Chlorophenol graphene-based molecularly imprinted solid-phase extraction column and preparation method and application thereof

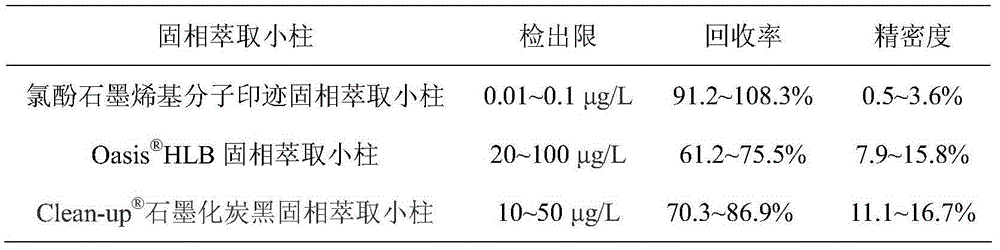

A solid-phase extraction cartridge, molecular imprinting technology, applied in separation methods, chemical instruments and methods, preparation of samples for testing, etc., can solve the problems of few polymer adsorption sites, single detection object, lack of application significance, etc. Achieve high selectivity and enrichment capacity, large adsorption capacity and strong selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

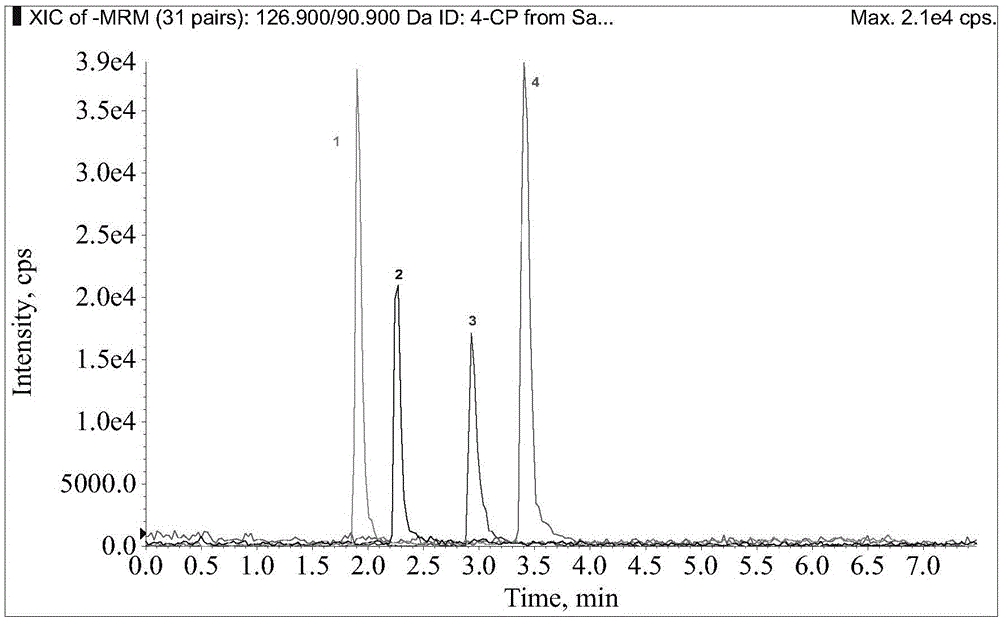

Image

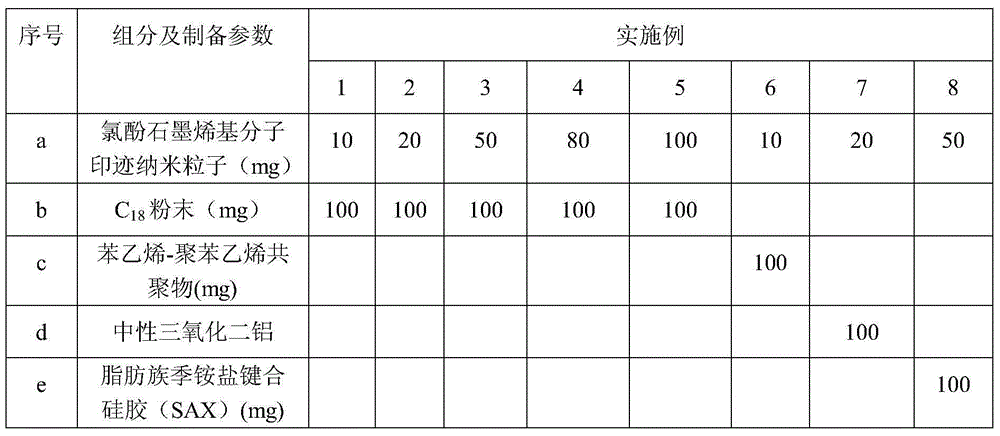

Examples

Embodiment 1

[0030] (1) Preparation of chlorophenol graphene-based molecularly imprinted nanoparticles:

[0031] (1.1) Preparation of monodisperse core-shell magnetic polymer microspheres with high magnetic response: by solvothermal method, 2.5g FeCl 3 ·6H 2O, 80g ethylene glycol, 6.5g sodium acetate and 2.0g polyethylene glycol were mixed, stirred and dissolved at 50°C for 0.5h, then the mixed solution was added to a polytetrafluoroethylene autoclave and reacted at 200°C for 8h to obtain magnetic tetrafluoroethylene Ferric oxide microspheres. Then weigh 80 mg of magnetic ferric oxide microspheres, add 100 mL of acetonitrile to ultrasonically disperse for 0.5 h, then add 0.6 g of divinylbenzene (DVB), 0.6 g of glycidyl methacrylate (GMA) as polymerized monomers and 0.02 g of Nitroisobutyronitrile (ABIN) was used as an initiator to prepare monodisperse core-shell magnetic polymer microspheres with high magnetic response by precipitation polymerization at 80°C for 2 hours.

[0032] (1.2) ...

Embodiment 2

[0039] (1) Preparation of chlorophenol graphene-based molecularly imprinted nanoparticles:

[0040] (1.1) Preparation of monodisperse core-shell magnetic polymer microspheres with high magnetic response: using solvothermal method, 1.0g FeCl 3 ·6H 2 O, 80g ethylene glycol, 5g sodium acetate and 2.0g polyethylene glycol were mixed, stirred and dissolved at 50°C for 1h, then the mixed solution was added to a polytetrafluoroethylene autoclave and reacted at 200°C for 4h to obtain magnetic trioxide Iron microspheres. Then weigh 80 mg of magnetic ferric oxide microspheres, add 100 mL of acetonitrile to ultrasonically disperse for 0.5 h, then add 0.6 g of divinylbenzene (DVB), 0.6 g of glycidyl methacrylate (GMA) as polymerized monomers and 0.09 g of diisocyanate Azodiisobutyronitrile (ABIN) was used as an initiator to prepare monodisperse core-shell magnetic polymer microspheres with high magnetic response by precipitation polymerization at 80°C for 4.5 hours.

[0041] (1.2) Acti...

Embodiment 3

[0048] (1) Preparation of chlorophenol graphene-based molecularly imprinted nanoparticles:

[0049] (1.1) Preparation of monodisperse core-shell magnetic polymer microspheres with high magnetic response: using solvothermal method, 3.5g FeCl 3 ·6H 2 O, 70g of ethylene glycol, 6g of sodium acetate and 2.0g of polyethylene glycol were mixed, stirred and dissolved at 50°C for 0.5h, and then the mixed solution was added to a polytetrafluoroethylene autoclave at 200°C for 6h to obtain magnetic tetraoxide Tri-iron microspheres. Then weigh 70 mg of magnetic ferric oxide microspheres, add 100 mL of acetonitrile to ultrasonically disperse for 0.5 h, then add 0.6 g of divinylbenzene (DVB), 0.2 g of glycidyl methacrylate (GMA) as polymerized monomers and 0.08 g of diisocyanate Nitroisobutyronitrile (ABIN) was used as an initiator to prepare monodisperse core-shell magnetic polymer microspheres with high magnetic response by precipitation polymerization at 80°C for 3.5 hours.

[0050] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ion source temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com