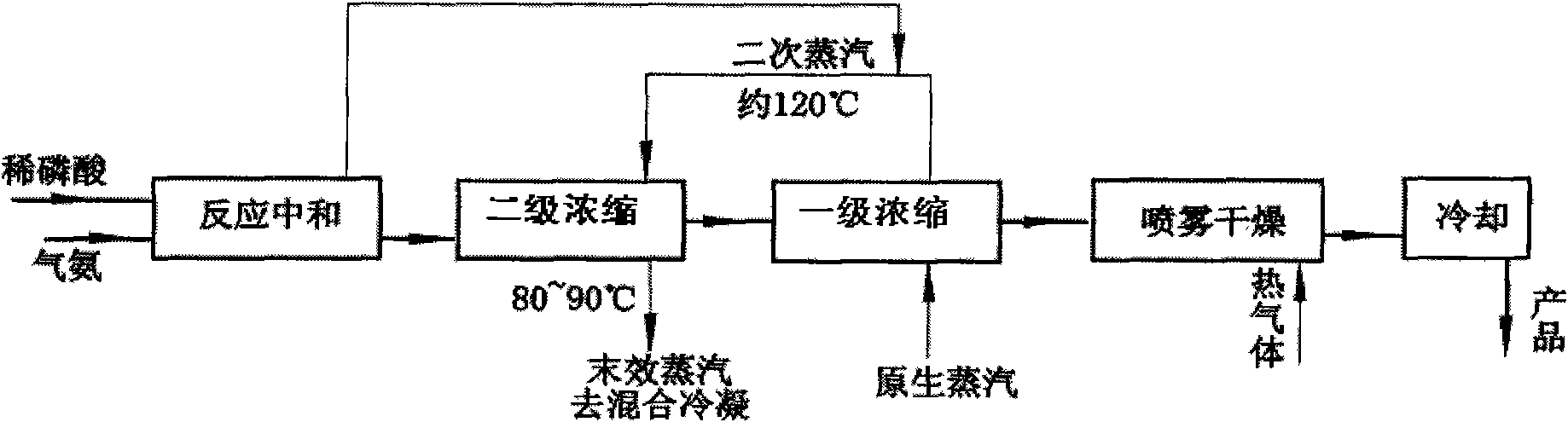

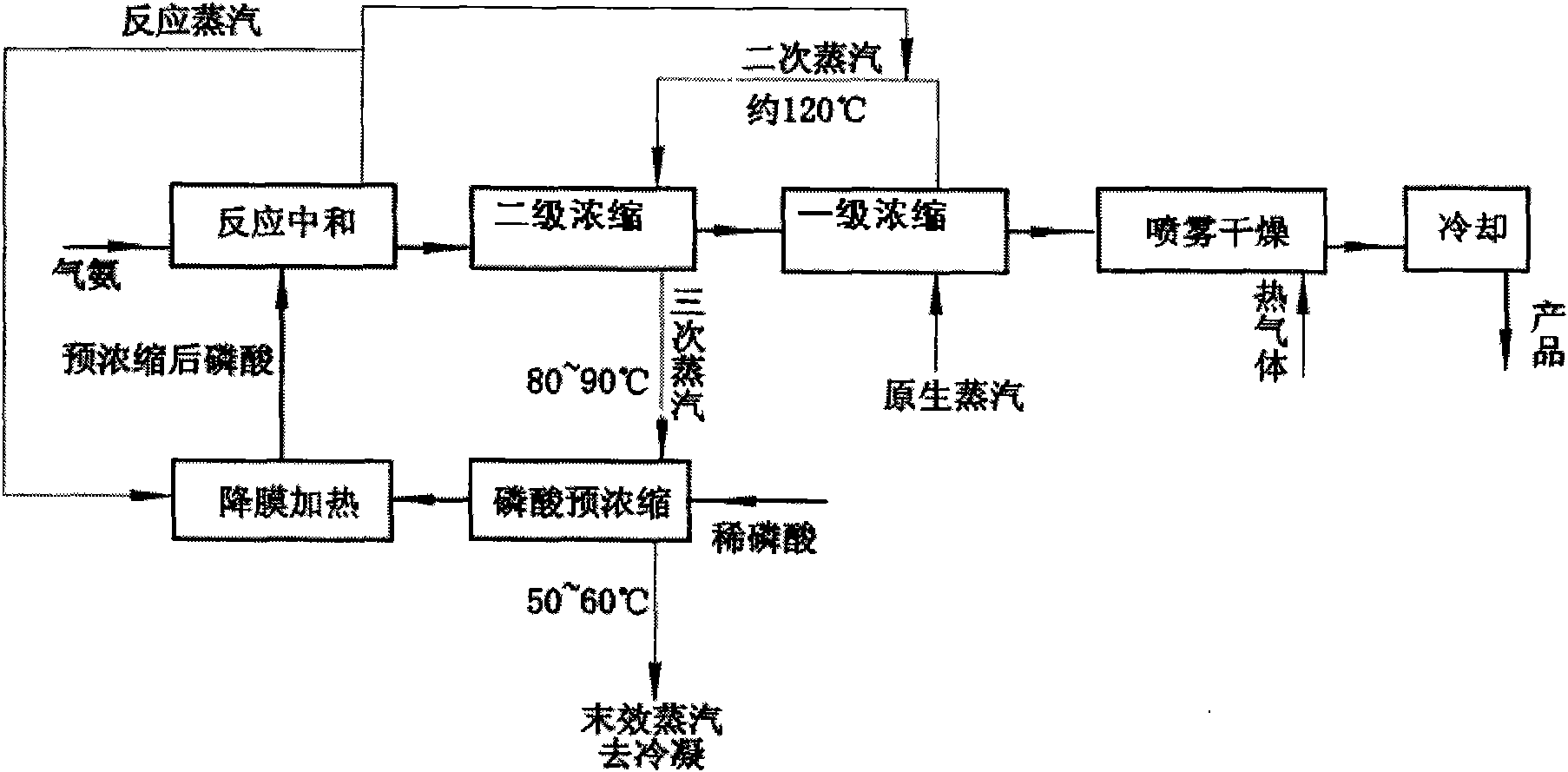

Stepped utilization method of steam in ammonium phosphate production

An ammonium phosphate and steam technology, applied in the field of ammonium phosphate salt, can solve the problems such as no patent application for ammonium phosphate steam utilization, energy waste, unconverted and utilized low-level heat sources, etc., so as to save the consumption of primary steam, equipment and pipelines. The effect of size reduction and scaling reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

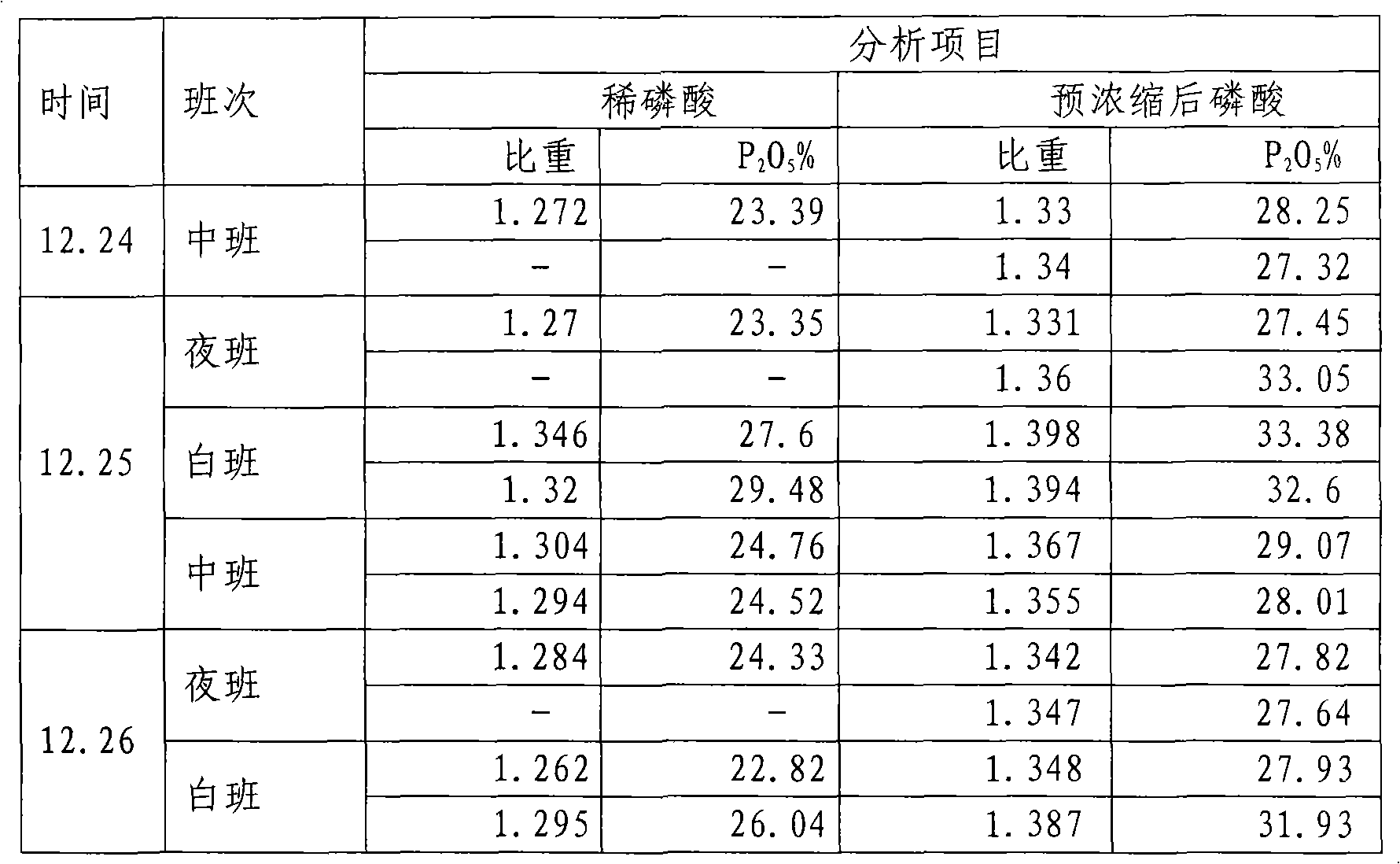

[0013] Embodiment Wengfu (Group) Co., Ltd. Wengfu Phosphate Fertilizer Factory adopted this technology in 2005 to carry out technical transformation of capacity expansion and consumption reduction of 240kt / a "neutralization slurry concentration method" powdery monoammonium phosphate (abbreviated as MAP), It was put into trial operation in July 2006. Successfully realized the low-temperature phosphoric acid pre-concentration MAP energy-saving process for recovering the waste heat of the slurry concentration tail gas (about 80°C), the comprehensive energy consumption was reduced by 39% year-on-year, and the slurry production capacity of the original equipment was increased to 360kt / a (the original design was 240kt / a Powdered MAP) capability. The operation after adopting the low-temperature phosphoric acid pre-concentration energy-saving function process is as follows:

[0014]

[0015] It can be seen from the data in the table that after phosphoric acid pre-concentration, ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com