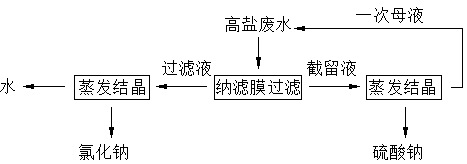

Recovery and treatment method for high-salinity wastewater containing sodium chloride and sodium sulfate

A high-salt wastewater, recycling and treatment technology, applied in the direction of energy wastewater treatment, chemical instruments and methods, multi-stage water treatment, etc., can solve the problems of inability to reuse, increase the cost of wastewater treatment, low purity, etc., and reduce the cost of wastewater treatment , Realize the effect of resource utilization and simple and stable process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

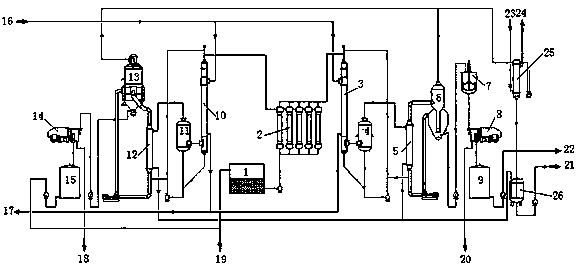

[0055] The technological process of this embodiment is as figure 2 As shown, the two-effect co-current evaporation process is adopted.

[0056] In this embodiment, the evaporation and crystallization of the retained liquid adopts a double-effect downstream process; the first-effect evaporator adopts a falling-film evaporator, including a first-effect separation chamber B11 and a first-effect heating chamber B10; the second-effect evaporator adopts a forced circulation evaporation crystallizer, Including the second-effect crystallizer B13 and the second-effect heating chamber B12. The filtrate evaporation and crystallization section adopts a double-effect downstream process; the first-effect evaporator adopts a falling film evaporator, including a first-effect separation chamber A4 and a first-effect heating chamber A3; the second-effect evaporator adopts a forced circulation evaporation crystallizer, including a second-effect crystallization Device A6 and two-effect heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com