Method for refining crude quinoline by continuous rectification

A quinoline and rectifying technology, applied in the field of refining crude quinoline, can solve the problems of easy residue, complicated production process, increase production cost and the like, and achieve the effects of large quantity, simple equipment and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

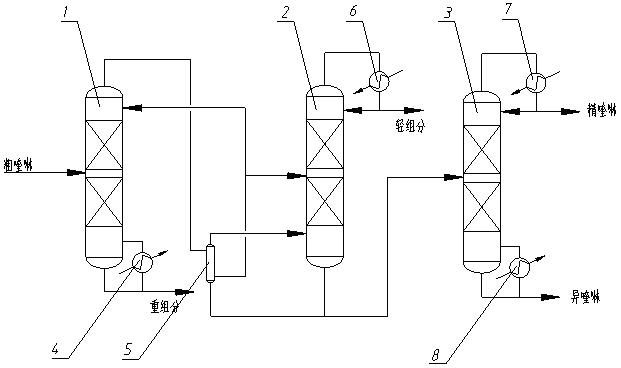

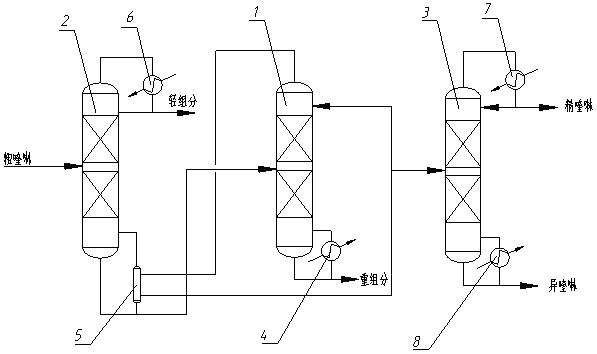

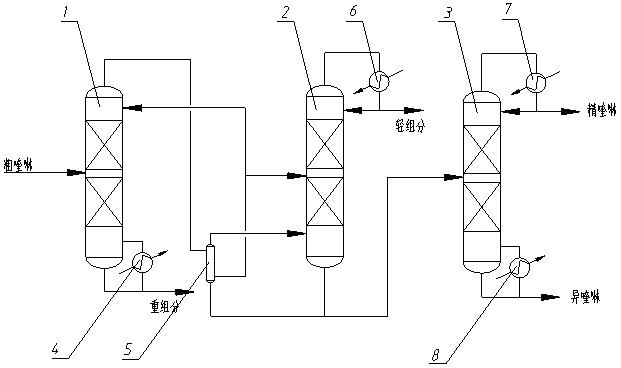

[0027] The method for continuous rectification and refining crude quinoline of the present invention comprises figure 1 , figure 2 Two workflows are shown.

[0028] exist figure 1 In the embodiment of shown working process, take the weight-removing rectification tower 1 as atmospheric tower or pressurized tower, light-removing rectification tower 2 is decompression tower; The tower top of described weight-removing rectification tower 1 has steam heating effect, its tower bottom is provided with a weight removal tower reboiler 4; the tower top of the described light removal rectification tower 2 is provided with a light removal tower condenser 6, and its tower bottom is provided with a condensation reboiler 5; by adjusting the tower pressure , the vapor temperature at the top of the de-lightening rectification tower 1 can be made to be higher than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com