Preparation method of X-ray zone plate

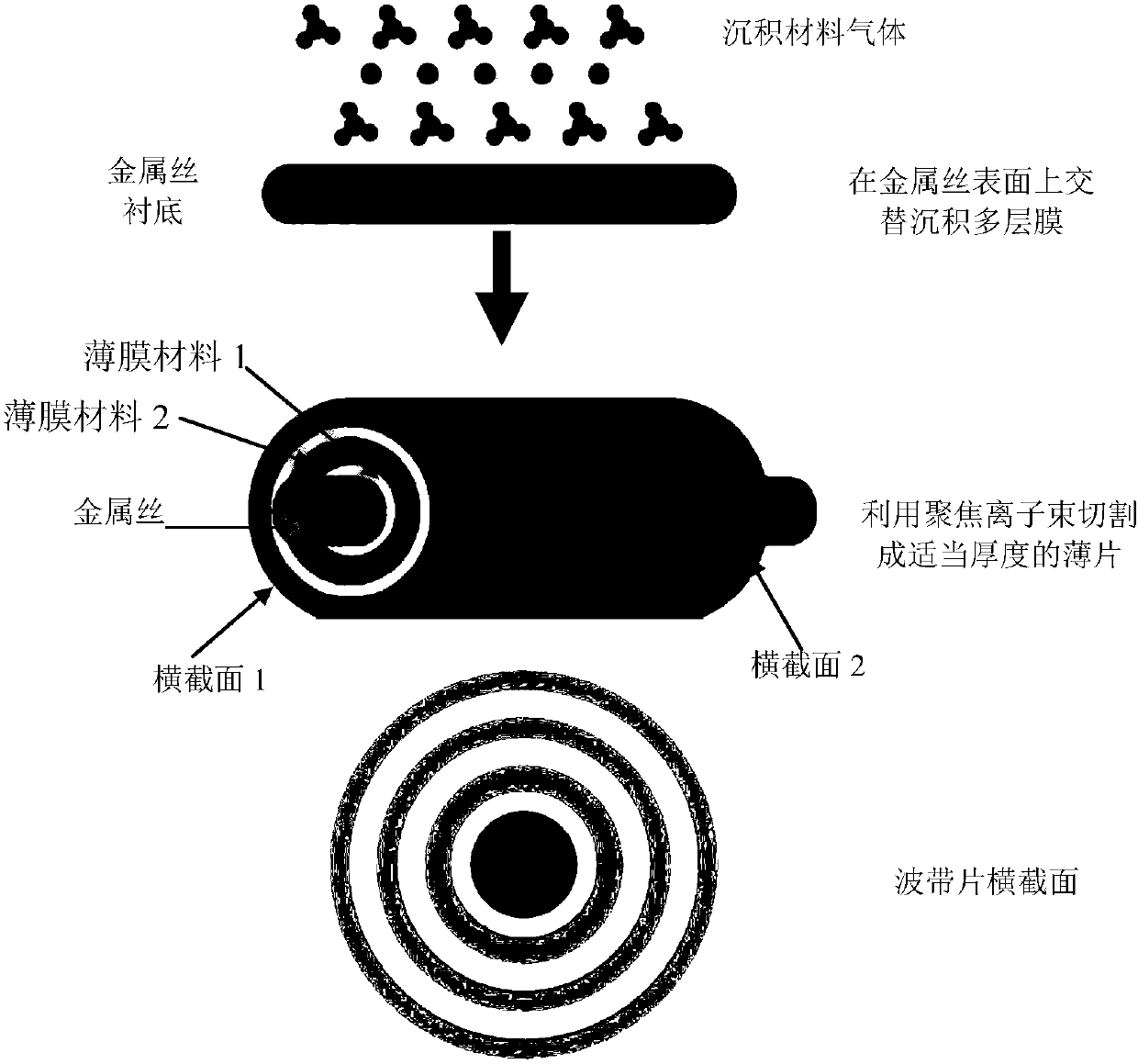

A zone plate and X-ray technology, which is applied in the field of preparation of X-ray zone plates, can solve the problems such as the inability of glass filament to effectively block X-rays, the difficulty in controlling the uniformity of the annular zone, the collapse of the photoresist structure, etc., and the diffraction efficiency can be solved. Low, good graphics consistency, high aspect ratio effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

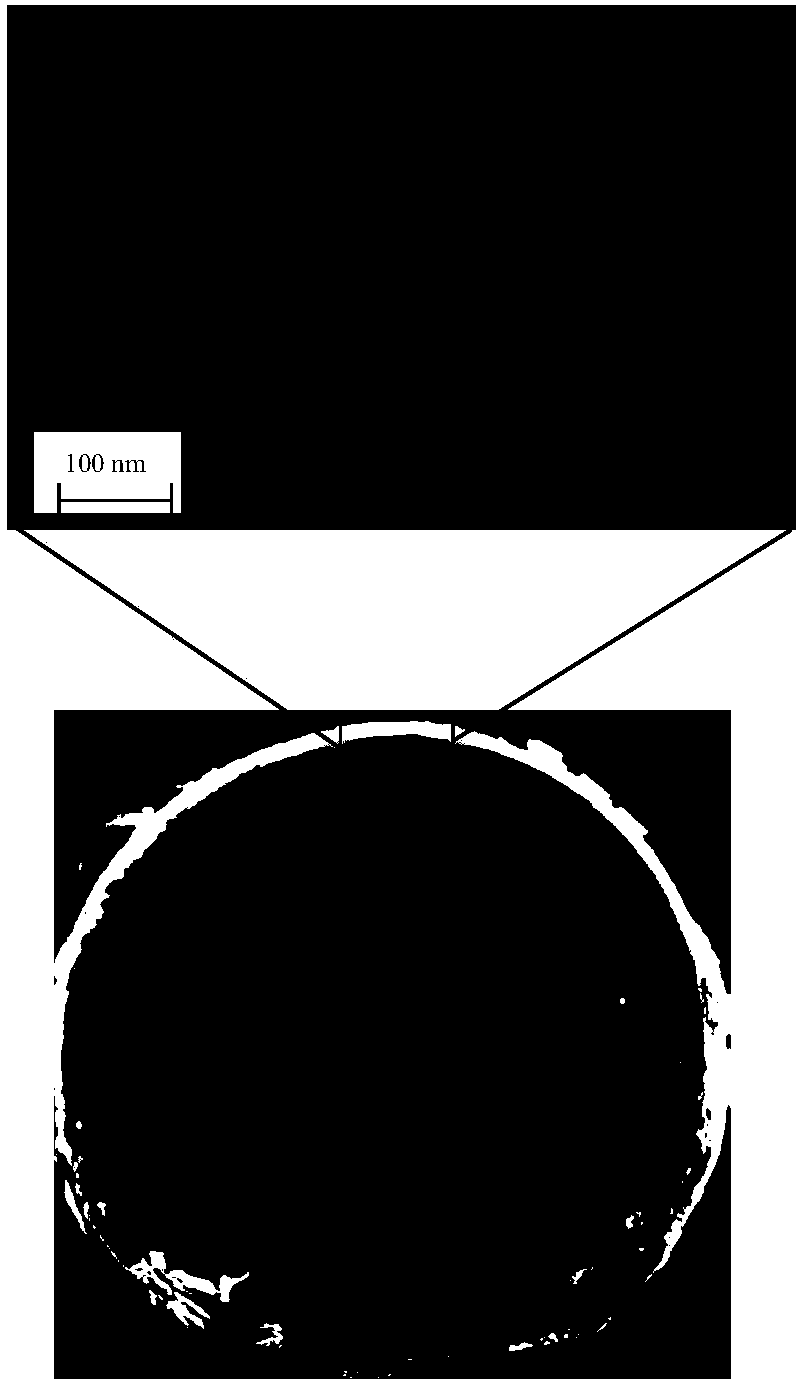

[0025] 1. Use a tungsten wire with a diameter of 30 μm and a surface roughness of 50 nm;

[0026] 2. The given X-ray energy is 8keV, the corresponding wavelength λ=0.155nm, the focal length f=19.3548mm, the outermost ring width is 20nm, r 0 =15μm, according to the formula Calculate the number of rings in the outermost layer of the zone plate N=1801;

[0027] 3. Calculate the radius and width of each half-wave band

[0028] According to the radius of each half-wave zone according to the formula Calculated, such as r1=15.0997μm,

[0029] According to the formula Calculate the width of each half-wave band, such as △r 1 =99.7nm;

[0030] 4. Put the tungsten wire into the atomic layer deposition (ALD) coating equipment, start the equipment, and perform coating according to the calculation results in step 3. The first layer deposits aluminum oxide, and the second layer deposits hafnium oxide. 1801 layers, completed deposition;

[0031] 5. Take the coated tungsten wire out...

Embodiment 2

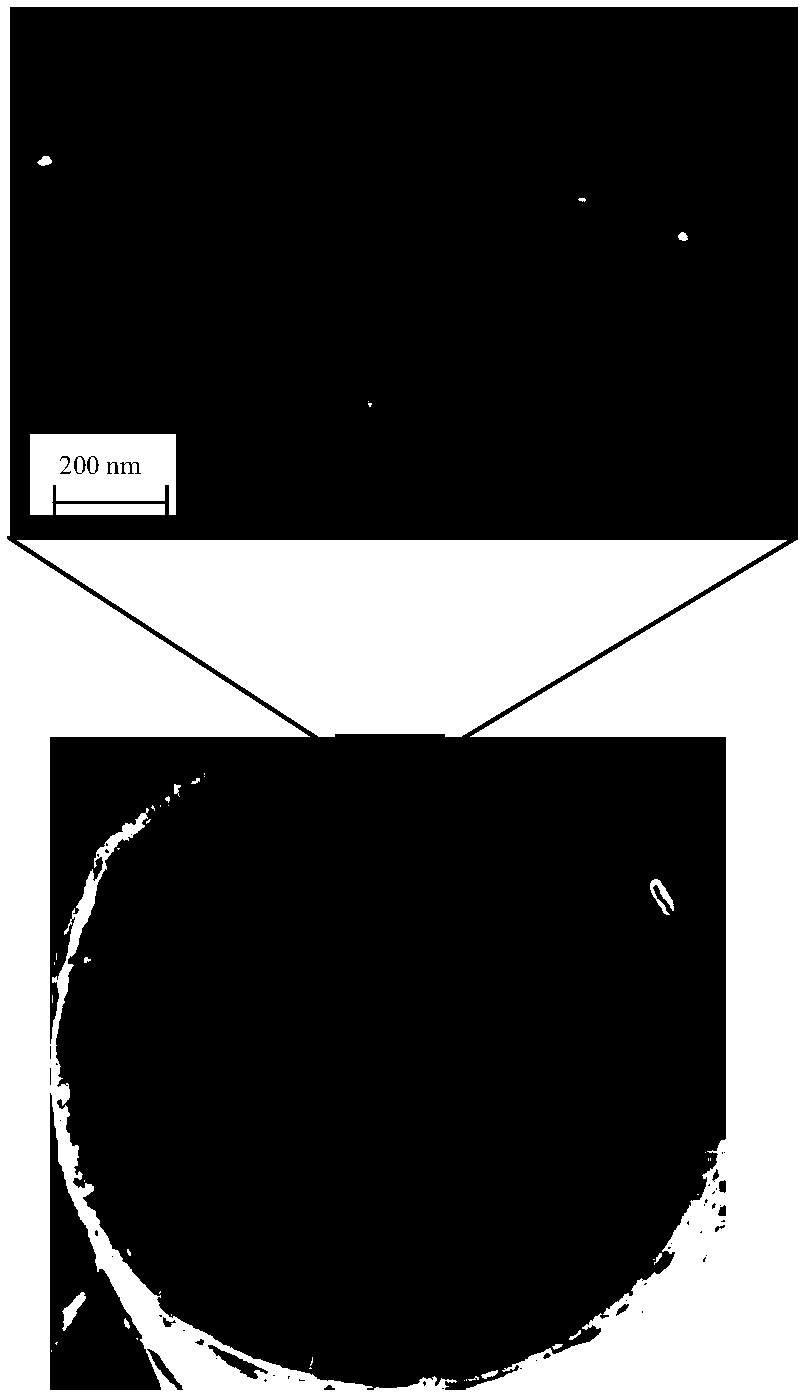

[0036] 1. Gold wire with a diameter of 20 μm is selected, and its surface roughness is 90 nm;

[0037] 2. The given X-ray energy is 8keV, the corresponding wavelength λ=0.155nm, the focal length f=19.3548mm, the outermost ring width is 40nm, r 0 =10μm, according to the formula Calculate the number of outermost rings of the zone plate N=436;

[0038] 3. Calculate the radius and width of each half-wave band

[0039] According to the radius of each half-wave zone according to the formula Calculated, such as r1=10.1489μm,

[0040] According to the formula Calculate the width of each half-wave band, such as △r 1 =148.9nm;

[0041] 4. Put the gold wire into the atomic layer deposition (ALD) coating equipment, start the equipment, and perform coating according to the calculation results in step 3. The first layer deposits aluminum oxide, and the second layer deposits iridium, so that the cycle is alternated until the 436th layer, to complete the deposition;

[0042] 5. Take ...

Embodiment 3

[0047] 1. Choose gold wire with a diameter of 5 μm, and its surface roughness is 70 nm;

[0048] 2. The given X-ray energy is 8keV, the corresponding wavelength λ=0.155nm, the focal length f=19.3548mm, the outermost ring width is 10nm, r 0 =2.5μm, according to the formula Calculate the number of rings in the outermost layer of the zone plate N=7498;

[0049] 3. Calculate the radius and width of each half-wave band

[0050] According to the radius of each half-wave zone according to the formula Calculated, such as r1=3.0414μm,

[0051] According to the formula Calculate the width of each half-wave band, such as △r 1 =41.4nm;

[0052] 4. Put the gold wire into the atomic layer deposition (ALD) coating equipment, start the equipment, and perform coating according to the calculation results in step 3. The first layer deposits aluminum oxide, and the second layer deposits iridium, so that the cycle is alternated until the 7498th layer, to complete the deposition;

[0053...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com