Preparation method of high-strength super-hydrophobic paper on the basis of layer by layer self-assembly and thermal induction treatment

A layer-by-layer self-assembly and super-hydrophobic paper technology, which is applied in the field of preparation of high-strength super-hydrophobic paper, can solve the problems of cumbersome preparation process, complex and expensive equipment, etc., to overcome the cumbersome preparation process, simple operation and equipment, and good application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation method of the high-strength superhydrophobic paper based on layer-by-layer self-assembly and heat-induced treatment, its specific steps are as follows:

[0021] (1) First, put plain paper in a chitosan solution with a concentration of 2g / L (add acid to the chitosan solution to adjust the pH value to 5~5.7) and soak it for 10 minutes. After taking it out, wash it with deionized water for 3 times. Dry at 60°C for 10 minutes;

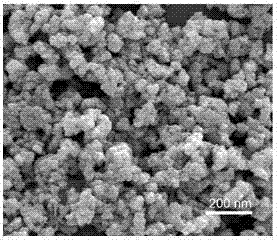

[0022] (2) Then soak the paper treated in step (1) in the nano-titanium dioxide-ethanol solution grafted with hexadecyltrimethoxysilane for 10 minutes, take it out and wash it with deionized water for 3 times, and then clean it at 60 Drying at ℃ for 10min, wherein the concentration of nano-titanium dioxide-ethanol solution modified by hexadecyltrimethoxysilane grafting is 2g / L; the preparation method of nano-titanium dioxide modified by hexadecyltrimethoxysilane grafting: first Mix anhydrous ethanol and deionized water at a volume r...

Embodiment 2

[0026] The preparation method of the high-strength superhydrophobic paper based on layer-by-layer self-assembly and heat-induced treatment, its specific steps are as follows:

[0027] (1) First, put plain paper in a chitosan solution with a concentration of 2.5g / L (add acid to the chitosan solution to adjust the pH value to 5~5.7) and soak for 15 minutes, take it out and wash it with deionized water for 4 times, Dry at 70°C for 15 minutes;

[0028] (2) Then soak the paper treated in step (1) in the nano-titanium dioxide-ethanol solution grafted with hexadecyltrimethoxysilane for 15 minutes, take it out and wash it with deionized water for 4 times, and at 70 ℃ of drying 15min, wherein the concentration of nano-titanium dioxide-ethanol solution modified by hexadecyltrimethoxysilane grafting is 3g / L; The preparation method of the nano-titanium dioxide modified by hexadecyltrimethoxysilane grafting: first Mix anhydrous ethanol and deionized water at a volume ratio of 95:5 to obta...

Embodiment 3

[0032] The preparation method of the high-strength superhydrophobic paper based on layer-by-layer self-assembly and heat-induced treatment, its specific steps are as follows:

[0033](1) First, put plain paper in a chitosan solution with a concentration of 3g / L (add acid to the chitosan solution to adjust the pH value to 5~5.7) and soak it for 20 minutes. After taking it out, wash it with deionized water for 5 times. Dry at 80°C for 20 minutes;

[0034] (2) Then soak the paper treated in step (1) in the nano-titanium dioxide-ethanol solution grafted with hexadecyltrimethoxysilane for 20 minutes, take it out and wash it with deionized water for 5 times. Drying at ℃ for 20min, wherein the concentration of nano-titanium dioxide-ethanol solution modified by hexadecyltrimethoxysilane grafting is 4g / L; the preparation method of nano-titanium dioxide modified by hexadecyltrimethoxysilane grafting: first Mix anhydrous ethanol and deionized water at a volume ratio of 95:5 to obtain an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

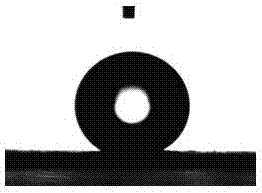

| Surface water contact angle | aaaaa | aaaaa |

| Surface water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com