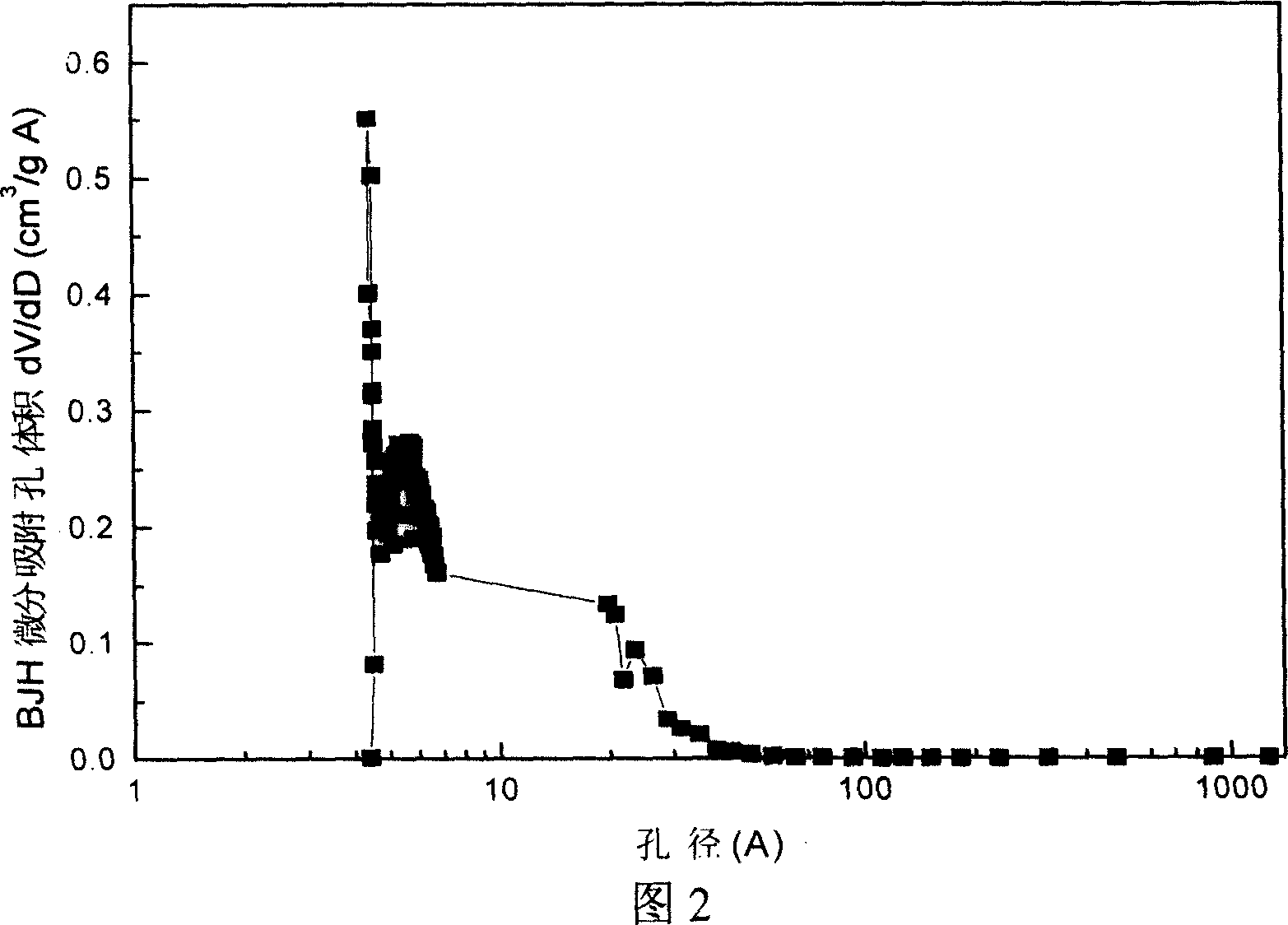

Preparation method of high specific surface area coal mass active carbon

The present invention discloses a preparation method of coal active carbon with high specific area. Said method includes the following steps: pulverizing the coal carbonization material into 24-40 meshes, fully and uniformly mixing the pulverized coal carbonization material with KOH according to the ratio of 1:1-7, placing them into a tubular reactor, then activating at 600-880 deg.C for 2-5 h under the protection of nitrogen gas, cooling to 20-30 deg.C, recovering by-product metal potassium before discharge of material and storing it in kerosene; firstly, using distilled water to wash the residual activated material, recovering residual KOH, repeatedly acid-washing and caustic washing, then using distilled water to wash until the pH value is 6-7, drying at 100-150 deg.C for 10-15 h so as to obtain the coal active carbon.

Owner:SOUTH CHINA UNIV OF TECH

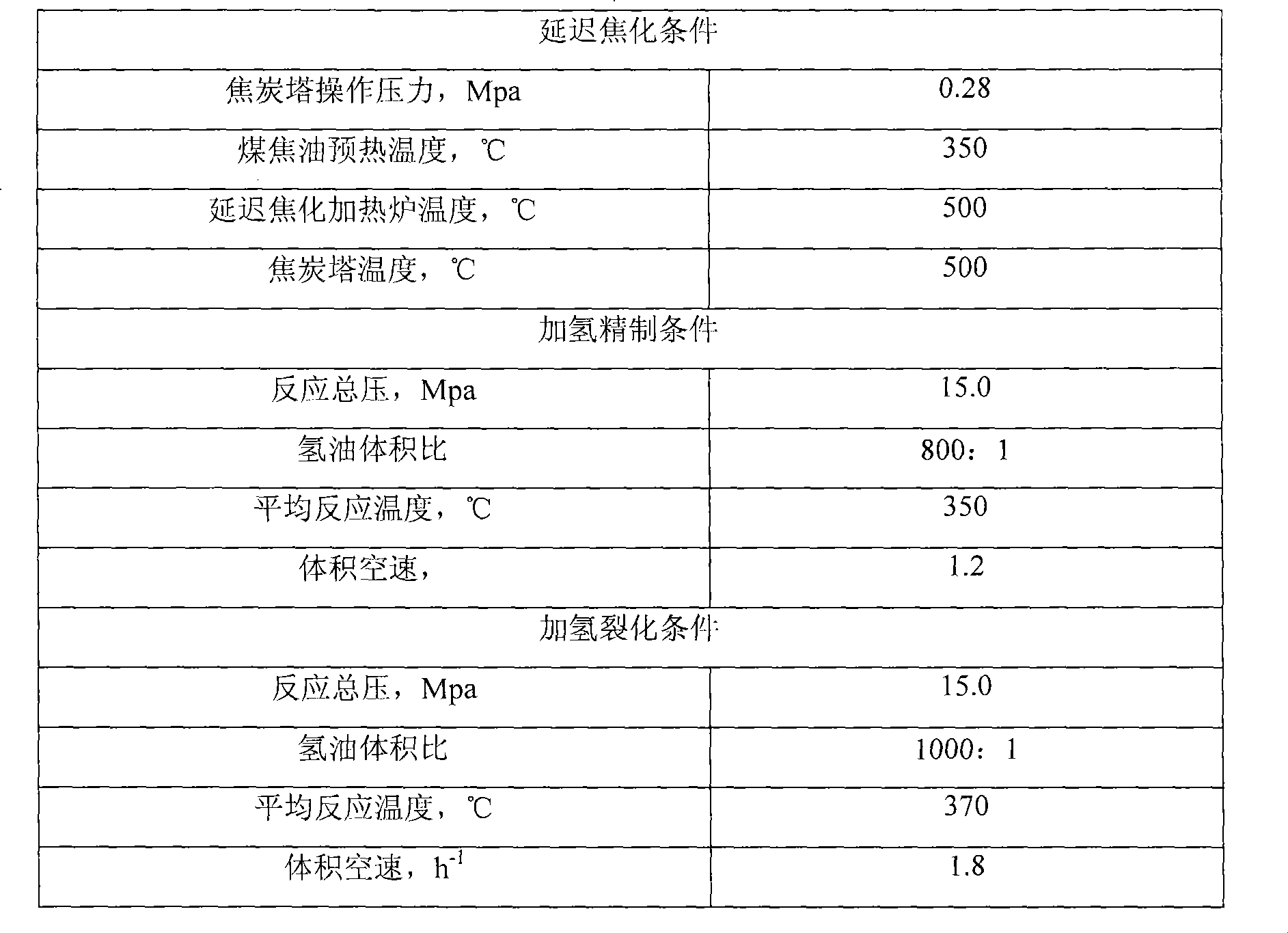

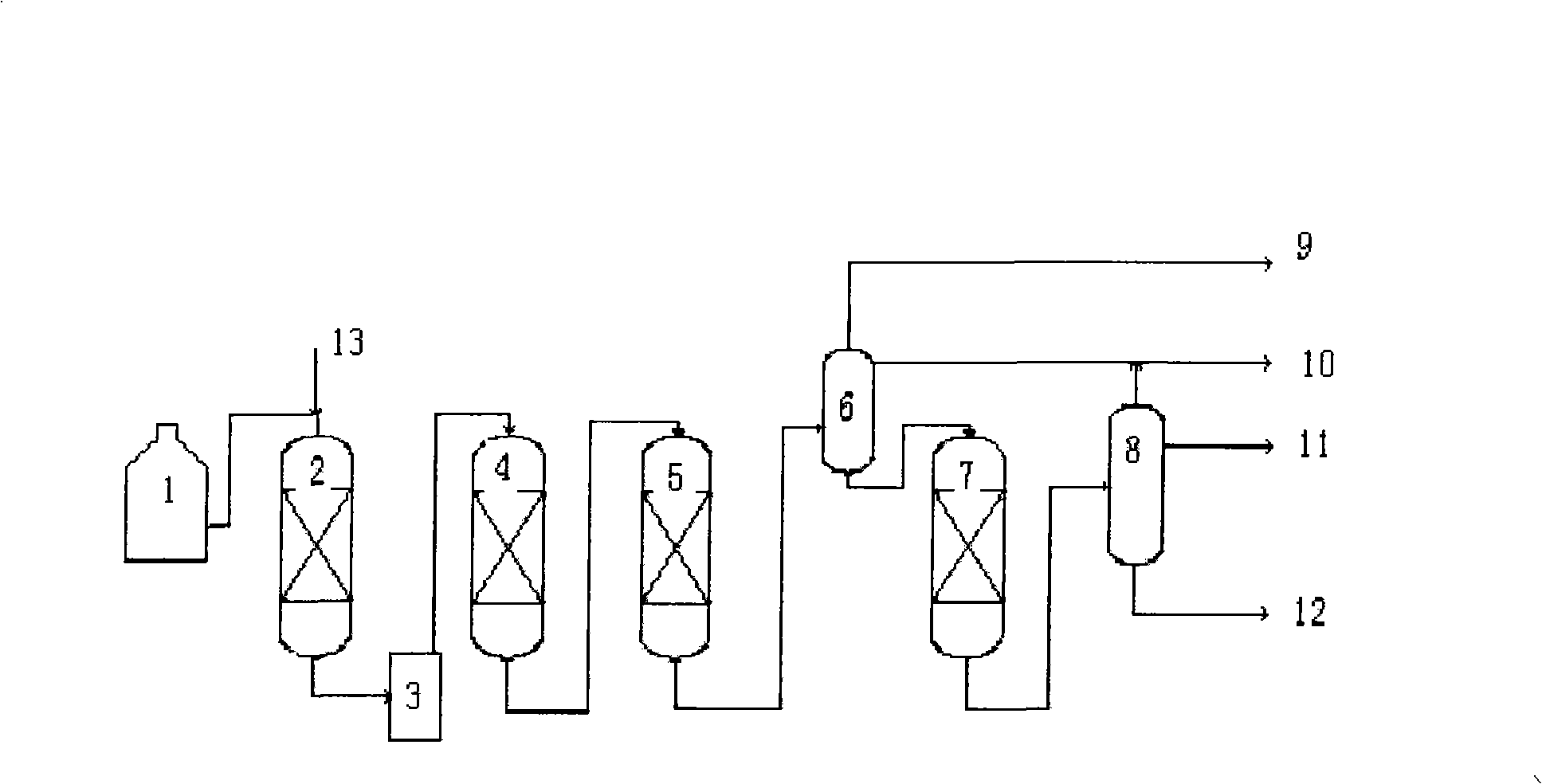

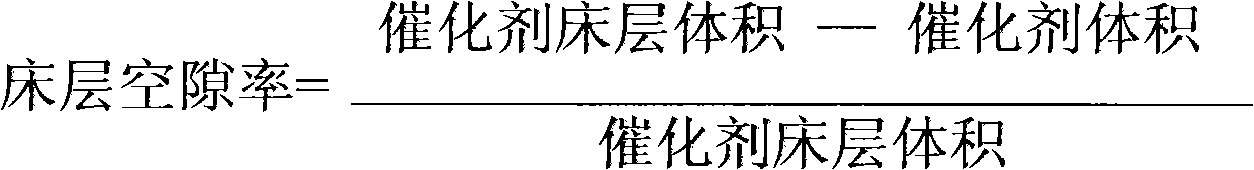

Delay coking hydrogenation combined process for coal oil

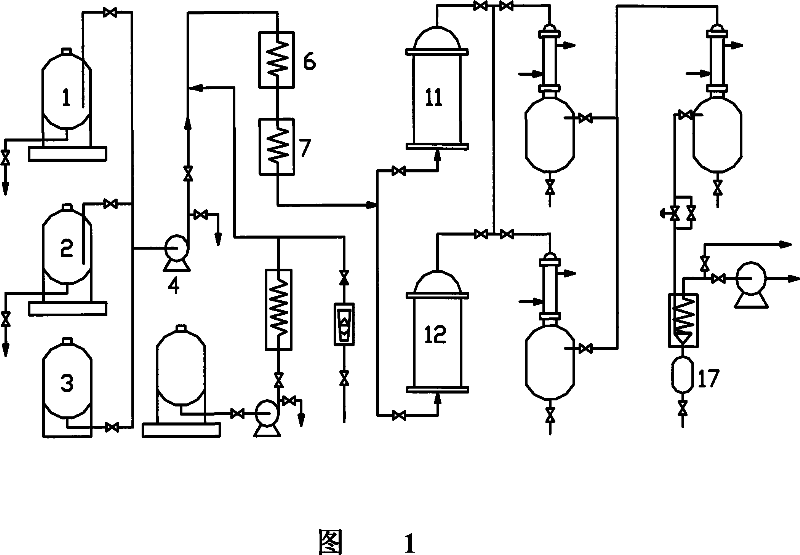

ActiveCN101429456AReduce pollutionIncrease added valueTreatment with hydrotreatment processesGasolineHydrogenation process

The invention provides a combined technique for delayed coking and hydrogenation of coal tar. The combined technique adopts the delayed coking and hydrogenation method to perform delayed coking, hydrogenation and final refining on the coal tar, wherein the hydrogenation process comprises hydrotreating, hydrorefining and hydrocracking; and liquefied gas, fuel oil and lube base oil are finally obtained. The key point of the combined technique is to utilize the combined technique of delayed coking and hydrogenation to adjust the technological conditions of the delayed coking technology and the hydrogenation technology, so as to realize final aim of modification of the coal tar. The combined technique converts the coal tar with low value and high pollution into clean and superior liquefied gas, gasoline, diesel fuel, lube and so on, improves the added value of products, and reduces environmental pollution.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND

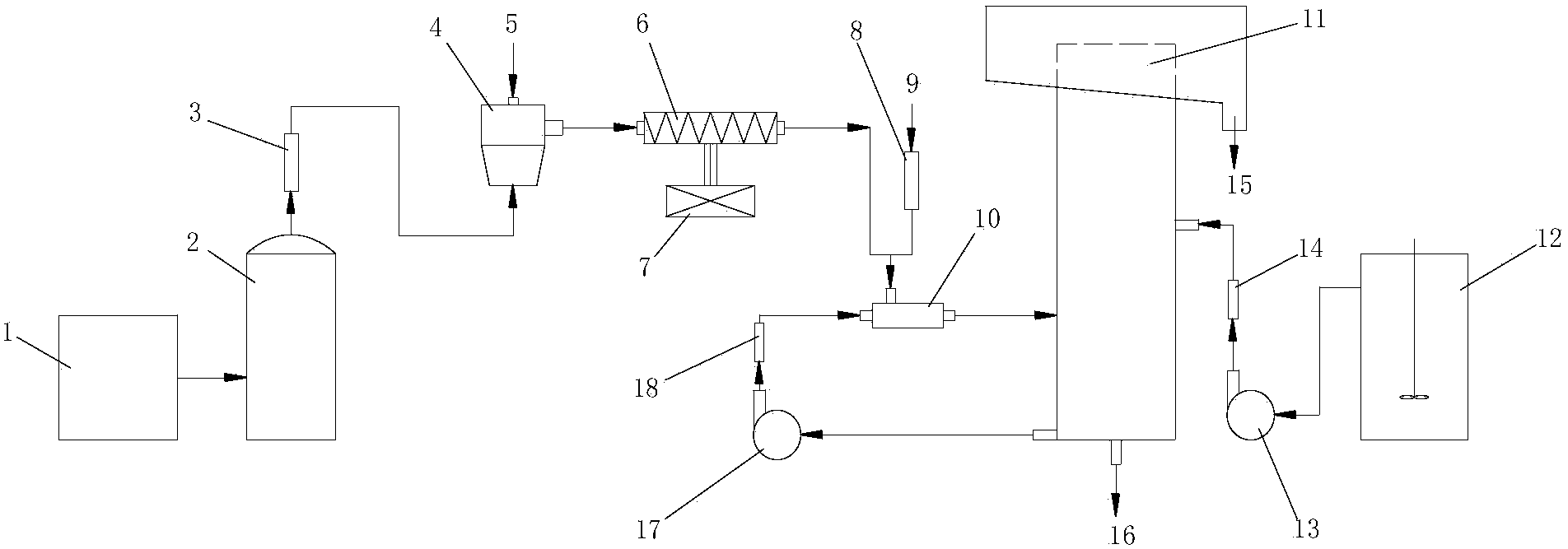

Technique for hydrogenation of coal oil

ActiveCN101343545AUniform and stable suspensionEasy to removeTreatment with hydrotreatment processesWorking-up tarCoal tar distillateGasoline

The invention discloses a coal tar hydrogenation processing method. The method of the invention comprises the steps that coal tar distillated oil or a full distillating pump with high content of impurities, colloid, asphaltene and oxygen elements is fed into a pre-hydrogenating reactor, the hydrogenation pre-treatment is performed under a certain reaction condition, the tiny impurities suspending in oil are separated through a separating device such as a filter and the like, then hydrogenating demetalization and deep hydrogenation refined reaction are performed in sequence, after water and light component are separated, and the material flow generated by the reaction enters into the hydrocracking reactor, thus gasoline fraction, diesel oil and hydrocracking tail oil are cut through a distilling device. Compared with the prior art, the method of the invention can ensure the device of long period of stable operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing jet fuel or jet fuel blending component

ActiveCN101928599ARelaxed reaction conditionsLow operating costTreatment with hydrotreatment processesJet fuelCoal liquefaction

The invention discloses a method for producing a jet fuel or a jet fuel blending component. A mixed oil is obtained by mixing a Fischer-Tropsch synthesis fuel and a direct coal liquefaction oil; and the jet fuel or jet fuel blending component is obtained by hydrorefining, hydrocracking, isocracking and fractionating the mixed oil. According to the method provided by the invention, two prepared coal oils can be converted into the high-quality jet fuel or jet fuel blending component. Compared with hydro-upgrading of the direct coal liquefaction oil, the method has the advantages of mild reaction conditions, low device investment cost and low operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Wet-method process for reclaiming zinc from zinc leaching residue

InactiveCN1837380AIncrease loadReduce the amount of acid used for leachingProcess efficiency improvementKeroseneSlag

This invention relates to wet process of recovering zinc from leach slag containing zinc. It belongs to a wet process for zinc ore, in particular to a process for slag containing zinc produced from the systerm of wet zinc metallurgy. This method comprises the following steps: washing residue with water or diluted acid to get slag, selecting P204 as extractant and coal oil as thinner to extract them to water phase, configuring the solution containing zinc and sulfuric acid, eluting the impurity loaded in organic phase, back extracting the load organic phase with depleted electrolyte and sulfuric acid, transferring zinc in organic phase to water phase, deoiling all water phases which contact with organic phase, finally, taking the liquid which has been back extracted as fresh liquid, and adding it into zinc electrodeposition systerm. The invention has high metal recovery ratio, and can recovery zinc from leach slag containing zinc, save resource, avoid environmental contamination. And it perfectly joins with the process of wet processing of zinc oxide ore, decreases the consumption of acid in the leaching of zinc oxide, and reduces the cost.

Owner:YUNNAN XIANGYUNFEILONG RESOURCES RECYCLING TECH CO LTD +1

Method for preparing fuel oil with coal oil hydrogenation

ActiveCN101294107AAdjust airspeedRegulating pressureTreatment with hydrotreatment processesNaphthaHydrogen

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and device for reinforcing oil bubble column floatation process of low-order coal

The invention discloses a method and a device for reinforcing an oil bubble column floatation process of low-order coal, and belongs to floatation methods and floatation devices for the low-order coal. The method comprises the following steps: (1) adding a surfactant into a hydrocarbon oil collecting agent proportionally; (2) atomizing hydrocarbon oil mixed with the surfactant into oily mist beads in an atomizer by using air flow provided by an air compressor; (3) heating the air flow of the oily mist beads in a tubular temperature control evaporator until the temperature reaches hydrocarbon oil evaporation temperature to form oil evaporation gas; (4) mixing the heated oil evaporation gas with air, feeding the mixture into a bubble generator, and forming modified oil bubbles by wrapping bubbles with thin surfactant-modified hydrocarbon oil layers under the jet action of the bubble generator; (5) pre-wetting and uniformly mixing the low-order coal in a stirring barrel, and pumping the low-order coal into a floatation column; (6) in the floatation column, mineralizing the modified oil bubbles and low-order coal particles, carrying clean coal to float up by using the modified oil bubbles as carriers, and keeping tailings and high-ash fine silt which are not mineralized in the column to obtain the clean coal and the tailings. The method and the device have the advantages that the consumption of the hydrocarbon oil collecting agent is reduced; the floatation selectivity and the recovery rate of the low-order coal are improved.

Owner:CHINA UNIV OF MINING & TECH

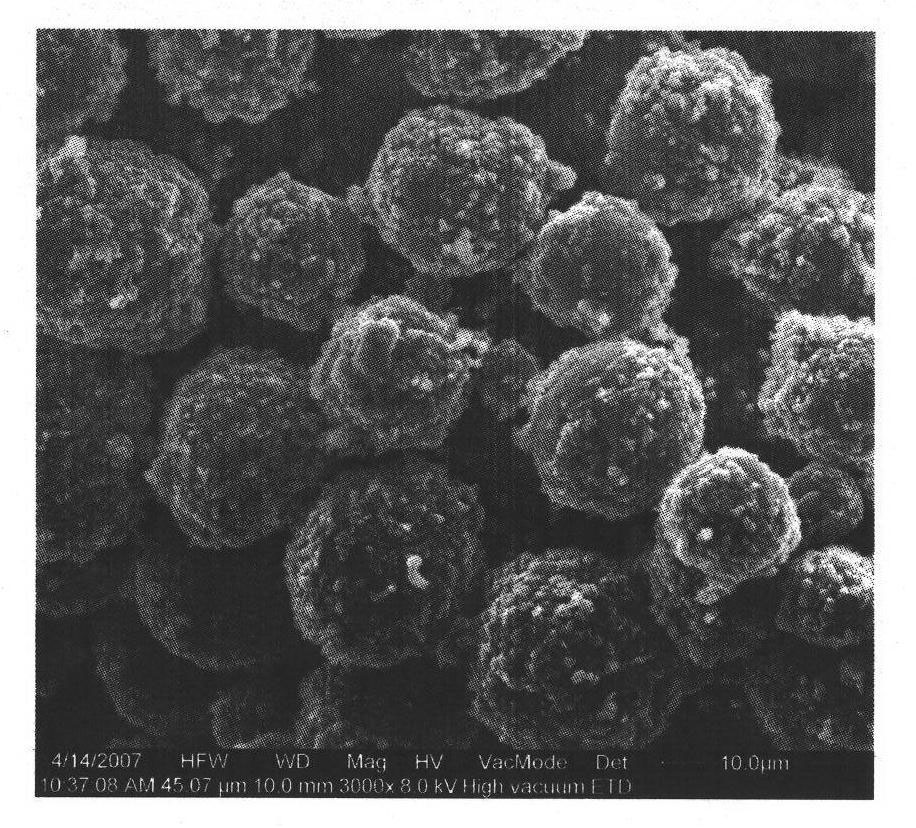

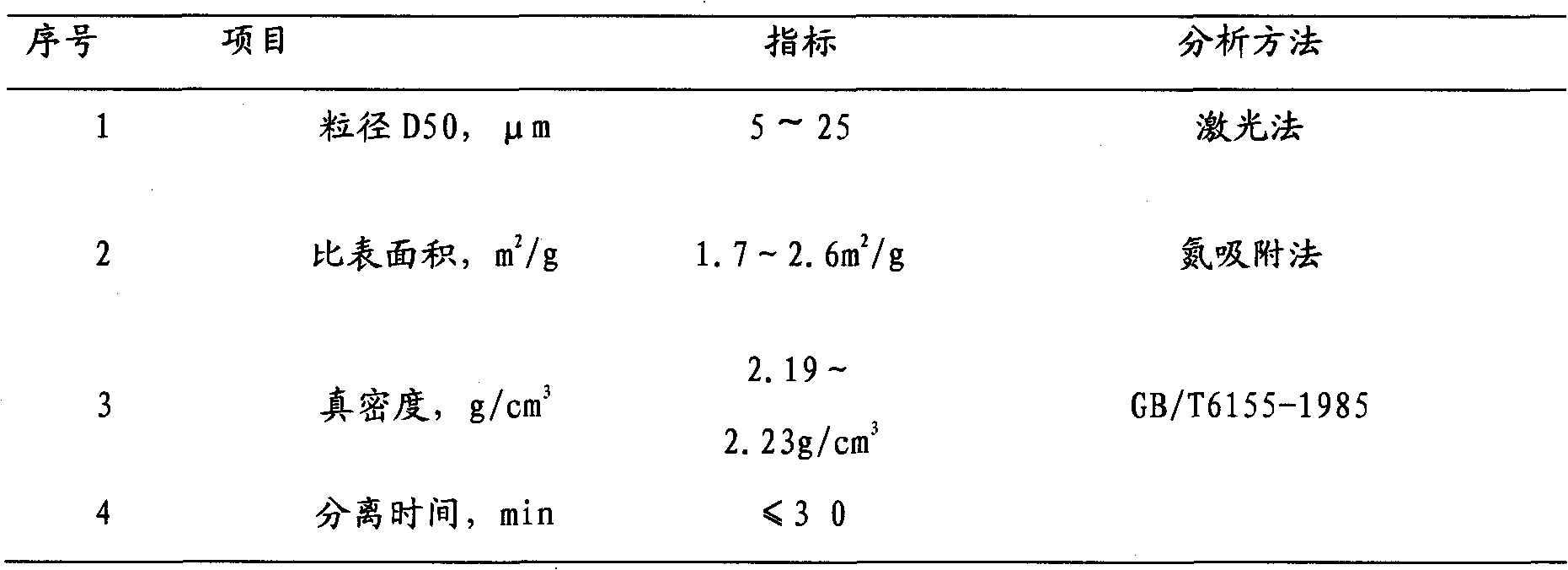

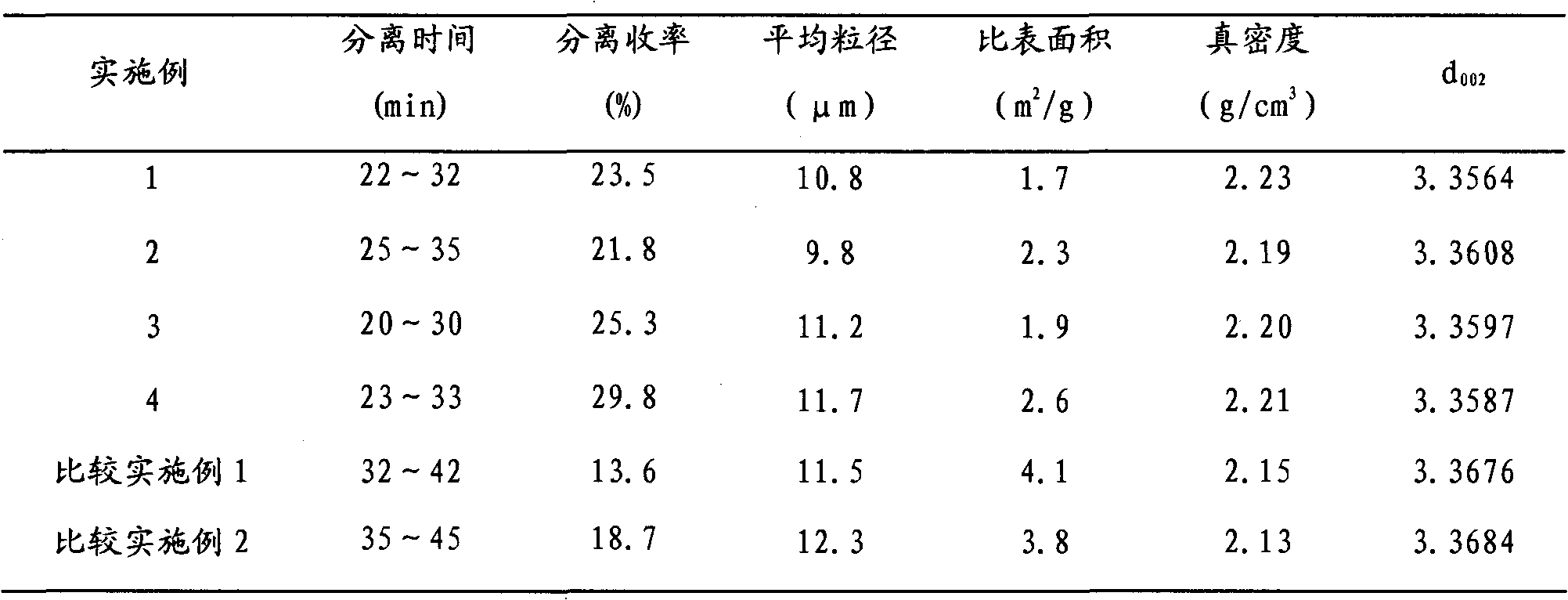

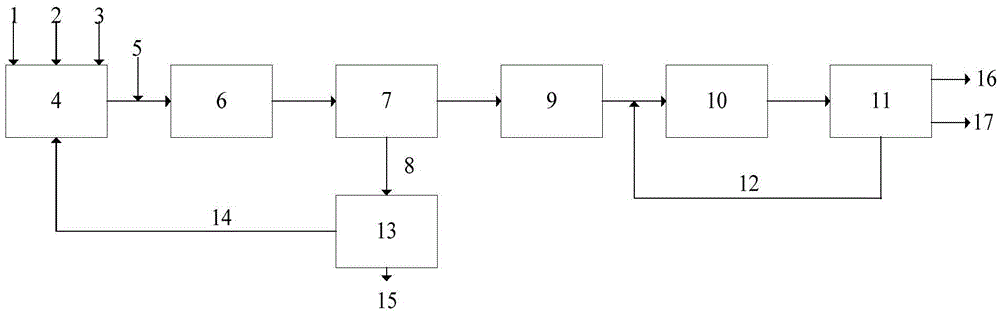

Preparation method of mesocarbon microbead

The invention discloses a preparation method of a mesocarbon microbead. The method comprises the following steps of: heating coal medium temperature pitch or coal modified pitch at the temperature rise speed of 60 to 300 DEG C / h in the protective nitrogen; heating the coal medium temperature pitch or the coal modified pitch with stirring to between 320 and 500 DEG C for polymerization to obtain a pitch polymerized mother liquid; stirring and mixing a solvent mixture of washing oil, light oil, kerosene or the mixture thereof and sodium dodecyl benzene sulfonate of an anion surface active agent, and the polymerized mother liquid, and filtering the mixture in vacuum; and further purifying the mixture to obtain a mesocarbon microbead product. Because the surface active agent is added into an extracting solvent in the process of purification, the method reduces viscosity of parent phase pitch of the carbon-containing microbead, improves separation efficiency of the mesophase microbead, and ensures that the obtained mesocarbon microbead product has narrow particle size distribution; the particle size range of the product is 1 to 30 mu m, and the product has good sphericity, and the specific surface area of 1.7 to 3.5 m<2> / g; moreover, the method is simple and convenient, raw materials are readily available and have low cost.

Owner:SHANGHAI INST OF TECH

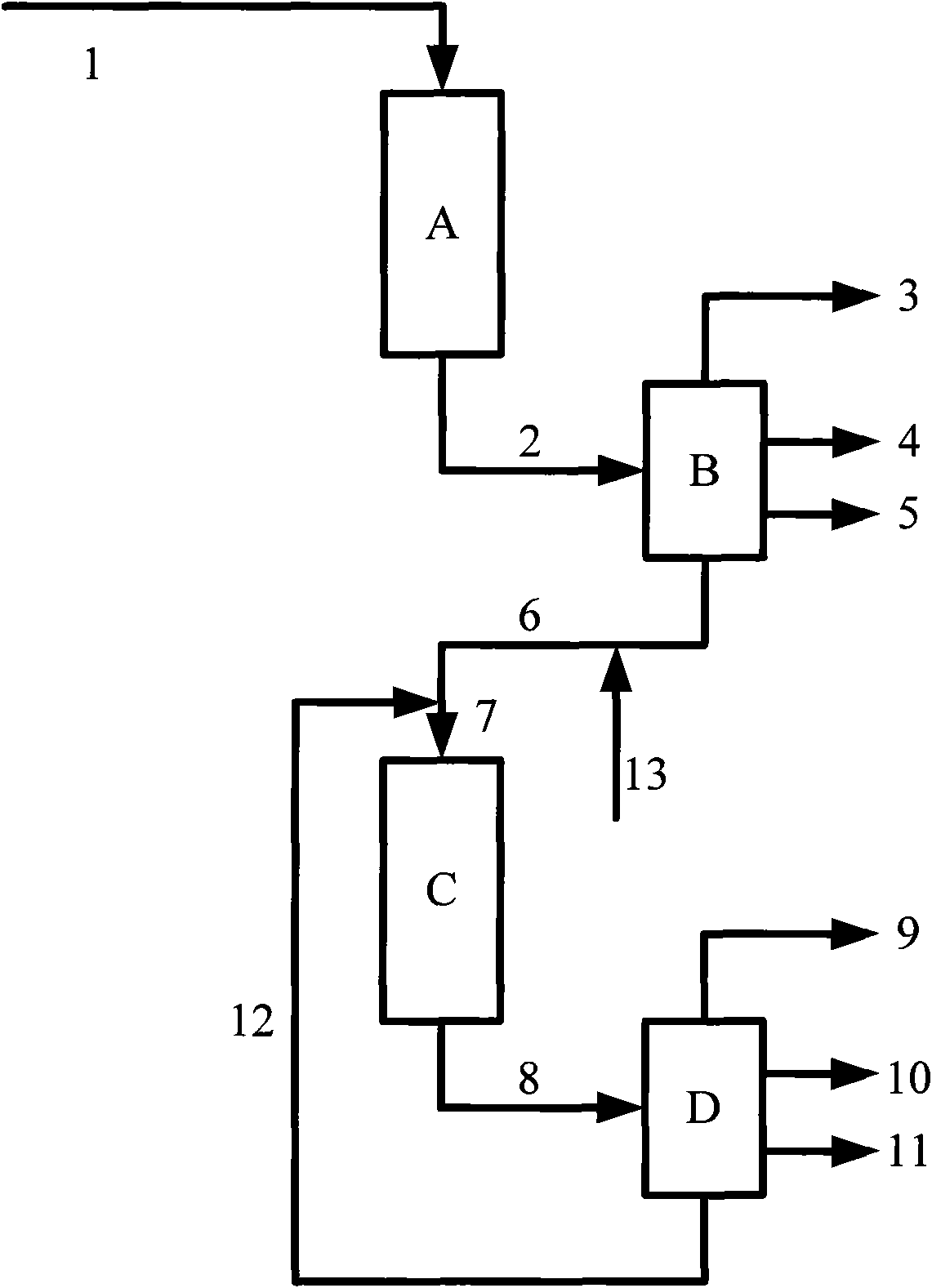

Method for producing oil product by corefining coal and oil

ActiveCN105567321AReduce difficultyHigh yieldLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesHydrogenGasoline

The invention relates to an oil product production method, particularly a method for producing an oil product by corefining coal and oil. The method comprises the following steps: mixing coal powder, heavy oil and a catalyst to prepare an oil coal slurry, mixing with hydrogen gas, preheating, sending into a coal-oil corefining reactor, reacting, separating hydrogen-rich gas, light oil, water, crude oil, solvent extracted oil and solid residues from the reaction products, sending the hydrogen-rich gas, light oil and crude oil into a hydrogenation modification unit to produce gasoline, diesel and other oil products, and circulating the solvent extracted oil back to an oil coal slurry preparation unit as heavy oil to prepare the oil coal slurry, wherein the solid residues can be used sold as semicoke and can also be used for preparing hydrogen gas. The method has the advantages of simple technique, mild reaction conditions, high oil product yield, no need of hydrogenation solvent circulation, low investment and the like.

Owner:上海竣铭化工工程设计有限公司

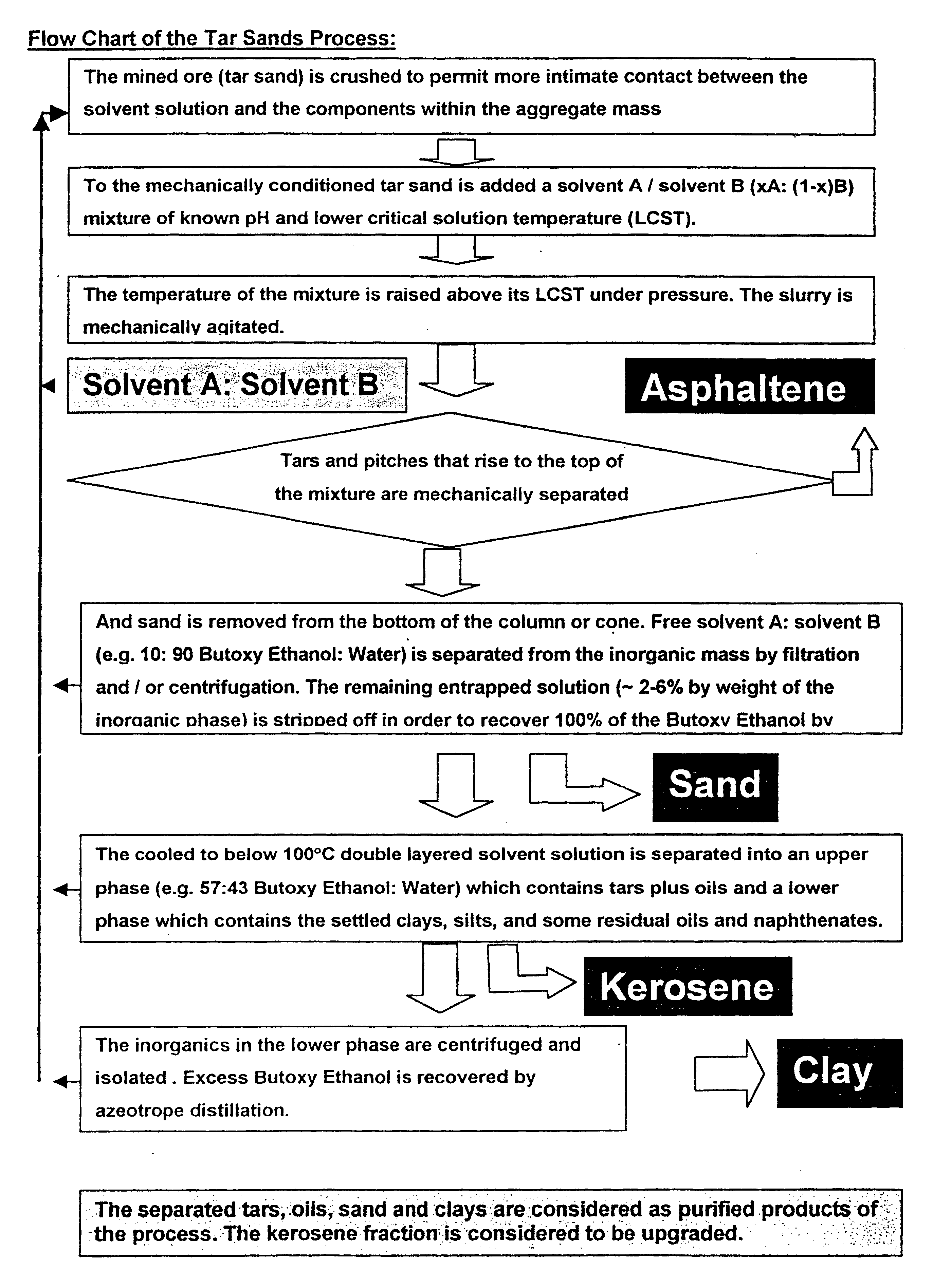

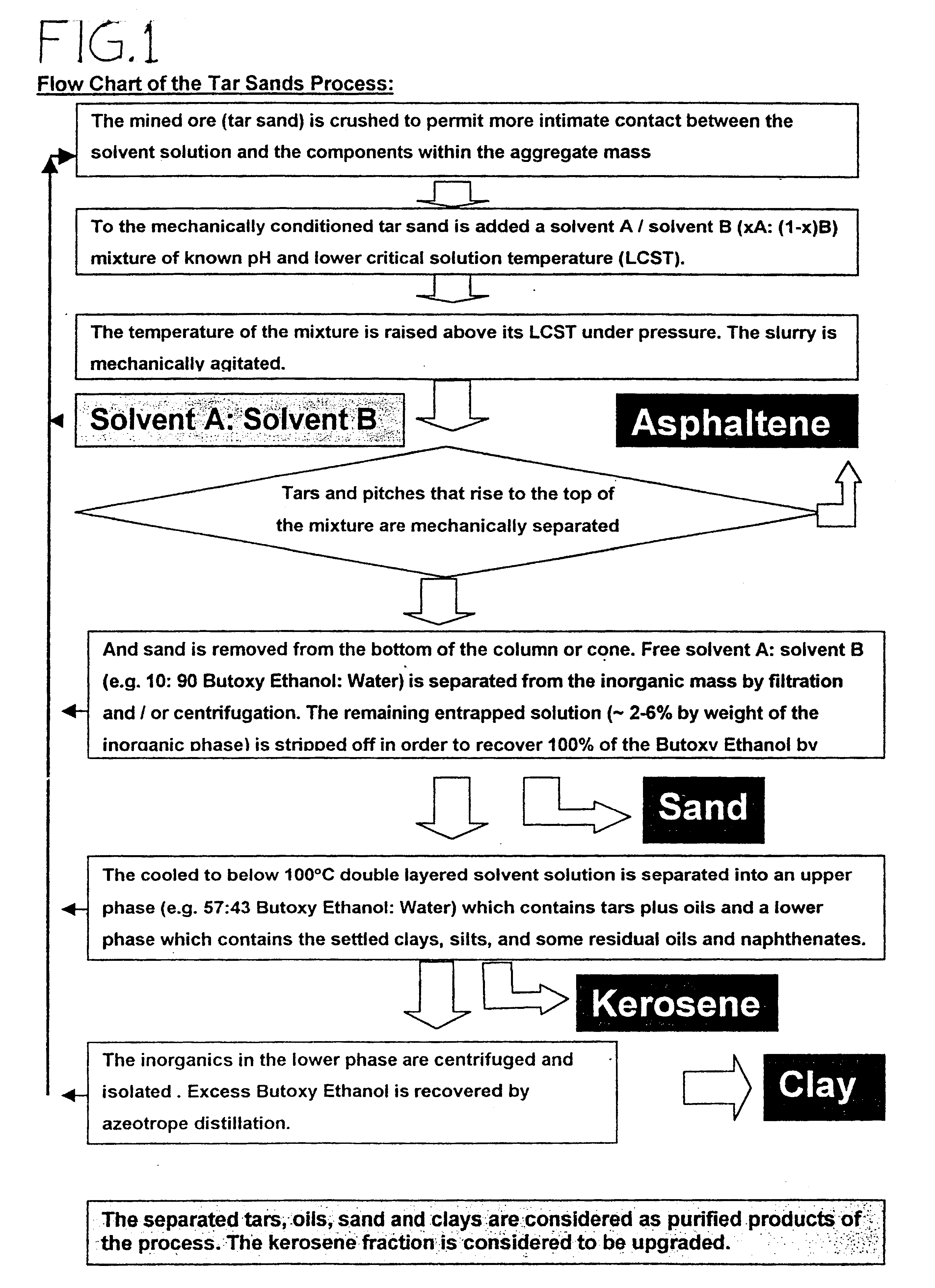

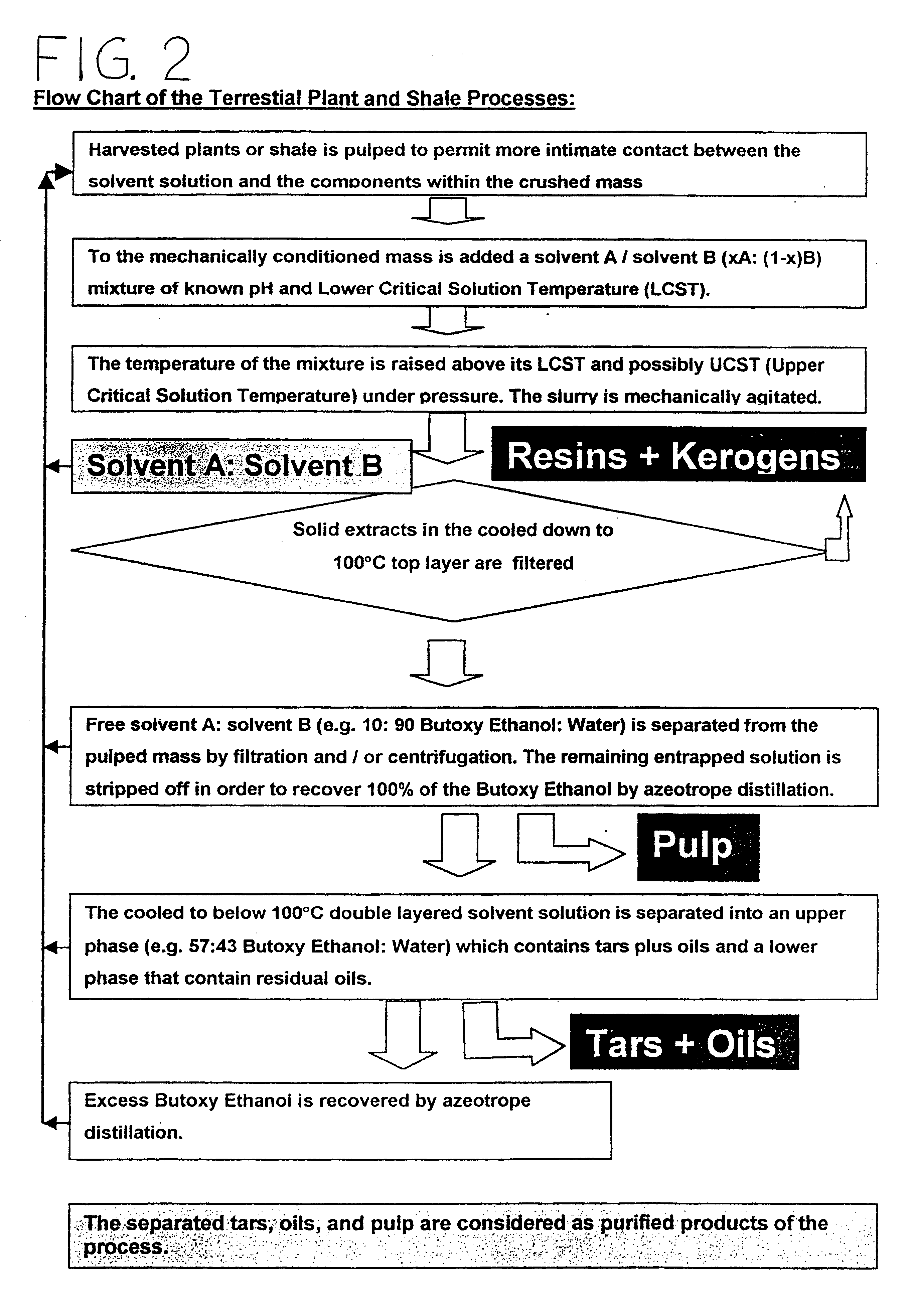

Separation of tars, oils and inorganic constituents from oil bearing sands or shales

InactiveUS6464856B1Improve featuresEasy to separateWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansCelluloseKerogen

An improved process for the total separation and recovery of four constituents, namely, 1) insoluble pitches and tars also known as asphaltenes, 2) a kerosene based oil fraction, 3) clays and silts of less than 80 mum mesh and 4) sands of greater than 80 mum mesh. Recombination of the hydrocarbon fractions is the bitumen portion of tar sands. A further process for the extraction and separation of plant resins from cellulose and kerogen from oil shale that on thermal depolymerization become a source for aromatic and kerosene based oil fractions respectively.

Owner:DEINKING SOLVENT EXTRACTION TECH

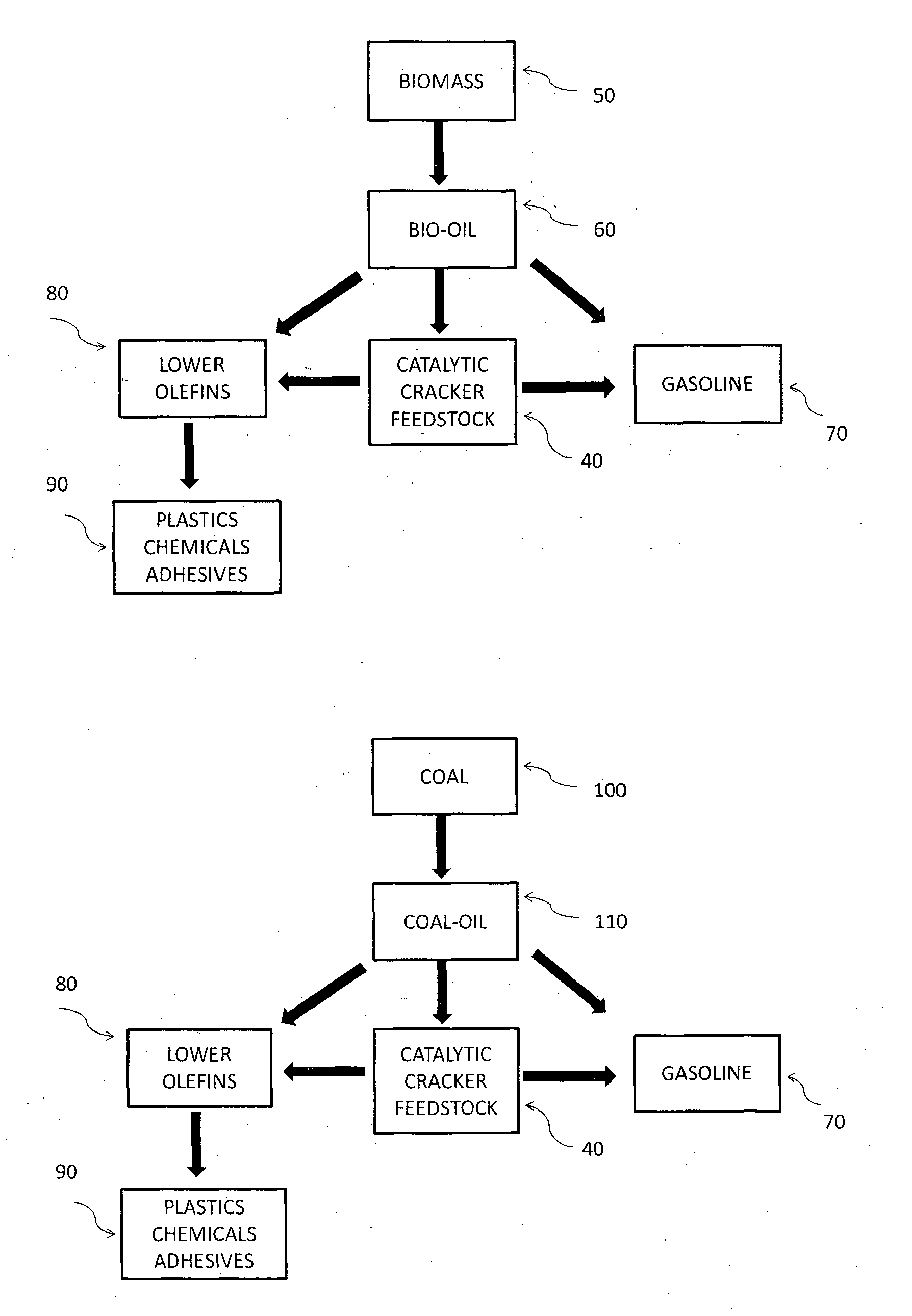

Methods for Producing Hydrocarbon Products from Bio-Oils and/or Coal-Oils

InactiveUS20130184505A1Reduced adverse environment effectReduce economic costsThermal non-catalytic crackingCatalytic crackingSulfurNitrogen

The present invention relates to a method for producing a hydrocarbon product from coal and / or biomass comprising the following steps: converting the coal to a coal-oil and / or converting the biomass to bio-oil, optionally processing the coal-oil and / or bio-oil in a hydroprocessing reaction to remove one or more of oxygen, nitrogen or sulfur from hydrocarbon compounds in the coal-oil and / or bio-oil; and using at least a portion of the coal-oil and / or bio-oil as a feedstock in a cracking reaction to convert hydrocarbon compounds in the feedstock into a mixture of smaller hydrocarbon compounds comprising the hydrocarbon product.

Owner:IGNITE RESOURCES

Solvent oil hydrogenation and quality change method

ActiveCN1769391AHigh yieldLow viscosityTreatment with hydrotreatment processesDistillates petroleumHydrogenation catalysis

The invention relates to a method of hydrogenation to improve quality of solvent oil. The invention takes one or more petroleum fractions from petrol, coal oil, diesel oil as raw materials, contactly reacting with hydrogenation catalysis containing ª

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for harmony production of bunker fuel by coal oil

InactiveCN101113346ASimple and fast operationEase of industrial implementationLiquid carbonaceous fuelsTar working-up by water removalCarbonizationEnvironmental engineering

The invention relates to a method used for producing bunker fuel oil by blending low-temperature carbonization coal tar. The method is to respectively measure the properties of the part over water and the part below water of the low-temperature carbonization coal tar, a blending experiment of the part over water and the part below water of coal tar is practiced according to the measurement result and bunker fuel oil standards and the main indexes of the blend oil are determined to obtain proper blending ration and polypropylene higher alcohols ester additive is added to get qualified bunker fuel oil.

Owner:SHAANXI SHENMU SAN JIANG COAL CHEM +1

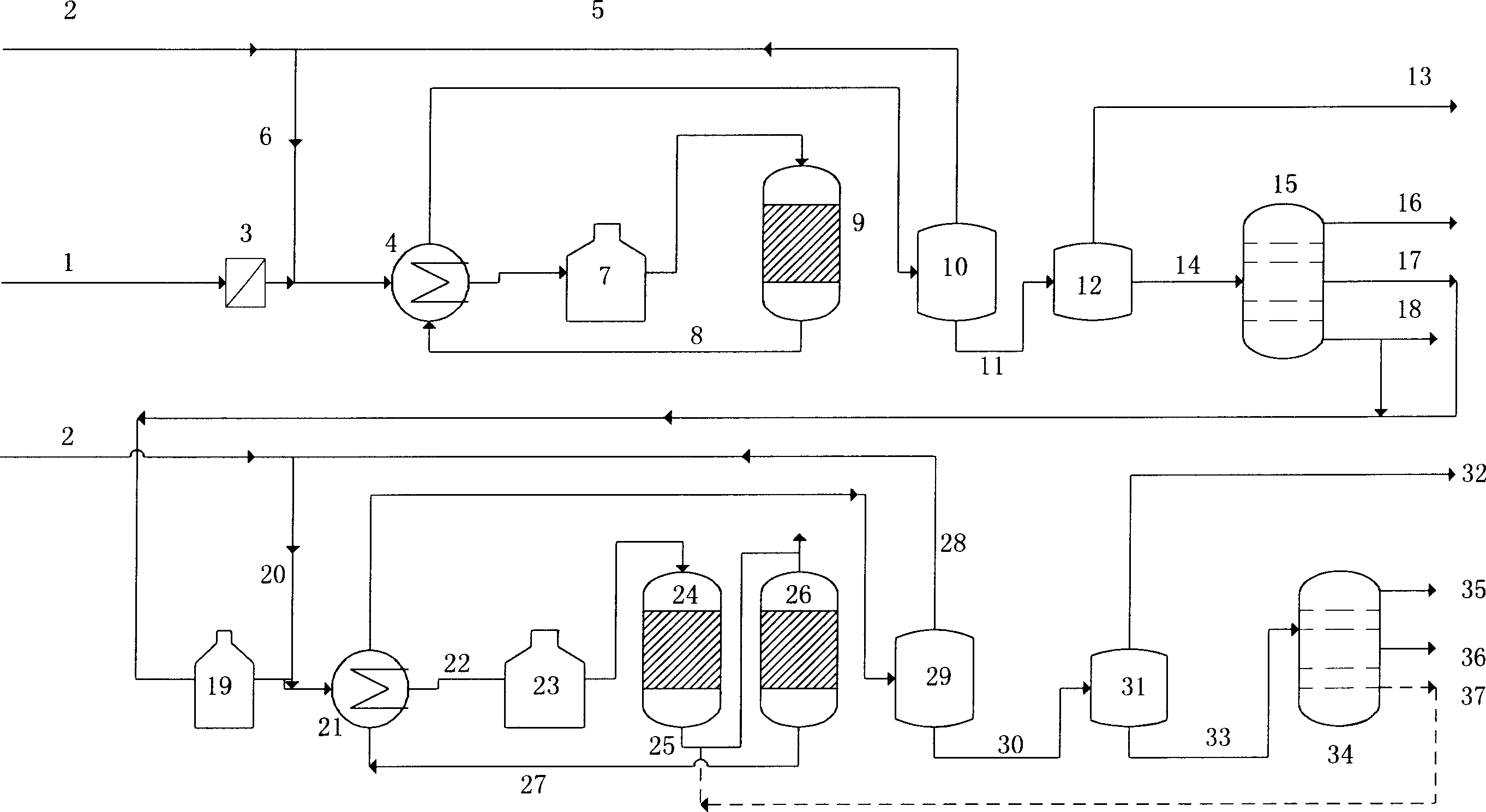

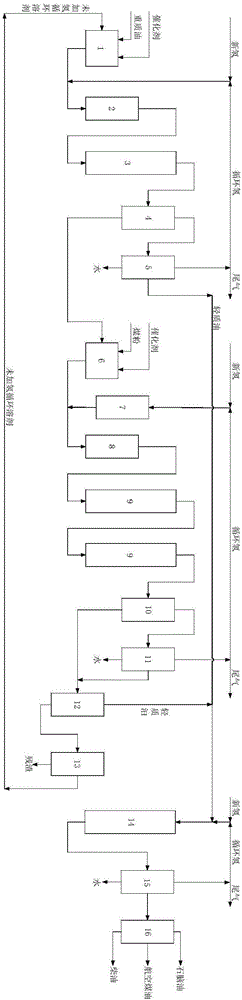

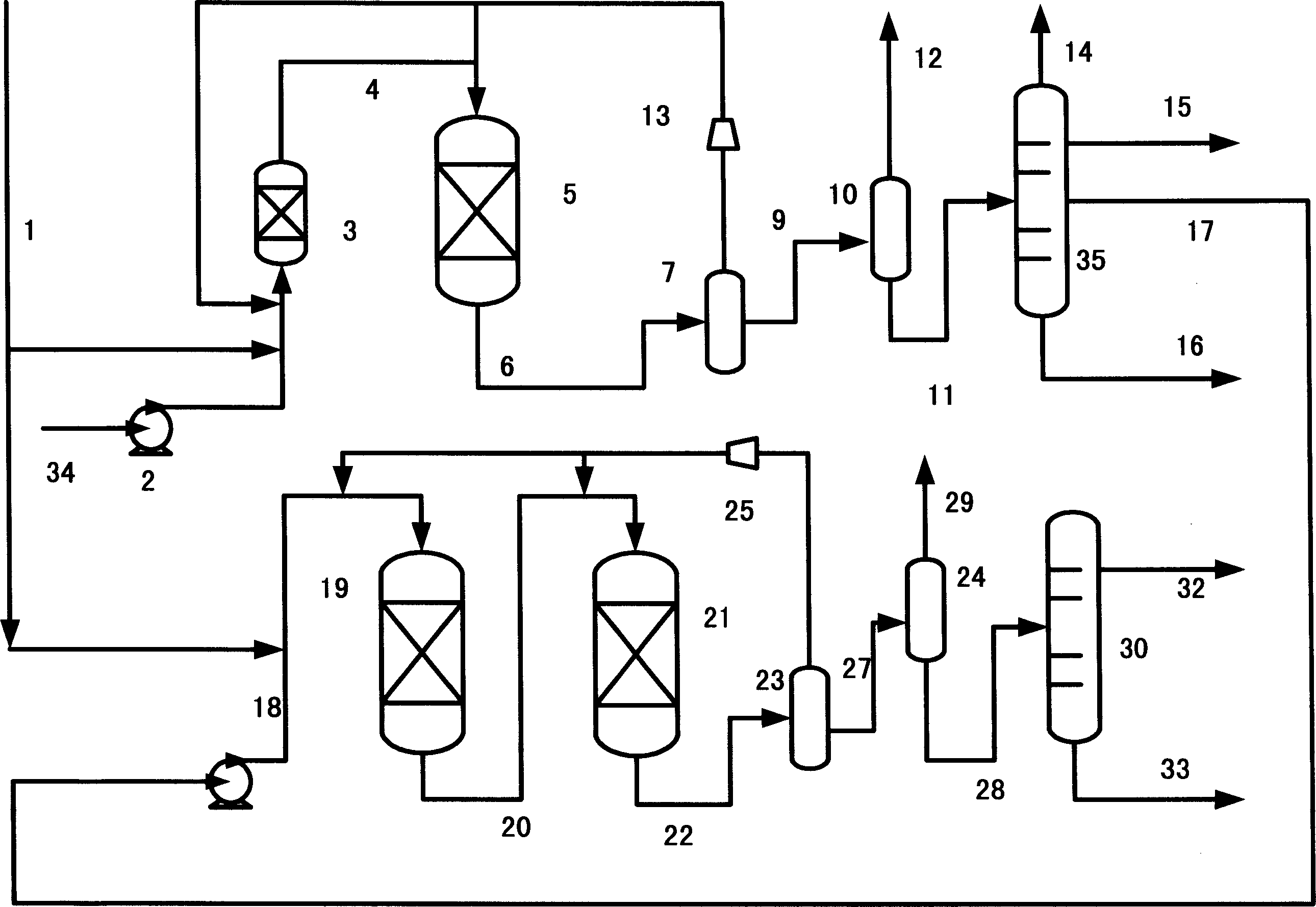

Coal and oil coprocessing method and device

ActiveCN106433775ALow viscosityImprove protectionTreatment with hydrotreatment processesSlurrySolvent

The invention relates to a coal and oil coprocessing method and device. The coprocessing method comprises steps as follows: step one, oil slurry pretreatment: heavy oil, a non-hydrogenated cycling solvent and a first catalyst are mixed, oil slurry is prepared and subjected to first hydrocracking reaction, a first product is obtained and separated, and first light distillate oil and first heavy distillate oil are obtained; step two, coal and oil coprocessing, solvent oil circulation and finished product separation. The coprocessing device comprises an oil slurry pretreatment device, a coal and oil coprocessing device body, a solvent oil circulating device and an oil product quality improving device. According to the coal and oil coprocessing method and device, selectivity for the heavy oil during coal and oil coprocessing is reduced, the percentage amount of pulverized coal in a coal and oil coprocessing process is increased, and the coal and oil coprocessing method and device are more suitable for practical application.

Owner:CCTEG CHINA COAL RES INST

Asphalt strip and preparation and construction methods thereof

ActiveCN104109399AEasy to carryImprove ductilityPaving detailsBuilding insulationsAntioxidantDust control

The invention discloses an asphalt strip and preparation and construction methods thereof, belonging to the technical field of asphalt pavement construction. The asphalt strip is characterized by comprising the following components in parts by weight: 70-90 parts of asphalt, 2-10 parts of a styrene-butadiene copolymer, 8-15 parts of solvent naphtha, 1-5 parts of a filler, 1-5 parts of a stabilizer and 0.1-0.3 part of an antioxidant, wherein the solvent naphtha is one of aromatic hydrocarbon oil, coal tar, diesel oil or kerosene; and the asphalt is petroleum asphalt or coal tar pitch. The construction method of the asphalt strip comprises the following steps: flushing, dedusting, caulking and welting. The asphalt strip has high viscidity and extensibility, filling of a pavement crack can be finished without heating, the construction method of the asphalt strip is short in used time, and can be finished without an assist of crack sealing equipment, and the construction effect is firm and lasting.

Owner:淄博恒信路面材料有限公司

Coal-based military fuel and preparation method thereof

ActiveCN103305266AReasonable processing processAppropriate processing depthTreatment with hydrotreatment processesProcess engineeringFuel oil

The invention discloses a coal-based military fuel and a preparation method thereof. The method comprises the steps of: (1) carrying out distillation cutting on raw oil so as to at least obtain a light fraction and a heavy oil fraction, wherein the raw oil is one or more of oil produced through direct coal liquefaction, oil produced through refining coal and oil together, and pretreated coal tar; (2) enabling the light fraction to enter a hydrofining reactor for hydrofining; and (3) enabling oil produced through hydrofining to enter a fractionating tower for fractionating after the oil is subjected to cooling and gas-liquid separation, thereby obtaining the military fuel. According to the method, the scope of application is wide, the process flow is reasonable, the raw material utilization ratio is high, the varieties of products are multiple, and the operation is flexible, so that the method can be applied to the mass production of various special oils.

Owner:CCTEG CHINA COAL RES INST

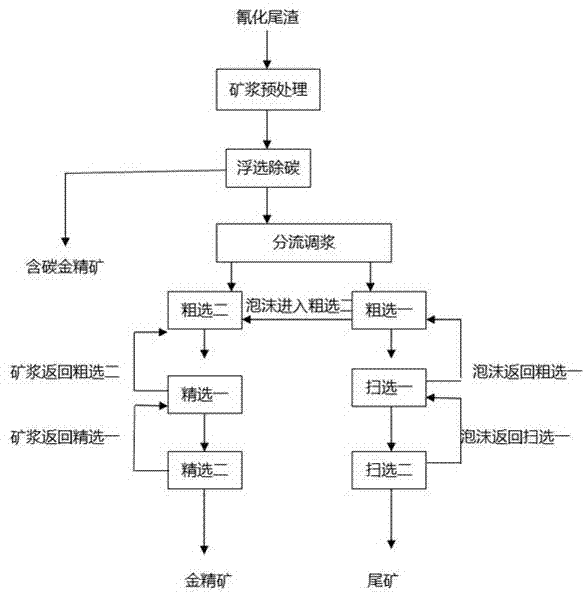

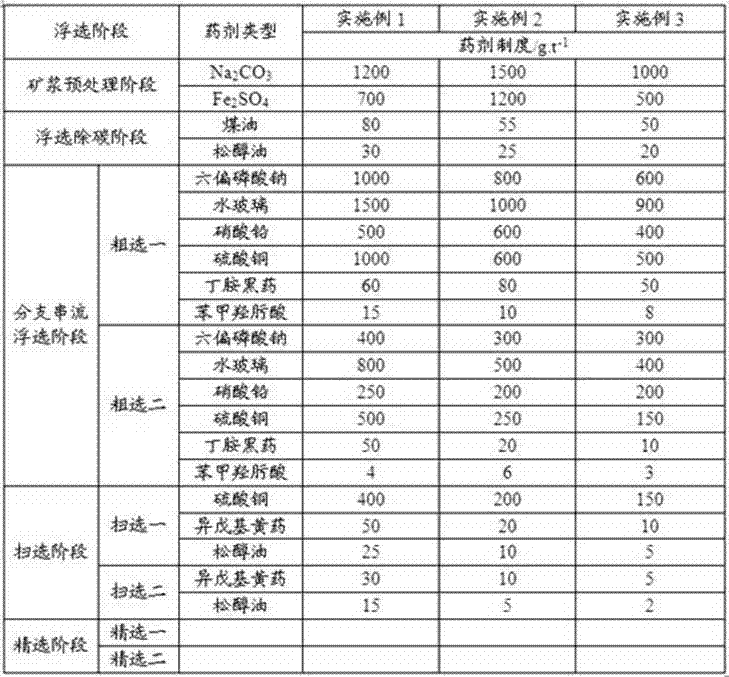

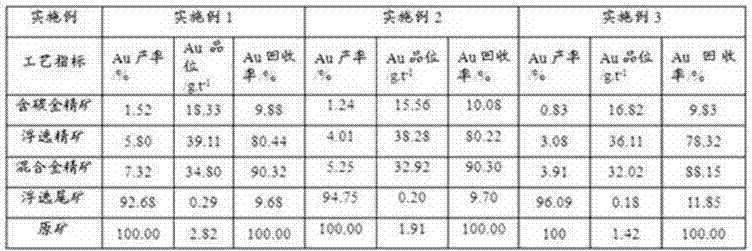

Method for recycling gold in cyanided tailings in ramified and series flotation mode

ActiveCN104722408AIncrease buoyancyHigh recovery rateFlotationPulp and paper industryFerrous sulphate

The invention discloses a method for recycling gold in cyanided tailings in a ramified and series flotation mode. The method includes the following steps that ore pulp pretreatment is conducted, and sodium carbonate and ferrous sulfate are used as ore pulp regulators; coal oil flotation decarbonizing is carried out; ramified pulp mixing is conducted, the decarbonized ore pulp automatically flows to a stirring and distributing groove, and the ore pulp is evenly distributed to two pulp mixing barrels for mixing pulp through the stirring and distributing groove; ramified and series flotation is performed, foam products in first rougher flotation fully enter in second rougher flotation to be subjected to flotation together with the decarbonized ore pulp, foam products in second rougher flotation undergo closed circuit concentration operation of first concentration and second concentration to obtain gold concentrate, and no drug is added in the concentration stage; products in the groove of first rougher flotation are subjected to closed circuit scavenging of first scavenging and second scavenging to obtain tailings. By the adoption of the method, the recovery rate of the gold can be improved obviously, meanwhile, drug consumption is lowered, and the cost is saved.

Owner:GUIZHOU ZIJIN MINING

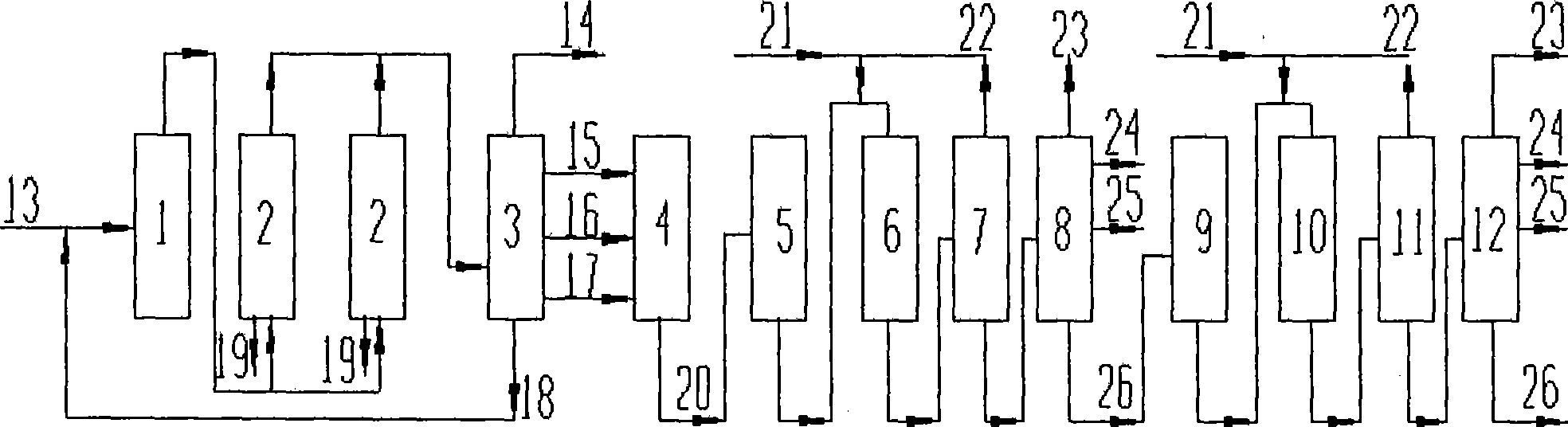

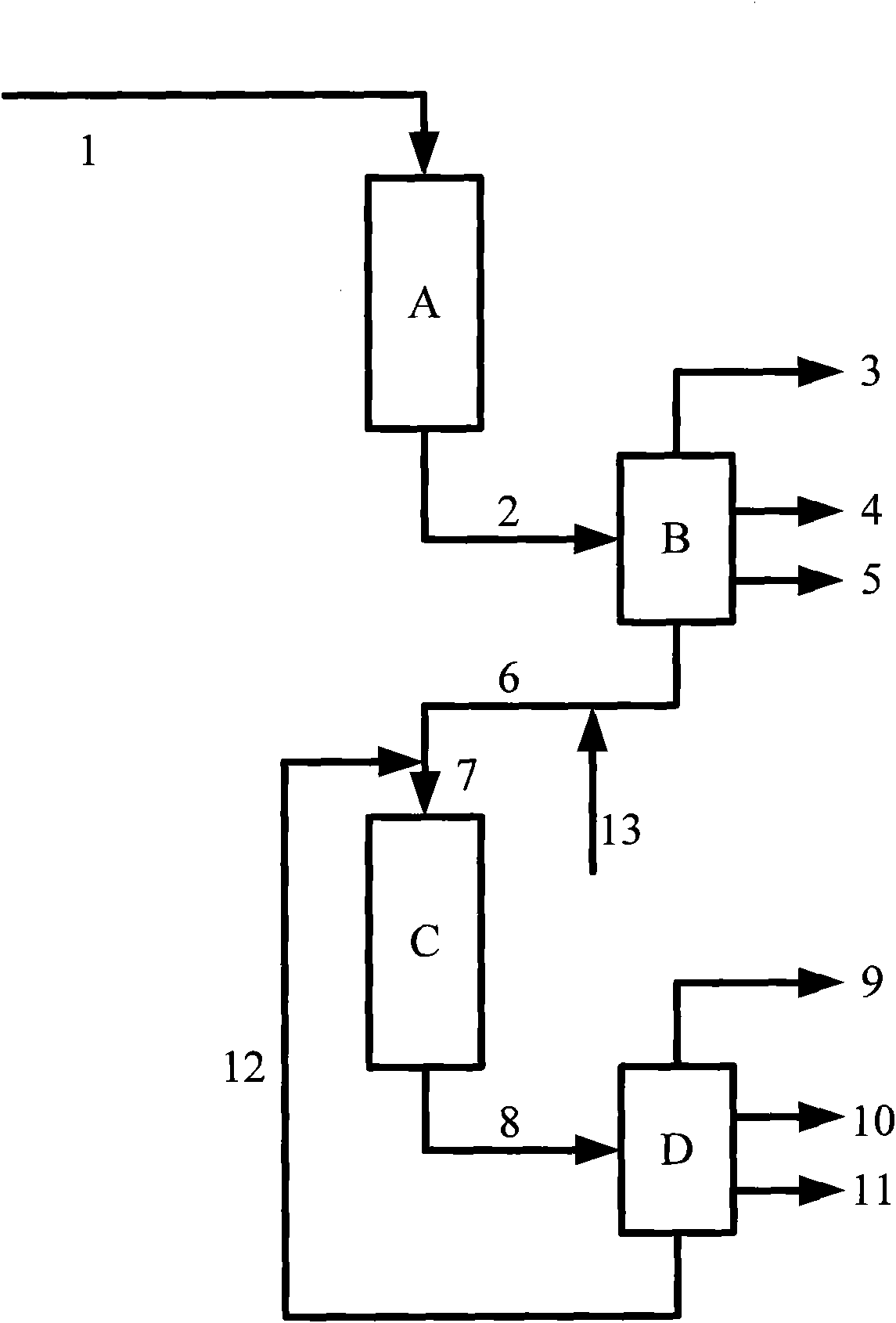

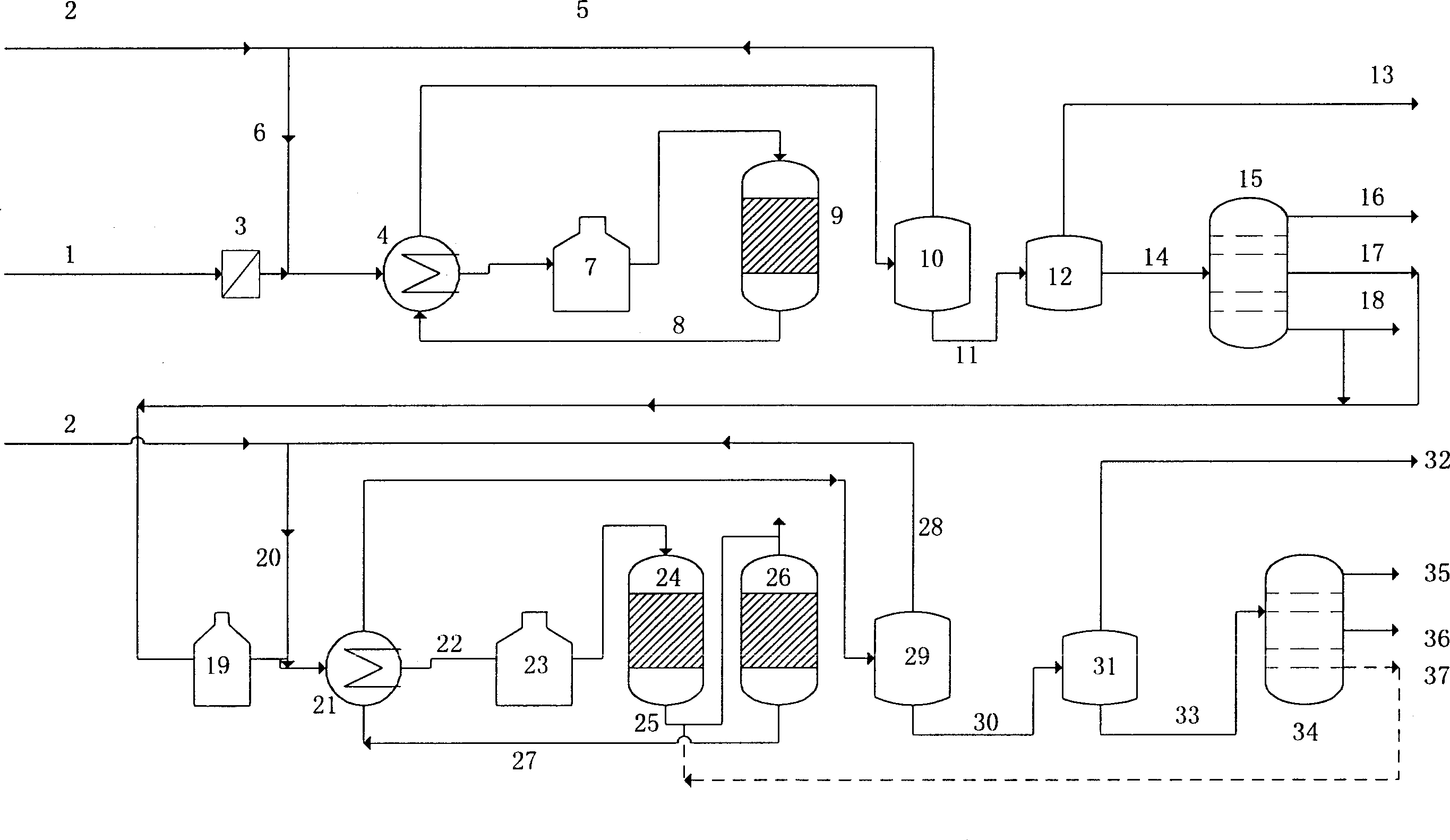

Production of large-specific-weight aircraft liquid petroleum oil at maximum from coal liquefied oil

ActiveCN1896189AHigh yieldLiquid hydrocarbon mixture productionRefining to eliminate hetero atomsHydrogenOil production

Production of large-specific weight aviation kerosene from coal liquefied oil at maximum is carried out by entering coal liquefied oil into protective reactor, contacting it with hydrogen and protective agent, entering reactant of protective reactor into stabilized hydrogenation main reactor, contacting with hydrogen and hydrogenation stabilized catalyst, separating for reactant of stabilized hydrogenation main reactor to obtain intermediate distillate, entering it into hydrogenation qualified reactor, contacting with hydrogen, hydrogenation refined catalyst and hydrogenation qualified catalyst and separating from reactant of hydrogenation qualified reactor to obtain the final product. The recovery rate of aviation kerosene can reach to 45% and its specific weight is >0.84g / cm3.

Owner:CHINA PETROLEUM & CHEM CORP

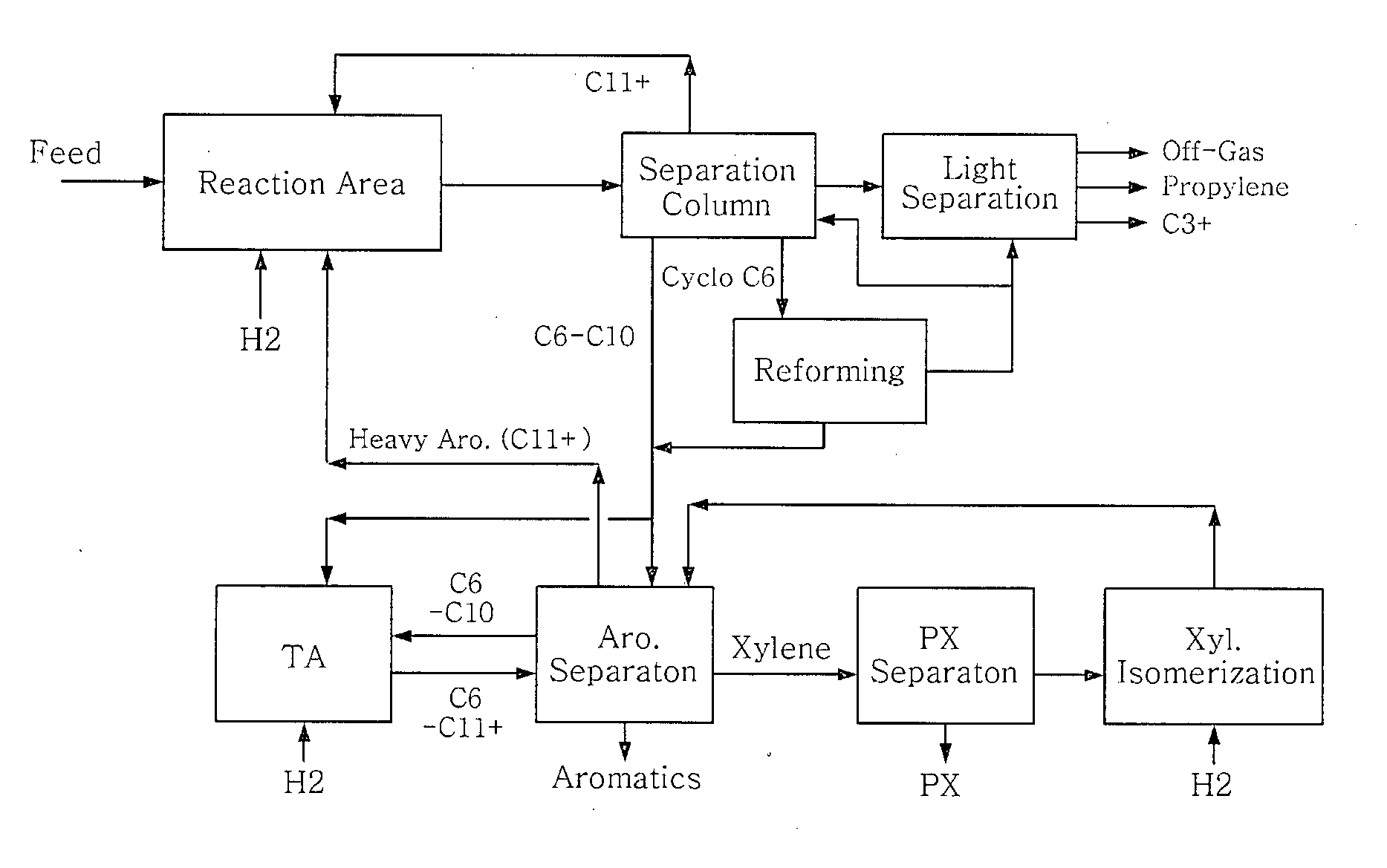

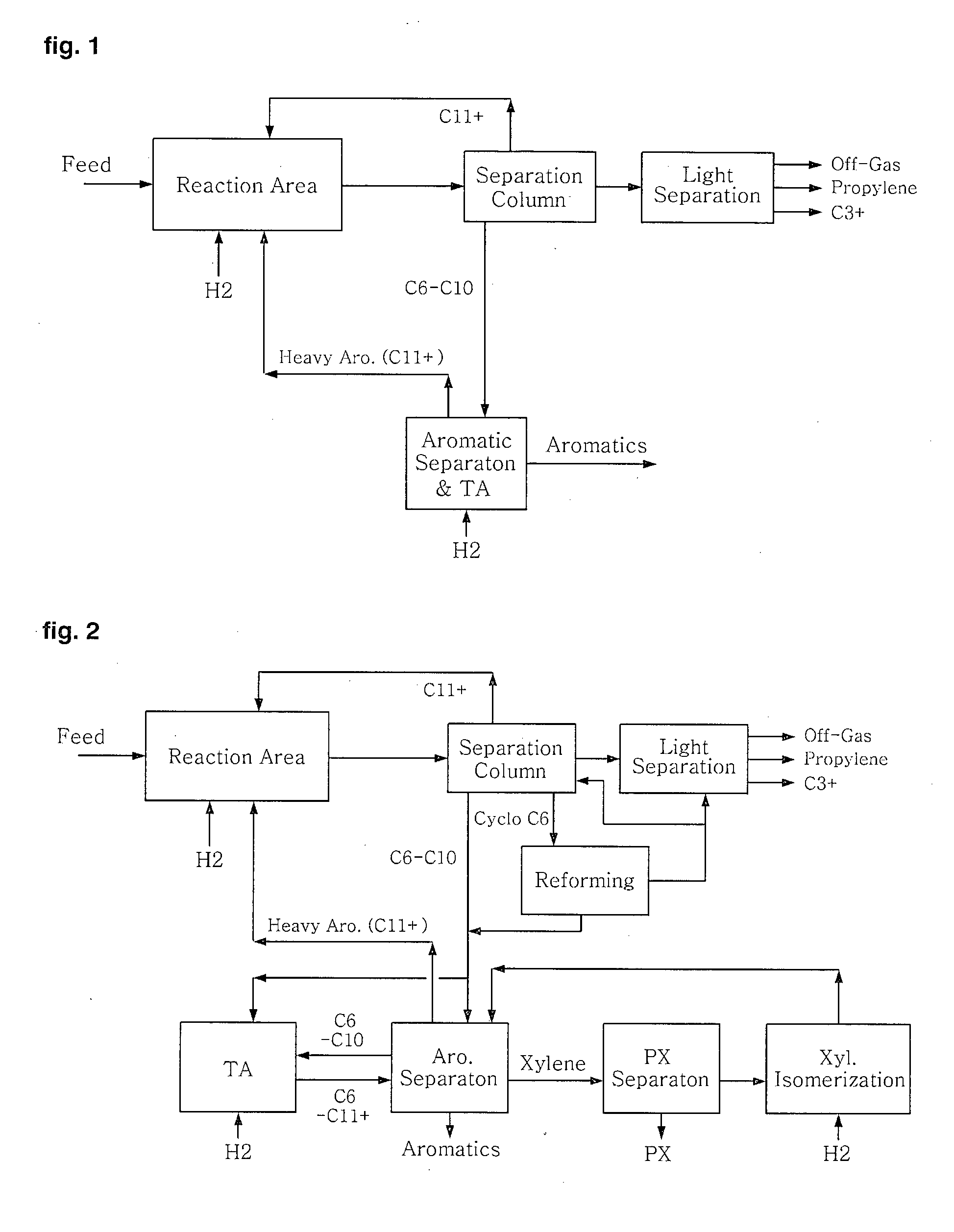

Method of producing valuable aromatics and olefins from hydrocarbonaceous oils derived from coal or wood

ActiveUS20130178673A1Increase valueIncrease valuablenessHydrocarbon by isomerisationMolecular sieve catalystSeparation processCoal

This invention relates to a method of producing aromatics and olefins from oils derived from coal or wood, including partially saturating and cracking the oils derived from coal or wood in a hydrogenation & reaction area, separating them depending on the number of carbons, recirculating heavy oils having 11 or more carbons to the hydrogenation & reaction area, feeding oils suitable for producing BTX to an aromatic separation process and a transalkylation process to recover aromatics, and feeding hydrocarbonaceous components having 5 or less carbons to a light separation process, thus obtaining olefins.

Owner:SK INNOVATION CO LTD

Stable hydrogenation process for liquefied coal coil

InactiveCN1382771AReduce olefinsLow aromatic contentHydrocarbon oils refiningHydrogenation processHigh pressure

A stable hydrogenation process of liquefied coal oil includes filtering the liquefied coal oil, adding it along with hydrogen gas to stable hydrogenation reactor, contacting with hydroprotector and hydrorefining catalyst, flowing in its product through high-pressure separator, low-pressure separator and fractional tower to respectively obtain hydrogen-enriched airflow, light fraction and tail oilfraction, mixing said hydrogen-enriched airflow with fresh hydrogen, and returning the mixture back to said stable hydrogenation reactor. It has high effect on removing impurities from liquefied oil to maximum.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process to upgrade kerosenes and a gasoils from naphthenic and aromatic crude petroleum sources

A process to prepare a kerosene and a gasoil product from a crude petroleum source having a Watson characterization factor K value of equal or below 12.0 by (a) isolation of a petroleum derived kerosene fraction and a petroleum derived gasoil fraction from said crude petroleum source, wherein the petroleum derived kerosene fraction has a smoke point of below 25 mm or below 19 mm if naphthalenes content of the kerosene fraction is below 3% vol and the petroleum derived gas oil has a cetane number of below 50 or a density higher than 845 kg / m3, ( ) adding a Fischer-Tropsch derived kerosene fraction to the petroleum derived kerosene fraction in an amount sufficient to obtain a mixture having a smoke point value of above 25 mm or above 19 mm if the naphthalenes content of the mixture is below 3% vol and (c) adding a Fischer-Tropsch derived gas oil fraction to the petroleum derived gasoil fraction such that the resultant mixture has a cetane number value of above 51.

Owner:SHELL OIL CO

Process for preparing hihg-quality diesel oil or jet fuel maximumly from coal liquefied oil

A process for preparing high-quality diesel oil or jet fuel from liquefied coal oil with the highest output includes filtering, stable hydrogenation to obtain diesel oil fraction and tail oil fraction, modifying them by deep hydrogenation, separating its product to obtain gas, naphtha fraction, diesel oil fraction, jet fuel, and tail oil fraction, and cyclic use of hydrogen-enriched gas. Its advantages are high output rate of diesel oil (more than 70 wt.%), low contents of S and N, low density and high hexadecane number.

Owner:CHINA PETROLEUM & CHEM CORP +1

Coking light distillate hydrogenation modification method

ActiveCN101434864AAdaptableSimple processTreatment with hydrotreatment processesLiquid productHydrogen

The invention relates to a method used for hydrogenation modification of coking light distillate oil; under hydrogenation refining condition, the raw material of the coking light distillate oil and hydrogen are contacted with W-Mo-Ni series of hydrogenation catalysts firstly; subsequently, naphtha distillate, coal oil distillate and diesel distillate are gained by stripping and distillation; wherein, the coal oil distillate and new hydrogen enter a low-pressure hydrogenation reactor and are contacted with Ni-series of hydrogenation catalysts; the product is separated by a gas-liquid separator; and the liquid product is used as high-quality jet fuel components and the hydrogen-rich gas is returned to the coking light distillate oil raw material and used for hydrogenation refining. The method can process the coking light distillate oil with bad quality into high-quality jet fuel, high-quality naphtha and clean diesel components by simple process, has the advantages of wide application of the raw material, flexible operation, stable running, and the like, and effectively improves the economical benefits of the enterprises.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com