Liquid rare earth calcium zinc stabilizer and preparation method thereof

The technology of zinc stabilizer and rare earth calcium is applied in the field of liquid rare earth calcium zinc stabilizer for PVC resin and its preparation field, which can solve the problems of poor initial coloring, affecting product quality stability, easy precipitation when the dosage is large, and achieves lubricating performance. Excellent, combined with antioxidant properties and stable process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

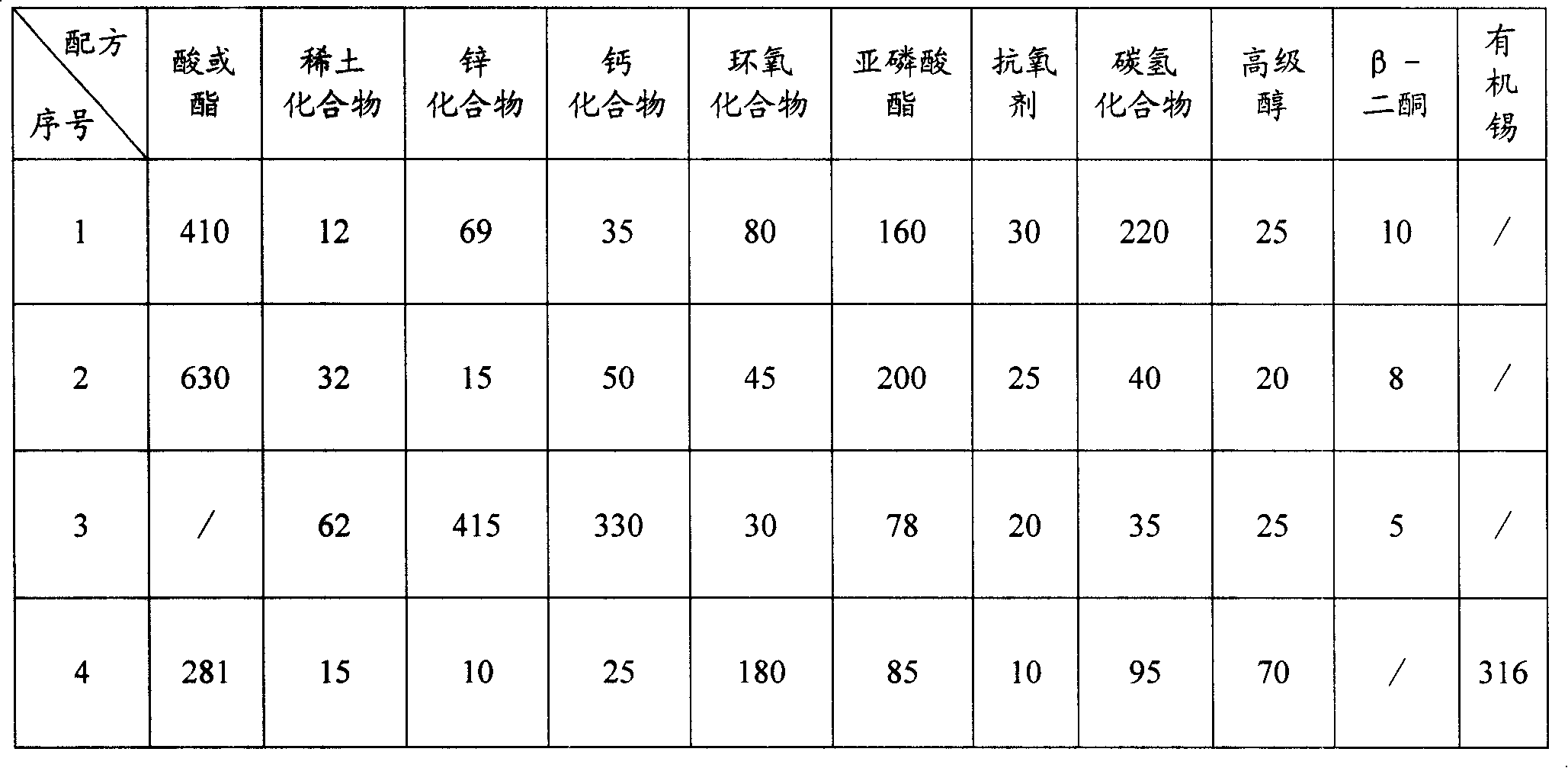

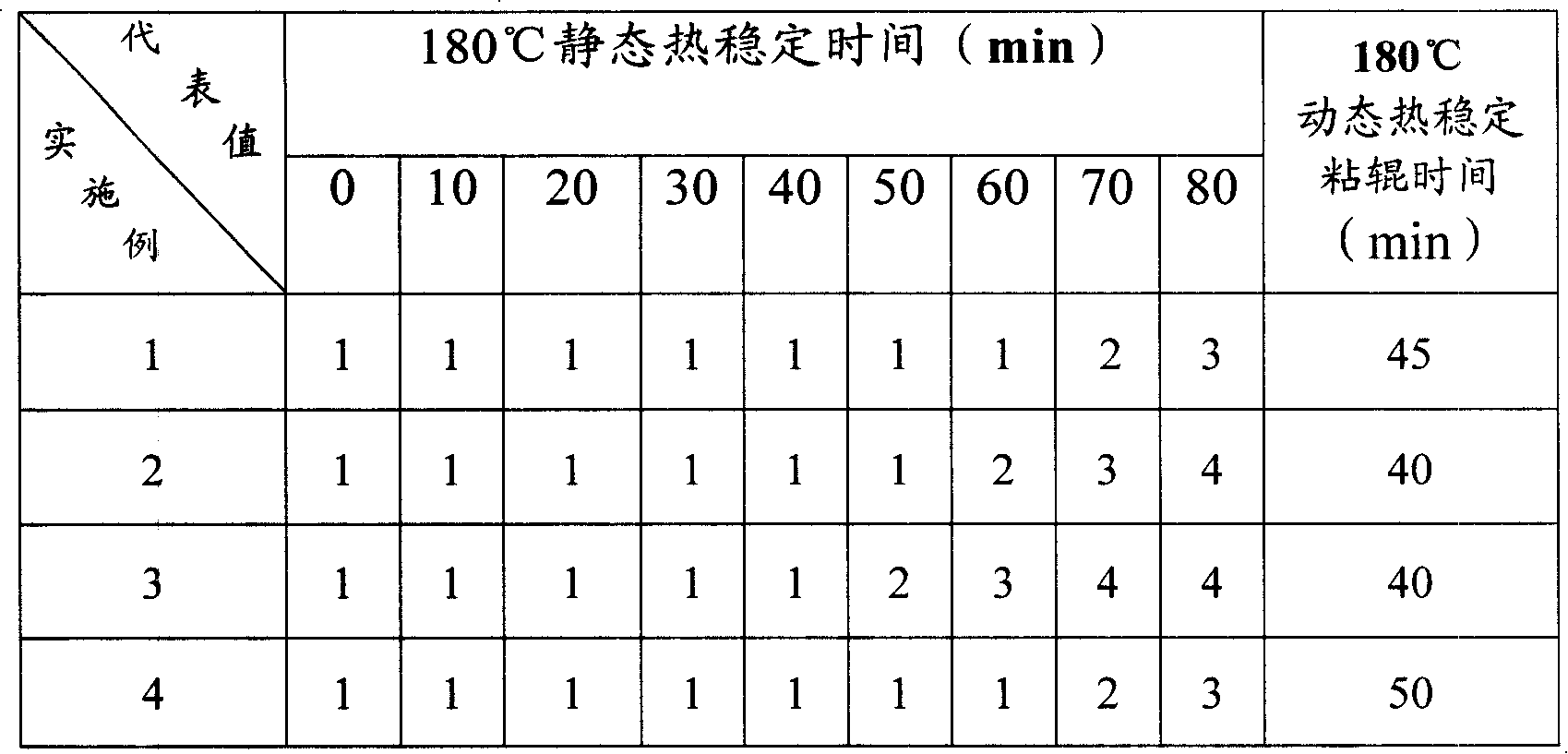

Embodiment 1

[0035] 1. Add 193kg of isooctanoic acid, 131kg of oleic acid and 86kg of p-tert-butylbenzoic acid into the reaction kettle. Heat up to 80°C to 100°C, add 5kg of mixed catalyst with a mass ratio of acetic acid and phosphorous acid of 2:3 under stirring (stirring speed 85-115 rpm), after the material is completely melted, slowly add light rare earth oxidation Lanthanum 12kg, reacted for 0.5 hours, zinc oxide 69kg, stirred and reacted for 1 hour (stirring speed 85~115 rpm), calcium hydroxide 35kg, continued to react for 0.5 hours, controlled temperature 110°C, then added 220kg of higher alkanes, at 100°C Temperature, 27.66kpa negative pressure, and 0.5 hour of pumping time to remove water and low molecular impurities to obtain a liquid rare earth calcium zinc mixture.

[0036] 2. Add 80kg of epoxidized soybean oil, 160kg of monophenyldioctyl phosphite, 25 parts of bisphenol A and 1010 of antioxidant to the prepared liquid rare earth calcium-zinc mixture, totaling 30kg, twelve to ...

Embodiment 2

[0039] 1. Put 200kg of phthalic anhydride and isooctyl alcohol in a molar ratio of 1:1 into the reactor, heat up to 130-140°C, start stirring (stirring speed 85-115 rpm), carry out esterification reaction, measure The reaction is completed when the acid value is 190-200 mg·KOH / g. Then add 173kg of isooctanoic acid, 122kg of oleic acid, 25kg of lauric acid, 103kg of benzoic acid, 7kg of mixed catalyst with a mass ratio of acetic acid and hydrogen peroxide of 5:2, stir and mix (stirring speed 85~115 rpm), control the reaction temperature 110°C , put 12kg of rare earth cerium oxide and 20kg of lanthanum oxide into the reactor in turn, and react for 0.5 hours; 15kg of zinc oxide, react for 0.5 hours; Kpa negative pressure, 0.5 hours of vacuuming to remove moisture and low molecular impurities, that is, liquid rare earth calcium zinc mixture.

[0040] 2. Add 40kg of effective substances epoxidized soybean oil, 200kg of triphenyl phosphite, 25kg of bisphenol A, 20kg of cetyl alcoho...

Embodiment 3

[0042] Embodiment 3 (comparative example):

[0043] Add 62kg of rare earth compound, 415kg of zinc compound, 330kg of calcium compound, 30kg of epoxy soybean oil, 78kg of phenylenedioctyl phosphite, 20kg of bisphenol A, 25kg of dodecyl alcohol, white 35kg of oil, heated up to 110°C, stirred for 1 hour (stirring speed 85-115 rpm), at 100°C, 27.66kpa negative pressure, vacuumed for 0.5 hours to remove a small amount of water and low-molecular impurities, press filter Packing, the liquid rare earth calcium zinc stabilizer is obtained.

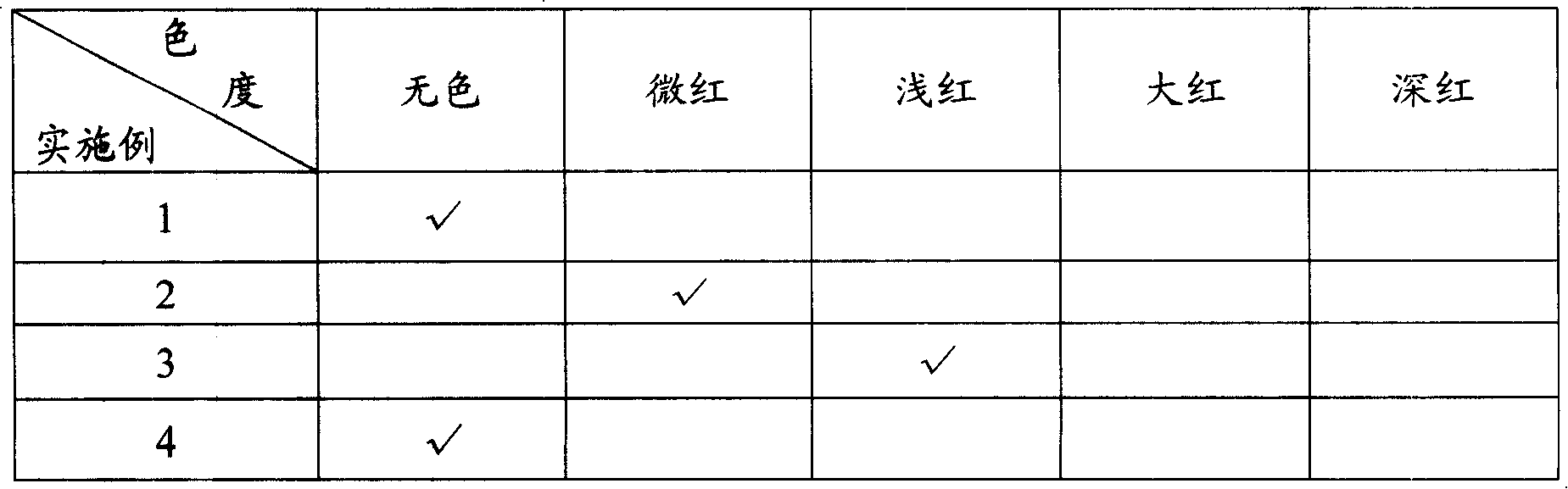

[0044] Product analysis indicators: metal content (%): 6.50, specific gravity (20°C) 0.93, color (Pt-Co): <300

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com