Method for preparing fuel oil with coal oil hydrogenation

A technology for coal tar and fuel oil, which is used in hydrotreating process, petroleum industry, processing of hydrocarbon oil, etc., can solve the problems that cannot be directly used as a product, affects the activity and stability of hydrocracking catalyst, and has high content of aromatics in diesel oil. The effect of cost-effective reforming reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

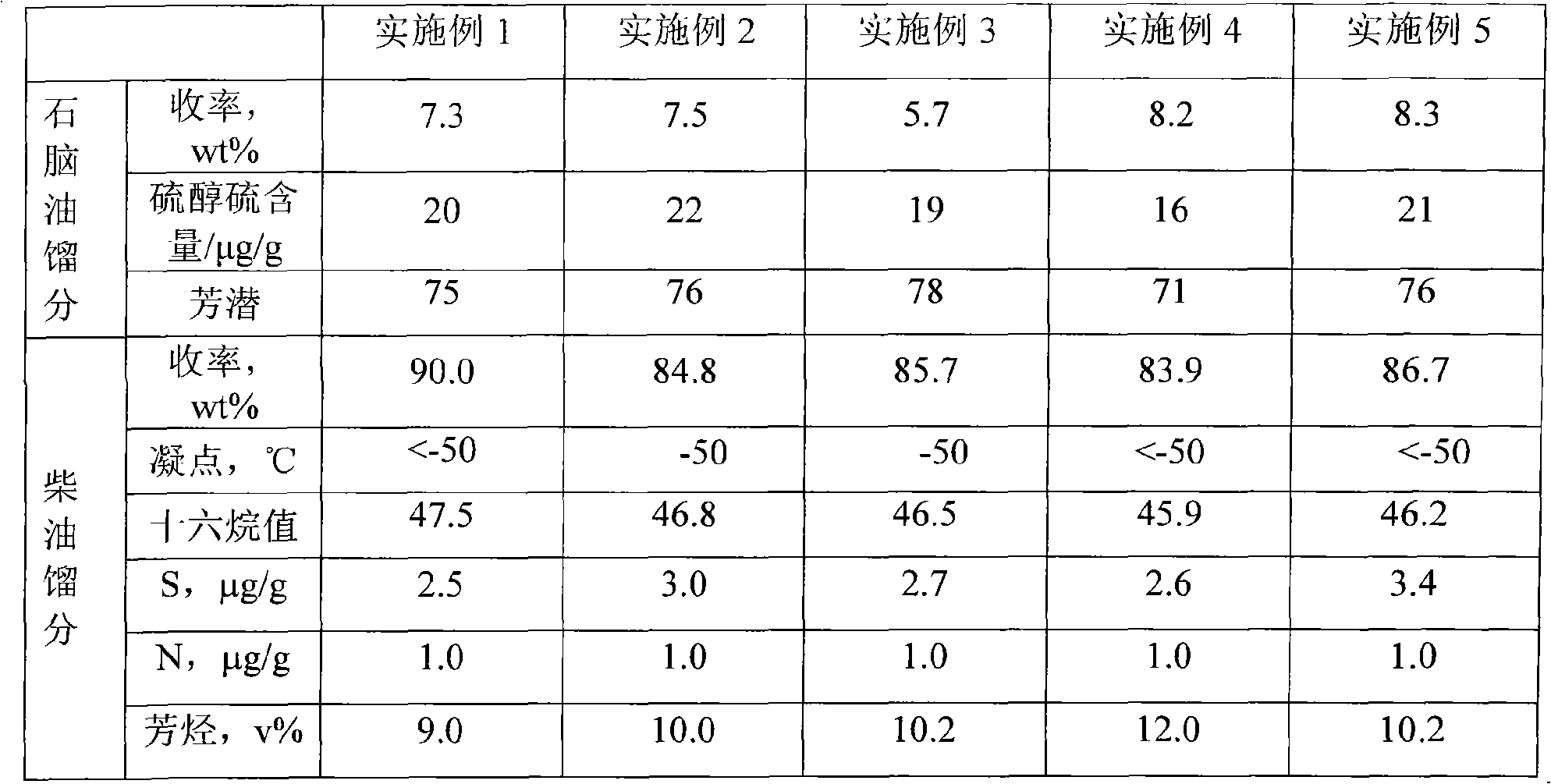

[0031] The examples 1-5 show the effect of using the first method to upgrade diesel oil.

[0032] The raw material oil used in the embodiment is heavy tar, and its properties are shown in Table 1. (wherein wt% is weight percent)

[0033] Table 1 Raw Oil Properties

[0034] Raw oil

1#

2#

Density, g / cm 3

1.10

1.16

Distillation range / ℃

190~420

250~600

Carbon residue, wt%

0.2

2.8

Sulfur content, wt%

0.49

0.52

Nitrogen content, wt%

0.99

1.11

Metal content, μg g -1

33.0

20.0

Oxygen content, wt%

1.3

2.0

Aromatic content, wt%

100.0

100.0

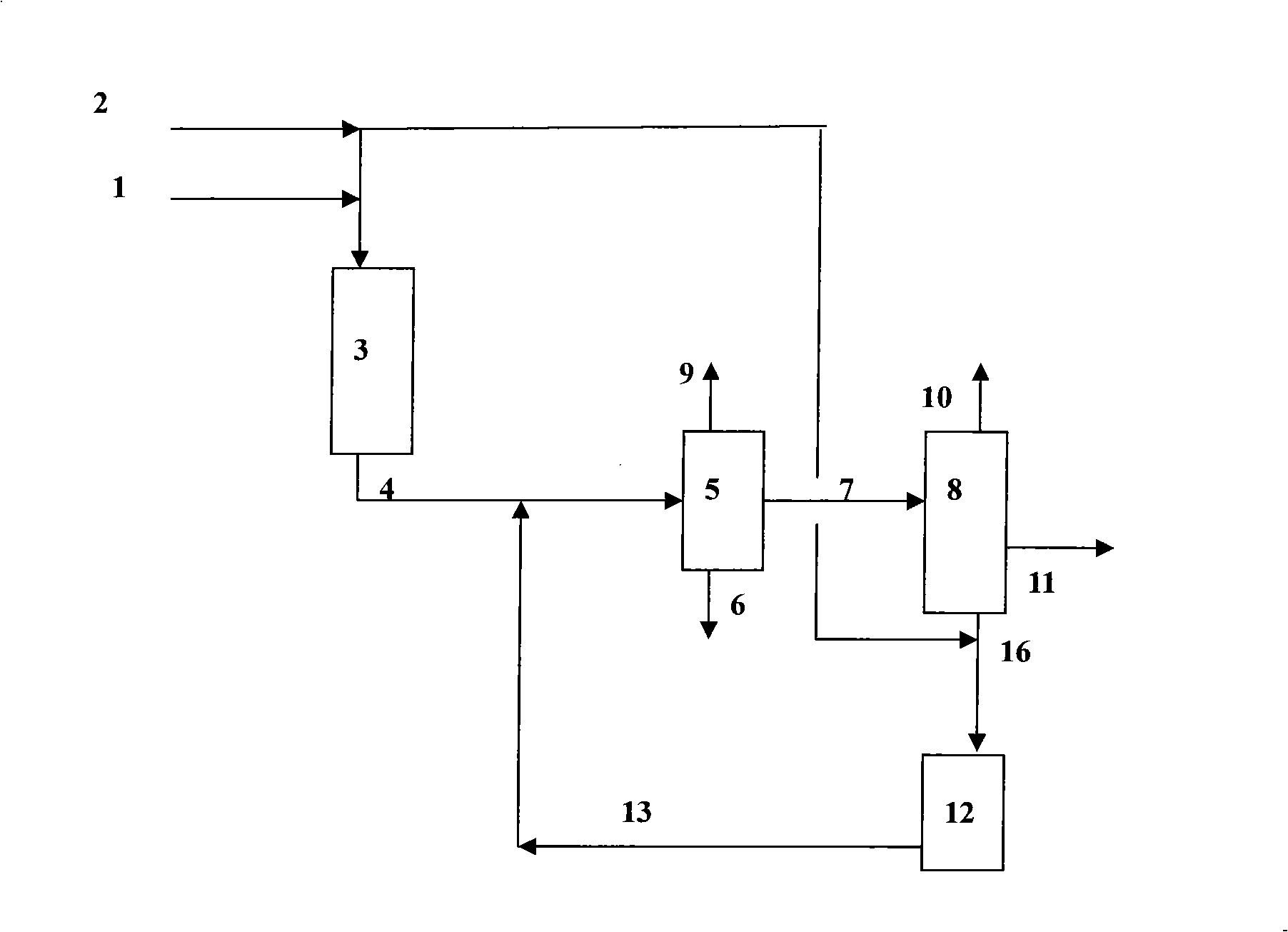

[0035] exist figure 1 On the basis of the process flow, the hydro-upgrading reaction part is added, and the details are as follows: a set of separation system is used for hydro-refining and hydro-refining / cracking, and the diesel fraction 11 separated from the fracti...

Embodiment 6~8

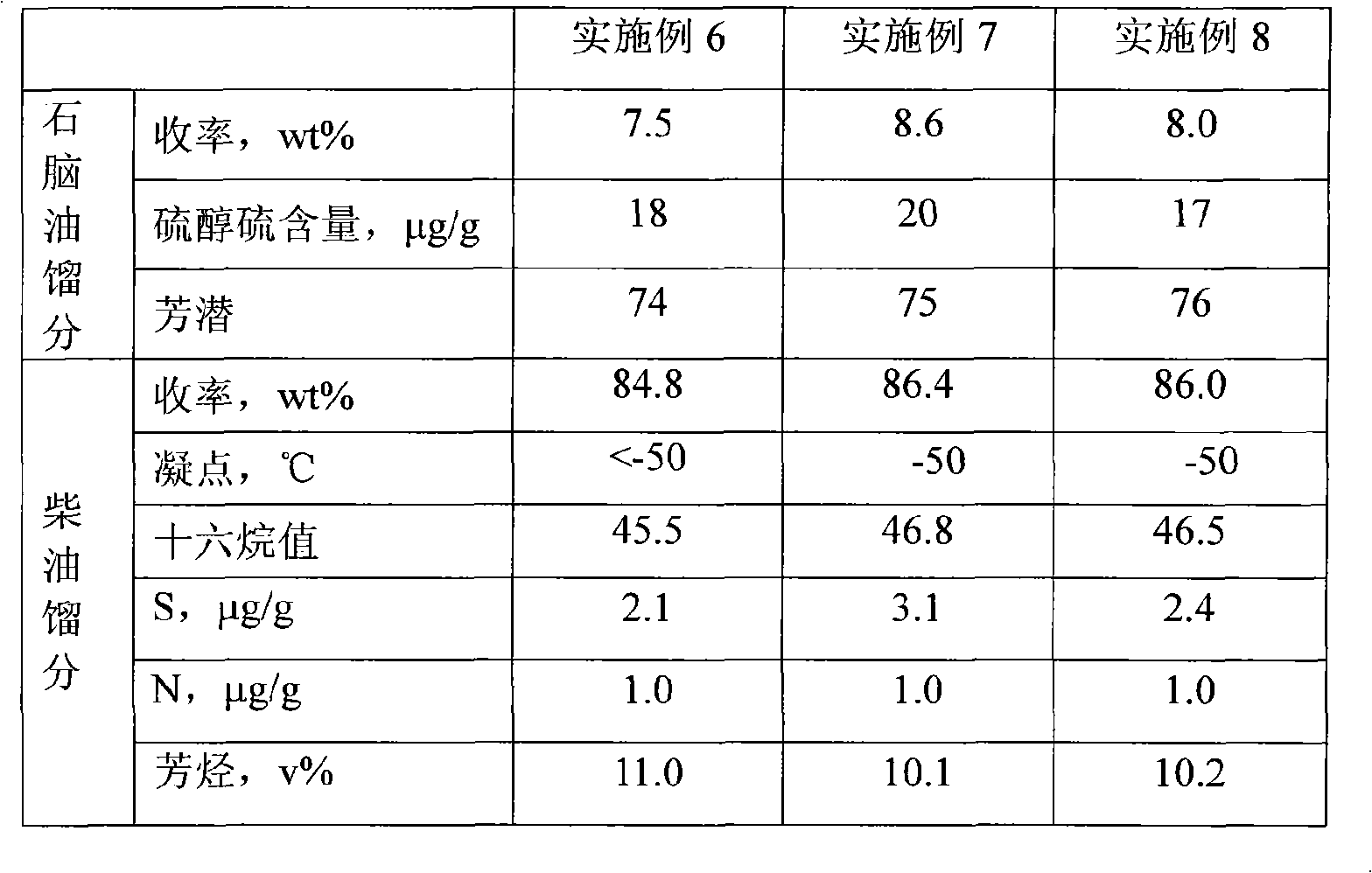

[0047] This example shows the effect of using the second method to upgrade diesel oil.

[0048] exist figure 1 On the basis of the flow process, a hydro-upgrading reactor is added, as follows: hydro-refining and hydro-refining / cracking adopt a set of separation system, which includes a gas-liquid separator 5 and a fractionation tower 8, and the liquid separated by the separator 5 The phase-generated oil enters the hydro-upgrading reactor, and the hydro-upgrading product enters the fractionation tower 8, and is fractionated to obtain naphtha 10, diesel oil 11, and heavy fraction 16, and the heavy fraction 16 enters the hydrotreating / cracking reactor. The resulting light fractions of different distillation ranges, process conditions and product properties are shown in Table 3. Wherein embodiment 6, embodiment 7 and the catalyst that the raw material that embodiment 6, embodiment 7 and embodiment 8 adopt, hydrorefining reactor and hydrorefining / cracking reactor are used and oper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com