Novel heat exchanger core

A heat exchanger, core technology, applied in the direction of heat exchanger conduit, heat exchanger type, indirect heat exchanger, etc., can solve the problems of reducing the service life of heat exchanger, blockage, flow channel scaling, etc. The effect of heat exchange demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

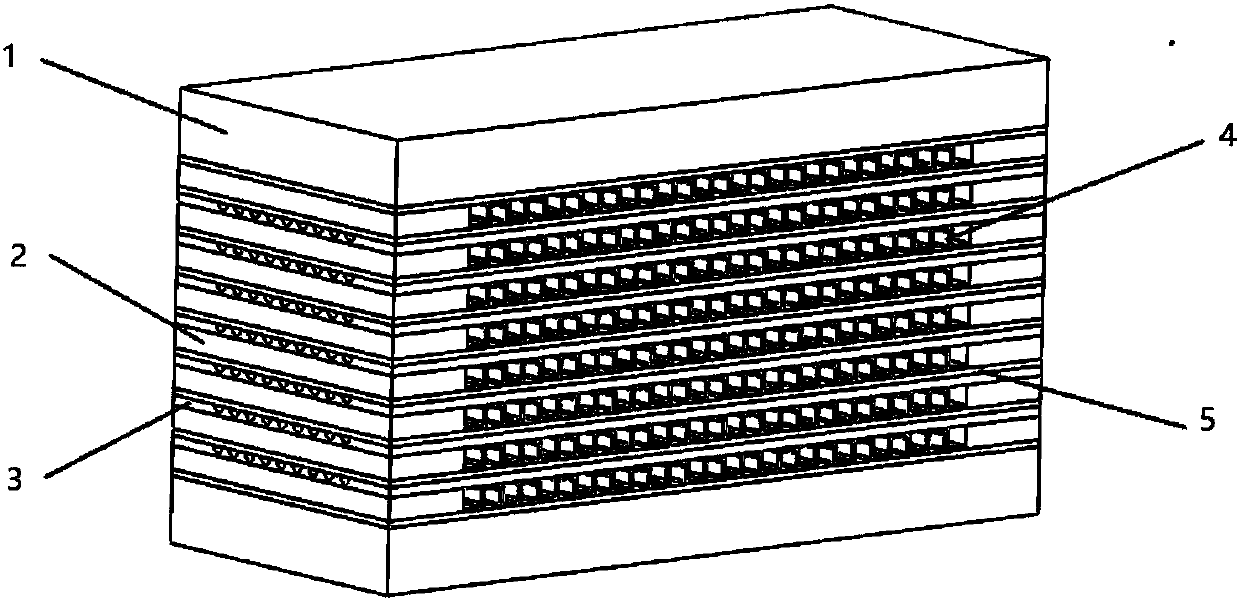

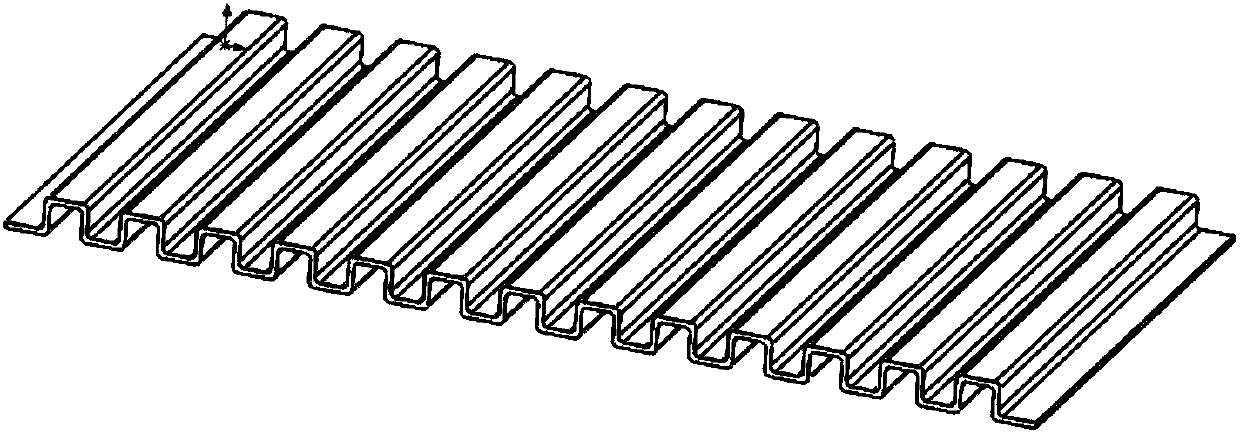

[0042] combine Figure 1-7 , this embodiment provides a new type of heat exchanger core, including two cover plates 1, baffle plates 2, etched plates 3, formed plates 4 and partitions 5; the formed plates 4 and partitions 5 constitute A structural unit A; the structural unit A and the etched sheet 3 are stacked alternately between the two cover plates 1; the non-etched surface of the etched sheet 3 is in contact with the forming sheet 4; the etched surface of the etched sheet 3 is in contact with the corresponding The partitions 5 of the adjacent structural unit A are butted against each other; two baffles 2 are provided at both ends of each of the forming plates 4; a partition 5 is also provided between the cover plate 1 and the etching plate 3; the cover plate 1 and A partition 5 is also arranged between the forming plates 4; the cover plate 1, the baffle plate 2, the etching plate 3, the forming plate 4 and the dividing plate 5 are processed into a cuboid; the forming plate...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 is: the cover plate 1, the baffle plate 2, the etching plate 3, the forming plate 4 and the partition plate 5 are processed into a cuboid; the forming plate 4 is rectangular, and the inlet and outlet of the flow channel are set On the wide side of the rectangle; the etching plate 3 is rectangular, and the inlet and outlet of the flow channel are arranged on the long side of the rectangle.

Embodiment 3

[0048] The difference between this embodiment and Embodiment 1 is that: the cover plate 1, the baffle plate 2, the etched plate 3, the forming plate 4 and the partition 5 are processed into a cube; the forming plate 4 is a square and the etched plate 3 It is a square; the inlets and outlets of the flow channels of the etched sheet 3 and the shaped sheet 4 are arranged on different sides of the square.

[0049] In this embodiment, when the cover plate is in contact with the forming plate, a spacer can be added between the two; when the cover plate is in contact with the etched surface of the etched plate, a spacer can be added between the two; When the non-etched sides of the plates are in contact, a spacer can optionally be added between the two.

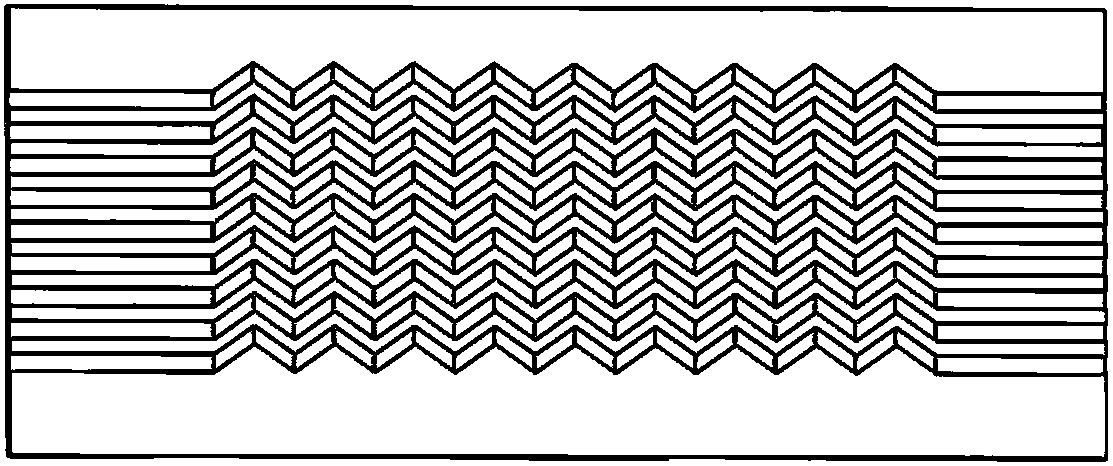

[0050] In this embodiment, the etched plate 3 is to process different forms of flow channels on the plate by chemical etching. The flow channels can be straight channels or zigzag channels. The flow channel inlet and outlet of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com