Patents

Literature

634results about "Heat exhanger conduits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

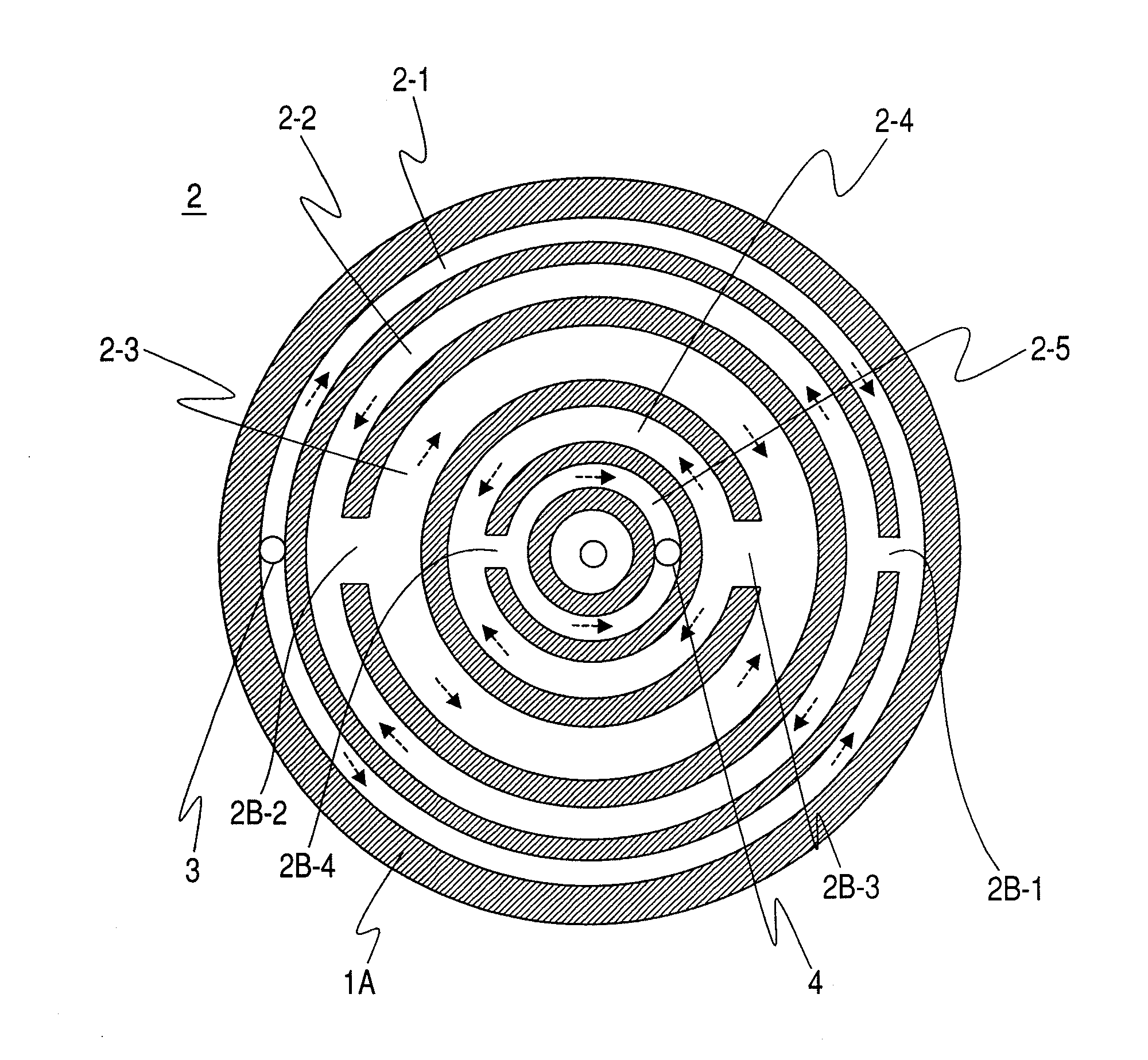

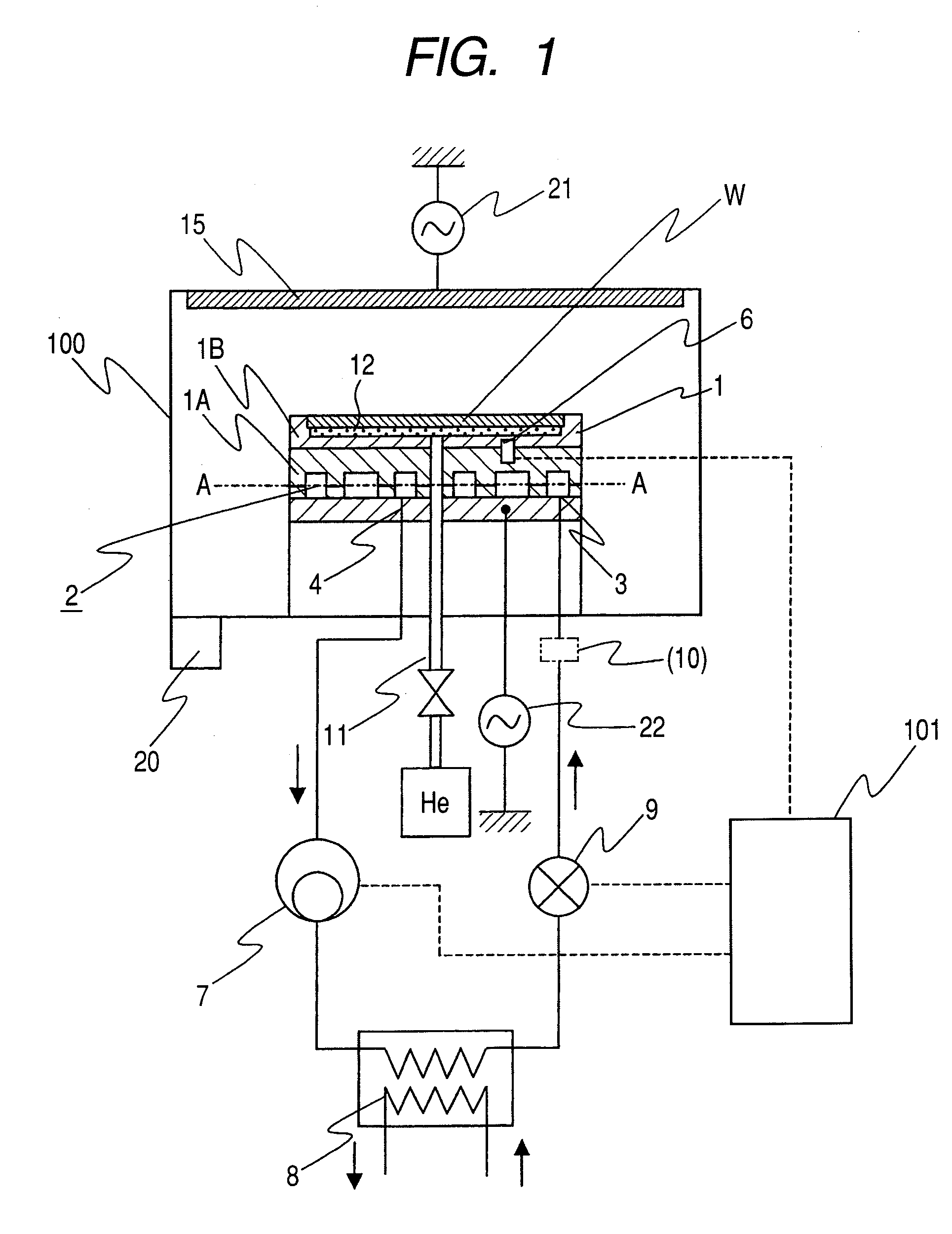

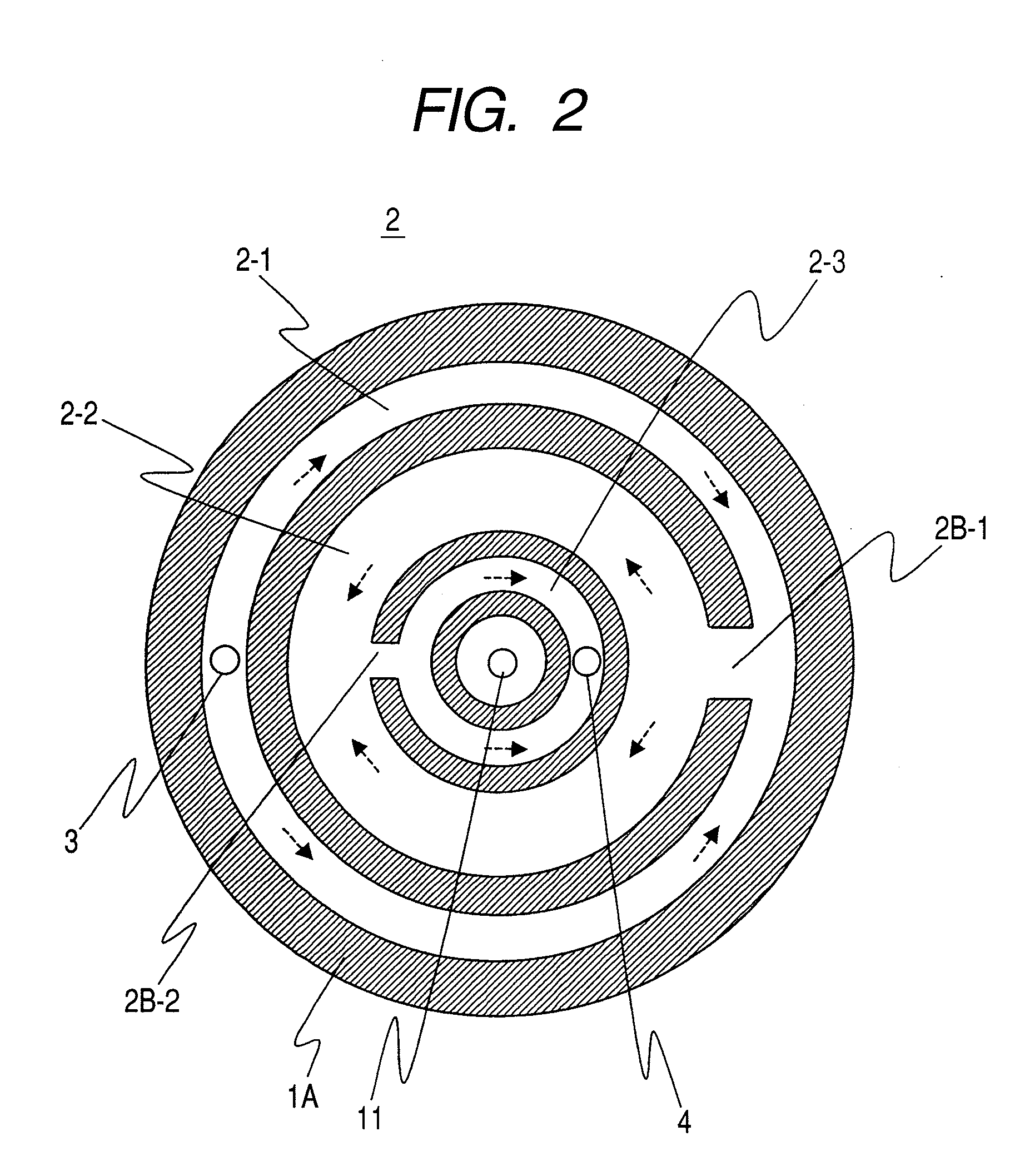

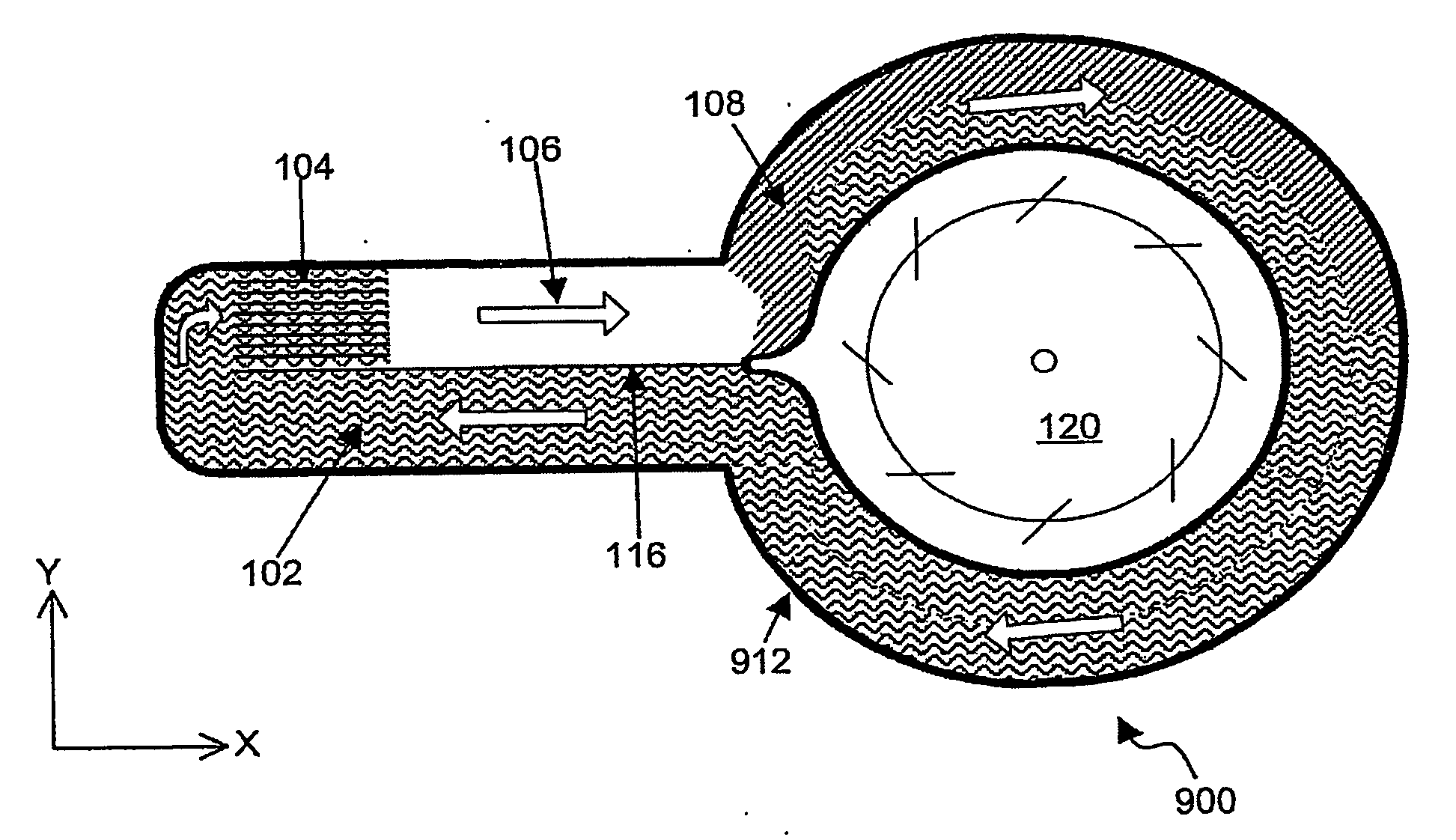

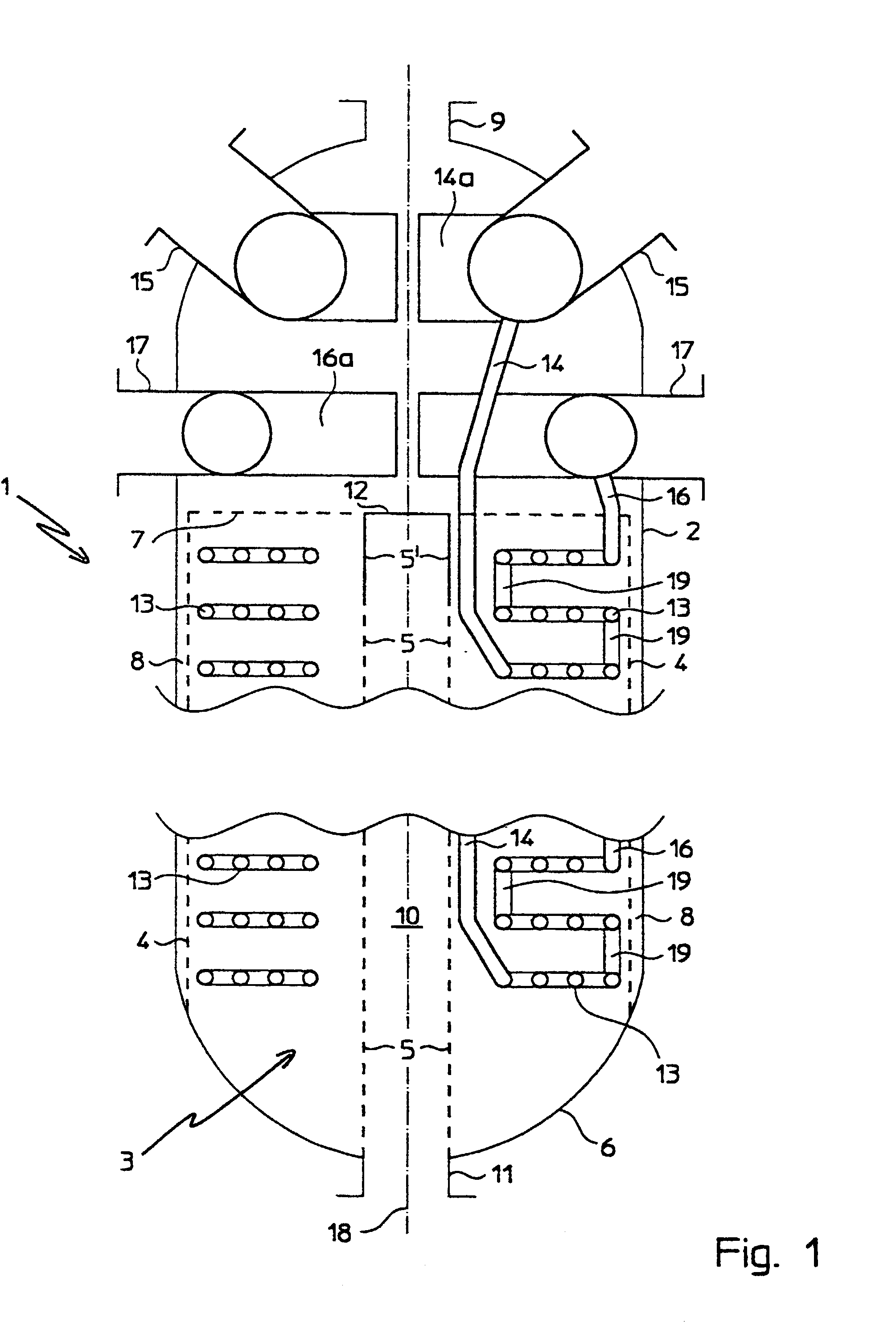

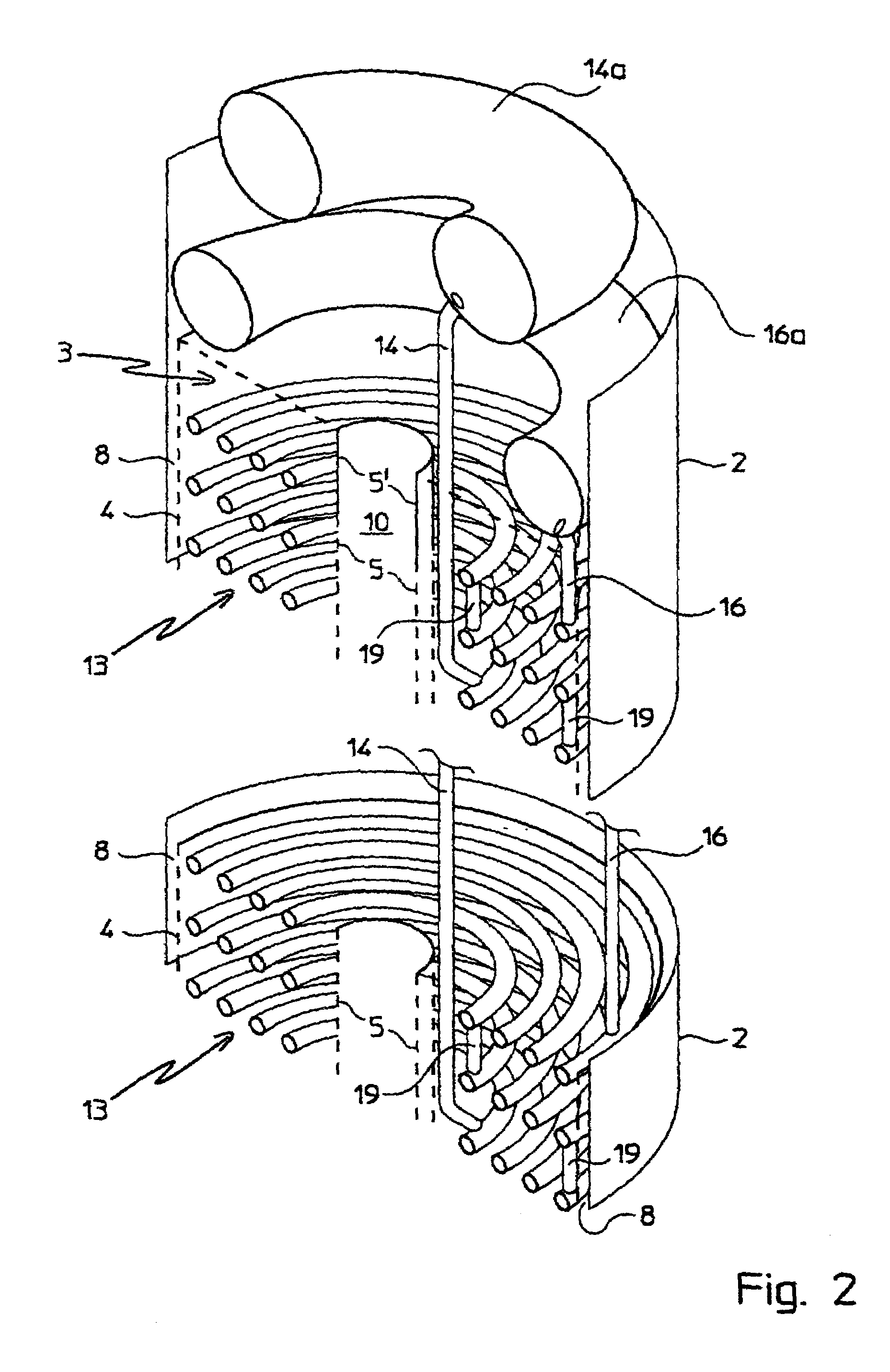

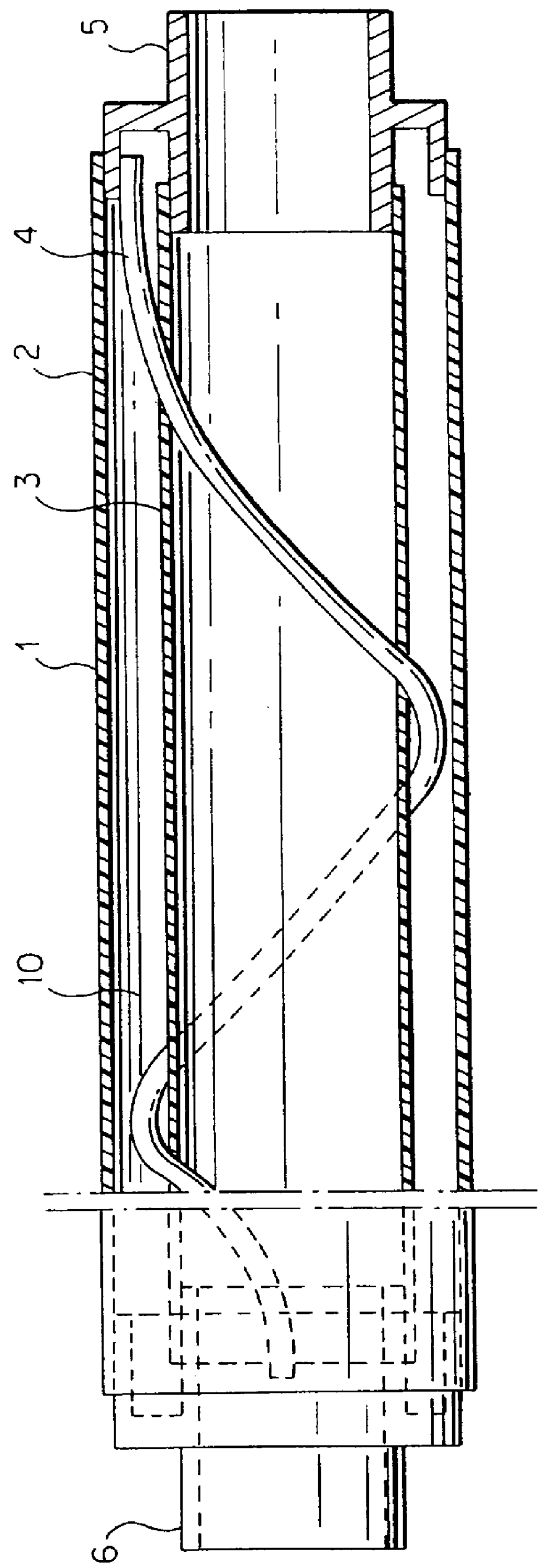

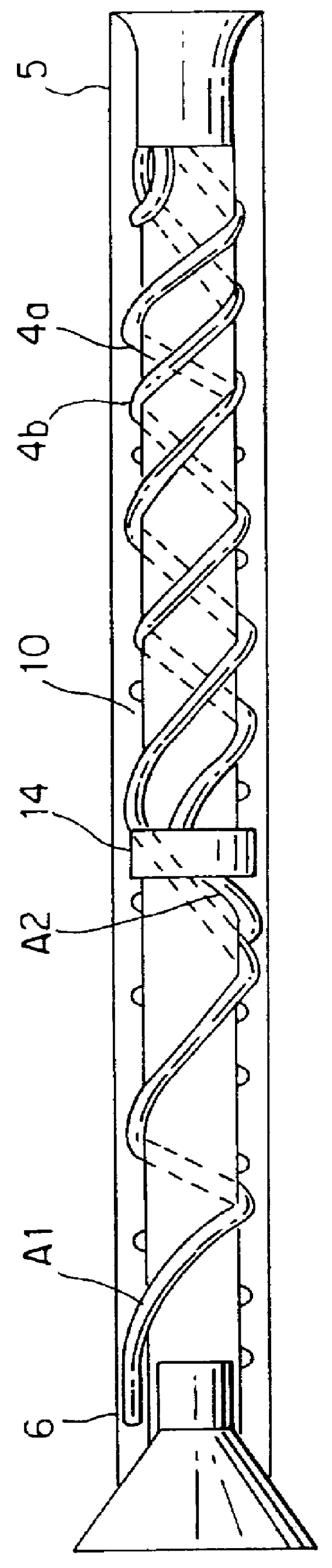

Plasma processing apparatus and plasma processing method

InactiveUS20080178608A1Reduce unevennessUniform maintenanceElectric discharge tubesHeat exhanger conduitsIn planeEngineering

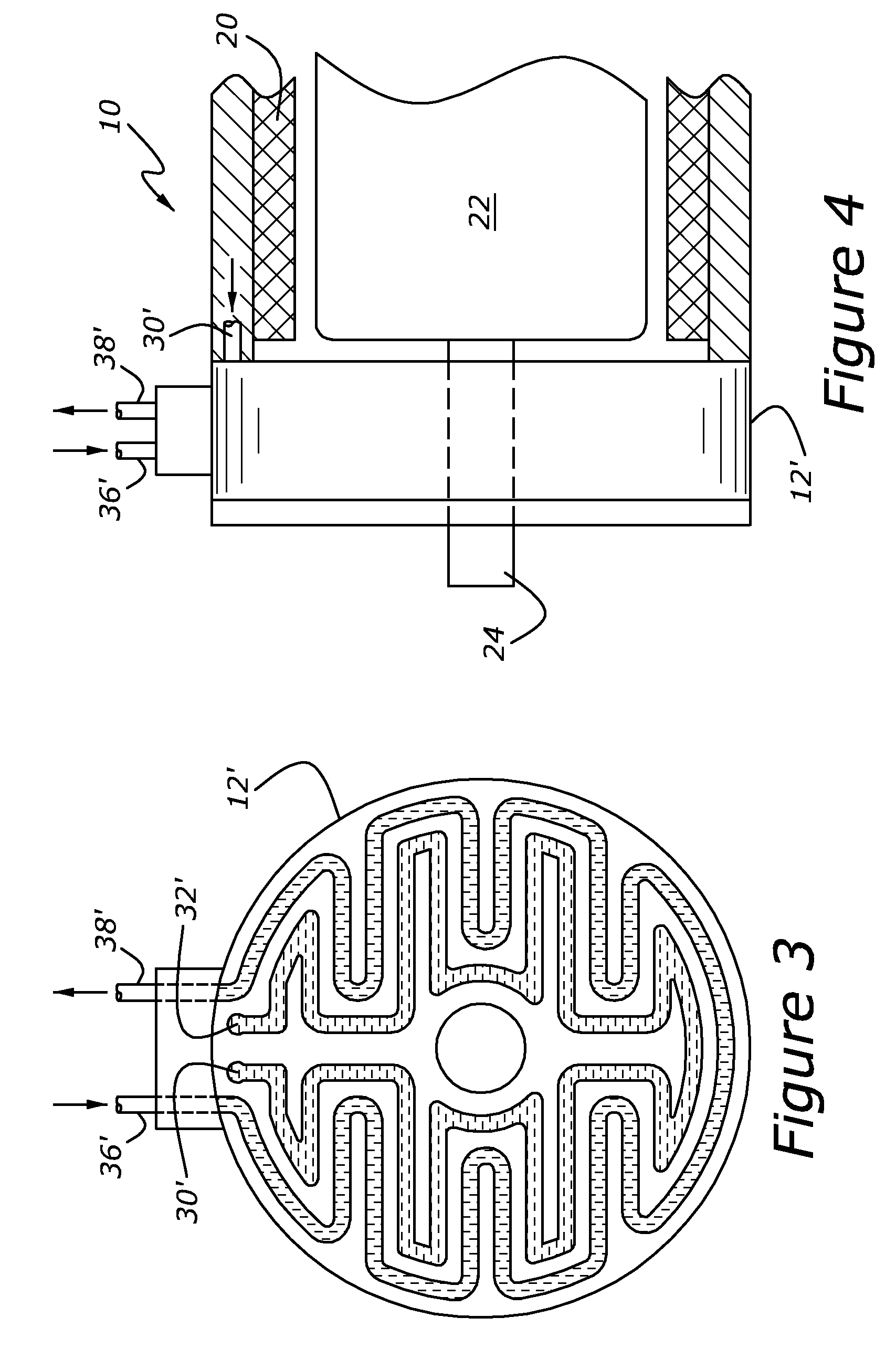

There is provided a means for uniformly controlling the in-plane temperature of a semiconductor wafer at high speed in a high heat input etching process. A refrigerant channel structure in a circular shape is formed in a sample stage. Due to a fact that a heat transfer coefficient of a refrigerant is largely changed from a refrigerant supply port to a refrigerant outlet port, the cross sections of the channel structure is structured so as to be increased from a first channel areas towards a second channel areas in order to make the heat transfer coefficient of the refrigerant constant in the refrigerant channel structure. Thereby, the heat transfer coefficient of the refrigerant is prevented from increasing by reducing the flow rate of the refrigerant at a dry degree area where the heat transfer coefficient of the refrigerant is increased. Further, the cross section of the channel structure is structured so as to be reduced from the second channel areas towards a third channel areas, and thereby the heat transfer coefficient of the refrigerant is prevented from decreasing. Accordingly, the heat transfer coefficient of the refrigerant can be uniformed in the channel structure.

Owner:TANDOU TAKUMI +2

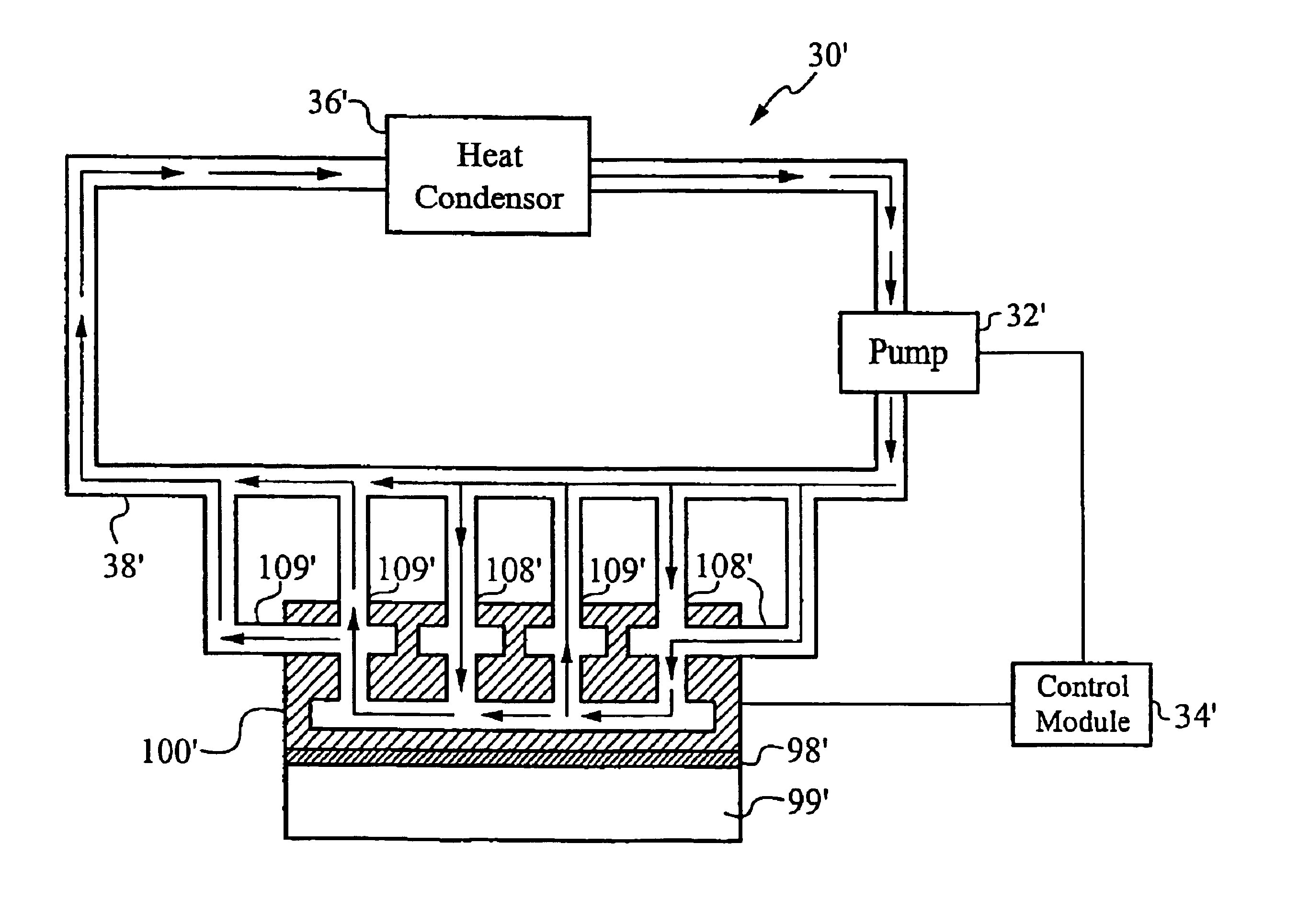

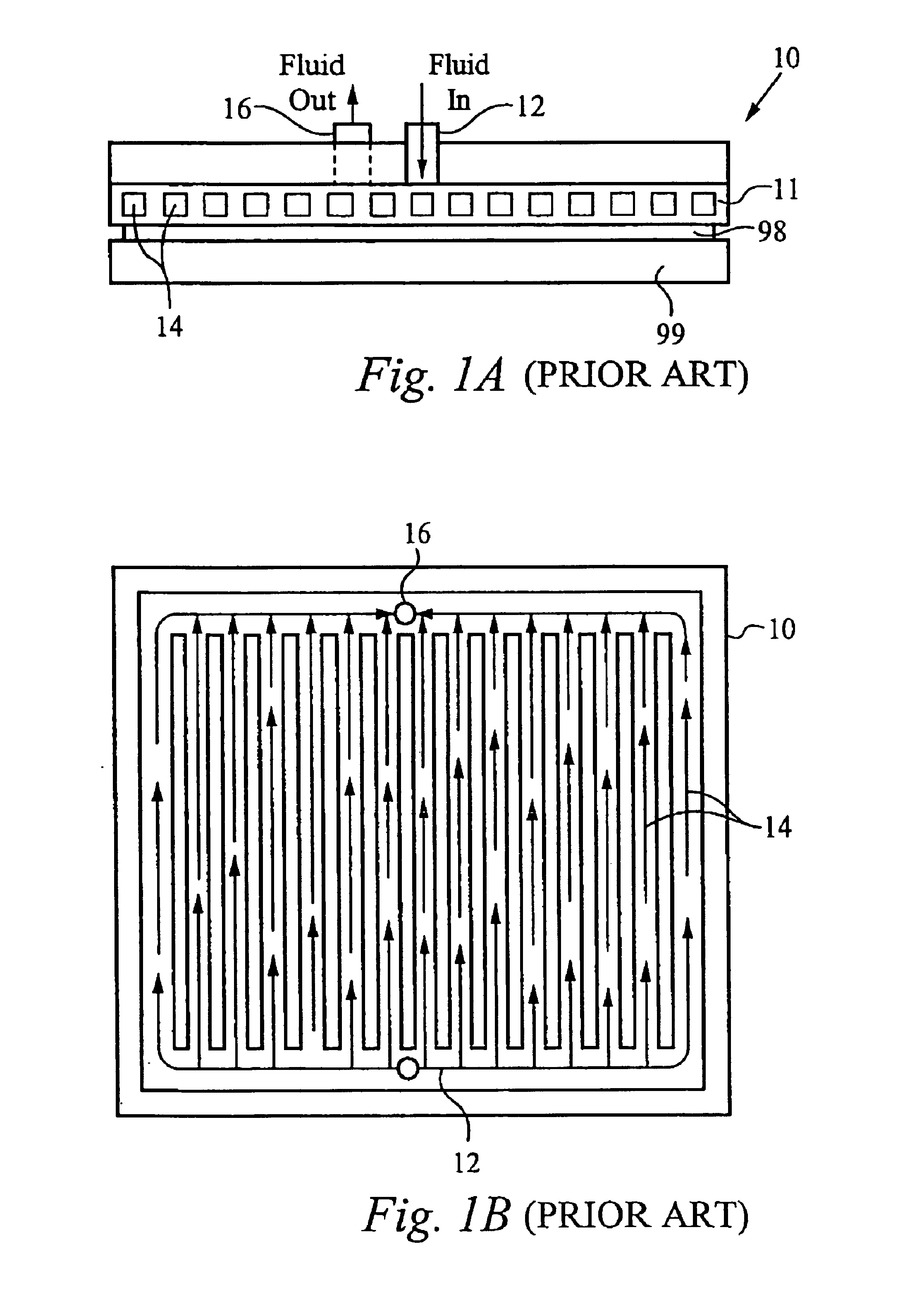

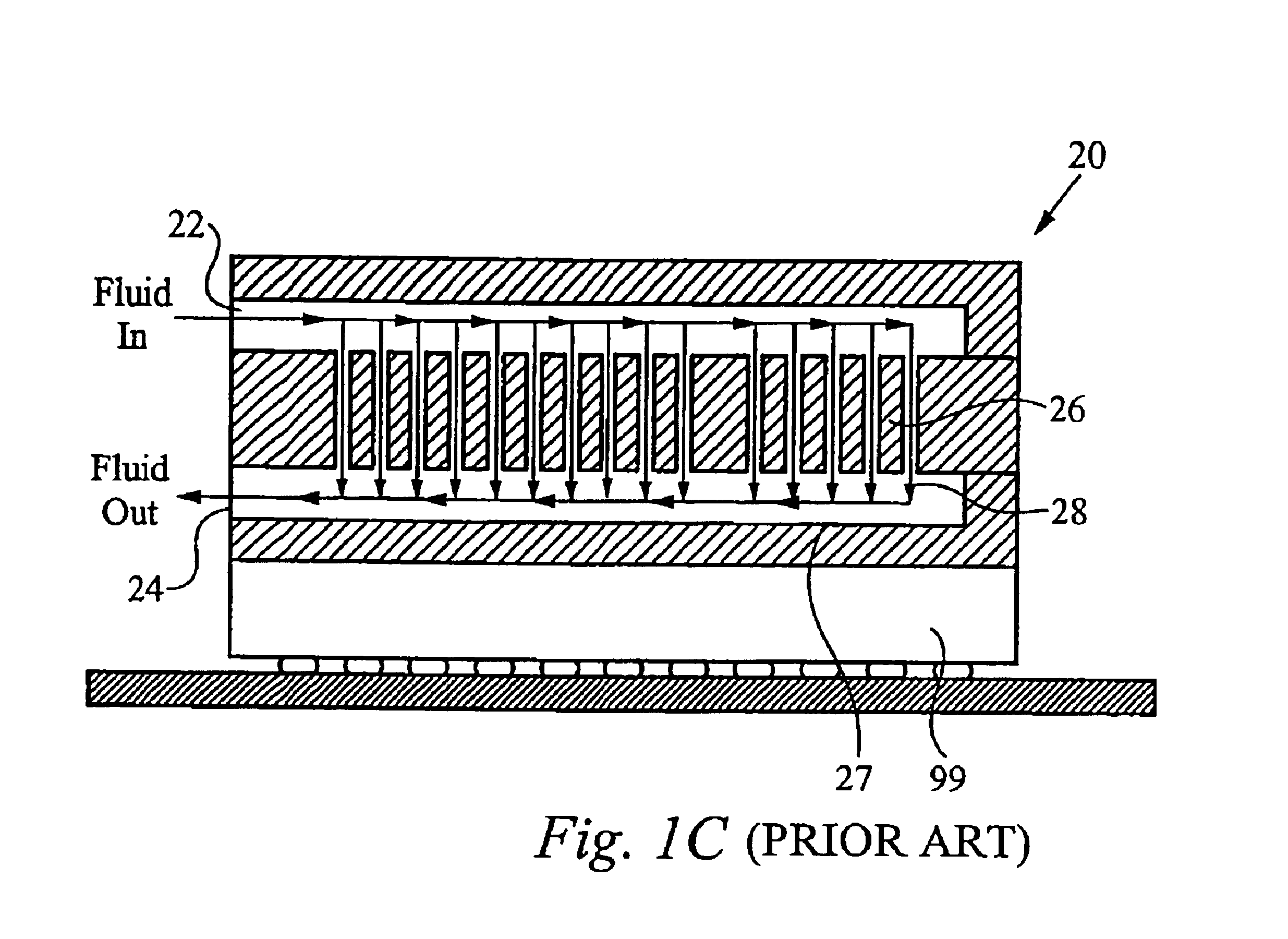

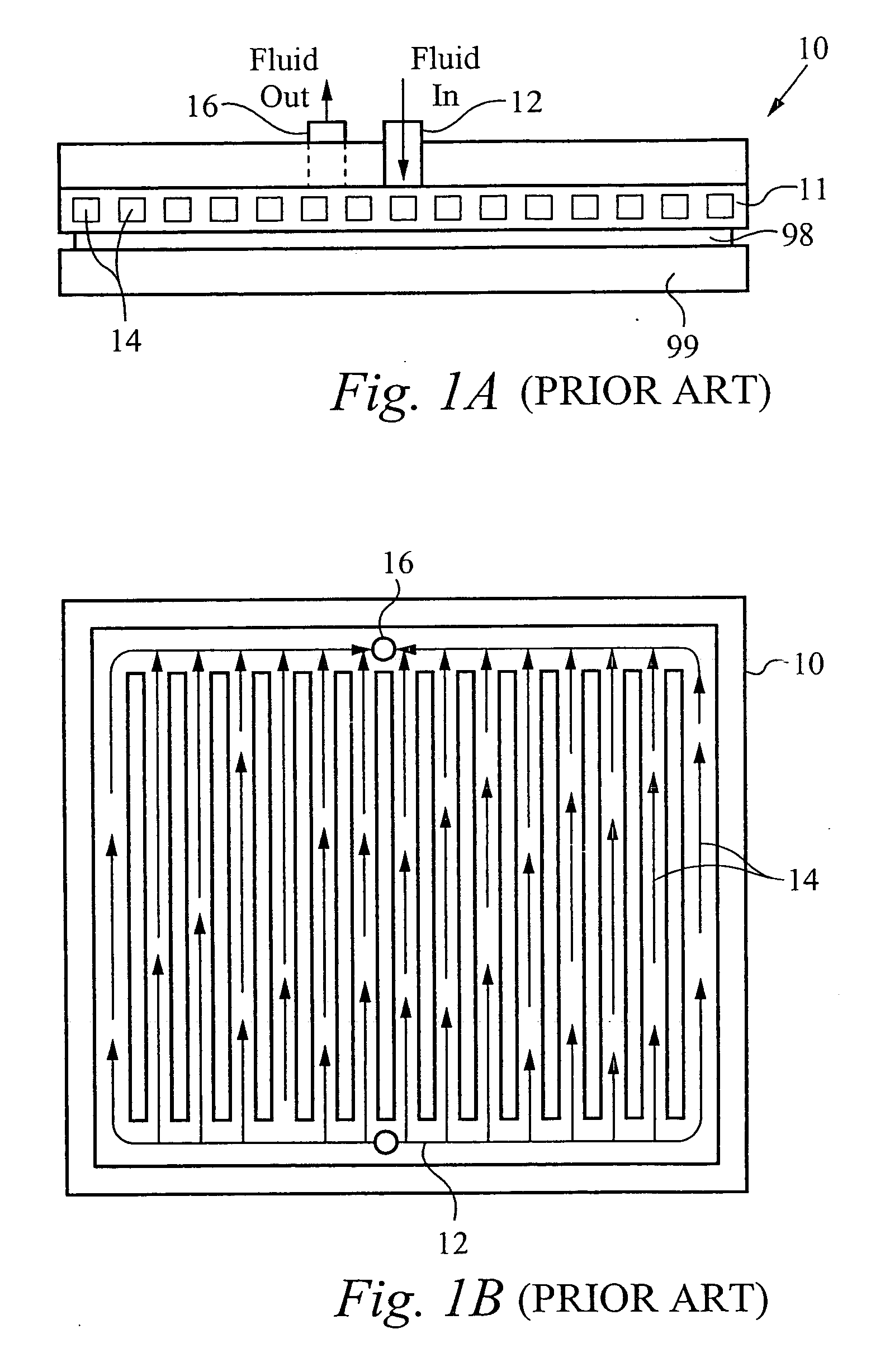

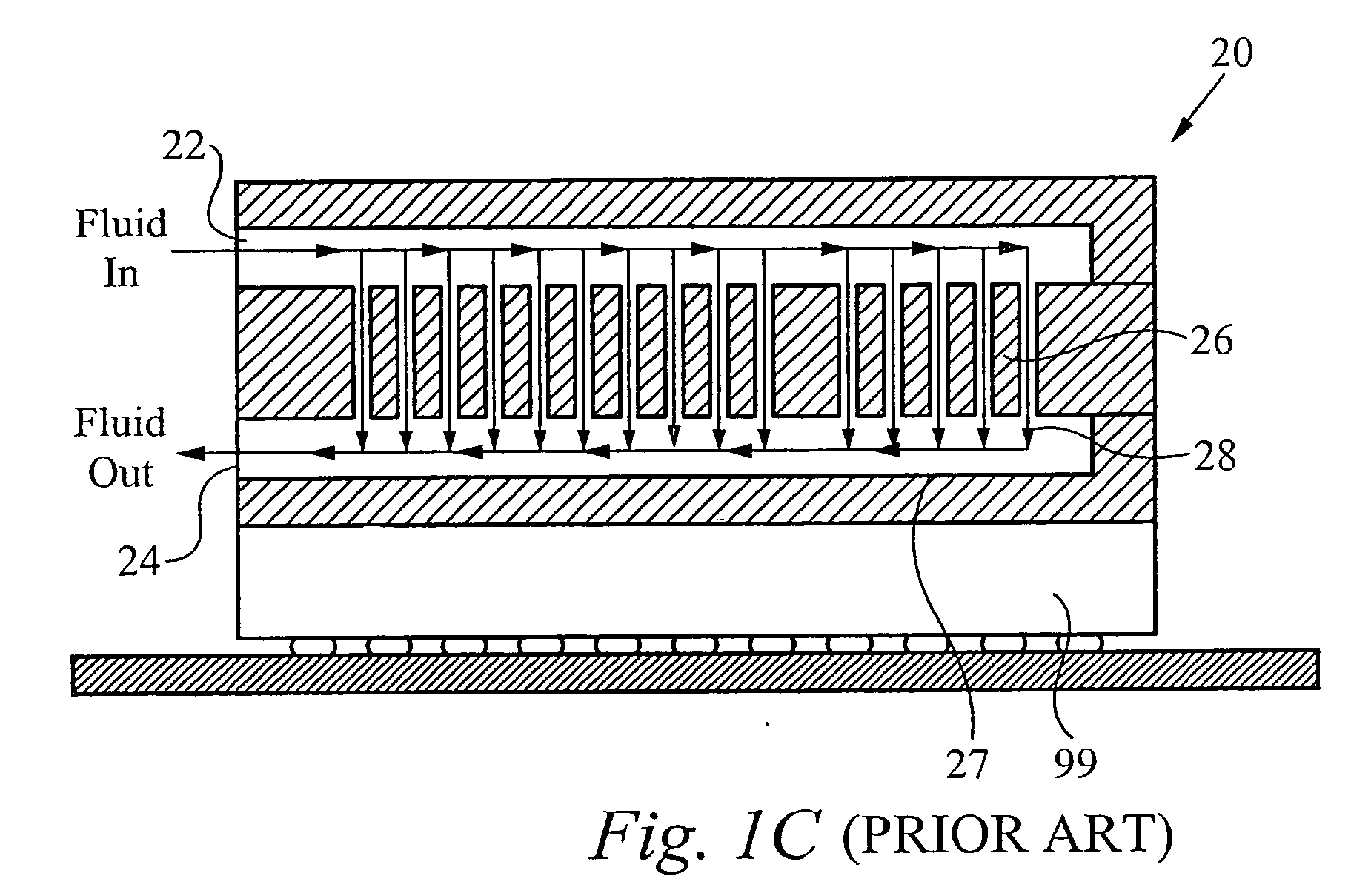

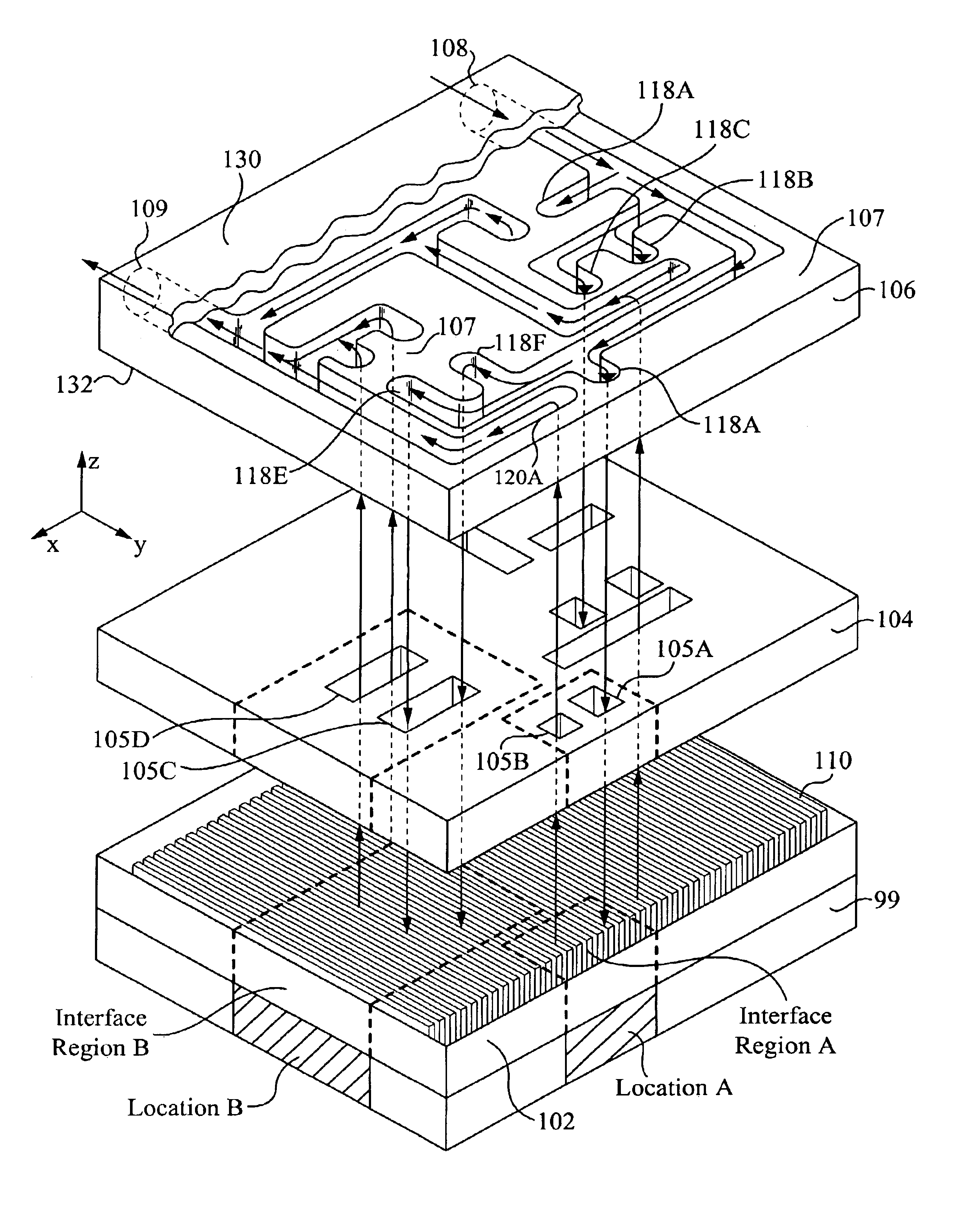

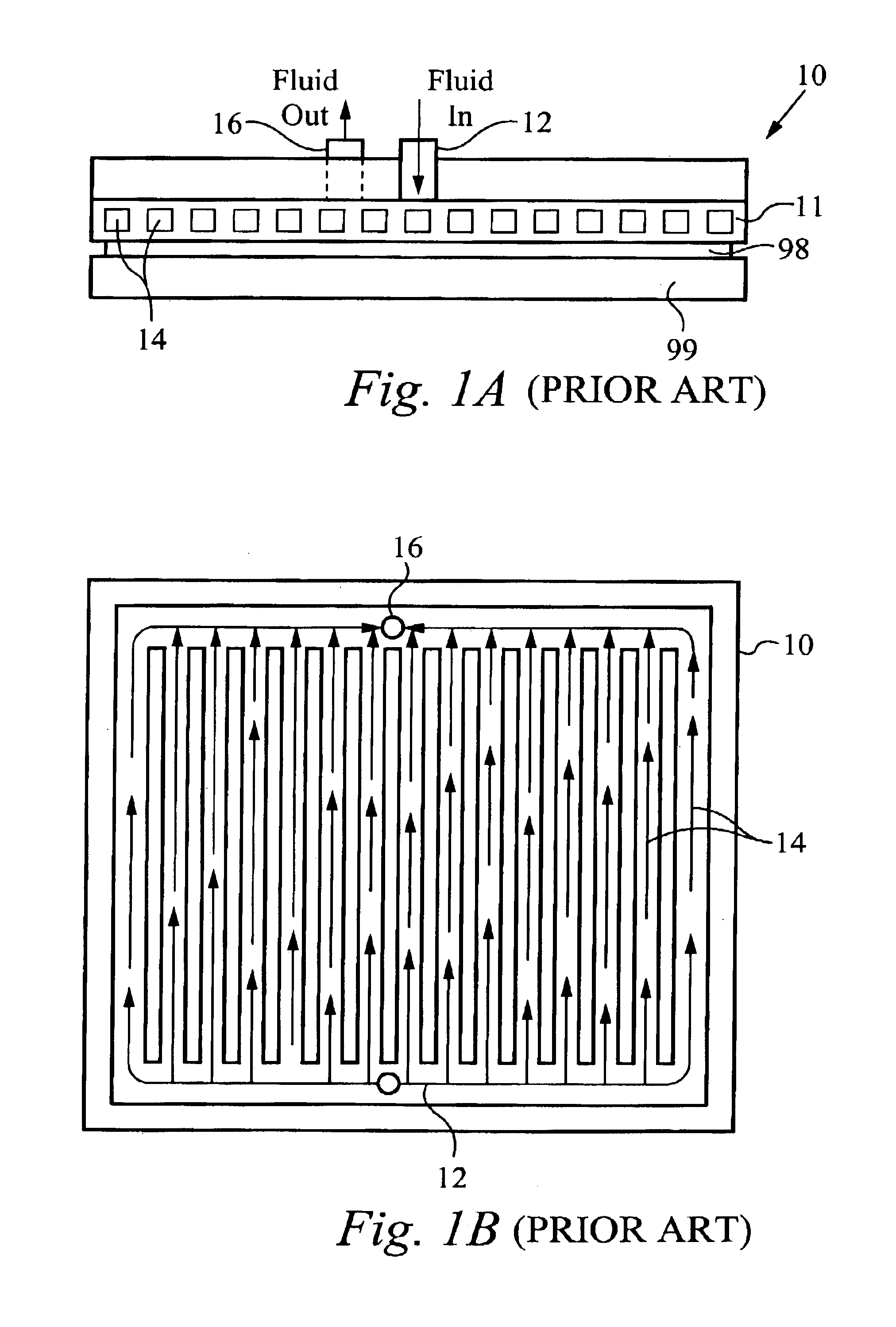

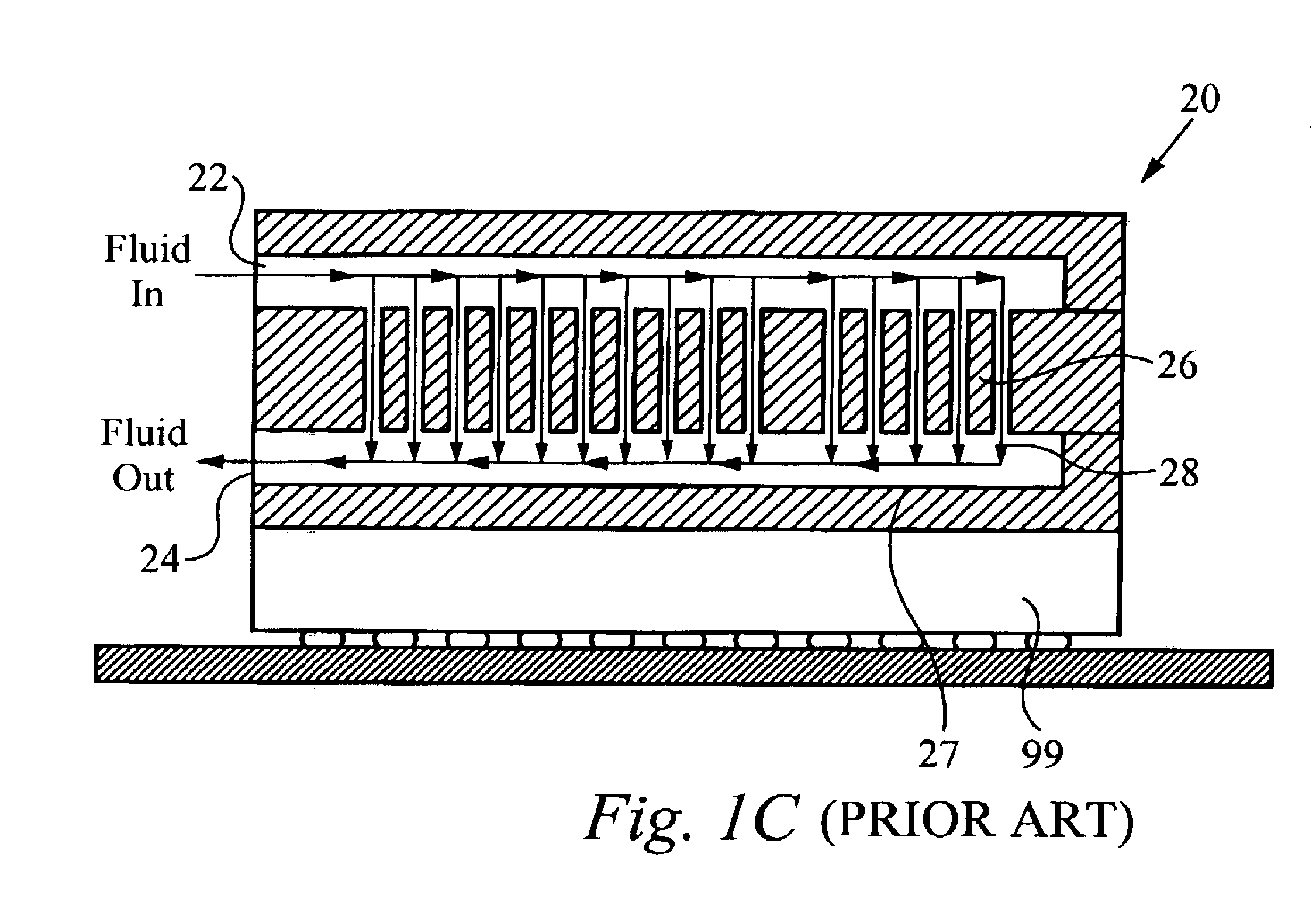

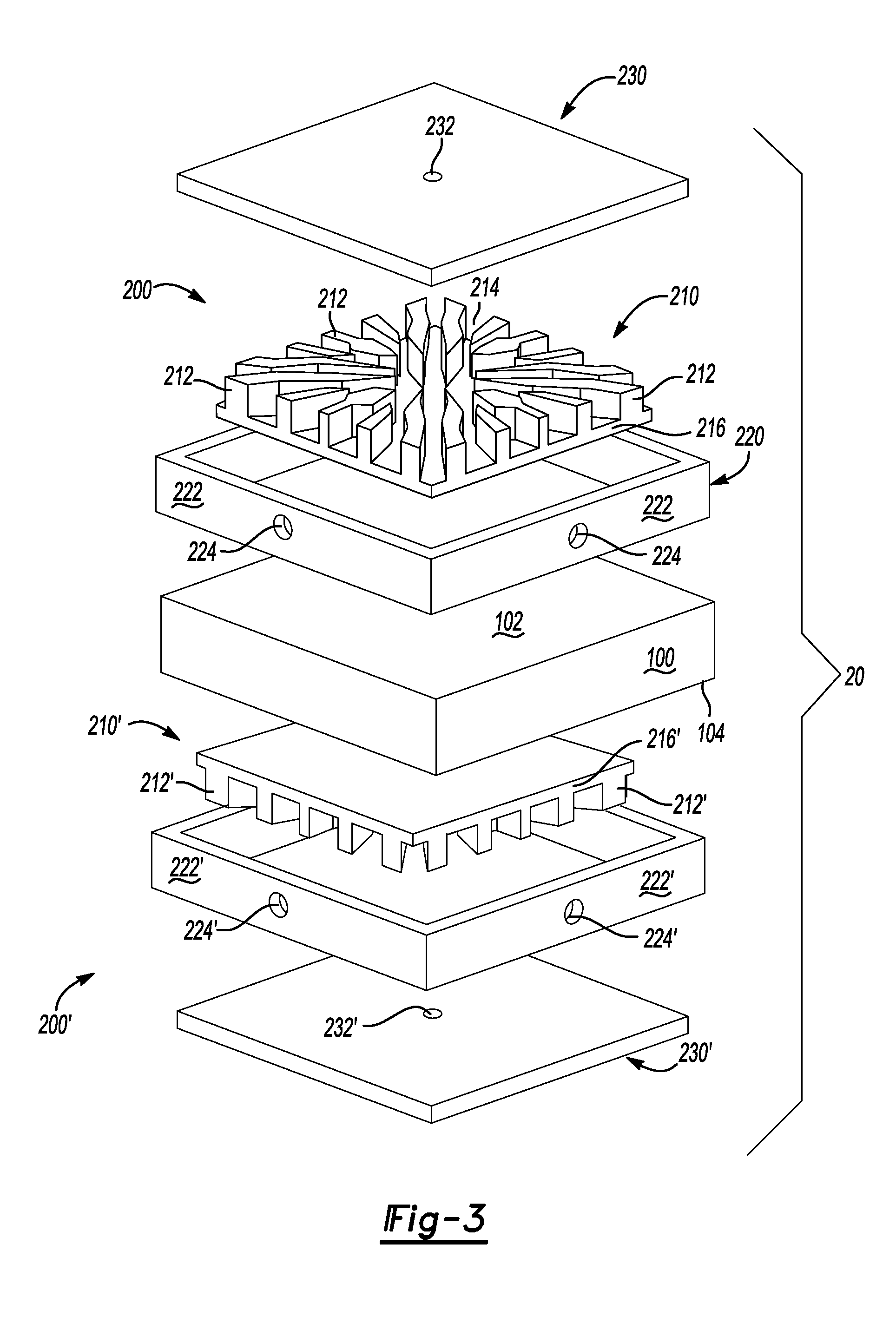

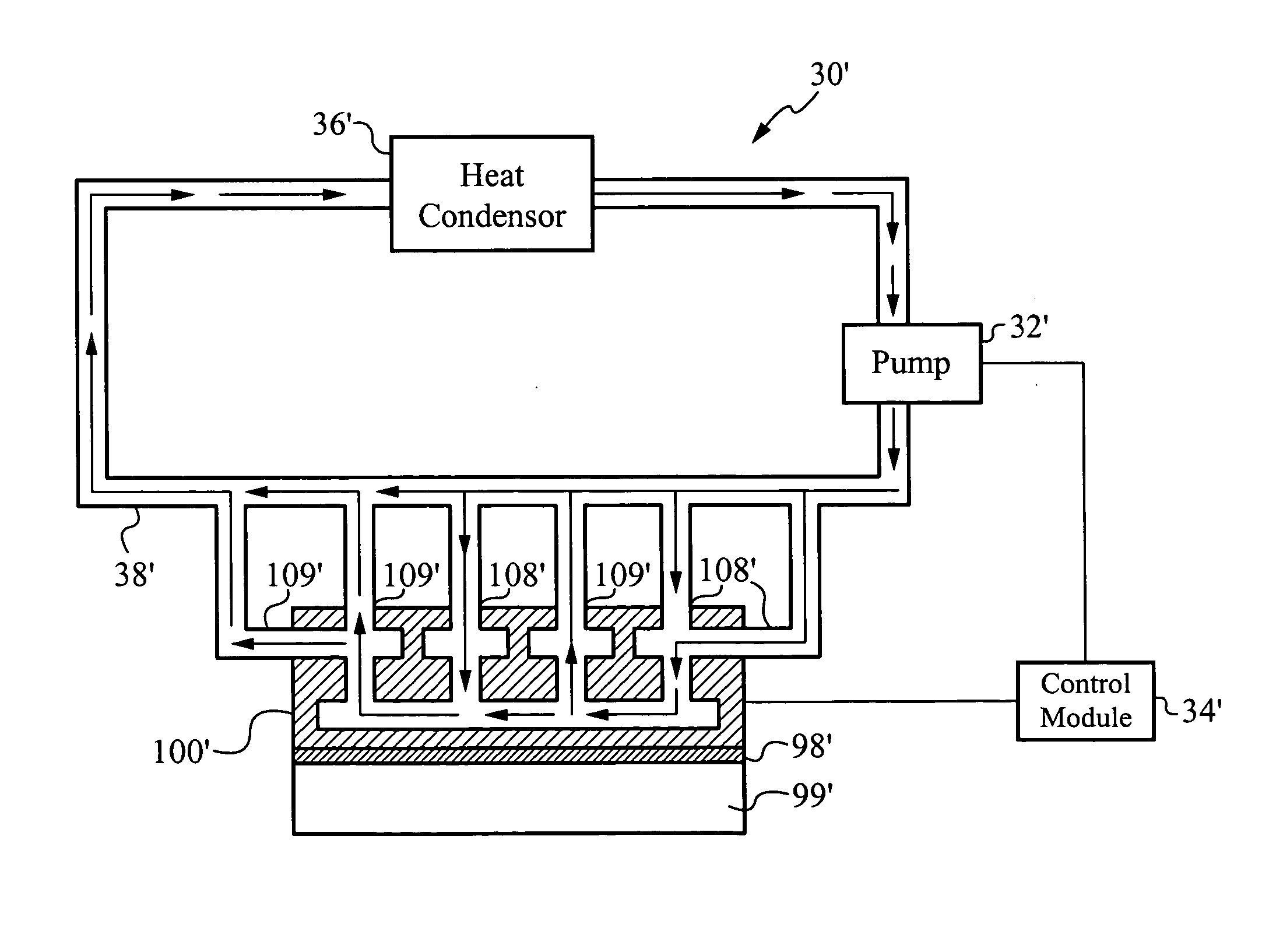

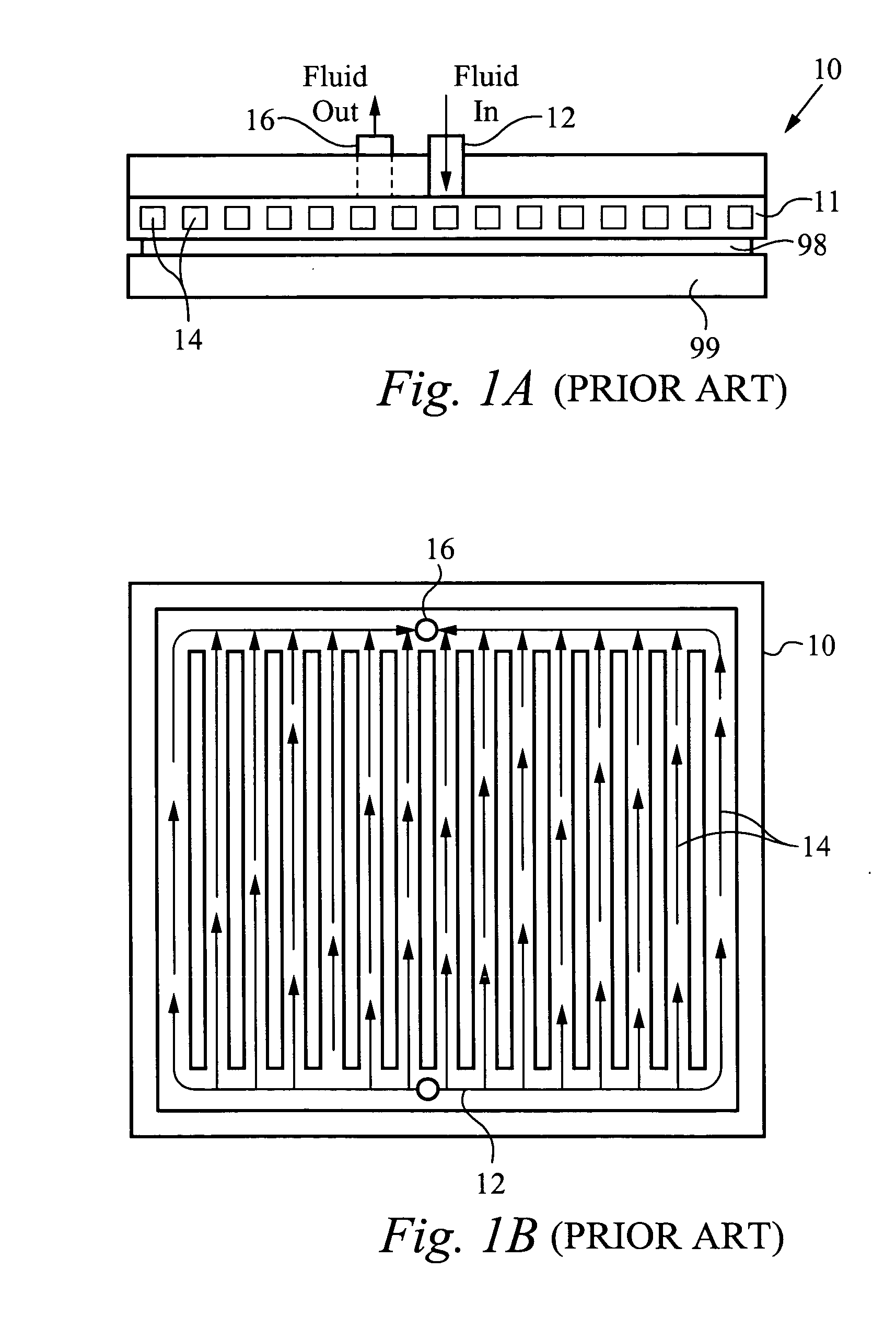

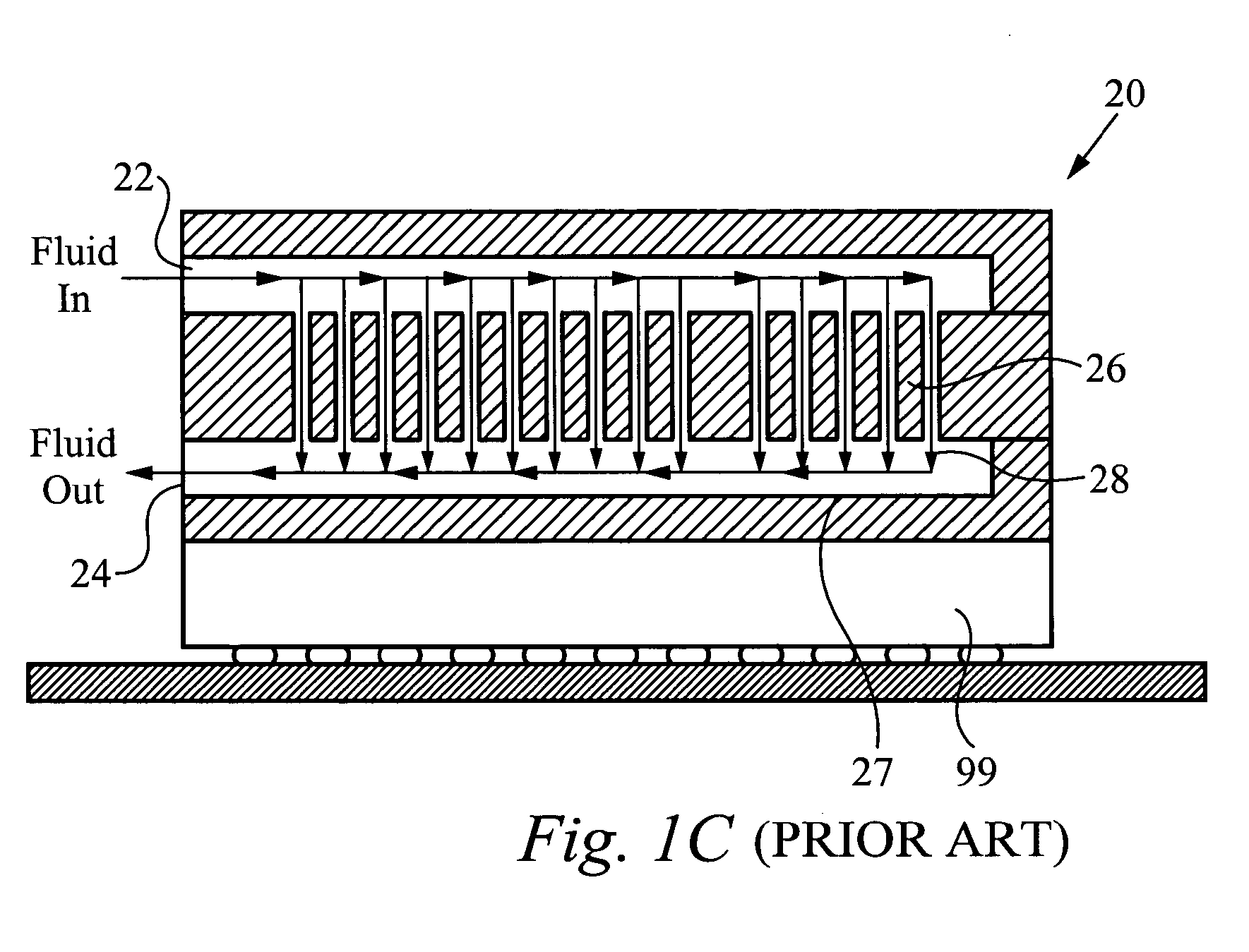

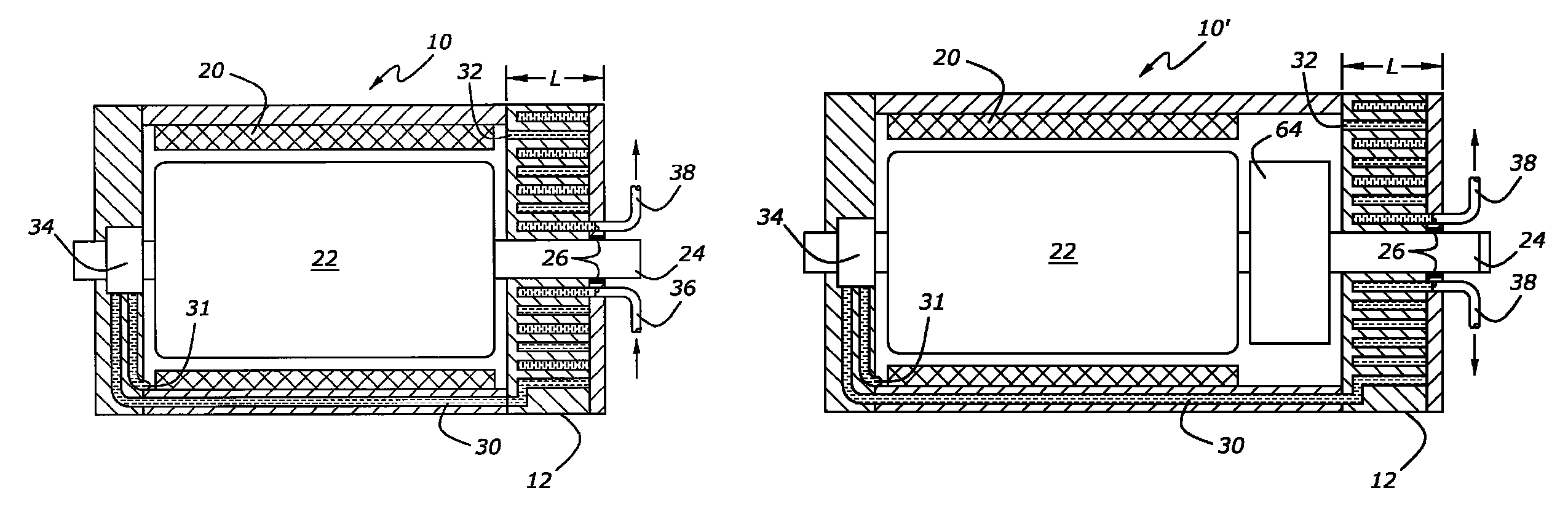

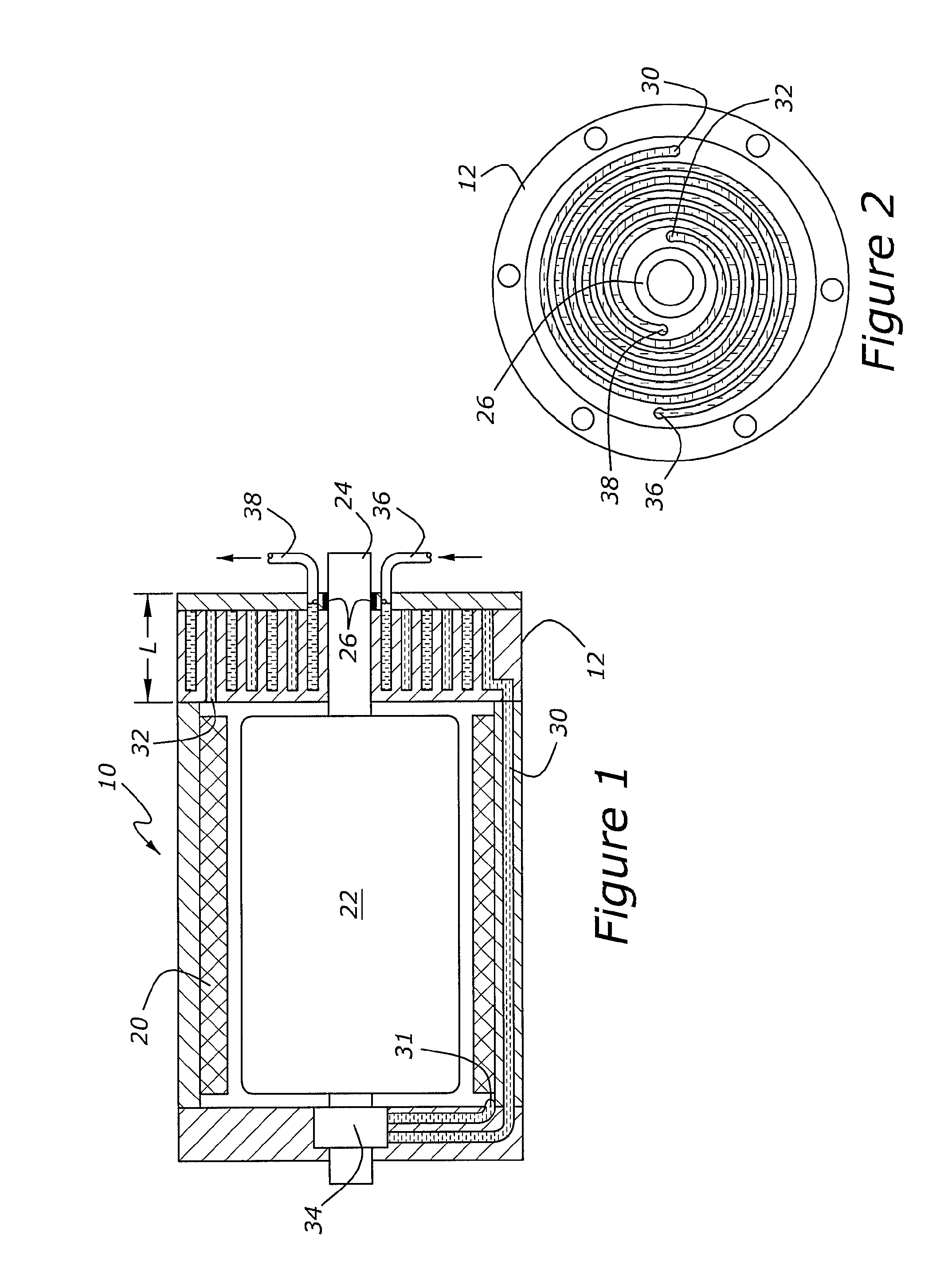

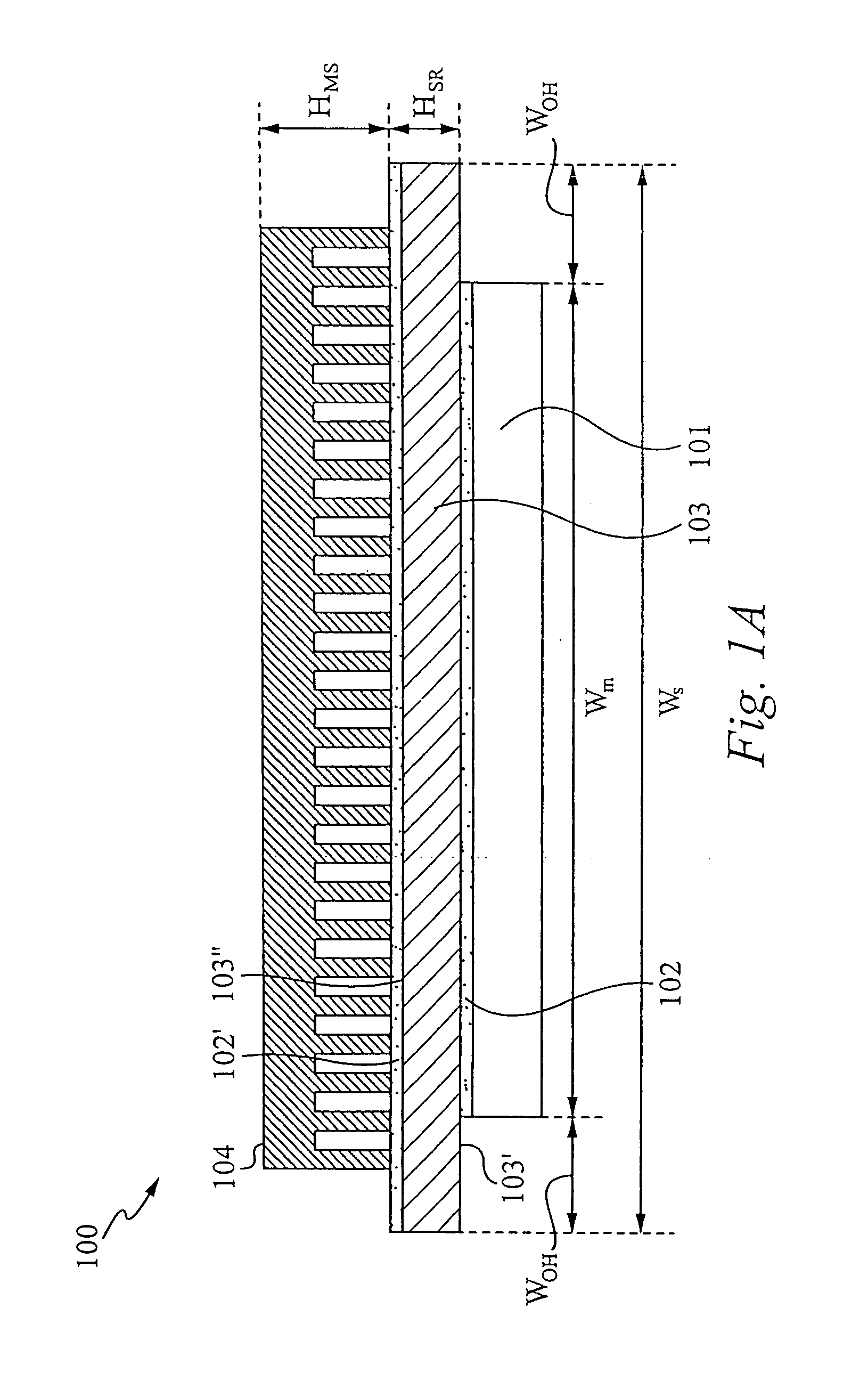

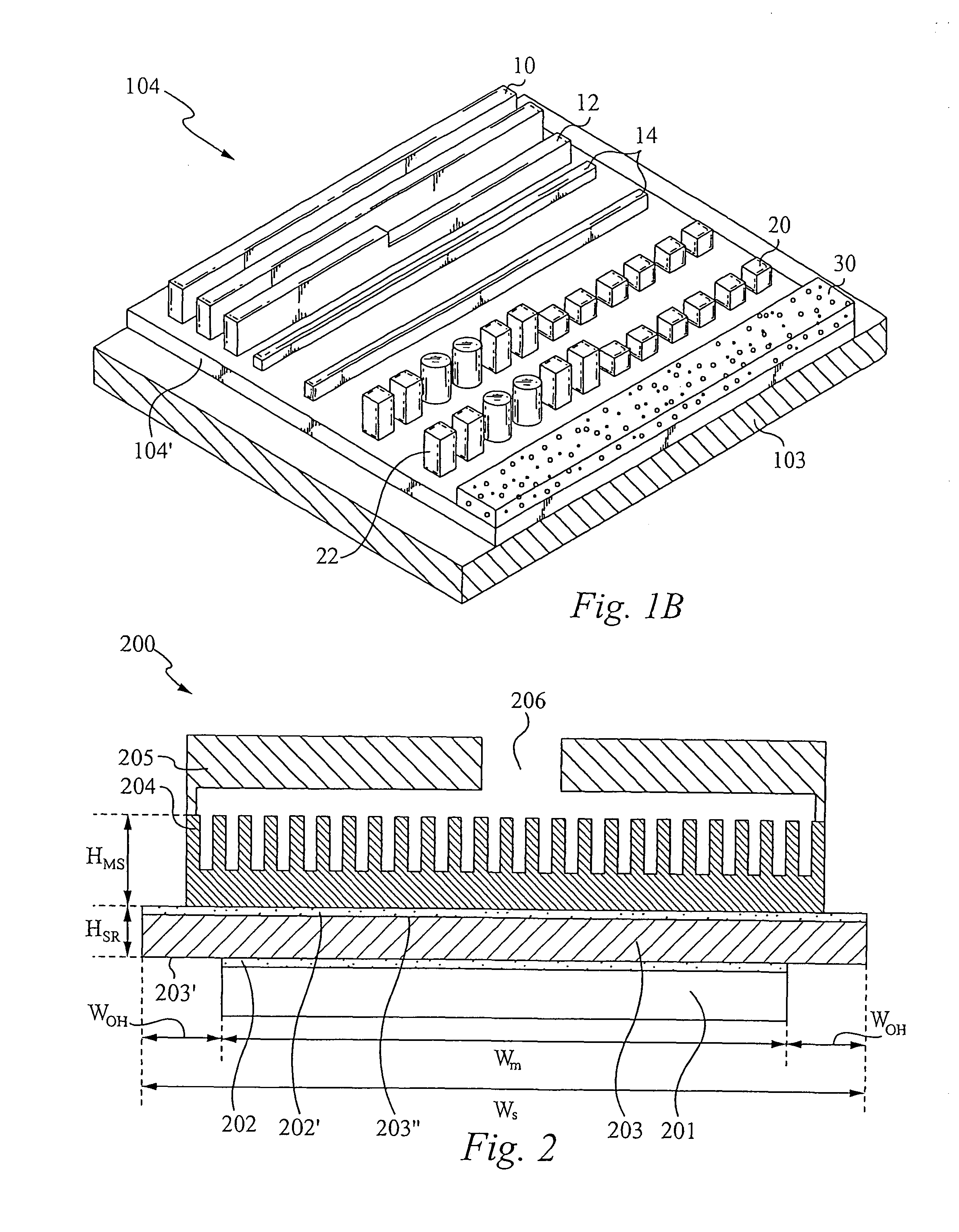

Method and apparatus for efficient vertical fluid delivery for cooling a heat producing device

InactiveUS7000684B2Minimized fluid path distanceImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesInterface layerPath distance

A heat exchanger and method of manufacturing thereof comprises an interface layer for cooling a heat source. The interface layer is coupled to the heat source and is configured to pass fluid therethrough. The heat exchanger further comprises a manifold layer that is coupled to the interface layer. The manifold layer includes at least one first port that is coupled to a first set of individualized holes which channel fluid through the first set. The manifold layer includes at least one second port coupled to a second set of individualized holes which channel fluid through the second set. The first set of holes and second set of holes are arranged to provide a minimized fluid path distance between the first and second ports to adequately cool the heat source. Preferably, each hole in the first set is positioned a closest optimal distance to an adjacent hole the second set.

Owner:VERTIV CORP

Cooling systems incorporating heat exchangers and thermoelectric layers

ActiveUS20070034356A1Thermoelectric device with peltier/seeback effectDigital data processing detailsEngineeringThermal contact

A method and system for cooling a heat source are presented. The system includes a fluid heat exchanger, a pump, a thermoelectric device having a cooling portion and a heating portion, and a heat rejector configured to be in thermal contact with at least a portion of the heating portion of the thermoelectric device. The pump is coupled with the fluid heat exchanger and configured to pass a fluid therethrough. The thermoelectric device is configured along with the heat exchanger in a cooling system to enhance the cooling efficiency of the system.

Owner:VERTIV CORP

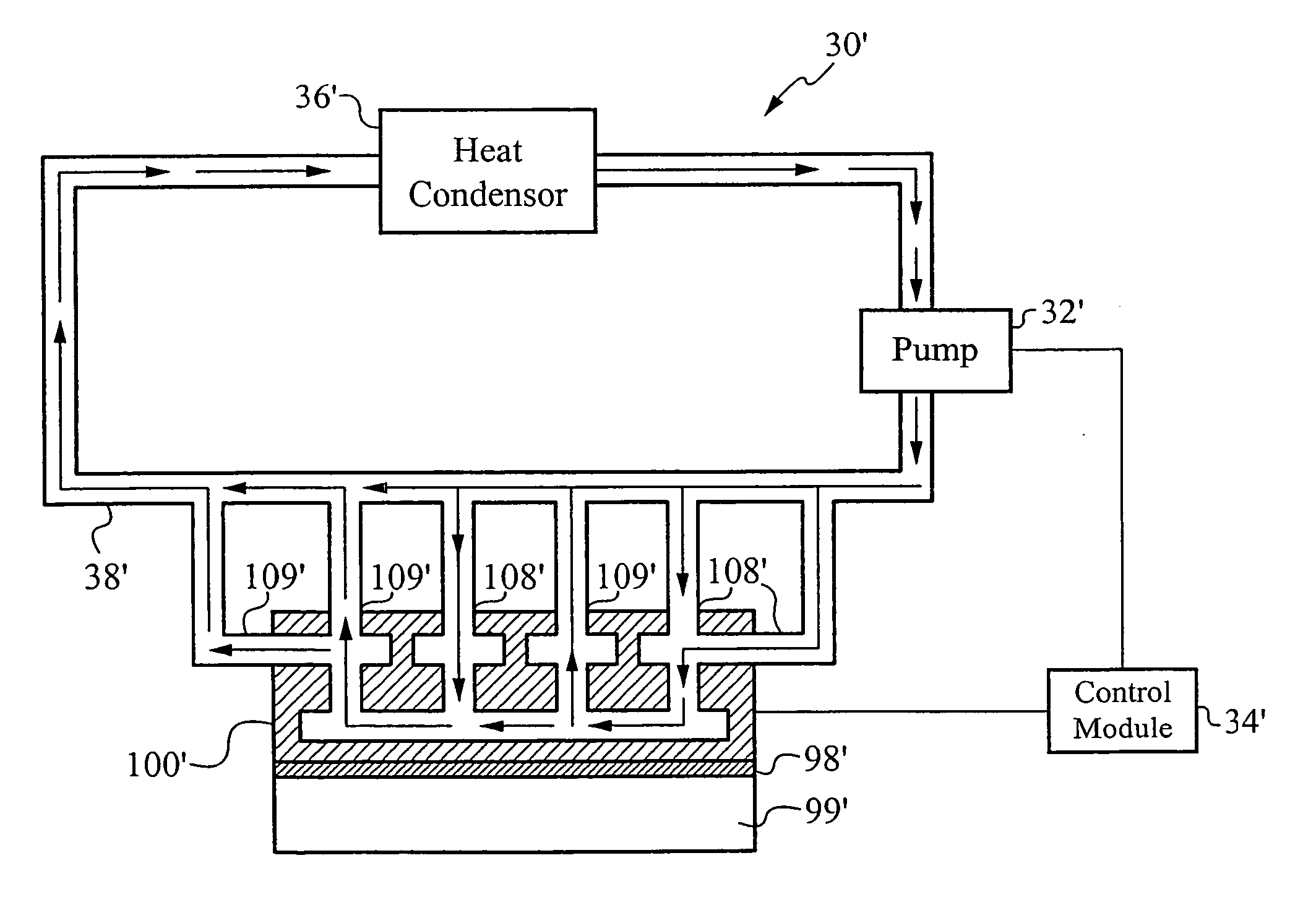

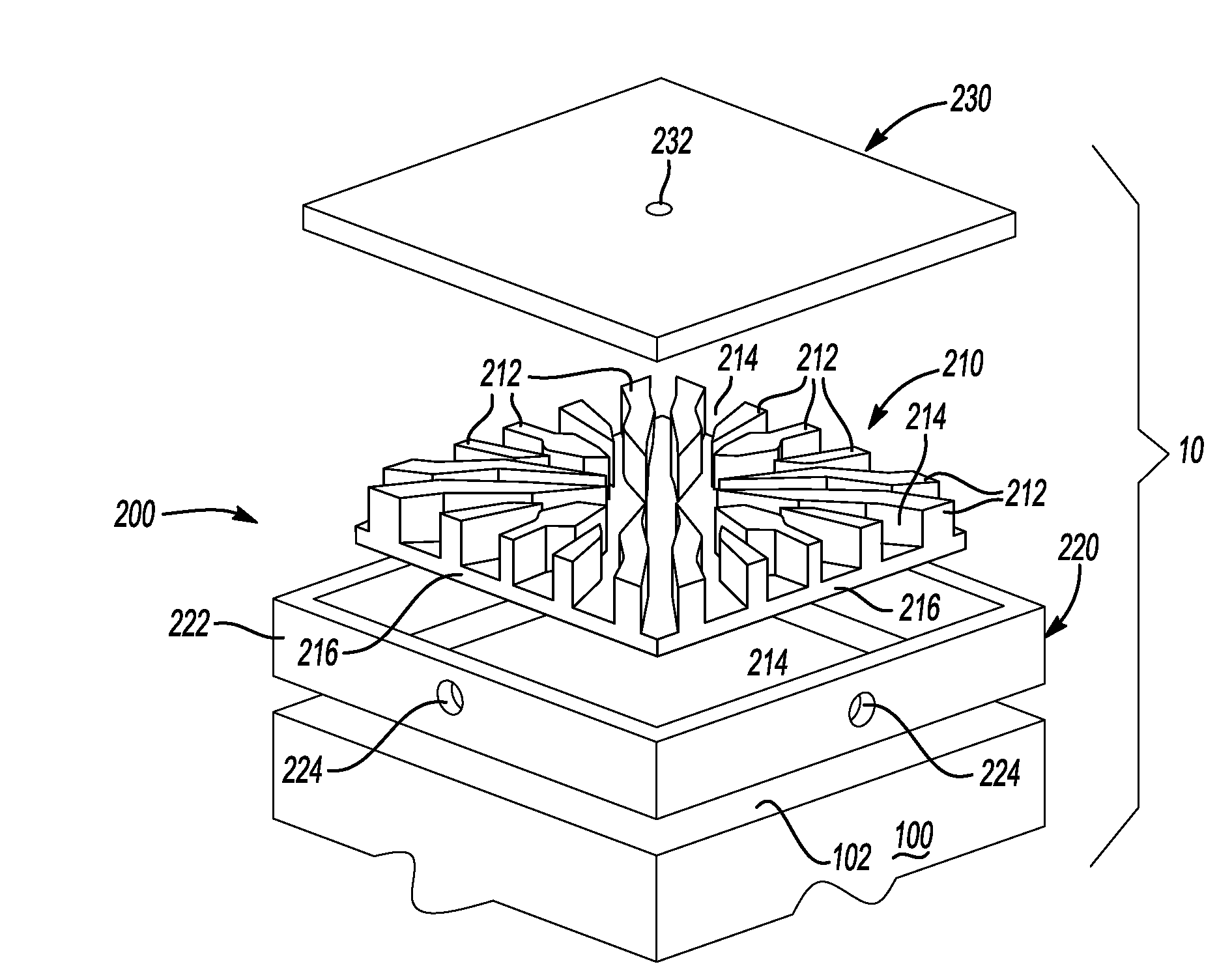

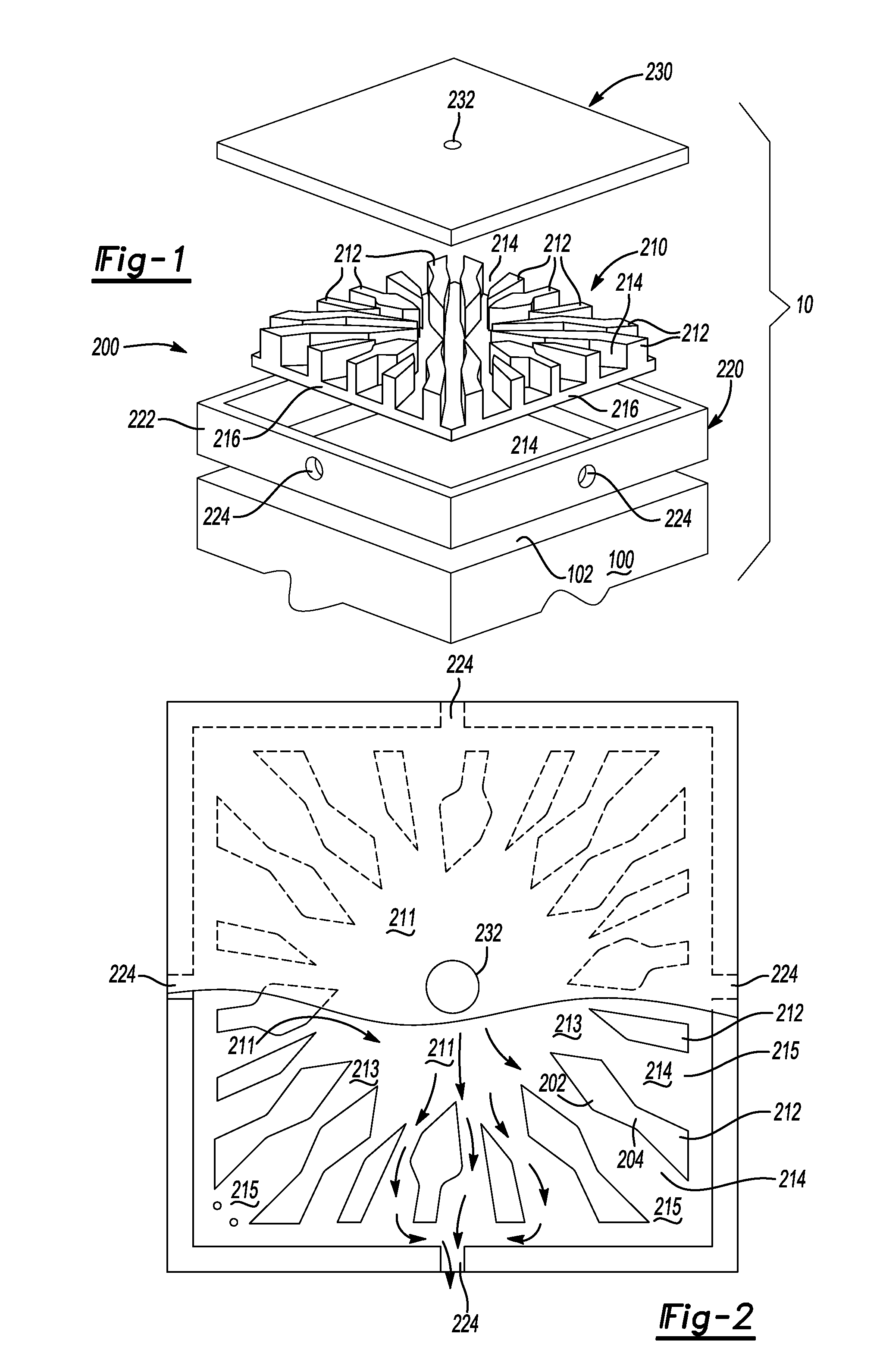

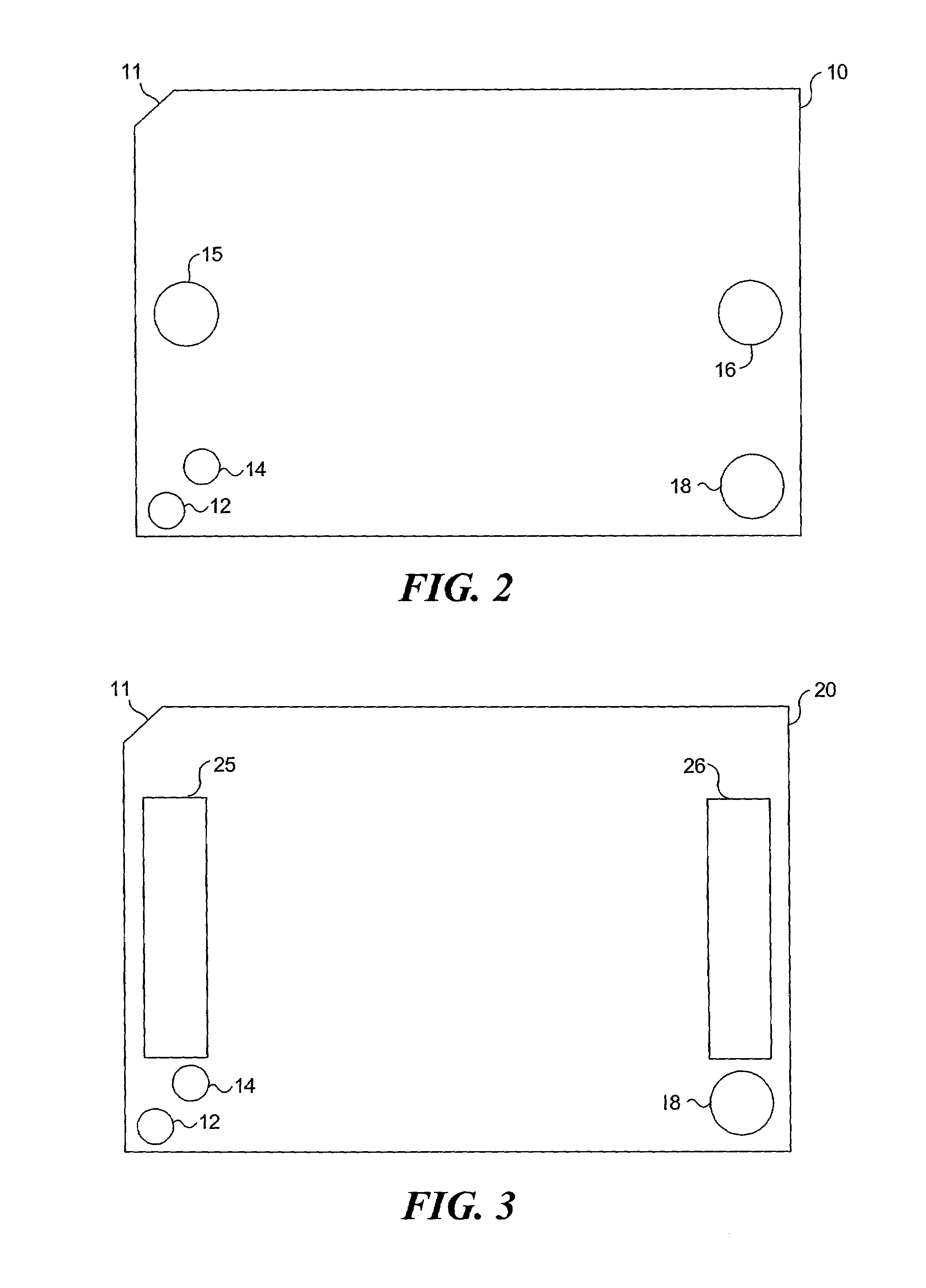

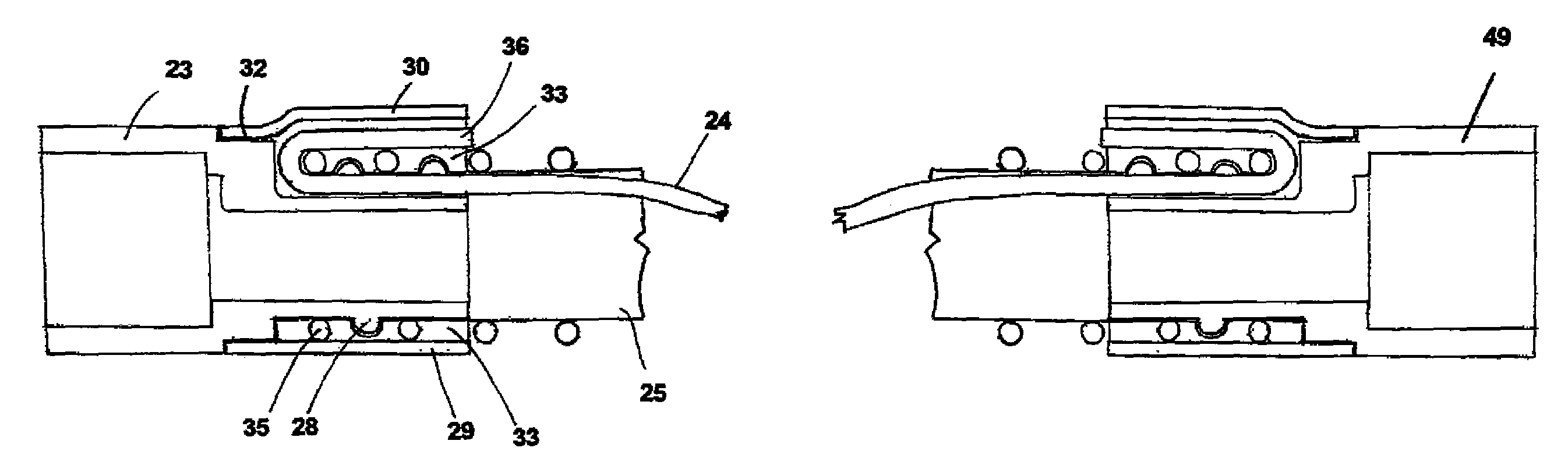

Method and apparatus for flexible fluid delivery for cooling desired hot spots in a heat producing device

InactiveUS6988534B2Temperatue controlSemiconductor/solid-state device detailsInter layerInterface layer

A heat exchanger apparatus and method of manufacturing comprising: an interface layer for cooling a heat source and configured to pass fluid therethrough, the interface layer having an appropriate thermal conductivity and a manifold layer for providing fluid to the interface layer, wherein the manifold layer is configured to achieve temperature uniformity in the heat source preferably by cooling interface hot spot regions. A plurality of fluid ports are configured to the heat exchanger such as an inlet port and outlet port, whereby the fluid ports are configured vertically and horizontally. The manifold layer circulates fluid to a predetermined interface hot spot region in the interface layer, wherein the interface hot spot region is associated with the hot spot. The heat exchanger preferably includes an intermediate layer positioned between the interface and manifold layers and optimally channels fluid to the interface hot spot region.

Owner:VERTIV CORP

Cooling member for heat containing device

InactiveUS20110299244A1Fixed capacitor electrodesDigital data processing detailsBiomedical engineeringIrregular shape

Owner:TOYOTA MOTOR CO LTD

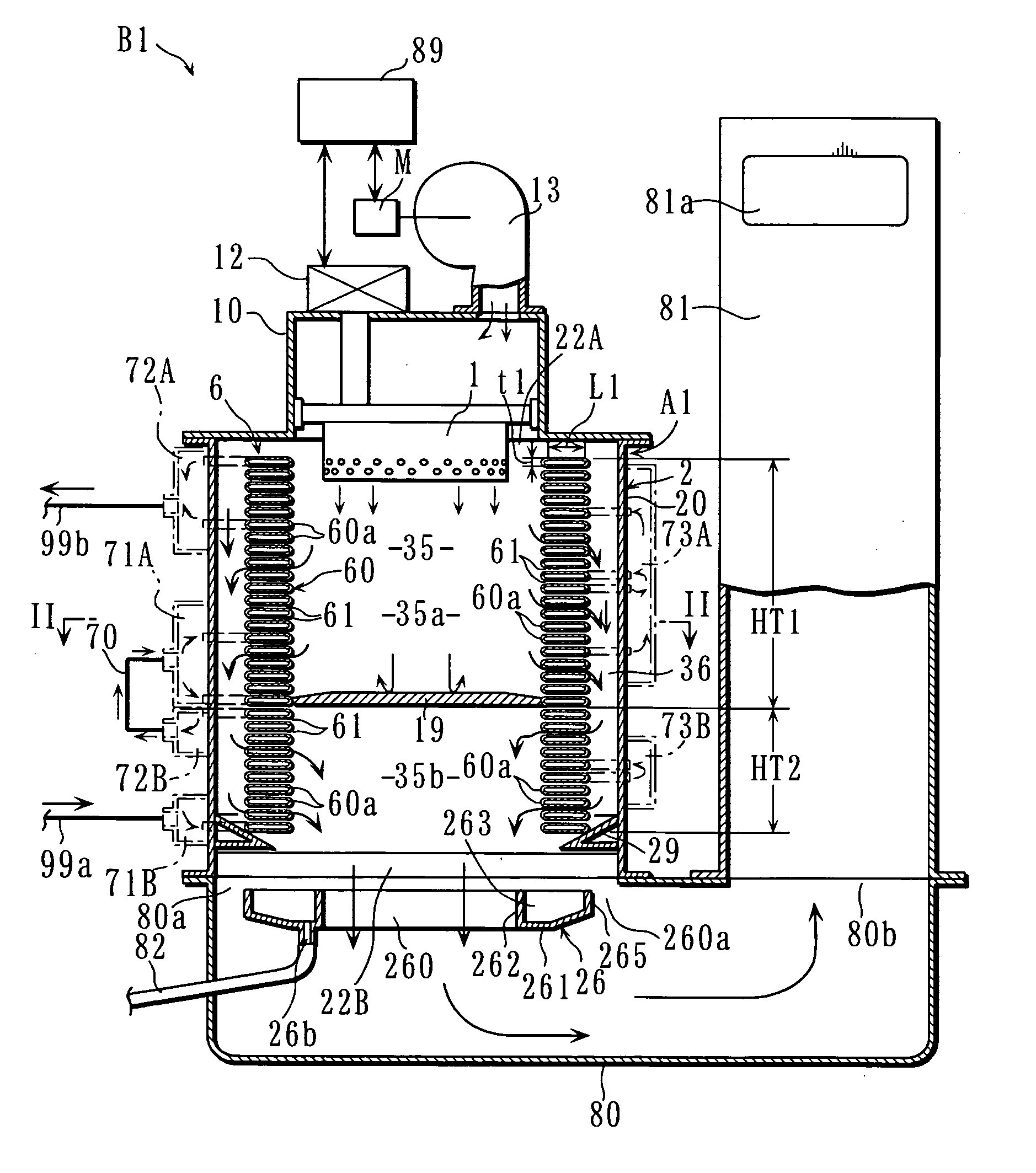

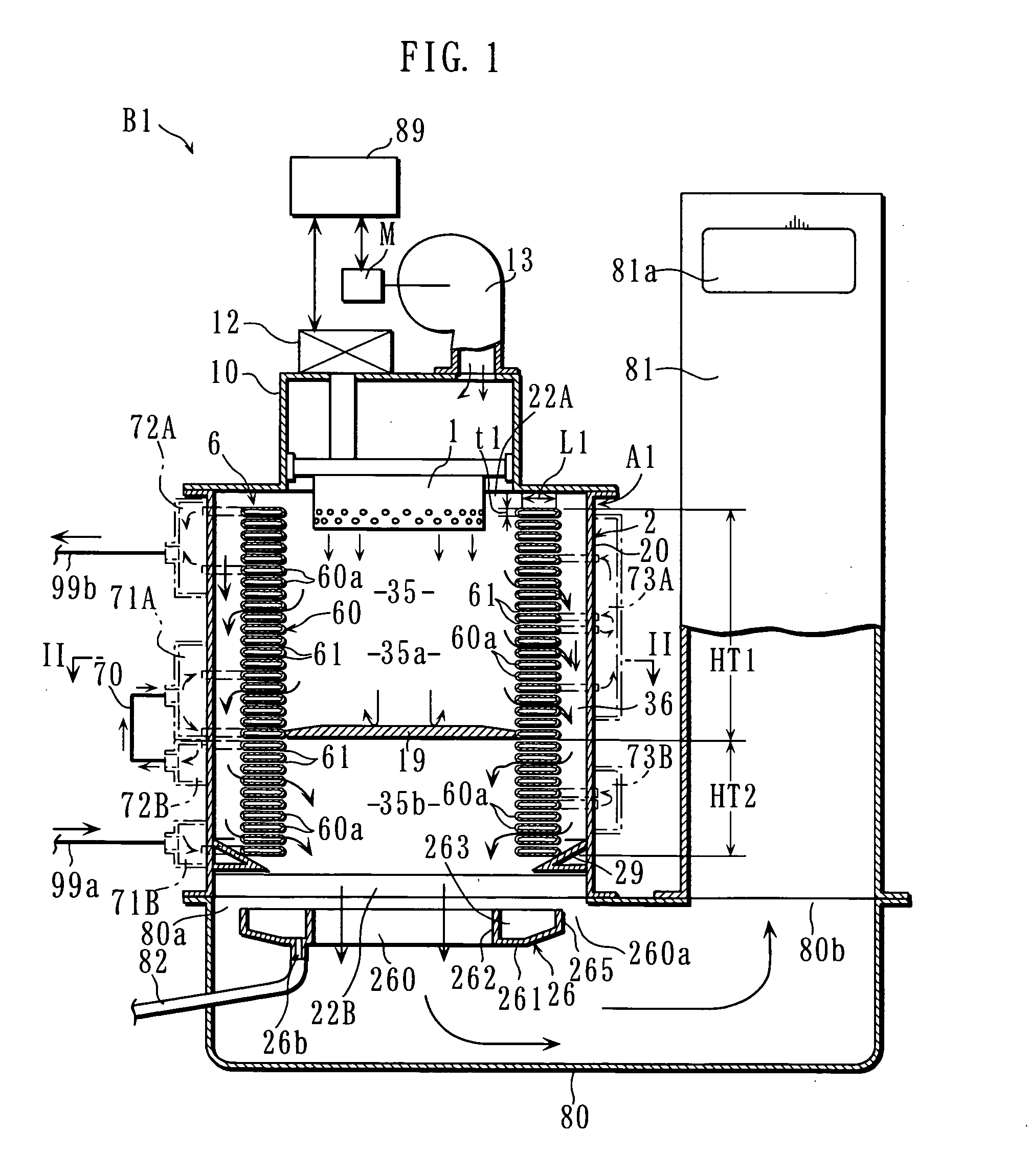

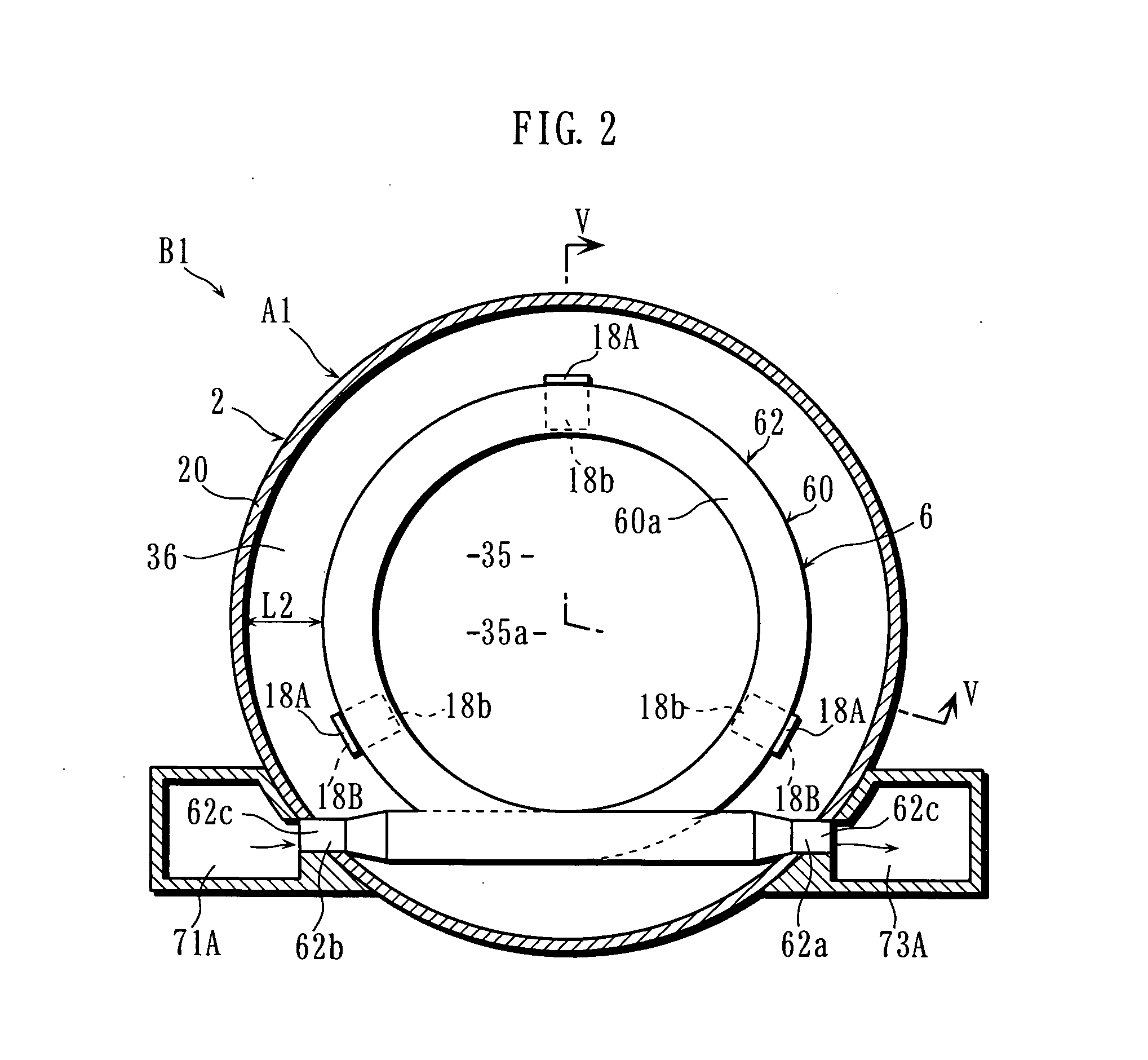

Heat Exchanger and Water Heater

A heat exchanger A1 includes a partition 19 partitioning the space 35 surrounded by a coiled tube 60 at an axially intermediate portion of a housing 2 into a first and a second regions 35a and 35b and partitioning the coiled tube 60 into a first and a second heat exchanging portions HT1 and HT2. The combustion gas supplied to the first region 35a flows to a combustion gas path 36 by passing through a clearance 61 of the first heat exchanging portion HT1 and then passes through a clearance 61 of the second heat exchanging portion HT2. With this structure, the amount of heat recovery is increased, and the heat exchange efficiency is enhanced while simplifying the overall structure of the heat exchanger A1 and reducing the size of the heat exchanger.

Owner:NORITZ CORP

Method and apparatus for efficient vertical fluid delivery for cooling a heat producing device

InactiveUS20050211418A1Digital data processing detailsSemiconductor/solid-state device detailsInterface layerEngineering

A heat exchanger and method of manufacturing thereof comprises an interface layer for cooling a heat source. The interface layer is coupled to the heat source and is configured to pass fluid therethrough. The heat exchanger further comprises a manifold layer that is coupled to the interface layer. The manifold layer includes at least one first port that is coupled to a first set of individualized holes which channel fluid through the first set. The manifold layer includes at least one second port coupled to a second set of individualized holes which channel fluid through the second set. The first set of holes and second set of holes are arranged to provide a minimized fluid path distance between the first and second ports to adequately cool the heat source. Preferably, each hole in the first set is positioned a closest optimal distance to an adjacent hole the second set.

Owner:COOLIGY INC

Geometry of heat exchanger with high efficiency

ActiveUS20130206374A1Additive manufacturing apparatusRecuperative heat exchangersHigh energyEngineering

The present disclosure includes geometry of a two-fluid heat exchanger to provide higher energy efficiency than conventional heat exchangers. The geometry is based upon sequential branching of nearly circular passages in sets, followed by some deformation and twisting of the sequential branches that intermingle flow passages of one fluid with flow passages of another fluid. The flow passages gradually vary in dimension from larger branching at fluid entrance and exit to smaller branching in the middle section of the heat exchanger. The heat exchanger is substantially symmetric, with the sequential branching in the first half being mirrored as serial regrouping in the second half. The present disclosure also provides stacking methods and layered manufacturing methods for fabricating the three-dimensional geometry of the heat exchanger.

Owner:TRUSTEES OF DARTMOUTH COLLEGE THE

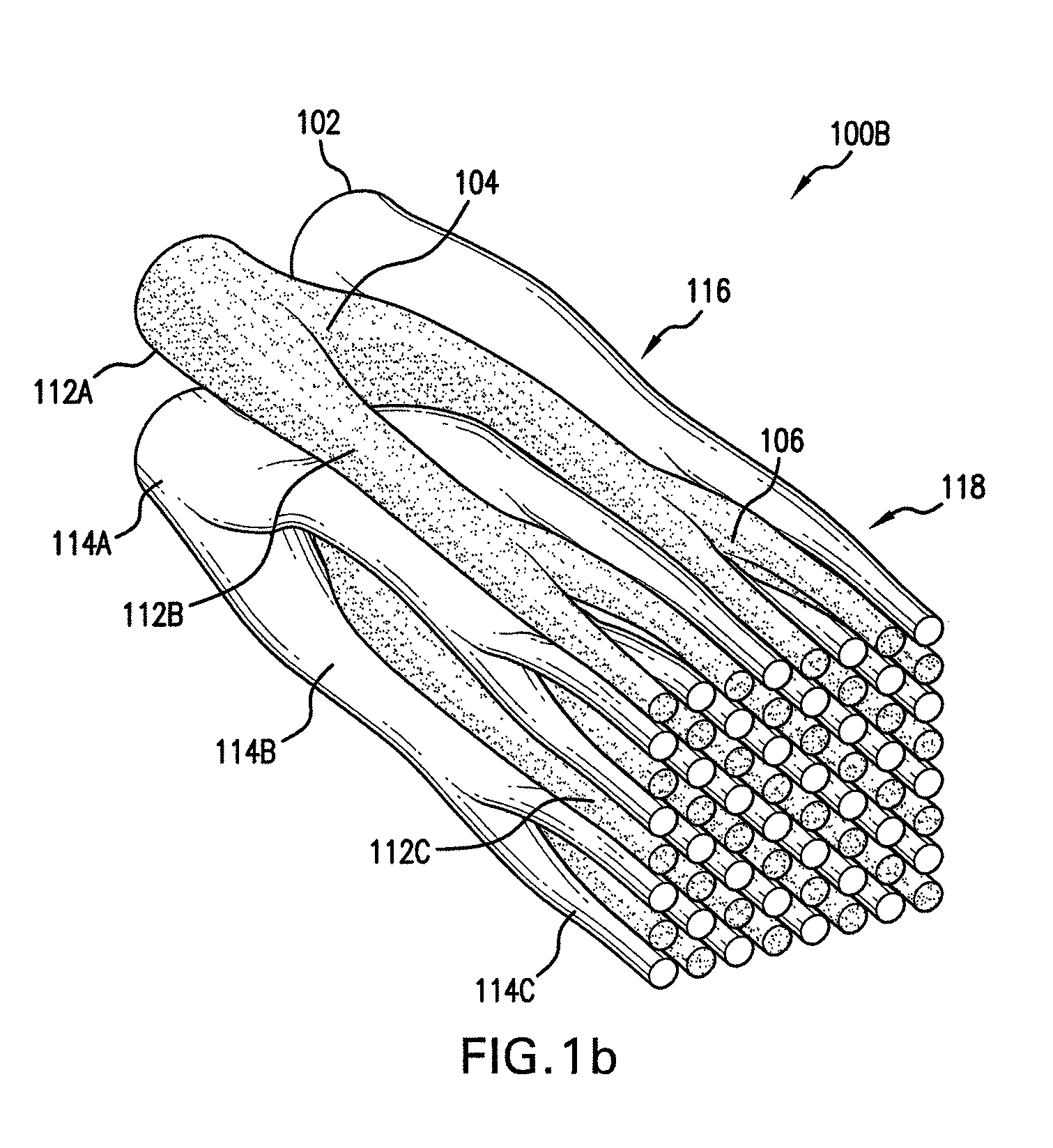

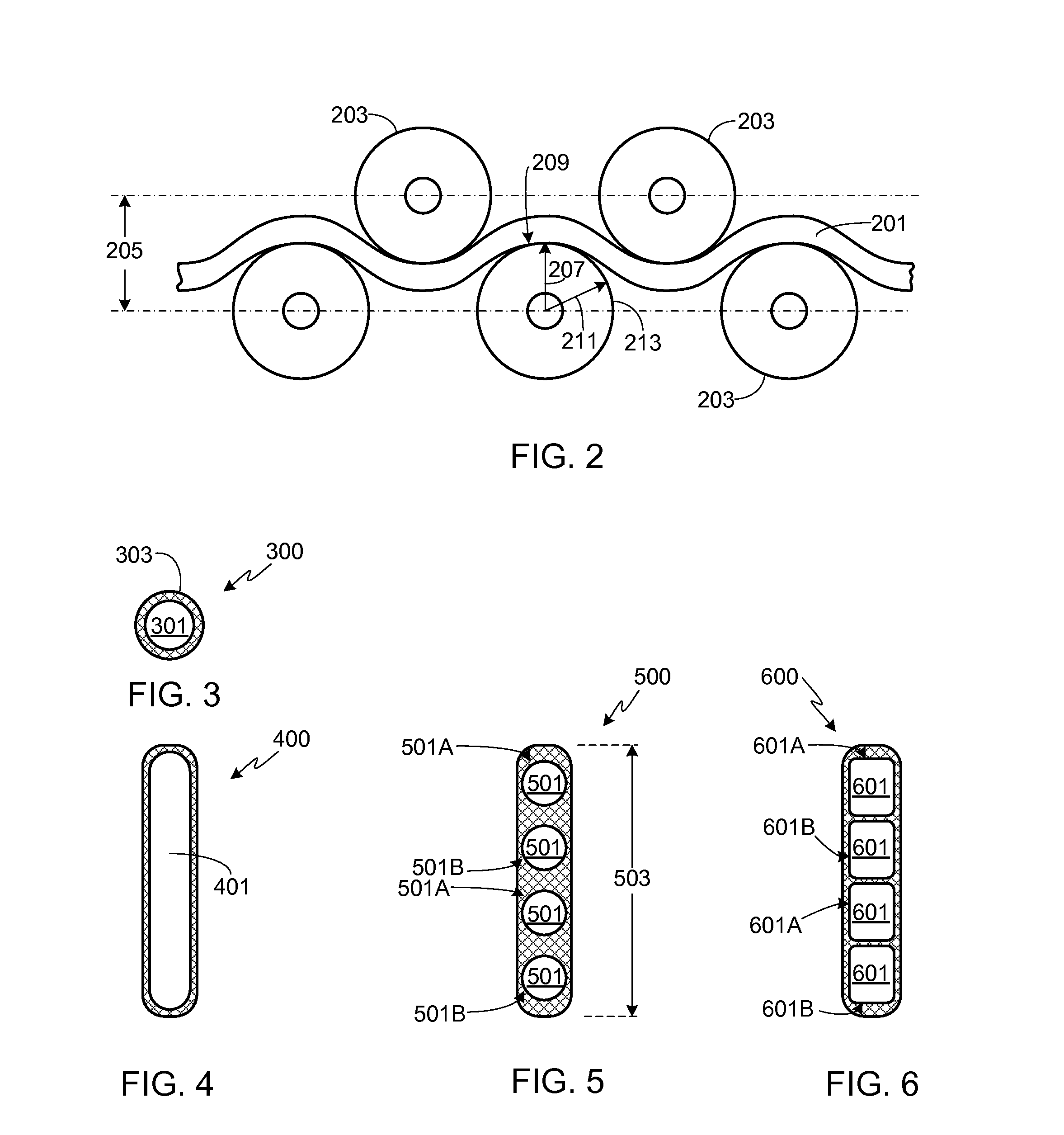

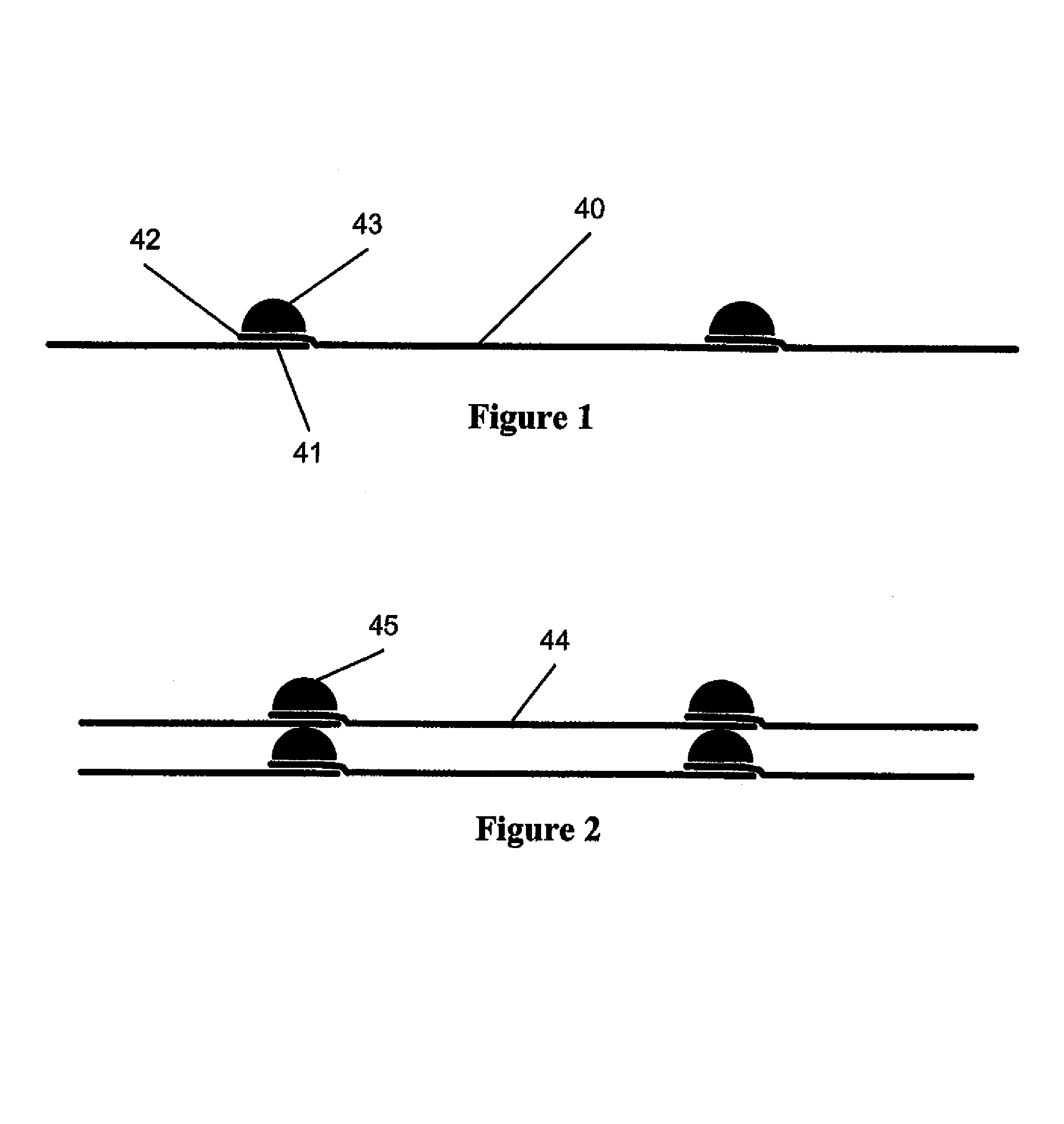

Extruded and Ribbed Thermal Interface for use with a Battery Cooling System

ActiveUS20110212356A1Cell temperature controlHeat exhanger conduitsInterface layerThermal management system

A cooling manifold assembly for use in a battery pack thermal management system is provided. The cooling manifold assembly includes a coolant tube that is interposed between at least a first row of cells and a second row of cells, where the first and second rows of cells are adjacent and preferably offset from one another. A thermal interface layer is attached to the cooling tube, the thermal interface layer including a plurality of pliable fingers that extend away from the cooling tube and are interposed between the cooling tube and the first row of cells, and interposed between the cooling tube and the second row of cells, where the pliable fingers are deflected by, and in thermal contact with, the cells of the first and second rows of cells.

Owner:TESLA INC

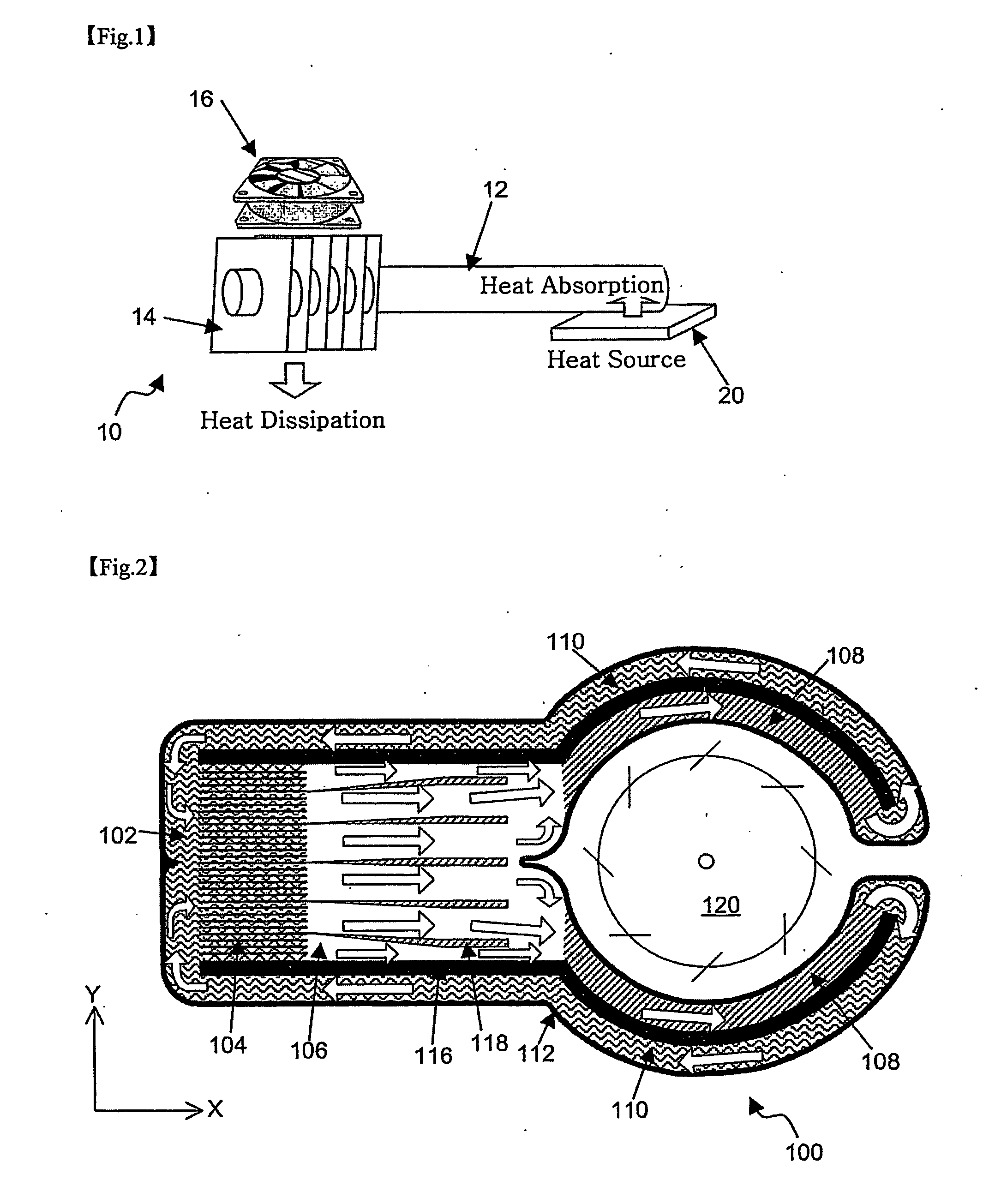

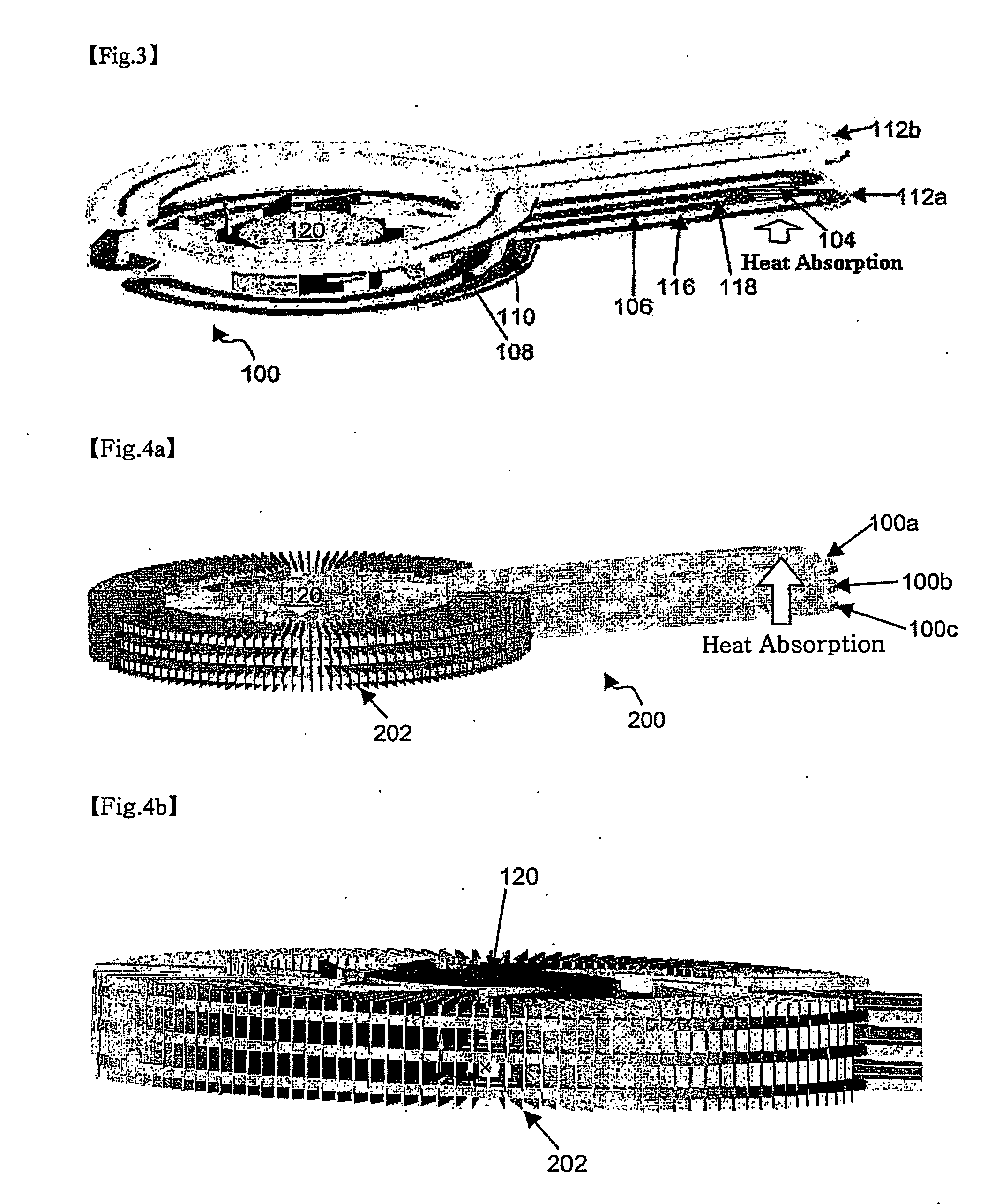

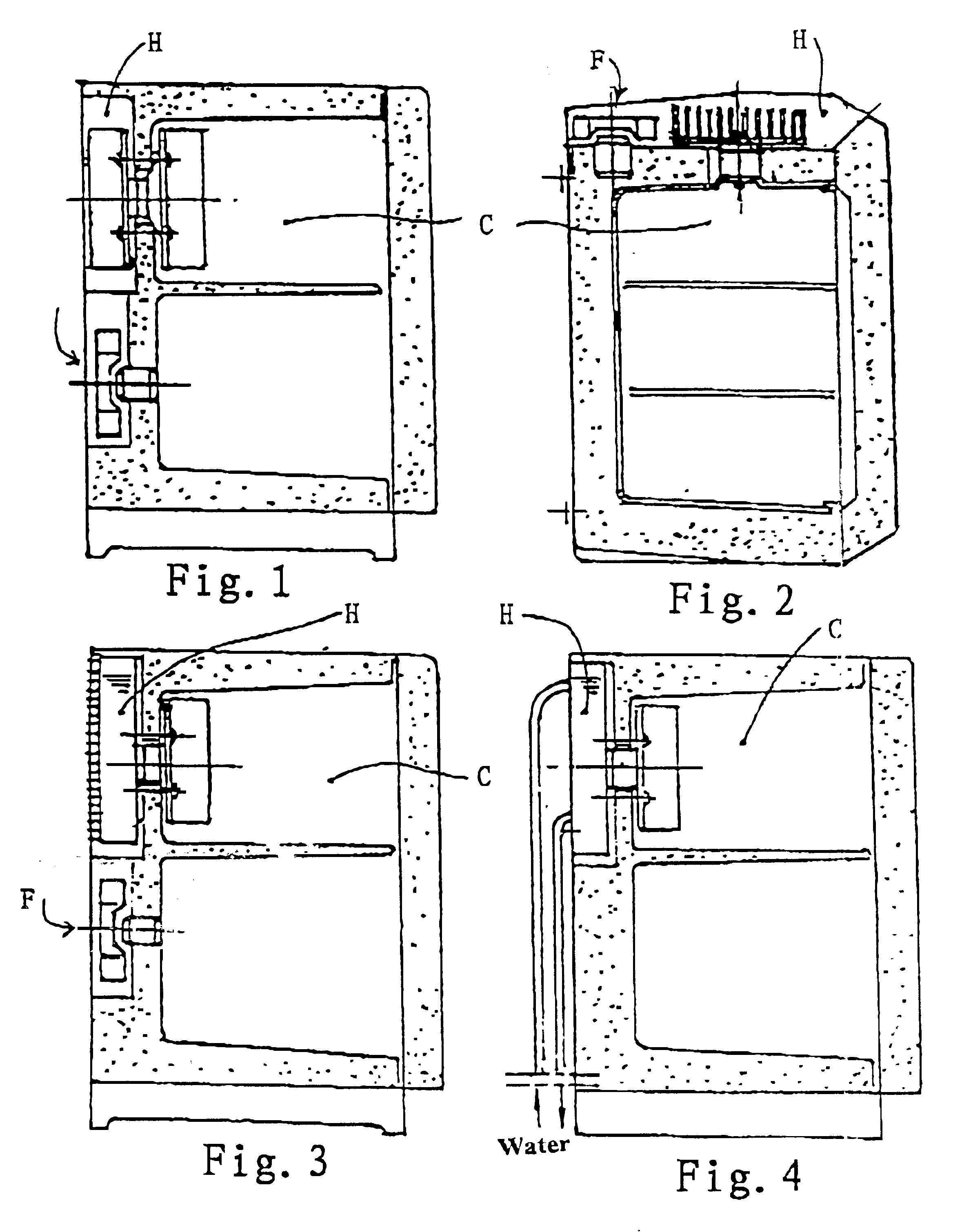

Cooling device of hybrid-type

InactiveUS20060266499A1Reduce lossesImprove cooling effectHeat storage plantsSemiconductor/solid-state device detailsHybrid typeEngineering

The present invention provides a hybrid-type cooling device which can perform cooling by phase transition, ventilation and convection.

Owner:CELSIA TECH TAIWAN INC

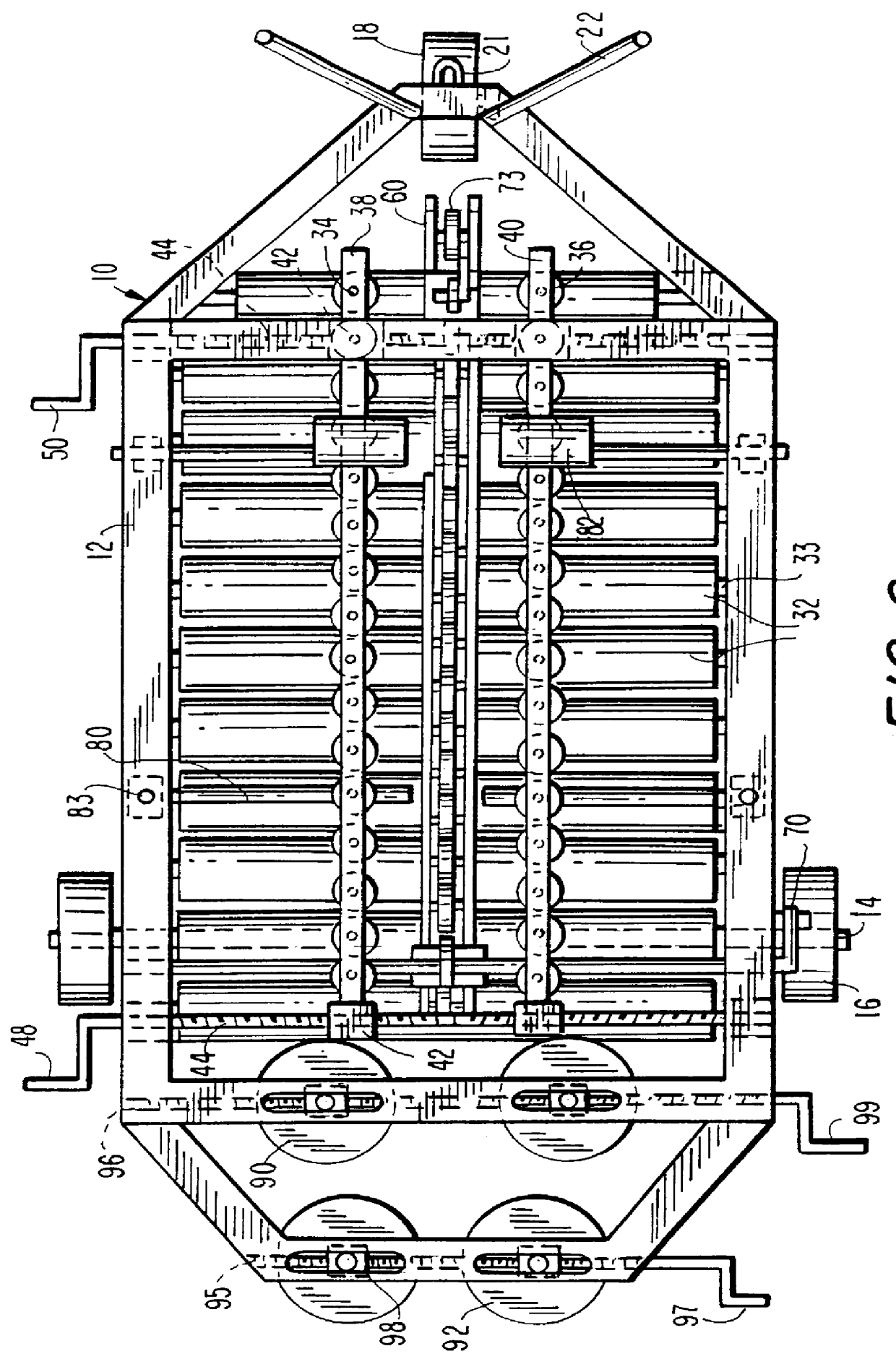

Polymeric pipe deformer and method for relining existing pipelines

InactiveUS6058978AEconomical and efficientReduce the overall diameterHeat exhanger conduitsPipe elementsInternal pressureEngineering

A method and apparatus for relining, repairing or reconstructing existing infrastructure pipeline systems that are new, structurally deficient or experiencing an excessive amount of exfiltration or infiltration, or converting new or damaged pipelines into dual-containment pipelines. A plurality of stock, high density polyethylene lining pipes having a cylindrical cross-section with a diameter up to 36 inches and lengths of 40-50 feet are joined together to a job specific length. The lining pipe is then heated to its flex temperature and gradually deformed to a reduced diameter. At the job site, the deformed lining pipe is inserted into the existing pipe and a controlled, pressurized environment is created therein for a period of time dependent on the pipe's length. Pressurized steam is first inserted to provide heat and internal pressure to expand the pipe. Then, compressed air is inserted to cool the pipe while maintaining the internal pressure to complete the expansion and set the pipe. When converting to dual-containment pipelines, the deformed pipe will have a plurality of spacers attached thereon such that the existing and deformed pipes are axially aligned and have an annular space therebetween.

Owner:CSR PARTIES

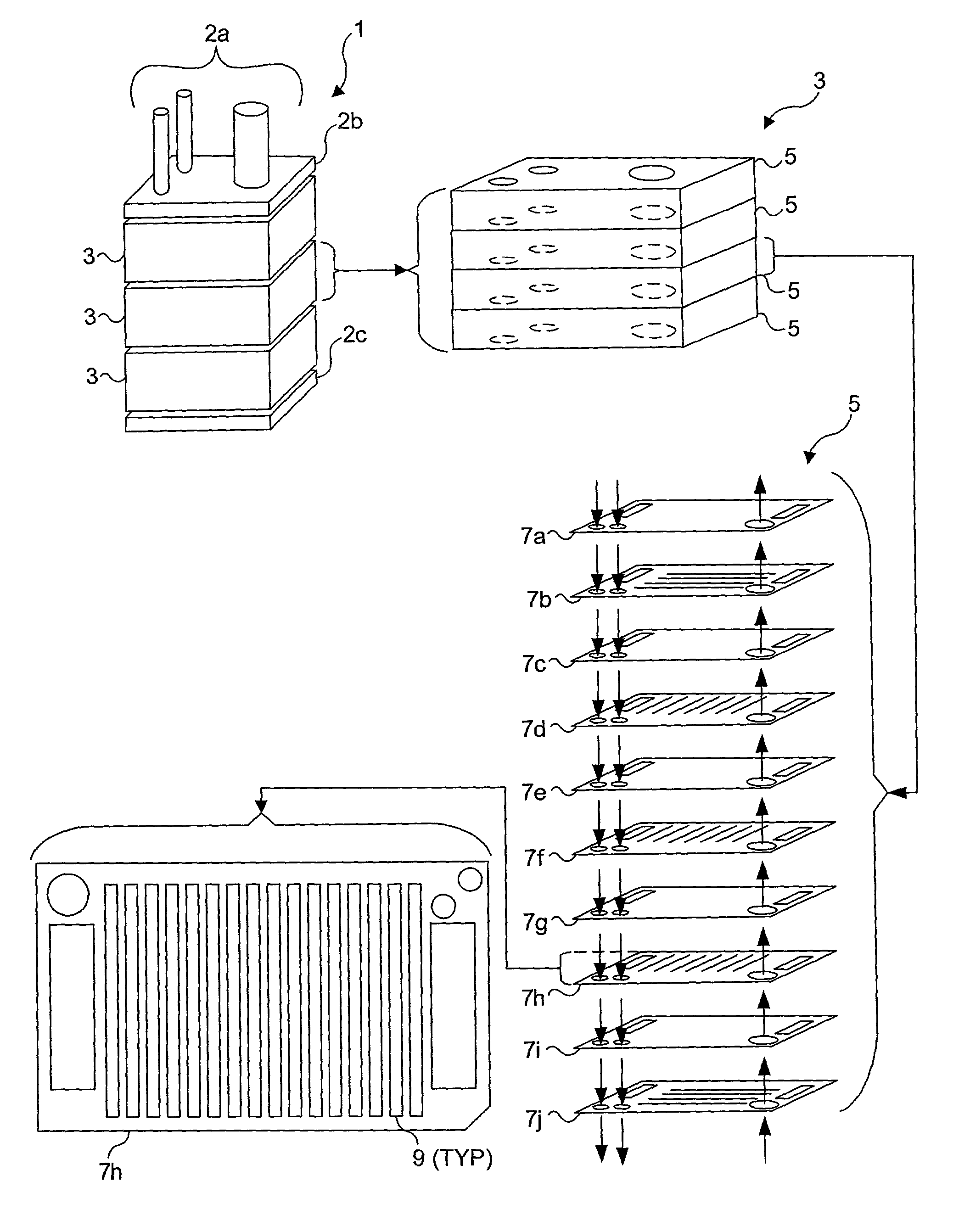

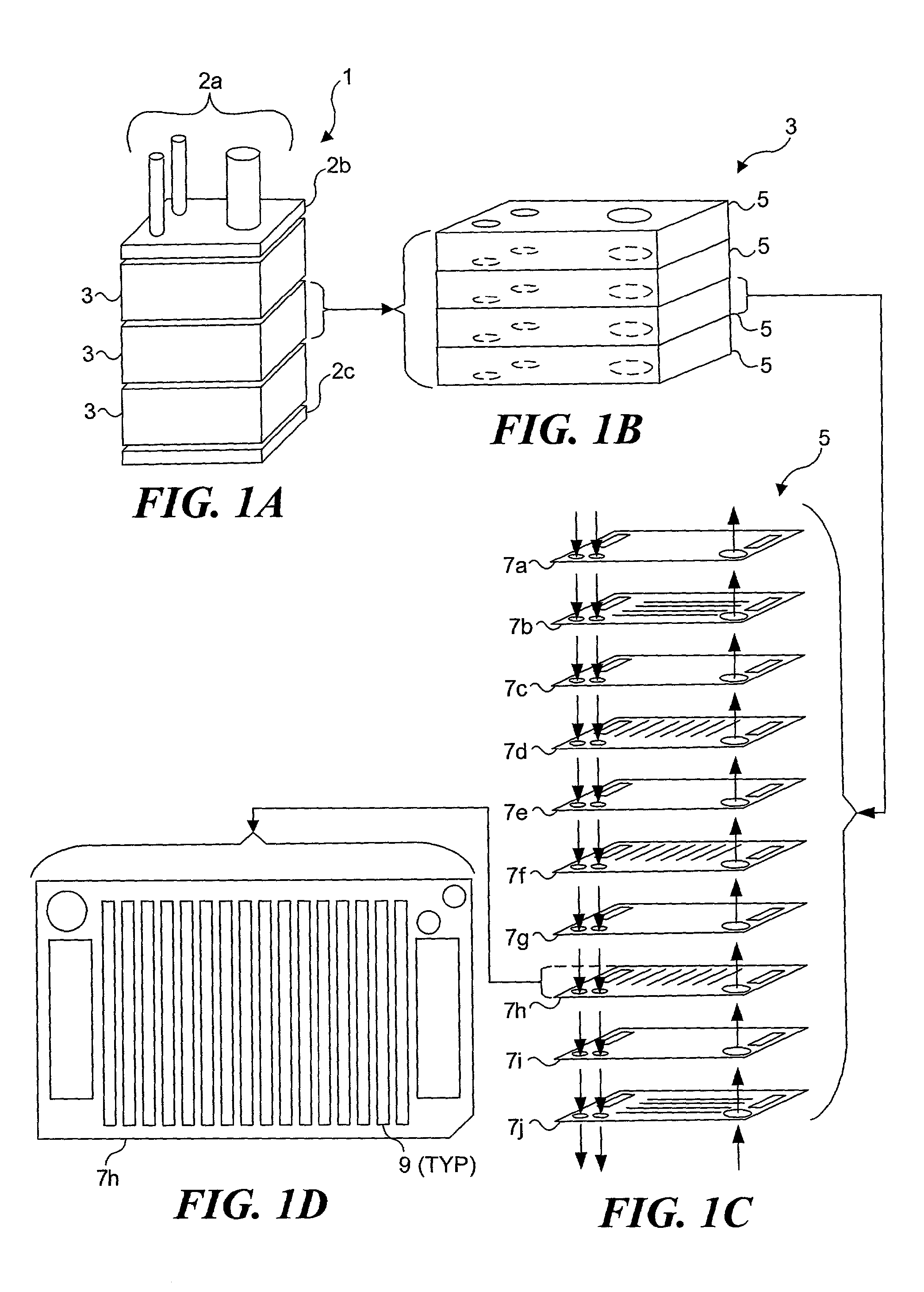

Enhancing fluid flow in a stacked plate microreactor

InactiveUS7241423B2Easy to reconfigureFree of scratchesFlow mixersTransportation and packagingMicroreactorChemical reaction

A stacked plate chemical reactor in which simple plates are stacked together to form the reactor. When openings in adjacent plates are properly aligned, fluid pathways and processing volumes are defined for chemical reactants, heat transfer medium, and a product. In one embodiment of the invention, an n-fold internal array is achieved by providing a first group of simple plates defining a reaction unit that includes bypass fluid channels and reaction fluid channels for each reactant, such that a portion of each reactant is directed to subsequent groups of simple plates defining additional reaction units. A chemical reactor with variable output is obtained in a preferred embodiment by reversibly joining reactor stacks comprising irreversibly joined reaction units, these reaction units consisting of a plurality of simple plates. Other embodiments employ at least one of an array of parallel fluid channels having different widths, bifurcated fluid distribution channels to achieve a substantially even flow equipartition for fluids with varying viscosities flowing within the fluid channels of each reaction unit.

Owner:EHRFELD MIKROTECHNIK BTS GMBH

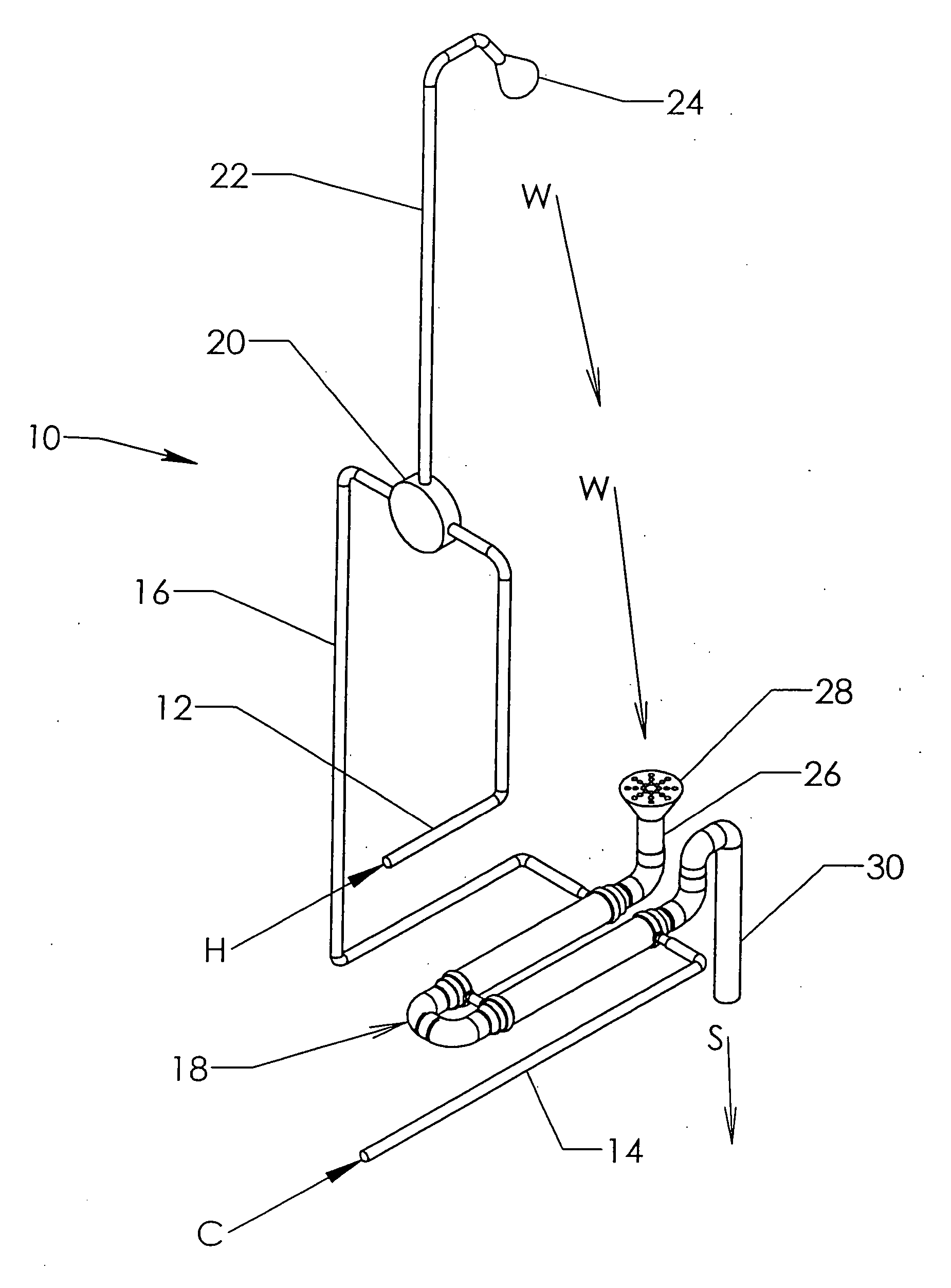

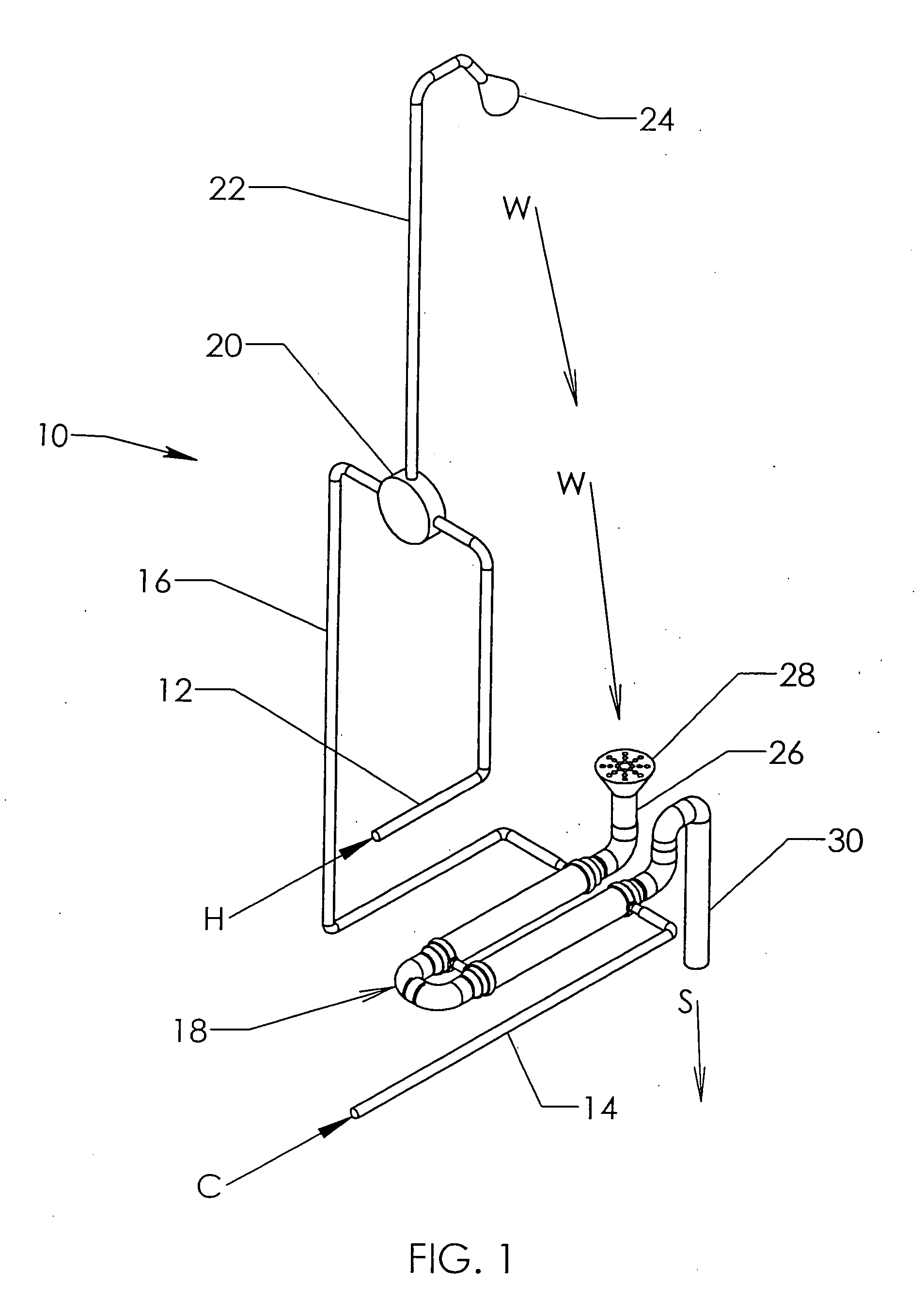

Heat exchanger and use thereof in showers

InactiveUS20080000616A1Well mixedImprove heat transfer efficiencyHeat recovery systemsRecuperative heat exchangersEngineeringShower

An improved heat exchanger design is disclosed. The design of the heat exchanger provides for a safe separation of the flow streams even in the event of leakage. An improved heat recovery device for use in the drain conduit of standard shower installations, comprising the heat exchanger of the invention, is also disclosed.

Owner:NOBILE JOHN R

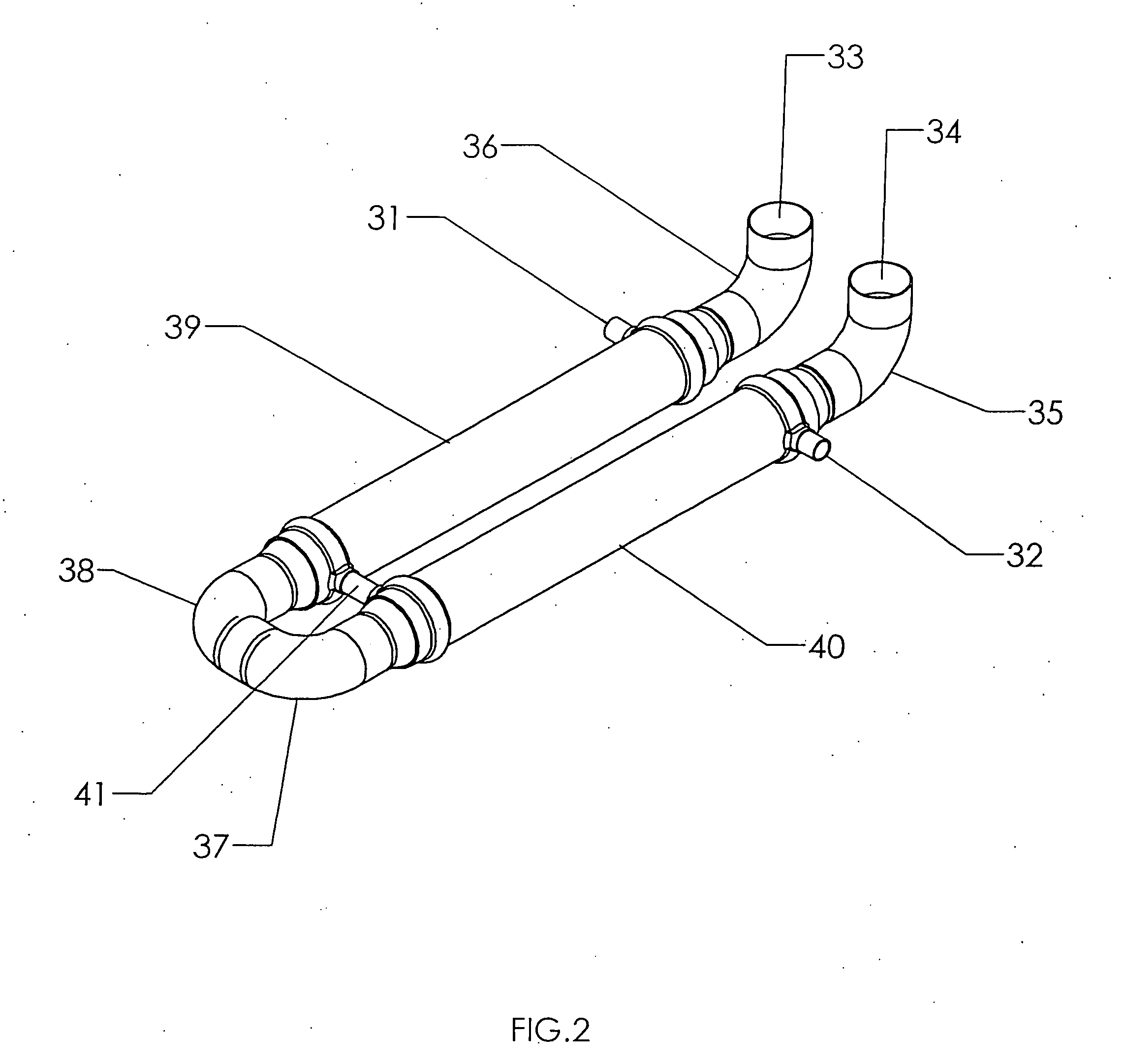

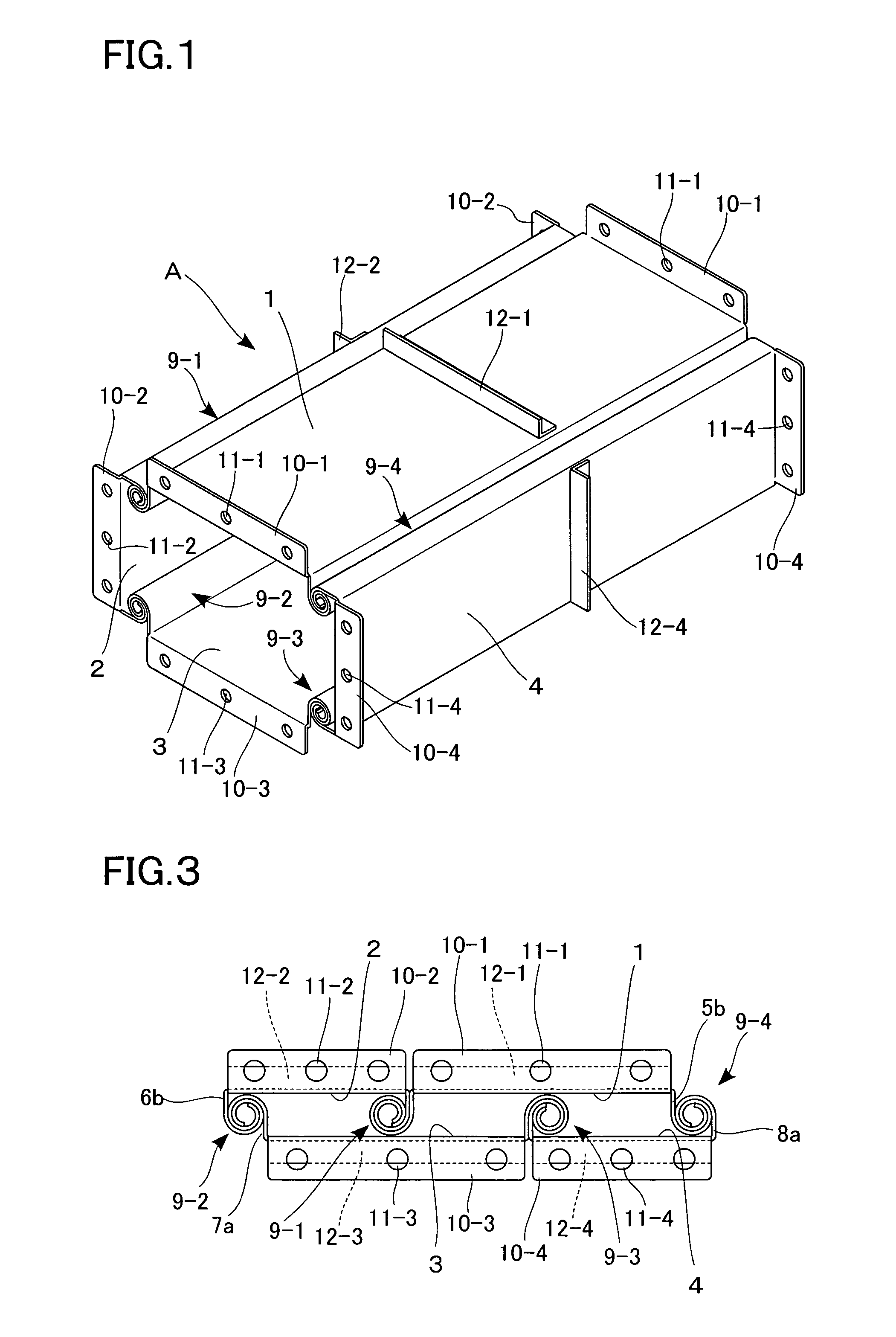

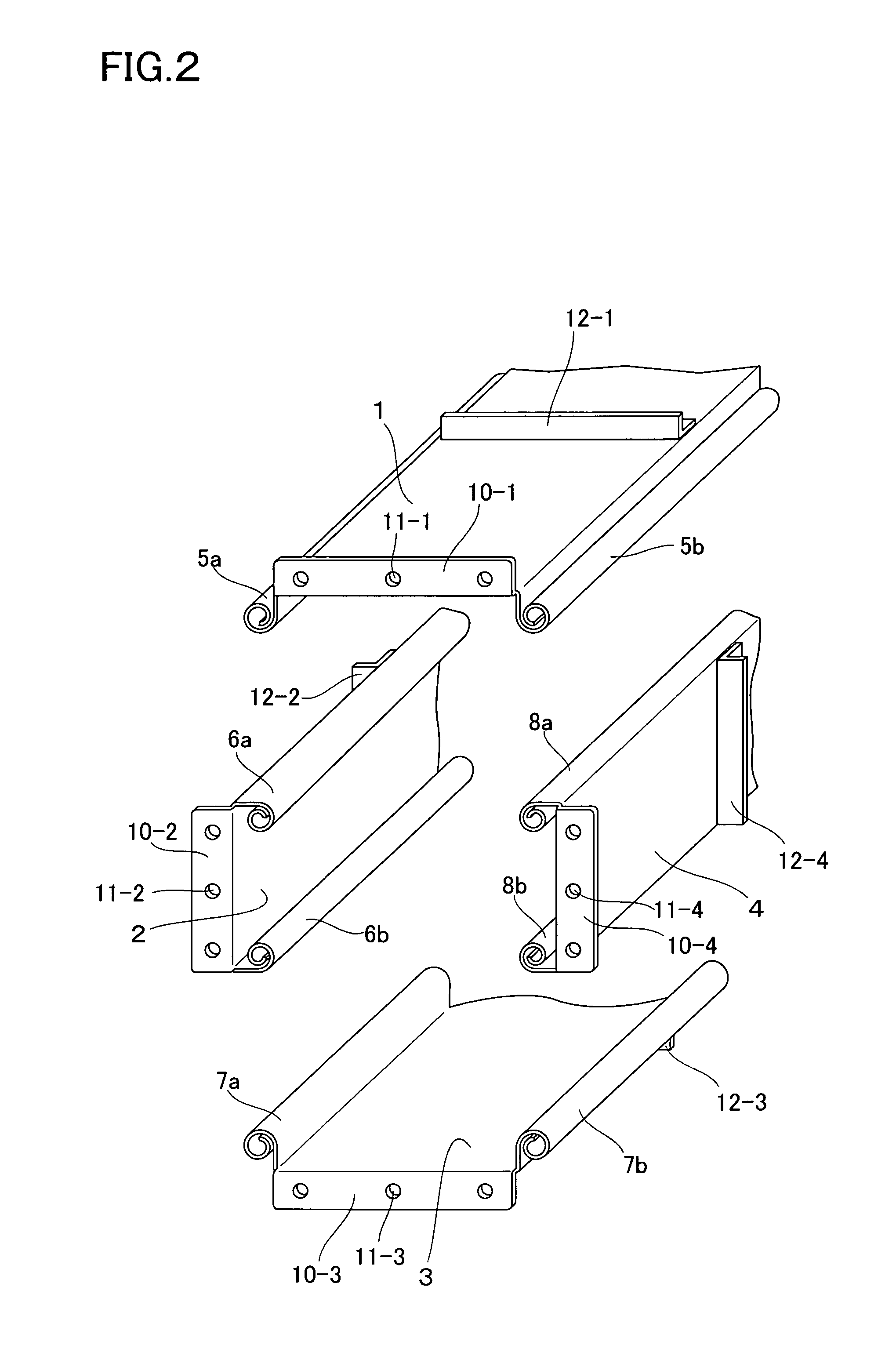

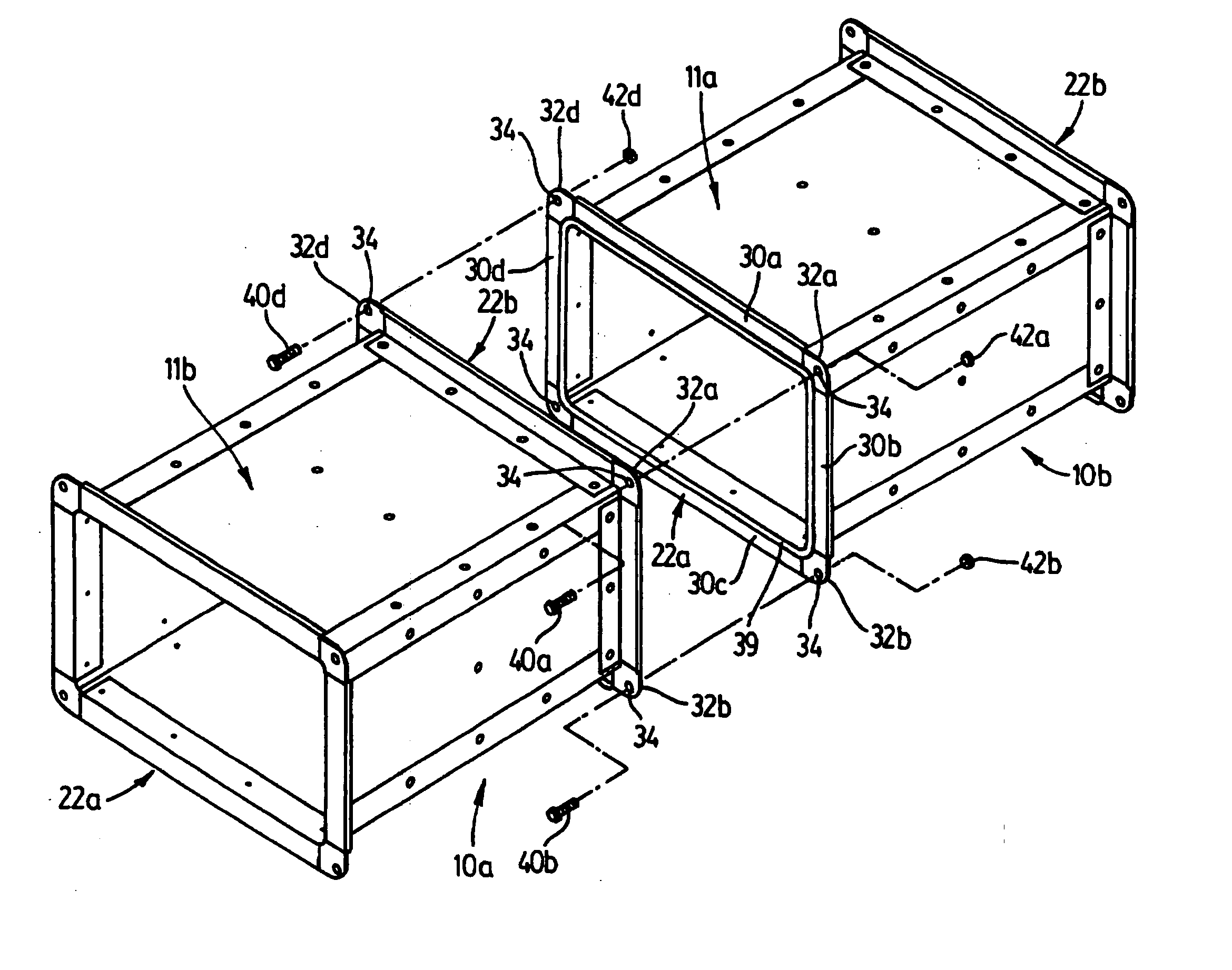

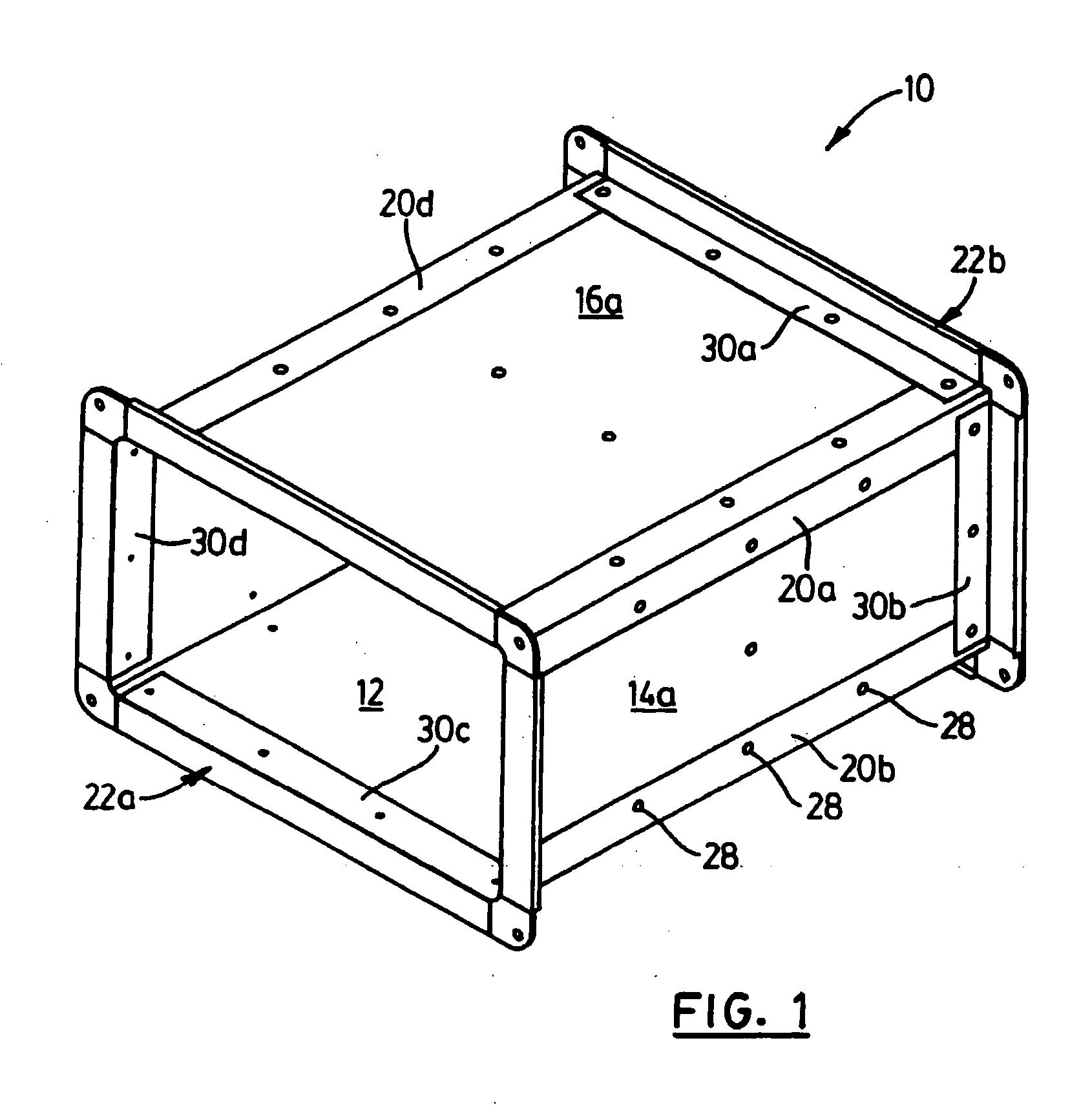

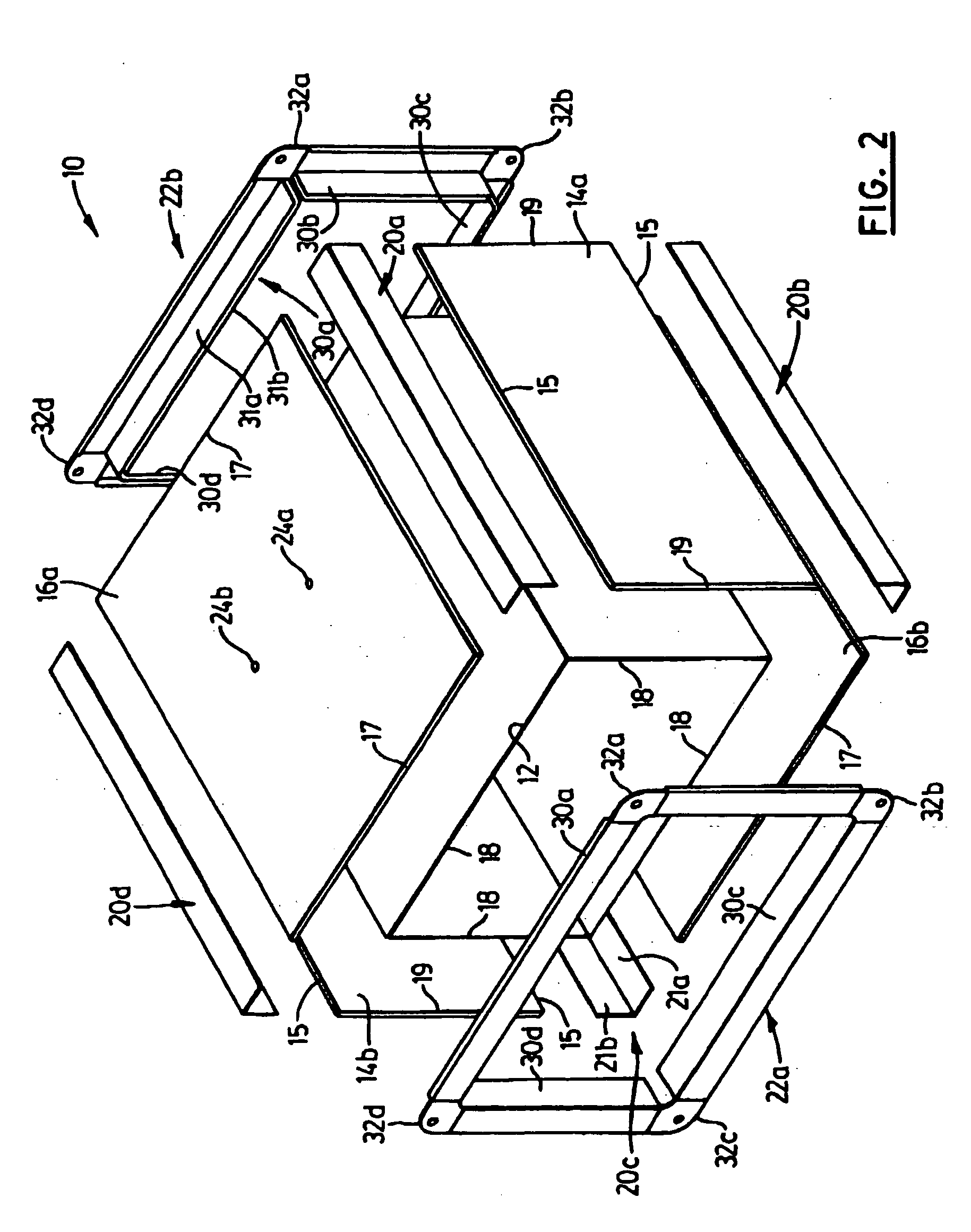

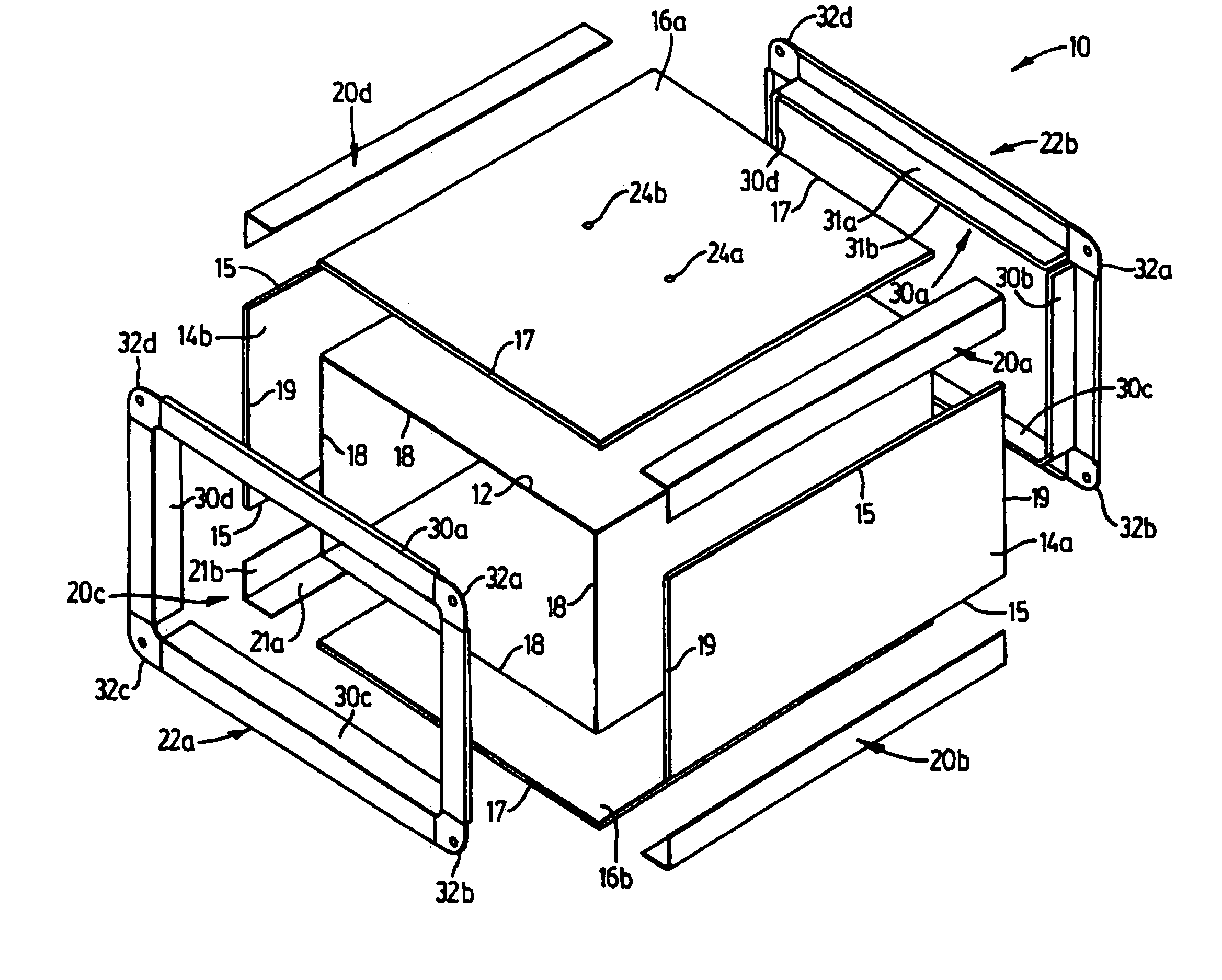

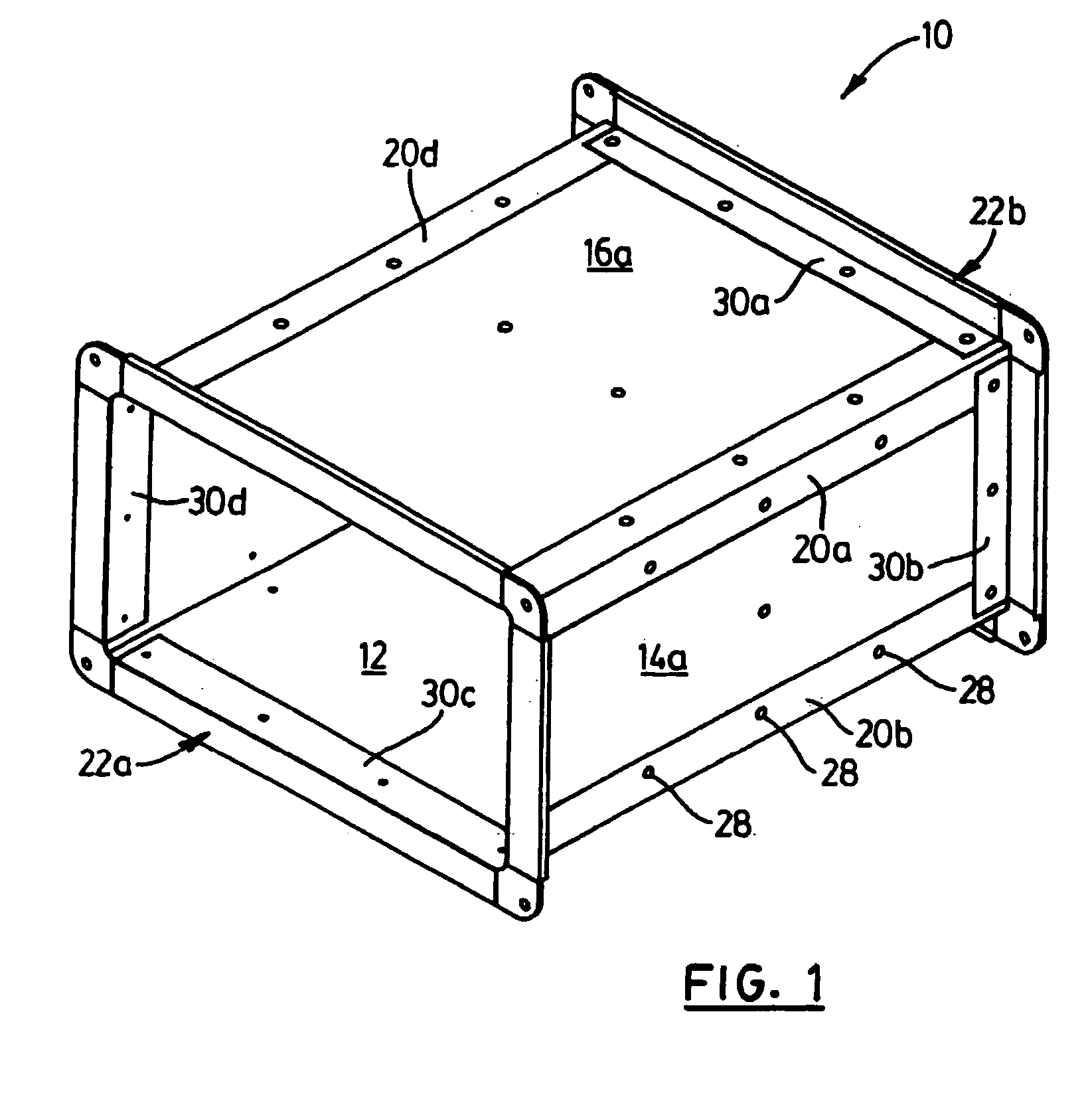

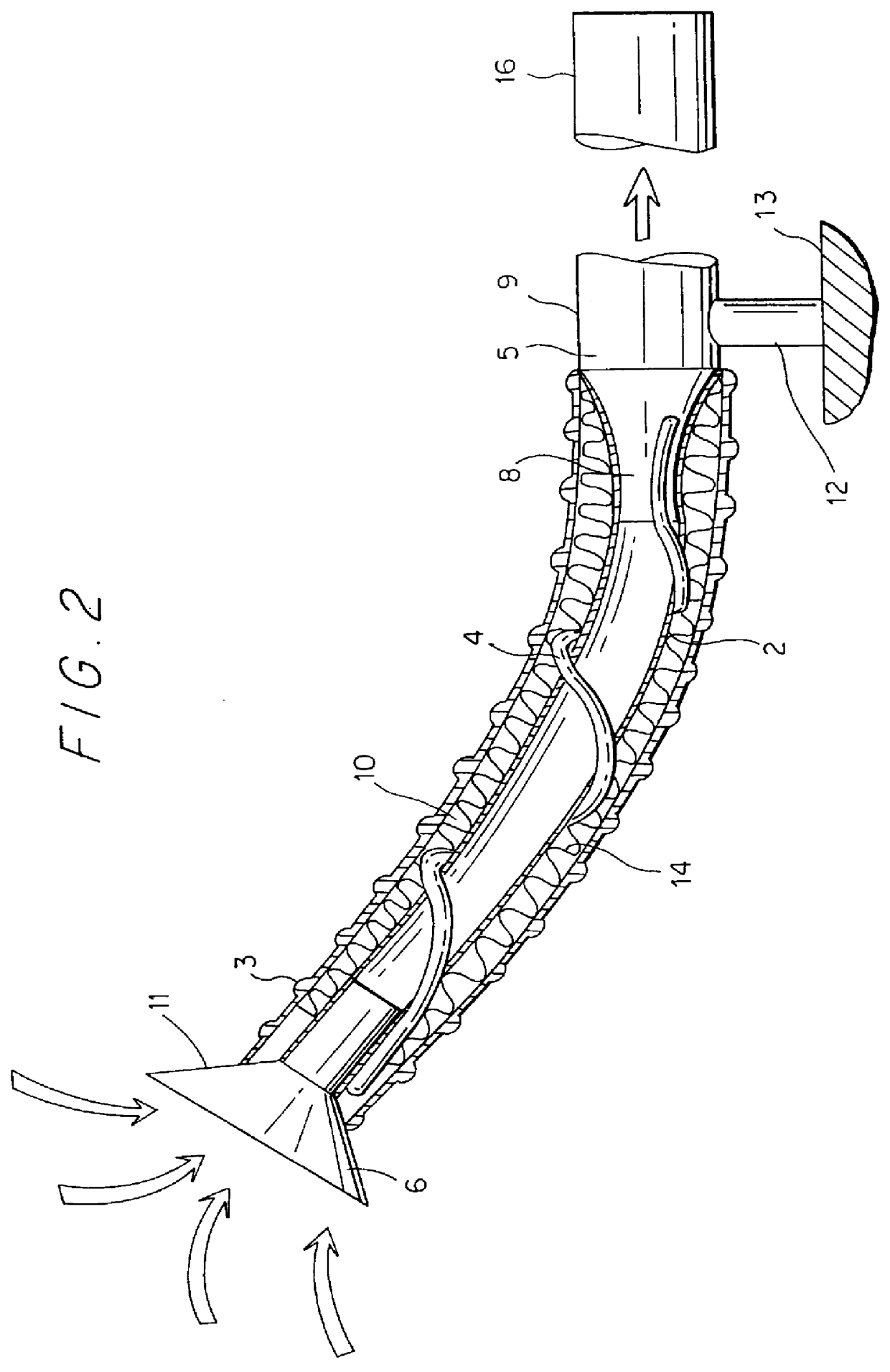

Duct unit for air-conditioner

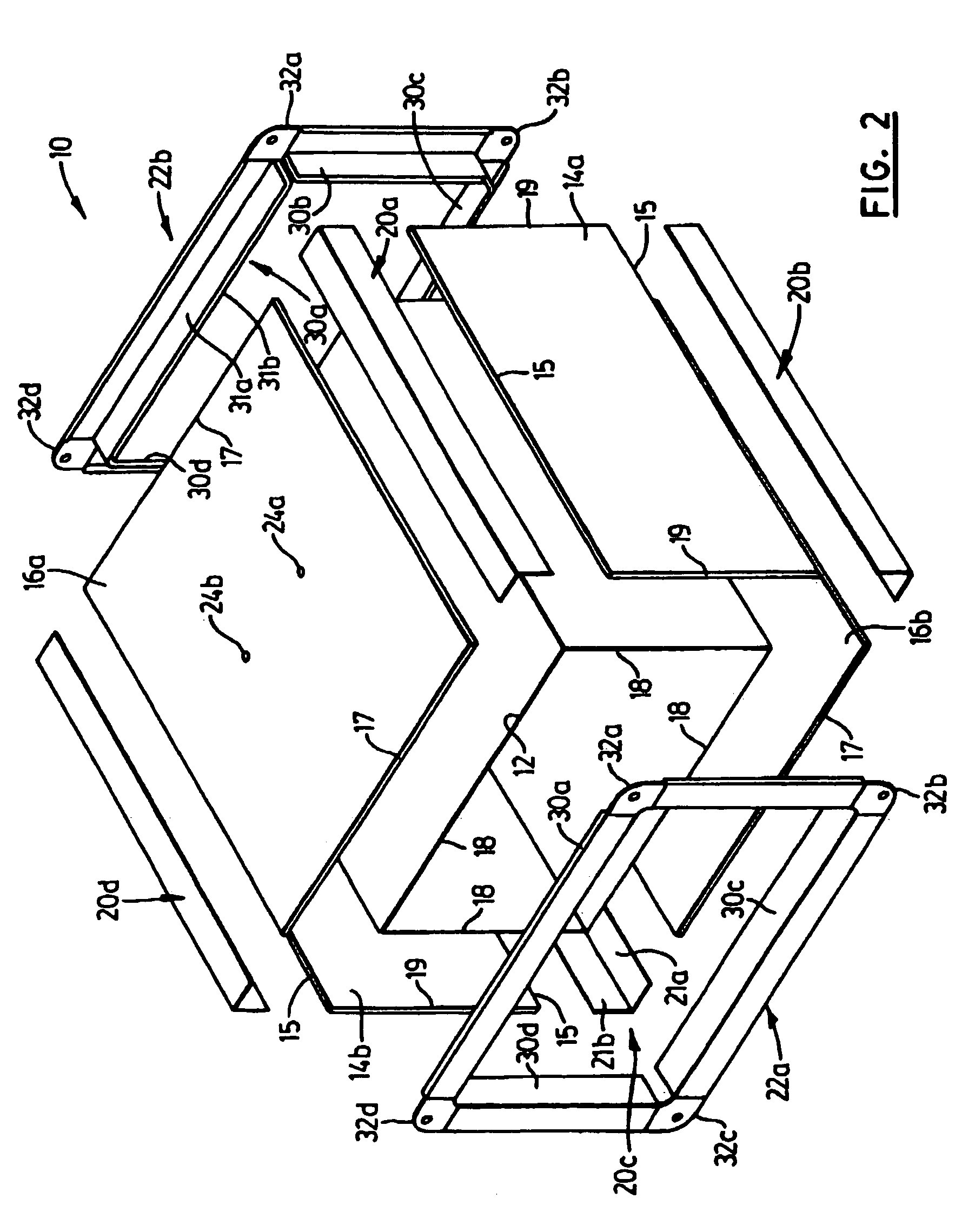

InactiveUS6957670B1Reduce capacitySufficient workspaceDucting arrangementsFlanged jointsMetal sheetStructural engineering

An object of the present invention is to provide an air-conditioning duct unit capable of being made compact when transported to largely reduce the cost of transport inside and outside a building as well as the cost of transportation by a truck.A duct unit A of the present invention has upper and lower wall portions 1 and 3 and right and left wall portions 2 and 4 formed of metal sheets, and spin locks curved into a curled shape, the spin locks being provided on the wall portions 1 to 4 at two side edges of the same along the longitudinal direction. One of the pair of spin locks provided on each adjacent pair of the wall portions is inserted in the other to form one of lock joints 9-1 to 9-4 rotatably. The wall portions 1 to 4 are linked so that the duct unit A can be changed in shape. Consequently, the duct unit can be folded so as to be flattened.

Owner:FUJI KUUCHOU KOUGYOU CO LTD

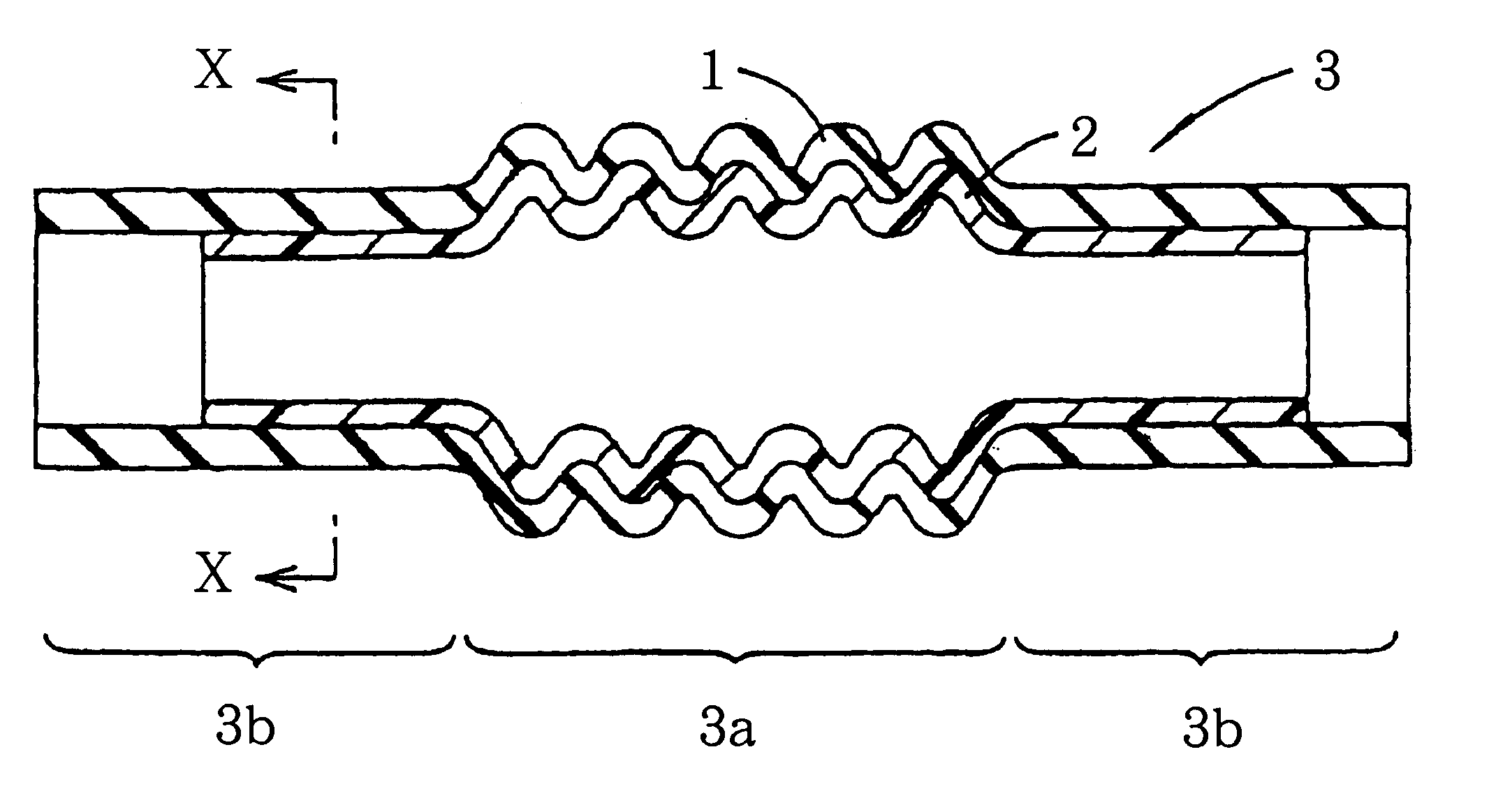

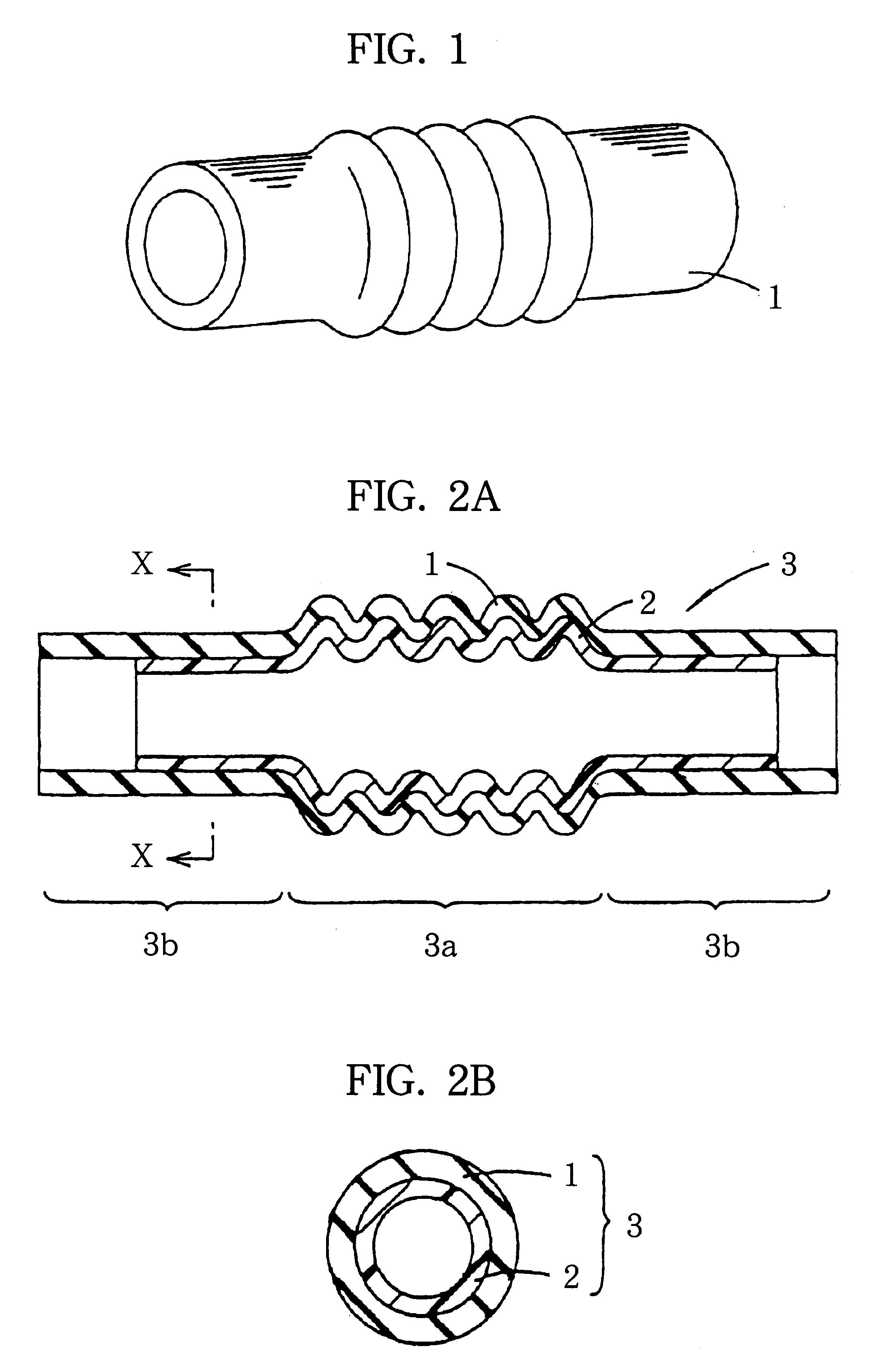

Fuel hose

InactiveUS6279615B1Excellent ozone resistanceLow melting pointHeat exhanger conduitsFlexible pipesAlcoholPolybutylene

A fuel hose comprises a single layered or multi-layered tubular rubber body and a thin film resin layer formed on the inner circumferential surface of the innermost layer of the tubular rubber body. The resin layer is formed of a resin such that an amount of permeation of 10% ethanol-mixed gasoline is 2 mg / cm2 / day (at 60° C.) or less when the thickness of the resin layer is 0.1 mm. A preferred example of such a resin is EVOH with an ethylene content of from 35 to 50 mol % or polybutylene aromatic ester. The fuel hose has necessary flexibility and shows excellent impermeability even to an alcohol-mixed gasoline.

Owner:SUMITOMO RIKO CO LTD

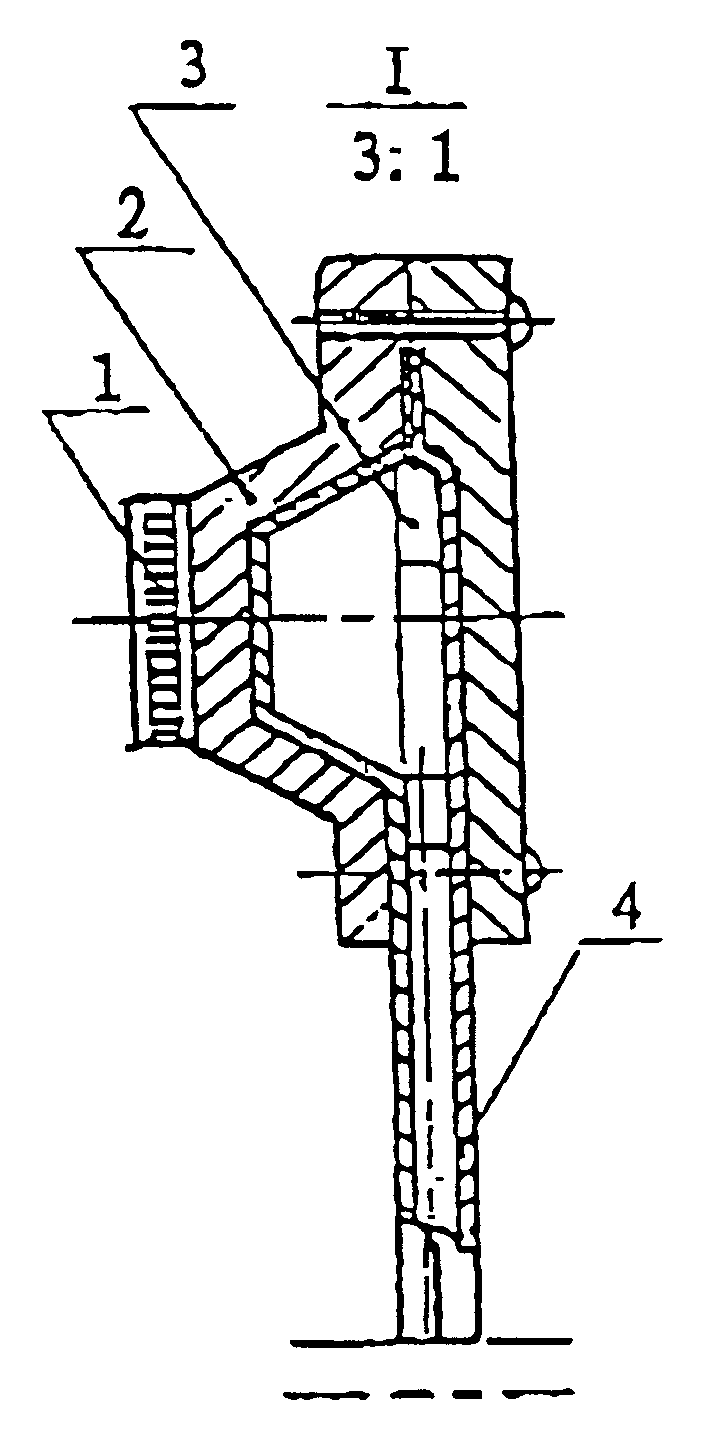

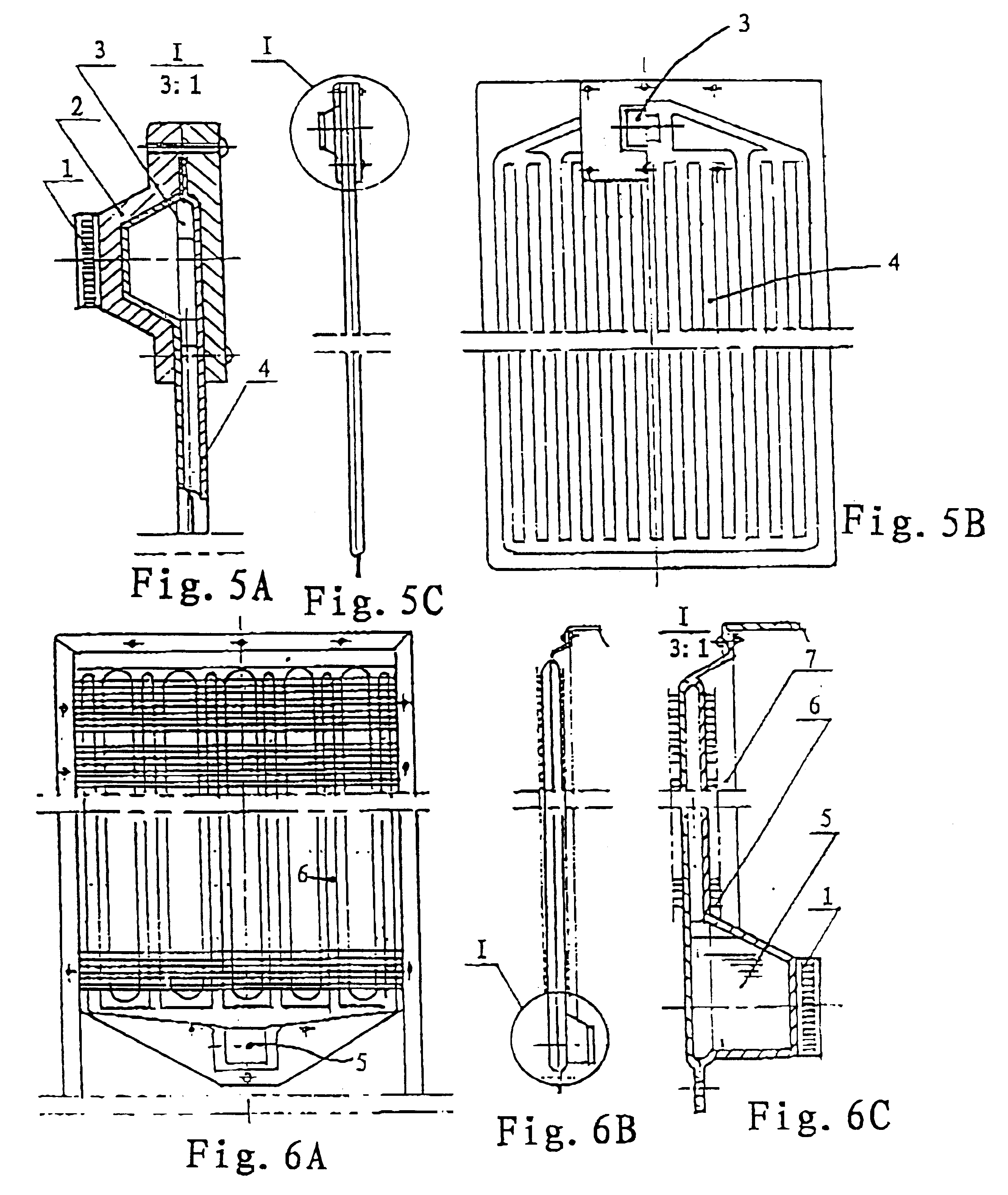

Limb for breathing circuit

A limb for a breathing circuit manufactured from very thin walled polymer materials has an elongate axial reinforcing spine lying freely inside the conduit and fixed to each end connector. The spine is laterally compliant but axially stiff. The spine provides resistance to tensile and compressive loads on the conduit, including that induced by prevailing internal pressures.

Owner:FISHER & PAYKEL HEALTHCARE LTD

Apparatus for a fire-rated duct

ActiveUS20050116470A1Avoid heatObstruct passageDucting arrangementsFlanged jointsFresh airWaste management

A duct system comprising duct sections which are factory manufactured and field modifiable. The field modifiable duct system comprises fire resistant materials and is fire-rated. The duct sections when assembled create a continuous conduit that allows air to flow from a fresh air source to the required area of the building.

Owner:DURASYST BARRIERS

Method and apparatus to clean and apply foamed corrosion inhibitor to ferrous surfaces

InactiveUS6841125B1Harm to environmentProblems harmInorganic/elemental detergent compounding agentsCationic surface-active compoundsFire protectionEngineering

The present invention relates to the application of a coating to a pipeline, FPS (Fire Protection System) or to pipe stock from which a pipeline is fabricated. A composition which when applied to the inside surface of the pipe prevents either chemical corrosion or microbiologically influenced corrosion is disclosed. Also disclosed is a method for utilizing this material to protect both existing pipelines and the raw stock used to construct pipelines and various apparatus for applying a coating of the composition, cleaning, and maintenance of the passive coating. Also disclosed is a method to recycle the composition to be used in other industrial pacification processes. The composition, methods, and apparatus are environmentally friendly and eliminate the need to use poisonous, environmentally damaging biocides currently used in the prevention of microbiologically influenced corrosion (MIC) in FPS, water treatment, nuclear, petroleum and natural gas transportation pipelines, and various processing equipment within industry.

Owner:POTTER ELECTRIC SIGNAL

Apparatus for a fire-rated duct

InactiveUS7195290B2Fire is prevented from jumpingAvoid heatDucting arrangementsFlanged jointsFresh airWaste management

A duct system comprising duct sections which are factory manufactured and field modifiable. The field modifiable duct system comprises fire resistant materials and is fire-rated. The duct sections when assembled create a continuous conduit that allows air to flow from a fresh air source to the required area of the building.

Owner:DURASYST BARRIERS

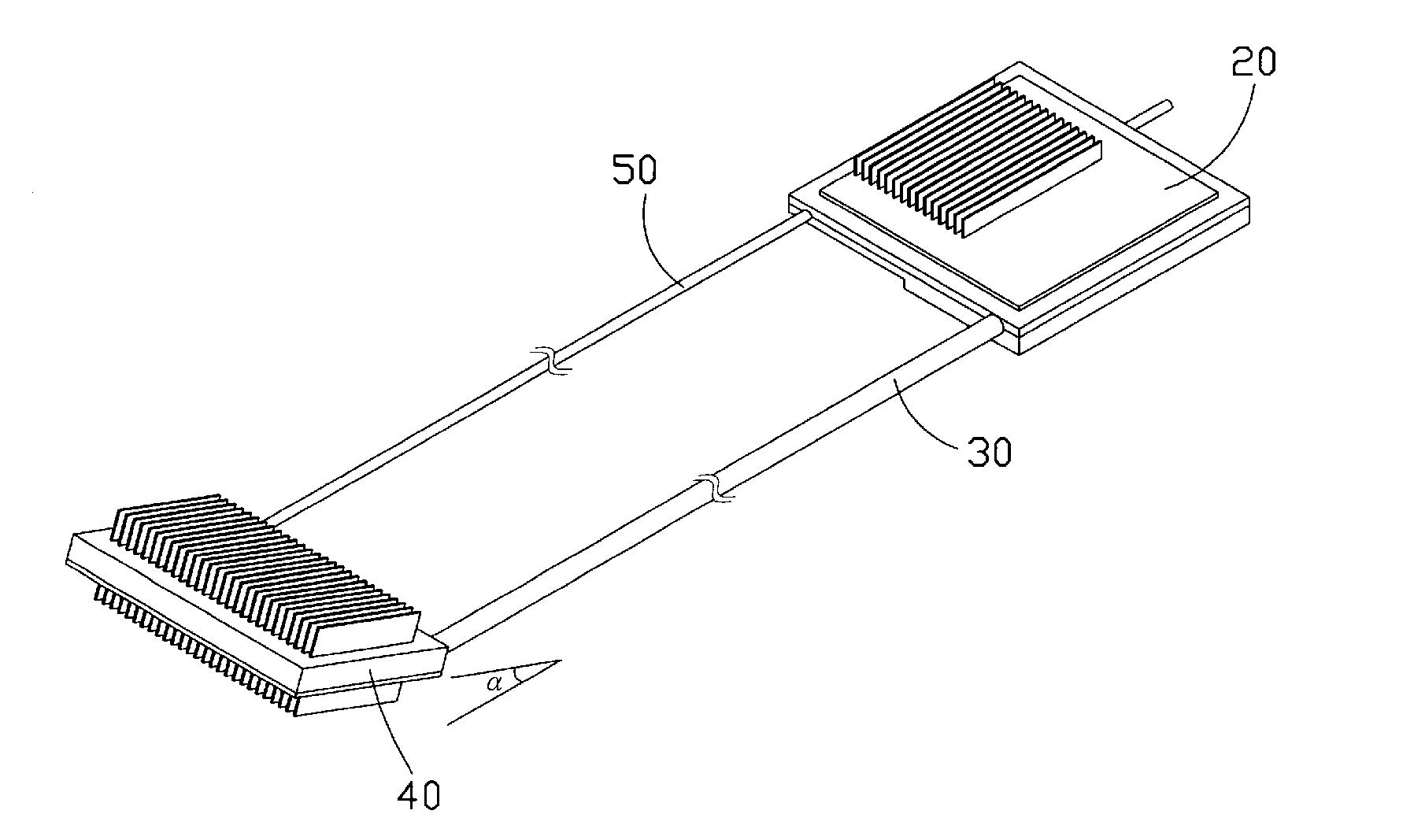

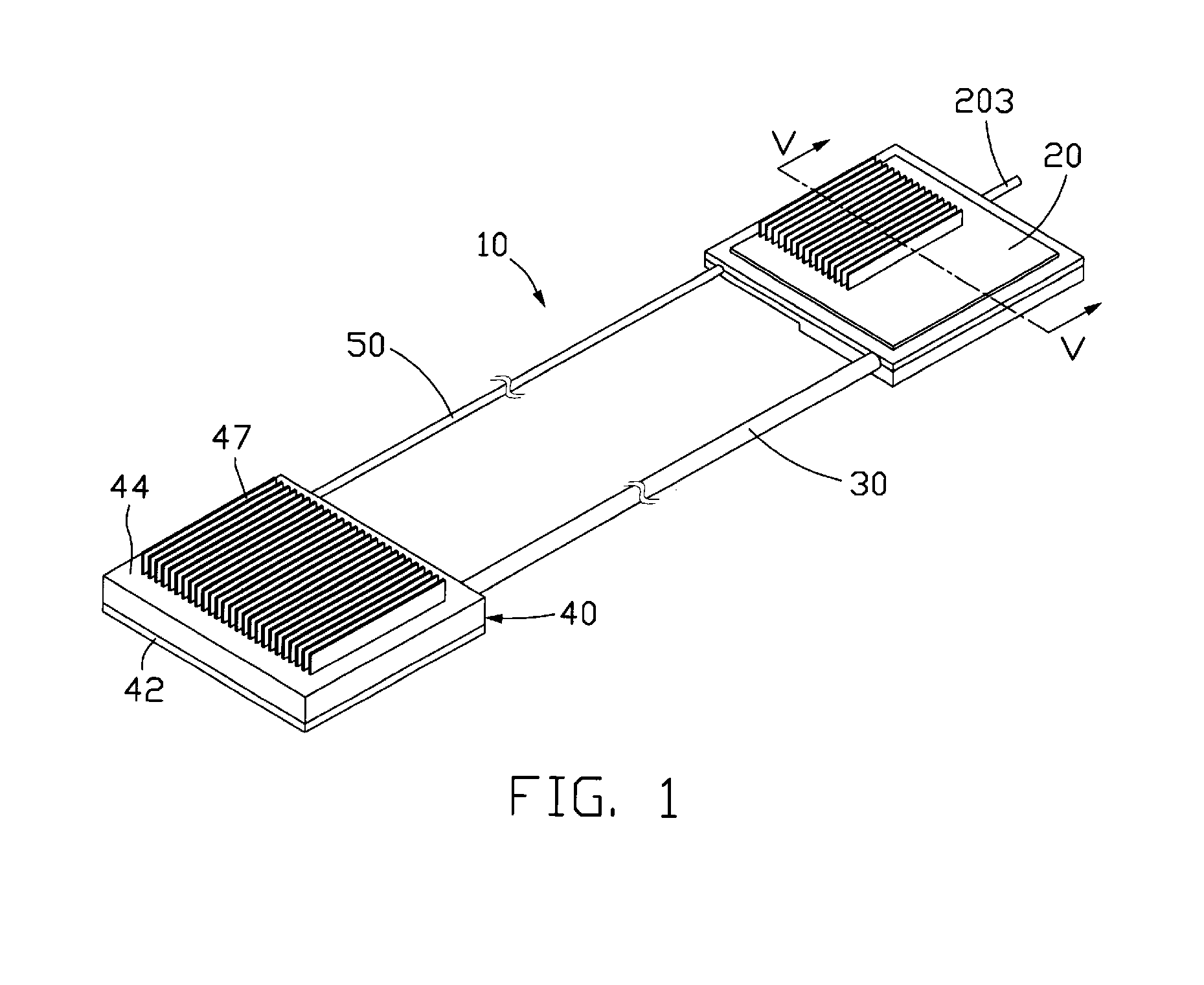

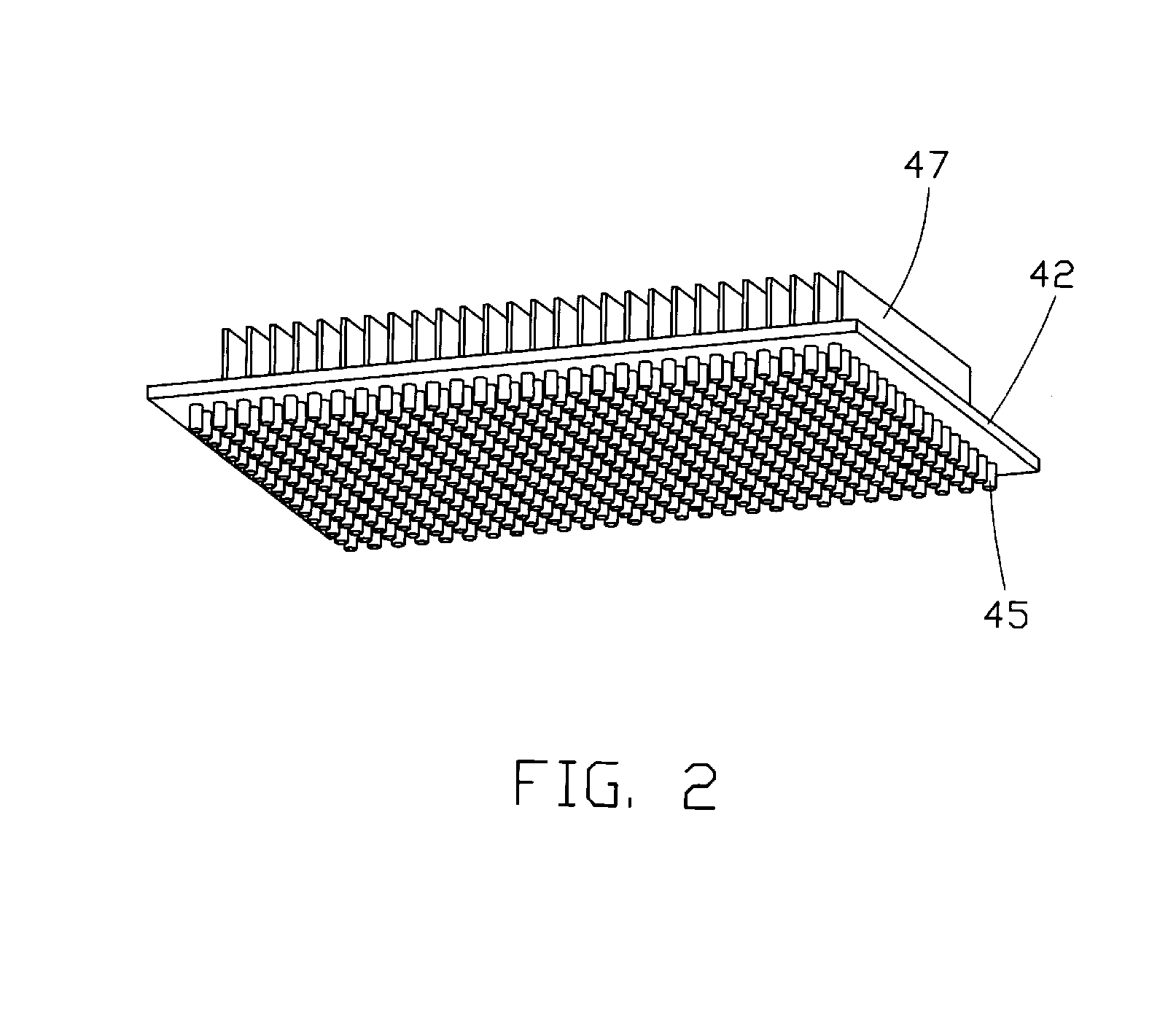

Loop-type heat exchange device

InactiveUS20060283577A1Improve heat exchange capacityHigh heat-absorbing surface areaSolar heat devicesHeat exhanger conduitsWorking fluidEvaporation

A loop-type heat exchange device (10) is disclosed, which includes an evaporator (20), a condenser (40), a vapor conduit (30) and a liquid conduit (50). The evaporator contains therein a working fluid. The working fluid in the evaporator evaporates into vapor after absorbing heat, and the generated vapor flows, via the vapor conduit, to the condenser where the vapor releases its latent heat of evaporation and is condensed into condensate. The condensate then returns back, via the liquid conduit, to the evaporator to thereby form a heat transfer loop. The condenser defines therein a chamber, and a plurality of heat-exchange pins is provided inside the chamber for effectively exchanging heat with the vapor entering into the condenser.

Owner:HON HAI PRECISION IND CO LTD

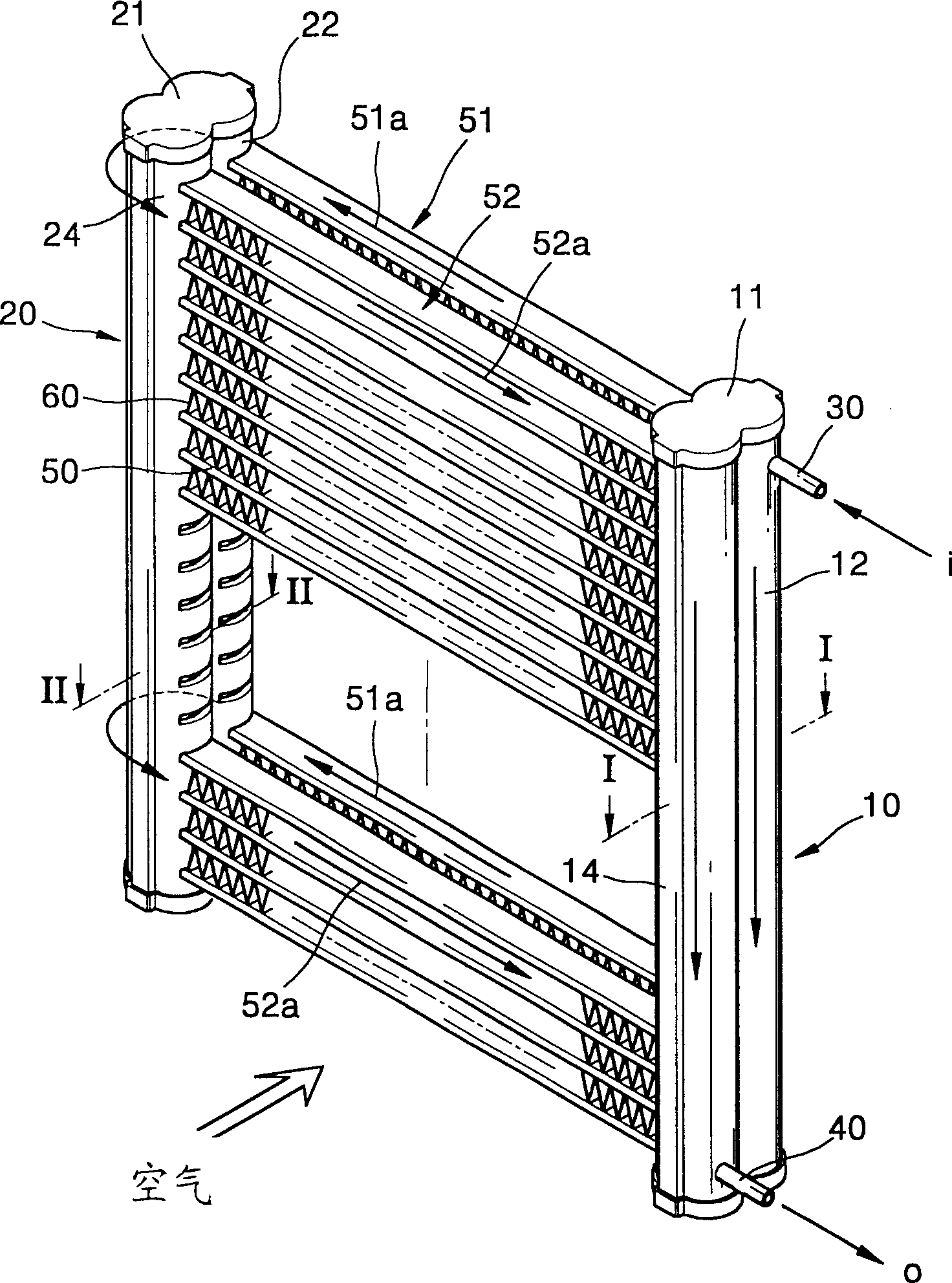

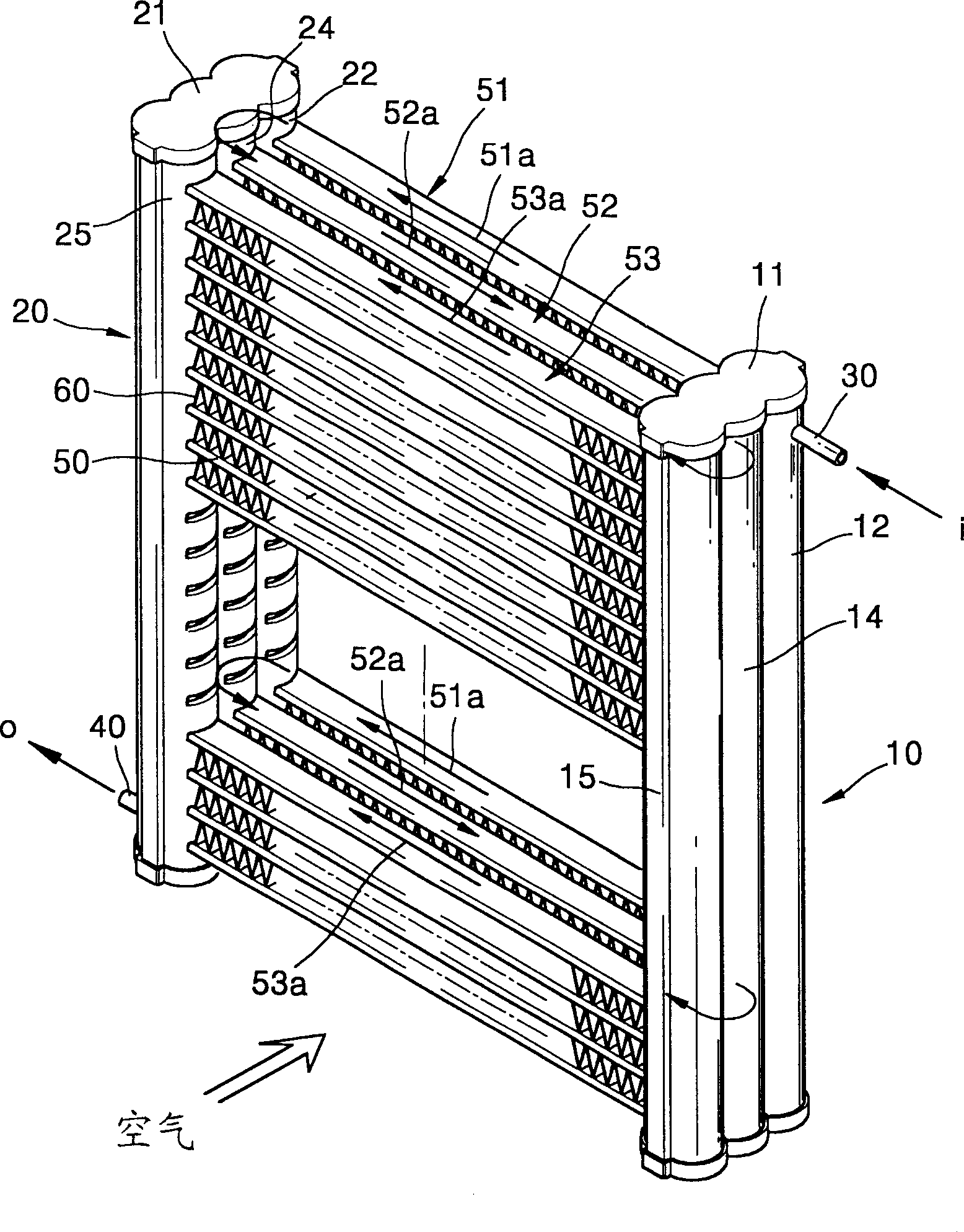

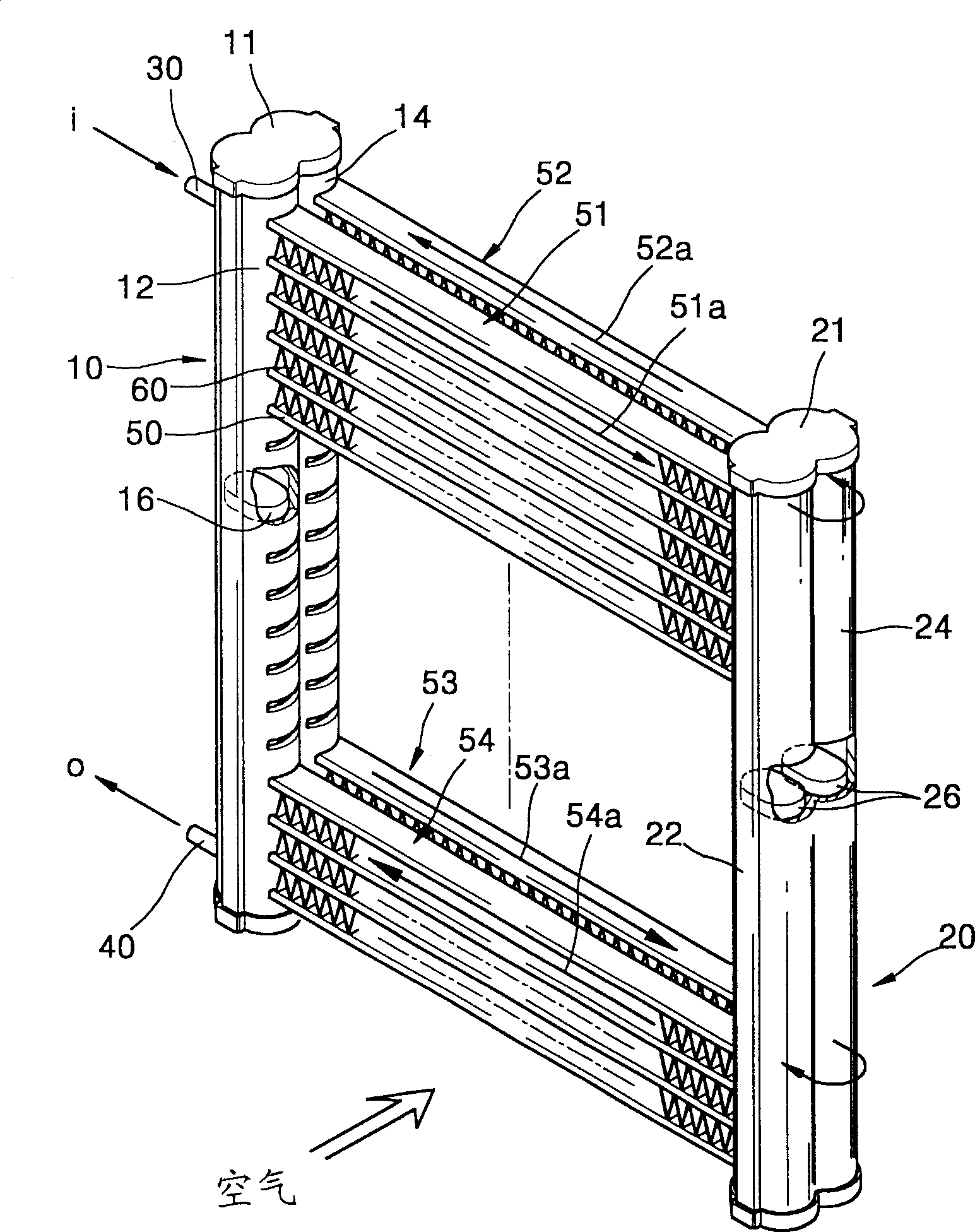

Heat exchanger

InactiveCN1410738AImprove pressure resistanceEvenly distributedReinforcing meansHeat exhanger conduitsWorking pressureHigh pressure

A heat exchanger uses a refrigerant acting under a high pressure, such as carbon dioxide, as a refrigerant. The heat exchanger includes first (10) and second (20) header pipes arranged a predetermined distance from each other and parallel to each other, each having at least two chambers (12,14,22,24) independently sectioned by a partition wall, a plurality of tubes (50) for separately connecting the chambers of the first (10) and second (20) header pipes, facing each other, wherein the tubes (50) are divided into at least two tube groups (51,52), each having a single refrigerant path, a refrigerant inlet pipe (30) formed at the chamber disposed at one end portion of the first header pipe (10), through which the refrigerant is supplied, a plurality of return holes (29) formed in the partition wall to connect two chambers adjacent to each other, through which the refrigerant sequentially flows the tube groups (51,52), and a refrigerant outlet pipe (40) formed at the chamber of one of the first and second header pipes connected to a final tube group of the tube groups along the flow of the refrigerant, through which the refrigerant is exhausted.

Owner:HANON SYST

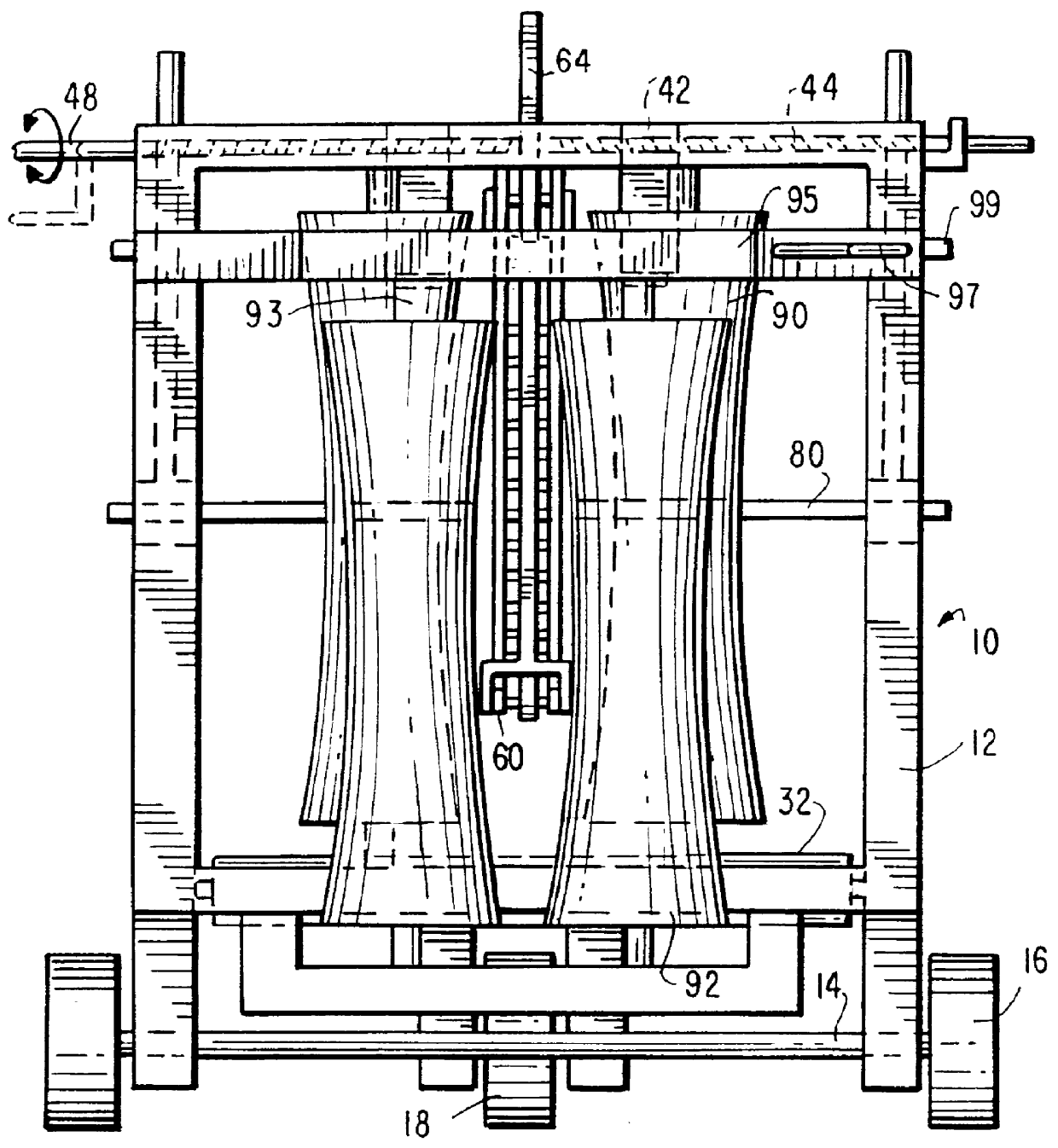

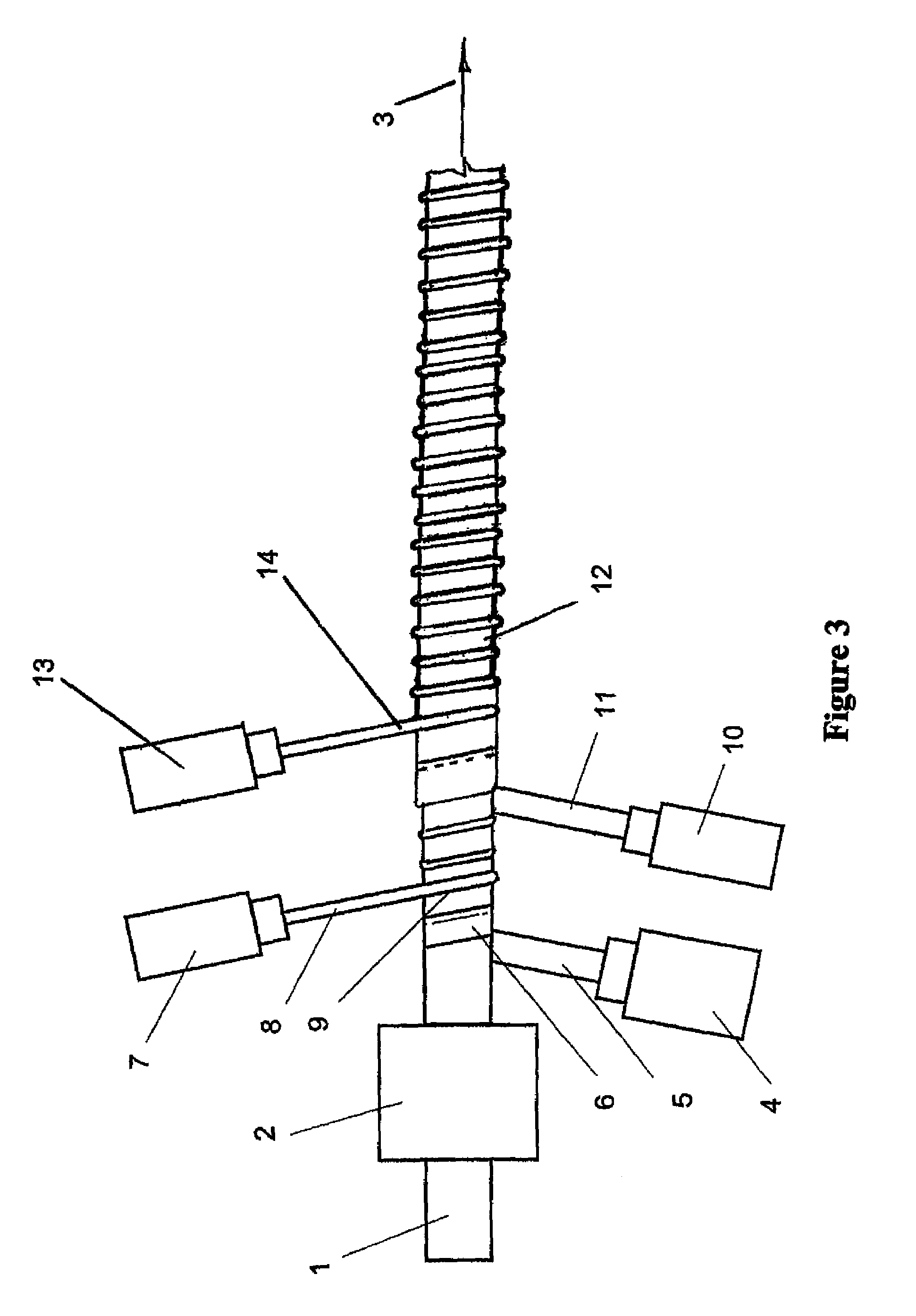

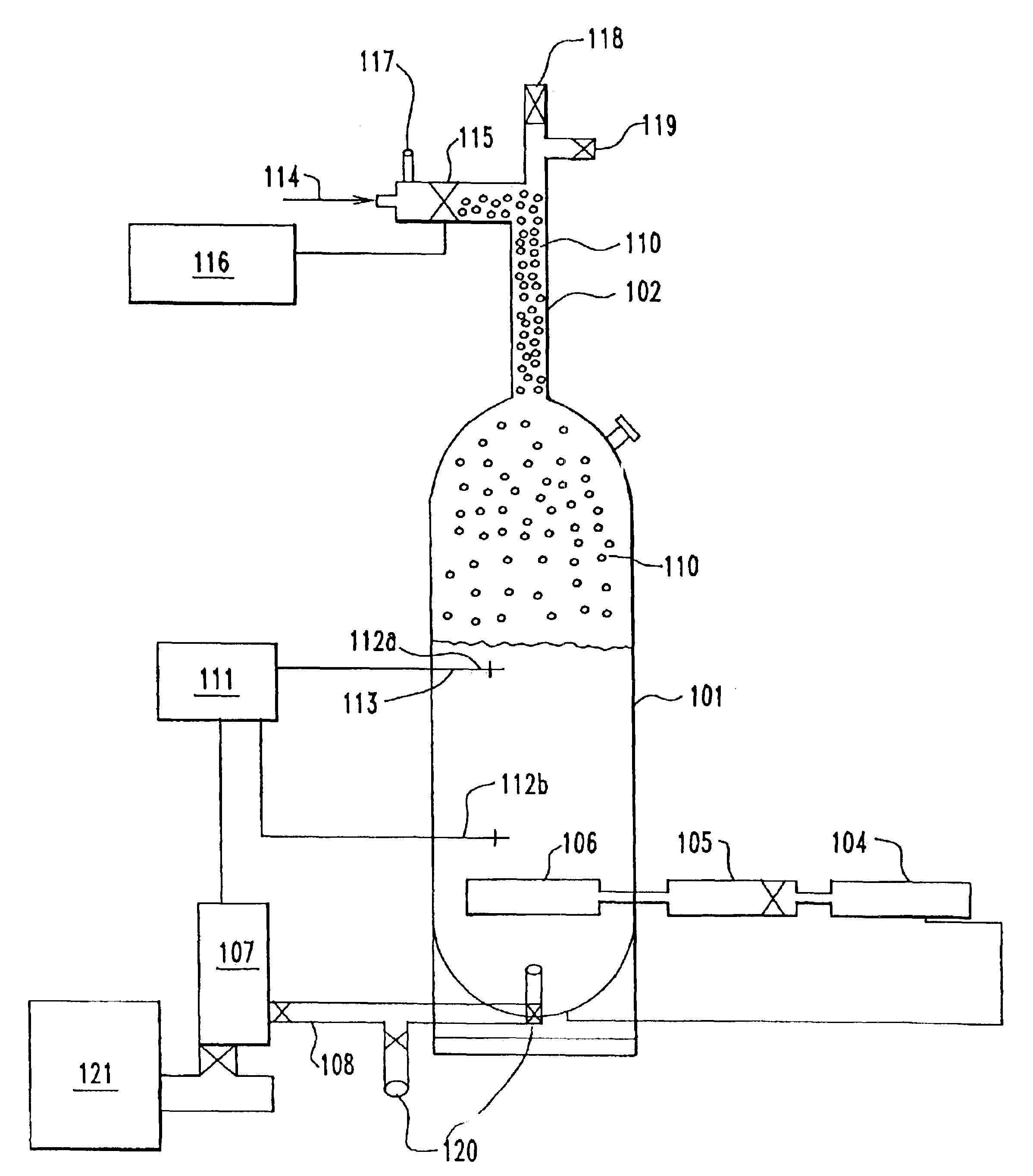

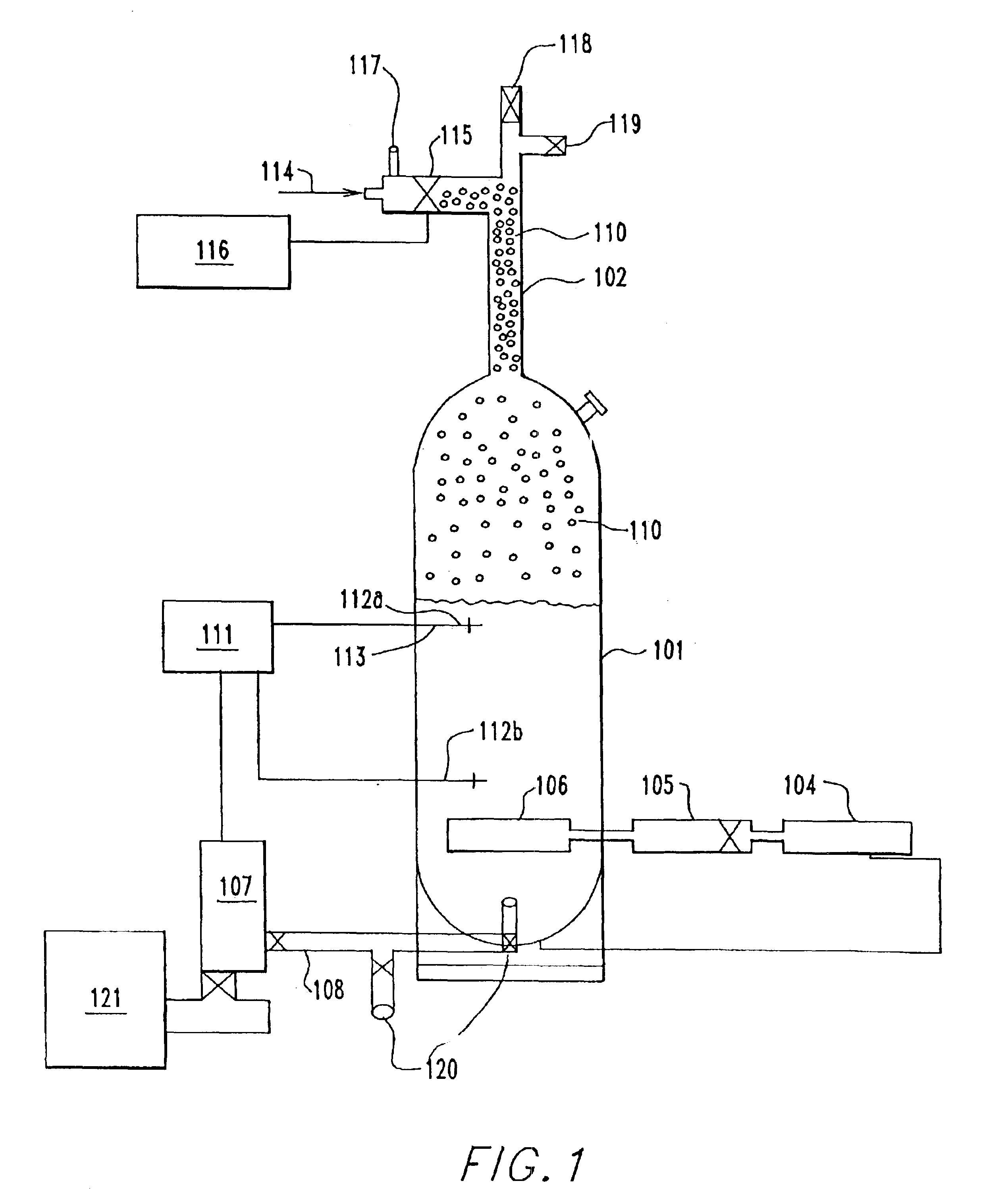

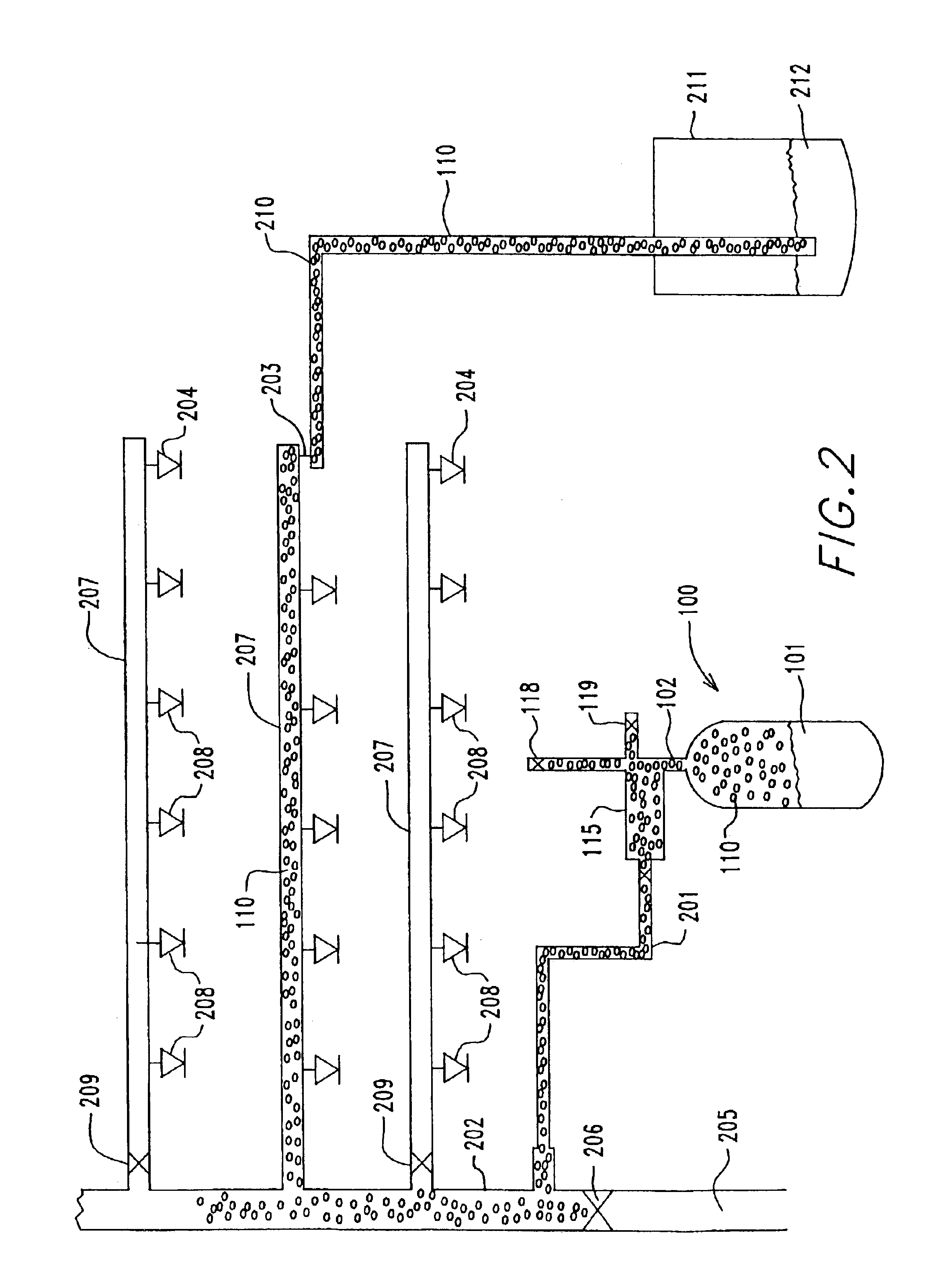

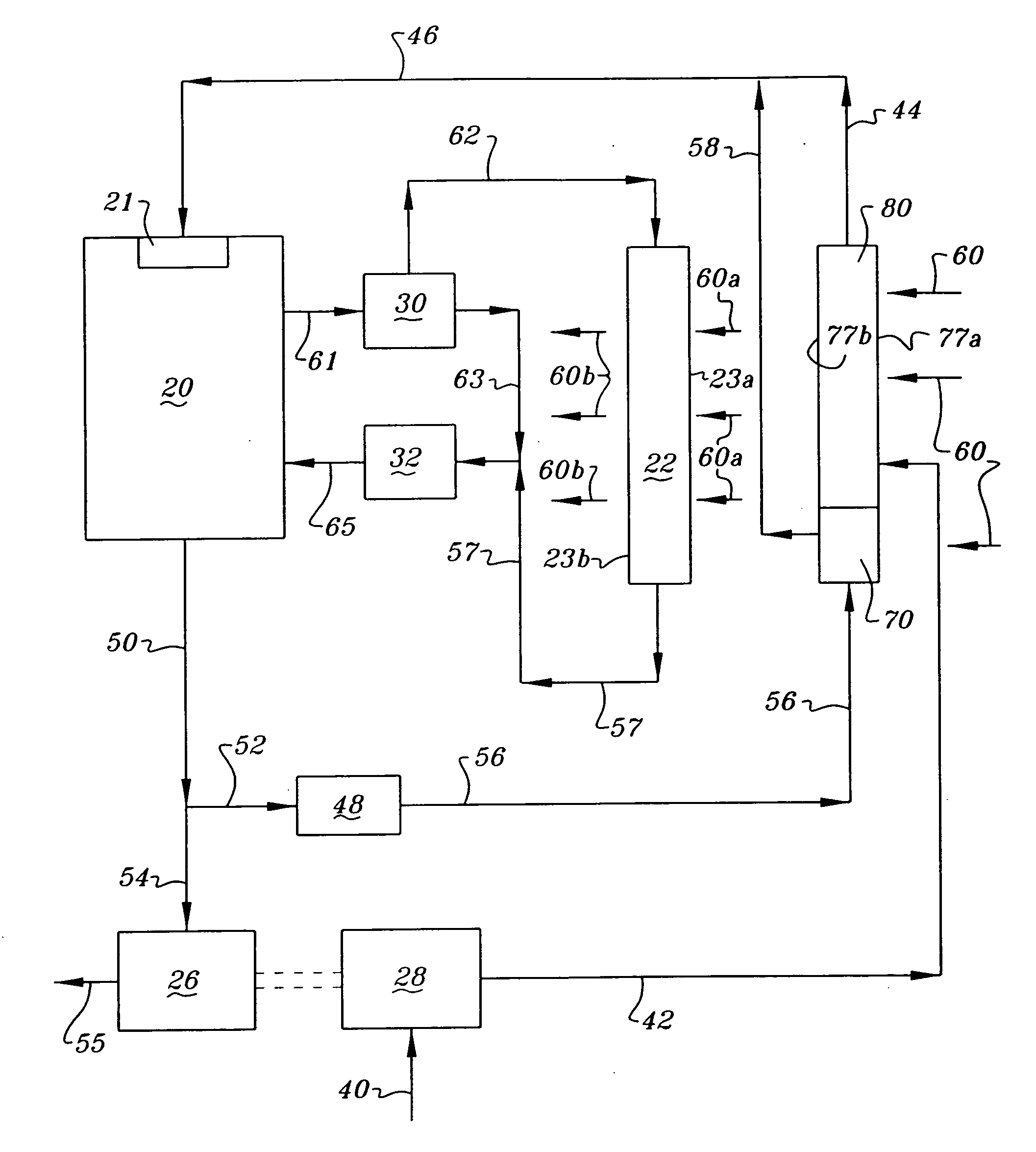

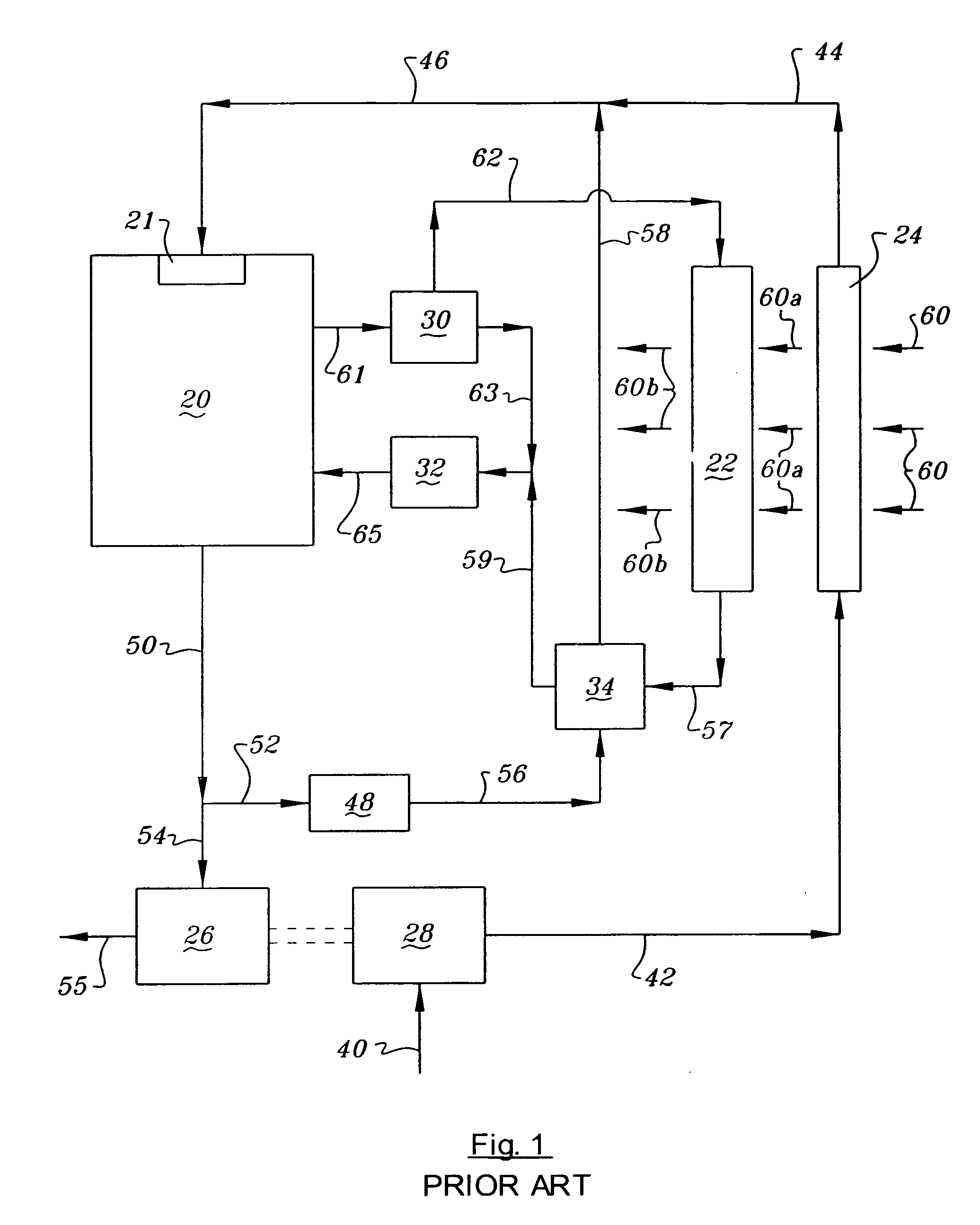

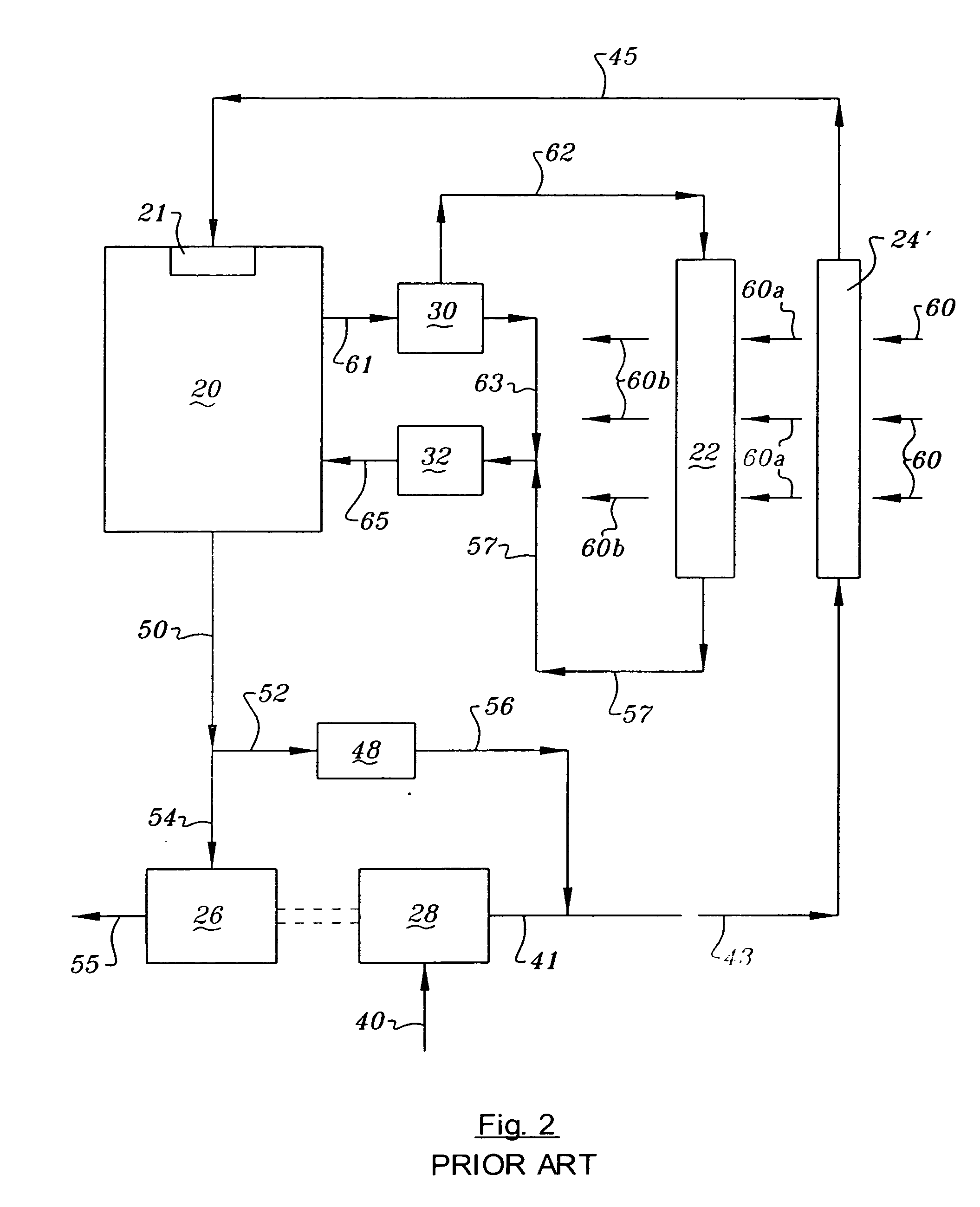

Isothermal reactor for exothermic or endothermic heterogeneous reactions

Owner:METHANOL CASALE SA

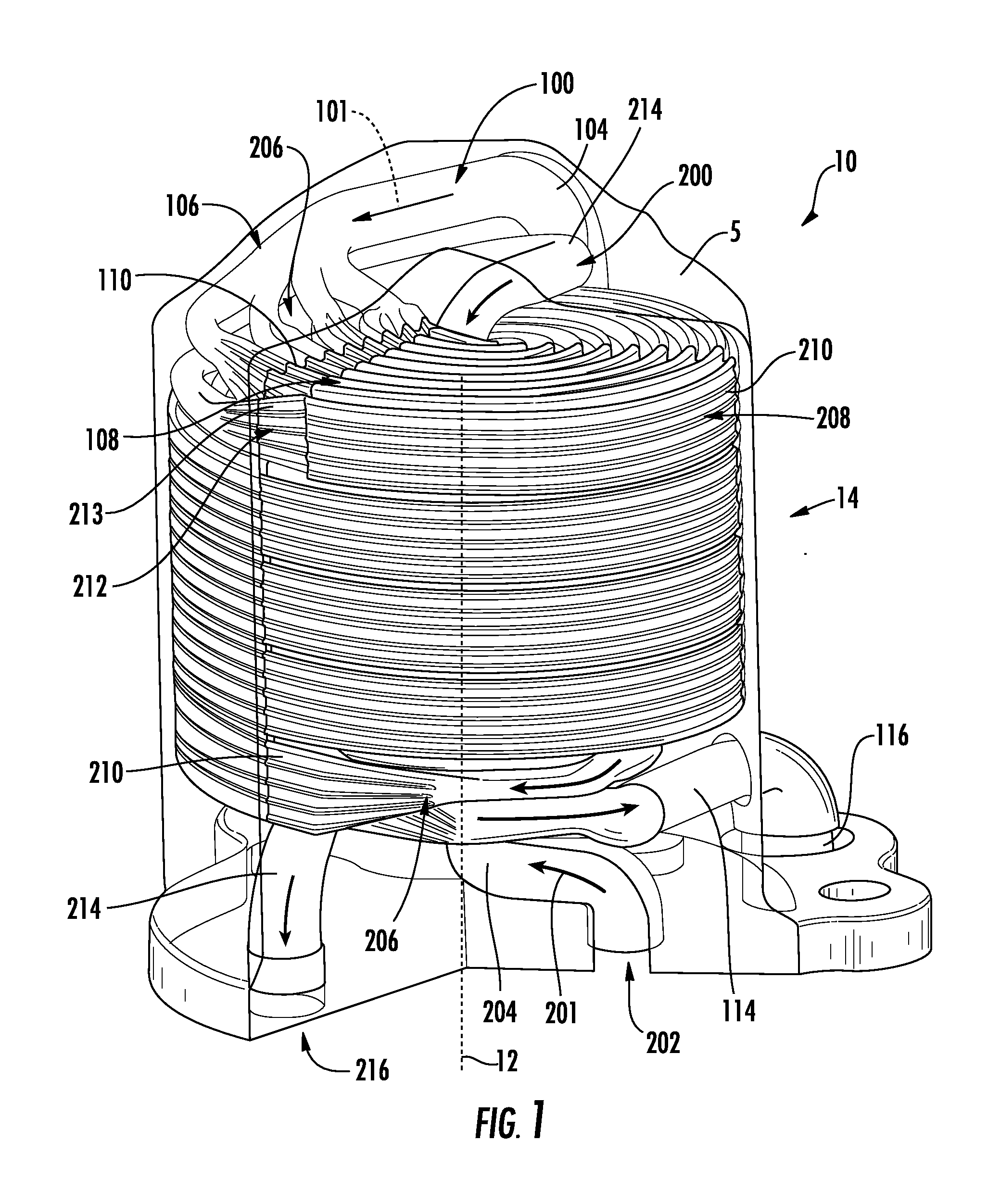

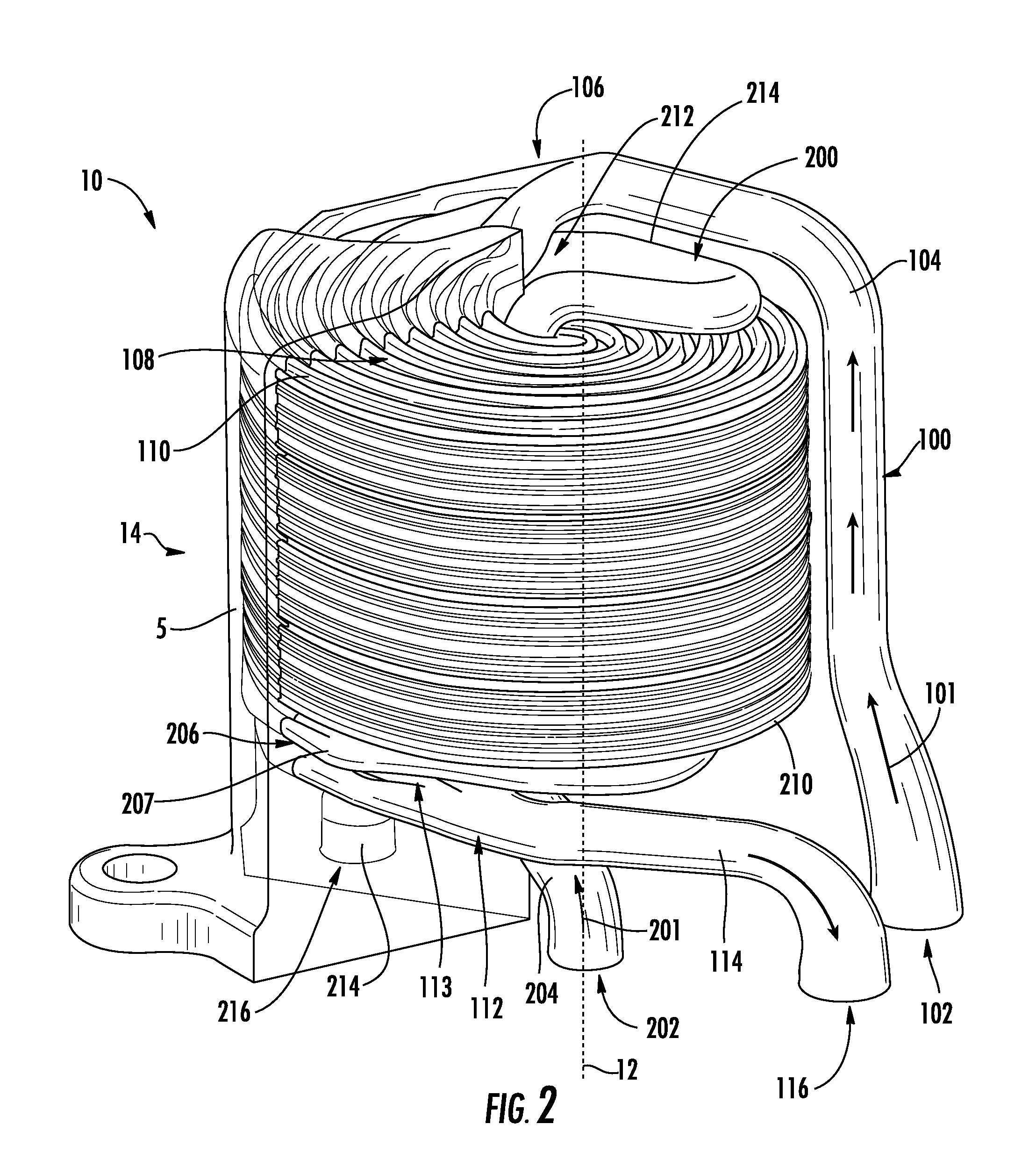

Cooling system and method for an electric motor

ActiveUS8080909B2Faster motor warm-upFast warm-upMagnetic circuit rotating partsHeat exhanger conduitsEngineeringInternal combustion engine

An electric motor which has a separate end cap heat exchanger, through which a liquid coolant is passed, is disclosed. In one example embodiment, the electric motor is a traction motor or motor-generator in a hybrid electric vehicle having an internal combustion engine. Additionally, in one embodiment, the heat exchanger has a low-temperature coolant loop configured to extract energy from the motor coolant. The electric motor may be installed in a variety of vehicles or other applications having greatly differing cooling requirements. By placing the heat exchanger and control componentry in the end cap, the cooling capability of the electric motor can be changed by selecting an end cap with the appropriate heat transfer characteristics and control componentry to provide the desired cooling. Consequently, a single electric motor, with a variety of end cap choices, can be used in a variety of applications.

Owner:FORD GLOBAL TECH LLC

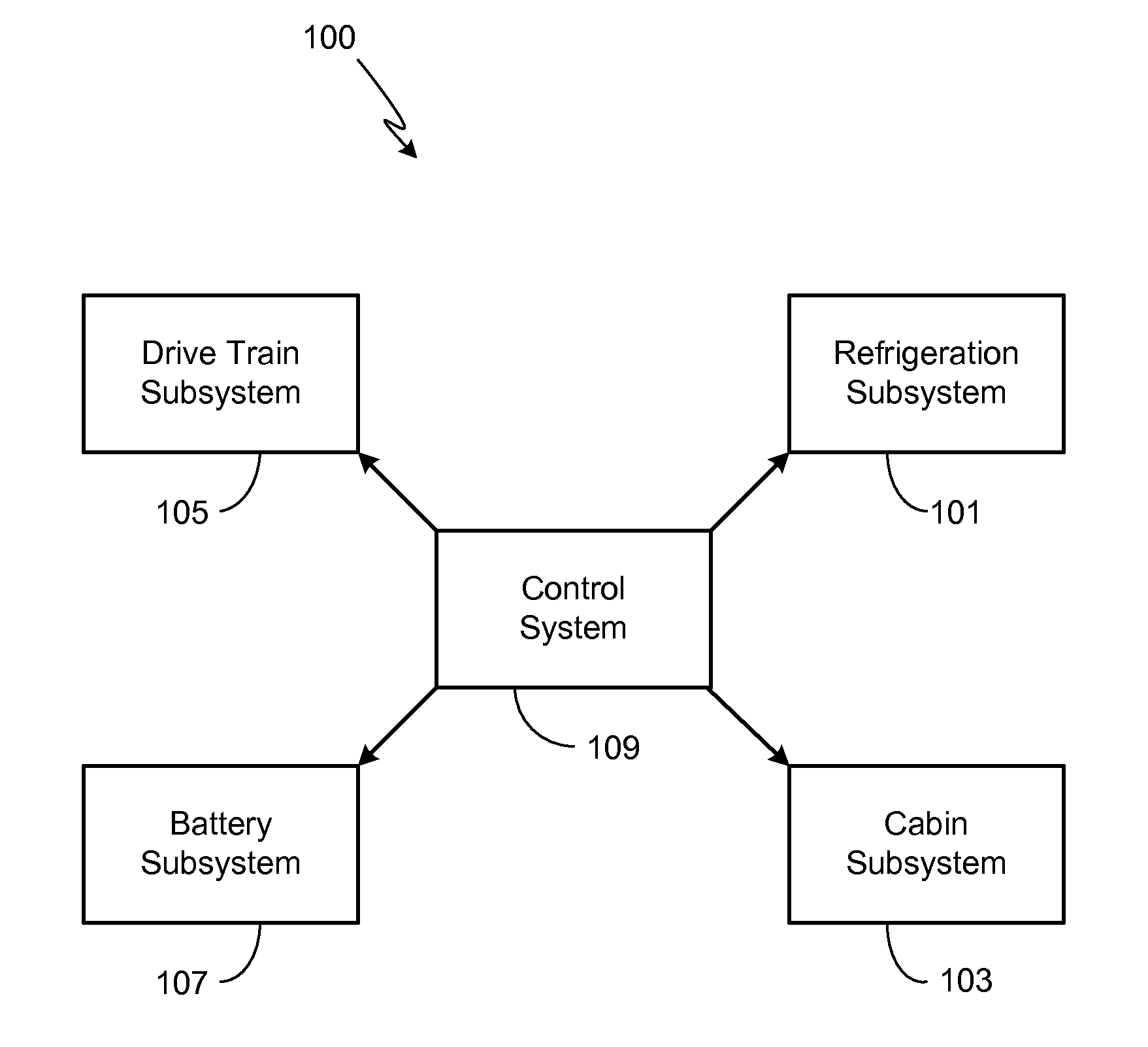

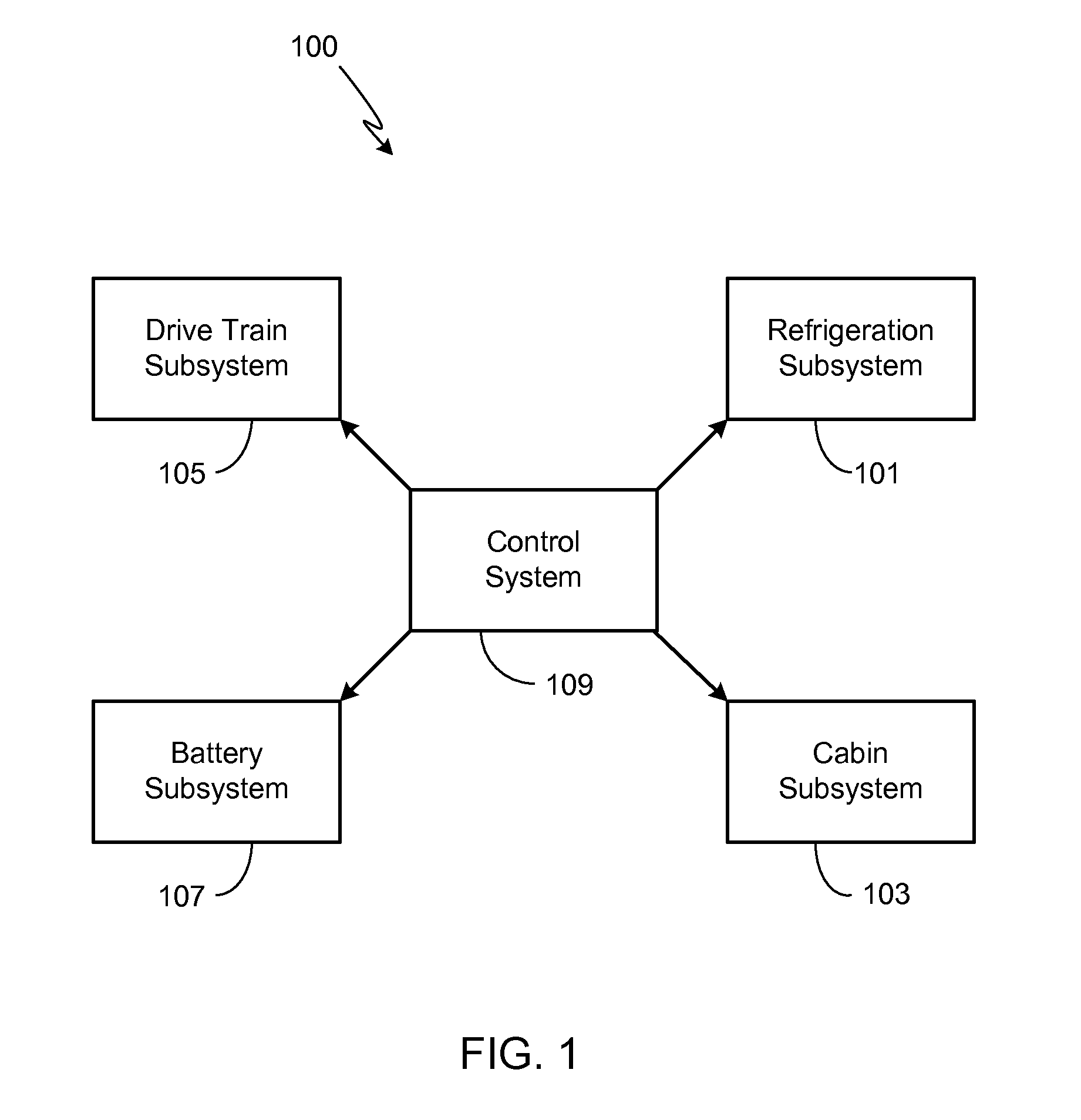

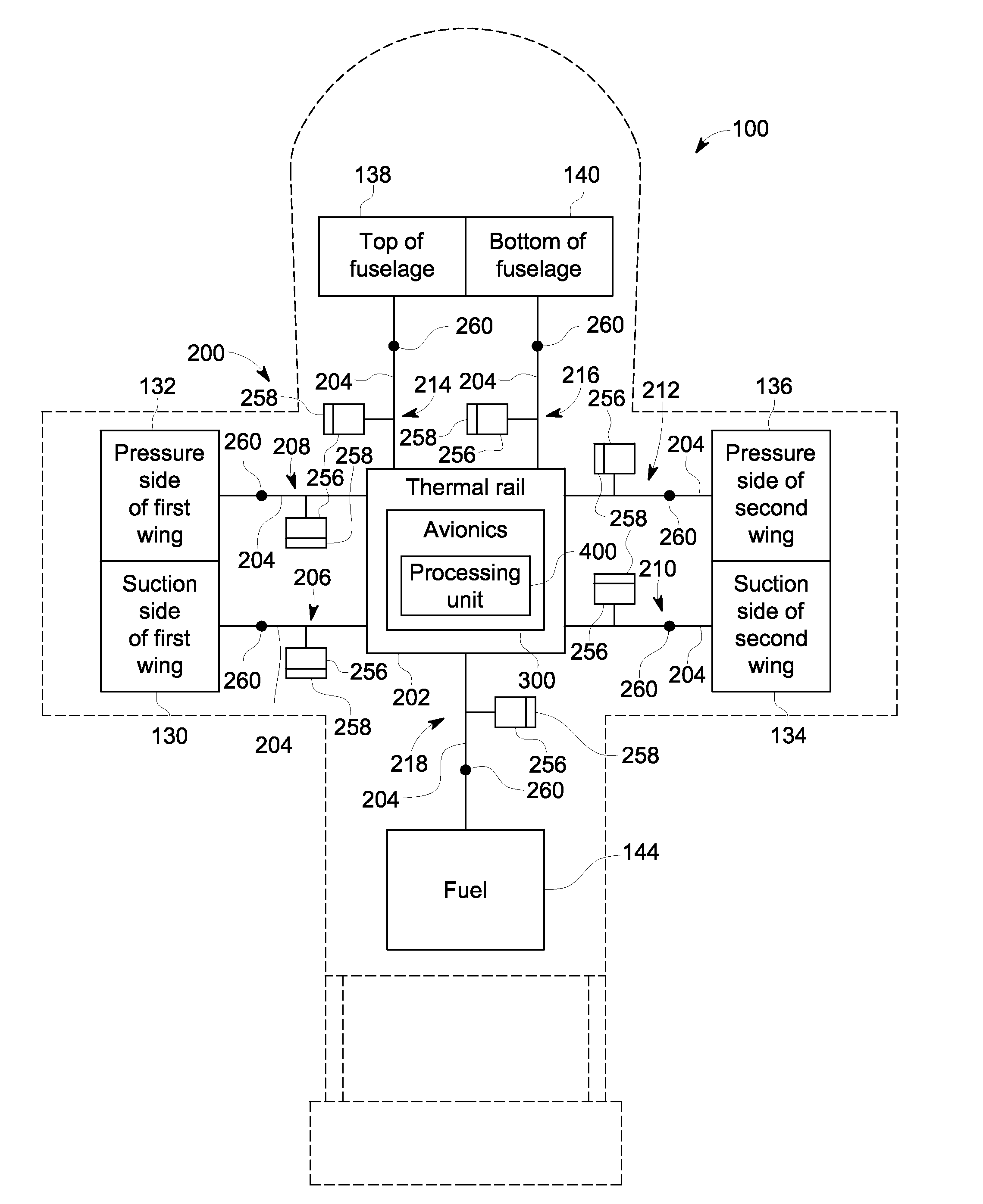

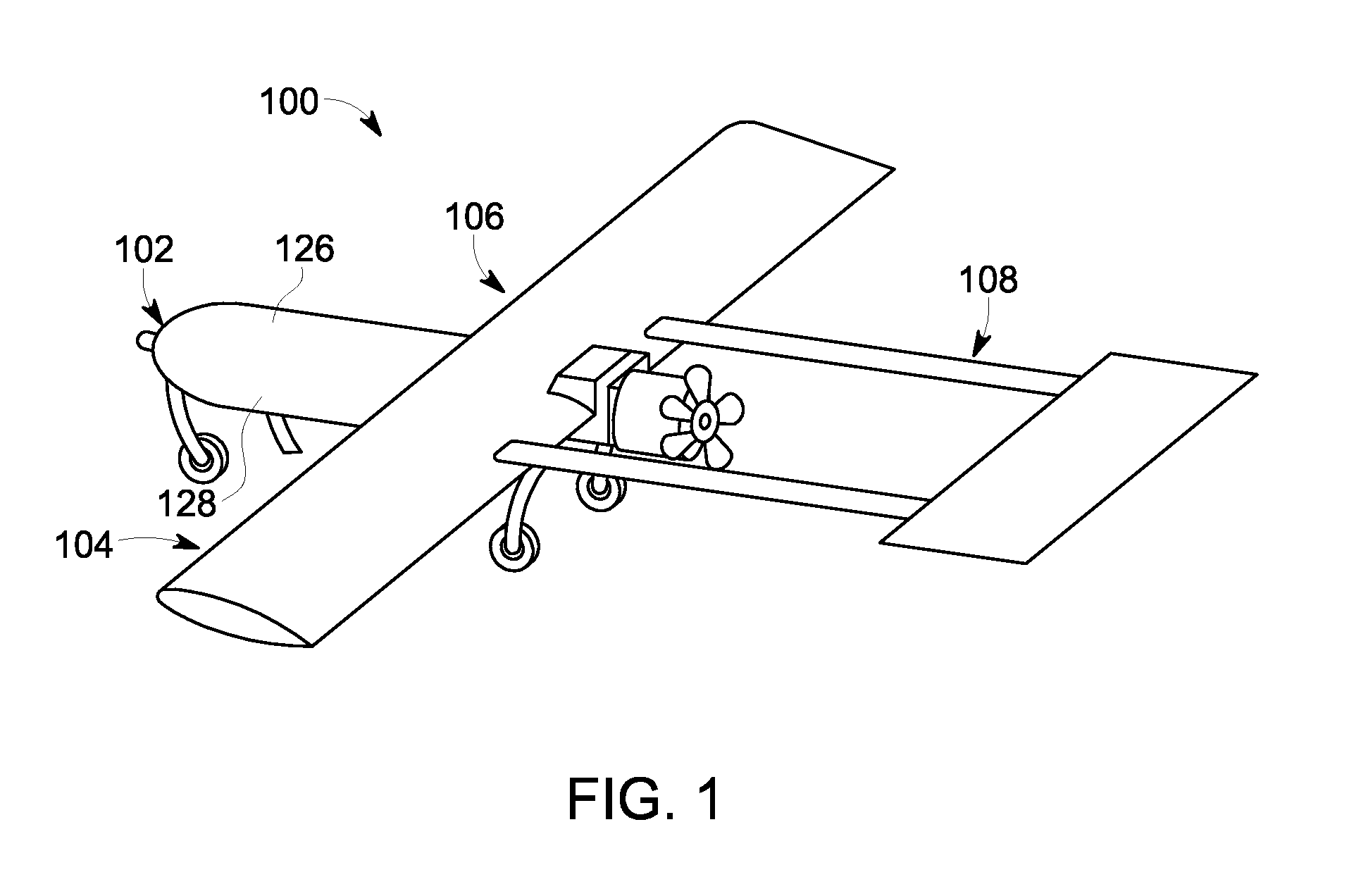

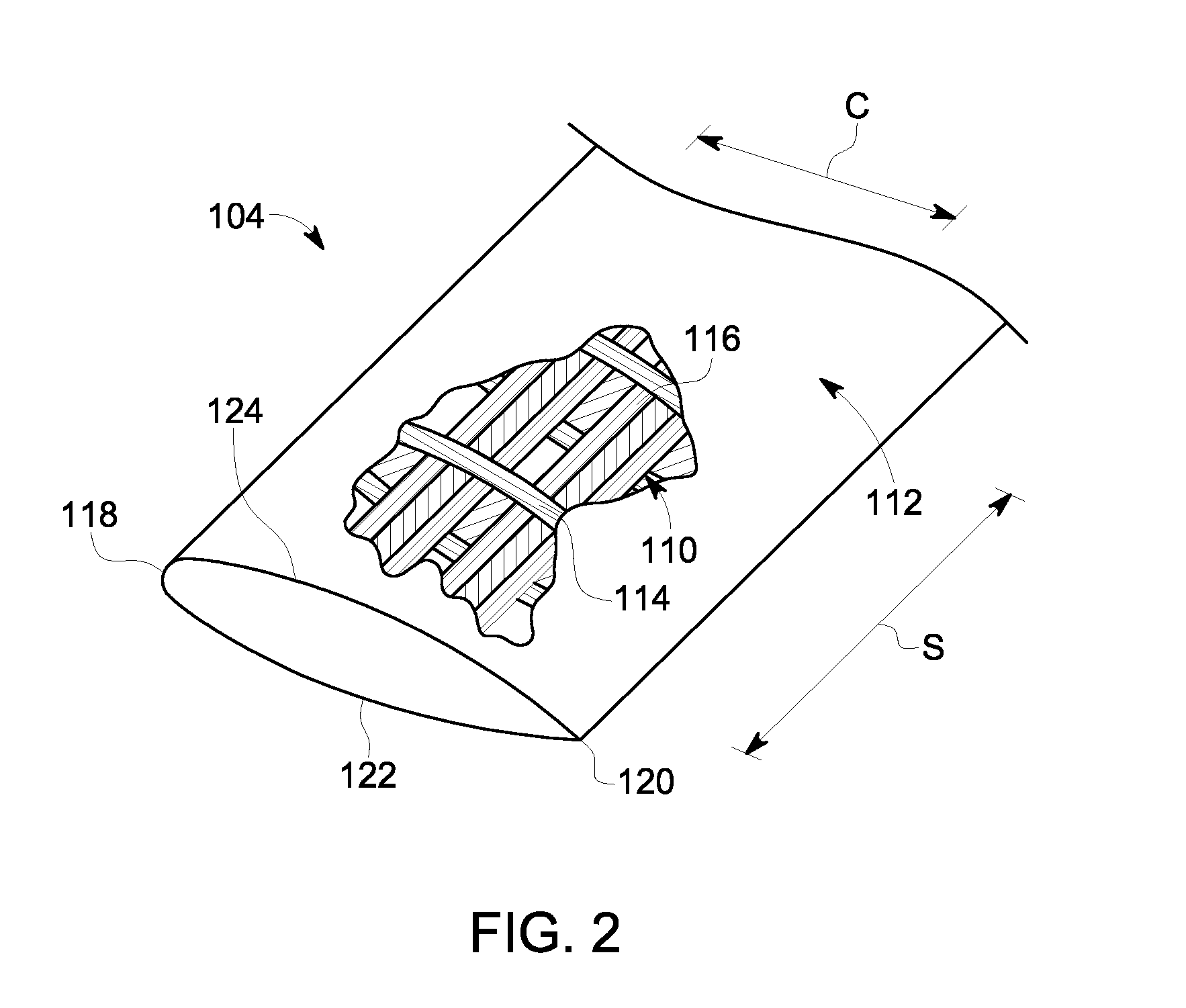

Thermal management system and method of assembling the same

InactiveUS20150068703A1Air-treating devicesAir-treatment apparatus arrangementsEngineeringThermal management system

A thermal management system for cooling a heat source onboard an aircraft that has a frame and a skin coupled to the frame such that the skin has a first segment and a second segment includes a first network of heat pipes coupled in conductive heat transfer with the heat source and the first segment of skin. The first network of heat pipes is configured to heat the first segment of skin using heat from the heat source. The thermal management system further includes a second network of heat pipes coupled in conductive heat transfer with the heat source and the second segment of skin. The second network of heat pipes is configured to heat the second segment of skin using heat from the heat source. The thermal management system is configured to selectively deactivate the first network of heat pipes and the second network of heat pipes.

Owner:GENERAL ELECTRIC CO +1

Thermoelectric cooling device using heat pipe for conducting and radiating

InactiveUS6351951B1Efficient and large conductionEfficient and large and dispersionHeat exhanger conduitsDomestic refrigeratorsThermoelectric coolingHeat conducting

A thermoelectric cooling device using heat pipes for heat conducting and dispersing, comprising a multi-bundle of the heat pipe conducting plates installed at the cold end of the thermoelectric cooling member and converged to condenser, a multi-bundle of the heat pipe heat exchangers installed at the hot end of the thermoelectric cooling member with fin plates or fin stripes and converged to the evaporator. It performs a fast cooling and heat dispersing by heat pipes and high efficient phase change and heat transport of the working medium. It can eliminate the heat exchange produced by the heat accumulation on the cold and hot ends, so as to run at the minimum operation temperature differences in order to obtain the maximum cooling capacity.

Owner:LUQUAN JIWEI ELECTRICAL APPLIANCE

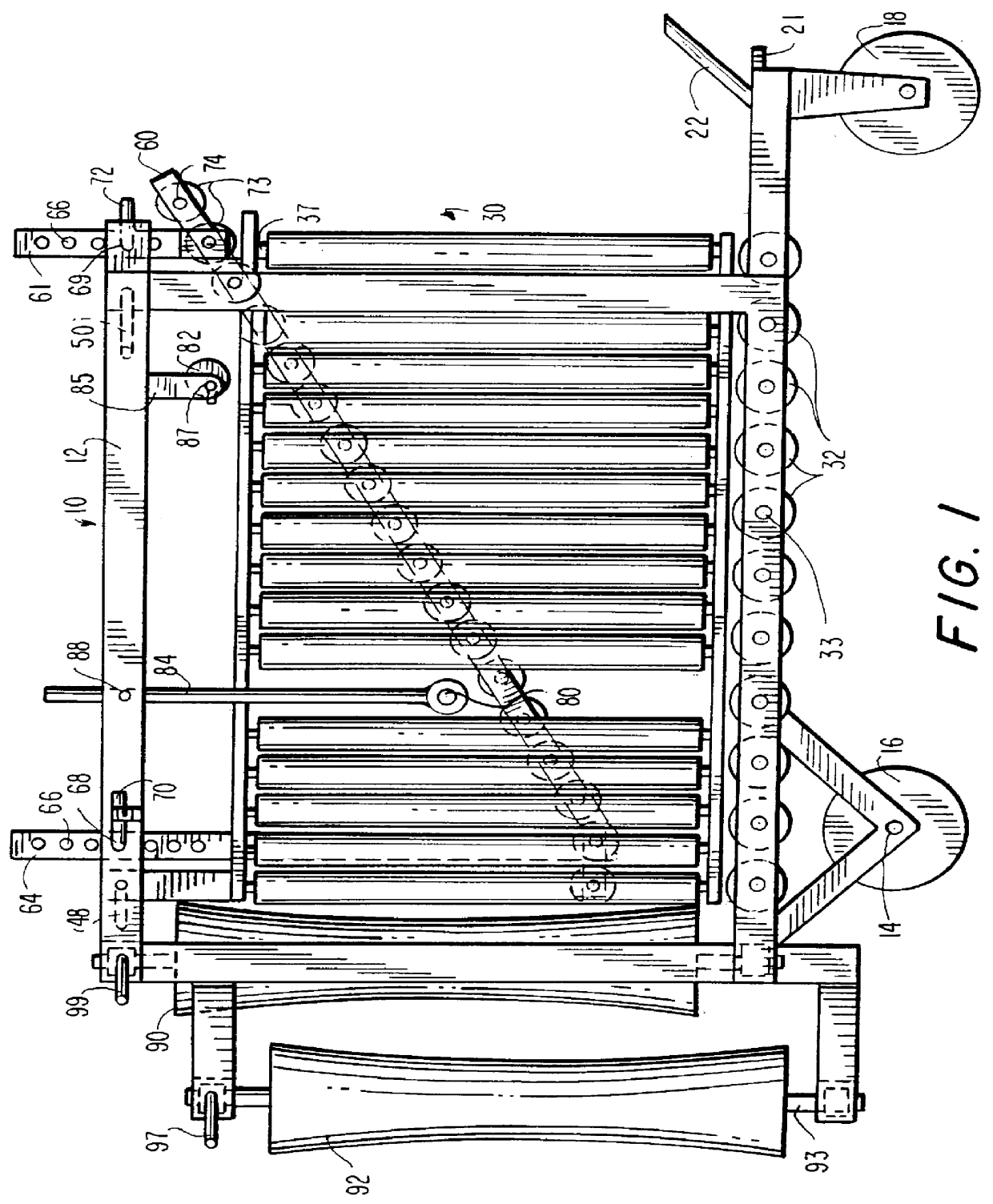

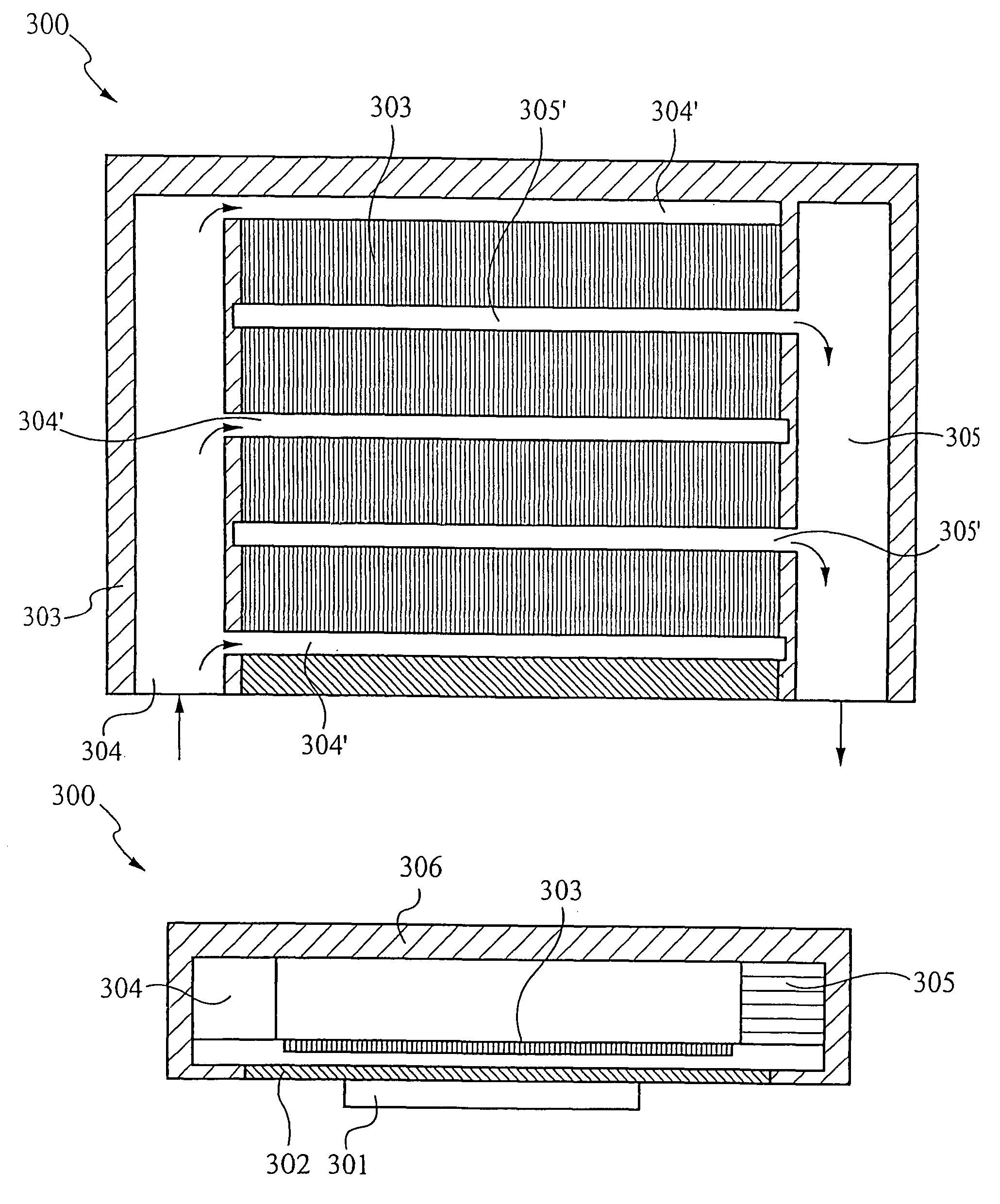

Optimal spreader system, device and method for fluid cooled micro-scaled heat exchange

ActiveUS7806168B2Increase heat transfer areaEfficient and economicalSemiconductor/solid-state device detailsHeat exhanger conduitsEngineeringConductive materials

A device, method, and system for a fluid cooled micro-scaled heat exchanger is disclosed. The fluid cooled micro-scaled heat exchanger utilizes a micro-scaled region and a spreader region with a highly thermally conductive material and sized to yield high heat dissipation and transfer area per unit volume from a heat source. The micro-scaled region preferably comprises microchannels.

Owner:VERTIV CORP

Flexible tube device

InactiveUS6105620AImprove adaptabilityCostHeat exhanger conduitsPipe elementsBending forceBiomedical engineering

Owner:HABERL JOHANN

Method for cooling an internal combustion engine having exhaust gas recirculation and charge air cooling

InactiveUS20070204614A1Low costSave spaceInternal combustion piston enginesExhaust apparatusTurbochargerExhaust fumes

A system for cooling charge air from a turbo- or supercharger and exhaust gas recirculated from an exhaust gas recirculation valve in an internal combustion engine. The system includes a rdiator and parallel charge air and exhaust gas heat exchanger units, the charge air heat exchanger unit having aluminum tubes and fins for air cooling the charge air, and the exhaust gas heat exchanger unit having stainless steel tubes and fins. The charge air heat exchanger and the exhaust gas heat exchanger units are each disposed adjacent the radiator, on the same or opposite sides. Alternatively, there is provided a pair of combined charge air cooler and exhaust gas cooler heat exchanger units, with a first heat exchanger unit having stainless steel tubes and fins, and a second heat exchanger unit having aluminum tubes and fins. The heat exchanger units are disposed on opposites sides of the radiator.

Owner:THERMAL SOLUTIONS MFG INC

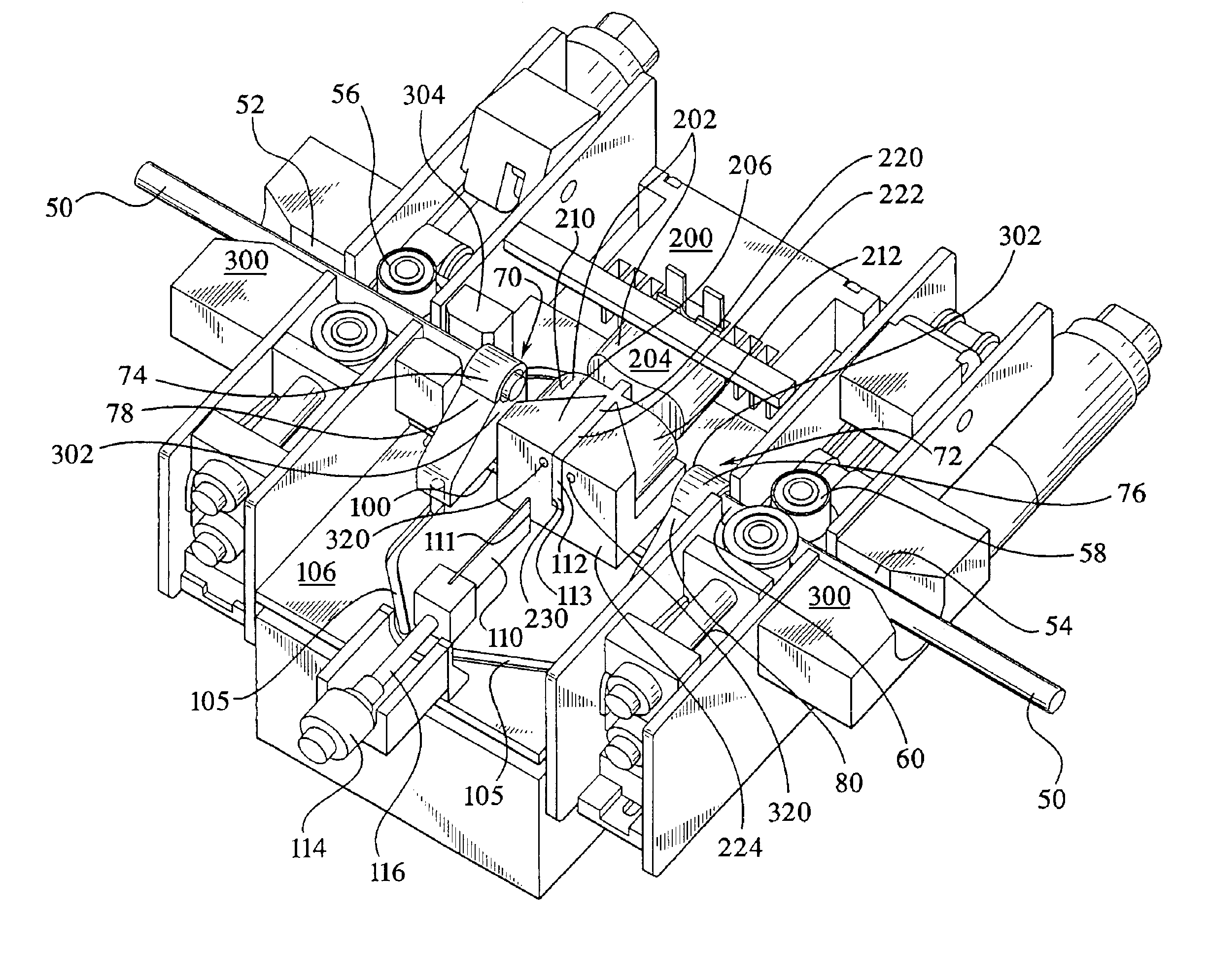

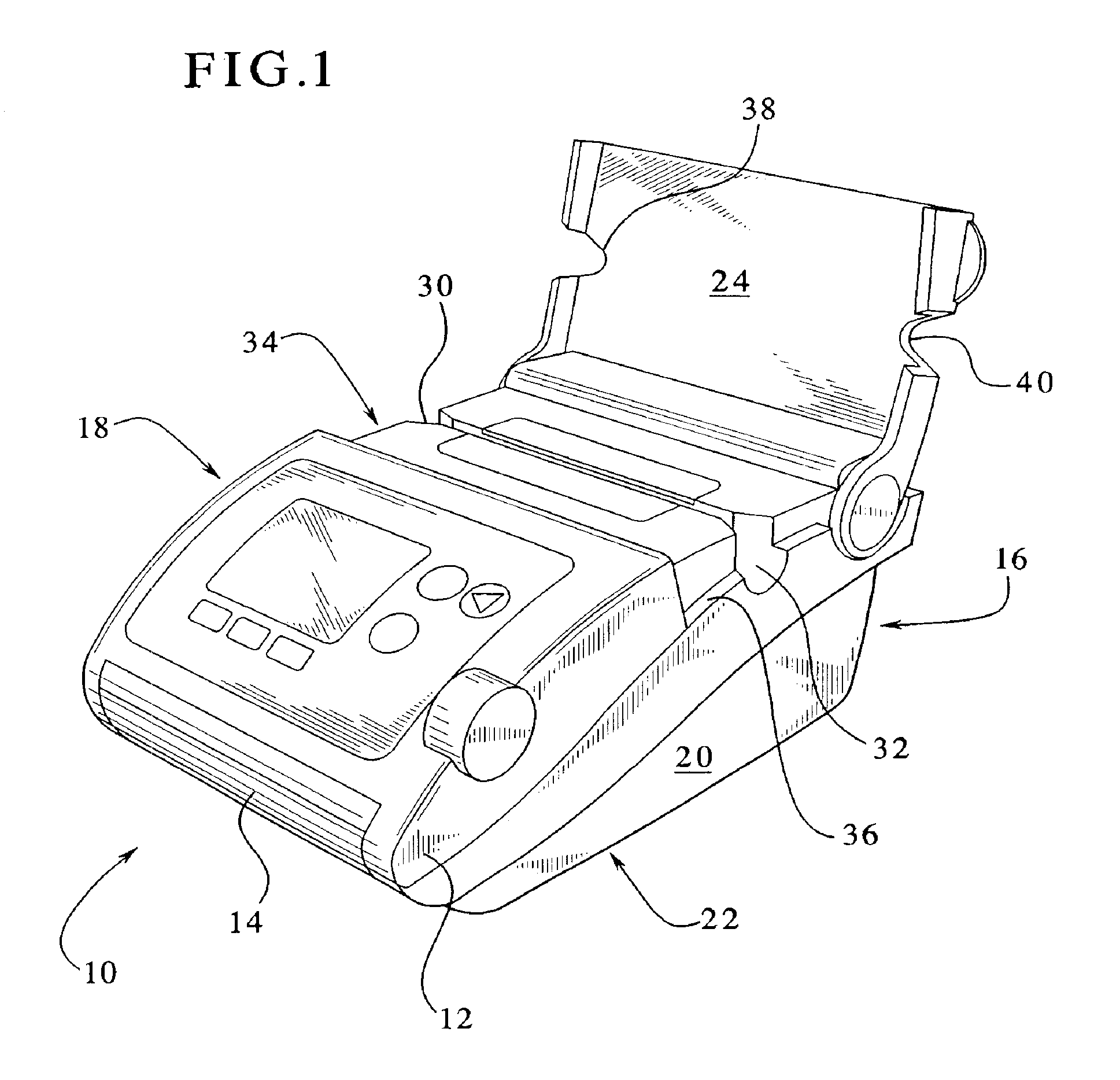

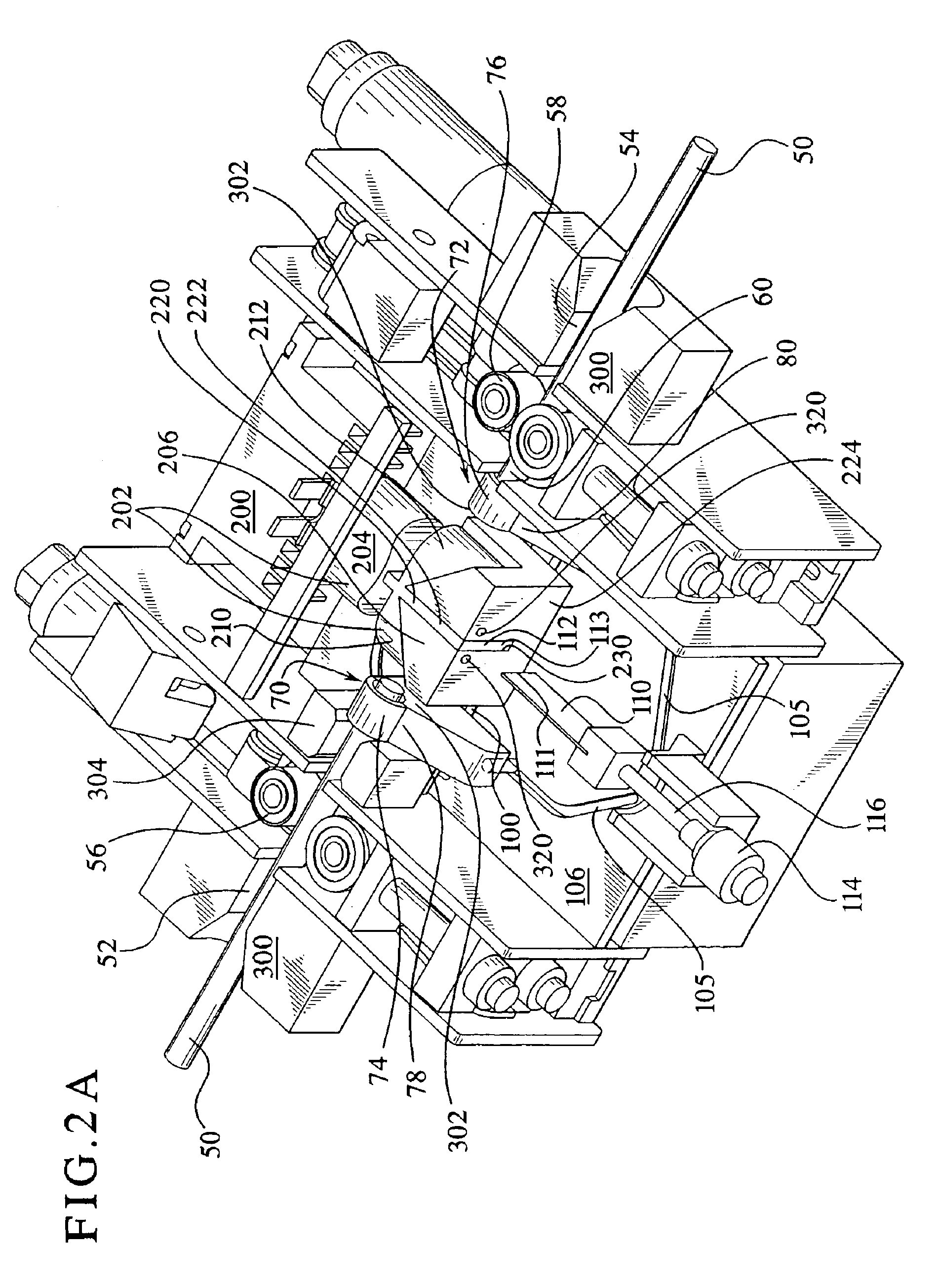

Apparatus and method for connecting and disconnecting flexible tubing

InactiveUS6913056B2Mechanical working/deformationWelding/cutting auxillary devicesMechanical engineeringLaser optics

A laser strikes and aseptically heats or sterilizes the end of two flexible tube ends for connection. Tube holders are pushed toward each other to bring the tube ends into contact. A weld detector checks the characteristics of the weld. A laser optics assembly may be used to change the direction of the laser and focus the laser at the tube ends. In addition, a crimping device is used to compress a single flexible tube for disconnection. The laser strikes the compressed area. The crimping device continues to pinch the area and forms a seal in the tube. The tube is separated into two tube segments, each segment has a sealed end.

Owner:BAXTER HEALTHCARE SA +1

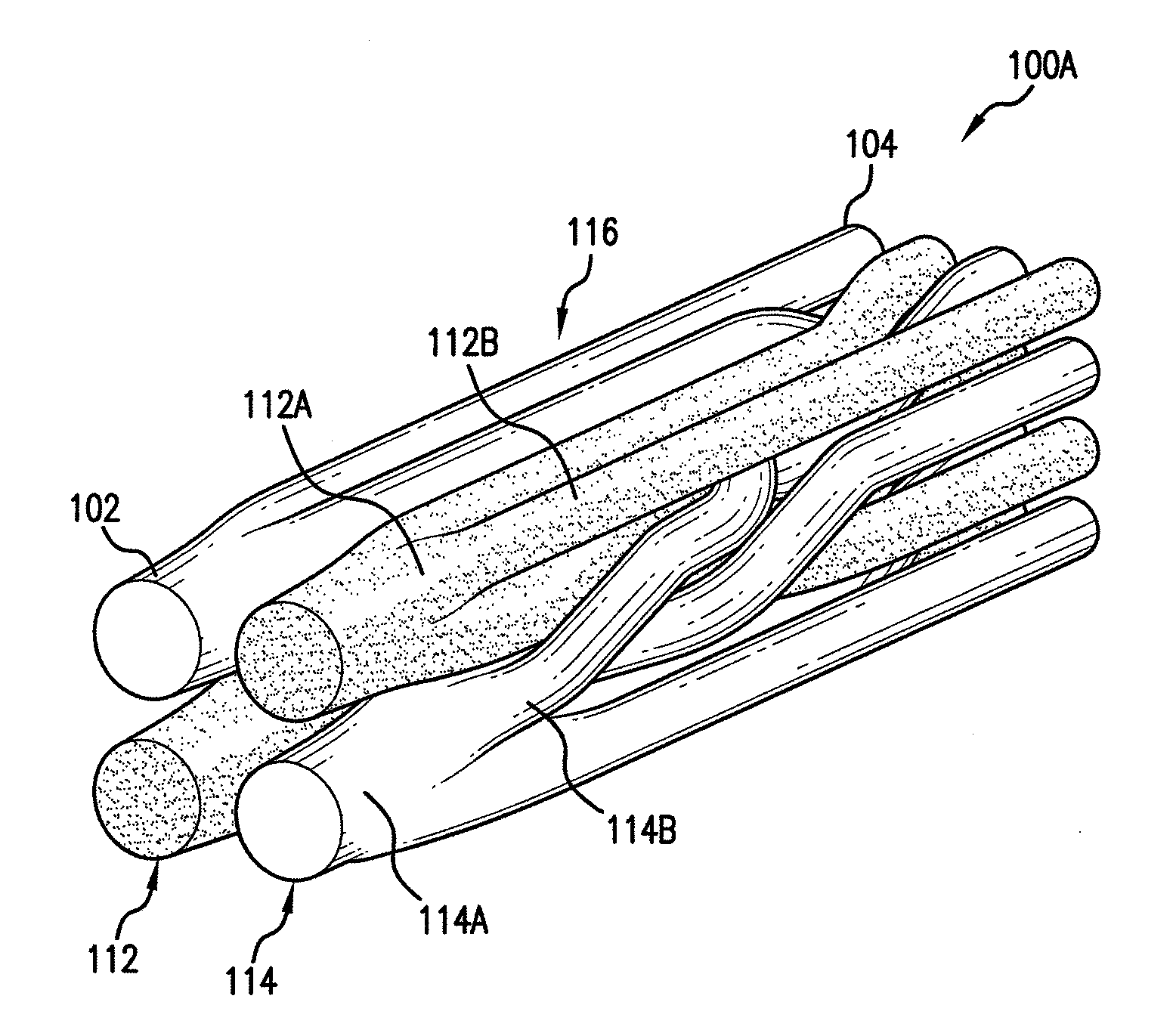

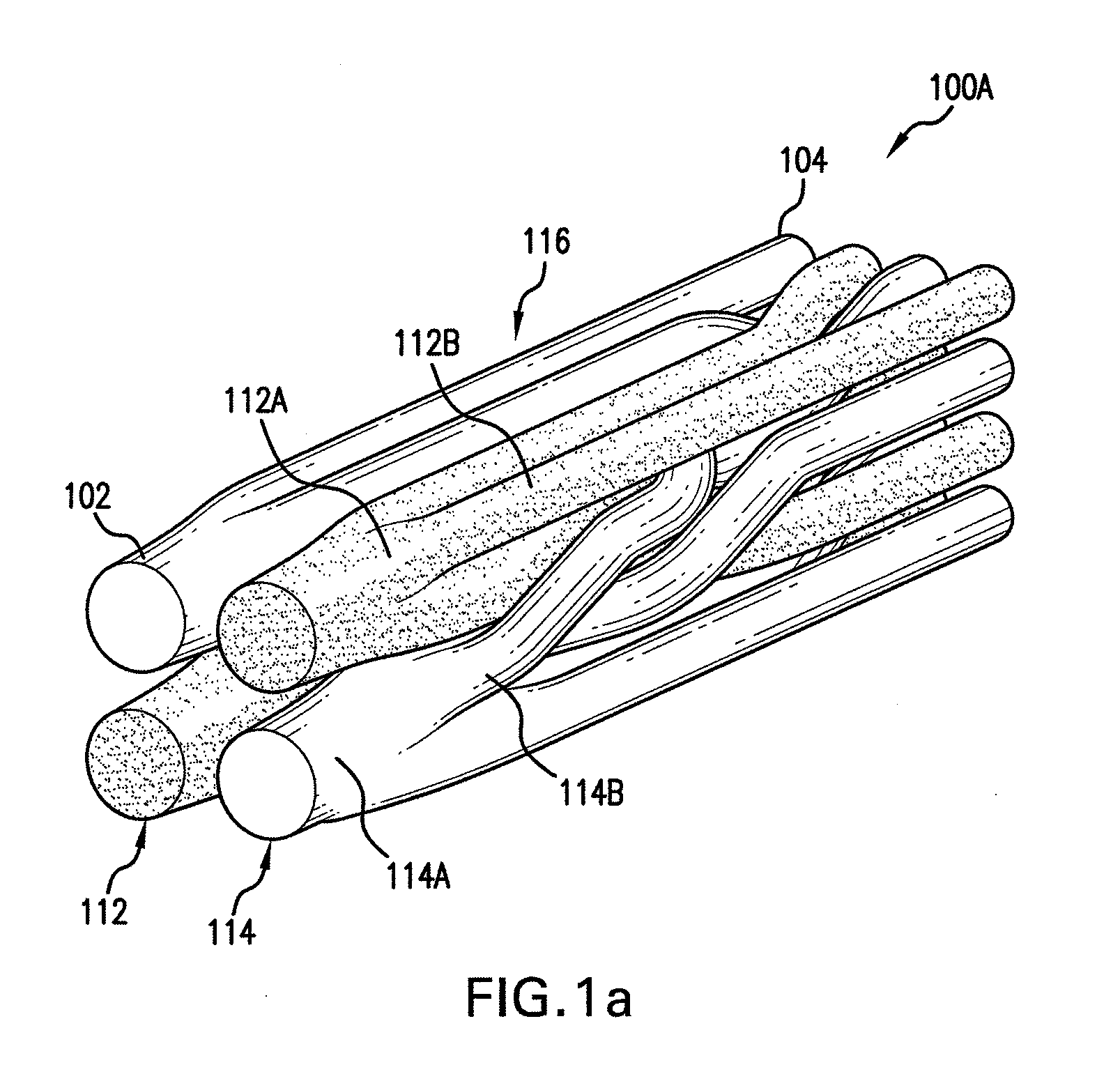

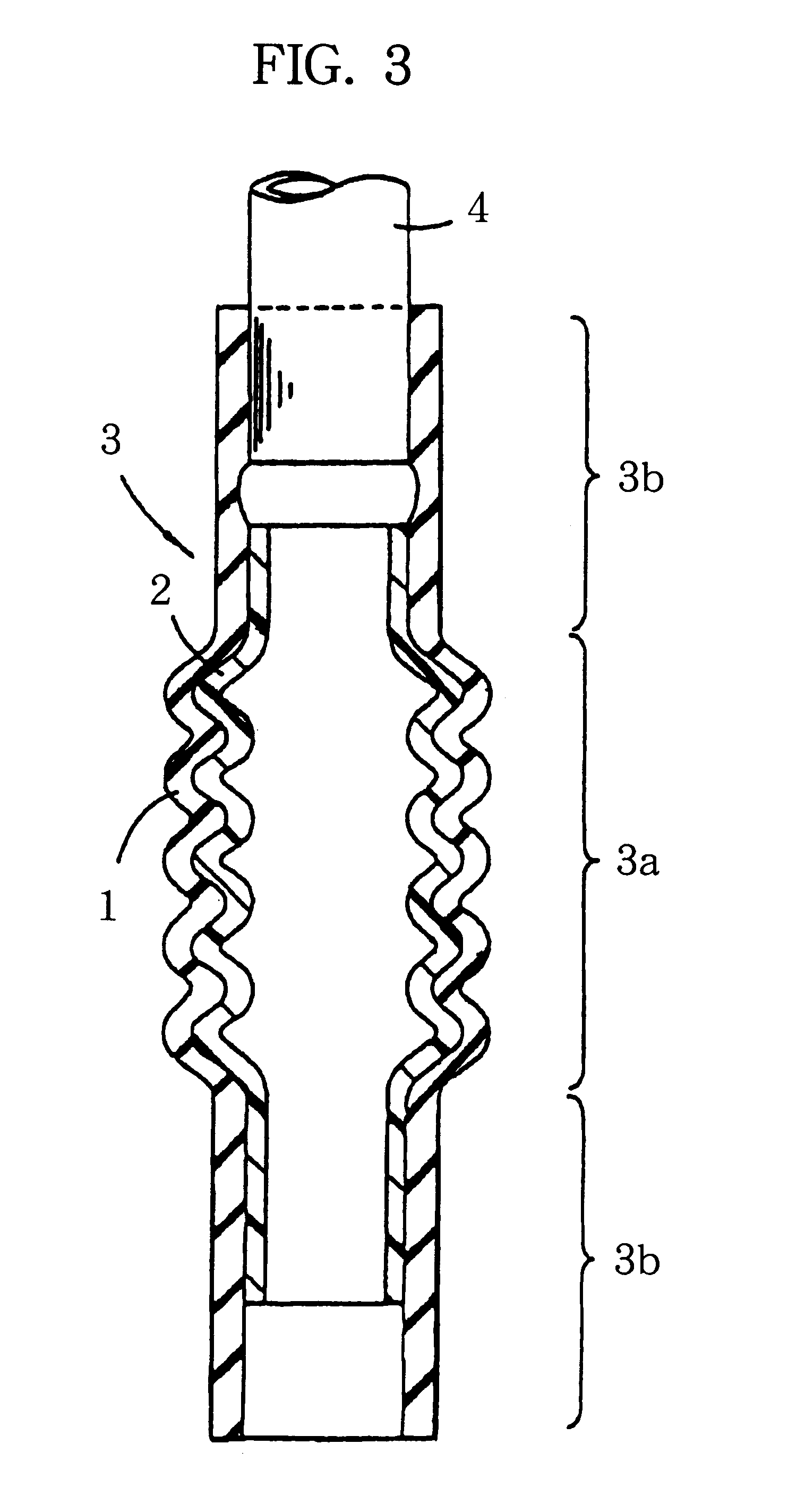

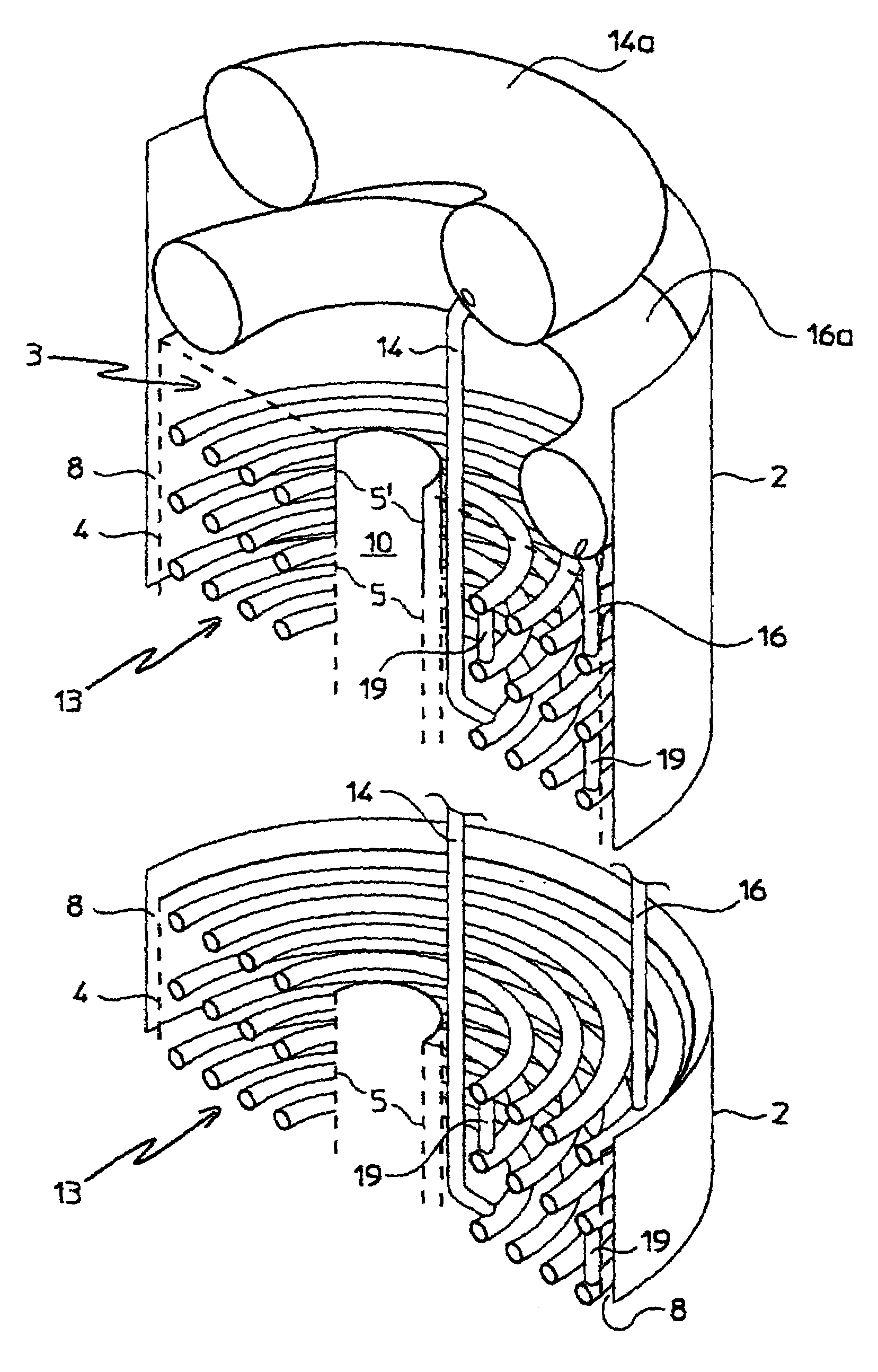

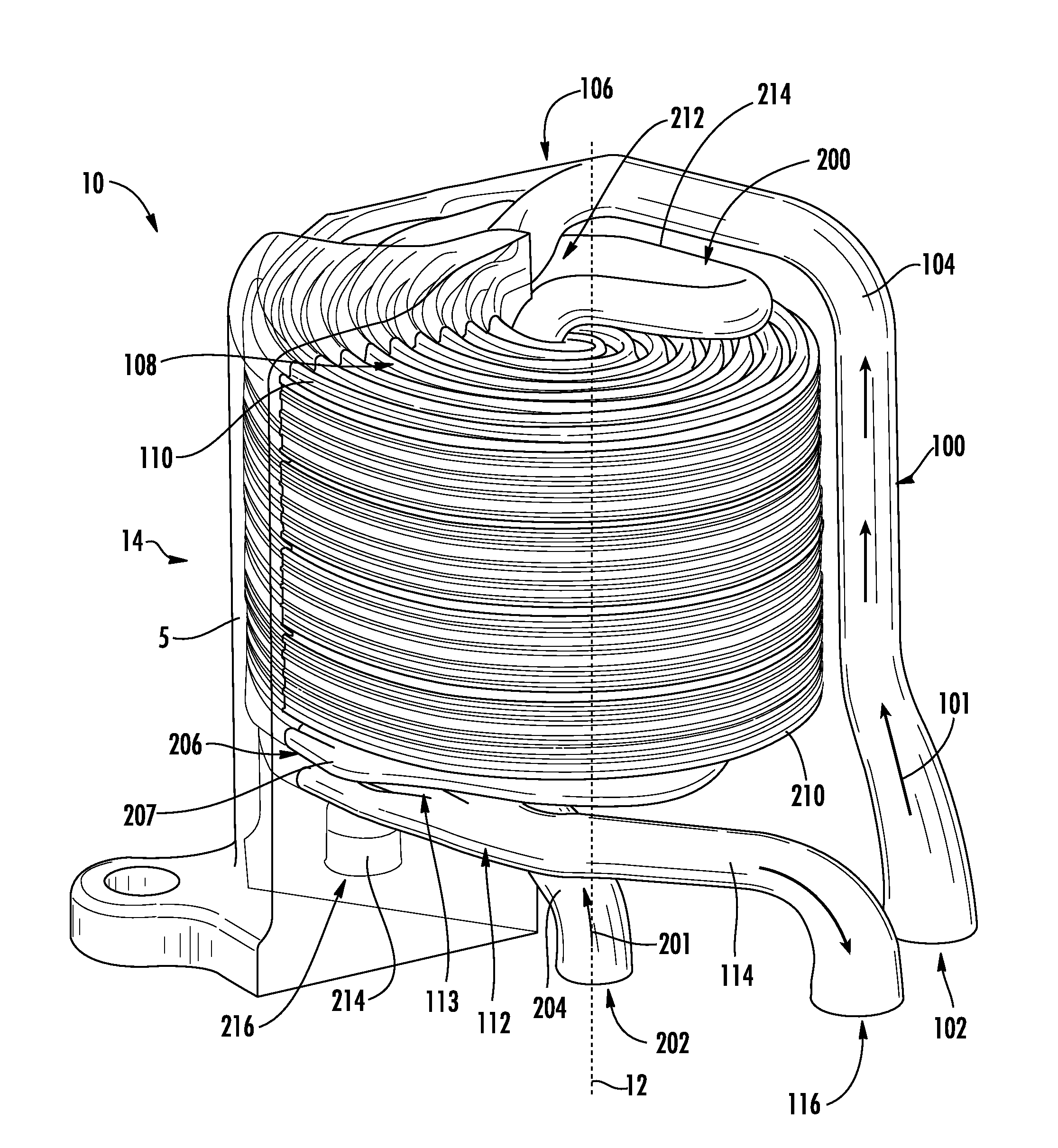

Counter-flow heat exchanger with helical passages

ActiveUS20170030651A1Heat exhanger conduitsStationary tubular conduit assembliesCounter flowEngineering

A counter-flow heat exchanger is provided that includes: a first fluid path having a first supply tube connected to a first transition area separating the first fluid path into a first array of first passageways, with the first array of first passageways merging at a first converging area into a first discharge tube; and a second fluid path having a second supply tube connected to a second transition area separating the second fluid path into a second array of second passageways, with the second array of second passageways merge at a second converging area into a second discharge tube. The first passageways and the second passageways have a substantially helical path around the centerline of the counter-flow heat exchanger. Additionally, the first array and the second array are arranged together such that each first passageway is adjacent to at least one second passageway.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com