Patents

Literature

192results about How to "Process conditions are stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

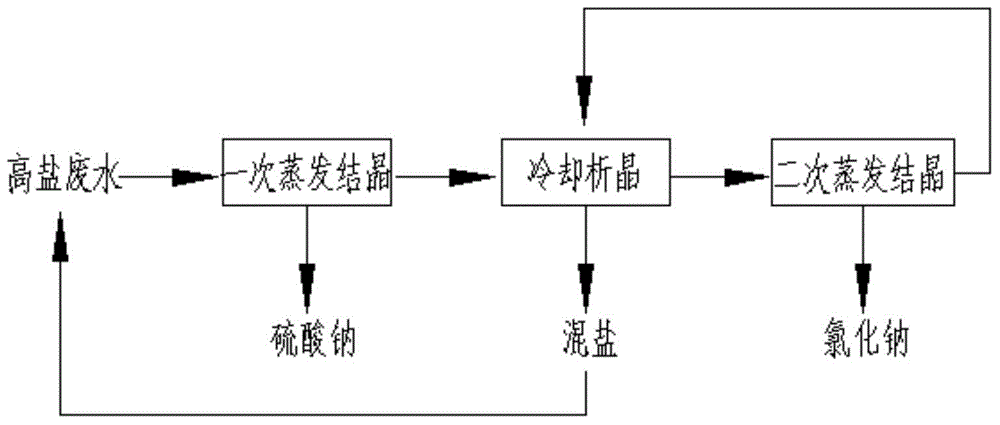

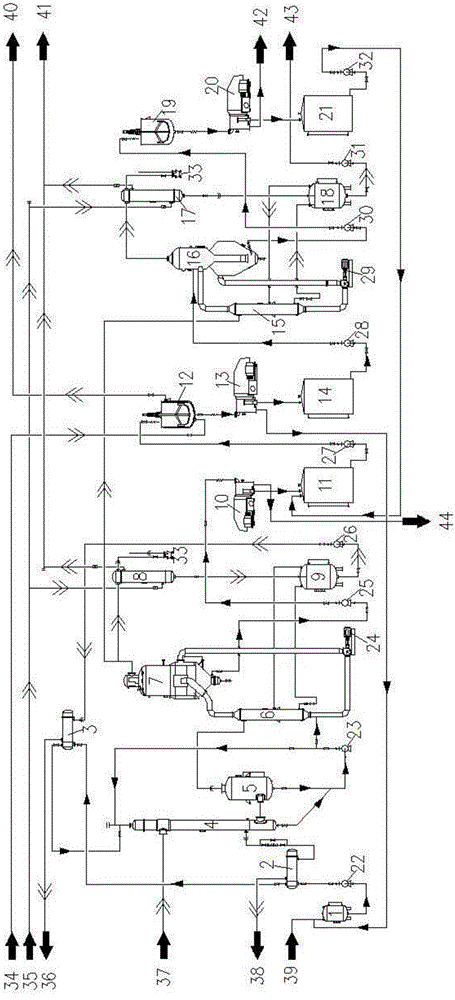

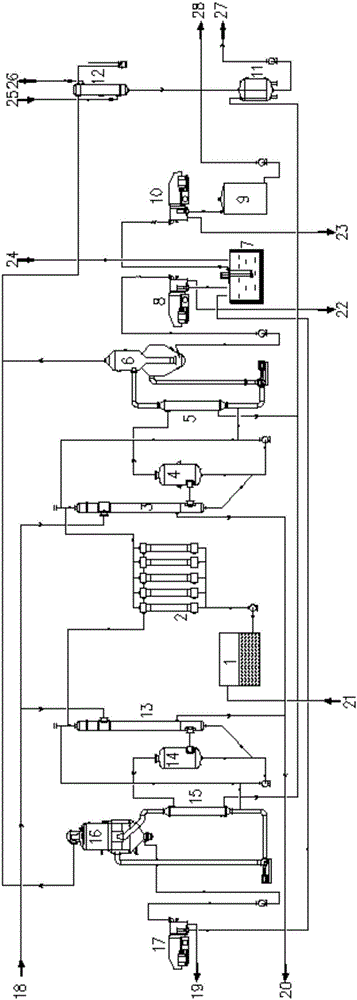

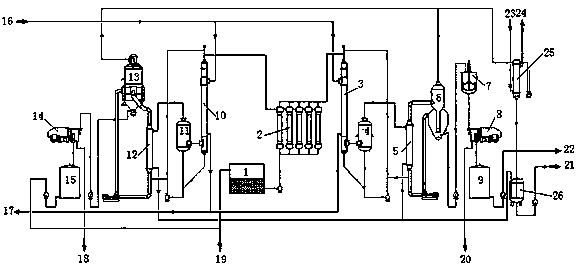

Recycling method of high-salinity wastewater

ActiveCN104591464AProcess conditions are stableEasy to industrializeMultistage water/sewage treatmentEnergy based wastewater treatmentChemistryCoal chemical industry

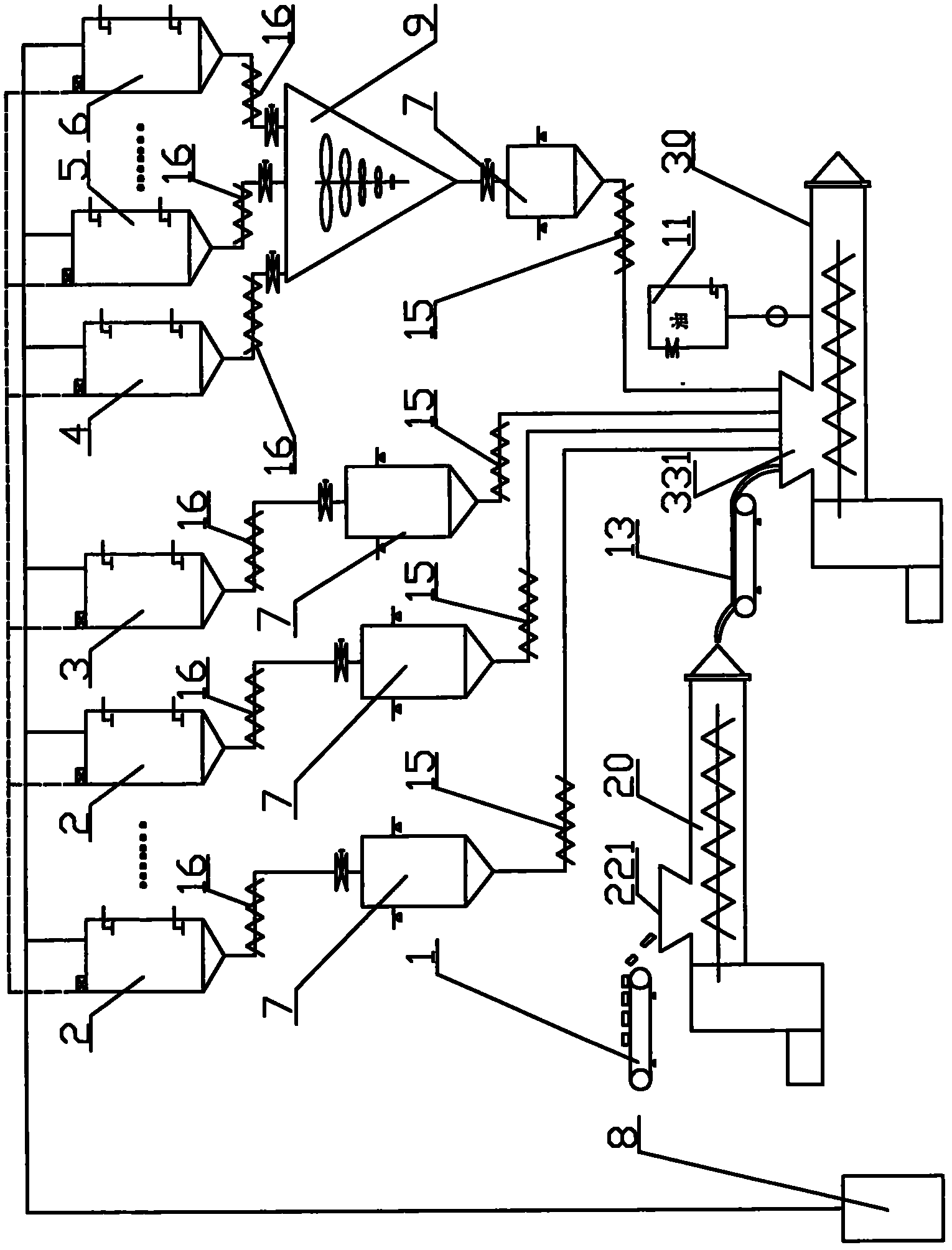

The invention discloses a recycling method of high-salinity wastewater. Sodium sulfate and sodium chloride are recycled through three steps of primary evaporative crystallization, cooling crystallization and secondary evaporation crystallization. According to the method disclosed by the invention, sodium sulfate and sodium chloride in the high-salinity wastewater of coal chemical industry can be effectively recycled; the method is simple and stable in technological conditions; industrial popularization is facilitated; the recycled sodium sulfate and sodium chloride meet the quality requirements of industrial products, and can be directly recovered and applied mechanically or sold as byproducts, so that the target of treating the high-salinity wastewater is reached; the requirements of the current environment-friendly situation are met; waste is changed into treasures; resource utilization of salts is achieved; and benefits of factories are improved.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP +1

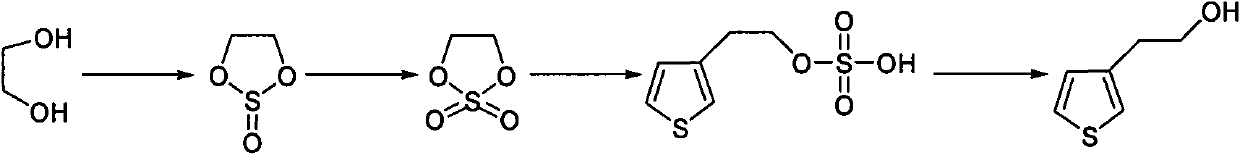

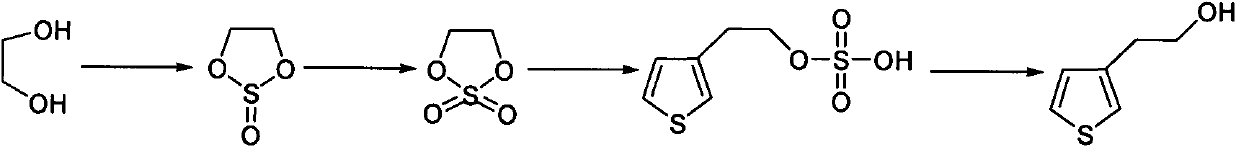

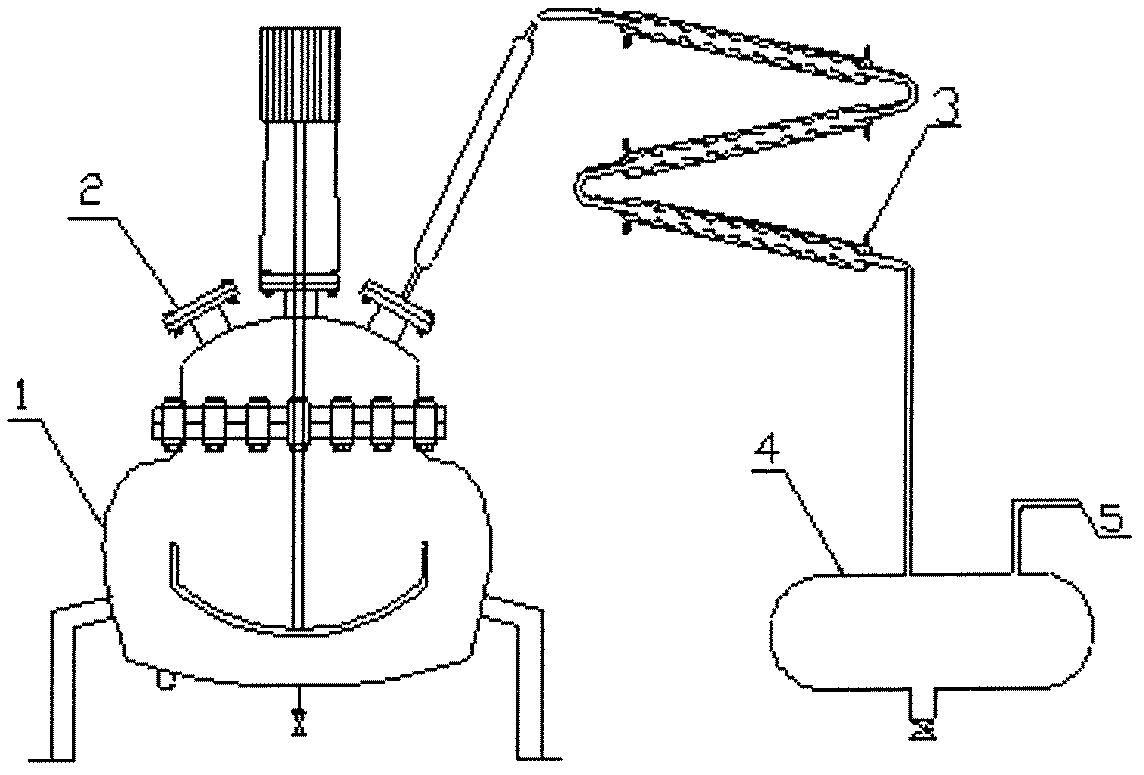

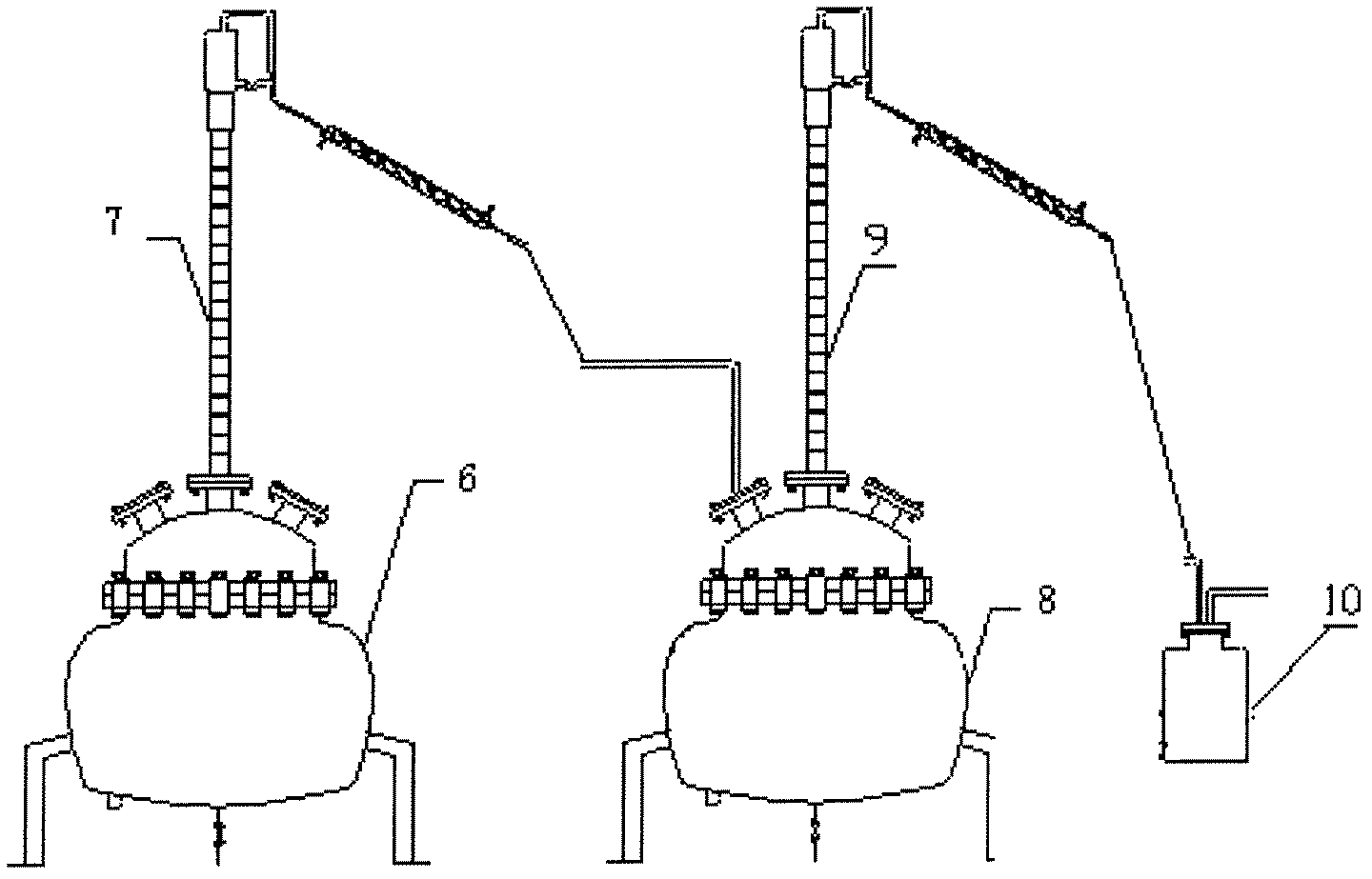

Synthetic method of thiophene-3-ethanol

The invention discloses a synthetic method of thiophene-3-ethanol. The method comprises the following steps of: adding a halogenated hydrocarbon solvent and ethylene glycol into a reaction kettle, dropwise adding thionyl chloride and preserving heat for reacting; separating liquid and extracting to obtain an organic phase containing a substance shown in the specifications; adding a ruthenium trichloride aqueous solution and a sodium bicarbonate aqueous solution in the presence of the halogenated hydrocarbon solvent and dropwise adding a sodium hypochlorite aqueous solution; after detecting that a system does not have oxidizing property, performing liquid separation, concentration, devitrification and drying to obtain a substance shown in the specifications, adding an ester solvent and butyl lithium into a reaction kettle, adding a prepared ester solution of tribromothiofuran and a prepared ester solution of the substance, separating the liquid and extracting to obtain a system containing a substance shown in the specifications; and adding a dilute sulfuric acid into the system containing the substance shown in the specifications, concentrating, neutralizing, extracting and concentrating to obtain an end product. The method has the advantages of high reaction purity and yield, stable process condition, easiness for operation and mass production capability; and the thiophene-3-ethanol is prepared from tribromothiofuran by performing low-temperature lithiation, so that the use of epoxy ethane serving as an explosive hazard is avoided, and mass production becomes possible.

Owner:ASYMCHEM LAB TIANJIN +4

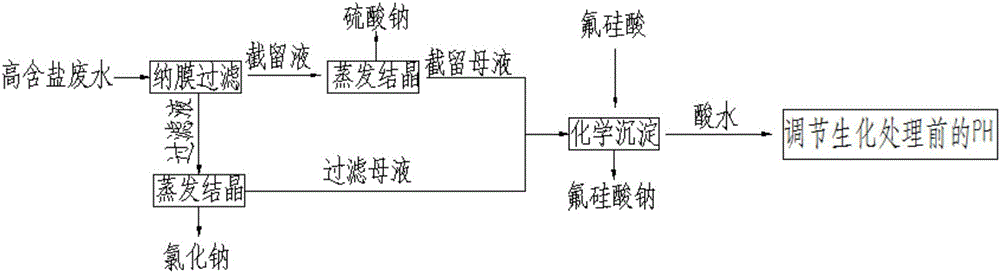

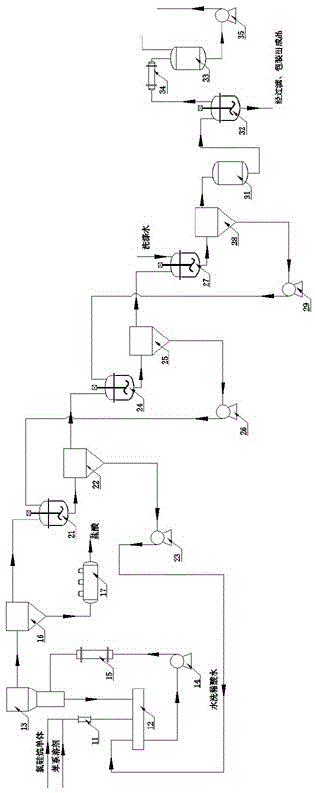

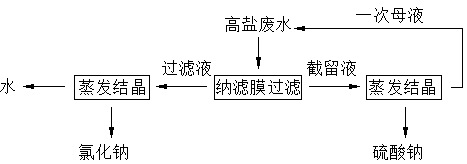

Recycling method for high-salinity wastewater containing sodium chloride and sodium sulfate

InactiveCN105110536AReduce processing costsRealize resource utilizationWater/sewage treatment by centrifugal separationWater contaminantsAcid waterWastewater

The invention discloses a recycling method for high-salinity wastewater containing sodium chloride and sodium sulfate and belongs to the field of wastewater treatment. The method comprises: filtering wastewater through a nanofiltration membrane; performing evaporative crystallization on filtrate through the nanofiltration membrane to obtain sodium chloride and filtered mother liquor; performing evaporative crystallization on retained liquor which does not pass through the nanofiltration membrane to obtain sodium sulfate and retained mother liquor; mixing the filtered mother liquor with the retained mother liquor to obtain a mixture and adding fluosilicic acid into the mixture; and stirring sufficiently the mixture to obtain sodium fluosilicate by filtering. Filtered acid water is used in pH value adjustment of a system before biochemical treatment.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

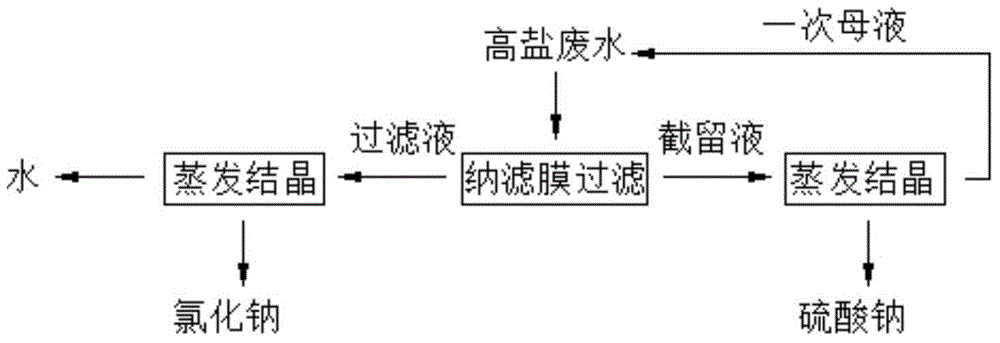

Method for recycling high-salt waste water containing sodium chloride and sodium sulfate

InactiveCN104961285AHigh purityMeet quality requirementsAlkali metal sulfite/sulfate purificationEnergy based wastewater treatmentIndustrial waste waterNanofiltration

The invention discloses a method for recycling high-salt waste water containing sodium chloride and sodium sulfate, and belongs to the field of industrial waste water treatment. The method comprises the steps of filtering by a nanofiltration membrane, evaporating and crystallizing filtrate penetrating through the nanofiltration membrane to obtain sodium chloride, evaporating and crystallizing trapped fluid which cannot penetrate through the nanofiltration membrane to obtain sodium sulfate, returning a primary mother solution to the system, and mixing the primary mother solution with raw materials to be continuously recycled. By adopting the method, sodium sulfate and sodium chloride in the high-salt waste water can be effectively recycled, a purpose of treating the high-salt waste water can be realized, and the current environmental-protection demand can be satisfied, waste can be converted into treasure, the recycling of salts can be realized, and the benefit of factories can be increased.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

Production method of small rice vinegar

InactiveCN101984037AHigh degree of automationKeep the scentMicroorganism based processesVinegar preparationAcetic acidSlurry

The invention belongs to the technical field of edible vinegar, in particular to a production method of small rice vinegar. The invention aims at solving the technical problems of low production efficiency, unstable process conditions, high labor intensity of workers, impacts on quality and taste of the rice vinegar and the like in manual control which is mostly adopted for making the vinegar at present. The production method of the small rice vinegar comprises the following steps: 1) taking small rice, preparing into rice flour, and adding a certain amount of water for preparing into slurry; 2) adding amylase and glucoamylase into the slurry, and preparing into serous fluid; 3) adding brewing yeast and Daqu into the serous fluid for preparing into wine mash; 4) taking a certain proportion of the wine mash, rice hull and wheat bran, placing into a fermentation tank, adding acetic bacteria, preparing into fermented material, further using water to leach acetic acid in the fermentation tank and preparing into vinegar liquor; 5) sterilizing the vinegar liquor, placing the vinegar liquor after sterilization into an aging tank for hermetical aging for at least 90 days, and preparing into mature vinegar; and 6) filtering the mature vinegar, carrying out instantaneous sterilization at 125-135 DEG C for 4-6s, and preparing into the small rice vinegar. The production method of the small rice vinegar adopts the automatic mechanical vinegar making way, has high production efficiency and stable process conditions, and can reduce the labor intensity of the workers and meet the market demand.

Owner:SHANXI SANSHENGHE BREWING

Blocky rubber continuous mixing method and device

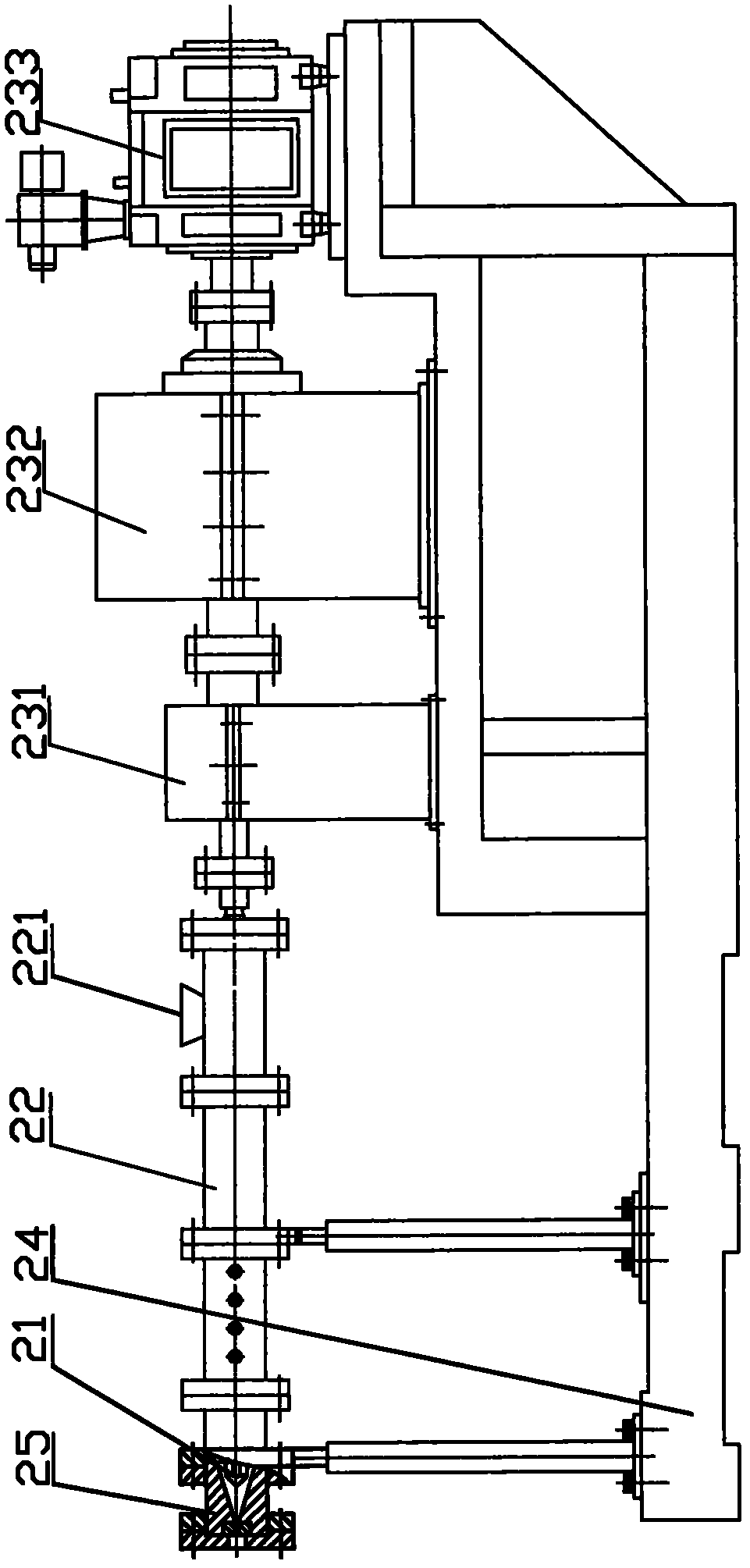

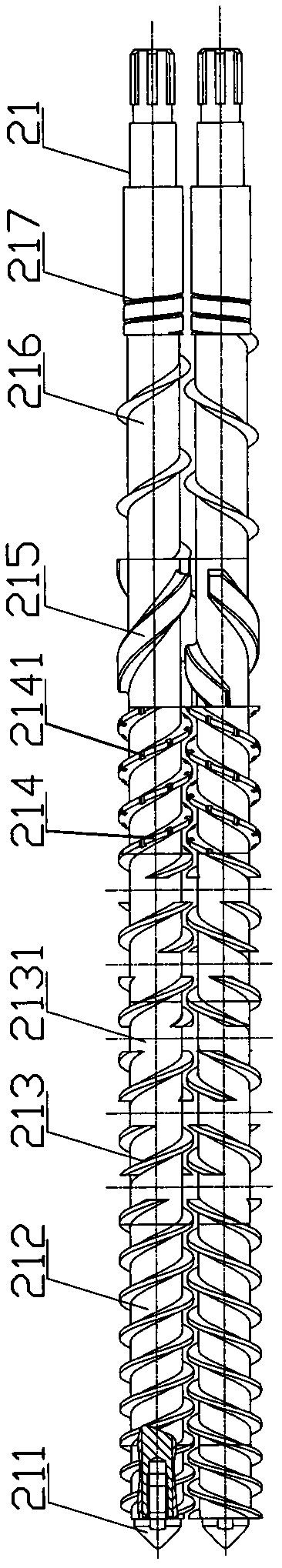

The invention discloses a blocky rubber continuous mixing method and device. A crude rubber conveying device is used for feeding a blocky rubber raw material into a rubber continuous plastifying device and conveying a solid compounding agent and an extruded plastifying rubber sheet into the rubber continuous mixing device; a rubber feeding controlling device and a compounding agent feeding controlling device are connected with an equipment control system; and the blocky rubber raw material is directly put into the blocky rubber continuous plastifying device to be continuously plastified without prophase treatment, plastified rubber is mixed through the rubber continuous mixing device, and continuous production of continuous feeding, discharging, continuous plastifying and continuous mixing is realized. The blocky rubber continuous mixing device has the advantages of less quantity of auxiliary devices, little investment of production devices, low energy consumption, high efficiency, and high mixing quality because stable device parameters and process conditions can be realized due to strong controllability.

Owner:QINGDAO UNIV OF SCI & TECH

Method for drying blueberries by utilizing vacuum freezing technology

InactiveCN101518280AAnthocyanin content does not decreaseQuality assuranceFruit and vegetables preservationWorking pressureFreeze-drying

A method for drying blueberries by utilizing vacuum freezing technology comprises the following processing steps: 1) blueberries are washed, pulped and uniformly agitated to prepare pulp material; 2) the pulp material is put into a vacuum freezing room by a stone holder to be dried under the process condition with the working pressure of 30 Pa to 70 Pa, the freezing temperature of -10 DEG C to -30 DEG C, the freezing time of 4h to 5h, the sublimation temperature of 10 DEG C to 50 DEG C and the resolution temperature of 10 DEG C to 50 DEG C until the pulp material has a thickness of 4-8 mm; and 3) the dried pulp material is crashed by a vacuum freezing drying muller and sieved by a sieve of 80 meshes to 120 meshes to obtain powder which is dry blueberry products. The invention has the advantages that the method for drying blueberries by utilizing the vacuum freezing technology can effectively ensure the quality and the active ingredient of the blueberry, is applicable to different kinds of blueberries and easy to implement, has stable process conditions and is suitable for large-scale manufacturing production.

Owner:WODELV WORLD TIANJIN BIOLOGY TECH

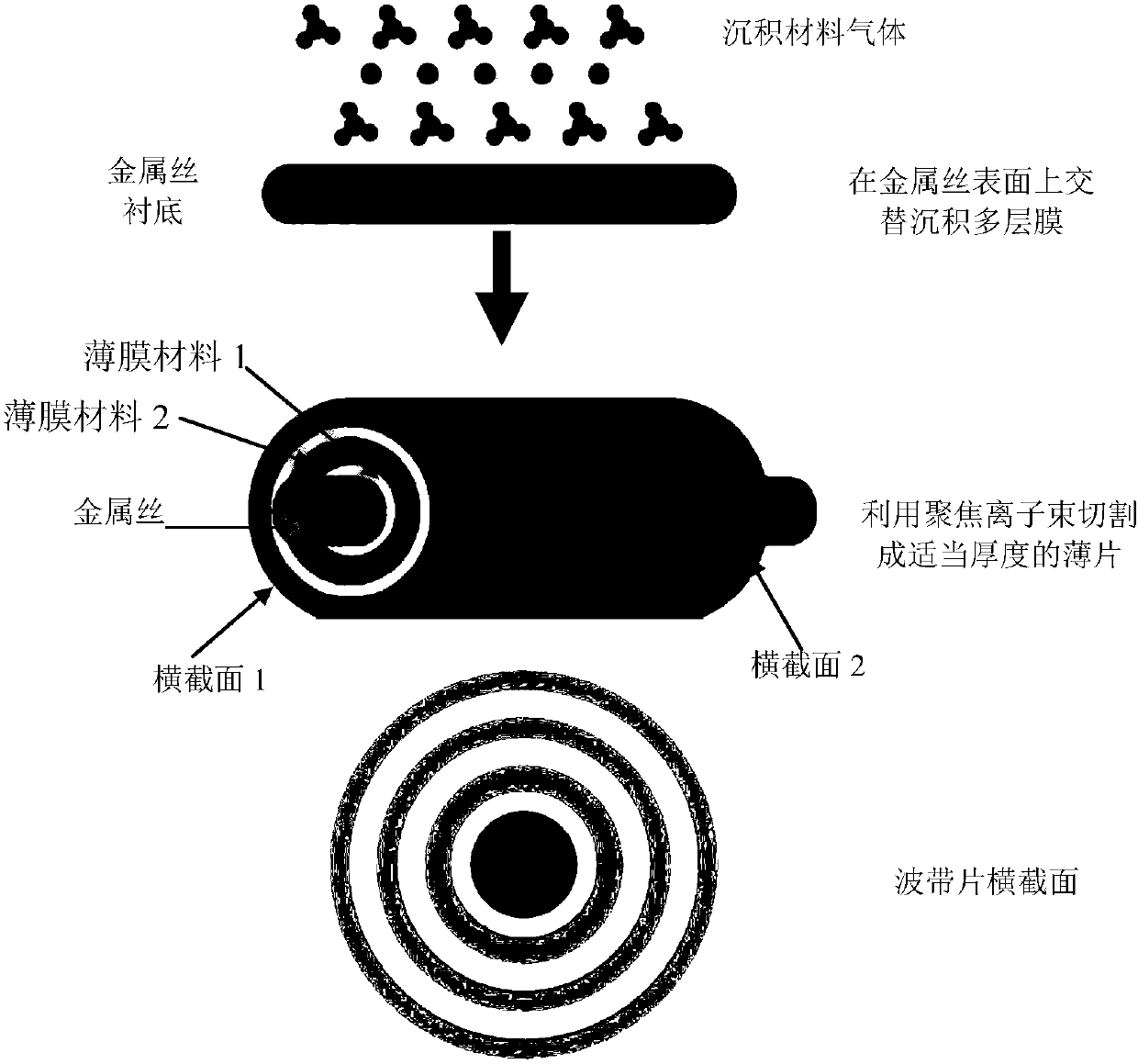

Preparation method of X-ray zone plate

ActiveCN107833649AStable outer ring widthImprove performanceHandling using diffraction/refraction/reflectionIridiumIon beam

The invention relates to a preparation method of an X-ray zone plate. An atomic layer deposition (ALD) method is used to depose alumina / hafnium oxide or alumina / iridium films of different density andthickness alternatively at the surface of a metal wire whose diameter is of a micron order, namely, a first deposed alumina film layer and a second deposed hafnium oxide film or iridium film layer arearranged alternatively and cyclically to form a series of concentric circular rings. The film plated metal wire is cut and polished by focusing ion beams after film plating, and the zone plate of therequired thickness and precision is obtained. The method is suitable for preparing different types of zone plates.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Preparation purification method of germanium tetrachloride for optical fiber

InactiveCN103183375AMeet the requirements of germanium tetrachlorideSuitable for mass production applicationsGermanium halidesPurification methodsDistillation

The invention provides a preparation purification method of germanium tetrachloride for optical fibers, which adopts germanium concentrate as a raw material; hydrochloric acid, sulfuric acid, and ferric trichloride are added into a chlorination reaction vessel according to a certain proportion for reaction to prepare crude germanium tetrachloride; the crude germanium tetrachloride is fully mixed with hydrochloric acid and manganese dioxide according to a certain proportion in a repeated distillation reaction vessel for distillation and purification to obtain preliminarily purified germanium tetrachloride; the germanium tetrachloride after repeated distillation purification is processed in a quartz rectifying tower in inert atmosphere by controlling a tower bottom temperature to be 75-95 DEG C, a tower column temperature to be 30-95 DEG C, and a reflux ratio of 4:1-14:1, so as to obtain high-purity germanium tetrachloride. The high-purity germanium tetrachloride prepared through three procedures of chlorination distillation, repeated distillation, and rectification purification, has a content of transition metal impurities of less than 3 ppb, a content of hydrogen-containing impurities of less than 1 ppm, and meets the requirements for perform rod germanium tetrachloride for optical fibers.

Owner:GRINM ELECTRO OPTIC MATERIALS

Highly transparent polyethylene shrink film and film blowing technology thereof

ActiveCN104175676AEnhance hazeHigh glossSynthetic resin layered productsPolymer scienceThin membrane

The invention relates to the technical field of shrink films, in particular to a highly transparent polyethylene shrink film and a film blowing technology. The highly transparent polyethylene shrink film consists of three films, namely an outer layer, a middle layer and an inner layer; the outer layer comprises 0%-20% of LDPF, 79%-99% of MPE, and 1%-5% of a nucleating agent in percentage by weight; the melt index of LDPE in the outer layer is greater than or equal to 2g / 10min, and the melt index of MPE is greater than or equal to 1g / 10min; the middle layer comprises 60%-80% of MDPE, 10%-20% of LDPE and 10%-20% of HDPE in percentage by weight; the melt index of MDPE in the middle layer is smaller than or equal to 0.5g / 10min, the melt index of LDPE is smaller than or equal to 0.5g / 10min, and the density of HDPE is greater than or equal to 0.960g / cm<3>; and the composition of the raw material of the inner layer and the composition of the raw material of the outer layer are the same. The highly transparent polyethylene shrink film has the haze of 7%, the light transmittance of greater than or equal to 92%, and the glossiness of 75%, so that the haze is good, the glossiness is good, and a printed pattern is more attractive and clearer when the highly transparent polyethylene shrink film is used for printing. The film blowing technology is stable in condition, precise in temperature and high in production efficiency.

Owner:ZHENGXIN PACKAGING CO LTD DONGGUAN

Honeycomb essence buccal tablet and preparation process thereof

InactiveCN103230012AFully absorbedEasy to GrindAnthropod material medical ingredientsPharmaceutical non-active ingredientsHoneycombUltra fine

The invention discloses a honeycomb essence buccal tablet and a preparation process thereof, belonging to the technical field of honeycomb preparation. The honeycomb essence buccal tablet disclosed by the invention is prepared from ultra-fine powder of a honeycomb essence composition, a filling agent, a sweetening agent, an acidulant, edible essence and a lubricating agent. The invention further provides the preparation process of the honeycomb essence buccal tablet. The honeycomb essence buccal tablet disclosed by the invention has the characteristics of being easy for taking, good in mouth feel and rapid in absorption and is capable of overcoming the disadvantages of being insufficient in honeycomb mouth feel and lower in absorption utilization rate, and obviously increasing the absorption utilization rates of effective components in the honeycomb essence; and the honeycomb essence buccal tablet has important value and contribution for clinical treatment, health care and prevention of nasopharyngitis.

Owner:FUJIAN XINZHIYUAN BIOLOGICAL PROD

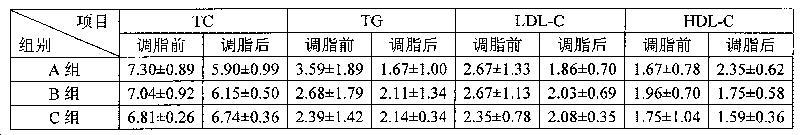

Lipid-lowering tea and production process thereof

ActiveCN101720832AImprove solubilityGood hypolipidemic effectPre-extraction tea treatmentPulverizerGynostemma

The invention relates to a lipid-lowering tea which is characterized in that the formula comprises lotus leaves, Gynostemma pentaphylla, green tea, fleece flower roots, cassia seeds, Pu'er tea and extractives, wherein the weight proportion of lotus leaves to Gynostemma pentaphylla to green tea to cassia seeds to Pu'er tea to extractive is 25 to 40:15 to 35:20 to 50: 5 to 20:5 to 18: 5 to 18:1 to 3. The production process comprises the steps of: first, pulverizing the lotus leaves, Gynostemma pentaphylla, green tea, fleece flower roots, cassia seeds, Pu'er tea and extractive into fine powder by using a universal pulverizer, screening, and mixing the five ingredients except the powder of lotus leaves; second, respectively pulverizing extractives of Se-enriched panax japonicus, aqueous extractives of corn silks and aqueous extractives of burdock into fine powder, screening, and mixing the three pulverized fine powder with the lotus leaves powder; third, mixing the mixtures prepared in the first step and the second step; and fourth, packing. The lipid-lowering tea can well reduce blood fat, and is suitable for all ages, especially for middle aged people and the aged. The lipid-lowering tea has the advantage of stable production process conditions, and is applicable to large-scale industrial production.

Owner:TIANJIN TIANSHI BIOLOGICAL DEV

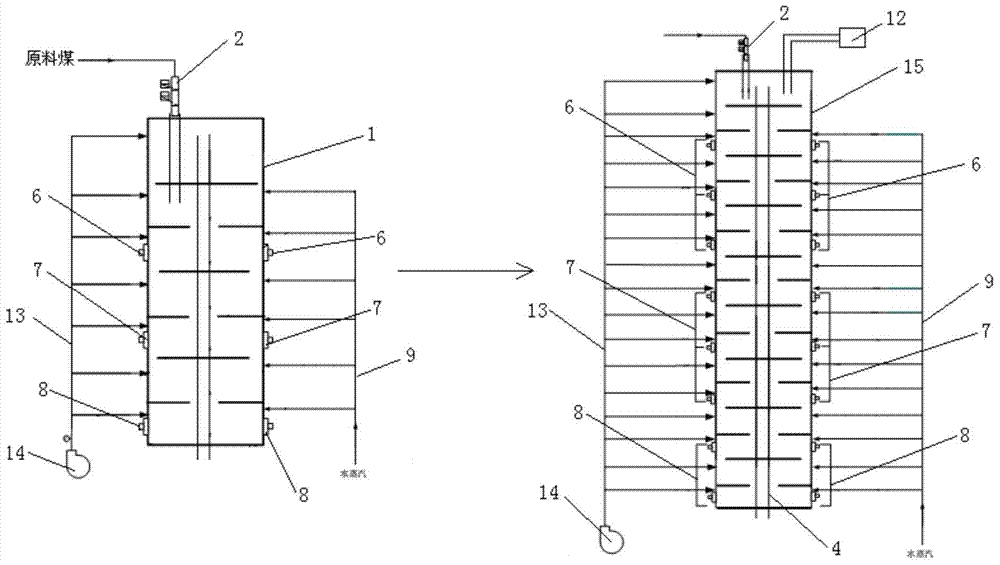

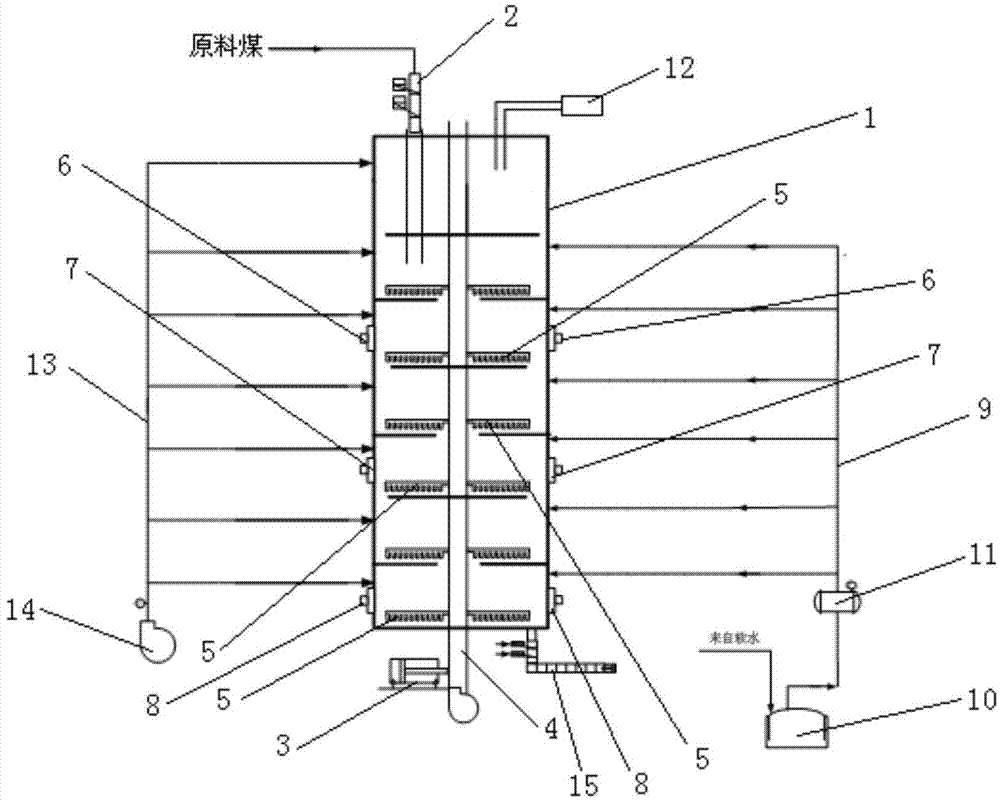

Method for preparing active carbon by using multi-hearth furnace

InactiveCN104773731AReduce consumptionSmall temperature fluctuation rangeCarbon compoundsActivated carbonGas solid

The invention relates to a method for preparing active carbon by using a multi-hearth furnace. The method comprises the following steps: 1) inputting a raw material from the feeding end on the top of the multi-hearth furnace into the multi-hearth furnace; 2) starting a combustor in the bottom of the multi-hearth furnace to heat the raw material, wherein the temperature of the raw material in the furnace layer in the bottom of the multi-hearth furnace is raised to be not less than 600 DEG C in the first place to reach an activating temperature; 3) introducing water vapor into the multi-hearth furnace, wherein the raw material reaching the activating temperature and water vapor which are overturned by virtue of a rabble blade are uniformly contacted to carry out gas-solid heterogeneous activating reaction to generate combustible gases H2 and CO; 4) generating a negative pressure by using an induced draft fan to control the flowing directions of H2 and CO, wherein the H2 and CO move upward from the bottom of the multi-hearth furnace; 5) injecting air into the multi-hearth furnace, wherein exothermic reaction is carried out on H2 and CO and oxygen in air, and released heat is taken as heat required for carrying out gas-solid heterogeneous activating reaction on the raw material and water vapor; and 6) forming active carbon after activating reaction of the raw material, wherein the active carbon is discharged from a discharge opening in the bottom of the multi-hearth furnace. The method provided by the invention can be widely applied to processes for preparing active carbon.

Owner:CCTEG CHINA COAL RES INST

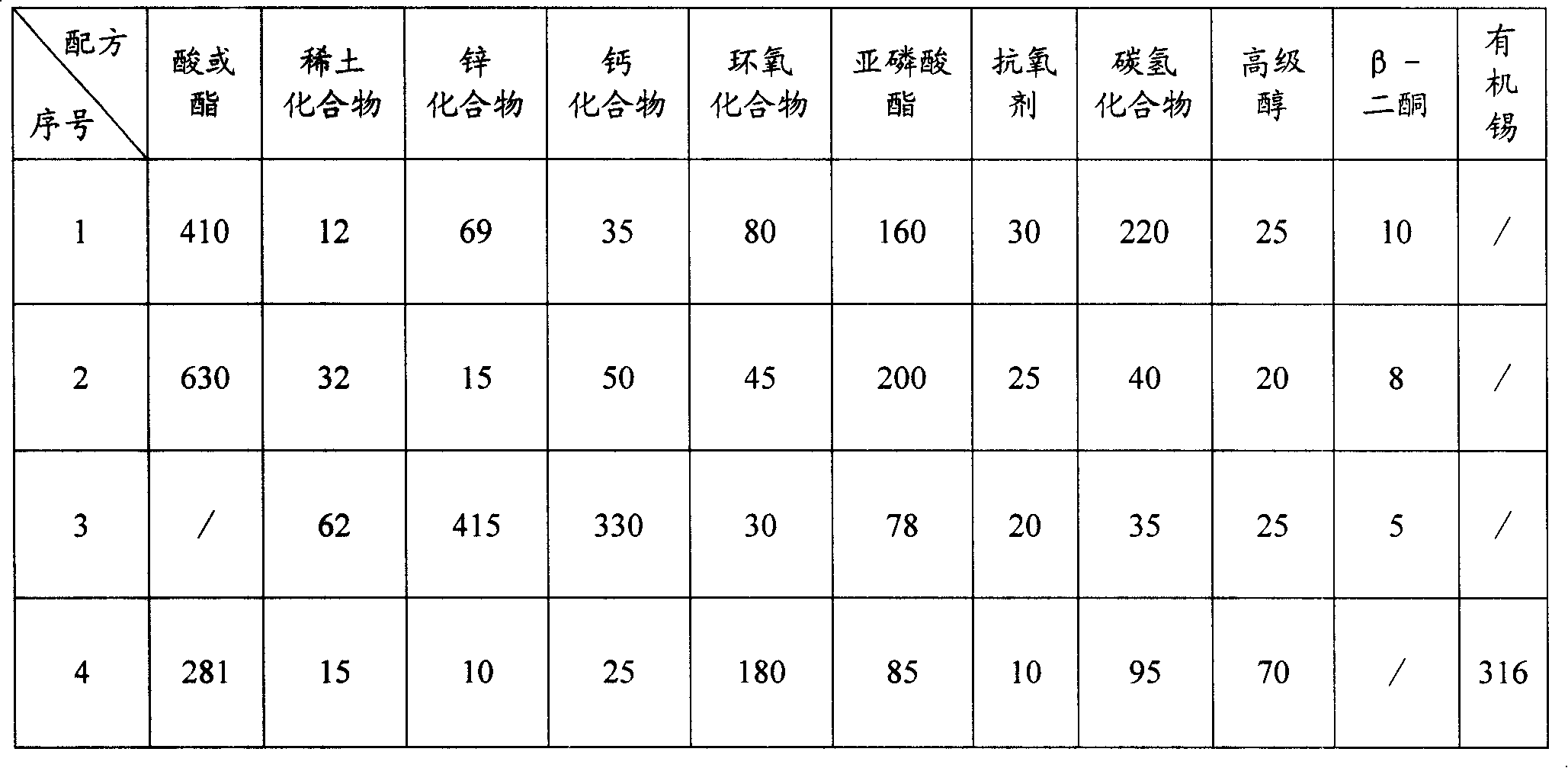

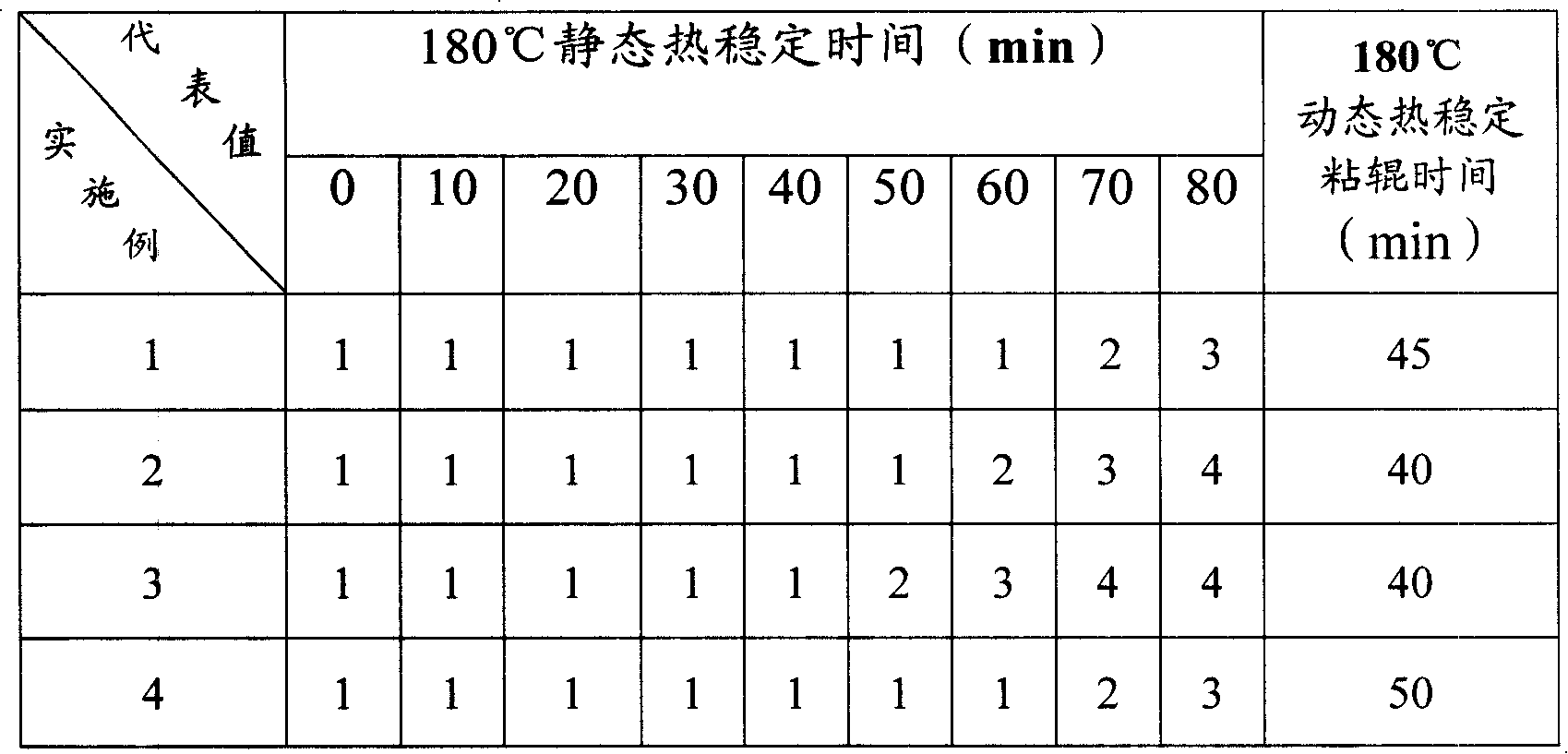

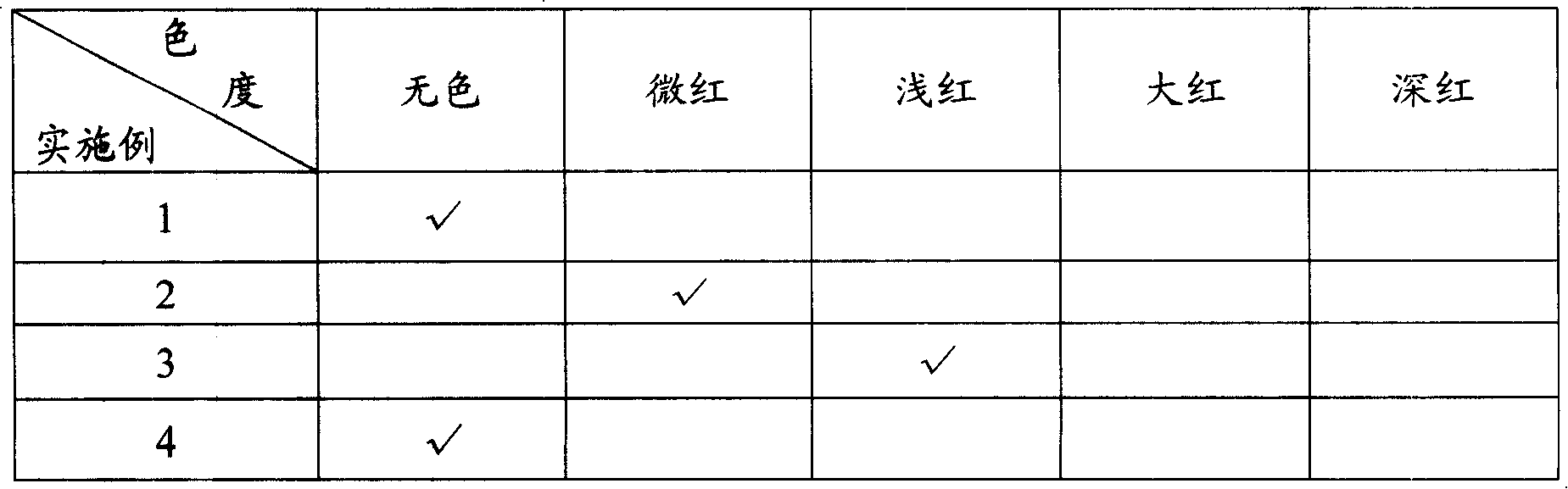

Liquid rare earth calcium zinc stabilizer and preparation method thereof

The present invention provides liquid rare-earth calcium-zinc stabilizer and the preparation method. The liquid rare-earth calcium-zinc stabilizer is compound made of rare-earth calcium-zinc compound and effectively cooperative material. The beneficial effects of the liquid rare-earth calcium-zinc stabilizer and the preparation method provided by the present invention is mainly shown in that (1) the liquid rare-earth calcium-zinc stabilizer has the advantages of high product quality, no toxin, environmental protection, no toxic heavy metal component in recipe, strong practicability and wide application range, which is particularly applicable to the transparent packaging material of food, candy and medicine, as well as the advantages of good processing performance, no precipitation, excellent lubricating performance, superior transparency, thermal stability and oxidation resistance; (2) the process condition is stable and easy to control, thus being applicable to industrialized mass production; the process flow has the advantages of simplicity, environment friendliness, easy access to raw materials and less energy consumption, thus greatly decreasing the production cost; in addition, the whole production process has anhydrous operation, safety and convenience, no discharge of three wastes and less environmental pollution.

Owner:高春福

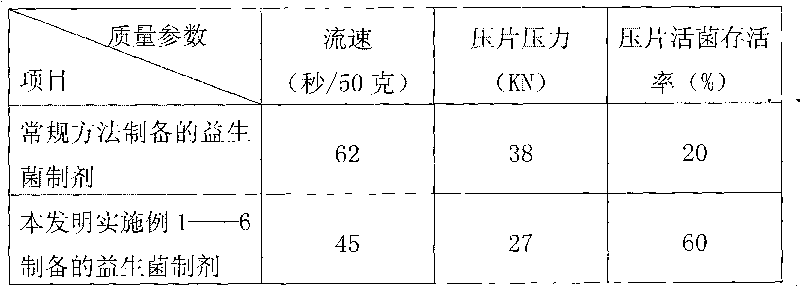

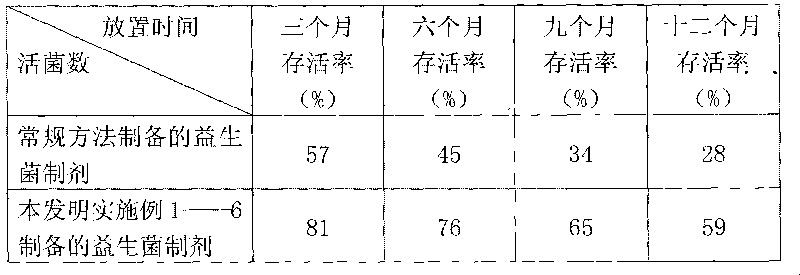

Probiotic tablet and preparation method thereof

ActiveCN101700253ALow costFast deliveryBacteria material medical ingredientsDigestive systemMagnesium stearateTherapeutic effect

The invention discloses a manufacturing method and a probiotic tablet with high living bacterium survival rate manufactured by applying the method; the manufacturing method is as follows: applying a dry method pelleting technique and a tabletting technique and taking auxiliary materials such as glucose, lactin, microcrystalline cellulose and the like as raw material to prepare particles, and then blending active ingredient probiotic powder and magnesium stearate to carry out tabletting, and finally obtaining the probiotic tablet. The invention has the advantages that the probiotic tablet is convenient to take and absorb and has obvious treatment effect owing to the high probiotic survival rate; the dry method pelleting technology provided by the invention has the advantages of low cost, fast discharging speed, stable technological conditions, good recurrence and high probiotic survival rate and is suitable for large-scale production.

Owner:内蒙古双奇药业股份有限公司

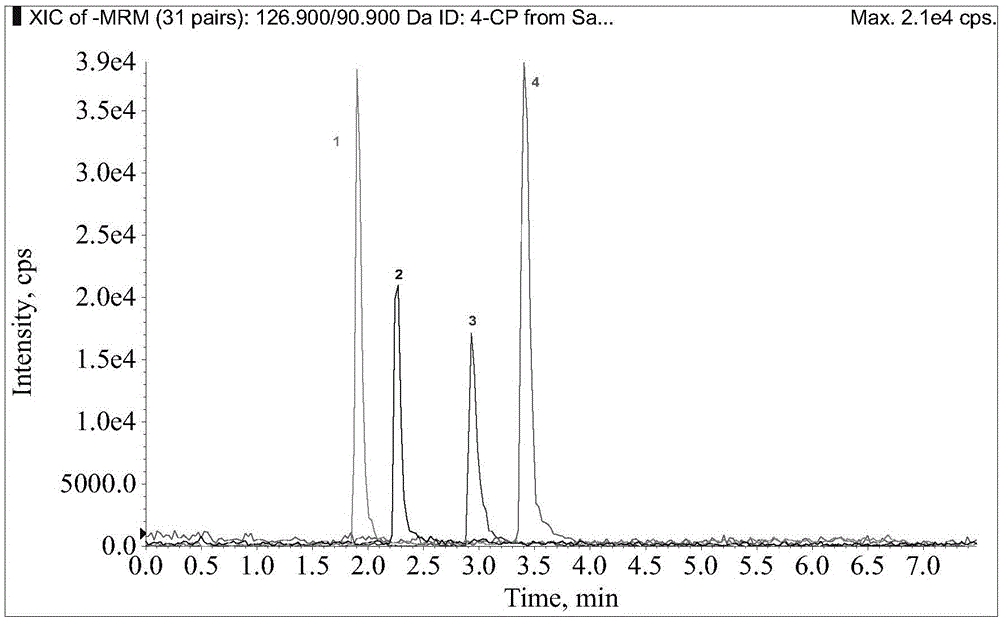

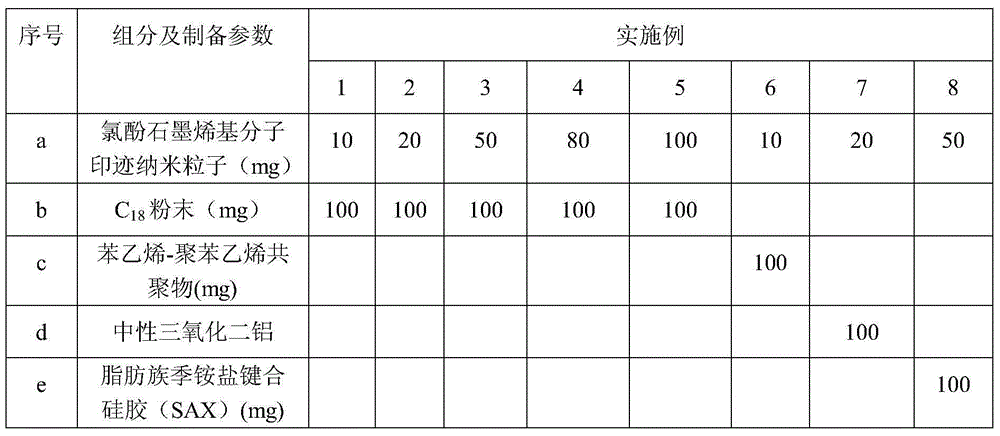

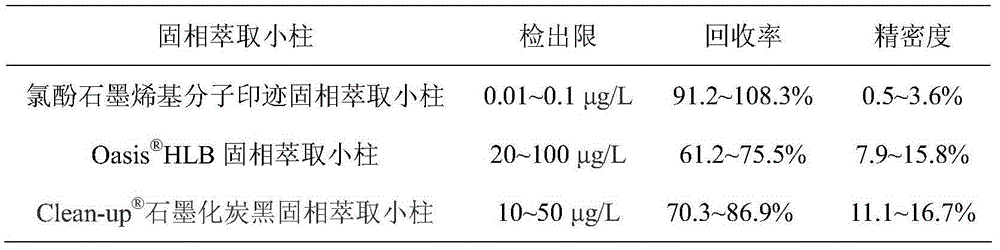

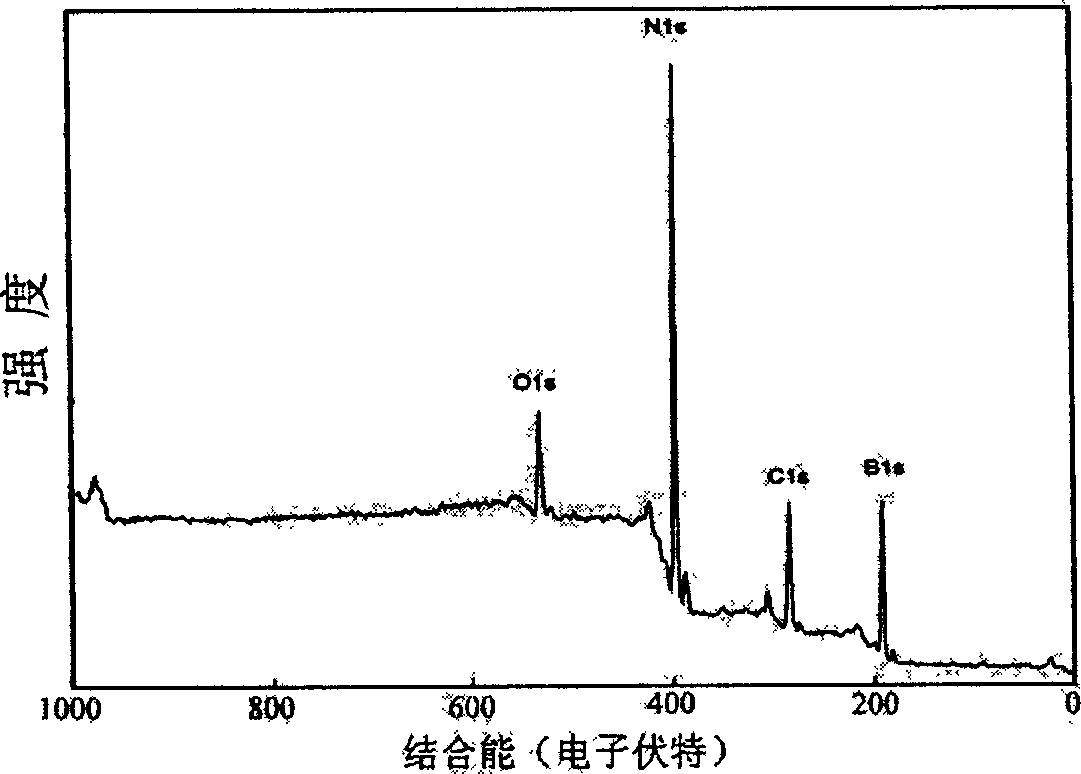

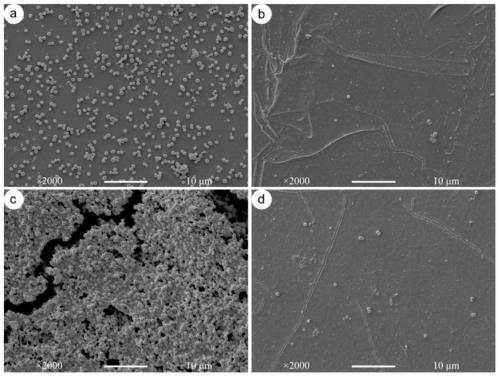

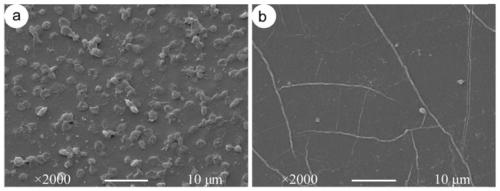

Chlorophenol graphene-based molecularly imprinted solid-phase extraction column and preparation method and application thereof

InactiveCN105688444AHigh selectivityReduce manufacturing costOther chemical processesPreparing sample for investigationNanoparticleMolecular materials

The invention relates to a chlorophenol graphene-based molecularly imprinted solid-phase extraction column, which comprises an empty column, a sieve plate and a filling material. The filling material is formed by mixing chlorophenol graphene molecularly imprinted nanoparticles and a conventional solid-phase extraction packing at the mass ratio of 1: 1-10. According to the chlorophenol graphene molecularly imprinted nanoparticles, a magnetic Fe3O4 high-molecular material is supported on the surface of graphene as a function unit, and a target chlorophenol compound to be adsorbed is used as template molecule. Meanwhile, the invention also relates to a preparation method and an application of the chlorophenol graphene-based molecularly imprinted solid-phase extraction column. The chlorophenol graphene-based molecularly imprinted solid-phase extraction column has large specific surface area, many adsorption sites, strong specific selectivity and good enrichment effect, can be used in enrichment of residual trace amount of chlorophenol compounds in an environmental water sample, and can achieve high enrichment factor and can remarkably reduce matrix effects. Meanwhile, the preparation method of the molecularly imprinted solid-phase extraction column is simple, technological conditions are stable, and production cost is low.

Owner:NINGBO MUNICIPAL CENT FOR DISEASE CONTROL & PREVENTION

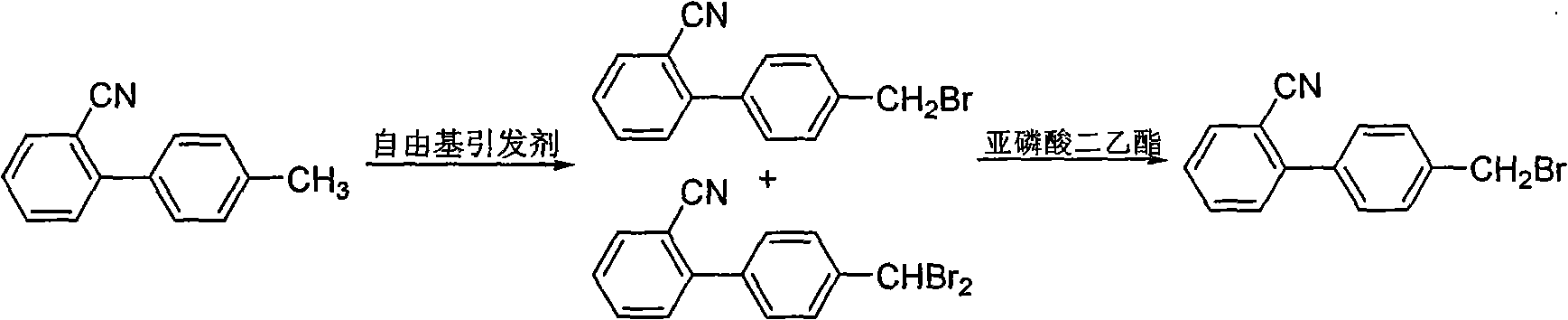

Synthesis method of 4'-Bromomethyl-2-cyanobiphenyl

ActiveCN101597243AEfficient dischargeRaw materials are easy to getCarboxylic acid nitrile preparationOrganic compound preparationSynthesis methodsNitrogen gas

The invention relates to a synthesis method of 4'-Bromomethyl-2-cyanobiphenyl, comprising the following preparation steps: 1) adding halogenated hydrocarbon solvent, 4'-Methyl-2-cycanobiphenyl, radical initiator and brominating agent in sequence into a reactor, evenly mixing them, and carrying out bromination reaction with the introduced nitrogen at the temperature of about 5 DEG C; 2) filter-pressing the reaction liquid after the reaction liquid is lowered to normal temperature, and then adding diethyl phosphite into the filter liquid to fully react at the temperature of about 30 DEG C; 3) performing reduced pressure concentration on the reaction product at the temperature of about 50 DEG C, and pumping pure water in for crystallization, to obtain the product of the invention after separation. The invention has the advantages of abundant raw material, low cost and high yield, and can directly obtain monobromo aromatic ring without separation and purification; the invention is finished by controlling lead-in speed of nitrogen under the condition of supplementing no radical initiator and can effectively discharge the rest bromine in time; the invention has stable process condition and simple operation, reduces three-waste discharge, and is suitable for industrial scale production.

Owner:ASYMCHEM LIFE SCI TIANJIN

Method for preparing boron nitride nanometer ring and tube

A process for preparing boron nitride nanoring and nanopipe, belonging to the technical field of preparing nano material, which in detail is a process for preparing nano ring and nano pipe by applying the heated solid material producing gas or evaporated solid material producing pressure, the process is carried out under low pressure which avoids the high temperature and high pressure, the equipment needed is simple and mass production of low cost is easily to be realized. The raw material is common chemical agent or chemical materials and the process is simple, which is good for increasing the product yield and reduces the cost; the parameter of the reaction is easy to be monitored and controlled, the reaction mechanism is easy to be researched to find out the critical influencing factors and stabilizes the technological condition in a short time; the invention is also environment-friendly

Owner:SHANDONG UNIV

Method for preparing mannitol utilizing dextrose

InactiveCN1524837ALower glucose levelsReduce consumptionPreparation by oxygen reductionChromatographic separationIsomerase

The invention relates to a process for preparing mannitol by using glucose as raw material, which comprises the steps of, converting glucose solution partly into mannose under acidic condition at temperature 60-160 deg. C by using molybdates as catalyst, separation by crystallization, converting part of the residual glucose in the mother liquid after separation by crystallization into fructose through glucose isomerase column, obtaining the miscible liquid of glucose, mannose and fructose, hydrogenation for obtaining the miscible liquid of sorbic alcohol and mannose, wherein the mannitol crystal can be prepared through the crystallization and purification of miscible liquids.

Owner:谭卫星

SOD complex capsule and preparation method thereof

ActiveCN101590223AEffect of dismutase activityActive influenceHydroxy compound active ingredientsPeptide/protein ingredientsPolygonum fagopyrumBULK ACTIVE INGREDIENT

The invention relates to an SOD complex capsule and a preparation method thereof. The SOD complex capsule contains resveratrol, coenzyme Q10, goose liver extracts, wheat germ extracts, safflower extracts and tartary buckwheat extracts; the weight ratio of the components is 10-50 : 10-75 : 75-150 : 75-150 : 75-150 : 200-500; every 100g of the complex capsule contains 40000-4000000 activity unit of SOD which is a tadpole extract. The preparation method is as follows: processing grape skins, pig hearts, goose livers, wheat, safflower, tartary buckwheat and tadpole by the steps of breaking, concentration, centrifugal separation, purification and the like to obtain active ingredients of various raw materials, embedding the tadpole extract for several times, mixing the tadpole extract with other components and palletizing the mixture, thus obtaining the finished product. The invention has the function of oxidation resistance, can alleviate physical fatigue and strengthen immunity of human body.

Owner:刘安荣 +1

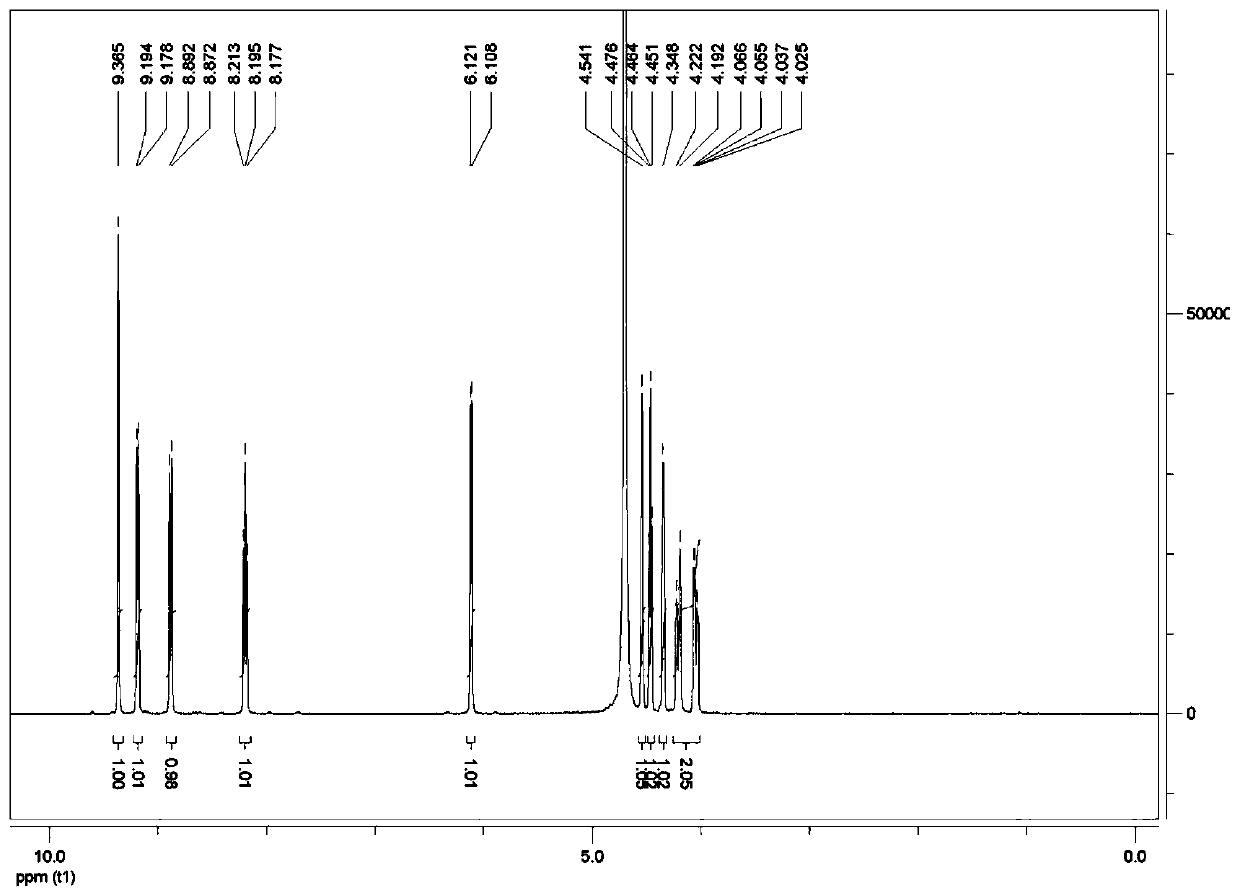

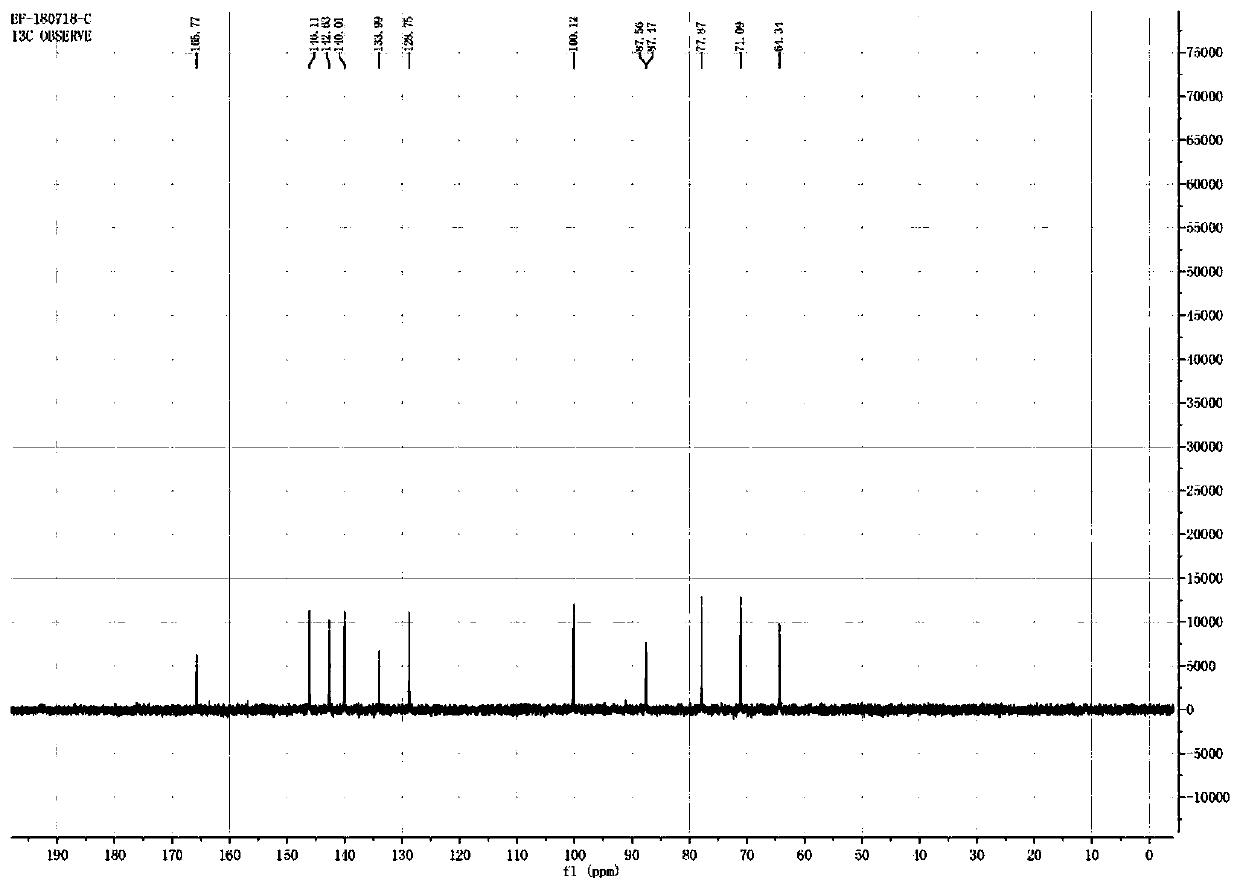

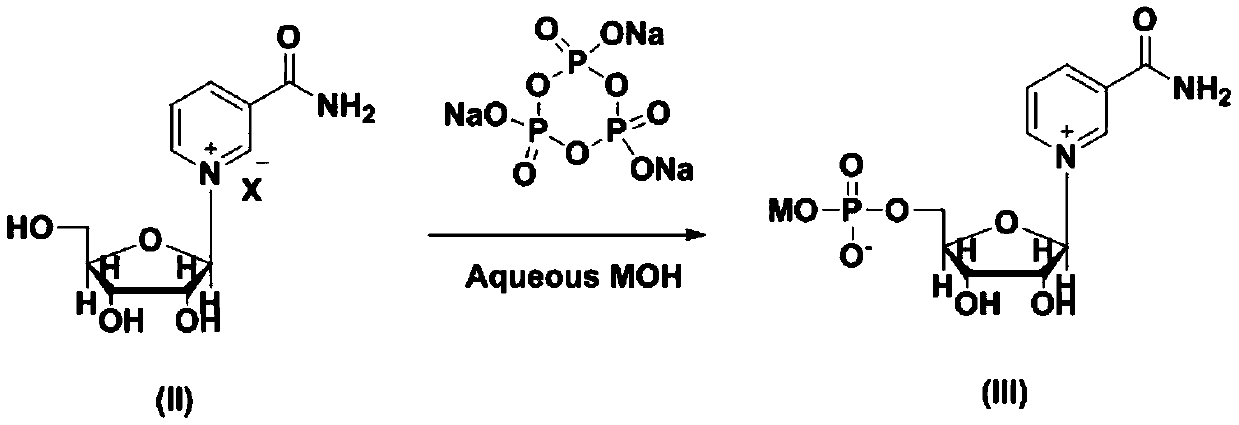

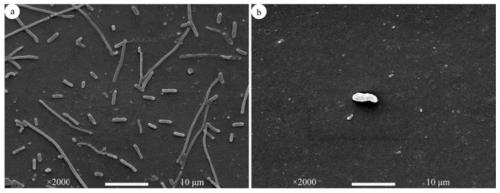

Preparation method of beta-nicotinamide mononucleotide

PendingCN111377983ADoes not involve genetically modified technologyLow costSugar derivativesSugar derivatives preparationMetaphosphateProtide

The invention relates to the technical field of medicines, and provides a preparation method of beta-nicotinamide mononucleotide. The preparation method comprises the steps of A: performing a phosphorylation reaction: in an aqueous alkaline solution of which the pH is 8-10, and under the condition that the temperature of a reaction system is 25-50 DEG C, enabling nicotinamide riboside and metaphophate to be subjected to the phosphorylation reaction for 2-5h, to obtain an intermediate product of the nicotinamide mononucleotide; B, performing an acidification reaction: adding acid to the reaction solution, regulating the pH value to 3-5, reducing the temperature of the reaction system, and performing acidification on the intermediate product of the beta-nicotinamide mononucleotide to obtainthe beta-nicotinamide mononucleotide; and C, purifying products: sequentially performing filtration with a protein membrane, concentration with a high-pressure desalination membrane, separation and purification with anion exchange resins and concentration and crystallizing on the reaction solution obtained in the step B to obtain pure products of the beta-nicotinamide mononucleotide.

Owner:EFFEPHARM (SHANGHAI) CO LTD

Anticoagulation, antibacterial, anti-adhesion, anti-anti-inflammation and lubricating copolymer coating material for surface of silicon rubber material and preparation method thereof

ActiveCN110204650AHigh densityHigh reactivitySurgeryPharmaceutical containersPhosphatePolymer chemistry

The invention provides an anticoagulation, antibacterial, anti-adhesion, anti-anti-inflammation and lubricating copolymer coating material for the surface of a silicon rubber material and a preparation method thereof. The material is a high molecular copolymer formed by polyelectrolyte and active ester; the polyelectrolyte is a zwitter-ion polyelectrolyte which is generated by polymerizing phosphate ammonium or carboxyl ammonia or sulphur ammonia zwitter-ion monomers. The monomers and active ester monomers of the prepared polyelectrolyte are directly mixed and polymerized, or a homopolymer ofone of the two monomers is prepared at first, the homopolymer is adopted as a chain transfer agent, and the other monomer is adopted as a polymer monomer to obtain the copolymer. The prepared copolymer coating can be bonded on the surface of silicon rubber through the single coating technology to form the stable polymer coating; the number and density of microorganisms and bacteria attached to thesurface of the modified silicon rubber material are remarkably decreased, and the anticoagulation, antibacterial, anti-adhesion and anti-anti-inflammation performance can be remarkably improved; thesurface of the silicon rubber is high in hydrophilicity, the friction coefficient is remarkably lowered, and the lubricating performance can be obviously enhanced.

Owner:NANJING NORMAL UNIVERSITY

Continuous environment-friendly preparation process of methyl phenyl silicone resin for high-temperature-resistant paint

ActiveCN105111440AReduce the degree of oxidationAverage molecular weight distributionCoatingsEnvironmental resistanceHydrolysate

The invention relates to a continuous environment-friendly preparation process of methyl phenyl silicone resin for high-temperature-resistant paint. The technical scheme includes: mixing according to a mass ratio of 1-20:1-10:1-10:1-20, and entering a tubular hydrolyzer to react with diluted acid water, wherein mass of benzene solvent is 1-3 times that of mixed chlorosilane monomer, and mass of the diluted acid water is 2-5 times that of the mixed chlorosilane monomer; stepwise washing hydrolysate at three or more stages to be neutral; continuously concentrating in vacuum, and allowing polycondensation when materials in a concentration polycondensation kettle reach 50-60% of volume of the kettle; after polycondensation is completed, detecting, filtering, packaging and recycling the solvent. The process has the advantages that no wastewater is discharged, the problem that conventional processes are large in discharging quantity, high in organic matter content and difficult in wastewater treatment is solved, product yield is increased, and devolatiligation time is reduced by feeding inert gas in the process of polycondensation.

Owner:TANGSHAN SANYOU SILICON IND

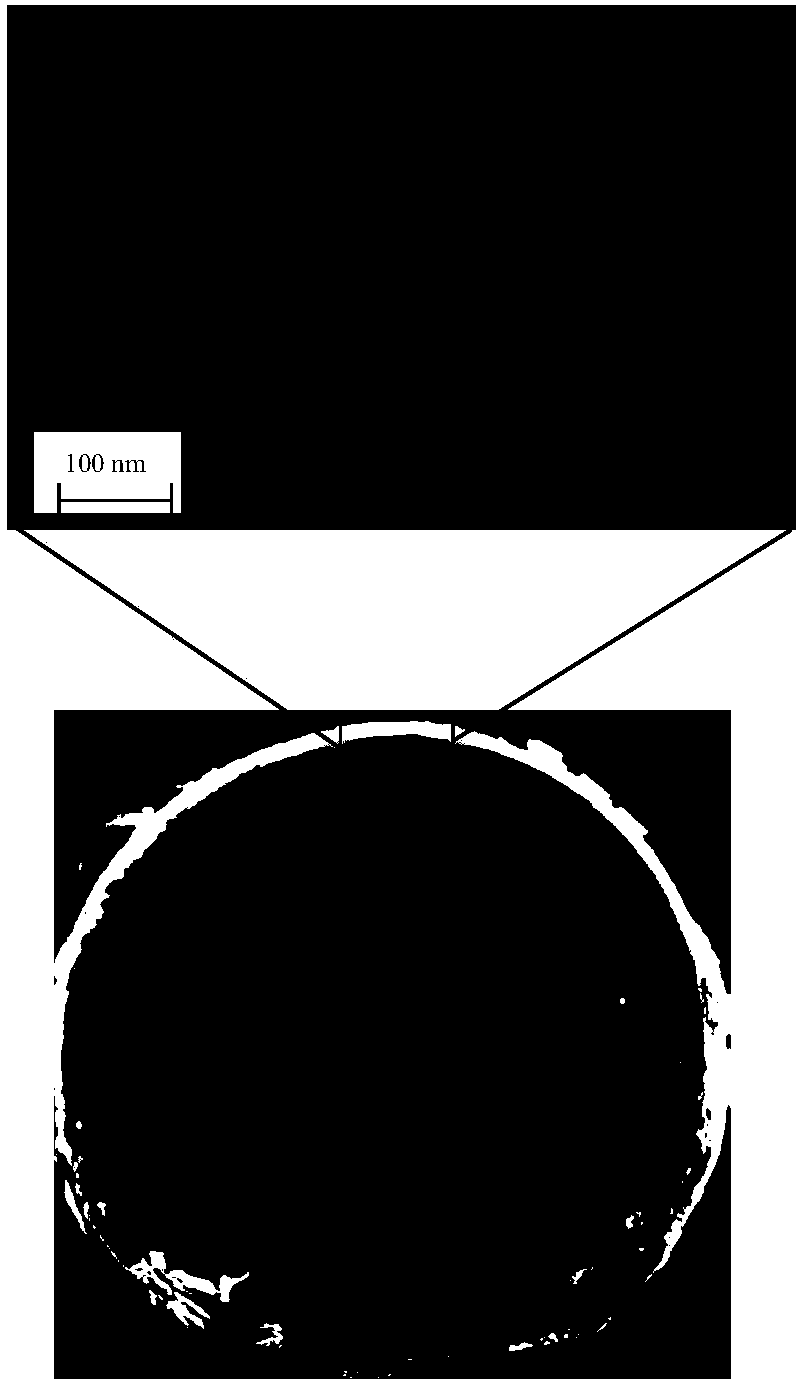

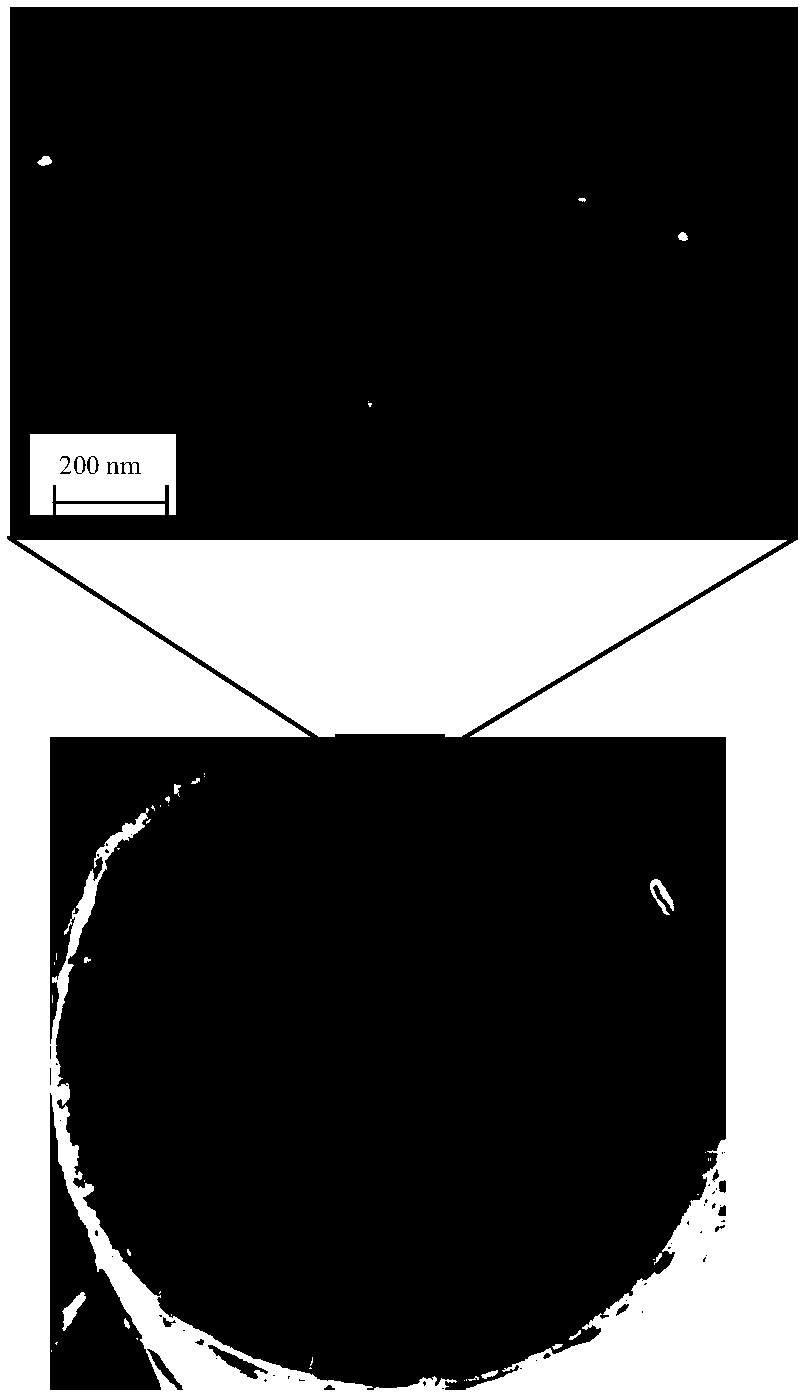

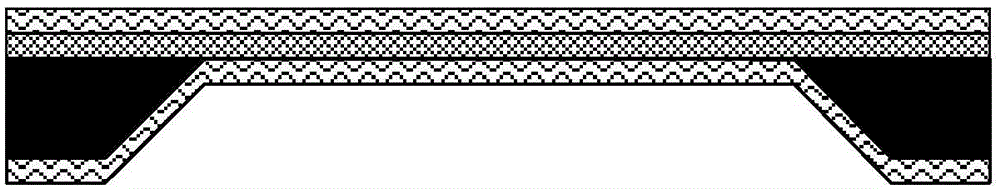

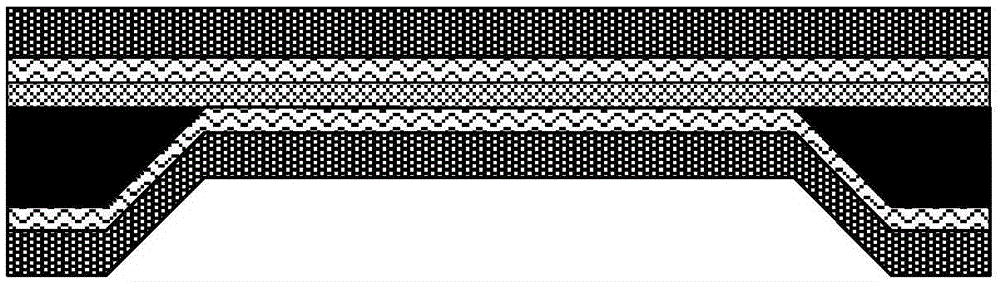

Preparation method of self-aligned double-layer X-ray zone plate

InactiveCN105006266AProcess conditions are stableImprove consistencyHandling using diffraction/refraction/reflectionNanotechnologyElectron-beam lithographyNanostructure

The invention belongs to the technical field of nanostructure preparation and specifically relates to a preparation method of a self-aligned double-layer X-ray zone plate. The method comprises steps of: depositing a metallic conductive seed layer on a substrate or diaphragm; spin coating the front side and the back side of the substrate or diaphragm with photoresist, and performing exposure and development by using electron beam lithography technology in order to obtain a designed graph; obtaining a double-layer X-ray zone plate structure by using nanometer electroplating technology; dissolving the photoresist by using organic solution such as acetone or the like; etching the seed layer at the surface by means of the ionic reaction etching to obtain the double-layer X-ray zone plate. The method is stable and controllable in technological condition, good in graphic consistency, and low in cost. The X-ray zone plate prepared by the method is ultrahigh in aspect ratio, high in diffraction efficiency, and high in spatial resolution.

Owner:FUDAN UNIV

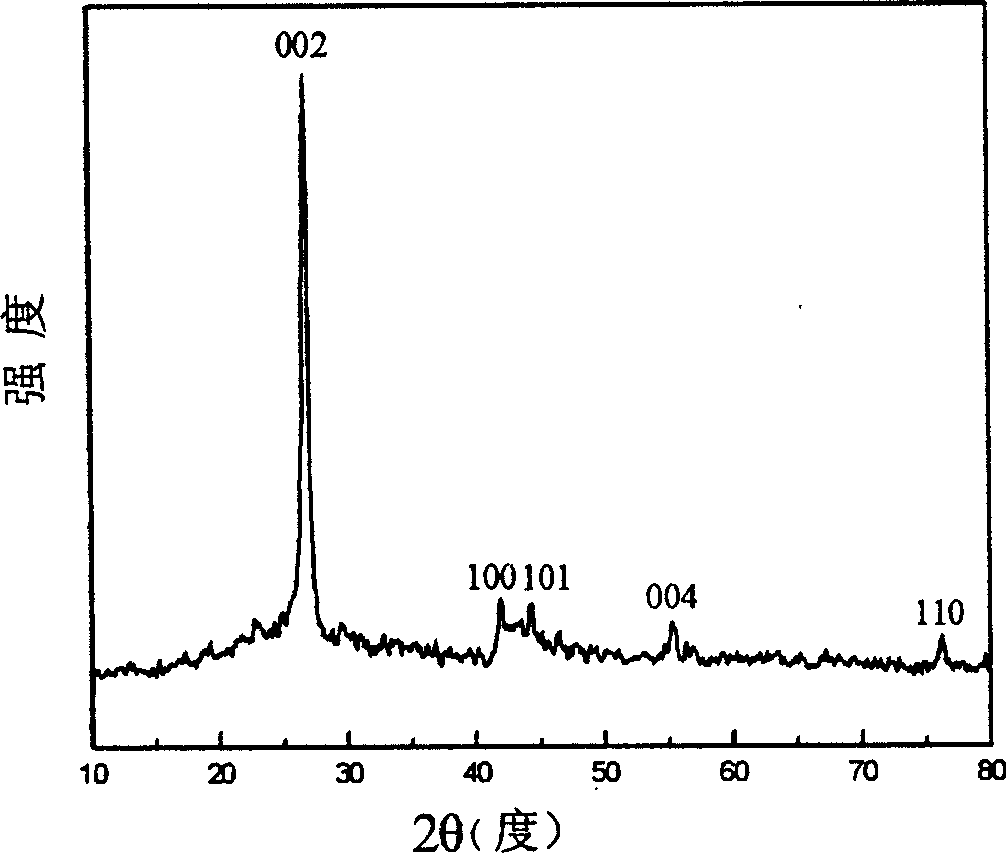

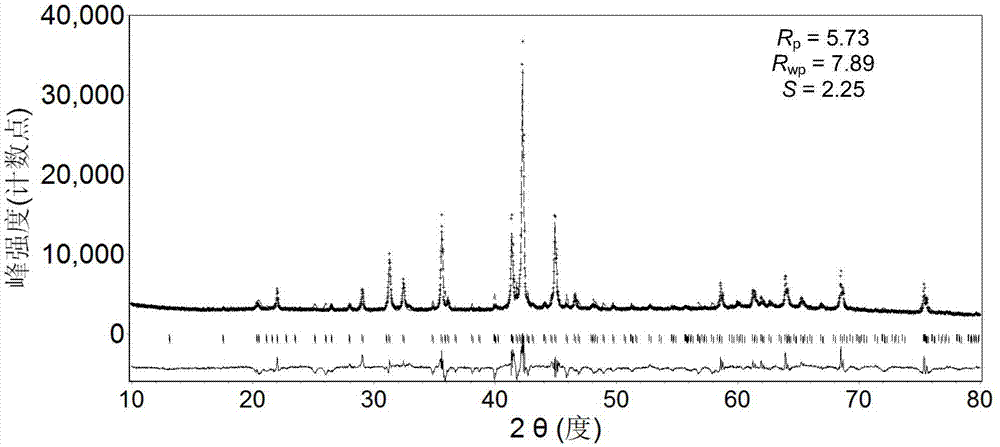

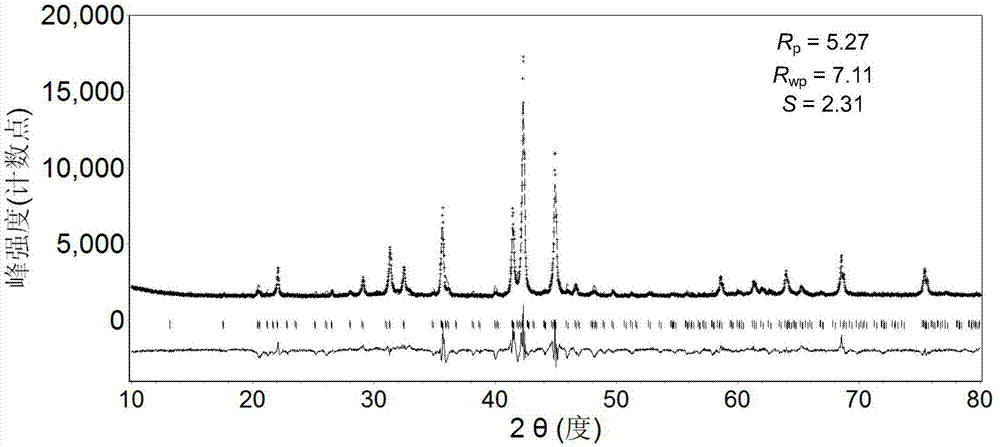

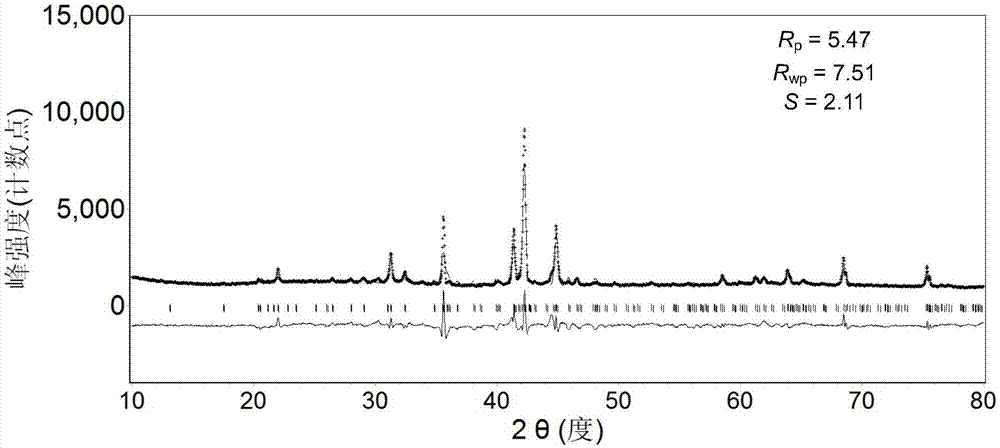

Single-phase AB4 type superlattice hydrogen storage alloy electrode material and preparation method thereof

ActiveCN107275626ASimple equipment and operationFacilitate industrial production and applicationCell electrodesSingle phaseLanthanum

The invention provides a single-phase AB4 type superlattice hydrogen storage alloy electrode material. The chemical composition of the single-phase AB4 type superlattice hydrogen storage alloy electrode material is La1-xMgx(NiAly)z, wherein x, y and z represent molar ratio; the numerical ranges of x, y and z are as follows: x is greater than or equal to 0.20 and is less than or equal to 0.24; y is greater than or equal to 0.021 and is less than or equal to 0.034; z is greater than or equal to 3.70 and is less than or equal to 3.93. The single-phase AB4 type superlattice hydrogen storage alloy electrode material is of a single-phase AB4 type superlattice structure; the space group is R-3m; the phase peakness is 100wt.%; a preparation method of the single-phase AB4 type superlattice lanthanum-magnesium-nickel-aluminum hydrogen storage alloy electrode material mainly comprises the following steps: putting alloy ingots into a stainless steel annealing pot with resistance to high temperature, controlling the ratio of the volume of the alloy to the volume of the annealing pot to be 2 to 3, then sealing the annealing pot by using a graphite sealing gasket, and putting the annealing pot in a vacuum annealing furnace for carrying out annealing treatment. The preparation method of the single-phase AB4 type superlattice hydrogen storage alloy electrode material is simple in operation and equipment; the process conditions are stable and easily controllable; the industrial production and application can be facilitated; the prepared single-phase AB4 type superlattice alloy can be directly used as nickel / metal hydride battery negative material; the alloy has the characteristics of high discharging capacity, long cycle life and low cost.

Owner:YANSHAN UNIV

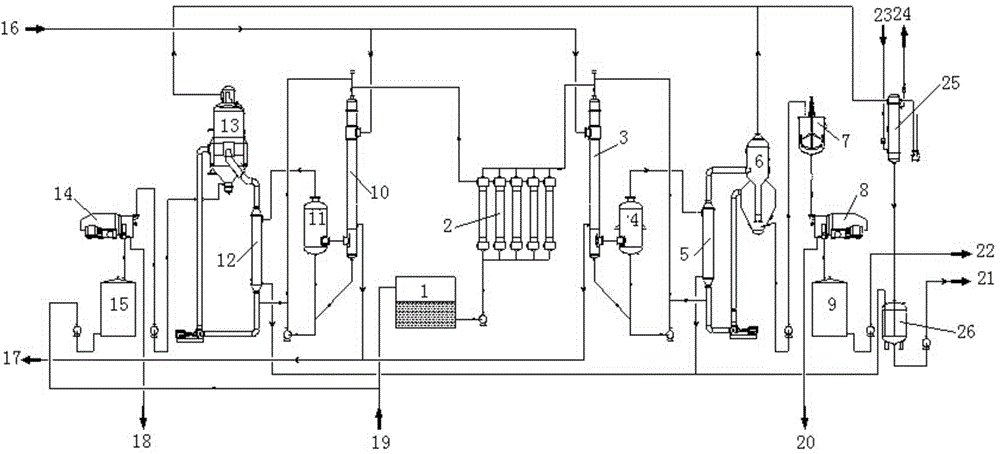

Recovery and treatment method for high-salinity wastewater containing sodium chloride and sodium sulfate

InactiveCN107902822AHigh purityMeet quality requirementsWater contaminantsWater/sewage treatmentSalinityNanofiltration

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

Composition for improving sexual function of males and application

InactiveCN105456522AEasy to prepareProcess conditions are stableDispersion deliveryNatural extract food ingredientsSexual dysfunctionOyster

The invention discloses a composition for improving the sexual function of males and an application. The composition is prepared from, by weight, 15-30 parts of fructus rubi extract, 15-30 parts of oyster aqueous extract, 10-20 parts of fructus lycii extract, 10-20 parts of grapefruit meal, 10-20 parts of sea-buckthorn meal, 1-10 parts of ginseng extract and 1-10 parts of maca extract. Human experiments prove that all the raw materials in the composition achieve the synergistic effect, and sexual dysfunction of the males can be effectively relieved. The composition is simple in preparation method, stable in process condition and suitable for large-scale industrial production.

Owner:TIANJIN YUANHENGDE TECH CO LTD

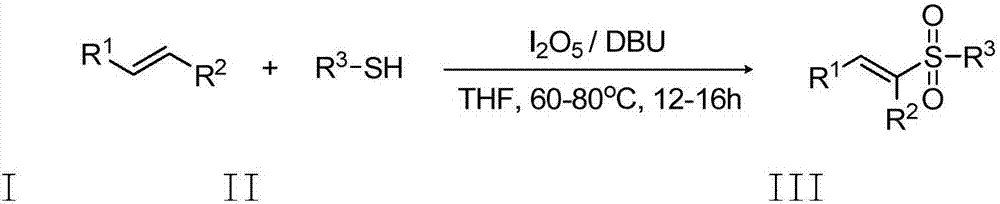

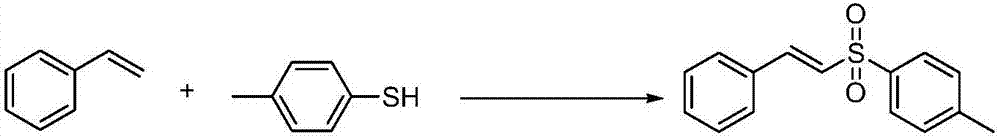

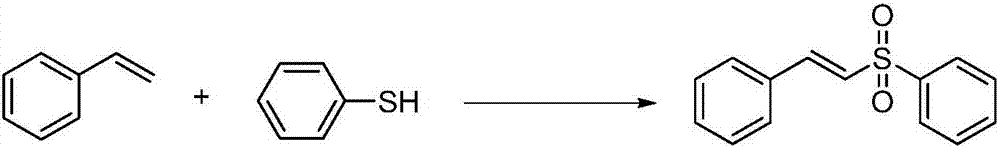

Preparation method of E-vinyl sulfones compound

InactiveCN107417582ARaw materials are cheap and easy to getAtom economy is highOrganic chemistryOrganic compound preparationOrganic baseOxygen

The invention discloses a preparation method of an E-vinyl sulfones compound. The preparation method comprises the following steps: dissolving raw materials of olefin and thiophenol (thioalcohol) into a tetrahydrofuran solvent; then adding lodine pentaoxide and organic base DBU (1,8-diazabicyclo undec-7-ene); directly reacting for 12 to 16 hours under 60 to 80 DEG C; separating and purifying a coarse product after stopping reacting, thus obtaining the E-vinyl sulfones compound. The preparation method has the advantages that raw materials are simple and can be easily obtained, the price is cheap, the reaction requires no metal catalyst, metal pollution is avoided, the operation is simple and is free of harsh conditions of water free, oxygen free and the like, the adaptive range of a substrate is wide, the reaction stereoselectivity is high, the process conditions are stable, and a prepared product is easy to purify.

Owner:QUFU NORMAL UNIV

Method for preparing 2-hydroxybenzeneboronic acid

ActiveCN103804403AReduce manufacturing costMeet the needs of large-scale productionGroup 3/13 element organic compoundsN-ButyllithiumBoric acid

The invention provides a method for preparing 2-hydroxybenzeneboronic acid, which relates to the technical field of industrial production for 2-hydroxybenzeneboronic acid. The method is characterized by comprising the following steps of: selecting raw material phenol which is already commercialized in the market as an initial raw material, in a normal-temperature condition, protecting hydroxyl at first, and then directly dripping n-butyllithium in the mixture of protected hydroxyl intermediate and borate compounds without separating crude products, and after the reaction is finished, hydrolyzing to prepare 2-hydroxybenzeneboronic acid. The method is easily-available in raw materials, high in both the purity and yield of the reaction product, stable in process conditions, simple to operate and suitable for large-scale production, and provides novel thinking and method for preparing 2-hydroxybenzeneboronic acid.

Owner:BENGBU CHINA SYNCHEM TECH CO LTD

Product for disintoxication and preparation method thereof

InactiveCN101757194AReduce entryReduce the burden onOrganic active ingredientsNervous disorderAlcoholVitamin C

The invention aims to provide a product for disintoxication and a preparation method thereof. The product comprises the following components in part by weight: 20 to 30 parts of cysteine, 25 to 40 parts of kudzuvine root extract, 25 to 40 parts of semen hoveniae extract, 1 to 2 parts of vitamin C and 5 to 15 parts of liquoric root extract. Natural Chinese medicinal herb extracts are specially combined with essential elements of a human body to quickly decompose alcohol in the human body and relieve drunken pain and harm to the human body due to disintoxication failure in time. The method has the advantages of simple preparation, stable process conditions, and suitability for large-scale industrial production.

Owner:沃德(天津)营养保健品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com