Heat exchanger and use thereof in showers

a technology of heat exchanger and shower head, which is applied in the direction of heat exchanger conduit, heat exchanger type, domestic hot water supply system, etc., can solve the problems of wasting energy, substantial amount of hot water being lost down the drain, and not providing the necessary equipment for showering, etc., to achieve the effect of improving mixing and heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

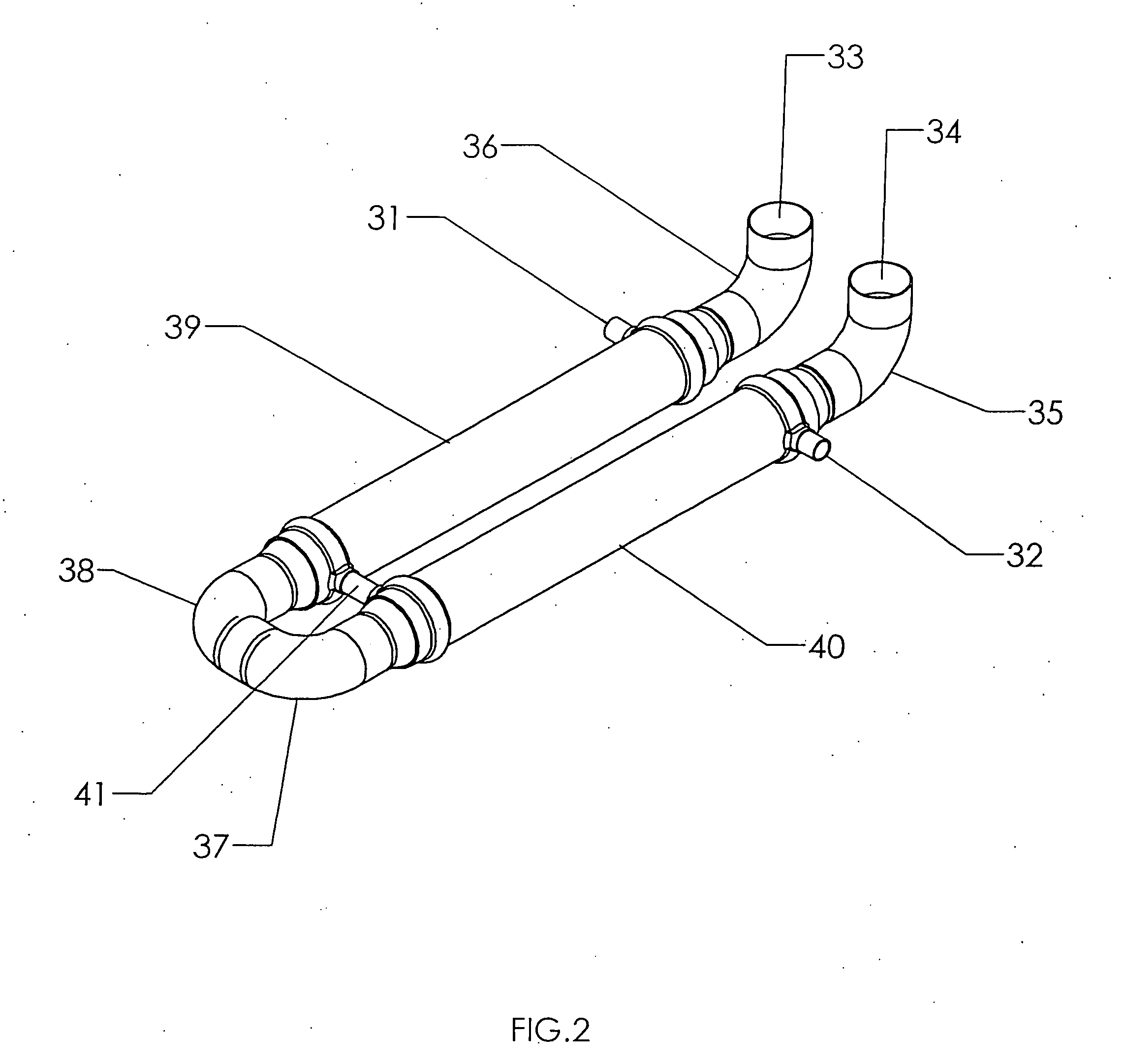

[0072] A heat exchanger of the general design depicted in FIG. 8 (without the sleeve layer 47 shown in FIGS. 6 and 7) was constructed from copper. The first (inner) conduit was 92 centimeters long, formed from a single first copper tube having an inner diameter of 1.5 inches and a wall thickness of 0.080 inches. Symmetrical helical convolutions were generated by a hydroforming process wherein the first copper tube was placed in a die containing the desired geometry of the desired convolutions, and expanded from the interior using a pressurized fluid against said die. Thus, the first copper tube took the outer shape corresponding to the die shape. The inner diameter of the thus convoluted first conduit ranged from 3.8 to 5.1 centimeters, with a helical pitch of 1.25 inches. The convoluted first conduit was then inserted into a single second copper tube (corresponding to feature 42 in FIG. 8) having a wall thickness of 0.058 inches, wherein the inner diameter was equal to or slightly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com