Single-phase AB4 type superlattice hydrogen storage alloy electrode material and preparation method thereof

A hydrogen storage alloy and electrode material technology, applied in the field of materials, achieves the effects of low cost, convenient industrial production and application, and strong market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

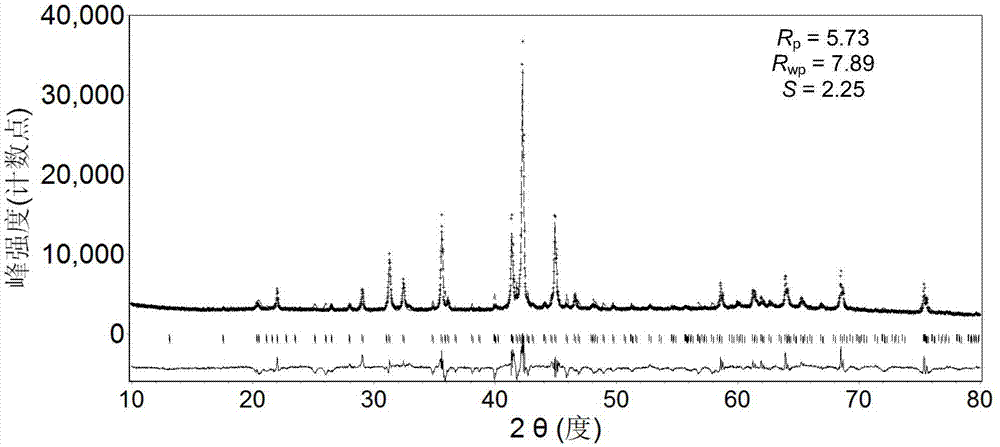

Embodiment 1

[0021] The alloy composition is: La 0.80 Mg 0.20 Ni 3.62 Al 0.08 , select metal elements La, Ni, Al and Mg 2 Ni alloy compound is used as the raw material, and the as-cast alloy is prepared by the conventional intermediate frequency induction melting method, and then the obtained alloy ingot is put into a high-temperature resistant stainless steel annealing tank, so that the volume ratio of the alloy to the volume of the annealing tank is 2 / 3, and then graphite The sealing gasket seals the annealing tank and places it in a vacuum annealing furnace, and performs annealing treatment under the protection of an argon atmosphere with a pressure of –0.02MPa: first, the temperature is raised from room temperature to 500°C for 1h and kept for 1h; then the temperature is raised from 500°C to 600°C, 700°C, 800°C and 900°C, the heating time of each temperature range is 0.5h, and the holding time of each temperature point is 1h; then continue to heat up from 900°C to 950°C for 0.5h and...

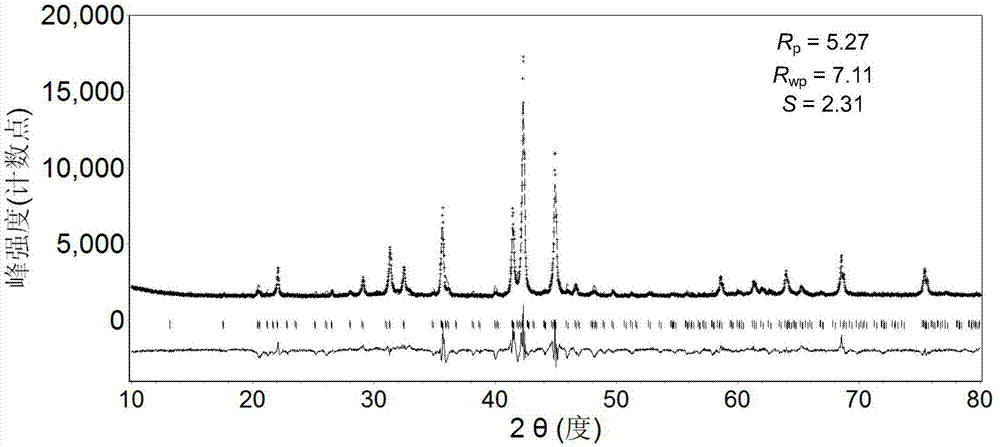

Embodiment 2

[0023] The alloy composition is: La 0.79 Mg 0.21 Ni 3.60 Al 0.10 , select metal elements La, Ni, Al and Mg 2 Ni alloy compound is used as the raw material, and the as-cast alloy is prepared by the conventional intermediate frequency induction melting method, and then the obtained alloy ingot is put into a high-temperature resistant stainless steel annealing tank, so that the volume ratio of the alloy to the volume of the annealing tank is 2 / 3, and then graphite The sealing gasket seals the annealing tank and places it in a vacuum annealing furnace. The annealing treatment is carried out under the protection of an argon atmosphere with a pressure of 0.02MPa: first, the temperature is raised from room temperature to 500°C for 1h and kept for 1h; then the temperature is raised from 500°C to 600°C ℃, 700℃, 800℃ and 900℃, where the heating time for each temperature range is 0.5h, and the holding time for each temperature point is 1h; then continue to heat up from 900℃ to 950℃ fo...

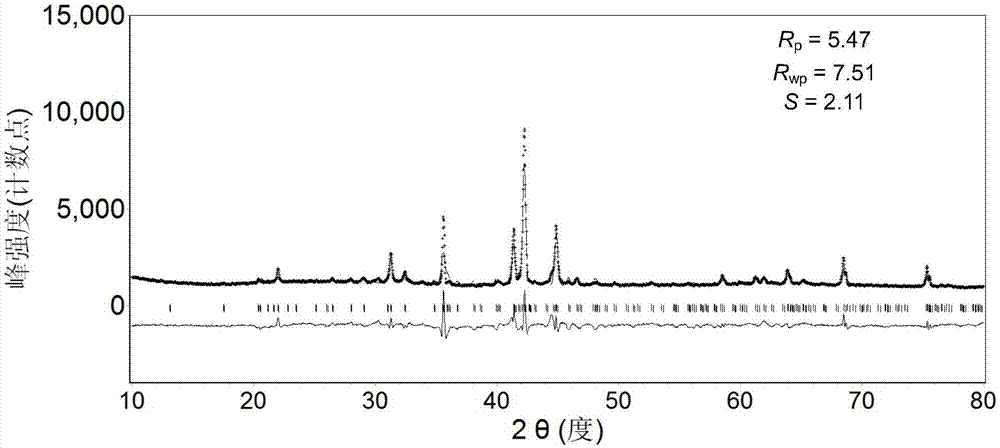

Embodiment 3

[0025] The alloy composition is: La 0.79 Mg 0.21 Ni 3.80 Al 0.13 , select metal elements La, Ni, Al and Mg 2 Ni alloy compound is used as the raw material, and the as-cast alloy is prepared by the conventional intermediate frequency induction melting method, and then the obtained alloy ingot is put into a high-temperature resistant stainless steel annealing tank, so that the volume ratio of the alloy to the volume of the annealing tank is 2 / 3, and then graphite The sealing gasket seals the annealing tank and places it in a vacuum annealing furnace, and performs annealing treatment under the protection of an argon atmosphere with a pressure of –0.01MPa: first, the temperature is raised from room temperature to 500°C for 1h and kept for 1h; then the temperature is raised from 500°C to 600°C, 700°C, 800°C and 900°C, the heating time of each temperature range is 0.5h, and the holding time of each temperature point is 1h; then continue to heat up from 900°C to 950°C for 0.5h and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com