Patents

Literature

56results about How to "Improve fouling problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

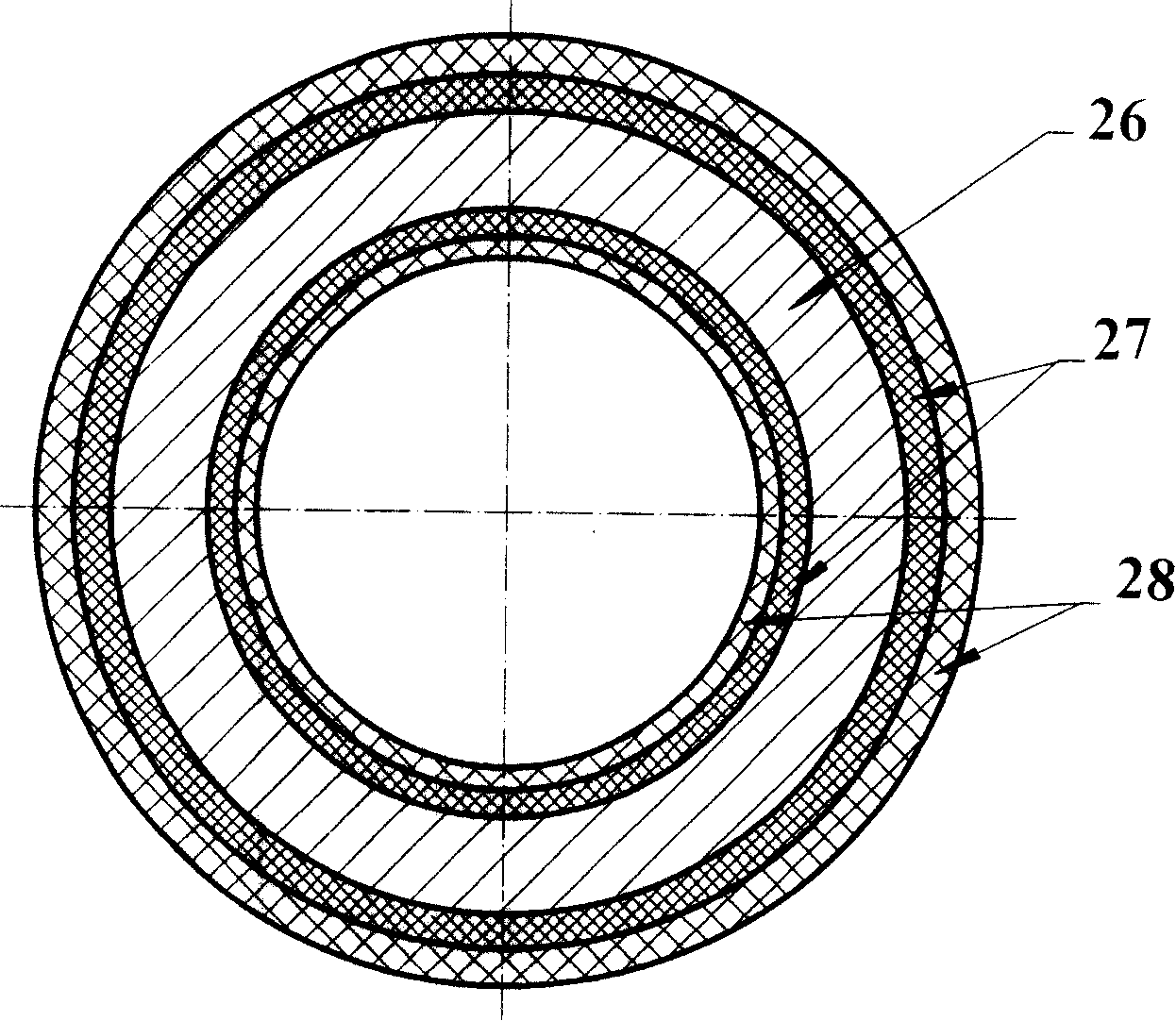

Nano coating protective pipe and its coating manufacture process

InactiveCN101169215ASmall volume shrinkageSmooth rotationCorrosion preventionPipe protection against corrosion/incrustationSteel tubeParaffin oils

The invention discloses a nanometer coating protective pipe prepared by nanometer squama coating and production technique of coating, wherein, the nanometer coating protective pipe consists of three parts of a pipe body, a basal layer and a function layer. The basal layer is the substrate of the nanometer coating and coated on the surface of the pipe body when contacts with a metal base body. The function layer is the facial layer of the nanometer coating and coated on the surface of the basal layer when the function layer contacts with corrosive medium. The nanometer coating the protective pipe disclosed in the invention changes the surface characteristic of the steel pipe products, and acquires a novel characteristic completely different from the original steel pipe products and enables the products to satisfy the need of people towards hi-tech development. The nanometer coating can provide oil pipe products with good performance in resisting corrosion, paraffin, scale and abrasion, so as to greatly prolong the maintenance period of the pipeline products in oil extracting wells, water injecting wells and conveying pipelines of oil fields.

Owner:白日忠

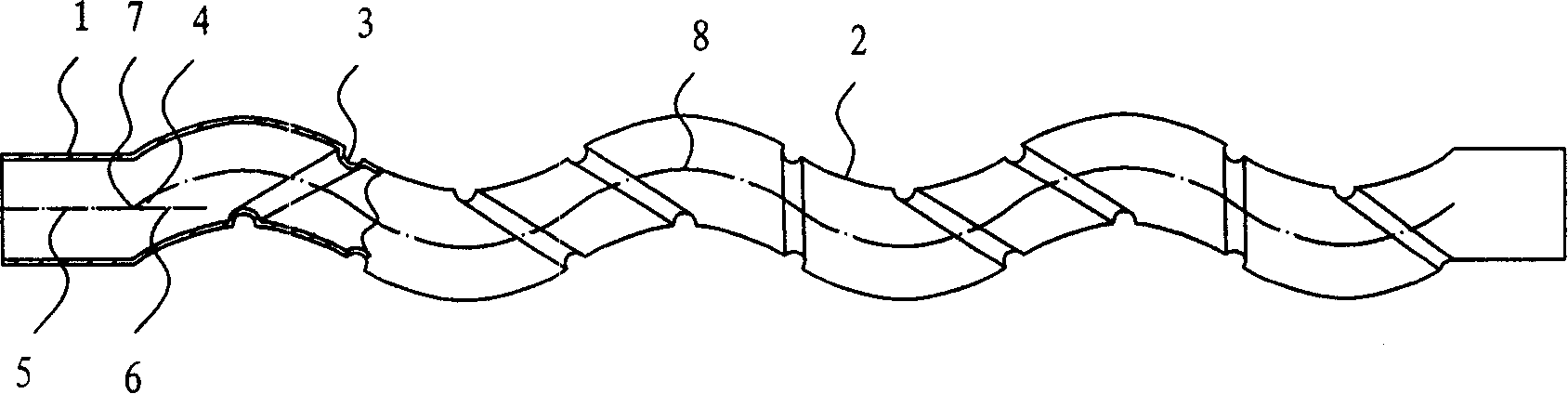

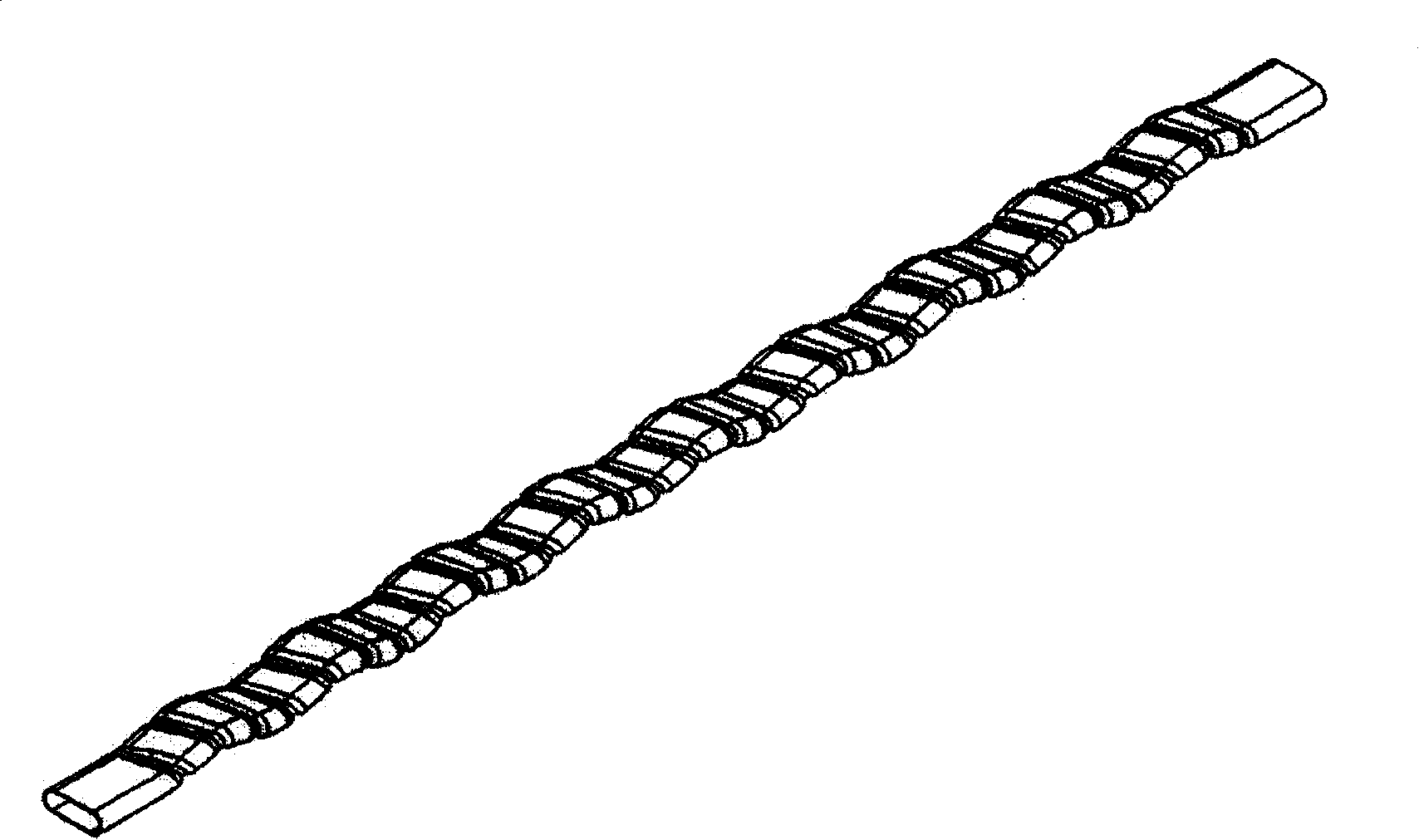

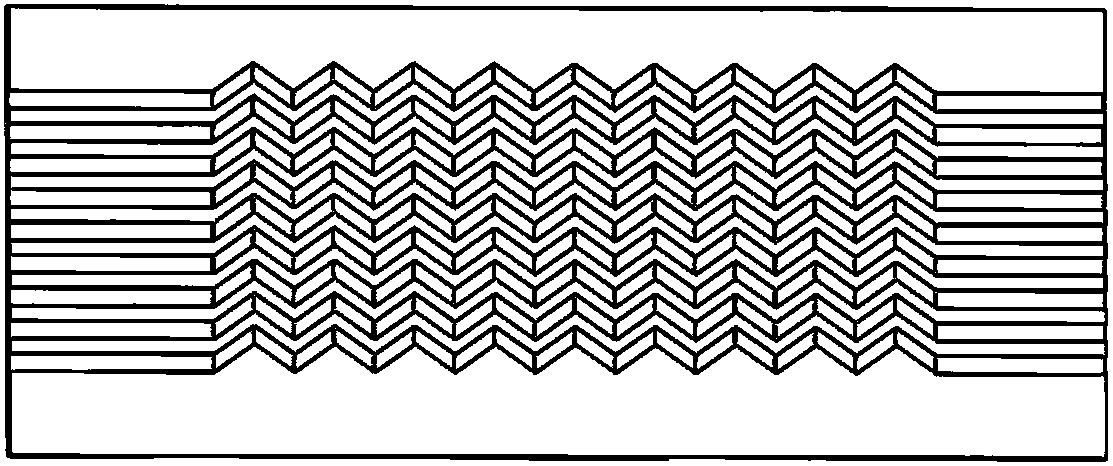

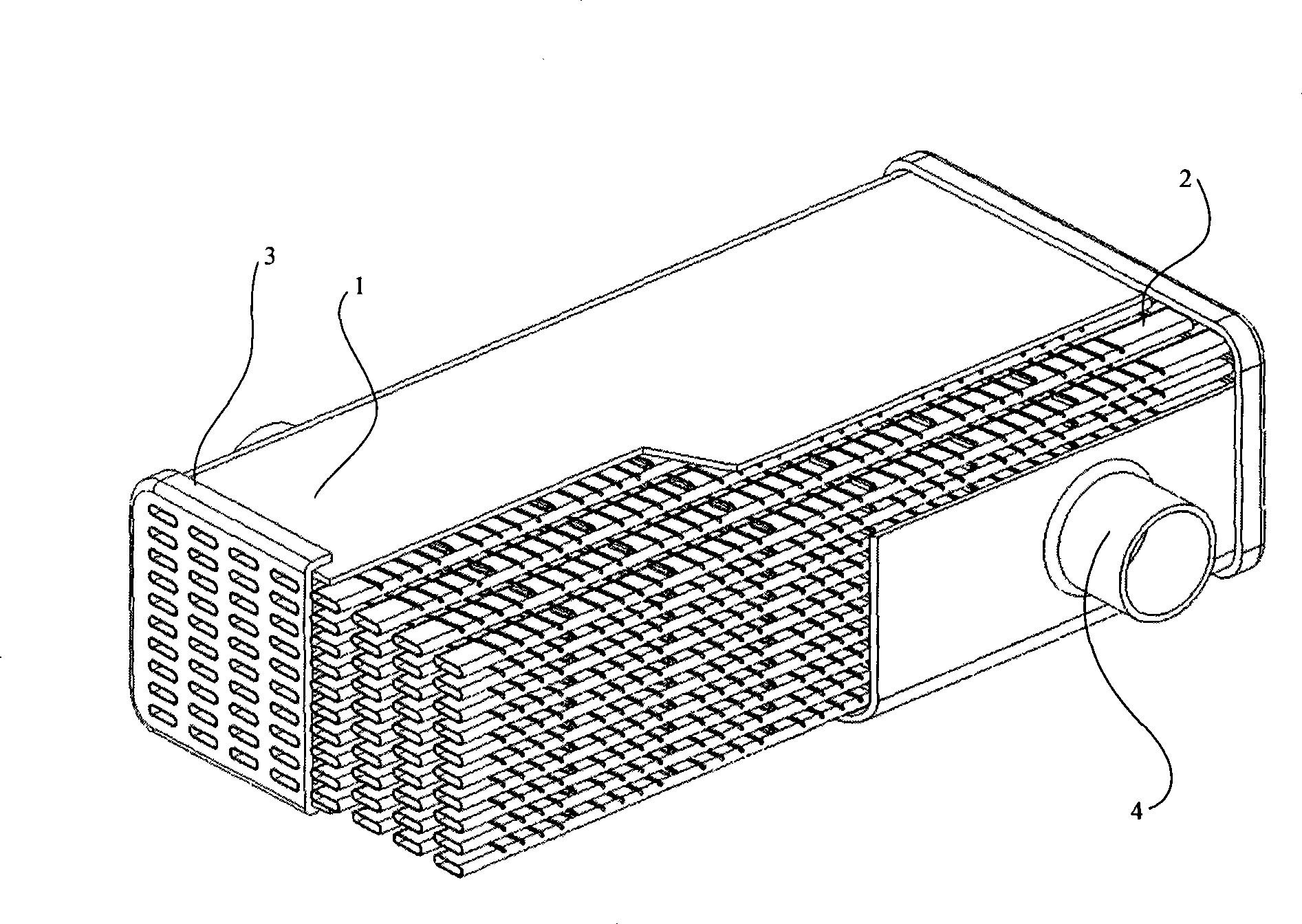

Wave-shaped helical groove heat exchange tube and heat exchanger thereof

ActiveCN101206101APromotes turbulent flowEasy to separateStationary conduit assembliesHeat transfer modificationHorizontal axisIntercooler

The invention relates to an undee helical groove heat exchange tube and a heat exchanger thereof; the surface of the heat exchange tube is provided with a helical groove protruding inward the tube; two ends of the heat exchange tube body along the length direction are straight tube sections; the middle section is an undee bended tube section; the undee shape is formed that the section center of the heat exchange tube bends upwards and downwards along the horizontal axis; the upper maximal bended range and the lower maximal range are the same; compared with the prior art: 1. Liquid in a bended flow channel is forced to change the flowing direction continuously by the bend setting of the heat exchange tube, thereby promoting the onflow flowing of the liquid; 2. The invention has the effect of strengthening the flowing and promoting the full and uniform mixing of the flowing of refrigerant outside the tube; 3. On the premise of not increasing the length of the heat exchanger, the length of the heat exchange tube is increased; 4. Compared with the prior art, the heat exchange efficiency of the heat exchanger of the invention improves by 5 percent to 10 percent. The invention is in particular suitable for an exhaust gas recycling cooler of an automobile engine to reduce the discharge of automobile tail gas pollutant or is used as an engine turbine pressurization intercooler to improve the performance of the engine.

Owner:BEIJING U BRIDGE CHAOYANG +1

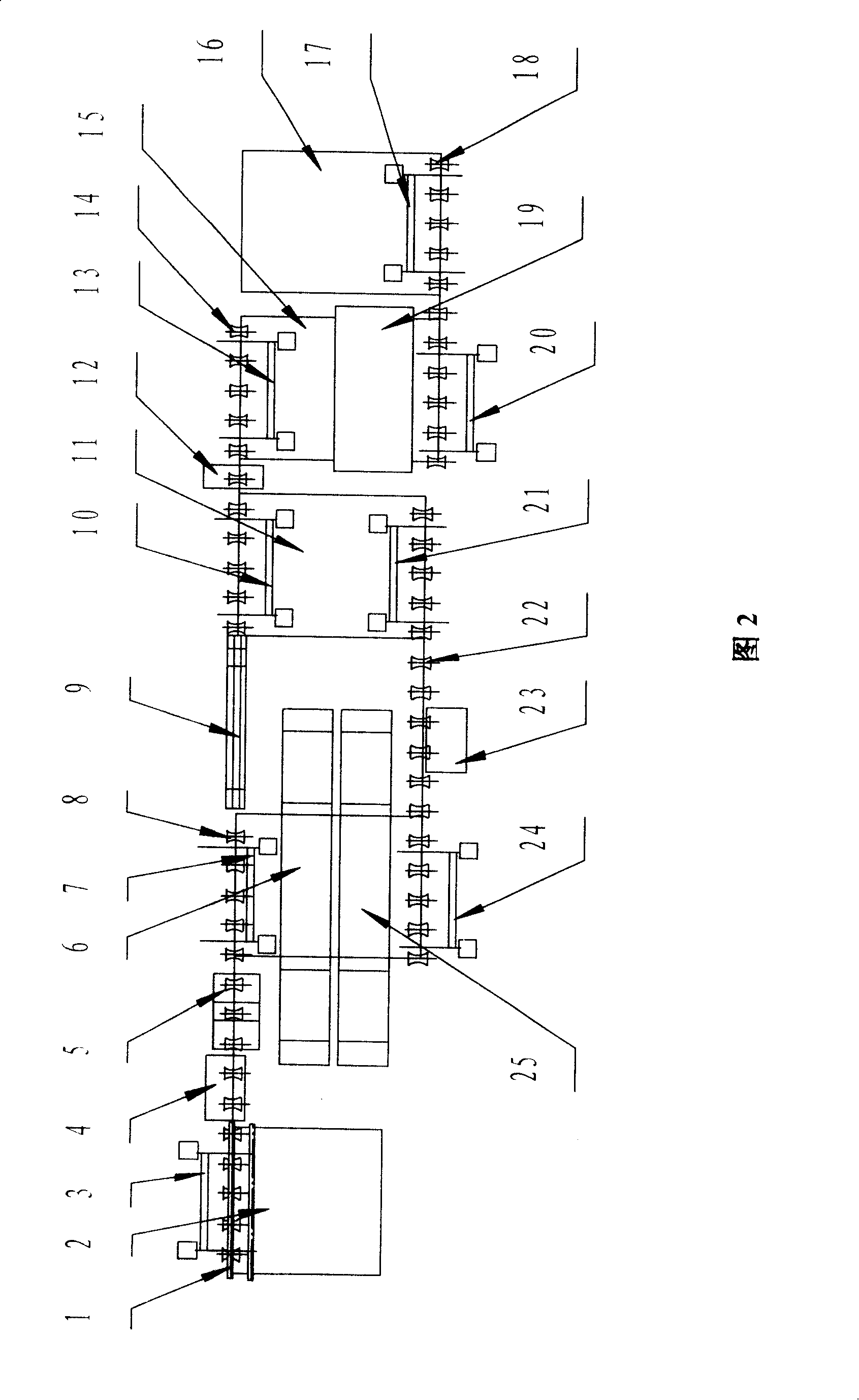

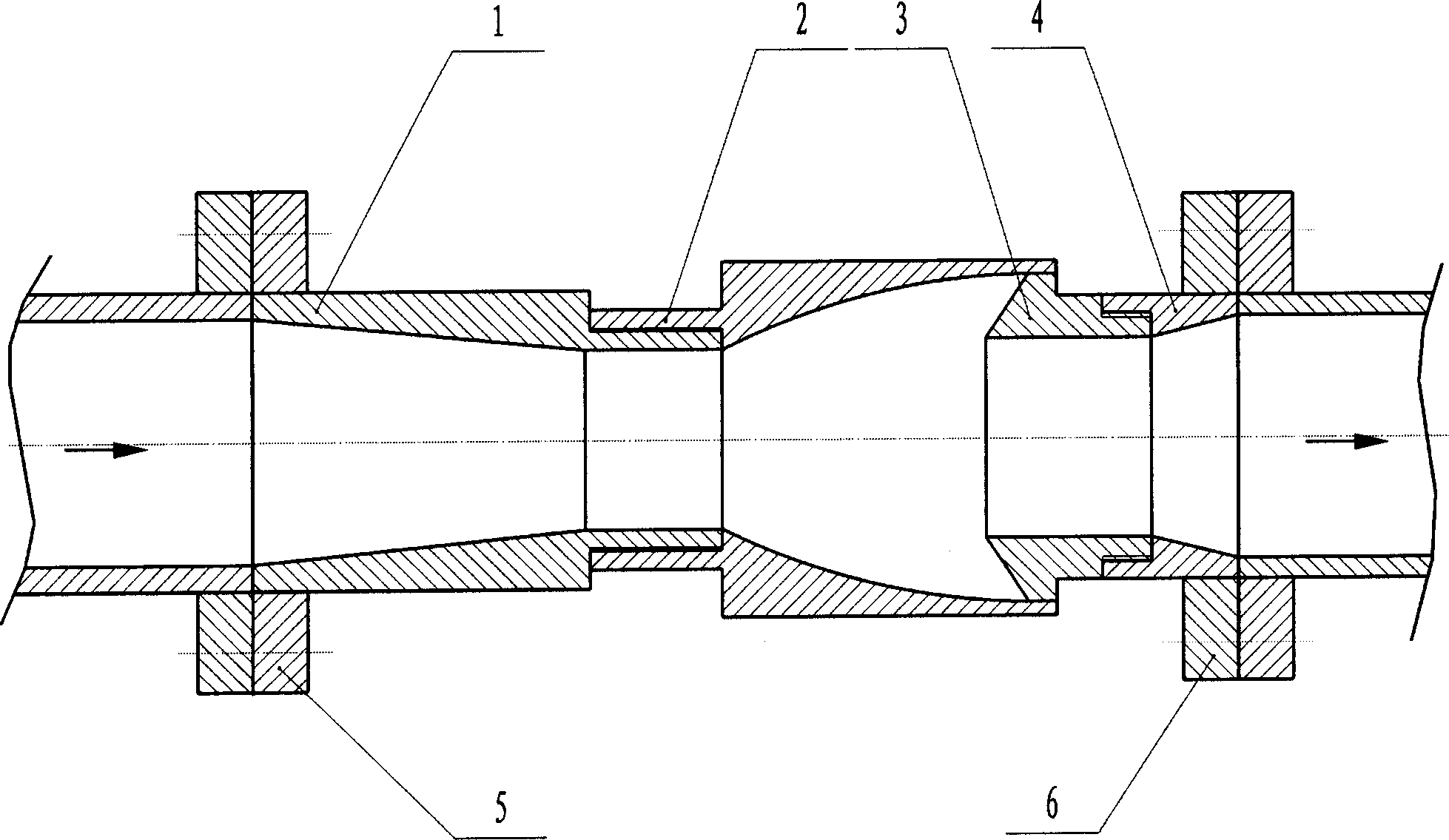

Pipe pulse stream generator

InactiveCN1800658AImprove flow characteristicsLittle resistance lossFluid dynamicsImpulse frequencyPulse stream

The invention relates to a pipe impulse flow generator, belonging to the heat-matter transmission high-efficiency energy-saving device of natural gas and oil. The invention can reduce the resistance of transmitting liquid, save energy, decrease the deposition of olefin, and improve the heat efficiency of transmitting heat and matter. The invention comprises a upper nozzle, a self-excite chamber, a lower nozzle, and a pipe which are sequentially sealed, fixed and connected; the inlet of upper nozzle and the outlet of pipe are individually connected to the inlet and outlet pipe. The invention can use said generator to transform the continuous liquid via the self-excite chamber into impulse liquid without any auxiliary device, and improved amplitude of output pressure as 15-30%, increased impulse frequency from tens to hundreds, to reduce the resistance, save energy consumption and apply variable industries.

Owner:CHONGQING UNIV

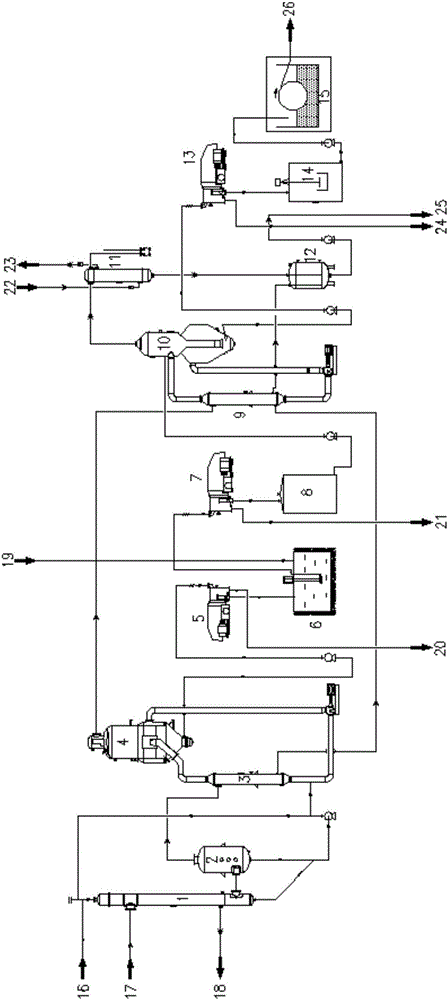

Technique for simple substance salt separation with co-production of sodium sulfide from high-salinity wastewater

InactiveCN105152186AUniform particlesProcess conditions are stableCalcium/strontium/barium sulfatesAlkali metal sulfides/polysulfidesSodium sulfateImpurity

The invention discloses a technique for simple substance salt separation with co-production of sodium sulfide from high-salinity wastewater containing sodium sulfate and sodium chloride and belongs to the field of sewage treatment. The technique comprises the following steps: producing sodium sulfate with a primary evaporative crystallization method, removing SO4<2-> from the high-salinity wastewater with a chemical precipitation method, producing sodium chloride with a secondary evaporative crystallization method and producing sodium sulfide from final mother liquor with a cooling method. The whole treatment process is required to be controlled under a slightly alkaline condition. According to the technique, sodium sulfate and sodium chloride in the high-salinity wastewater can be recycled effectively, residual mother liquor can be used for producing sodium sulfide, most impurities can be removed, zero emission can be realized, the environmental protection pressure and the wastewater treatment cost are reduced greatly, and new economic benefit points can be created.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

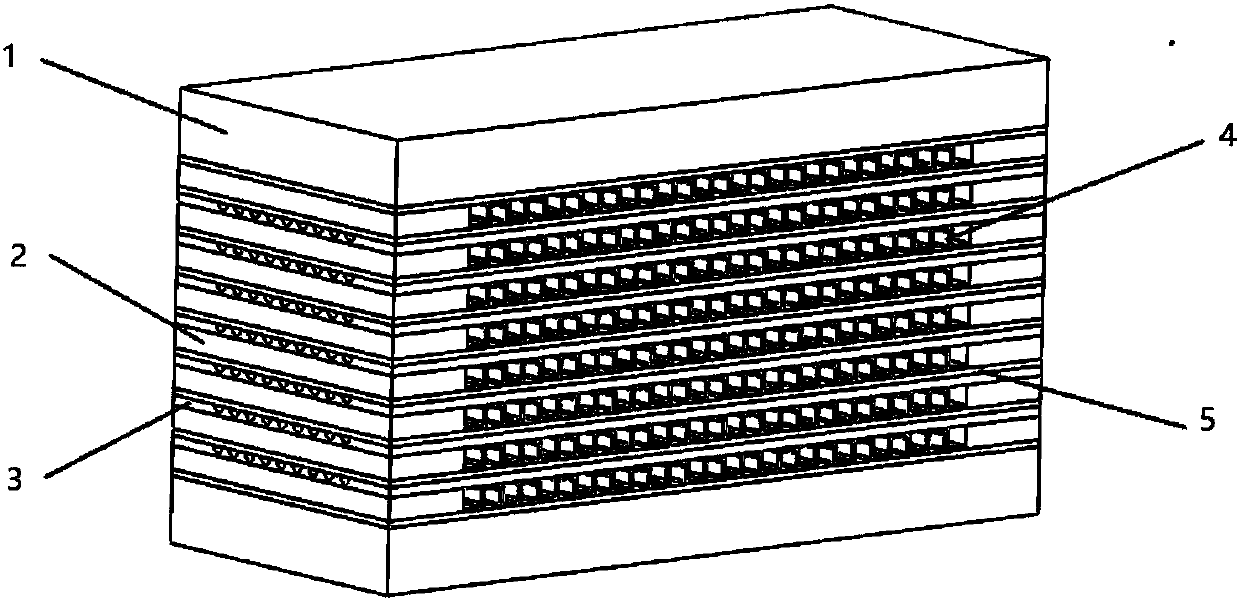

Novel heat exchanger core

PendingCN107782181AReduce dependenceRunner size is smallHeat exhanger conduitsCorrosion preventionPlate heat exchangerMechanical design

The invention discloses a novel heat exchanger core and belongs to the technical field of mechanical design. The heat exchanger core includes two cover plates, an etching plate piece, a forming platepiece and partition plates. The forming plate piece and the partition plate form a structural unit. The structural unit and the etching plate piece are alternately overlaid between the two cover plates, the non-etched surface of the etching plate piece is in butt joint with the forming plate piece, the etched surface of the etching plate piece is in butt joint with the adjacent structural unit, the partition plates are arranged between the cover plates and the etching plate piece, and the partition plates are arranged between the cover plates and the forming plate piece. The cover plates, theetching plate piece, the forming plate piece and the partition plates are machined into a whole. The novel heat exchanger core integrates the characteristics of a microchannel heat exchanger and a plate heat exchanger and can meet the use conditions that the working medium cleanliness is not high, and the novel heat exchanger core is particularly suitable for natural gas cooling processes of an offshore work platform.

Owner:AEROSPACE HIWING HARBIN TITANIUM IND

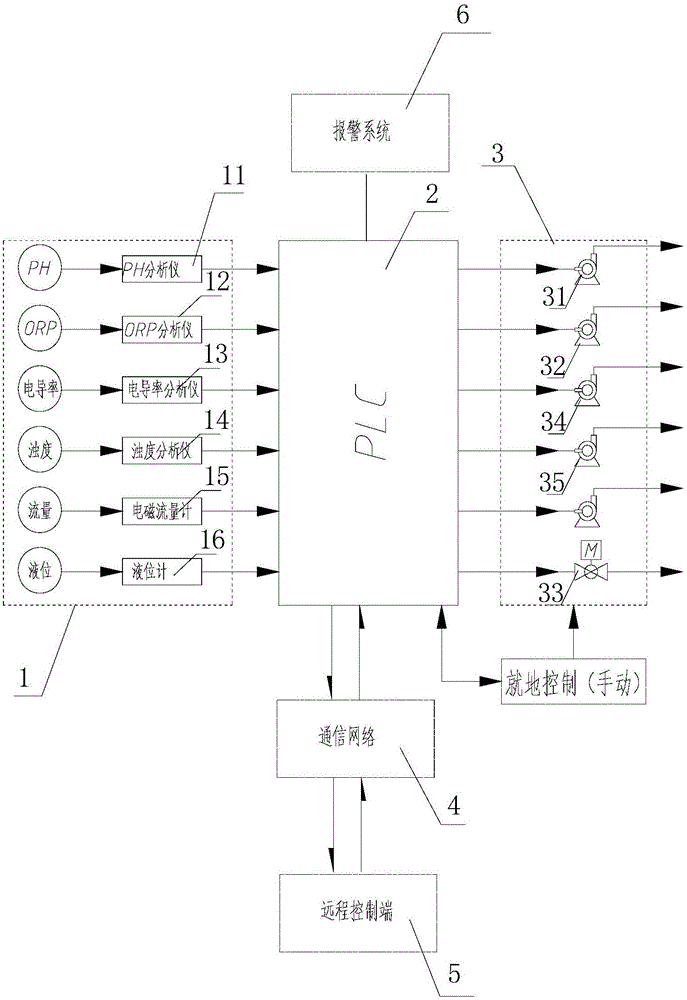

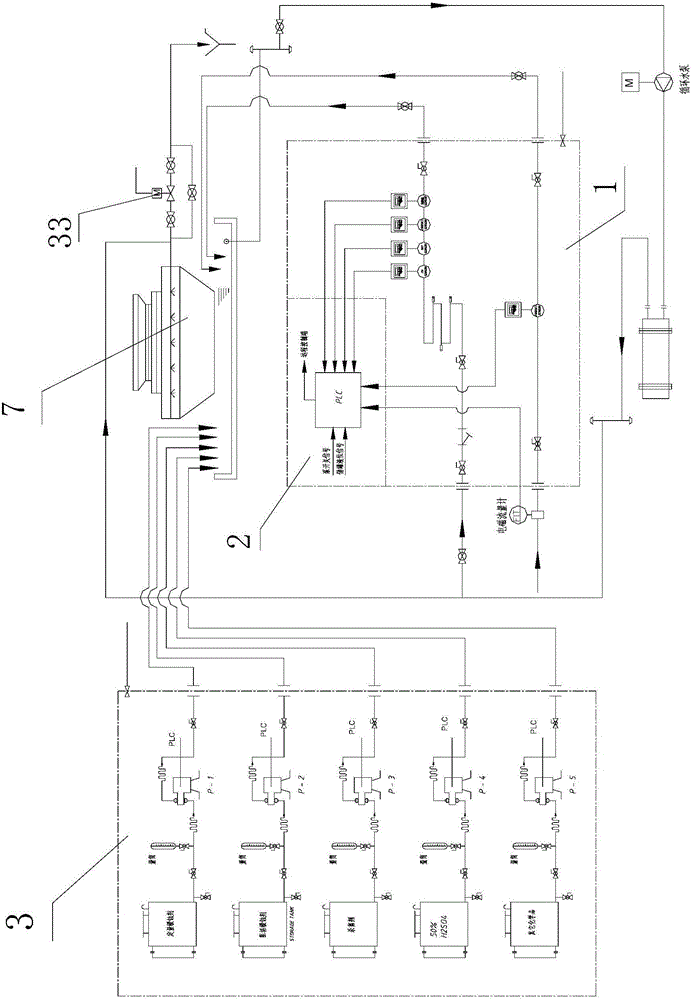

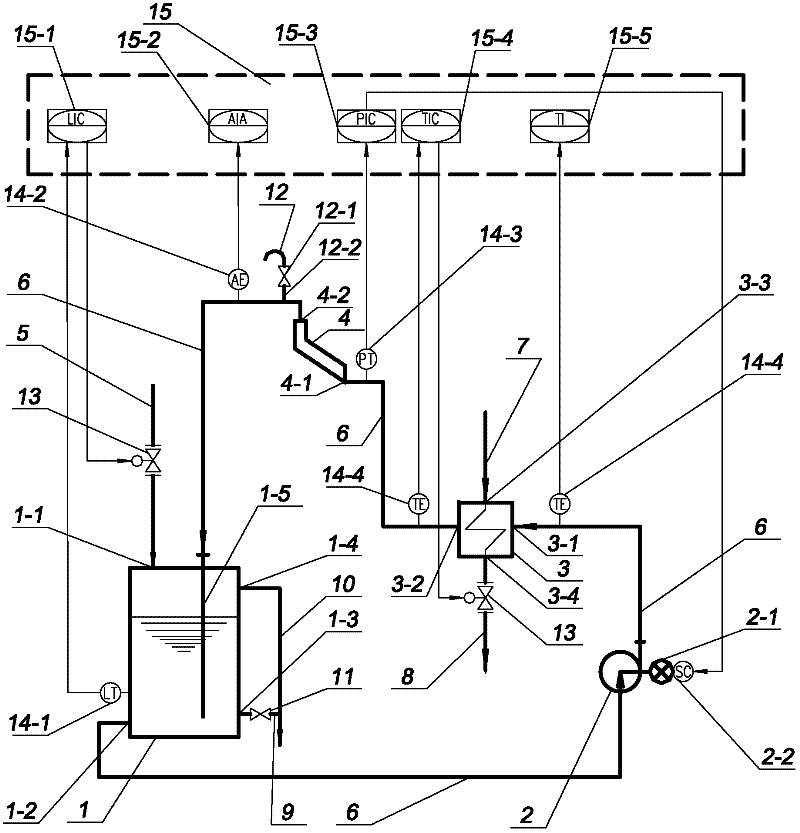

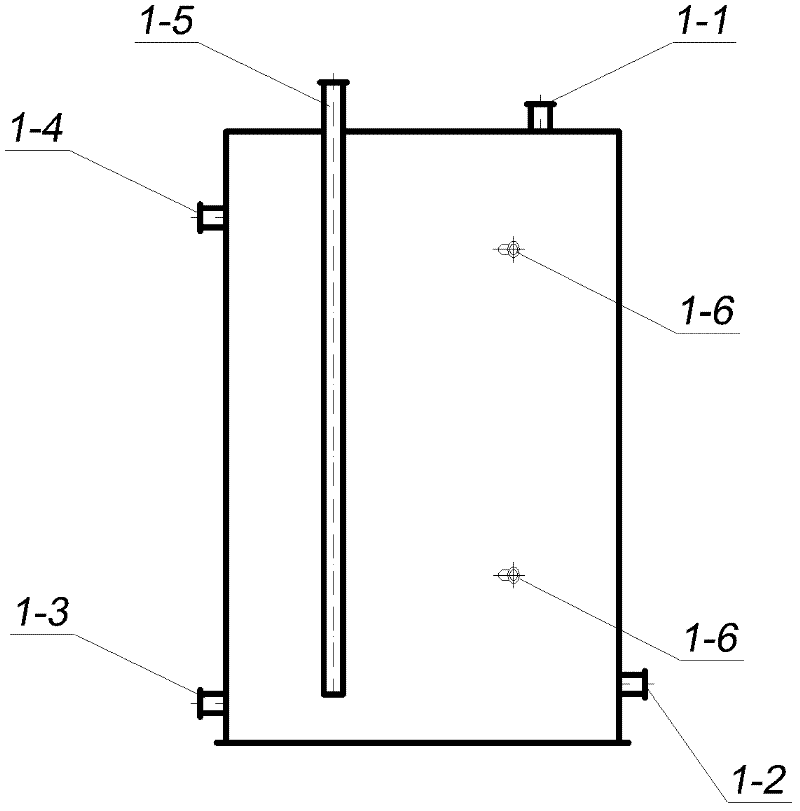

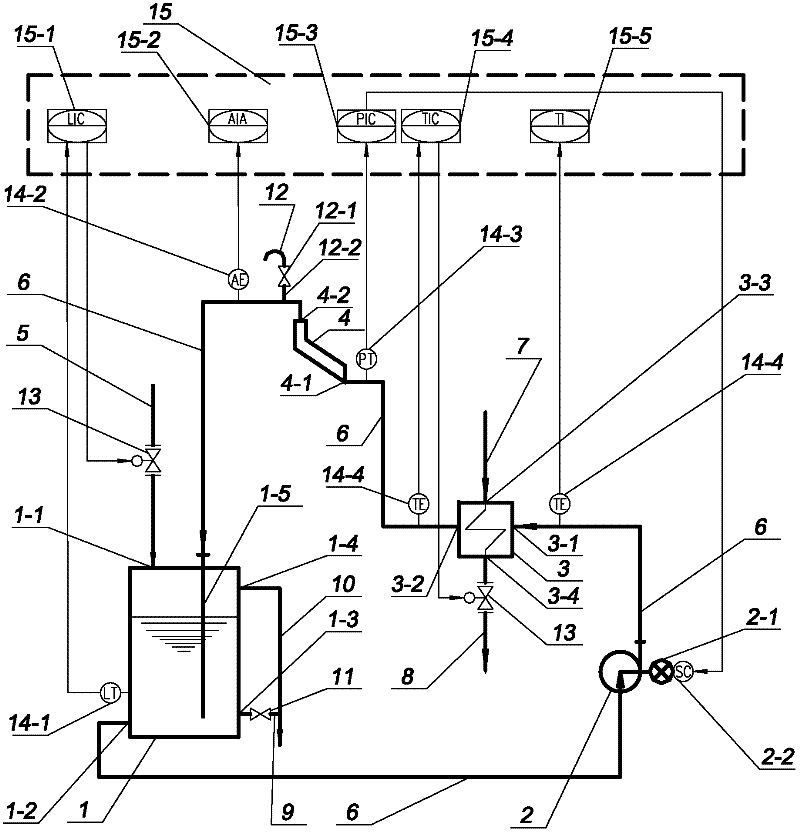

Online water quality monitoring and treating system for circulating water of fully-automatic cooling tower

InactiveCN105948315AImprove fouling problemImprove running stabilityWater treatment parameter controlScale removal and water softeningCooling towerControl signal

The invention discloses an online water quality monitoring and treating system for circulating water of a fully-automatic cooling tower. The online water quality monitoring and treating system comprises a signal acquisition unit, a PLC unit and an operation unit, wherein the signal acquisition unit is used for acquiring various water quality signals of the circulating water of the cooling tower and outputting the various water quality signals; the PLC unit is used for outputting corresponding control signals and alarm signals according to the received water quality signals; the operation unit is used for realizing automatic pollution discharge and automatic adding of various corresponding chemical agents according to the various received control signals. The online water quality monitoring and treating system can effectively improve the operation stability of the circulating water.

Owner:慈颂(上海)环保科技有限公司

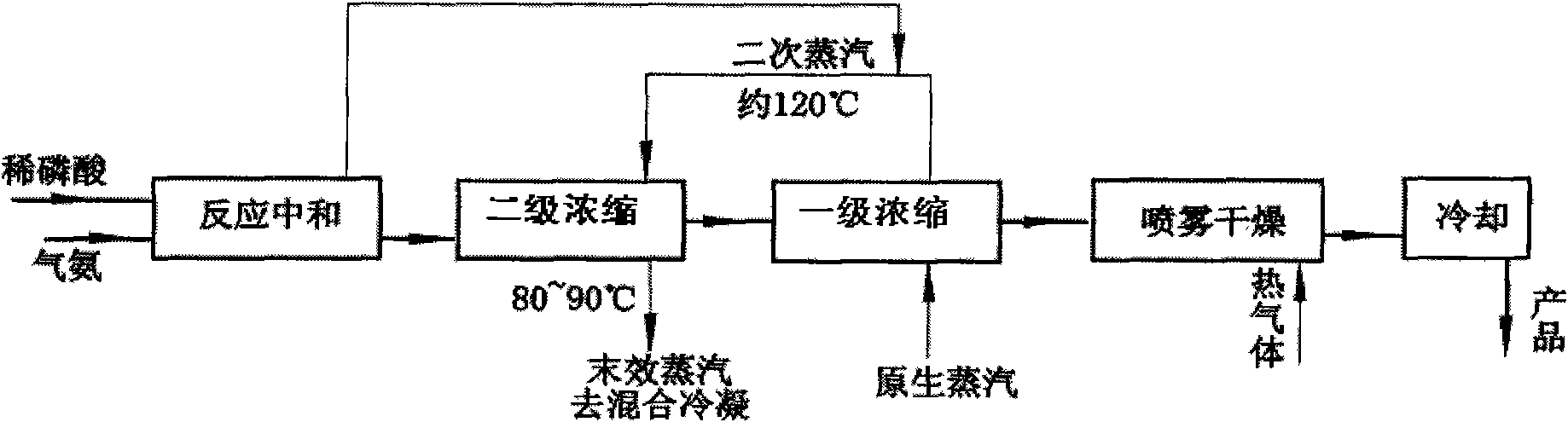

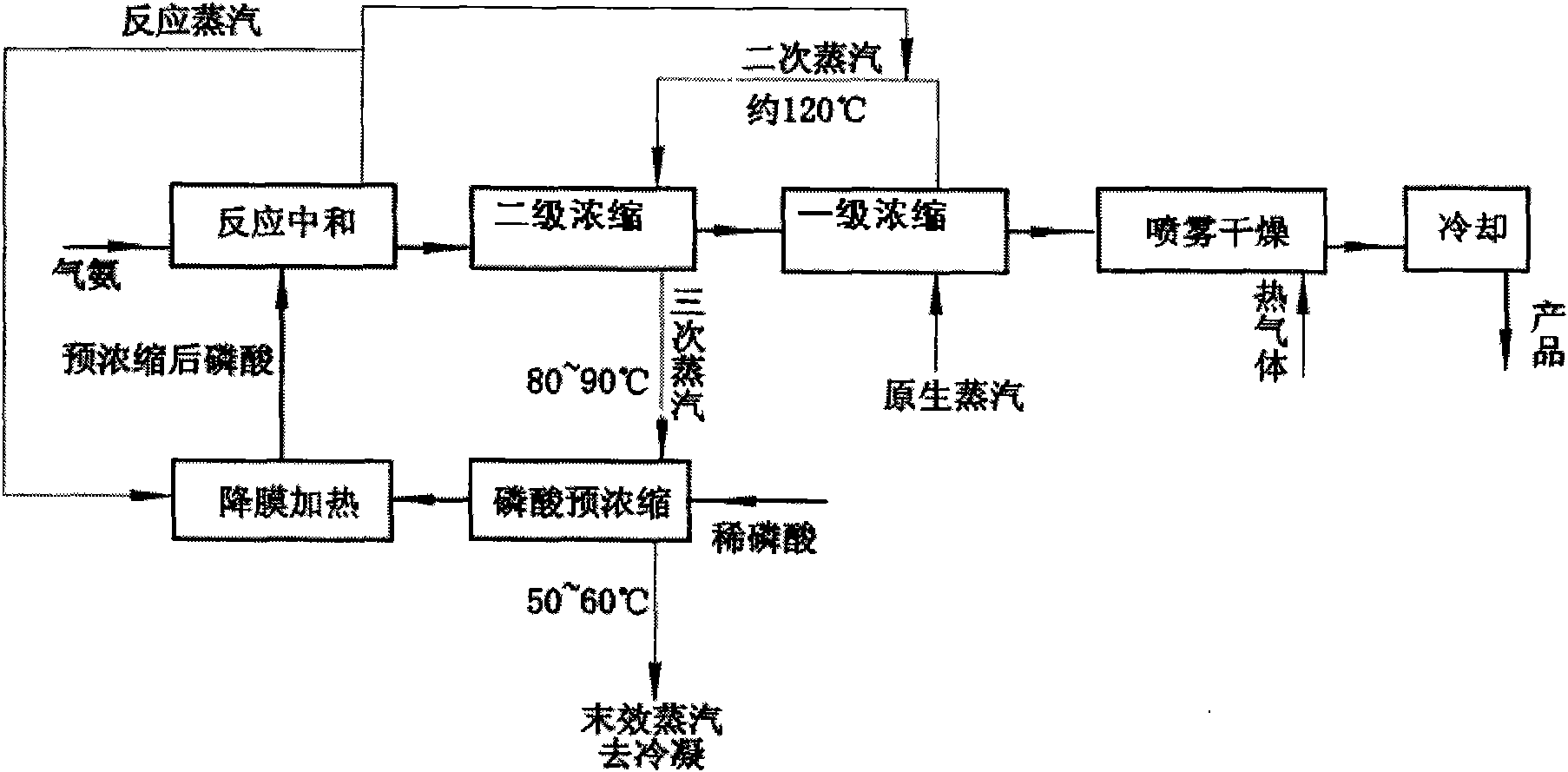

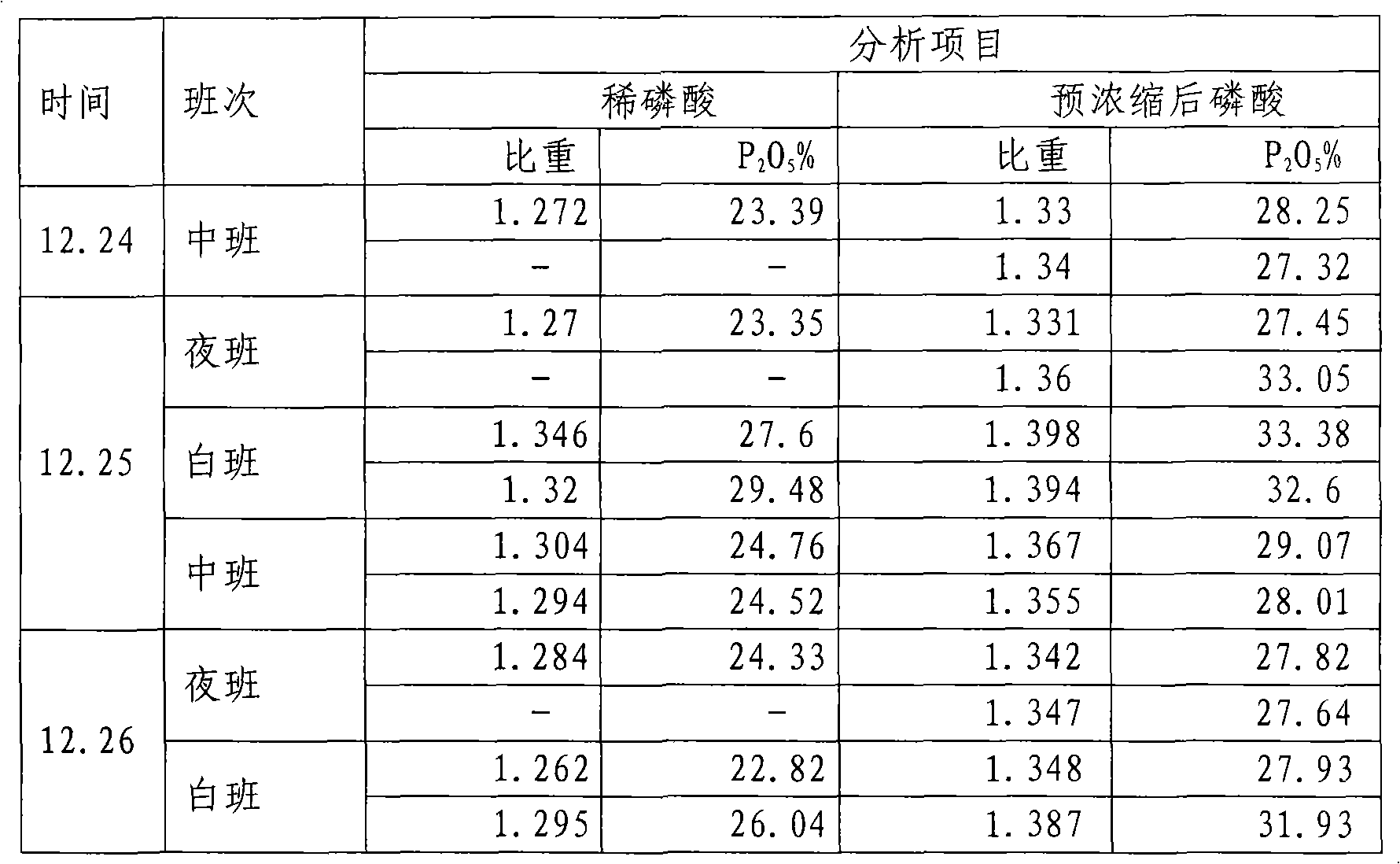

Stepped utilization method of steam in ammonium phosphate production

ActiveCN101837963AReduce consumptionEmission reductionPhosphatesEnergy inputEvaporationPhosphoric acid

The invention discloses a stepped utilization method of steam in ammonium phosphate production, which comprises the following steps: 1. three-time steam generated by two-stage concentration is introduced into a heat exchanger to heat and pre-concentrate raw material of thin phosphoric acid, and after heating, the steam at the terminal is discharged and condensed, the temperature of which is lowered; and 2. part reaction heat generated by neutralization of raw material of the phosphoric acid and ammonia is still used for secondarily concentrating ammonium phosphate slurry, and the other part of the steam continues to heat the raw material of the phosphoric acid by single-pass falling film evaporation so as to further pre-concentrate the phosphoric acid. The method has the advantages that: (1) by lowering the vaporization temperature at the terminal to 50DEG C-60DEG C, low-temperature pre-concentration of the phosphoric acid is realized, which saves the consumption of primary steam and reduces the emission of waste heat and gas; (2) auxiliary equipment runs steadily, forced circulation has high evaporation intensity, circulating power consumption is reduced, and the size of the equipment and pipelines is reduced; (3) the operation temperature is obviously reduced, and the corrosion and scaling on a heating surface caused by a concentrated medium are improved; and (4) the concentration operation expands towards a low-temperature area, thus improving the functions of the equipment.

Owner:WENGFU (GRP) CO LTD

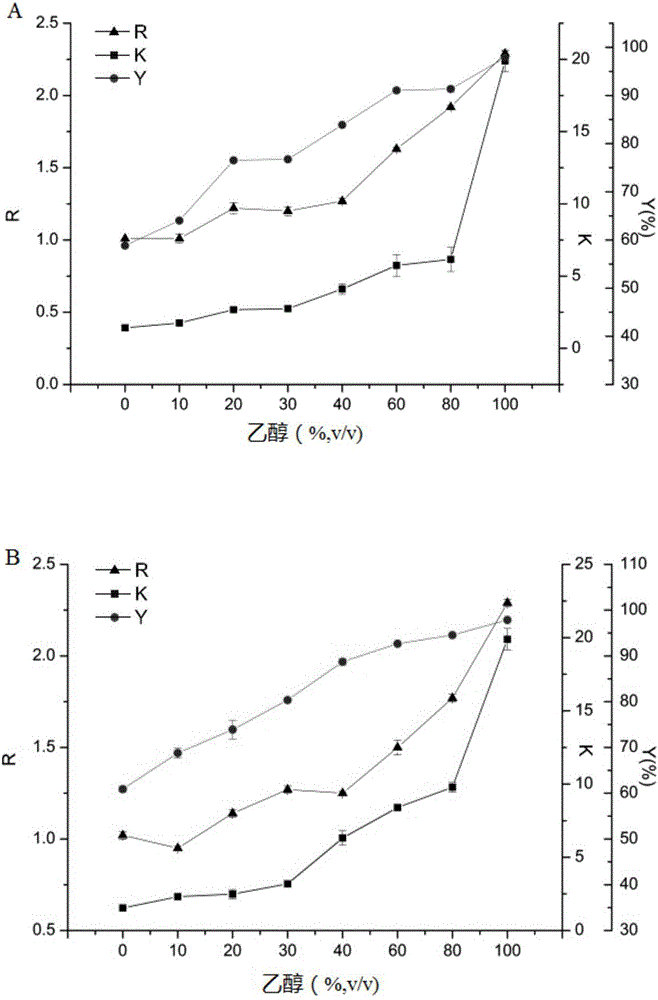

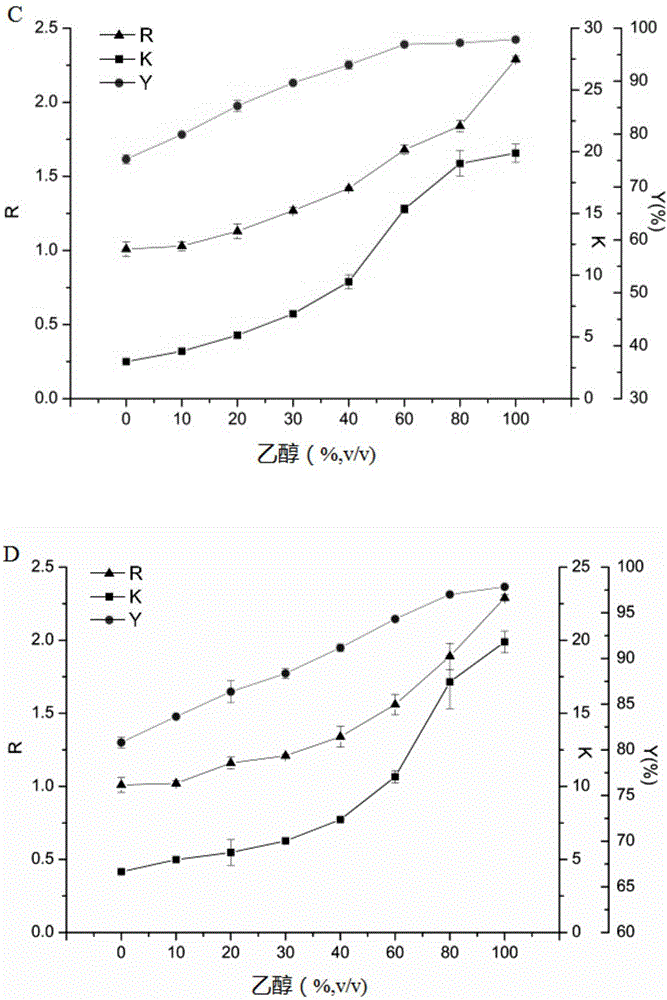

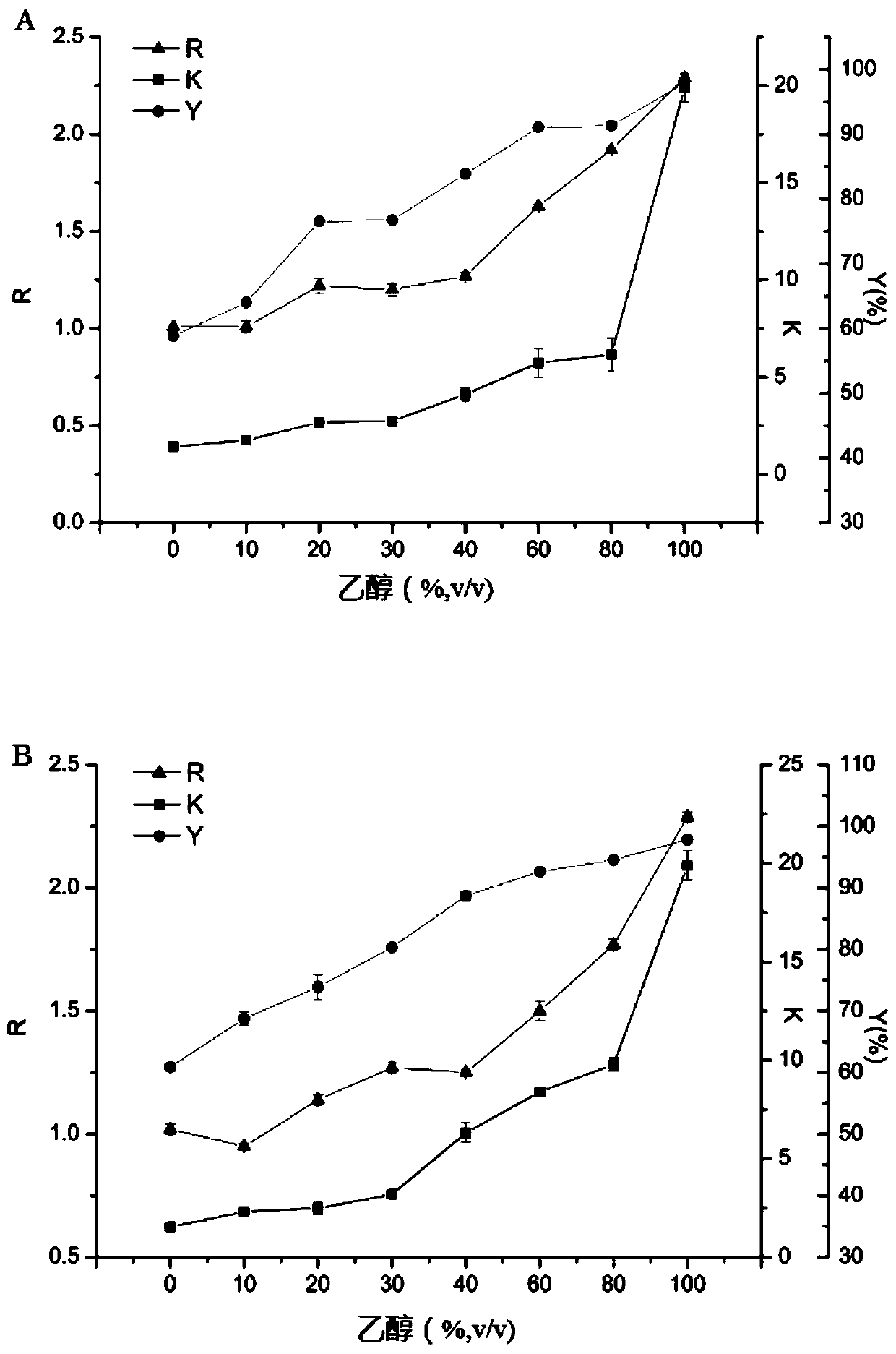

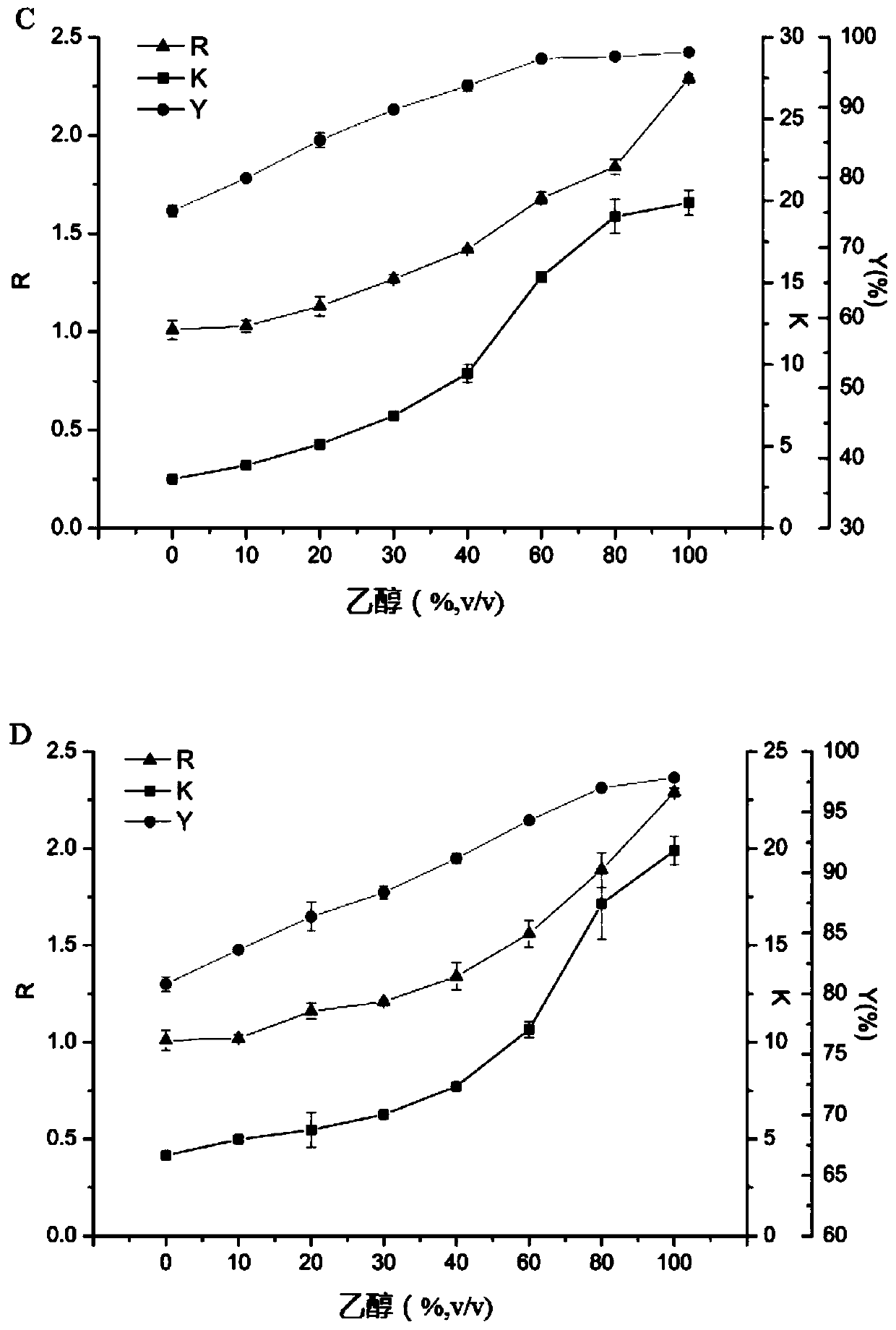

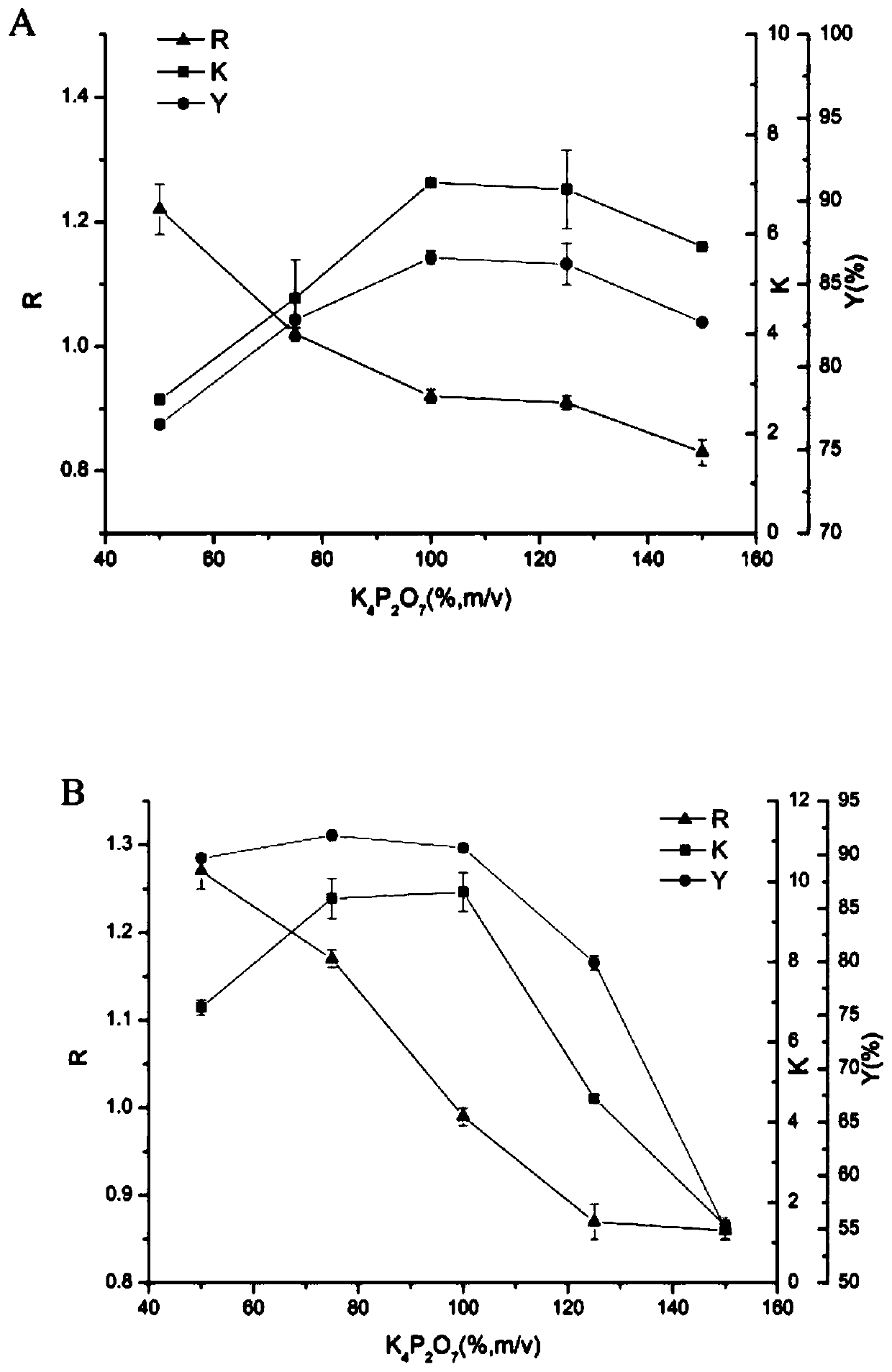

Method for separating and purifying acetoin in fermentation liquor

ActiveCN106588617AReduce moisture contentLow boiling pointCarbonyl compound separation/purificationEthyl acetateImpurity

The invention discloses a method for separating and purifying acetoin in fermentation liquor. The method includes the step of adding inorganic salt and a weak polar organic solvent are added into the fermentation liquor for extraction, wherein the addition amount of the inorganic salt accounts for 25-125% of the volume of the fermentation liquor, and the volume ratio of the organic solvent and the fermentation liquor is (1-2):1. The weak polar organic solvent is one of ethyl acetate, methyl tertiary-butyl ether, butyl acetate, dimethyl carbonate and diethyl carbonate. By means of the method, an extraction phase containing acetoin hardly contains pigment, residual sugar and organic acid impurities, an extraction solution can be directly rectified, and the scaling phenomenon is not likely to happen to a column reactor in the rectification process. Polarity of the solvent in use is small, the specific heat capacity is low, the upper phase water content is low, energy consumption for recycling is low, and acetoin loss in the recycling process is small. Operation is easy, and the method is an acetoin separation and extraction technology with industrial application prospects.

Owner:DALIAN UNIV OF TECH

Process for extracting and concentrating total flavone in hawthorn

InactiveCN104138670AShorten extraction and concentration timeIncrease concentrationEvaporationEnergy based chemical/physical/physico-chemical processesHigh concentrationEvaporation

The invention relates to a process for extracting and concentrating total flavone in hawthorn. The process comprises a process for extracting total flavone in hawthorn and a process for evaporating and concentrating total flavone in hawthorn. The process is characterized in that the process for extracting total flavone in hawthorn and the process for evaporating and concentrating total flavone in hawthorn are respectively completed in integrated ultrasonic extraction, evaporation and concentration equipment. The process is scientific and reasonable in design, has the advantages of simplicity in operation, short extraction and concentration time, high concentration degree, uniformity in extraction, high circulation speed, good solution property, small possibility of scaling, convenience in equipment washing and repair and simplicity, and is relatively high in innovativeness.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +1

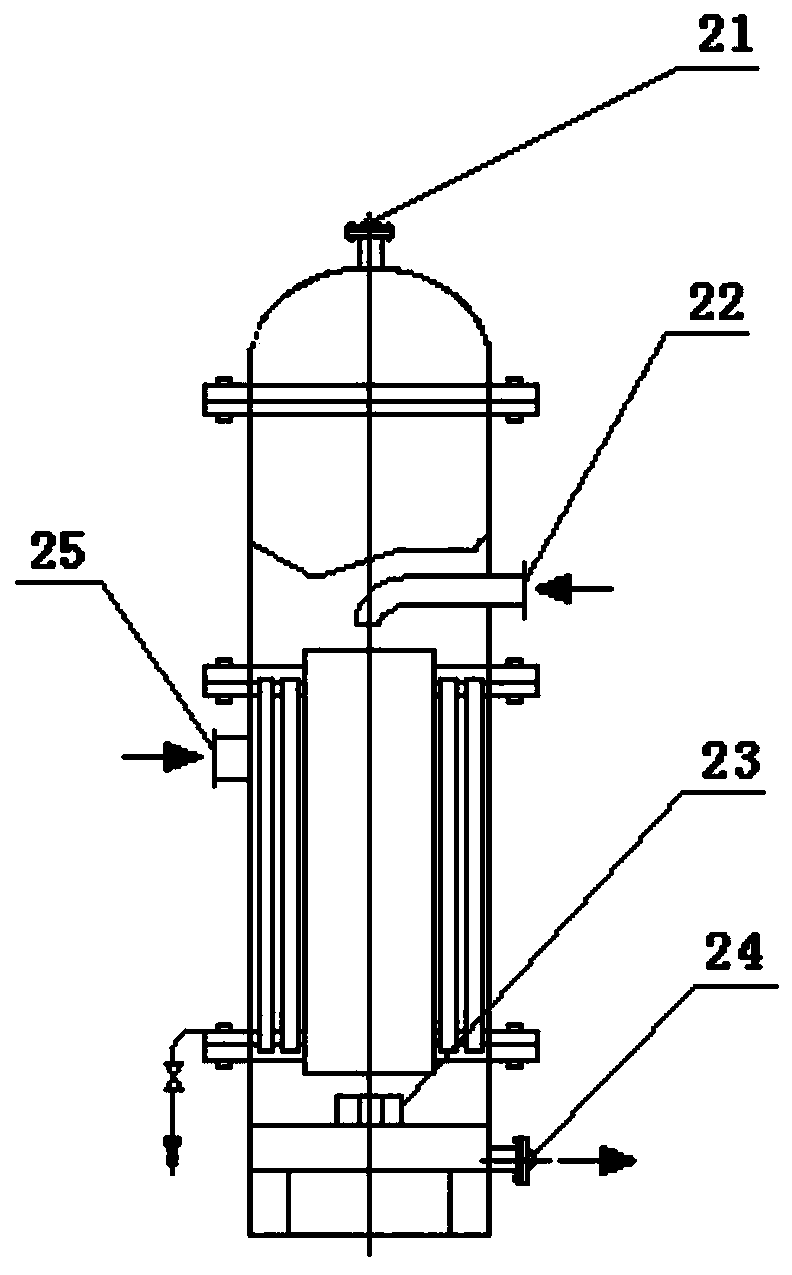

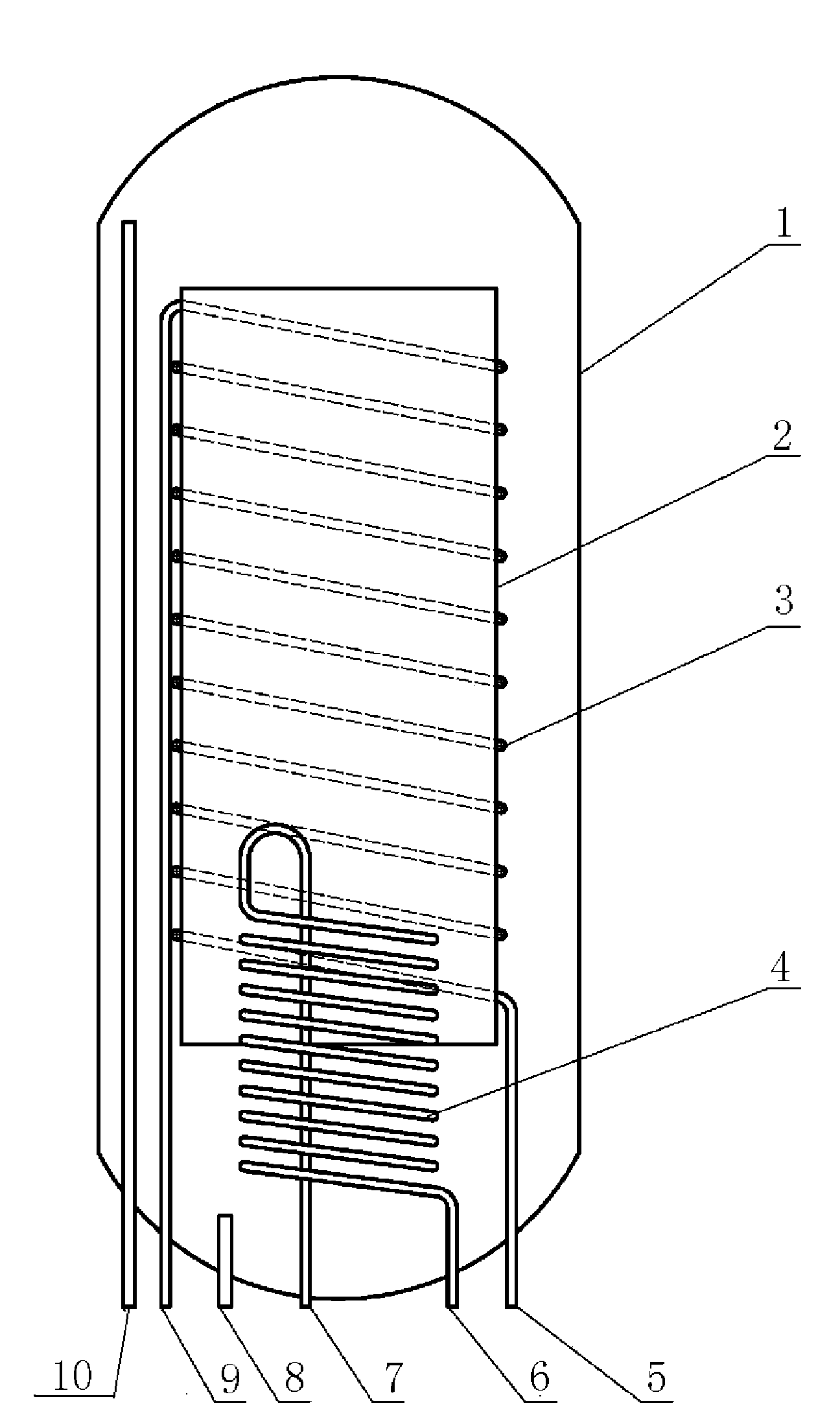

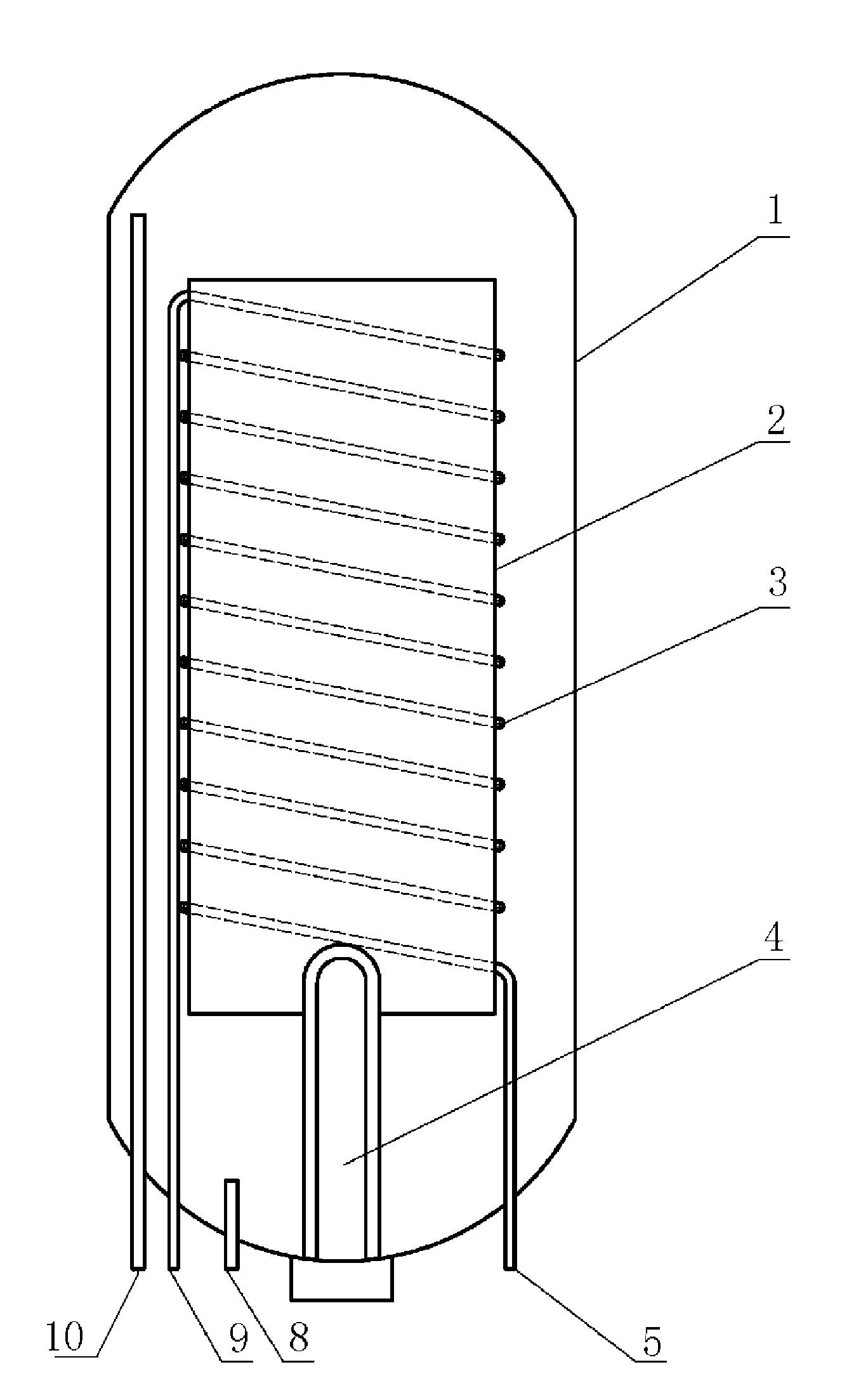

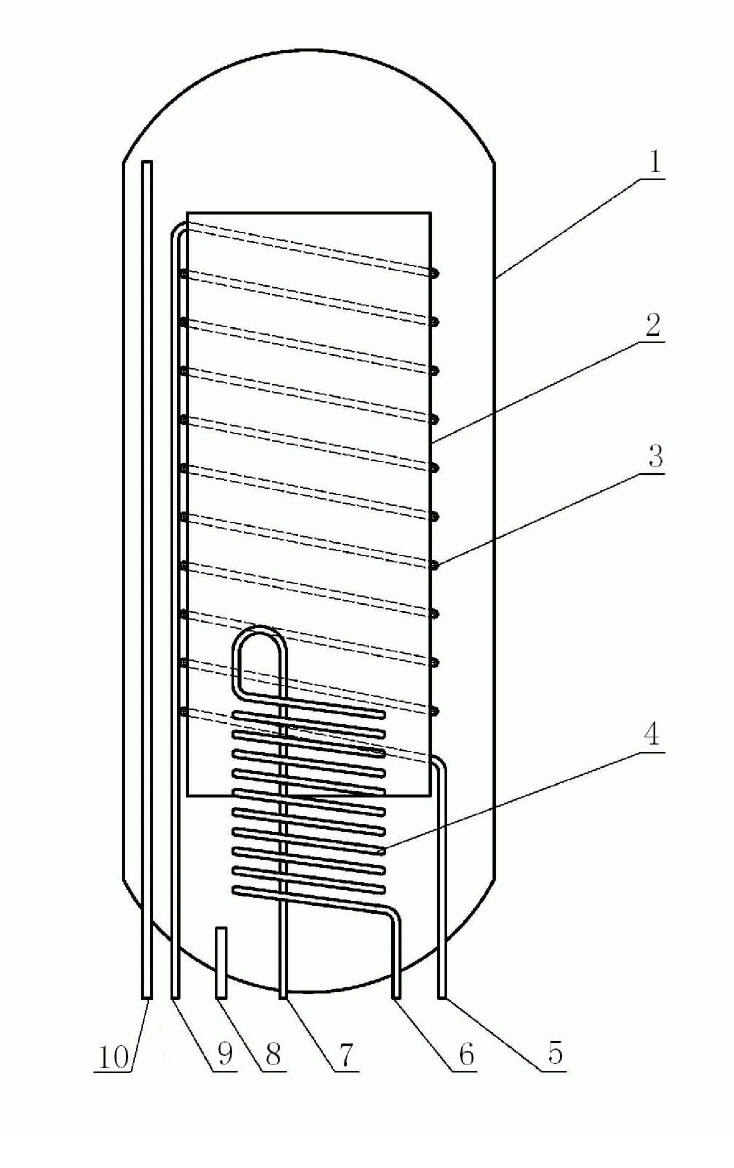

Heat exchange and flow guide structure of hot water storage tank

InactiveCN101825411AImprove anti-corrosion performanceImprove fouling problemHeat storage plantsHeat exchanger casingsEngineeringProduced water

The invention relates to a heat exchange and flow guide structure of a hot water storage tank, which realizes temperature layering of thermal mediums in a hot water storage tank in the using process and avoids mixing of cold water and hot water in the hot water storage tank, so that the water outlet temperature of a heat exchanger is stably maintained above the required temperature for a long time, the produced water which can meet using requirement is increased and the heat utilization efficiency in the hot water storage tank is sufficiently improved.

Owner:李博峰

Circulation cooling device for chute of soda recovery furnace

ActiveCN102230292AAvoid overall overheatingCorrosion resistanceFurnace coolingRegeneration of alkali lyeSalt waterEngineering

The invention discloses a circulation cooling device for a chute of a soda recovery furnace. A cooling water channel is provided with a desalted water inlet, a drain outlet, an overflow vent, a sealing water pipe and a liquid level meter interface, wherein the sealing water pipe is inserted below the liquid surface of the cooling water channel, the liquid level meter interface is connected with aliquid level transmitter; a desalted water outlet at the bottom of the cooling water channel is connected with a circulation cooling water pipe, the outlet of a frequency variable water pump is connected to a cooling water inlet of a heat exchanger, a cooling water outlet of the heat exchanger is connected to the water inlet of a chute water jacket at the lower end of the chute water jacket by virtue of the circulation cooling water pipe, the water outlet of the chute water jacket at the upper end of the chute water jacket is connected to the sealing water pipe of the cooling water channel, the desalted water inlet is arranged at the top of the cooling water channel, the desalted water pipe is used for introducing the desalted water into the cooling water channel by virtue of the desaltedwater inlet, and the desalted water pipe is provided with a regulating valve. The circulation cooling device disclosed by the invention has simple structure, low operation energy consumption, less water discharge and automatic operation; and a crack of the chute water jacket can be timely alarmed, and an accident is prevented.

Owner:CHINA LIGHT IND WUHAN DESIGN ENG CO LTD

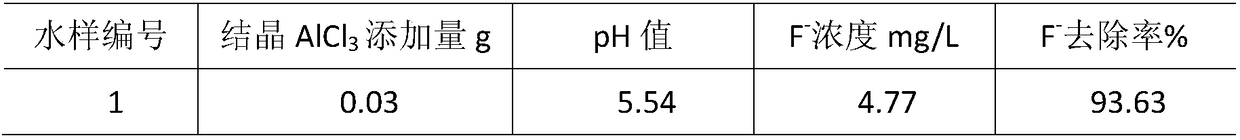

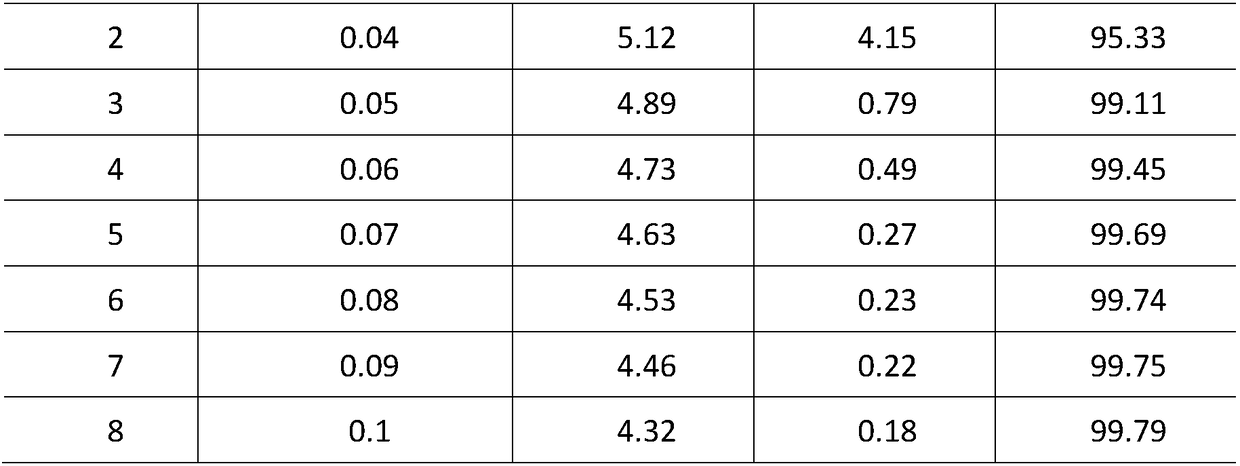

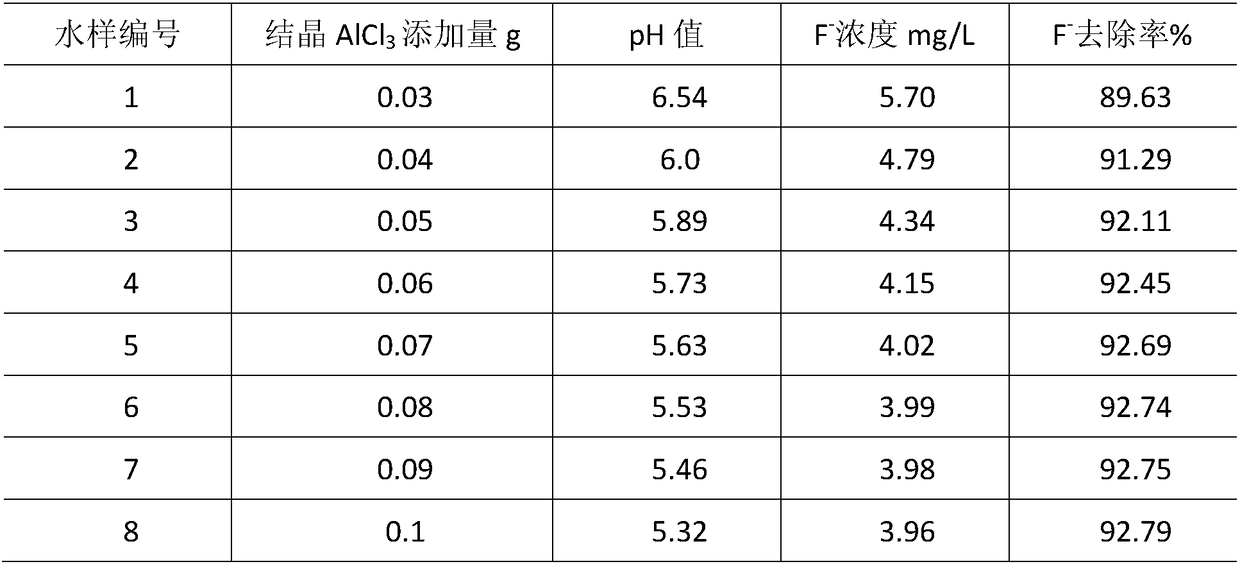

Method for removing fluorides from coal conversion wastewater

InactiveCN108585157ABest fluoride removal rateLower pHWater treatment parameter controlWater contaminantsHigh concentrationUltrafiltration

The invention discloses a method for removing fluorides from coal conversion wastewater, particularly fluorides in high-concentration brine of the coal conversion wastewater. The method comprises thespecific steps: draining the wastewater into a treatment tank, then, adding crystals AlCl3, and lowering the fluoride ion concentration of the coal conversion wastewater by adopting a coagulation settling method, wherein the mass / volume ratio of the crystals AlCl3 to the wastewater is 0.3g / L to 0.5g / L, and the fluoride ion content of treated wastewater is lower than 6mg / L. The coal conversion wastewater is complicated in water mass, is subjected to pretreatment and biochemical treatment, then, is subjected to ultrafiltration and reverse-osmosis membrane treatment and is subjected to advanced wastewater treatment and recycling. If the fluorides in the coal conversion wastewater enter a reverse osmosis membrane system for circulating concentration and produce calcium fluoride scales, flux and service lives of reverse osmosis membranes are seriously affected. According to the method disclosed by the invention, for complicated coal conversion wastewater, the crystals AlCl3 are selected asa coagulant, the coal conversion wastewater prior to entering the membrane system and the high-concentration brine subjected to membrane treatment are subjected to fluorine removing treatment, thus, the wastewater can meet the requirements of reverse osmosis concentrating, and the calcium fluoride scales are not produced.

Owner:TIANJIN UNIV

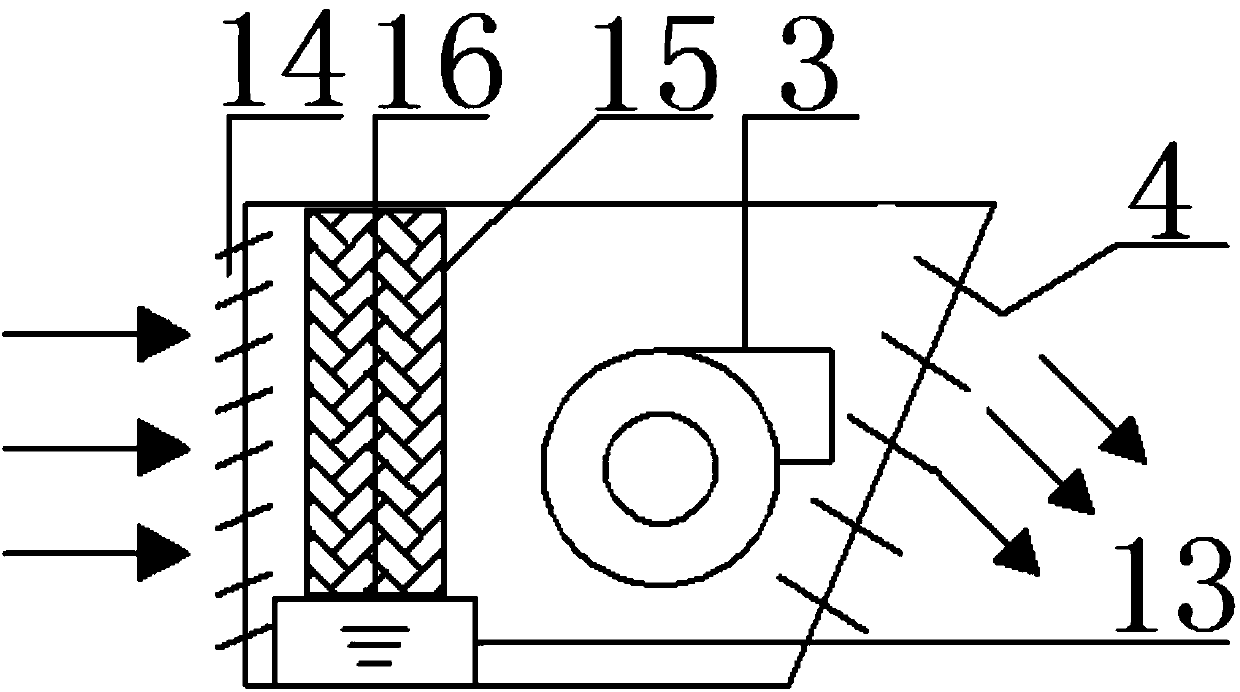

Fan and wet pad cooling device for bus station and based on solar technology

InactiveCN107620491AEasy to assemble and disassembleUse portableRoof covering using slabs/sheetsRoof covering using tiles/slatesHot weatherPhotoelectric conversion

The invention discloses a fan and wet pad cooling device for a bus station and based on a solar technology. The fan and wet pad cooling device comprises an arc-shaped ceiling of the bus station, a photoelectric conversion unit is arranged on the upper part of the ceiling, and a wet pad unit is arranged at the lower part of the ceiling and is further connected with a water supplying unit which is located at the bottom of the bus station through a pipeline; and the photoelectric conversion unit comprises a solar cell panel which is erected on the ceiling, and the solar cell panel is sequentiallyconnected with a controller, an inverter and a storage battery through circuits. According to the fan and wet pad cooling device for the bus station, own installation design of the bus station is notaffected, and an air conditioner system is replaced by the wet pad unit; and the principle of direct evaporative cooling is utilized, so that air is cooled through a wet film and is slantly sent downward to the place where people feel comfortable through a cross-flow fan, and cooling and refreshing are brought for people waiting for a bus in the outdoor space in high-temperature and hot weather conditions.

Owner:XI'AN POLYTECHNIC UNIVERSITY

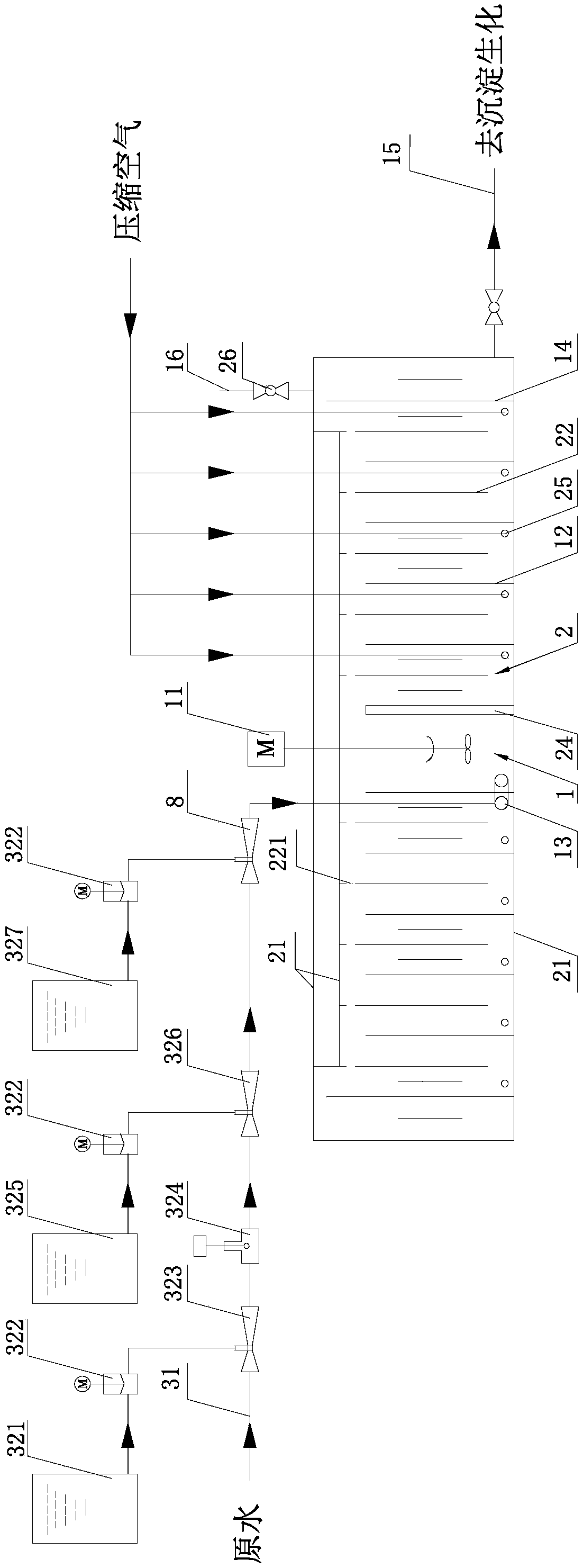

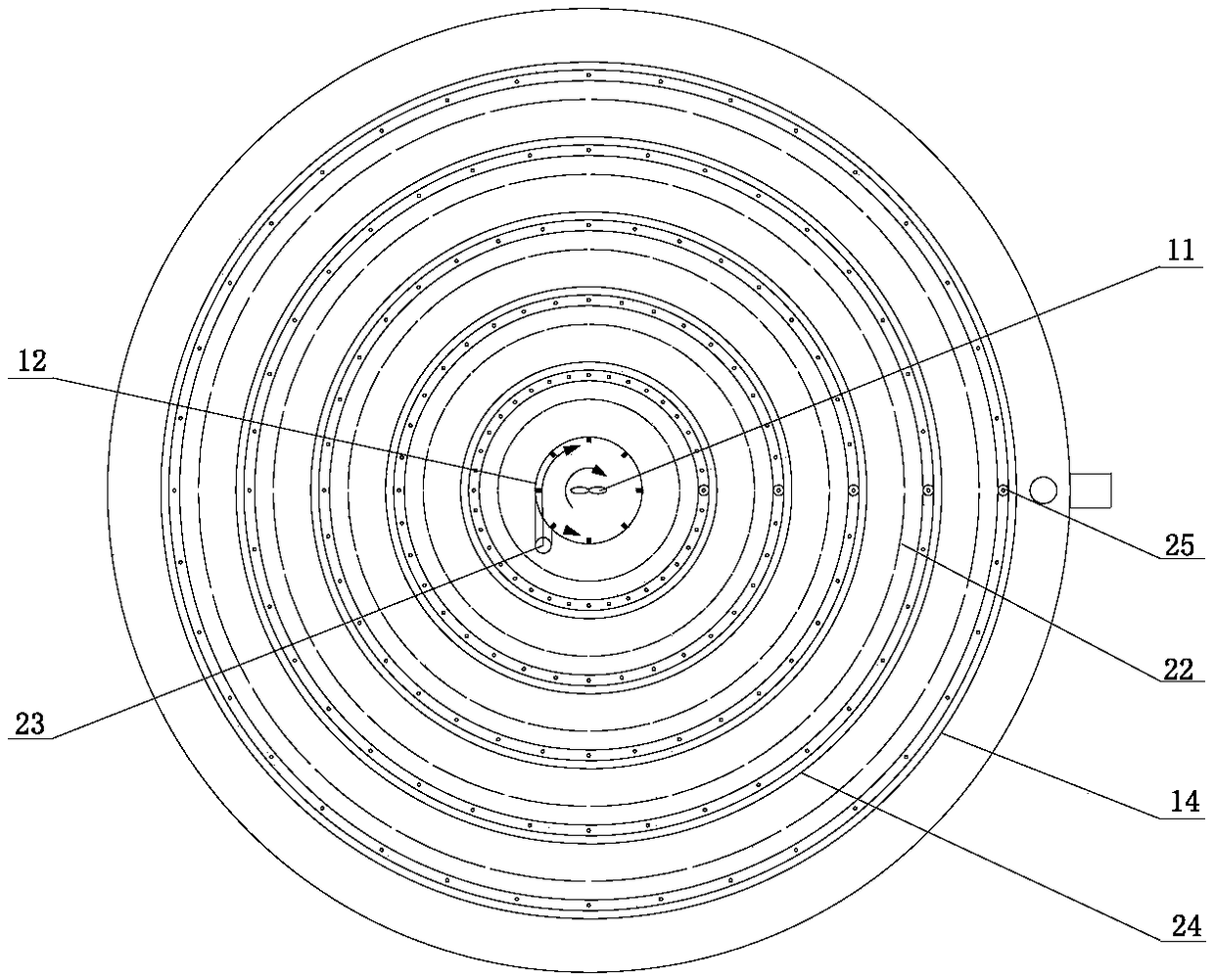

Baffled Fenton oxidation reactor and organic wastewater treatment method

ActiveCN108689475AMixing helpsIncreased turbulenceWater/sewage treatment apparatusWater/sewage treatment by oxidationFenton reactionFenton oxidation

The invention relates to a baffled Fenton oxidation reactor and an organic wastewater treatment method. The baffled Fenton oxidation reactor comprises a chemical mixing area, a baffled reaction area ,and four pipeline connectors, the chemical mixing area and the baffled reaction area are sequentially arranged from the inside to the outside of concentric sleeves, wherein the bottom central area isprovided with a wastewater inlet, a series of compressed air connectors are arranged on the bottom of the reaction area, and a drain outlet and an exhaust outlet are arranged at a position far from the center. The organic wastewater treatment method comprises the following steps: after wastewater is filtered and pH is regulated, metering pumps quantitatively add FeSO4 solution and H2O2 solution in sequence into a water inlet pipeline by means of a jet device to get into the reactor, an aerator is switched on, the mixed wastewater gets into the chemical mixing area in a tangential feeding manner, and rapidly spirals upwards along the internal wall of the barrel under the action of an agitating pump, the disturbance and turbulence of the wastewater are further intensified by fin baffles, and thereby the uniform mixing of the wastewater and chemical is promoted; in the baffled reaction area, and the mixed wastewater passes through in the form of plug flow, carries out rapid Fenton reaction, and flows out of the reactor via a downflow weir.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

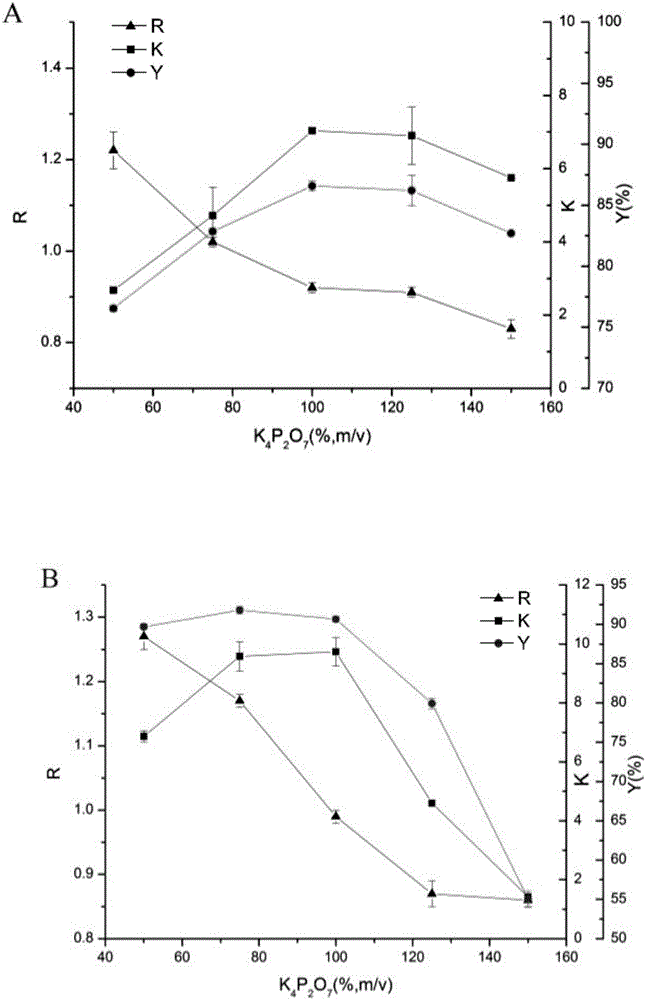

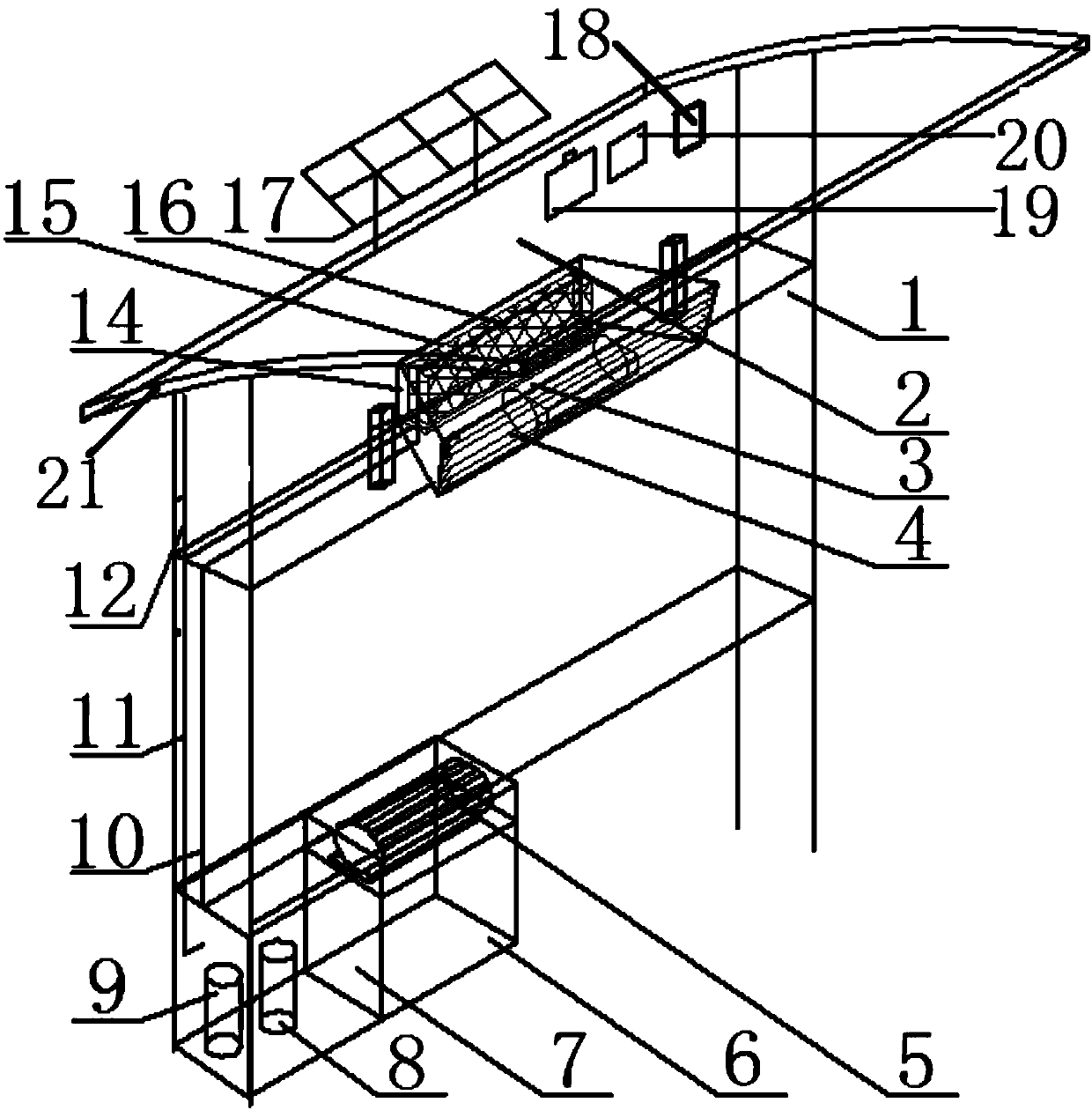

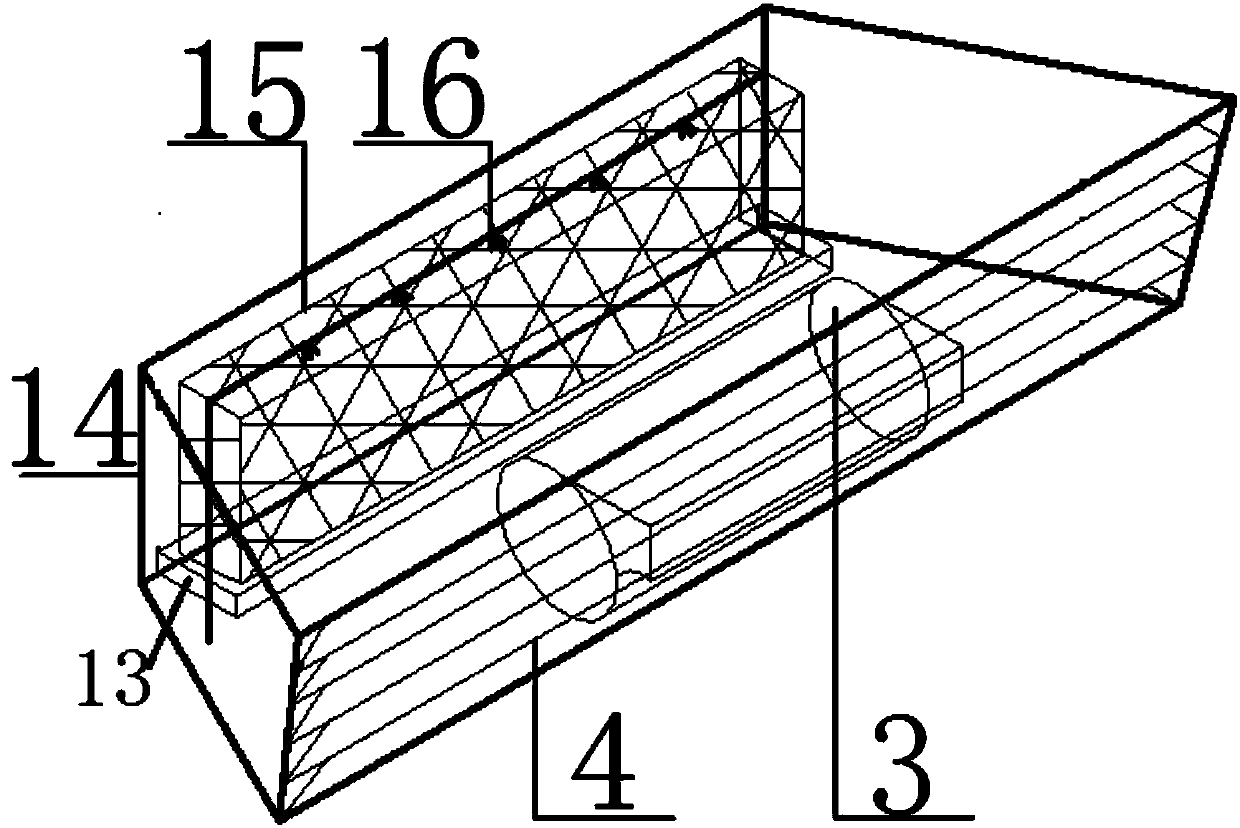

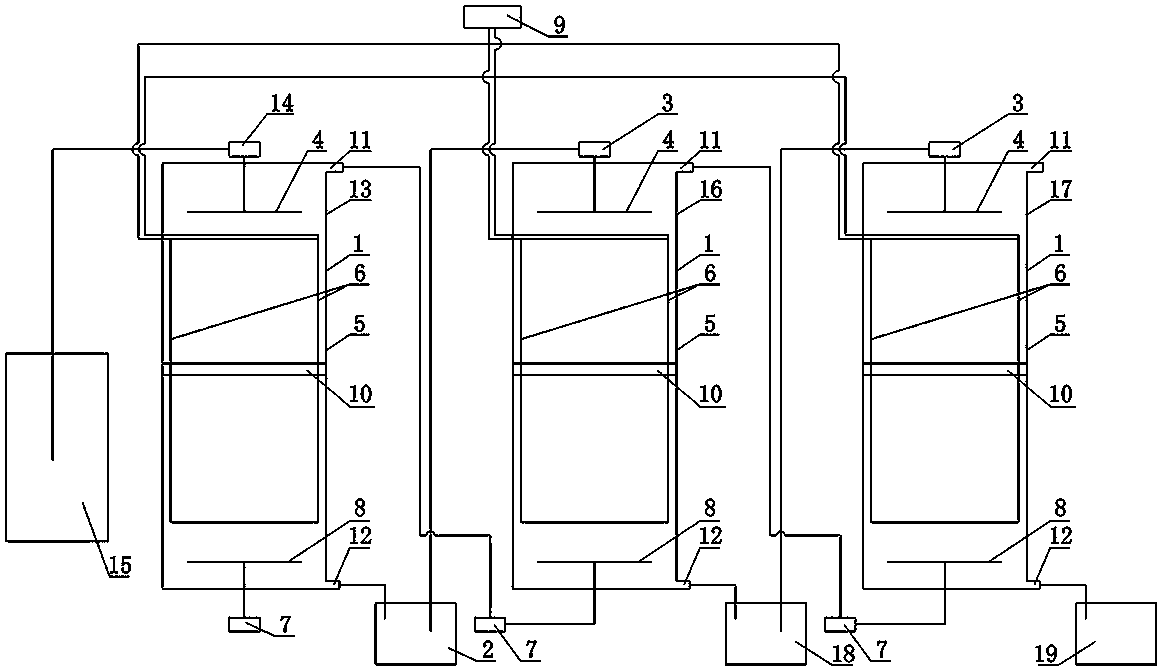

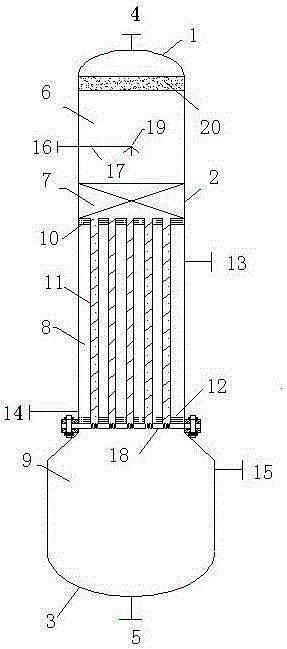

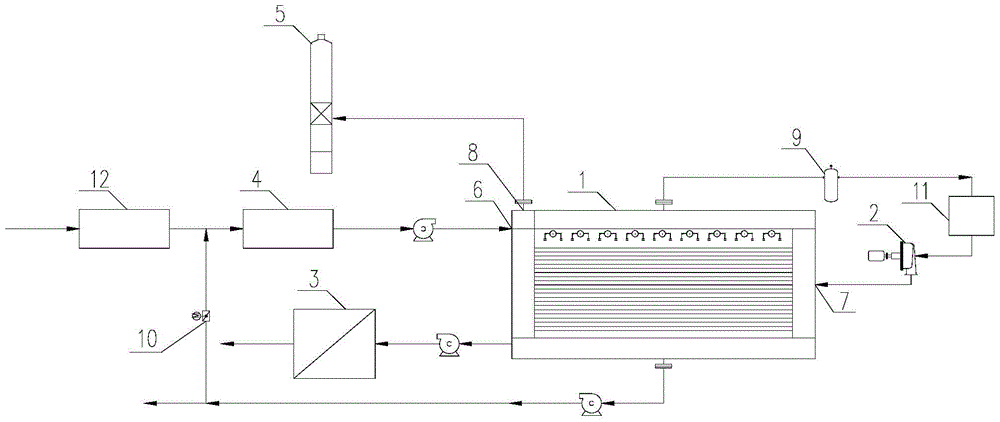

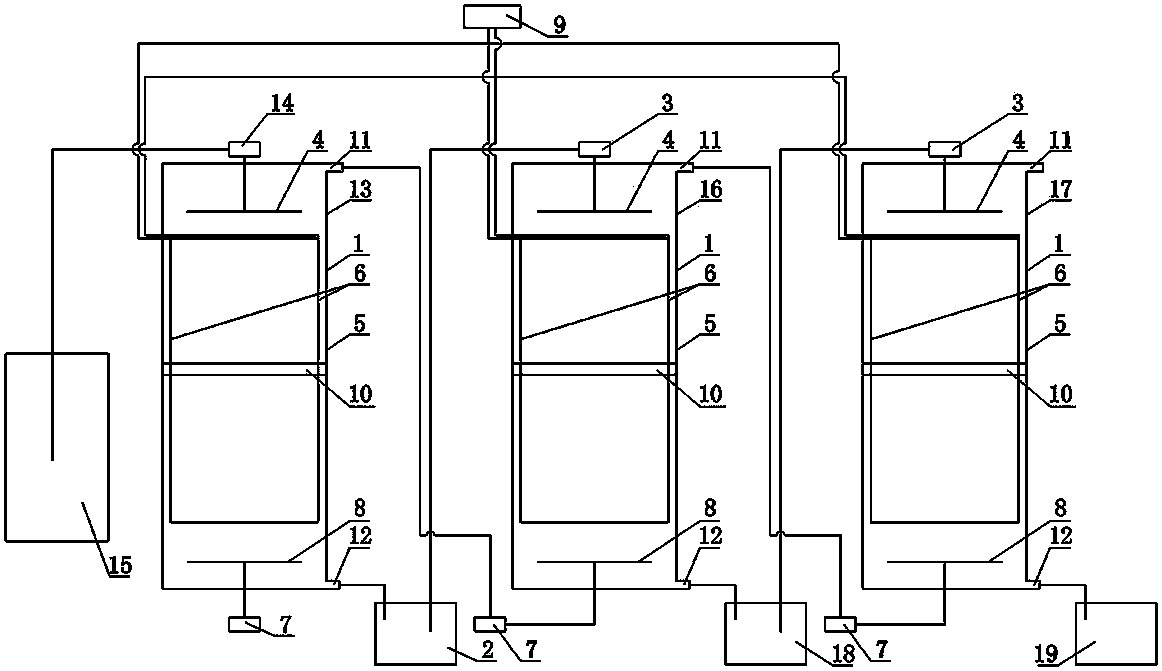

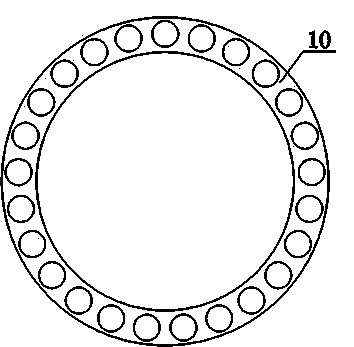

Micro and nano-grade light calcium carbonate tube-condensation-type double-circulation multi-level carbonation system

InactiveCN102936026AAvoid technical problems that are prone to cloggingEasy to cleanCalcium/strontium/barium carbonatesMaterial nanotechnologyCarbonizationReaction temperature

The invention discloses a micro and nano-grade light calcium carbonate tube-condensation-type double-circulation multi-level carbonation system. The system comprises at least three carbonization towers (1) connected in series. A slurry tank is provided between each two adjacent carbonization towers (1). A carbonization tower (1) comprises a high-pressure pump (3), a spraying mist-making device (4), a tower body (5), condensing tubes (6), an air compressor (7), a gas plate (8), a refrigerator (9), and an accumulated liquid and scale removing device (10). The condensing tubes (6) are connected with the refrigerator (9). The spraying mist-making device (4) is connected with the high-pressure pump (3). The gas plate (8) is connected with the air compressor (7). The accumulated liquid and scale removing device (10) is sleeved on the outside of the condensing tubes (6). The system provided by the invention has the advantages that: spraying and a high-liquid-level bubbling carbonization method are adopted, continuity is high, and carbonization efficiency is high. The condensing tubes are added, such that the reaction temperature in the tower can be conveniently controlled. The accumulated liquid and scale removing device is provided, such that condensing tube scale can be conveniently removed.

Owner:SICHUAN HAIYA POWDER TECH CO LTD

Feed method for coal tar hydrogenating unit

The invention relates to a feed method for coal tar. After the pressure of a coal tar raw material is boosted by a hydrogenation reaction raw material booster pump, the coal tar raw material enters a hydrogenation reactor without any indirect heat exchange; and before the pressure of the coal tar raw material is boosted, the coal tar raw material can be hot stream from a fractionating tower. The method can avoid a high-pressure heat-exchange temperature-rise process of the coal tar, eliminate the problem of fouling of high-pressure coal tar heat exchangers, reduce the hydrogenation catalyst bed pressure drop, slow down the coking, and prolong the operation cycle.

Owner:何巨堂

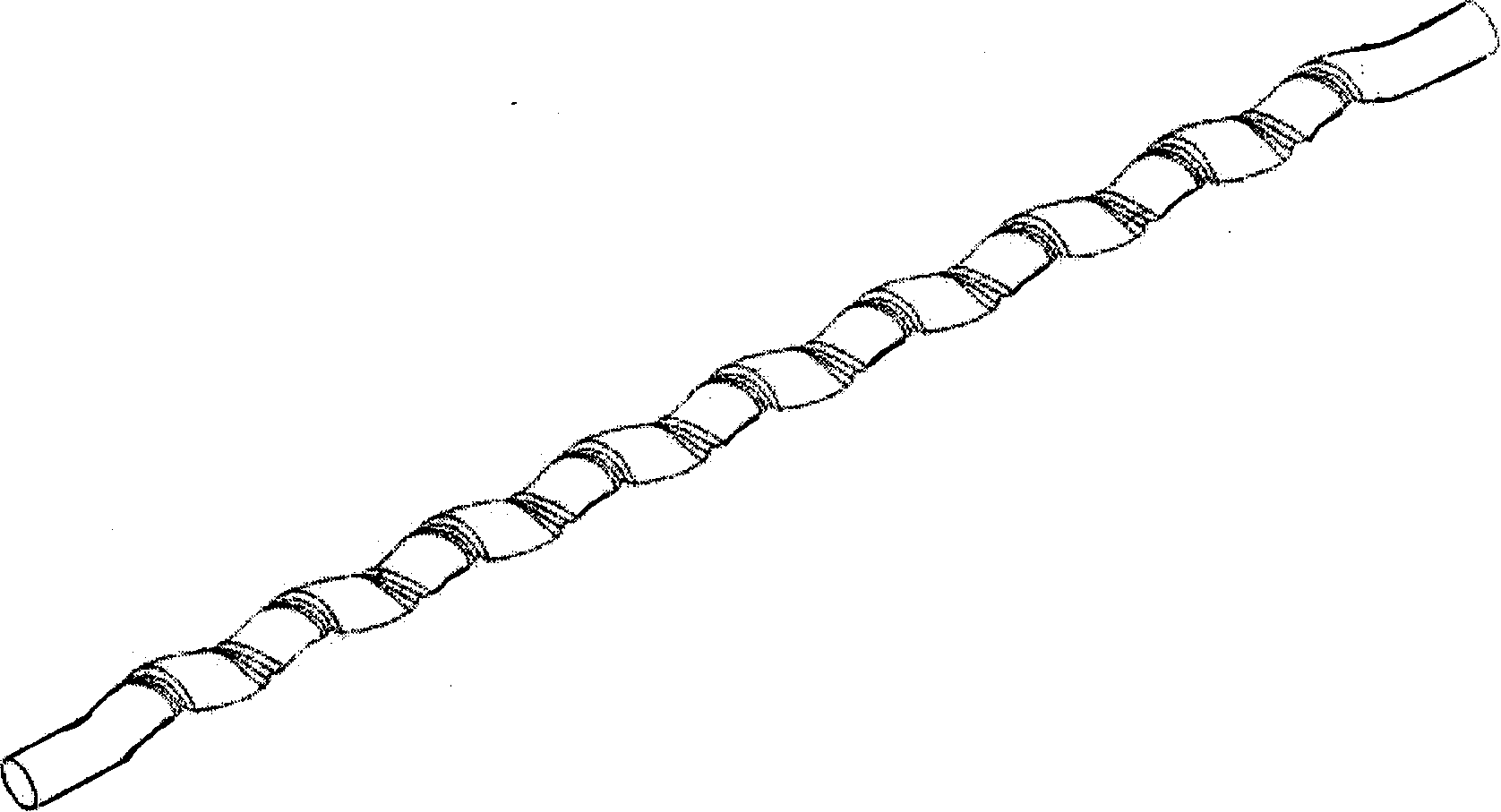

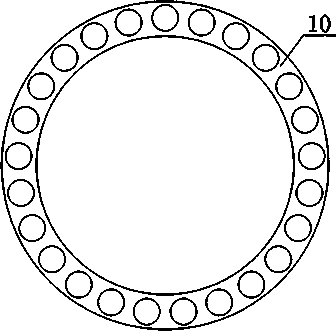

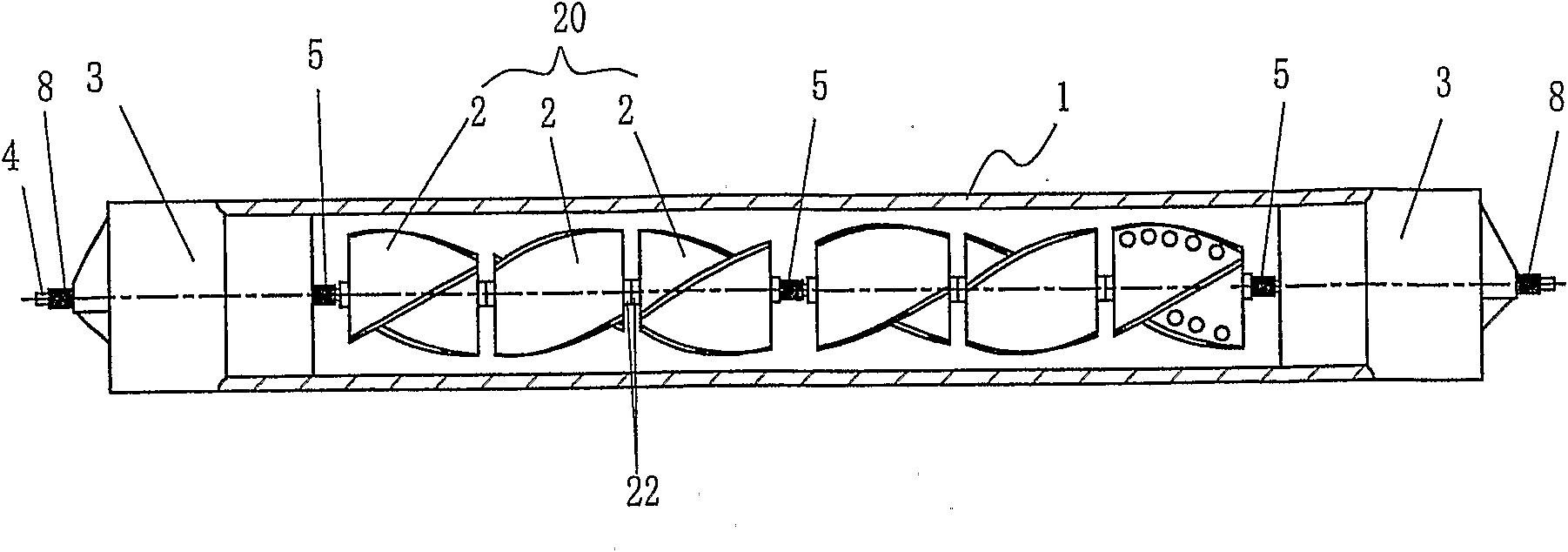

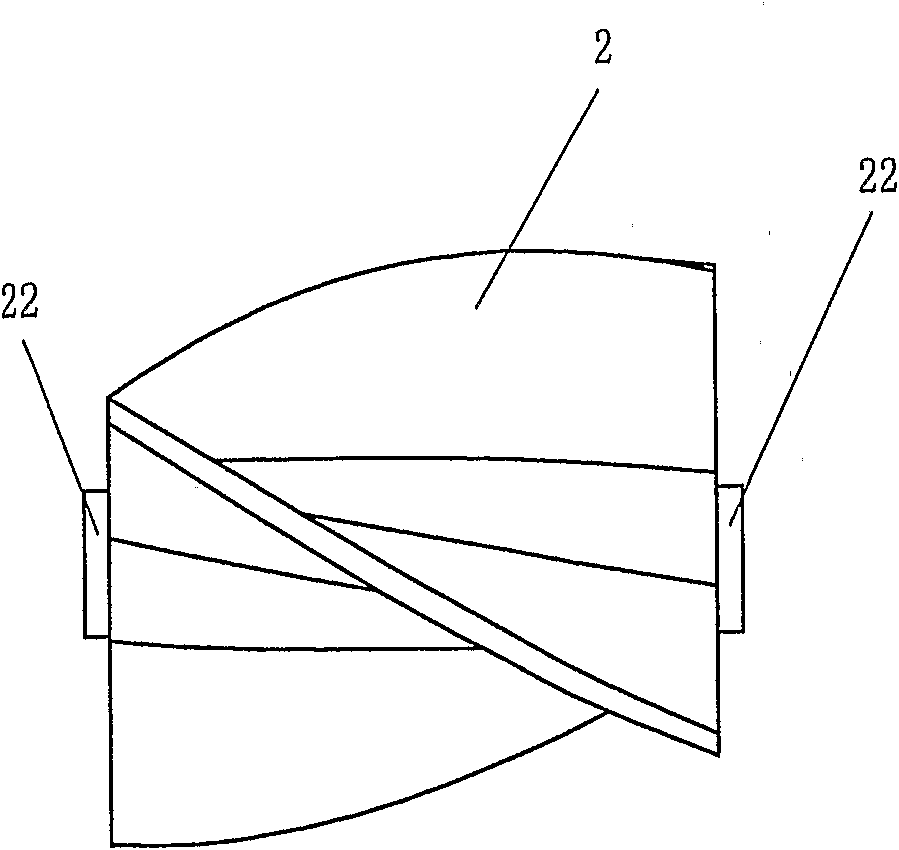

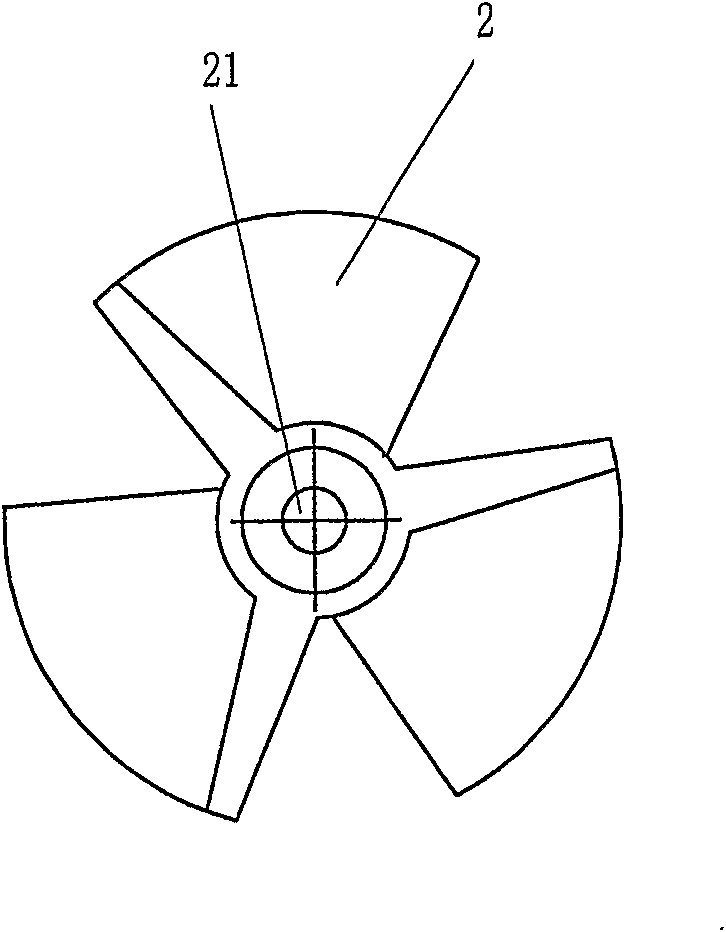

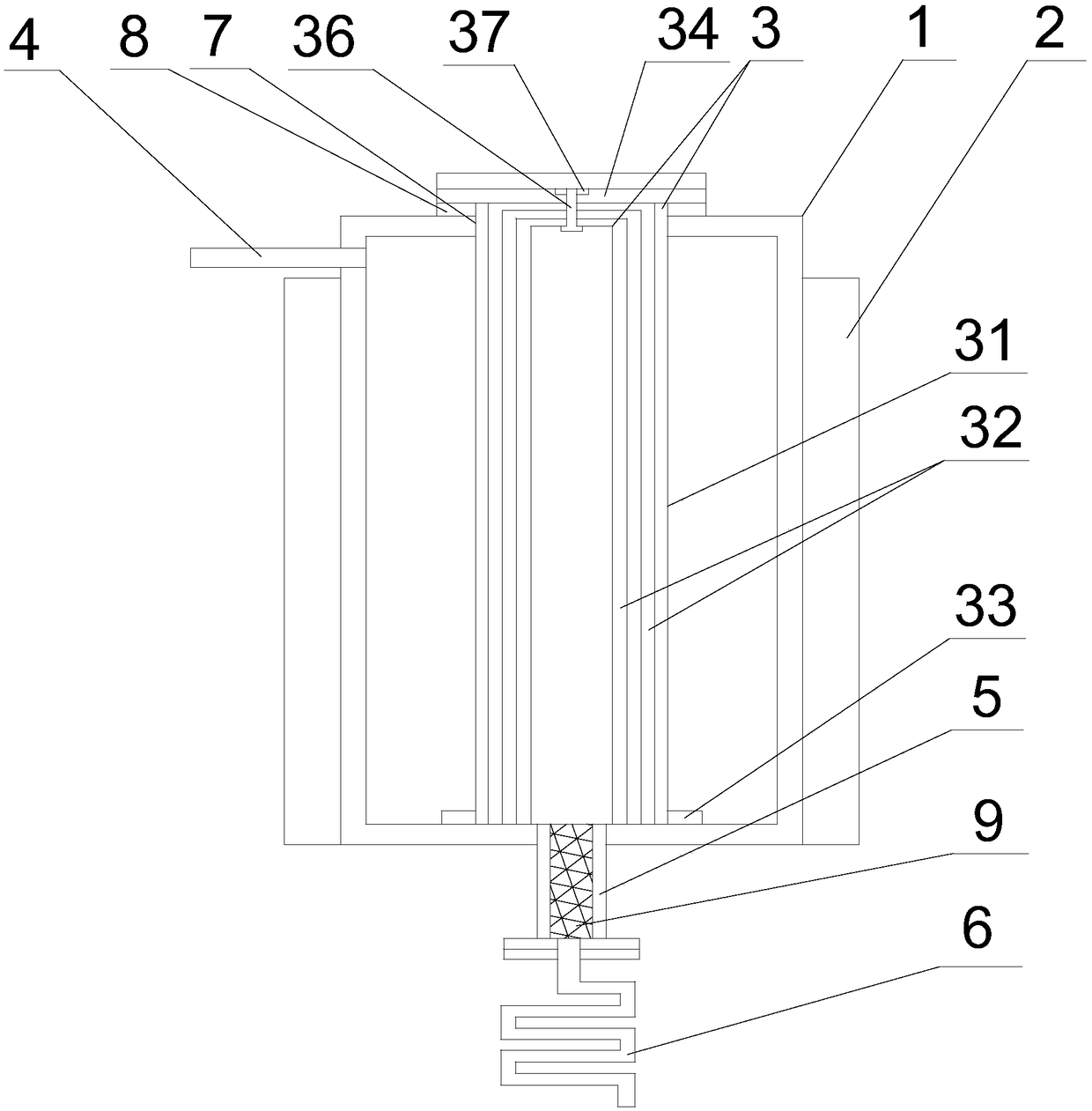

A self-cleaning enhanced heat transfer device inside a tube

InactiveCN101506611BExtended service lifeReduce mutual frictionHollow article cleaningHeat transfer modificationEnhanced heat transferEngineering

A self-cleaning enhanced heat transfer device inside a tube comprises multiple rotary members (2) mounted inside a heat transfer tube (1). A fixing frame (3) is mounted at each end of the heat transfer tube (1). A supporting shaft (4) passes through the heat transfer tube (1) and the two ends of the supporting shaft (4) are fixed at the fixing frames (3). The rotary members (2) are pivotally mounted at the supporting shaft (4). A limiting member (5) is mounted between at least a pair of adjacent rotary members (2) for separating the ends of the adjacent rotary members (2).

Owner:BEIJING UNIV OF CHEM TECH

Wastewater treater

ActiveCN106621424AIncrease evaporation areaIncrease heat transfer rate and heat transfer coefficientWater/sewage treatmentEvaporators with vertical tubesLiquid phaseMaterial flow

The invention provides a wastewater treater. The treater comprises an upper head, a shell and a lower head, wherein a gas outlet is arranged on the upper head; a concentrated liquid outlet is arranged on the lower head; the shell comprises a vapor-liquid separationsection, a material distribution section, an evaporation section and a liquid storage section along a liquid-phase material flowing direction; a feeding port is arranged on the shell above the material distribution section; a heating vapor inlet and a condensate outlet are arranged on the shell of the evaporation section, and an auxiliary vapor inlet are arranged on the shell of the liquid storage section. The treater provided by the invention can improve the wastewater evaporation area and the liquid film updating speed, and increases a heat transfer rate and a heat transfer coefficient of the vapor and the wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

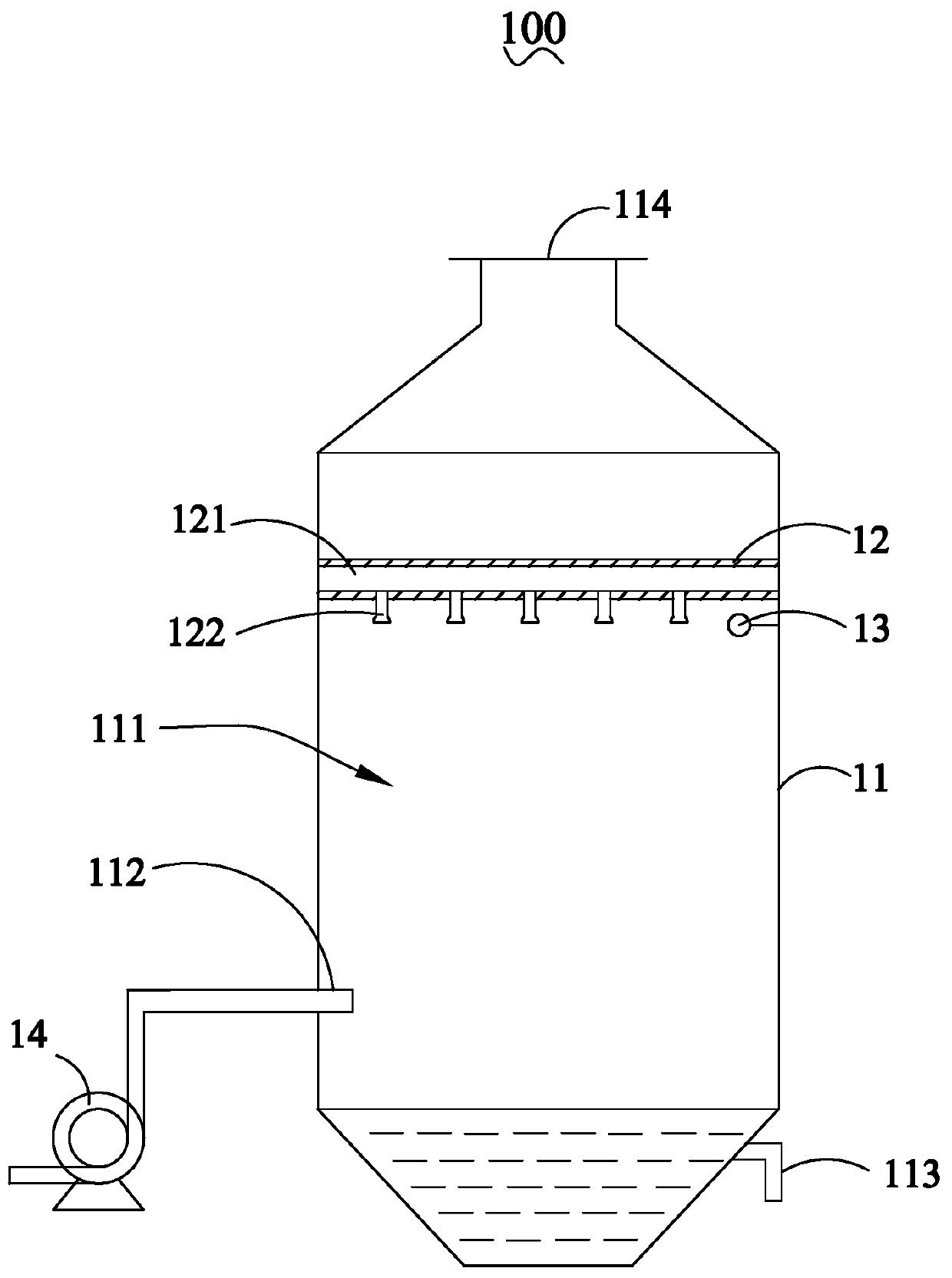

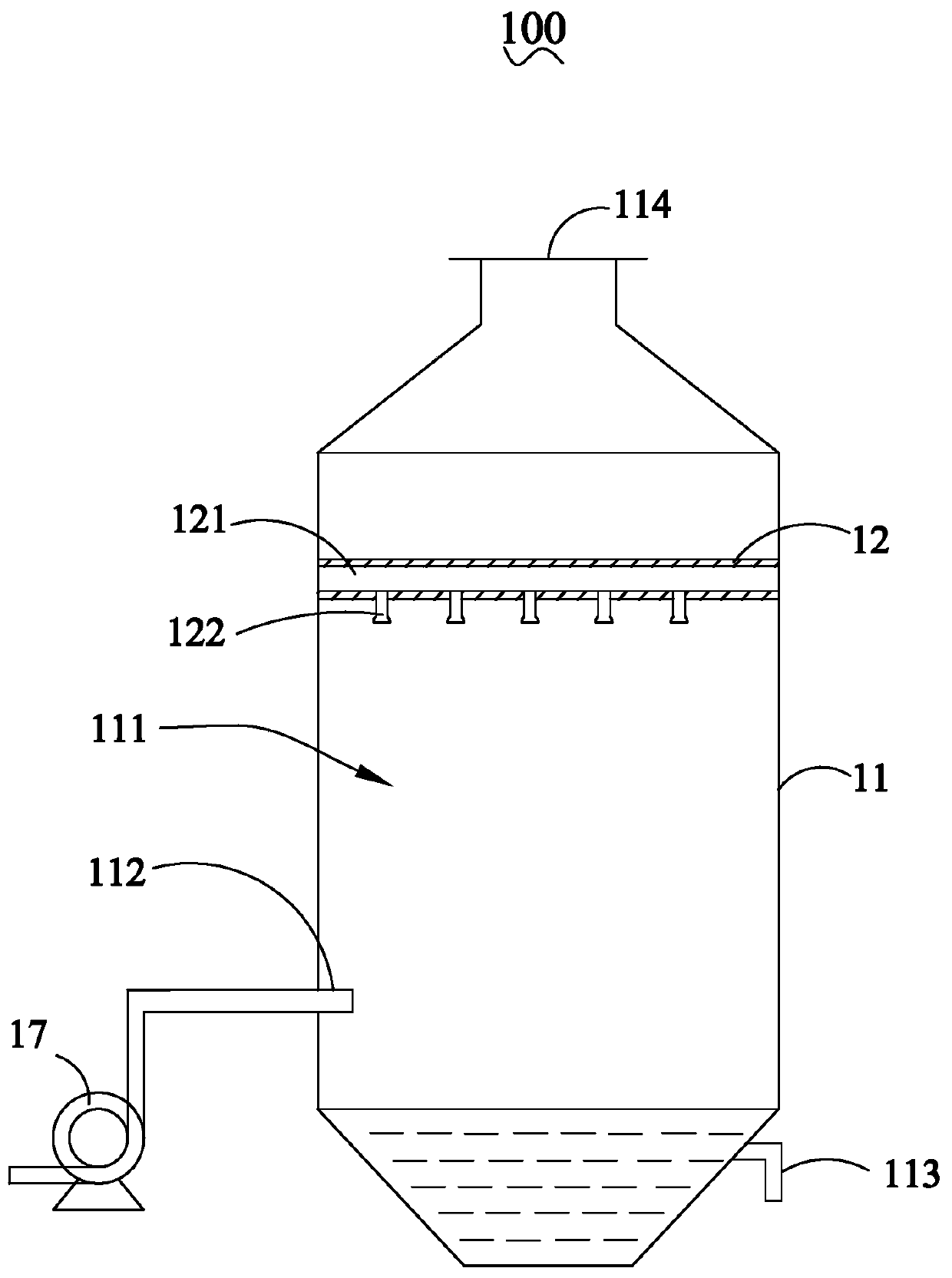

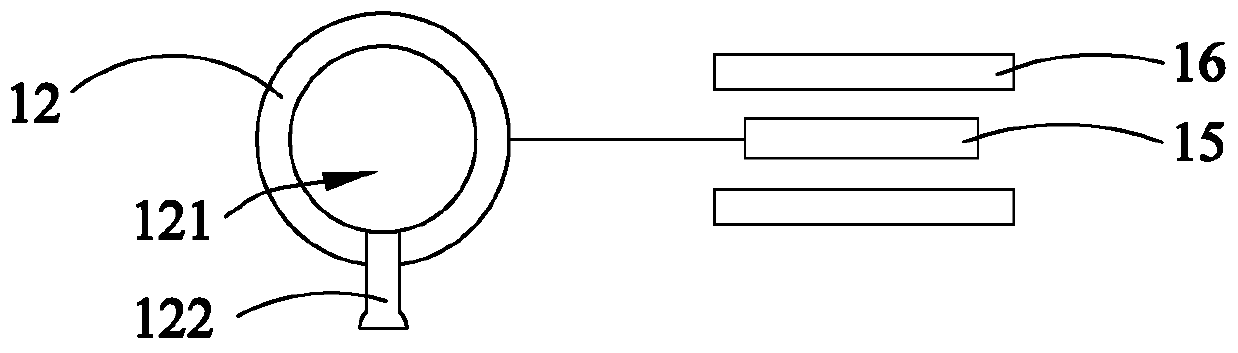

Flue gas desulfurizing tower based on Karman vortex street

InactiveCN109908731AReduce use costImprove fouling problemDispersed particle separationHollow article cleaningFlue gasEngineering

The invention provides a flue gas desulfurizing tower based on Karman vortex street. The flue gas desulfurizing tower comprises a casing with an internal cavity and a cylindrical Karman vortex streetgenerator arranged in the internal cavity, wherein the cylindrical Karman vortex street generator comprises a spraying liquid pipeline arranged in the cylindrical Karman vortex street generator alongthe length direction of the cylindrical Karman vortex street generator and a plurality of spouts which are arranged in an array form along the length direction of the cylindrical Karman vortex streetgenerator and are communicated with the spraying liquid pipeline; a flue gas inlet is formed in the bottom of the casing; flue gas containing SO2 flows into the casing through the flue gas inlet. Theflue gas desulfurizing tower provided by the invention has the beneficial effects that the Karman vortex street phenomenon is applied in the desulfurizing tower; scales in the spraying liquid pipelineare automatically cleared by vibration generated by the Karman vortex street phenomenon to the Karman vortex street phenomenon generator, so that the problem of scaling in the spraying liquid pipeline is obviously improved and the use cost of the flue gas desulfurizing tower is reduced.

Owner:JISHOU UNIVERSITY

Method for treating circulating cooling water

ActiveCN109133390AAvoid badSolve corrosiveScale removal and water softeningNon-contaminated water treatmentAlkalinityWater flow

The invention relates to the field of circular cooling water treatment, and discloses a method for treating circulating cooling water. The method comprises the steps that fresh water is adopted as cooling water of an air precooling system, and first agentia is put in the air precooling system; water flowing out of the air precooling system is taken as supplementary water of a circulating cooling water system, and second agentia is put in the supplementary water of the circulating cooling water system; the sum of calcium ion concentration and total alkalinity of the fresh water is less than orequal to 100 mg / L; the first agentia comprises a copolymer of crylic acid and 2-methyl-2'-acrylamide propane sulfonic acid, zinc salt and organic phosphonic acid. According to the method, by changingthe water supplementing point of the fresh water and reasonably adding the scale and corrosion inhibition components, the scaling and corrosion problems of the air precooling system and the circulating cooling water system are solved, the adding amount of the agentia is lower, and the method is especially beneficial for reducing production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

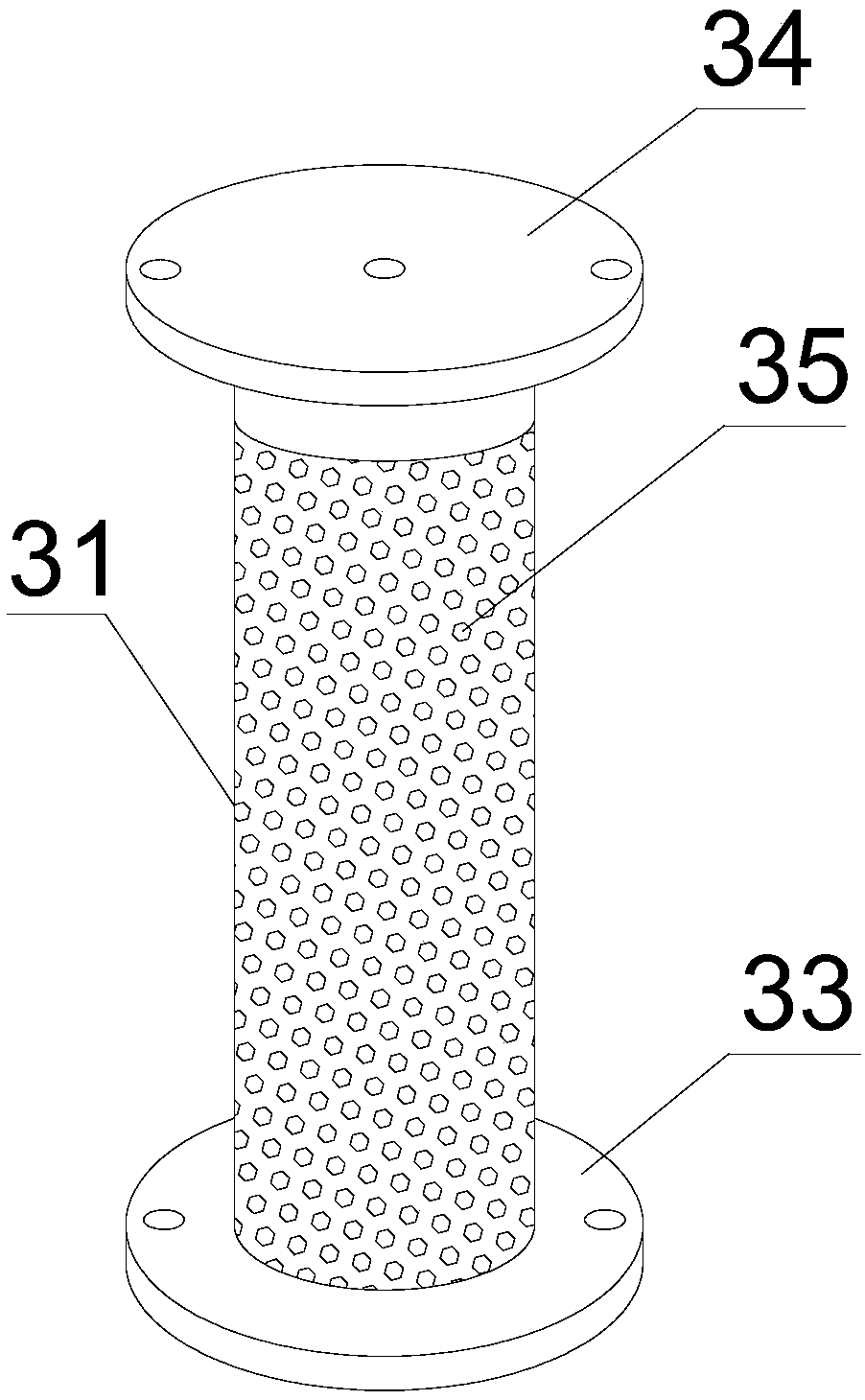

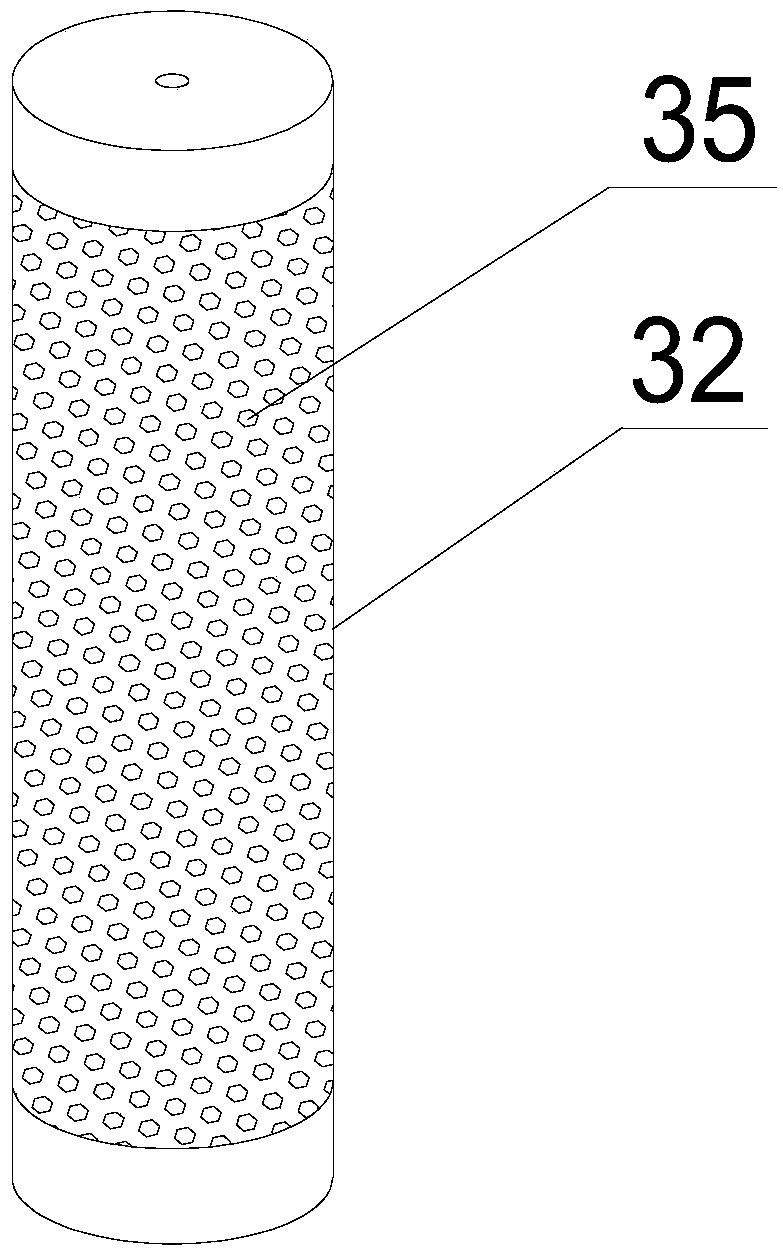

Anti-scaling dosing device for sodium hypochlorite generator

ActiveCN109368817BPrevent scalingGood for post-cleanupScale removal and water softeningTreatment involving filtrationEngineeringMechanical engineering

Owner:SICHUAN QILI LVYUAN WATER TREATMENT TECH CO LTD

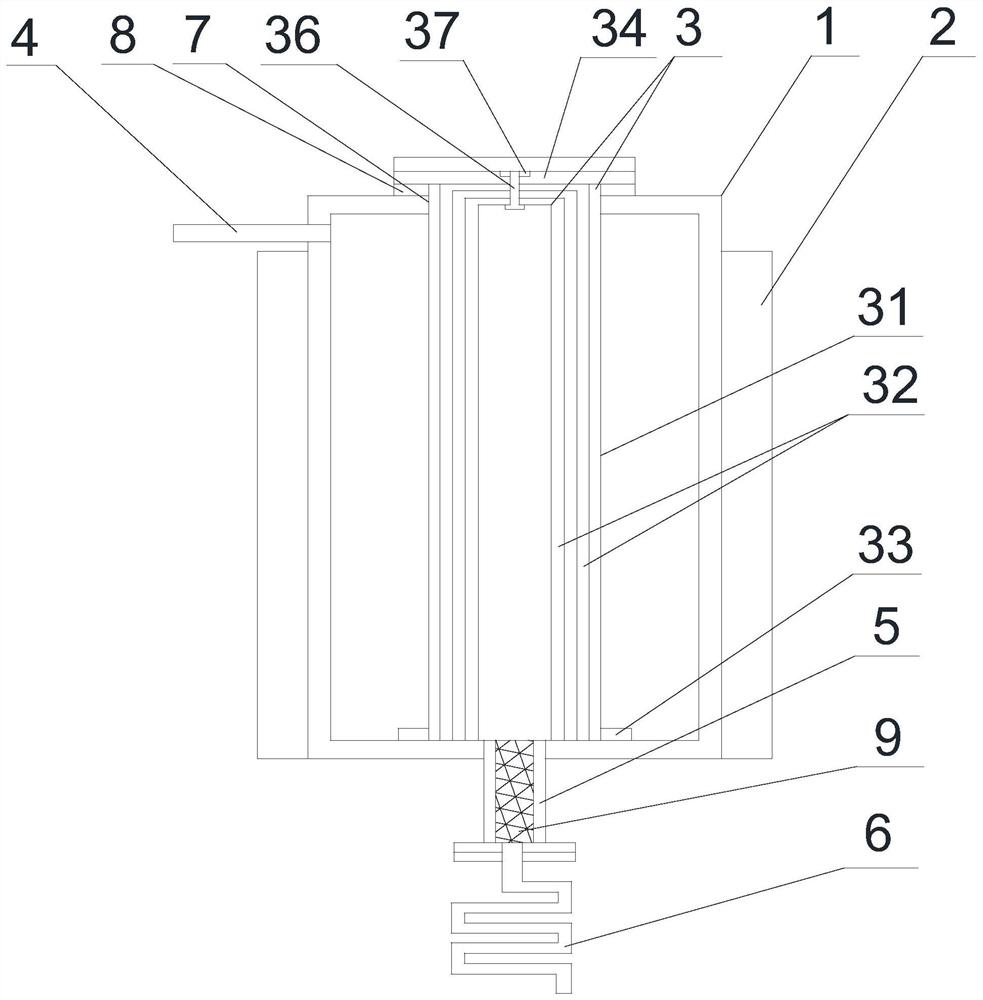

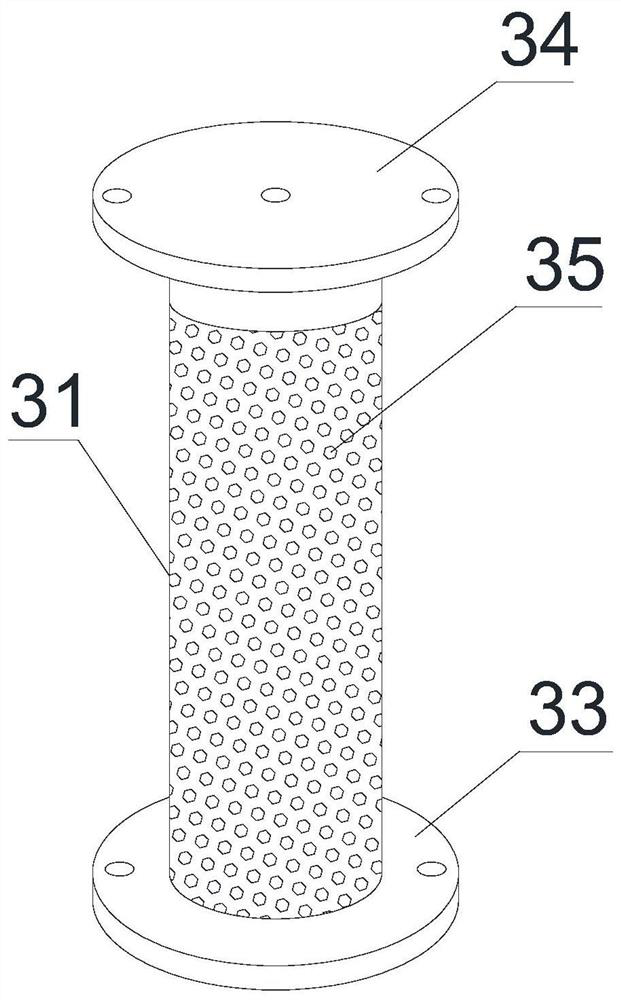

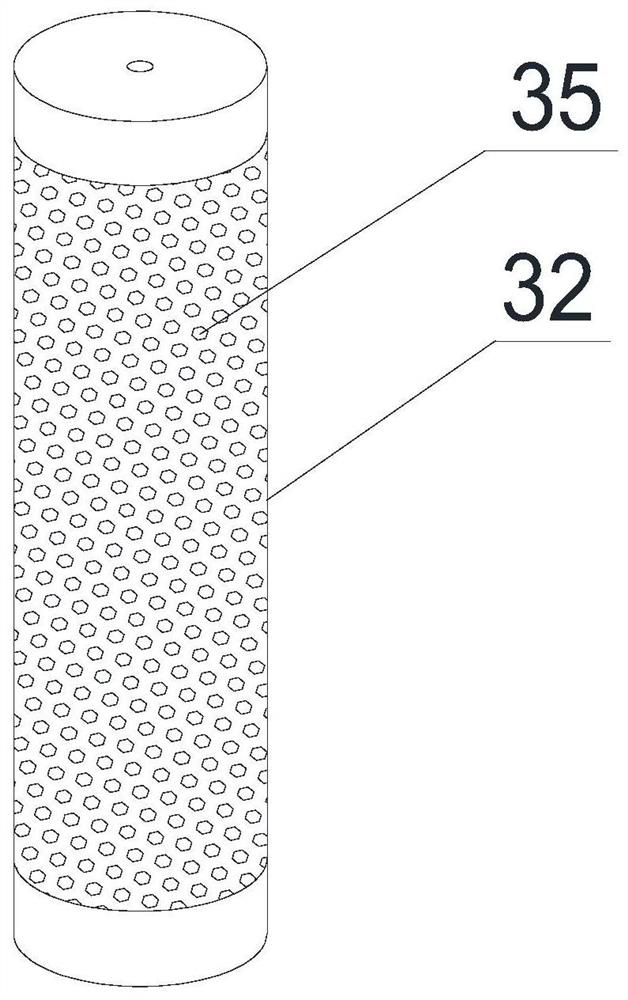

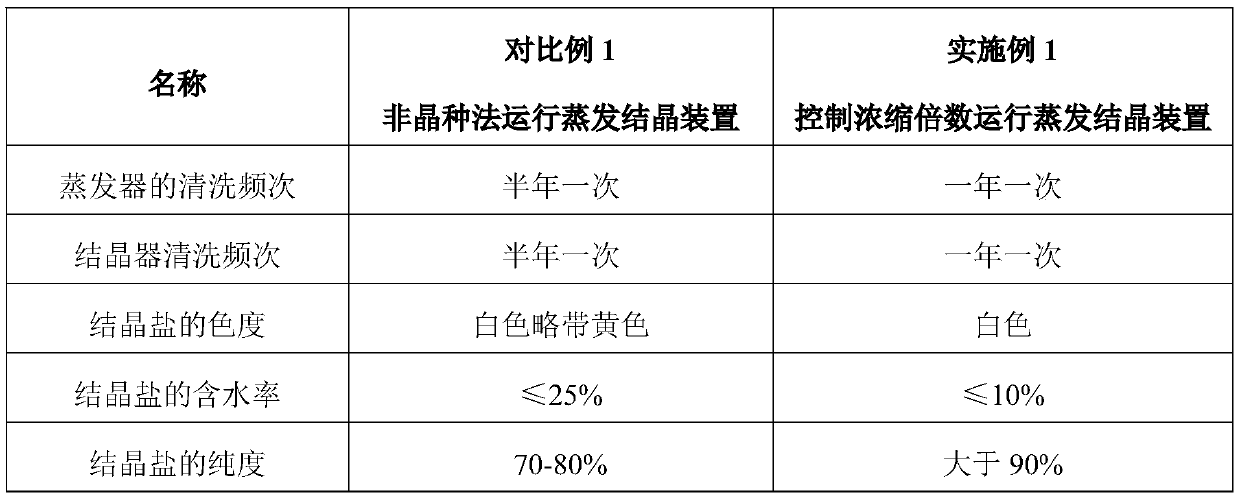

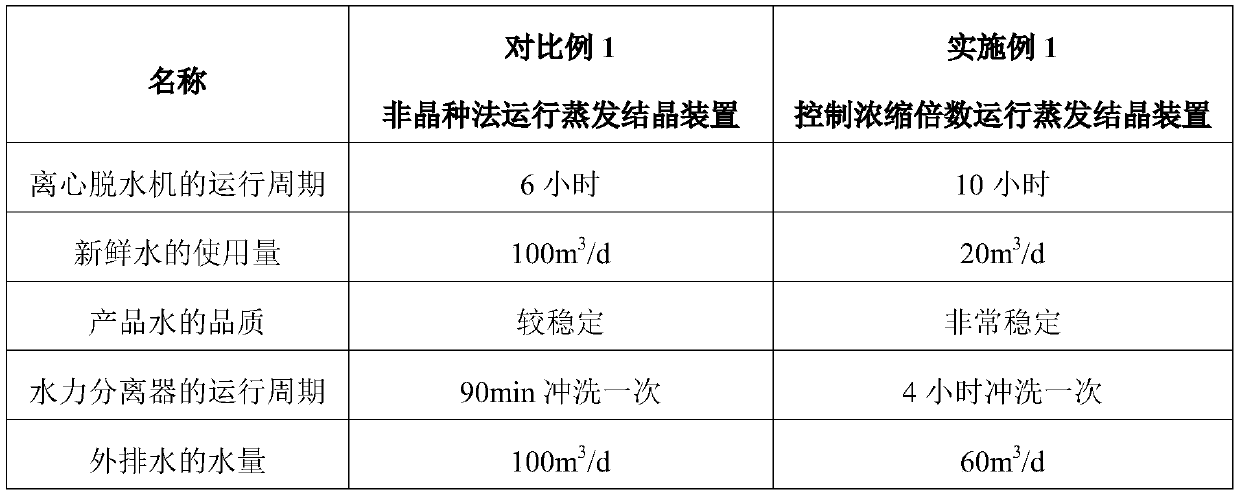

Evaporative crystallization method for salinity wastewater

ActiveCN110028119AGuaranteed uptimeImprove fouling problemWater/sewage treatment by heatingSaline waterEvaporation

The invention provides an evaporative crystallization method for salinity wastewater. The method comprises the following steps: S1, preheating salinity wastewater and then degassing; S2, carrying outevaporation treatment on degassed wastewater in an amorphous seeding operation mode to obtain secondary steam and discharge water in the evaporation process; in addition, carrying out real-time adjustment of the discharge amount of the discharge water according to the incoming water quality of the degassed wastewater so as to control concentration multiple of an evaporation system; S3, carrying out crystallization treatment on the discharge water in the amorphous seeding operation mode to obtain secondary steam and strong brine in the crystallization process, adding a defoaming agent into a crystallizer body for defoaming, concentrating the defoamed strong brine by starting a hydroseparator and starting a centrifuge for centrifugal dewatering to obtain solid carnallite; besides, in the process of running the hydroseparator, carrying out real-time adjustment on the discharge amount of supernate in the hydroseparator according to the water quality of the discharge water to control the concentration multiple of the crystallization system. The method disclosed by the invention solves the operational stability problem of the amorphous seeding evaporative crystallization system.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

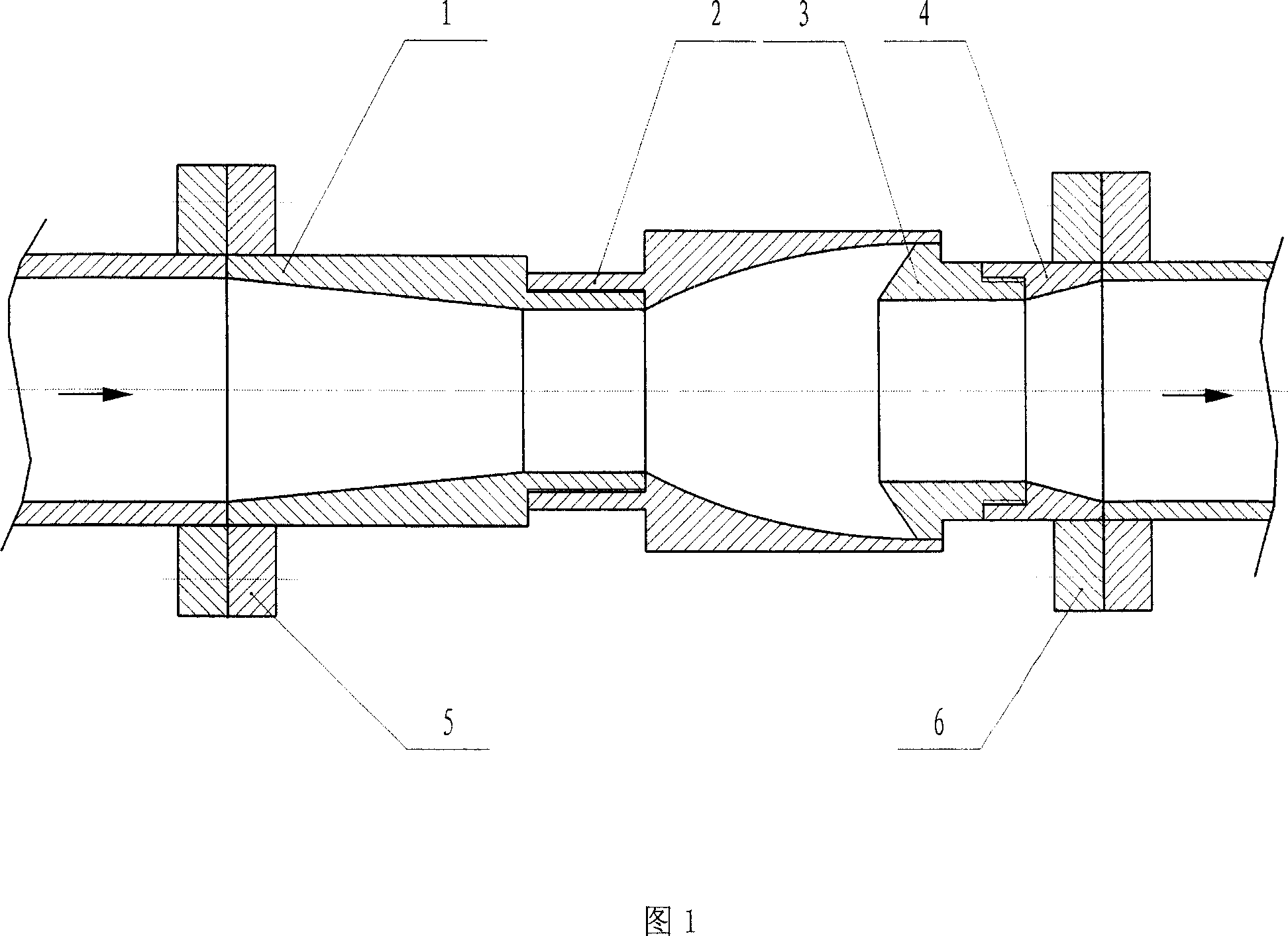

Pipe pulse stream generator

InactiveCN1325806CImprove flow characteristicsLittle resistance lossFluid dynamicsImpulse frequencyPulse stream

The invention relates to a pipe impulse flow generator, belonging to the heat-matter transmission high-efficiency energy-saving device of natural gas and oil. The invention can reduce the resistance of transmitting liquid, save energy, decrease the deposition of olefin, and improve the heat efficiency of transmitting heat and matter. The invention comprises a upper nozzle, a self-excite chamber, a lower nozzle, and a pipe which are sequentially sealed, fixed and connected; the inlet of upper nozzle and the outlet of pipe are individually connected to the inlet and outlet pipe. The invention can use said generator to transform the continuous liquid via the self-excite chamber into impulse liquid without any auxiliary device, and improved amplitude of output pressure as 15-30%, increased impulse frequency from tens to hundreds, to reduce the resistance, save energy consumption and apply variable industries.

Owner:CHONGQING UNIV

A method for separating and purifying acetoin in fermentation broth

ActiveCN106588617BReduce moisture contentLow boiling pointCarbonyl compound separation/purificationEthyl acetateImpurity

The invention discloses a method for separating and purifying acetoin in fermentation liquor. The method includes the step of adding inorganic salt and a weak polar organic solvent are added into the fermentation liquor for extraction, wherein the addition amount of the inorganic salt accounts for 25-125% of the volume of the fermentation liquor, and the volume ratio of the organic solvent and the fermentation liquor is (1-2):1. The weak polar organic solvent is one of ethyl acetate, methyl tertiary-butyl ether, butyl acetate, dimethyl carbonate and diethyl carbonate. By means of the method, an extraction phase containing acetoin hardly contains pigment, residual sugar and organic acid impurities, an extraction solution can be directly rectified, and the scaling phenomenon is not likely to happen to a column reactor in the rectification process. Polarity of the solvent in use is small, the specific heat capacity is low, the upper phase water content is low, energy consumption for recycling is low, and acetoin loss in the recycling process is small. Operation is easy, and the method is an acetoin separation and extraction technology with industrial application prospects.

Owner:DALIAN UNIV OF TECH

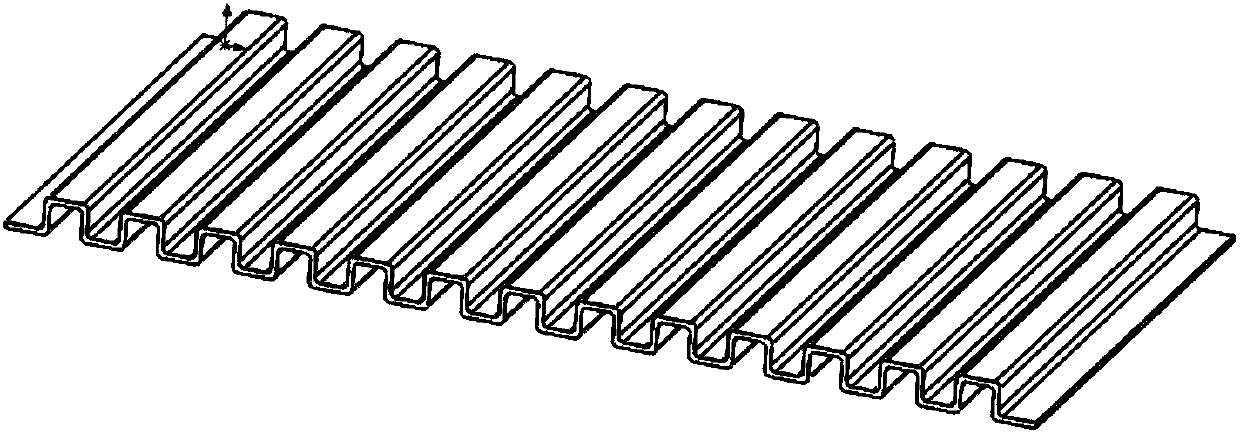

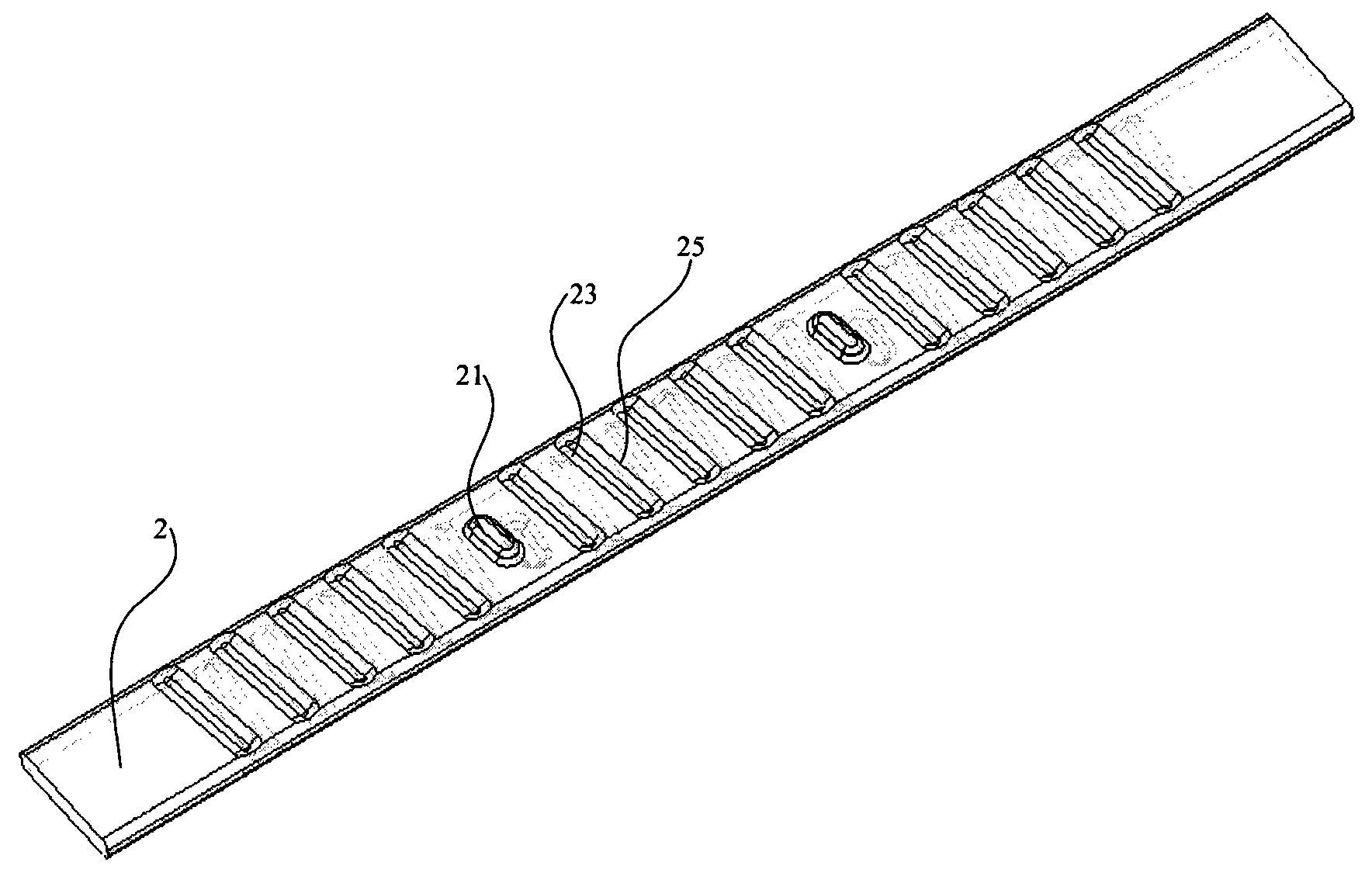

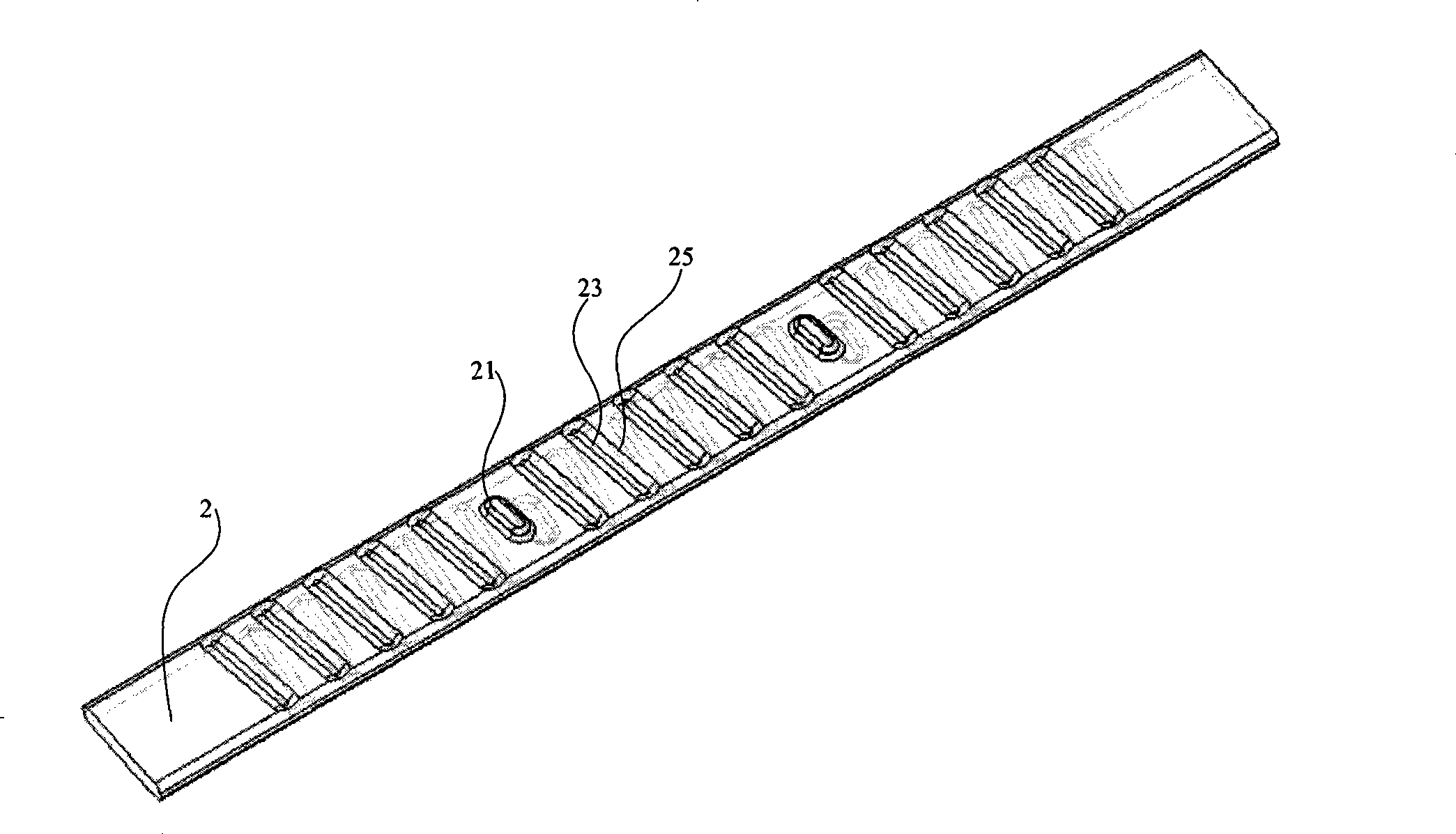

Flat-shaped groove heat exchange tube and heat exchanger using the same

ActiveCN101413765BAvoid deformationReduce distortionInternal combustion piston enginesNon-fuel substance addition to fuelEngineeringThermal efficiency

The invention discloses a flat groove heat exchange tube and a heat exchanger using the heat exchange tube. The heat exchanger is applied to an automobile engine waste gas recycling system as an engine waste gas recycling cooler and comprises a section-shaped stainless steel tube body with unequal height and width. The upper surfaces and lower surfaces of the tube body are provided with internally concave short grooves which are parallelly arranged and the upper surfaces and lower surfaces among a plurality of grooves are provided with bulges protruding externally. By the combination of the grooves and the bulges of the flat groove heat exchange tube, the heat exchange tube does not easily deform and generates stable heat exchange effect when bearing fierce temperature and pressure change. The short grooves for increasing the heat exchange efficiency can increase the strength of a plane in the long axis direction of the flat tube, inhibit deformation, and the mutual support of the bulges among the tubes forcefully improves the stress condition on the tube wall; thus leading to the minimum deformation of the flat tube, sparing an enough space among the tubes in spite of deformationand being beneficial to the flow of a medium outside the tubes.

Owner:BEIJING U BRIDGE CHAOYANG

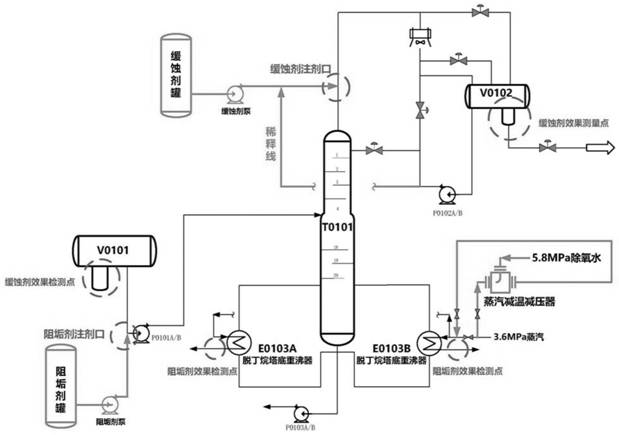

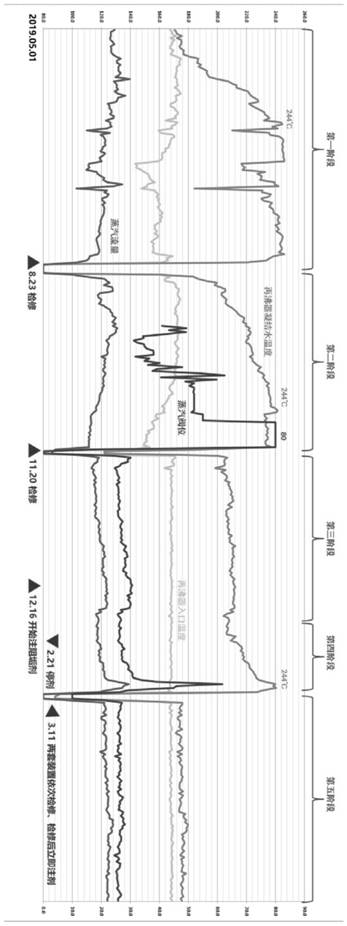

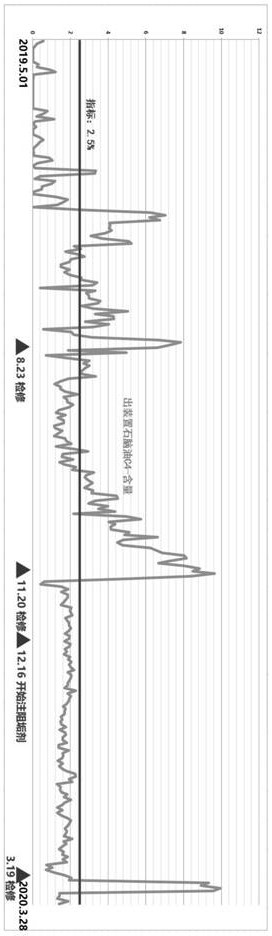

Scaling control method for debutanizer bottom reboiler of light hydrocarbon recovery device

InactiveCN112316472AImprove fouling problemReduce foulingDistillation regulation/controlFractional distillationReboilerProcess engineering

The invention belongs to the technical field of chemical engineering, and particularly relates to a scaling control method for a debutanizer bottom reboiler of a light hydrocarbon recovery device. Themethod comprises the steps that a scale inhibitor is injected in the feeding stage of a debutanizer, and based on the feeding amount of the debutanizer, the injection amount of the scale inhibitor is25-35 mg / kg; a corrosion inhibitor can be injected into a gas-phase volatilization section at the top of the debutanizer, and the injection amount of the corrosion inhibitor is 3-8 mg / kg based on theflow of liquefied gas at the top of the debutanizer; and a temperature and pressure reducer can also be used on a heat source steam pipeline, and deoxygenated water is injected into the temperature and pressure reducer. The method effectively improves the scaling problem of the debutanizer bottom reboiler, reduces the scaling rate of the debutanizer bottom reboiler, reduces the overhaul frequencyof the debutanizer, and prolongs the operation period of the debutanizer.

Owner:恒力石化(大连)炼化有限公司

Anti-scaling adding device for sodium hypochlorite generator

ActiveCN109368817APrevent scalingGood for post-cleanupScale removal and water softeningTreatment involving filtrationSaline waterElectrolysis

The invention discloses an anti-scaling adding device for a sodium hypochlorite generator. The anti-scaling adding device comprises a shell body, wherein a heating mechanism covers on an outer wall ofthe shell body; the shell body is internally provided with a scaling filtering screen; a liquid inlet pipe is arranged at the top of the shell body and is used for communicating a chamber between aninner wall of the shell body and the scaling filtering screen; a liquid discharging pipe is arranged at the bottom of the shell body and is used for discharging saline water filtered by the scaling filtering screen; an output end of the liquid discharging pipe is connected with an input end of a cooling mechanism; and an output end of the cooling mechanism is communicated with the sodium hypochlorite generator. The anti-scaling adding device has a working principle that scaled impurities including calcium and magnesium ions and the like in the saline water are transformed into a visible form from an invisible form under a high-temperature condition of 50 to 100 DEG C and water scales are directly formed on the scaling filtering screen and are convenient for post-period cleaning; and the descaled saline water is conveyed into the cooling mechanism and is cooled, and then is introduced into the sodium hypochlorite generator to be subjected to electrolysis reaction, so that the surface ofan electrode of an electrolytic tank can be effectively prevented from being scaled and the electrolysis efficiency is ensured.

Owner:SICHUAN QILI LVYUAN WATER TREATMENT TECH CO LTD

Vacuum low-temperature evaporation concentration treatment method of landfill leachate

ActiveCN104229911BImprove fouling problemAccelerated corrosionMultistage water/sewage treatmentWater/sewage treatment by heatingEnvironmental engineeringHeat losses

The invention discloses a vacuum low-temperature evaporation concentration treatment method for landfill leachate, which is characterized in that: the landfill leachate is separated into steam and concentrated liquid by low-temperature evaporation in a vacuum state through a vacuum evaporator, and the operating pressure of the vacuum evaporator is controlled at 4.5‑7.5kPa, the evaporation temperature is controlled at 30‑40°C. Because the invention adopts low-temperature evaporation, it reduces fouling of the evaporator and facilitates cleaning, prevents ammonia nitrogen from overflowing with steam, improves heat exchange efficiency, reduces heat loss, has low energy consumption, and low leachate treatment cost.

Owner:CHINA GDE ENG

Micro and nano-grade light calcium carbonate tube-condensation-type double-circulation multi-level carbonation system

InactiveCN102936026BAvoid technical problems that are prone to cloggingEasy to cleanCalcium/strontium/barium carbonatesMaterial nanotechnologyReaction temperatureCarbonization

The invention discloses a micro and nano-grade light calcium carbonate tube-condensation-type double-circulation multi-level carbonation system. The system comprises at least three carbonization towers (1) connected in series. A slurry tank is provided between each two adjacent carbonization towers (1). A carbonization tower (1) comprises a high-pressure pump (3), a spraying mist-making device (4), a tower body (5), condensing tubes (6), an air compressor (7), a gas plate (8), a refrigerator (9), and an accumulated liquid and scale removing device (10). The condensing tubes (6) are connected with the refrigerator (9). The spraying mist-making device (4) is connected with the high-pressure pump (3). The gas plate (8) is connected with the air compressor (7). The accumulated liquid and scale removing device (10) is sleeved on the outside of the condensing tubes (6). The system provided by the invention has the advantages that: spraying and a high-liquid-level bubbling carbonization method are adopted, continuity is high, and carbonization efficiency is high. The condensing tubes are added, such that the reaction temperature in the tower can be conveniently controlled. The accumulated liquid and scale removing device is provided, such that condensing tube scale can be conveniently removed.

Owner:SICHUAN HAIYA POWDER TECH CO LTD

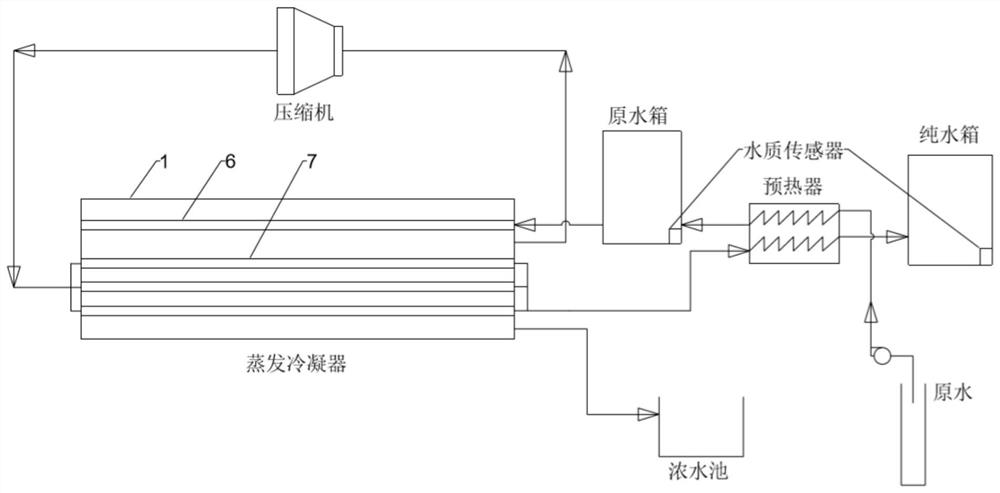

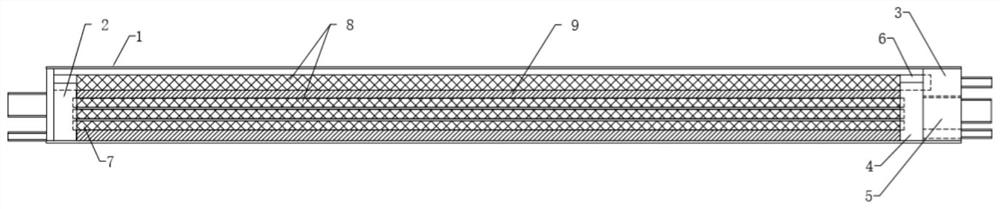

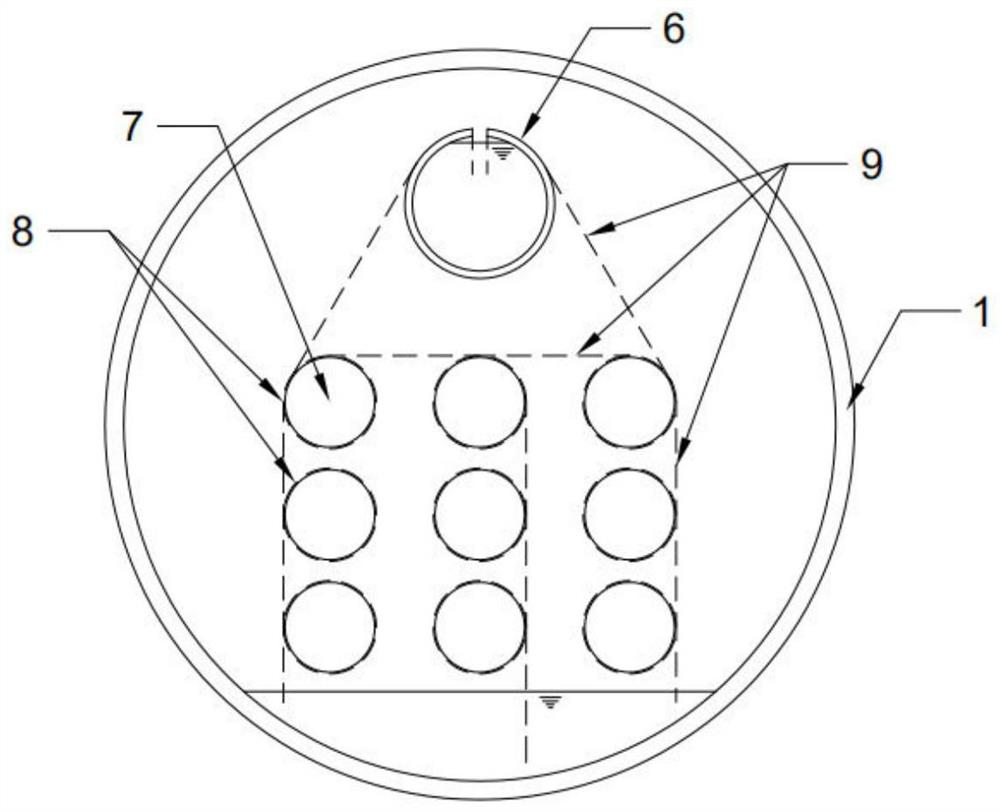

An all-glass tube mvc low-solubility sewage evaporation condensation purification system

ActiveCN111792684BClear distributionTo play the case of uneven thicknessWater/sewage treatment by heatingWater/sewage treatment apparatusSewagePurified water

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com