Patents

Literature

299results about How to "Improve particle size distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

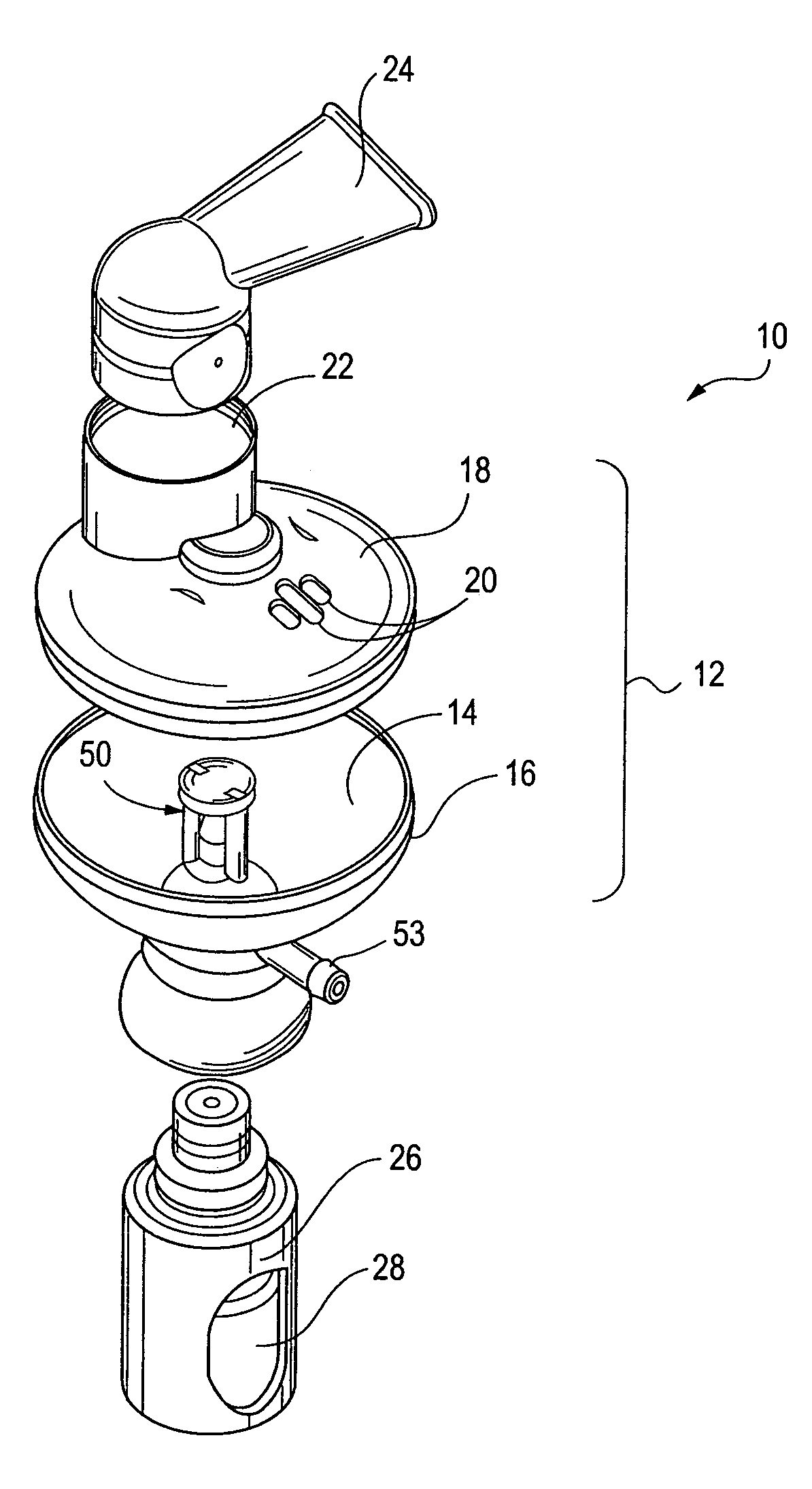

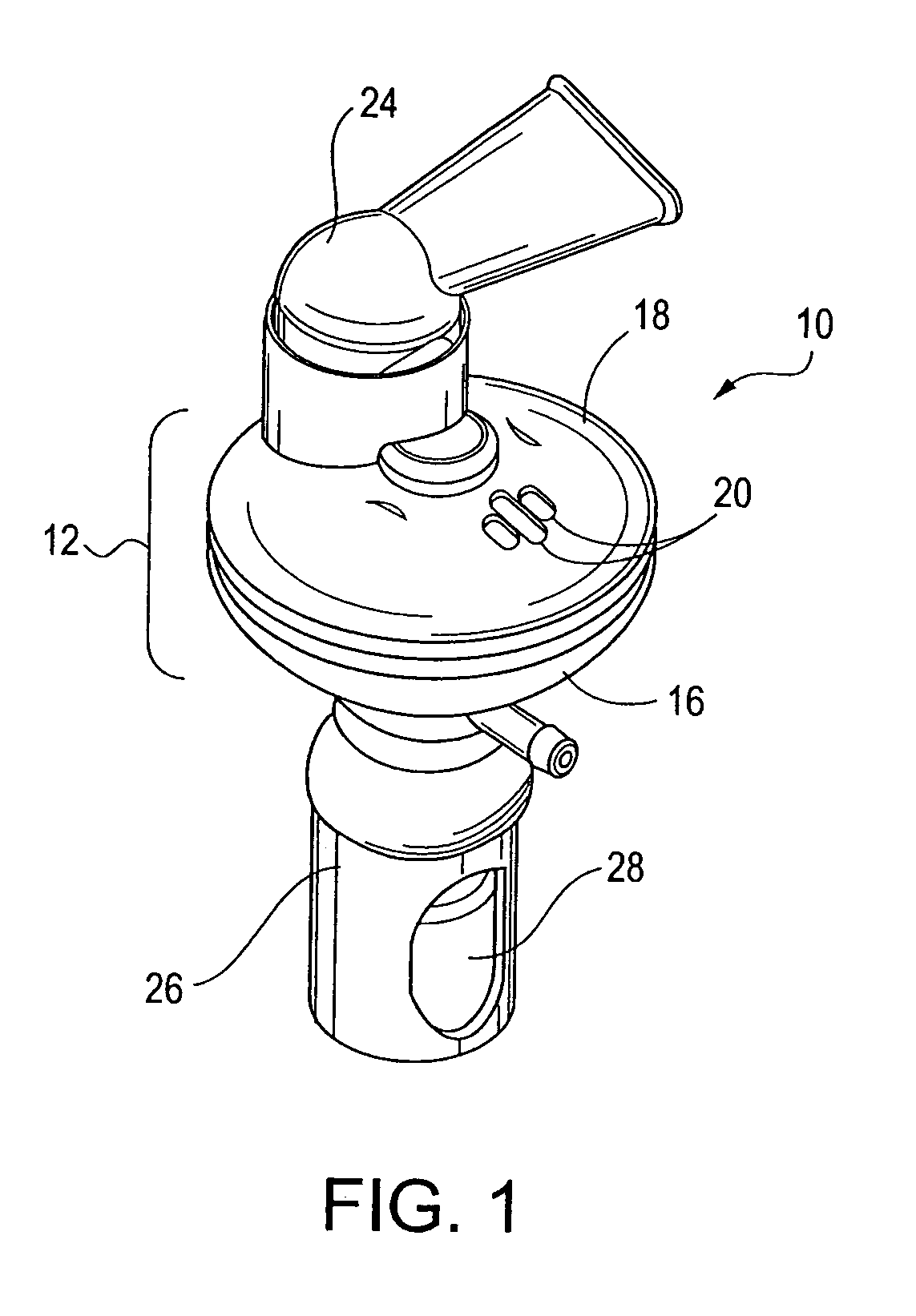

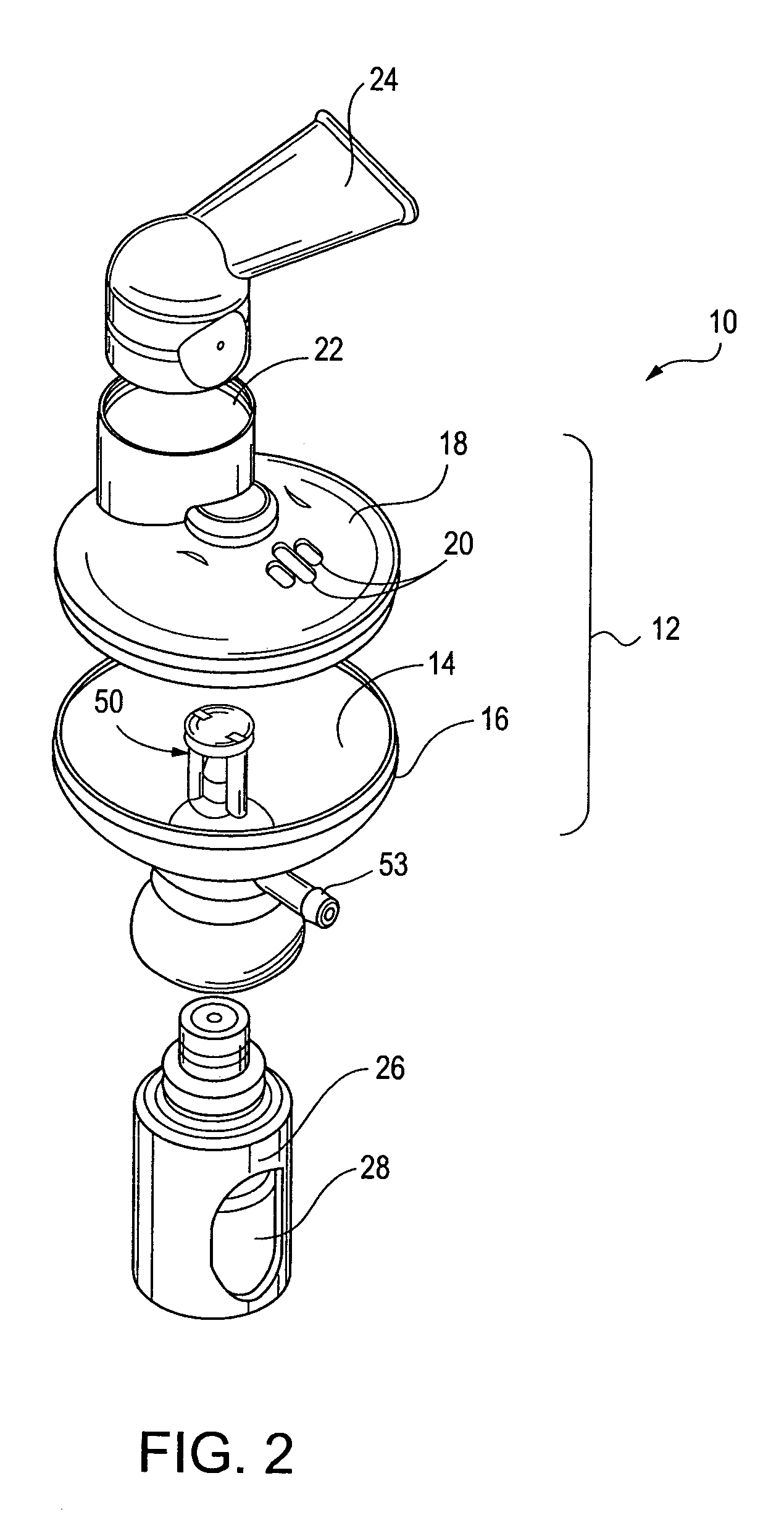

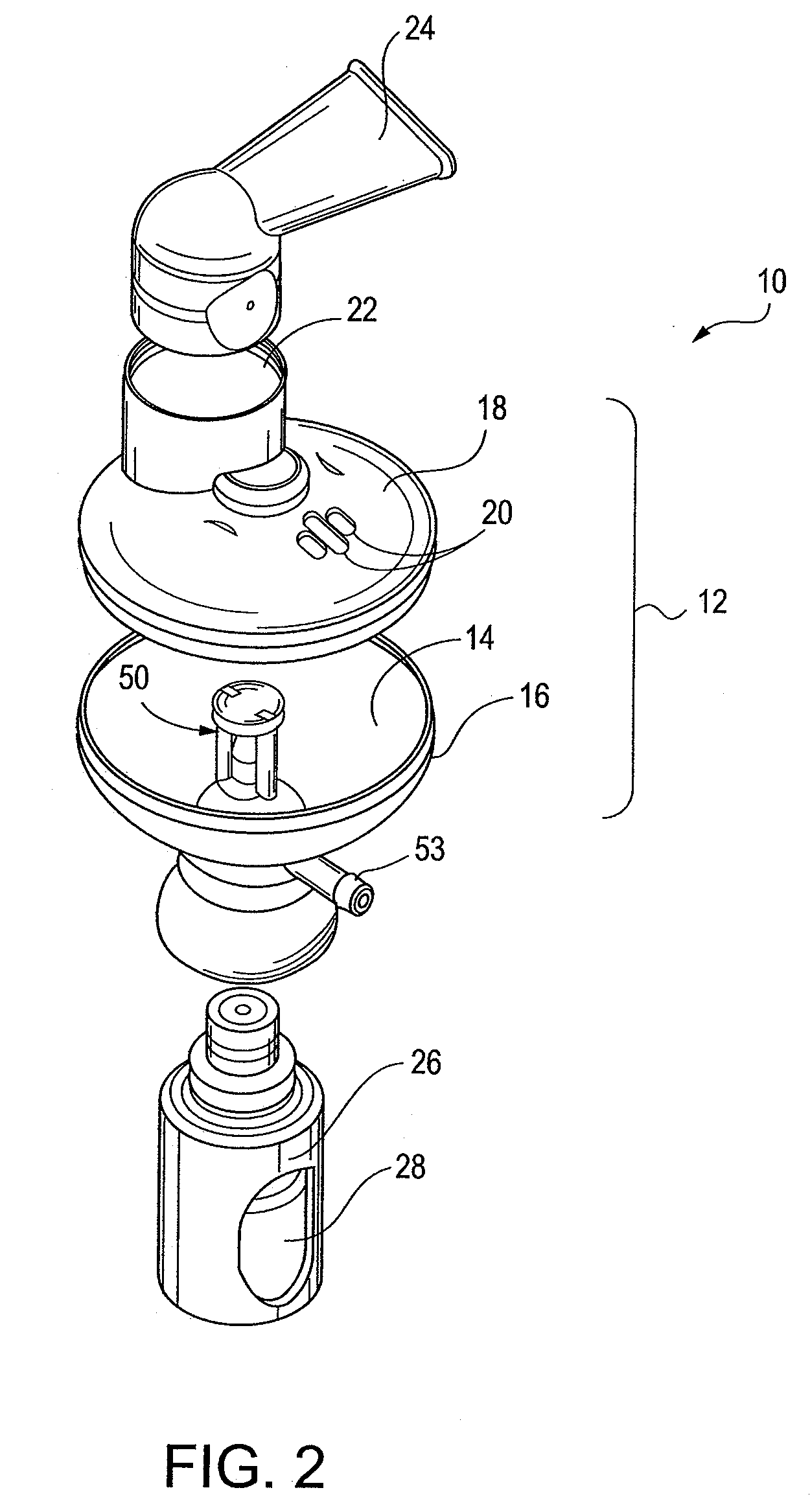

Nebulizer apparatus and method

ActiveUS7270123B2Reduce impactImprove particle size distributionRespiratorsSpray nozzlesNebulizerInlet valve

Owner:TRUDELL MEDICAL INT INC

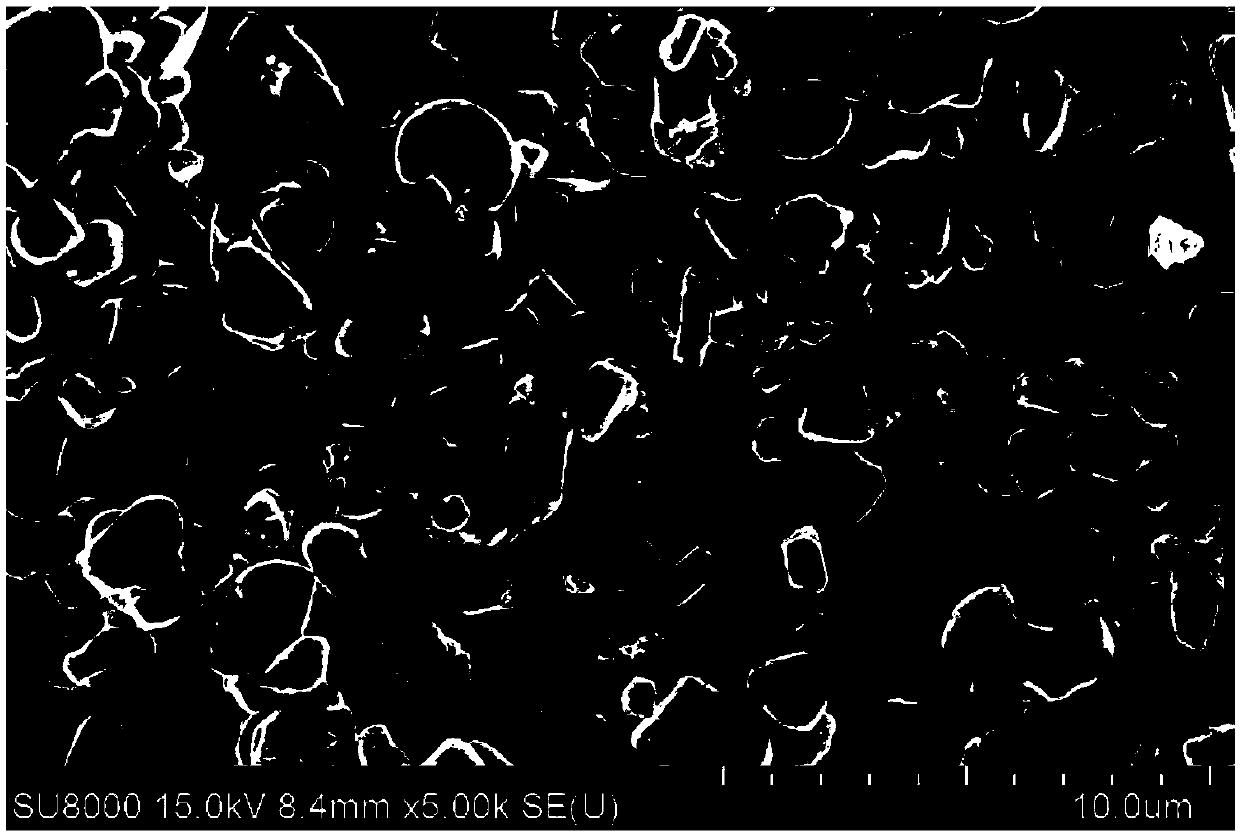

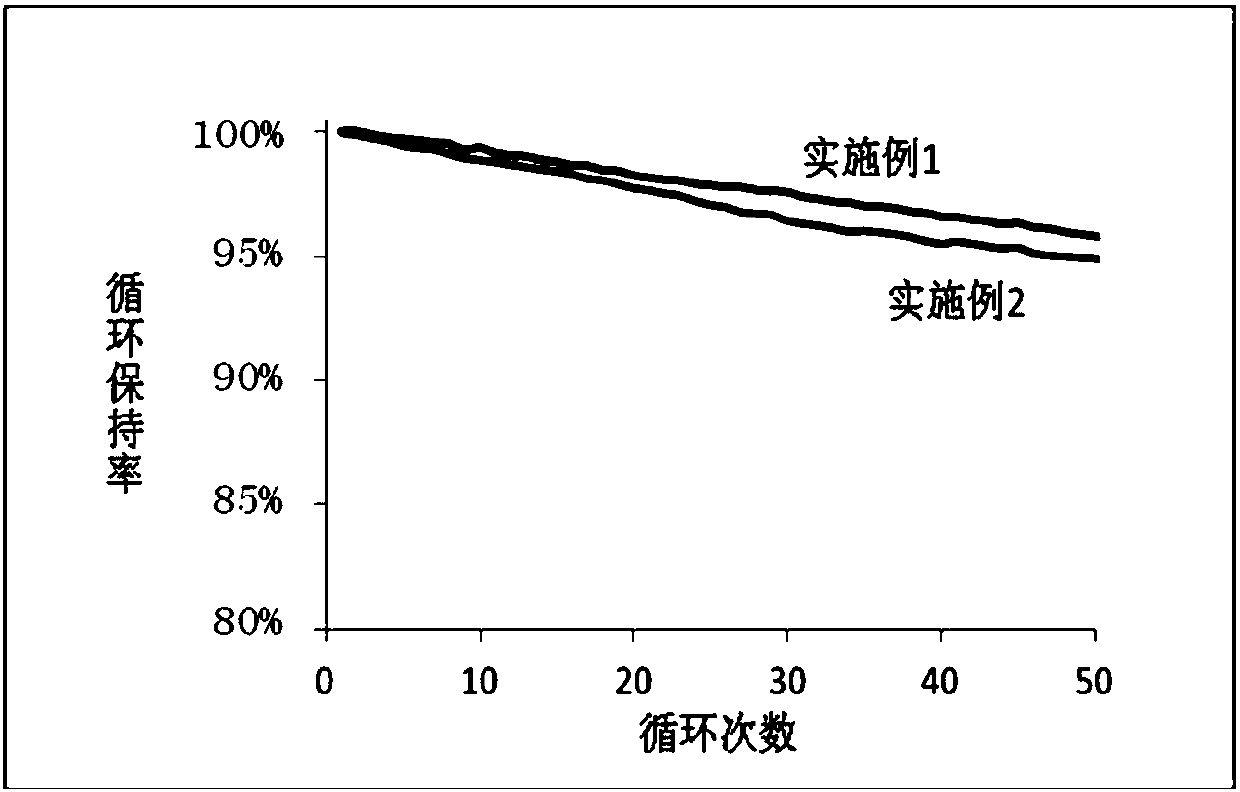

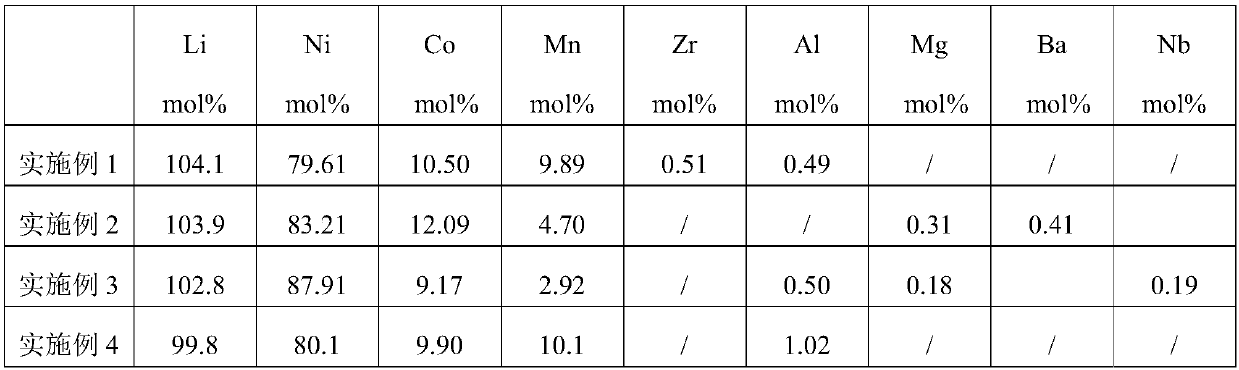

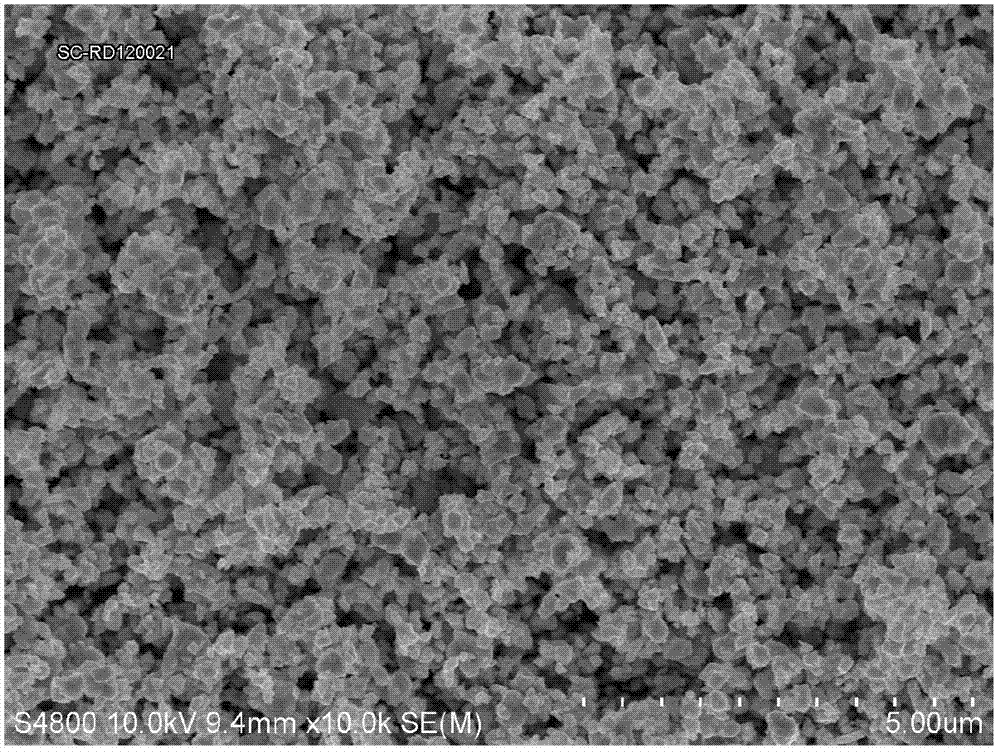

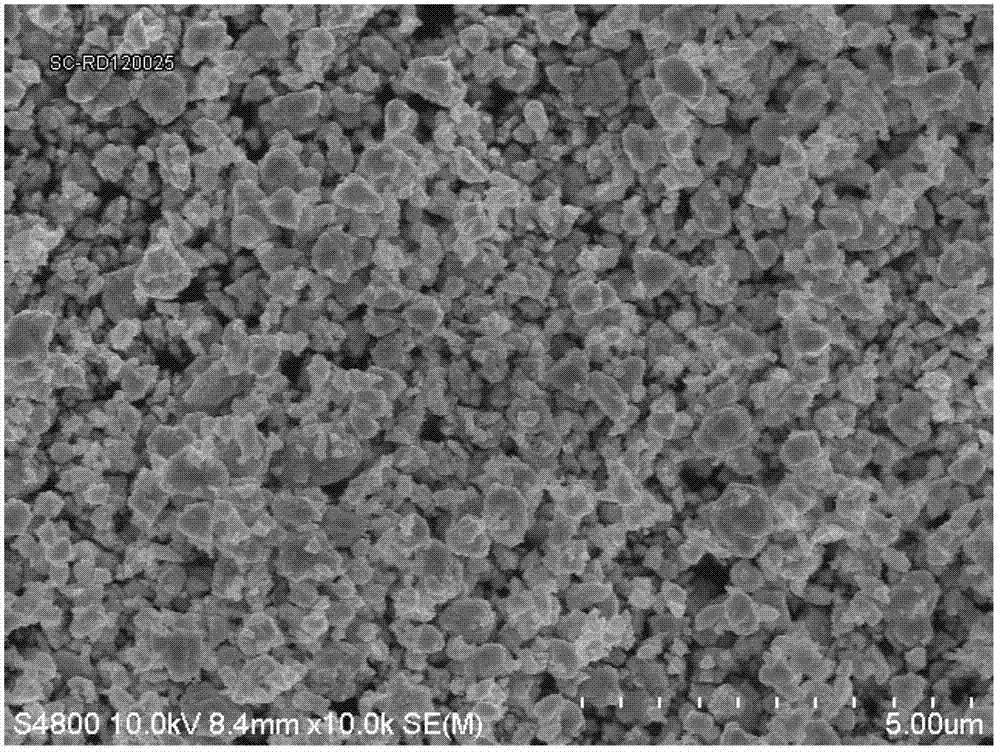

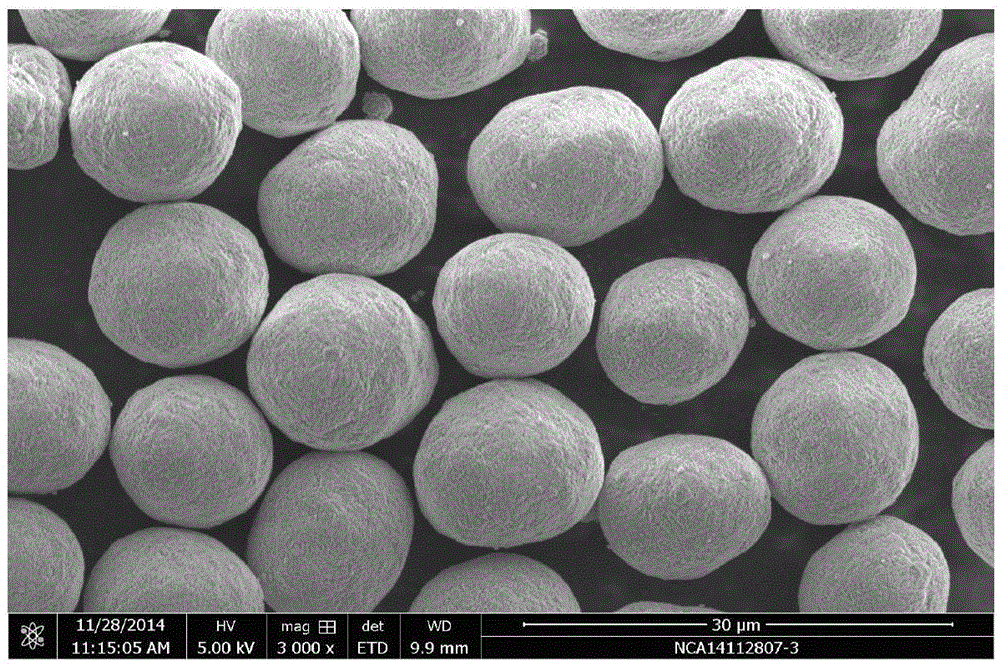

High-nickel ternary positive electrode material with monocrystal morphology and preparation method of high-nickel ternary positive electrode material

InactiveCN108023078AImprove particle size distributionIncrease the coating processCell electrodesSecondary cellsLithium compoundLithium electrode

The invention discloses a high-nickel ternary positive electrode material with monocrystal morphology and a preparation method of the high-nickel ternary positive electrode material. The preparation method comprises the following steps of (1) mixing a soluble nickel salt, a soluble cobalt salt, a soluble manganese salt, a precipitant and a complexing agent, and performing heating reaction to obtain a precursor; (2) mixing the precursor, a lithium compound and a doping metal compound, and sintering in an oxygen atmosphere to obtain a base material; (3) mixing the base material and a detergent,performing stirring, centrifuging and drying, and uniformly mixing with a coating agent to obtain a coated product; and (4) sintering the coated product to obtain the high-nickel ternary positive electrode material with monocrystal morphology. The high-nickel positive electrode material prepared by the method has morphology similar to that monocrystal, and is high in compaction density and energydensity, low in resided alkali amount and good in processability; and meanwhile, with the introduction of a doping element, a lithium ion battery prepared from the high-nickel positive electrode material has relatively high cycle property, and the cycle property and the safety of the material are also improved by the coating layer.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

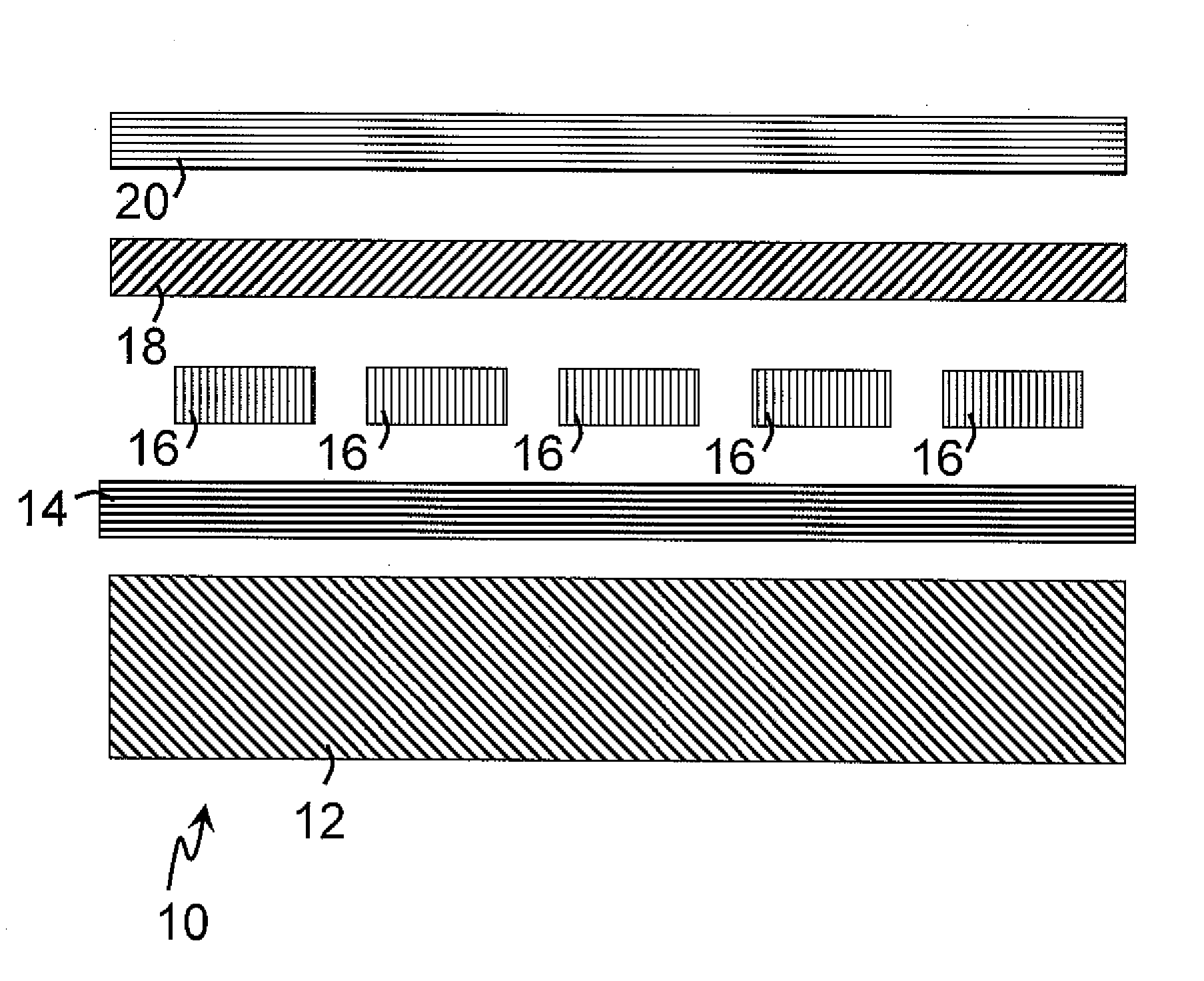

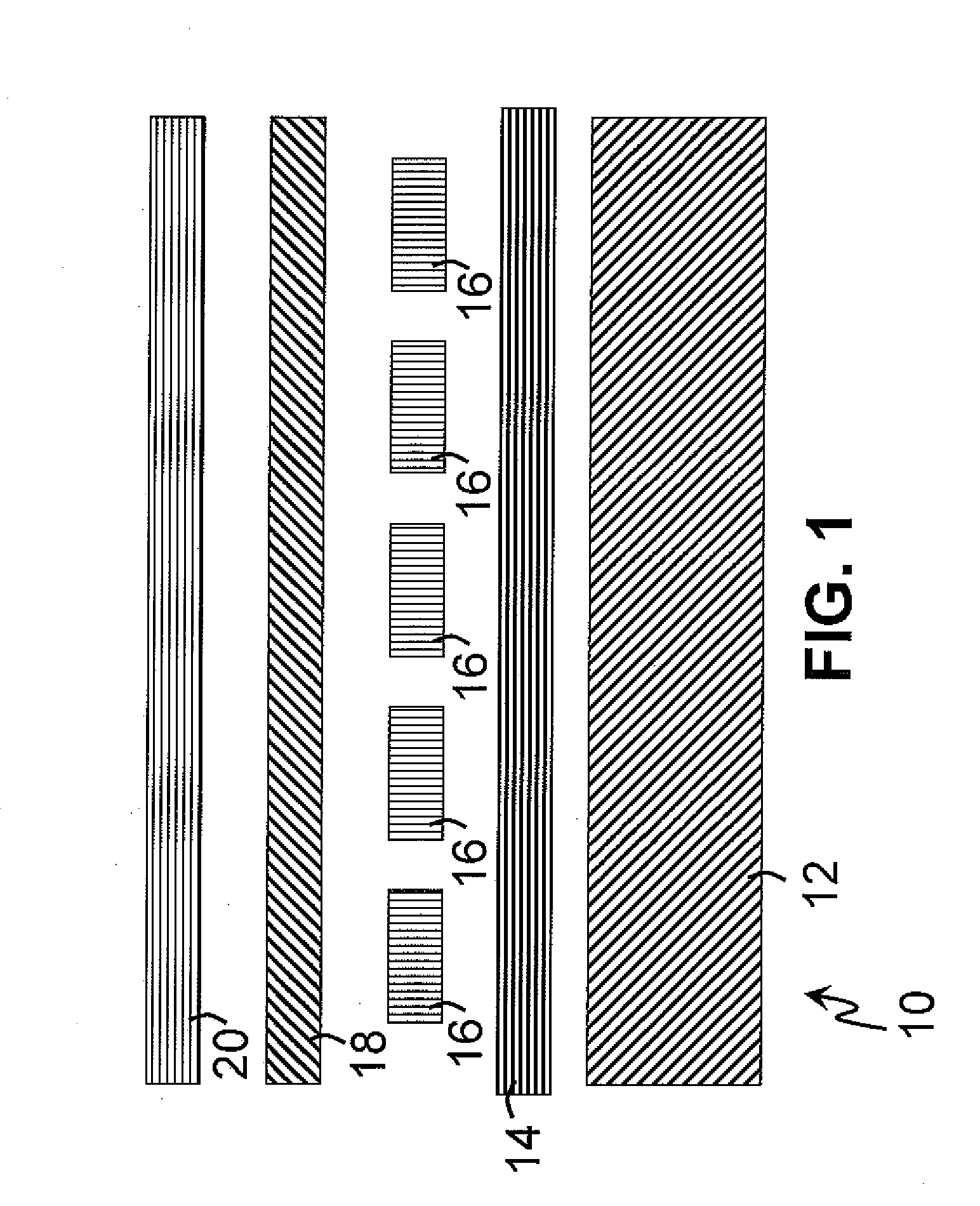

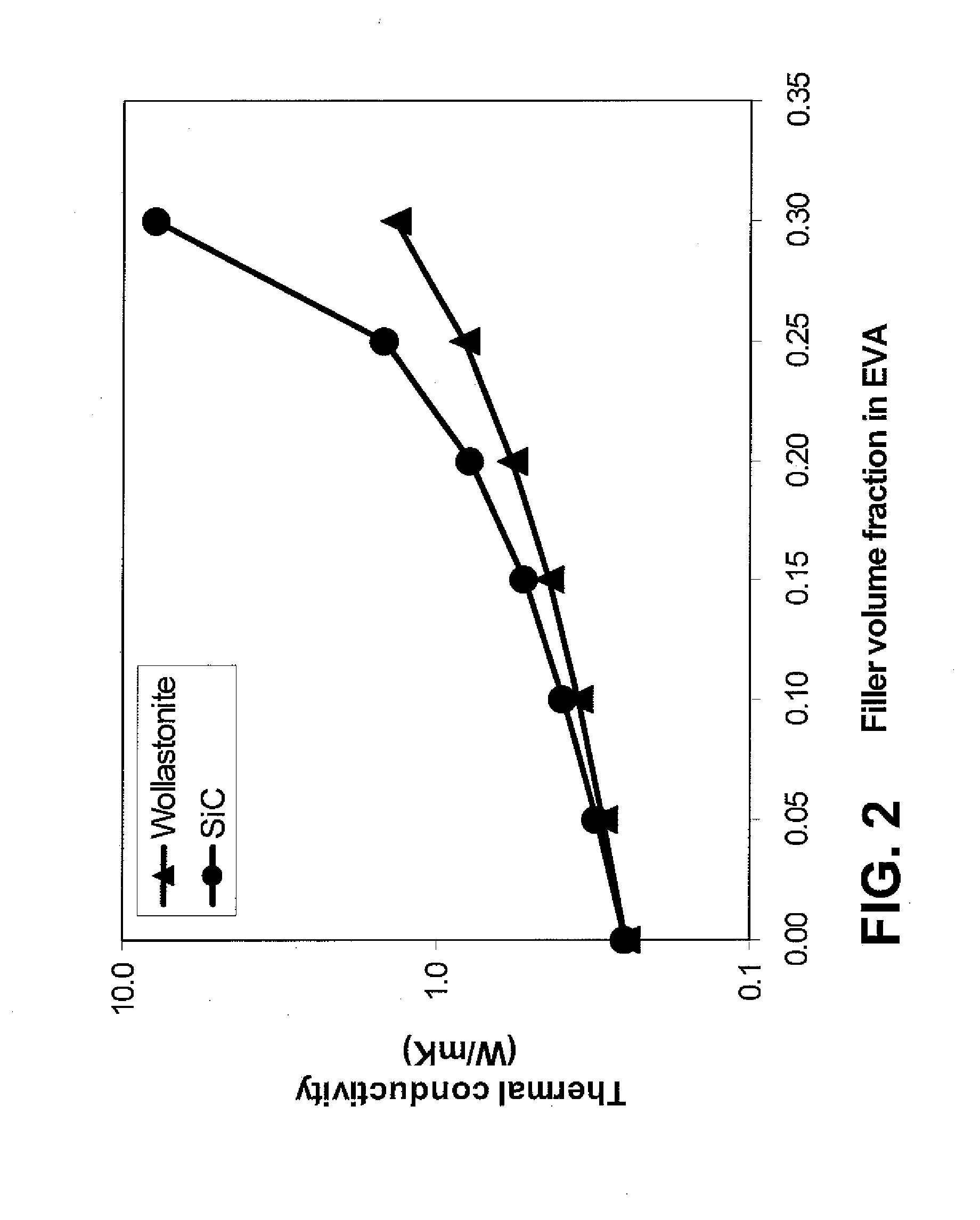

Thermal Conducting Materials for Solar Panel Components

InactiveUS20100043871A1Optimize power outputImprove efficiencyOther chemical processesPV power plantsComputer moduleEngineering

This invention relates to solar panels with improved encapsulants and back sheets for greater power output and / or increased efficiency by using materials with higher thermal conductivity than conventional solar panels. According to certain embodiments the improved materials include fillers while maintaining sufficient dielectric properties. According to certain other embodiments, the invention includes a solar panel with the improved encapsulant between solar cells and the improved back sheet. The invention also includes a method of making a solar panel including the improved materials. The invention also includes solar modules and methods related to encapsulants and the back sheets including filler materials with an enhanced particle size distribution, a brightening agent, or an infrared extinguisher.

Owner:BP CORP NORTH AMERICA INC

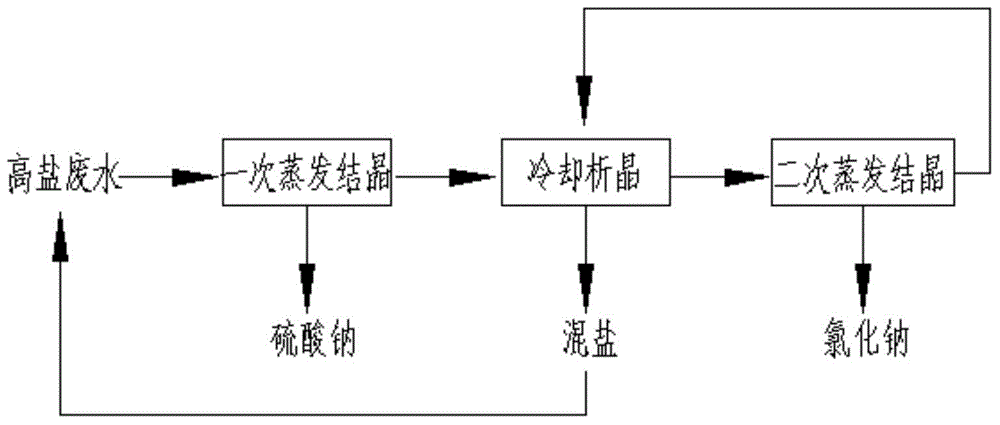

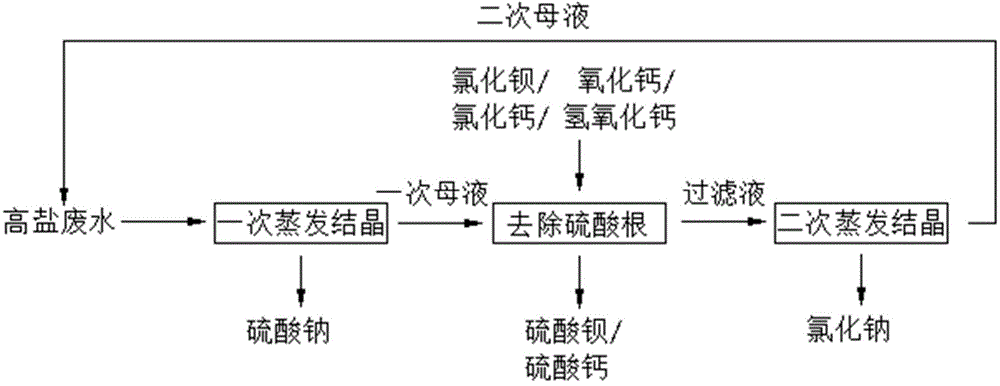

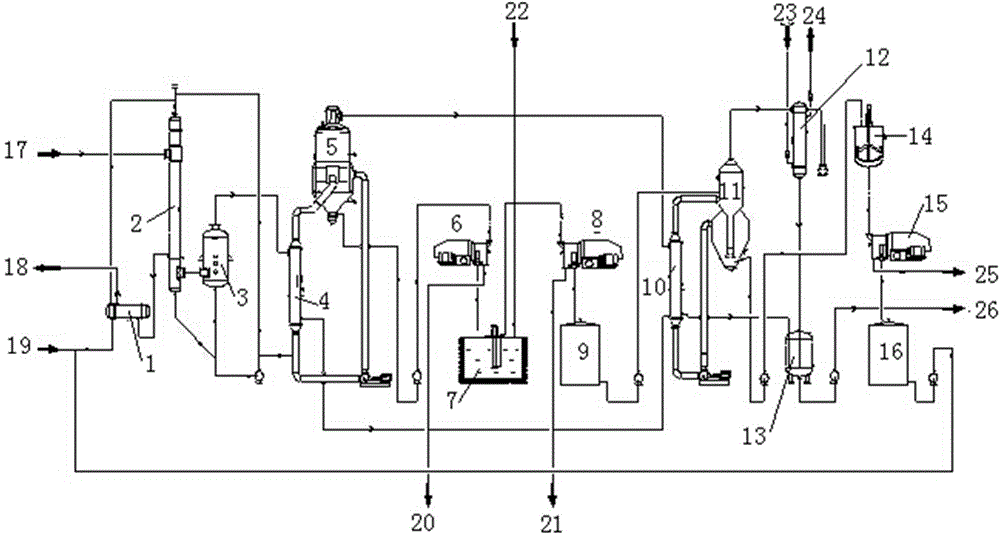

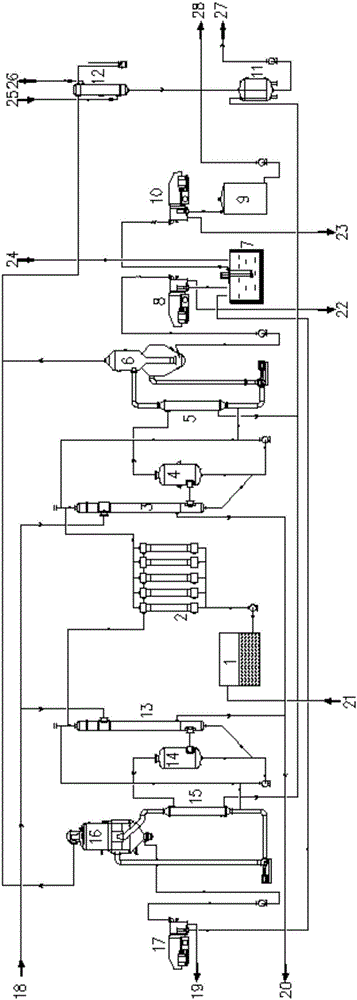

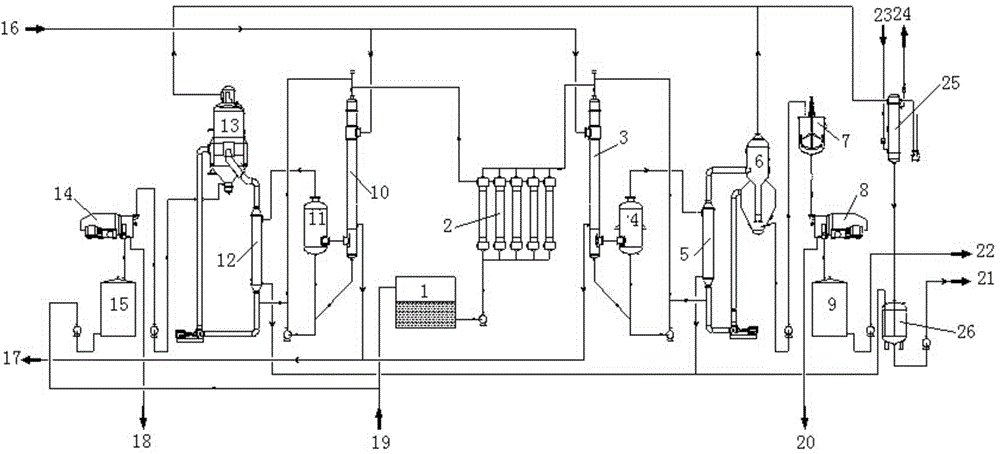

Recycling method of high-salinity wastewater

ActiveCN104591464AProcess conditions are stableEasy to industrializeMultistage water/sewage treatmentEnergy based wastewater treatmentChemistryCoal chemical industry

The invention discloses a recycling method of high-salinity wastewater. Sodium sulfate and sodium chloride are recycled through three steps of primary evaporative crystallization, cooling crystallization and secondary evaporation crystallization. According to the method disclosed by the invention, sodium sulfate and sodium chloride in the high-salinity wastewater of coal chemical industry can be effectively recycled; the method is simple and stable in technological conditions; industrial popularization is facilitated; the recycled sodium sulfate and sodium chloride meet the quality requirements of industrial products, and can be directly recovered and applied mechanically or sold as byproducts, so that the target of treating the high-salinity wastewater is reached; the requirements of the current environment-friendly situation are met; waste is changed into treasures; resource utilization of salts is achieved; and benefits of factories are improved.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP +1

Process for preparing an olefin polymerization catalyst component

InactiveUS7271119B2Easy to shapeImprove particle size distributionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationEmulsionElectron donor

Process for preparing an olefin polymerisation catalyst component in the form of particles having a predetermined size range, said process comprising the steps of a) preparing a solution of a complex of a Group 2 metal and an electron donor by reacting a compound of said metal with said electron donor or a precursor thereof in an organic liquid reaction medium; b) adding said solution of said complex to at least one compound of a transition material to produce an emulsion, the dispersed phase of which contains more than 50 mol % of the Group 2 metal in said complex; c) agitating the emulsion, optionally in the presence of an emulsion stabilizer, in order to maintain the droplets of said dispersed phase within the average size range 5 to 200 m; d) solidifying said droplets of the dispersed phase; and e) recovering the solidified particles of the olefin polymerisation catalyst component, wherein a turbulence minimizing agent (TMA) is added to the reaction mixture before solidifying said droplets of the dispersed phase, said TAM being inert and soluble in the reaction mixture under the reaction conditions.

Owner:BOREALIS TECH OY

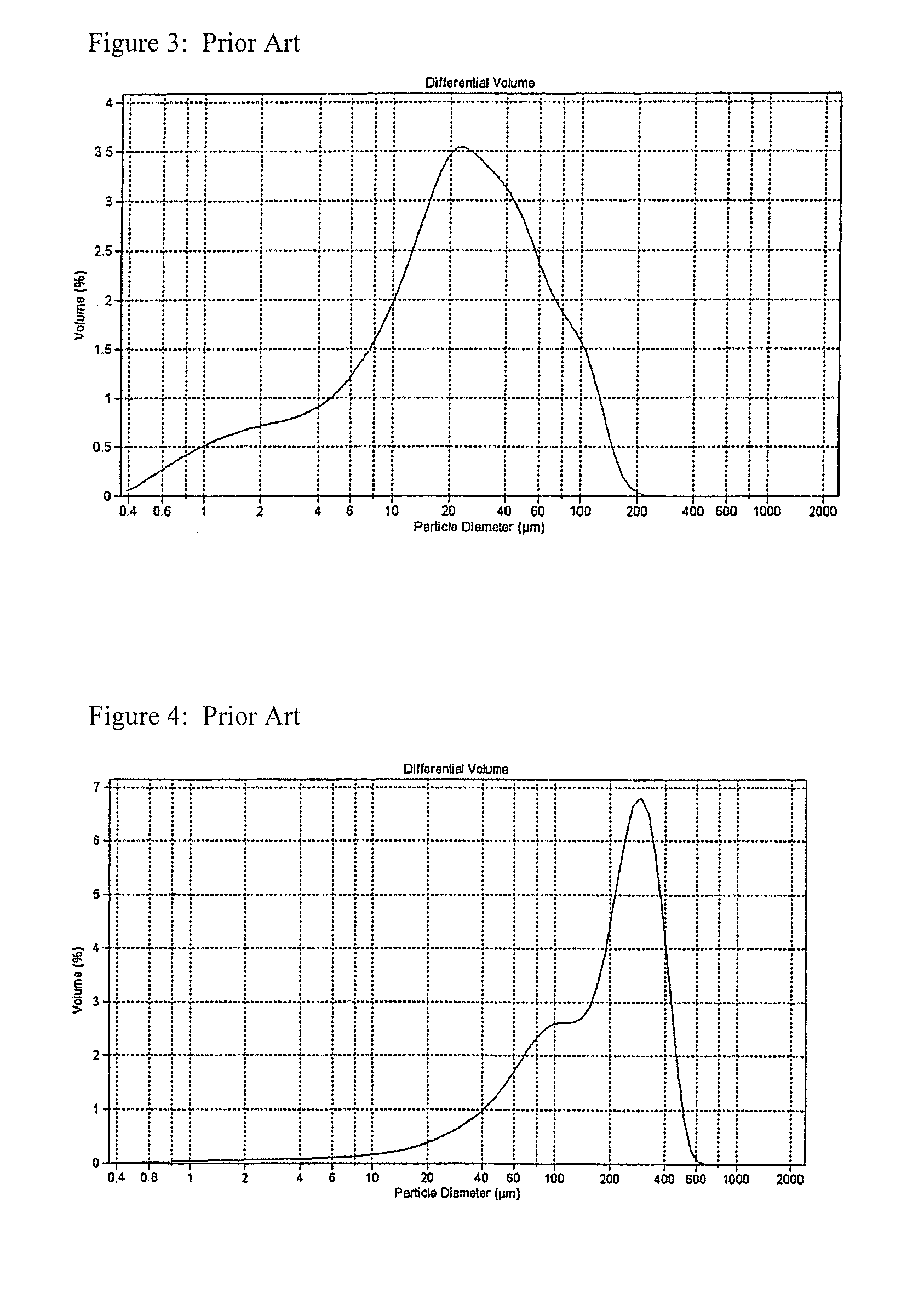

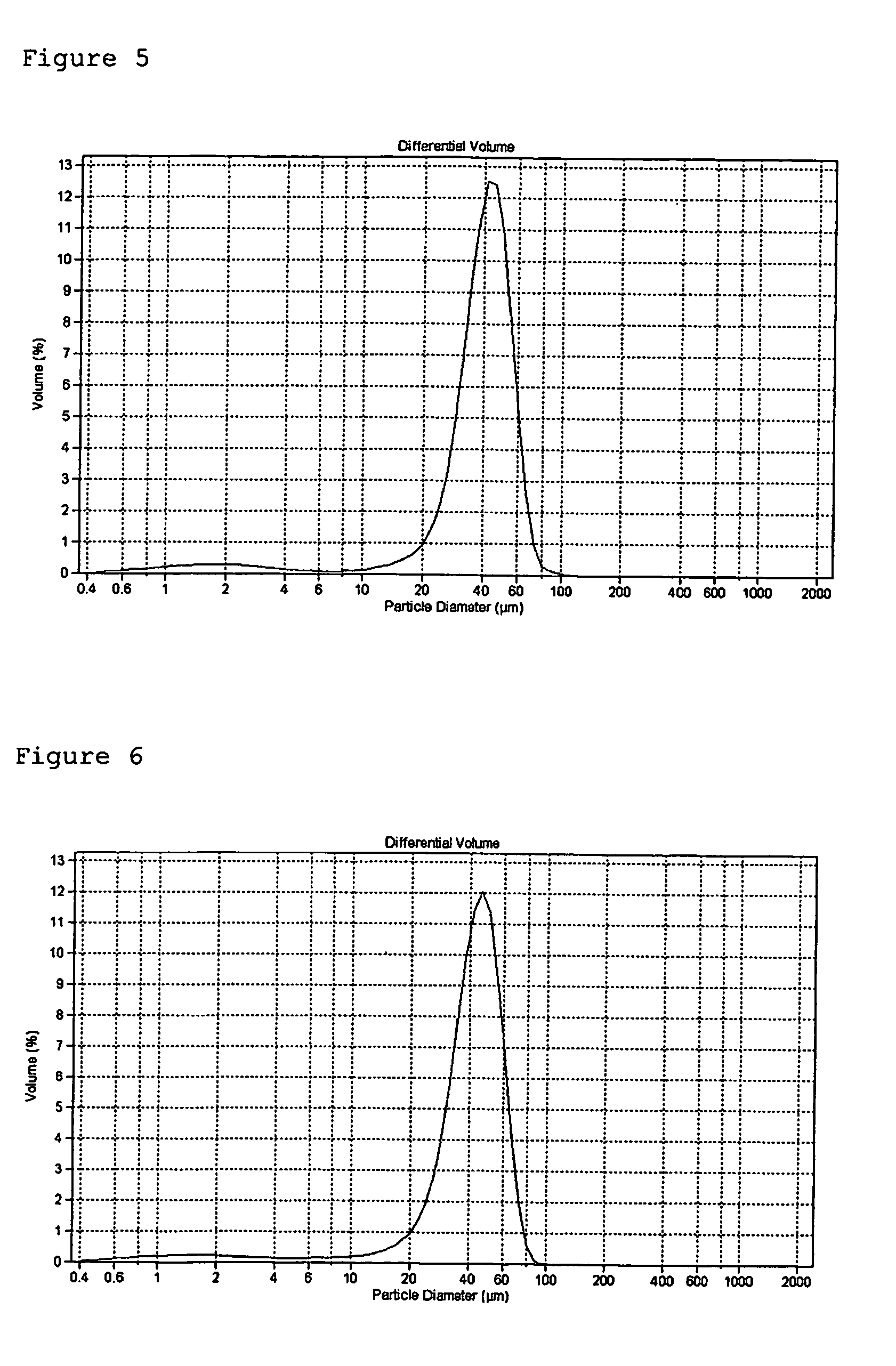

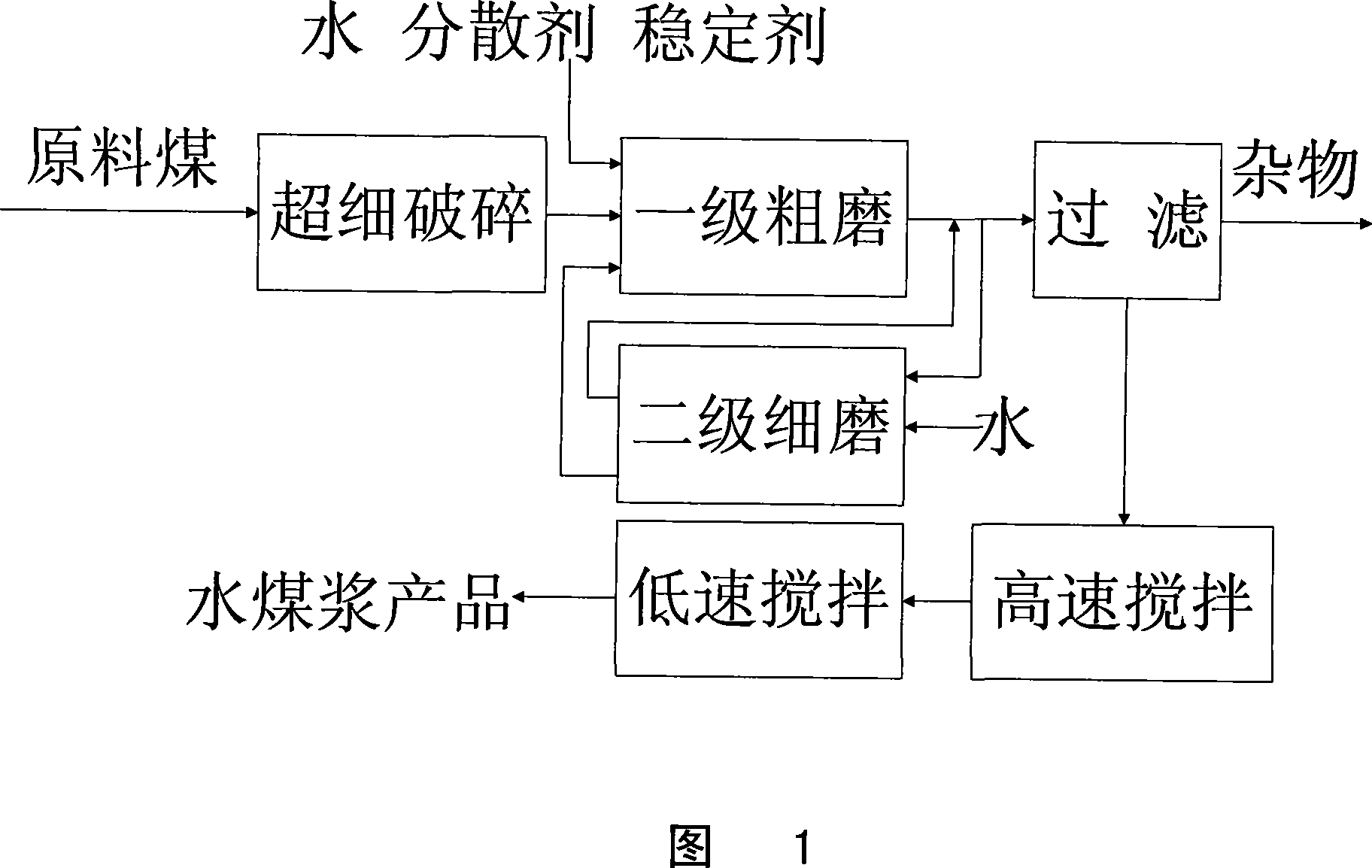

Method for preparing high concentration water-coal-slurry by low-rank coal

ActiveCN101173765AImprove particle size distributionReduce preparation energy consumptionLump/pulverulent fuel preparationHigh concentrationCoal water

The invention relates to a method for preparing high-concentration coal-water slurry by using low-rank coal. The steps include: 1) ultrafine crushing of low-rank coal; 2; 3) wet coarse grinding of the mixture; 4) ① mix 10% to 30% of the total amount of coal slurry after coarse grinding with water in a mass ratio of 5:1 to 2, and then carry out Wet fine grinding; ②The coal slurry after wet coarse grinding other than wet fine grinding is directly sent to the filter device; 5) The coal slurry after step 4) ① fine grinding is processed in the following way: ①Return all the coal slurry to step 3 ) for circulating coarse grinding; or ② return part of the coal slurry to step 3) for circulating coarse grinding, and send another part of finely ground coal slurry directly into the filter device; or ③ directly send all the coal slurry into the filter device; 6) The coal slurry sent to the filter device is filtered through a 18-20 mesh filter, and then stirred at a high speed in the stirring device, left standing, or stirred at a low speed to obtain a high-concentration coal-water slurry product.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

Carbon black

InactiveUS6290767B1Low structural requirementsReduction in carbon black throughputPigmenting treatmentMaterials sciencePigment

Carbon blacks doped with elements that are not carbon, wherein pairs of carbon atoms have been replaced by iso-electronic pairs of elements or combinations of elements. They can be used as a pigment or filler in rubber, plastics, paints, inks or the like.

Owner:UBS AG

Recovery processing method of high salinity wastewater containing sodium chloride and sodium sulfate

InactiveCN104973726AHigh purityMeet quality requirementsEnergy based wastewater treatmentMultistage water/sewage treatmentResource utilizationSULFATE ION

The invention discloses a recovery processing method of high salinity wastewater containing sodium chloride and sodium sulfate, and belongs to the field of industrial wastewater treatment. According to the recovery processing method, sodium chloride and sodium sulfate are recycled via primary evaporative crystallization, removing of sulfate ions via adding of materials and generation of precipitations, and secondary evaporative crystallization. The recovery processing method can be used for effective recovery of sodium chloride and sodium sulfate in coal chemical industry high salinity wastewater; process conditions are simple and stable; the recovery processing method is convenient for industrialized popularization; recovered sodium chloride and sodium sulfate are capable of satisfying quality requirements of industrial-grade products, and can be recycled and reused directly or be sold as by-products; processing of high salinity wastewater is realized; environmental requirements are satisfied; waste is changed into valuables; salt resource utilization is realized; and factory income is increased.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

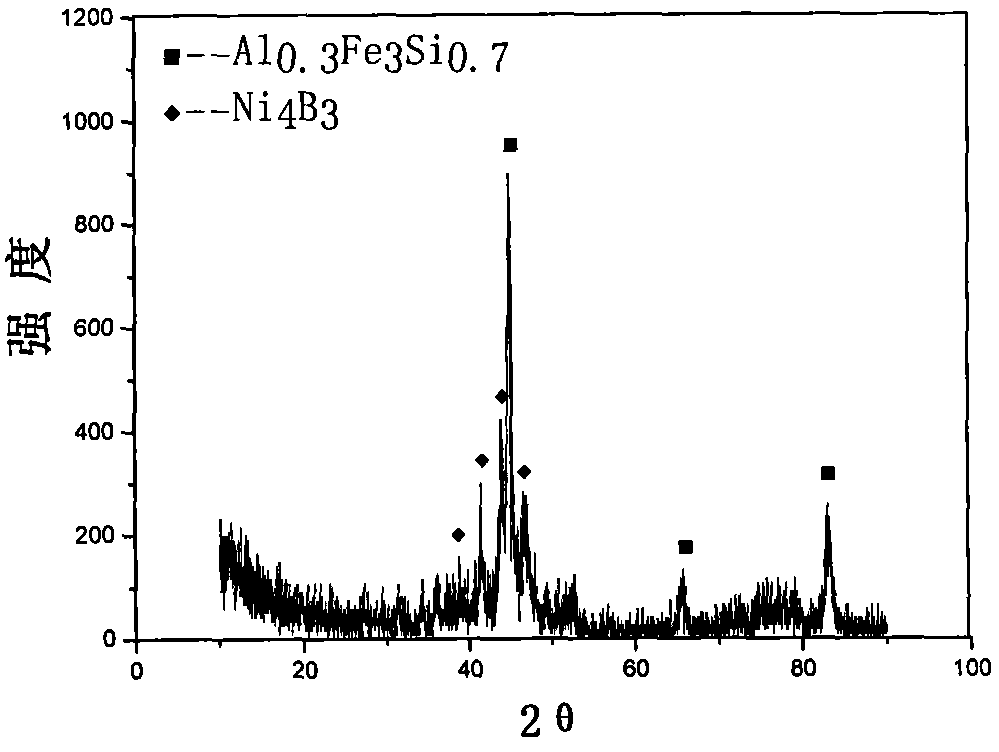

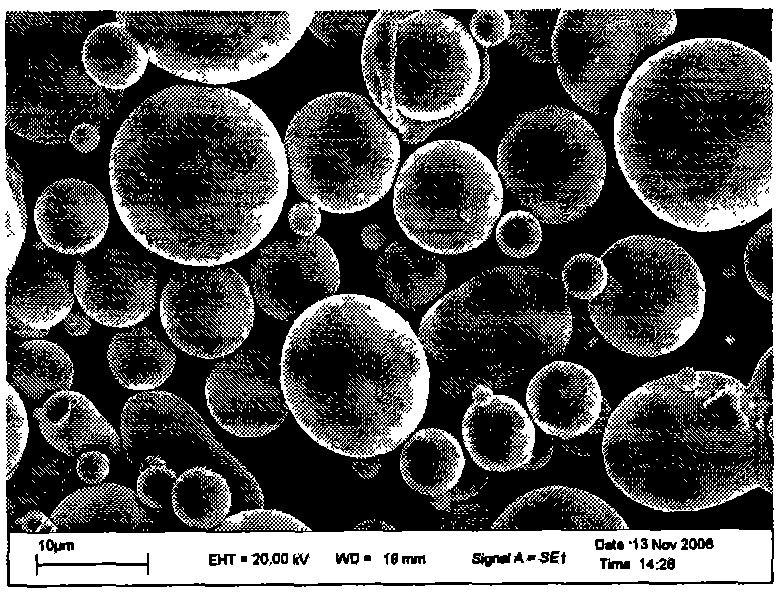

Fe-based amorphous nano-coating powder and its argon atomization production

A Fe-based amorphous nano-crystal spraying powder and its argon atomizing production are disclosed. The spraying powder consists of Cr 8-15wt%, Ni 8-16wt%, Si 2.8-5.7wt%, B 2.8-5wt%, W 2-8wt%, Mo 2-8wt%, Co 0.5-1wt%, Al 1-4wt% and Fe residues. The process is carried out by proportioning for ingredients, vacuum smelting, atomizing and screening powders. It has excellent fluidity and stability.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method for asphalt concrete with conduction function

InactiveCN101215124ALow costAlleviate problems such as insufficient aggregateSolid waste managementForeign matterMaterials preparation

The invention relates to a process for preparing asphaltic concrete with conducting function, which is characterized in that the process includes the procedures of 1), preliminary treatment of aggregates, which means washing away the foreign matters of the steel slag with water. 2), raw materials preparation, which means that the percentage by weight of each component is that rough aggregates is 55%-80%, fine aggregates is 13%-30%, mineral filler is 7%-15%, the rough aggregates, fine aggregates and mineral filler are selected to reserve as aggregates, consumption of asphalt cement is 6%-8% of the weight of the aggregates, consumption of fabric stabilizer is 0.1%-0.5% of the gross weight of the aggregates and the asphalt cement, consumption of conducting material is 10-30% of the weight of the asphalt cement, and gradation design of SMA mixture is employed. 3), mixture blending, which means charging fractionally and blending multitime, the temperature is kept not lower 150 DEG C when molding. The preparing process has simple technique and low cost. The prepared asphaltic concrete has good conducting function and pavement using property.

Owner:WUHAN UNIV OF TECH

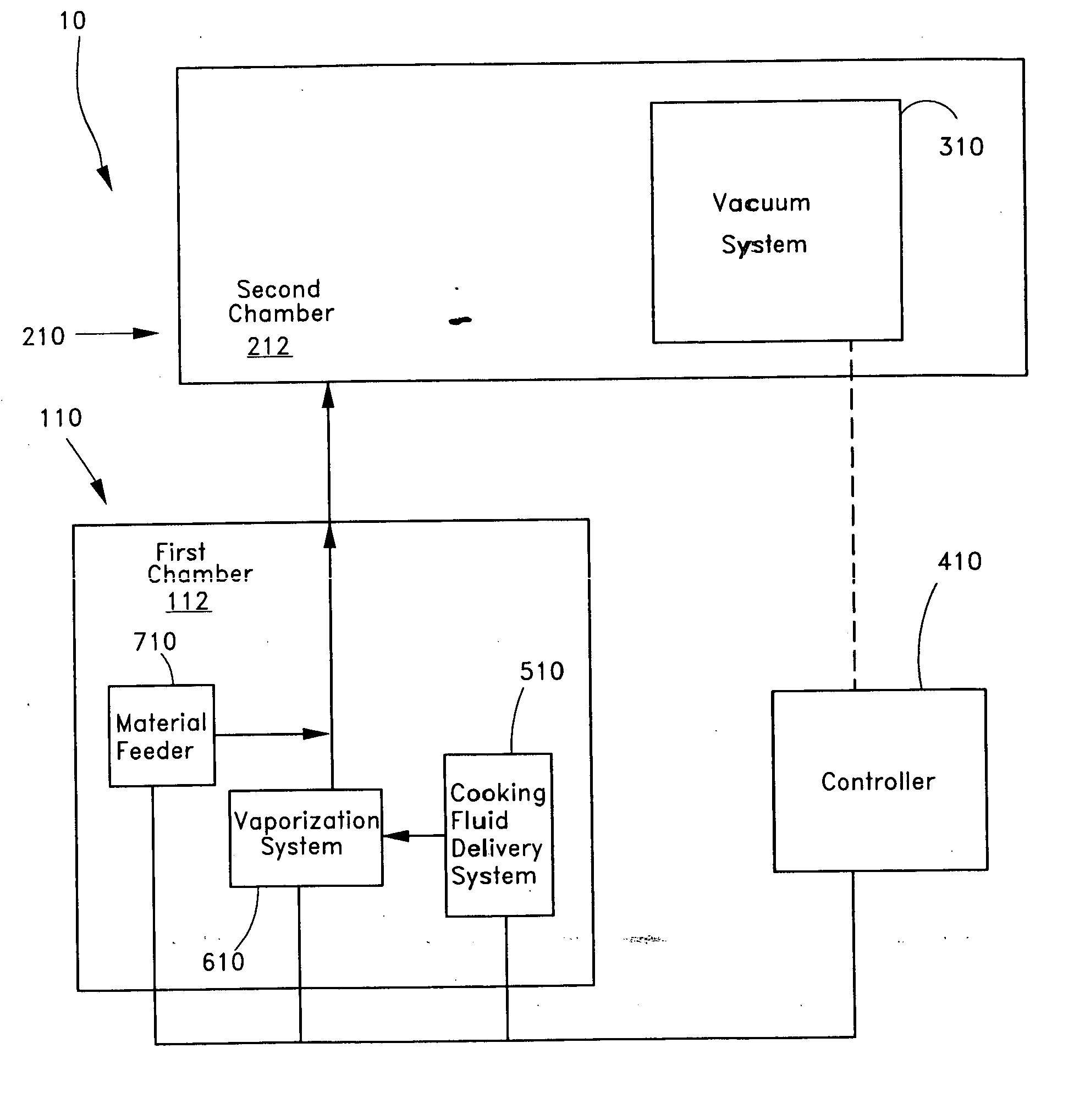

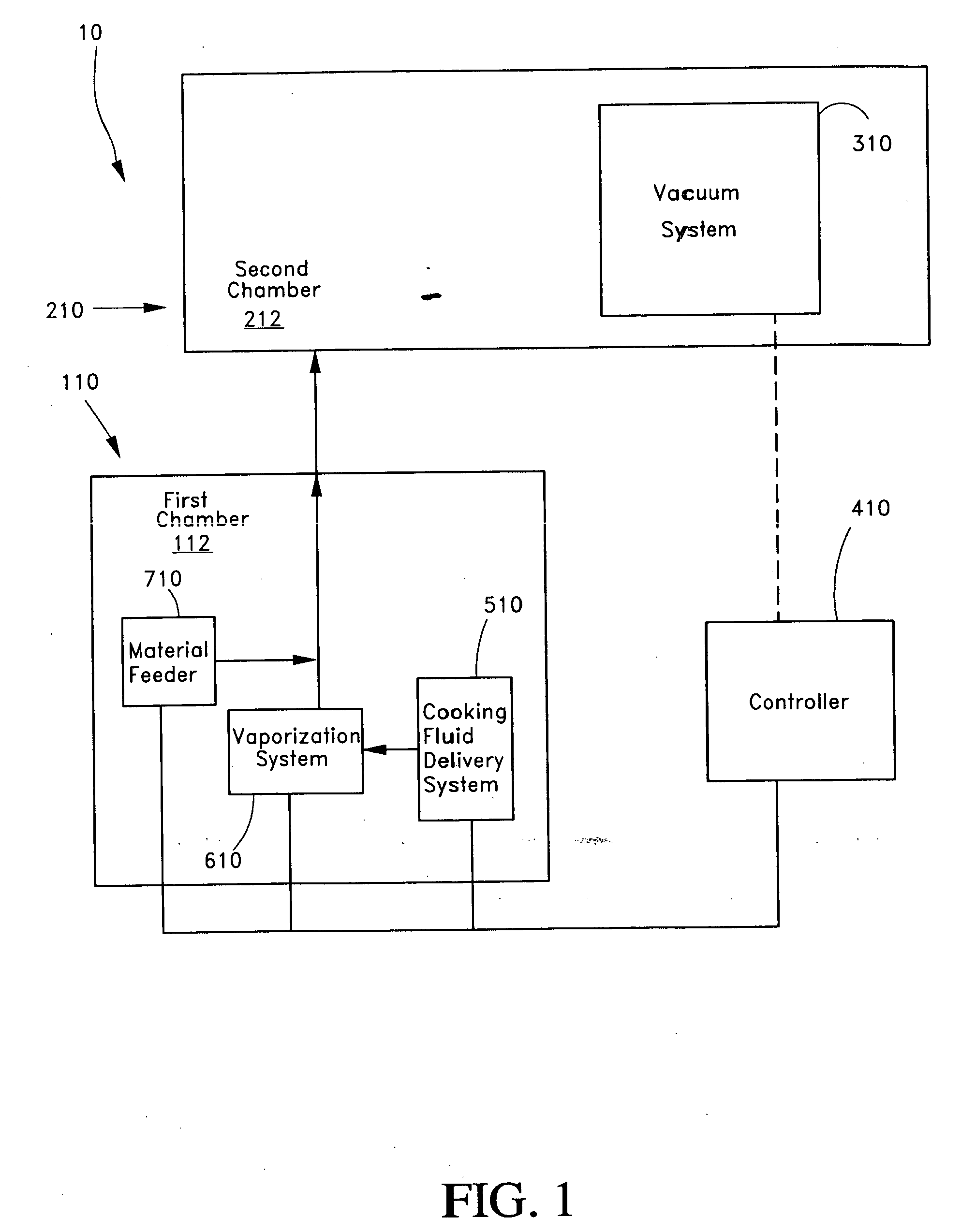

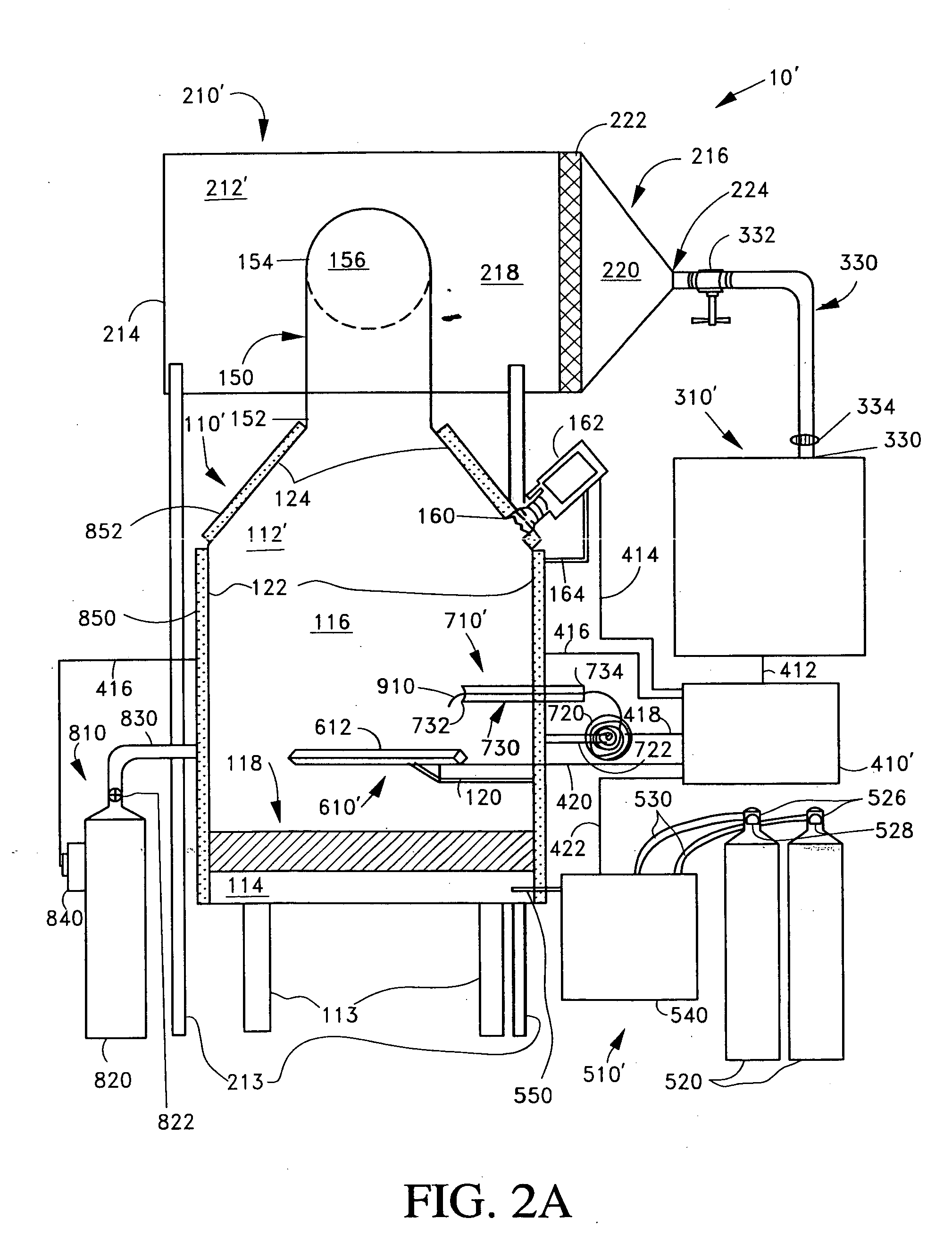

Method and apparatus for forming nano-particles

ActiveUS20060226564A1Improve particle size distributionReduce flow turbulenceMaterial nanotechnologyTransportation and packagingMetallurgyNanometre

Nano-scale particles of materials can be produced by vaporizing the material and allowing the material to flow in a non-violently turbulent manner into thermal communication with a cooling fluid, thereby forming small particles of the material that can be in the nano-scale size range.

Owner:VIVAKOR INC +1

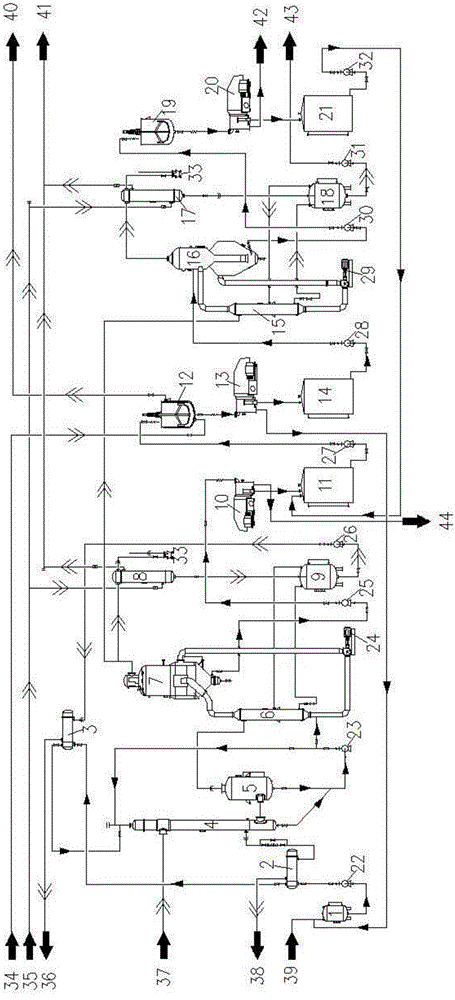

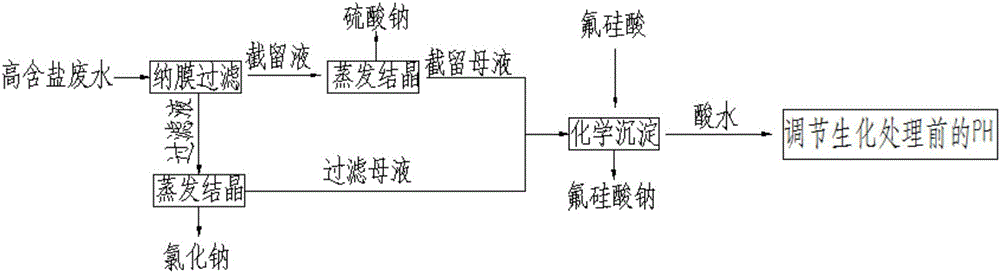

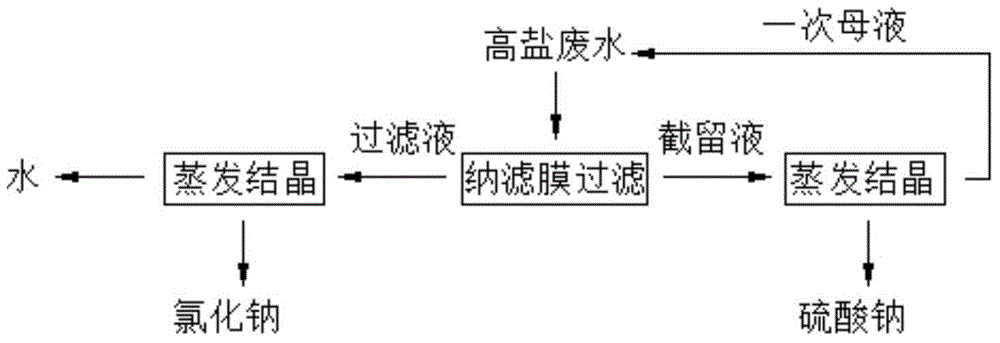

Recycling method for high-salinity wastewater containing sodium chloride and sodium sulfate

InactiveCN105110536AReduce processing costsRealize resource utilizationWater/sewage treatment by centrifugal separationWater contaminantsAcid waterWastewater

The invention discloses a recycling method for high-salinity wastewater containing sodium chloride and sodium sulfate and belongs to the field of wastewater treatment. The method comprises: filtering wastewater through a nanofiltration membrane; performing evaporative crystallization on filtrate through the nanofiltration membrane to obtain sodium chloride and filtered mother liquor; performing evaporative crystallization on retained liquor which does not pass through the nanofiltration membrane to obtain sodium sulfate and retained mother liquor; mixing the filtered mother liquor with the retained mother liquor to obtain a mixture and adding fluosilicic acid into the mixture; and stirring sufficiently the mixture to obtain sodium fluosilicate by filtering. Filtered acid water is used in pH value adjustment of a system before biochemical treatment.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

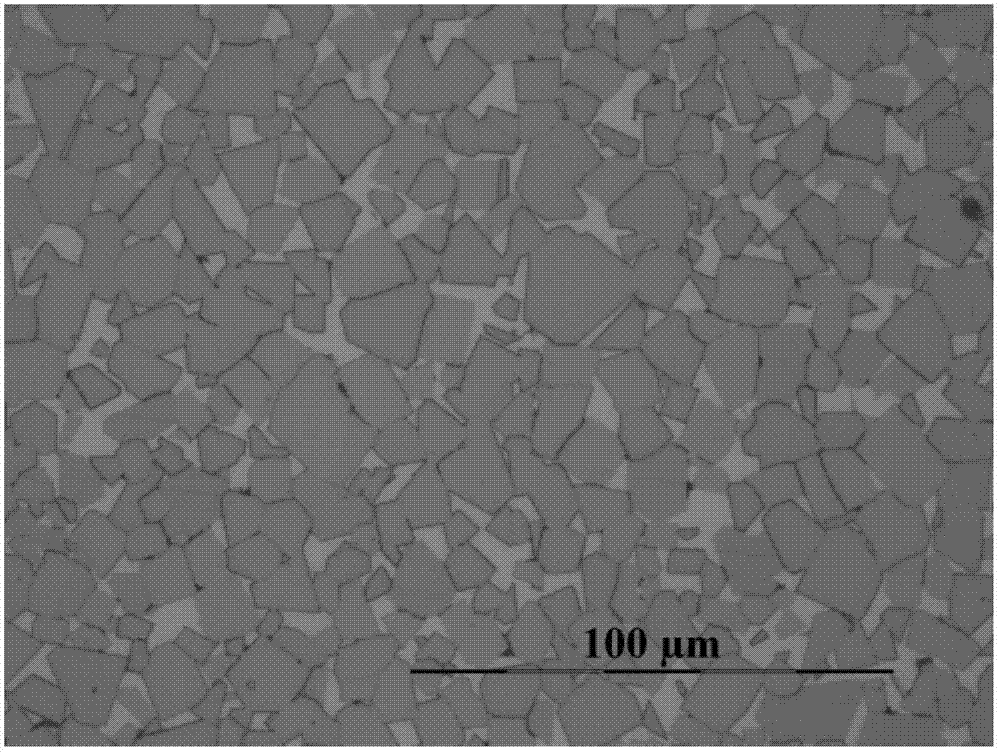

Preparation method for super coarse crystal WC-Co hard alloy

The invention discloses a preparation method for a super coarse crystal WC-Co hard alloy. According to the preparation method, a proper amount of fine tungsten carbide powder is added into a raw material, and the super coarse crystal WC-Co hard alloy is prepared by proper ball milling and sintering processes, so that the super coarse crystal hard alloy with the grain size of 6.0 to 14.0 microns can be prepared successfully. The preparation method has the characteristics that the process is simple, the process is easy to control, the production cost is low, and the WC grain size distribution in the alloy product is uniform.

Owner:XIAMEN TUNGSTEN +1

Method for recycling high-salt waste water containing sodium chloride and sodium sulfate

InactiveCN104961285AHigh purityMeet quality requirementsAlkali metal sulfite/sulfate purificationEnergy based wastewater treatmentIndustrial waste waterNanofiltration

The invention discloses a method for recycling high-salt waste water containing sodium chloride and sodium sulfate, and belongs to the field of industrial waste water treatment. The method comprises the steps of filtering by a nanofiltration membrane, evaporating and crystallizing filtrate penetrating through the nanofiltration membrane to obtain sodium chloride, evaporating and crystallizing trapped fluid which cannot penetrate through the nanofiltration membrane to obtain sodium sulfate, returning a primary mother solution to the system, and mixing the primary mother solution with raw materials to be continuously recycled. By adopting the method, sodium sulfate and sodium chloride in the high-salt waste water can be effectively recycled, a purpose of treating the high-salt waste water can be realized, and the current environmental-protection demand can be satisfied, waste can be converted into treasure, the recycling of salts can be realized, and the benefit of factories can be increased.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

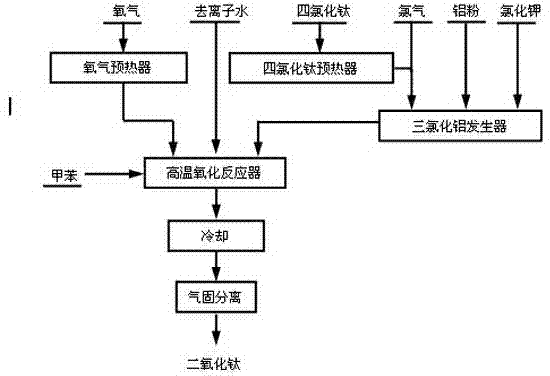

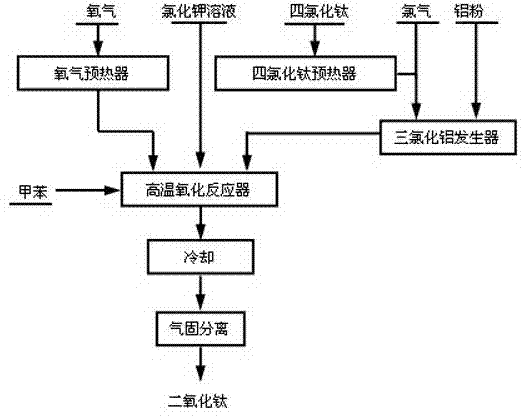

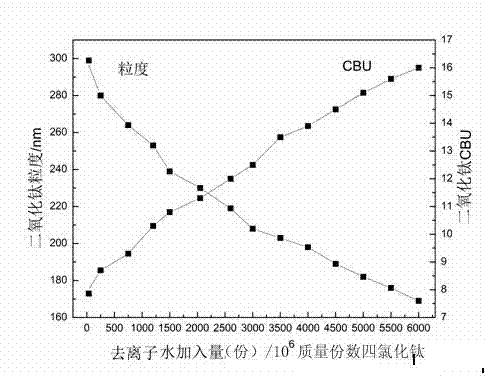

Production method of granularity-controllable titanium dioxide

ActiveCN102583531AIncrease the conversion rate of crystal formGood dispersionNanotechnologyTitanium dioxideFiberGas phase

The invention provides a production method of granularity-controllable titanium dioxide. Titanium tetrachloride and oxygen gas are preheated under pressure of 200kPa to 800kPa and respectively led into a high temperature oxidation reactor; hot oxygen is secondarily preheated in the high temperature oxidation reactor by using heat produced during toluene combustion to enable the titanium tetrachloride and the oxygen gas to produce a gas-phase oxidation reaction, and meanwhile, aluminum chloride, potassium chloride and deionized water are added to the high temperature oxidation reactor; and a gas-solid mixture generated through the reaction is cooled and subject to gas-solid separation, and then the titanium dioxide with the granularity of 160nm to 310nm is obtained. The method has the advantages that the cost is low, the operation is simple, the granularity of the titanium dioxide can be controlled within a large range through regulating the addition amount of the deionized water in the reaction process, and the application field of pigment is widened; and the method can be widely applied to the industries of coatings, plastics, building materials, papermaking, printing, ink, chemical fiber, rubber, ceramics, and the like.

Owner:中信钛业股份有限公司

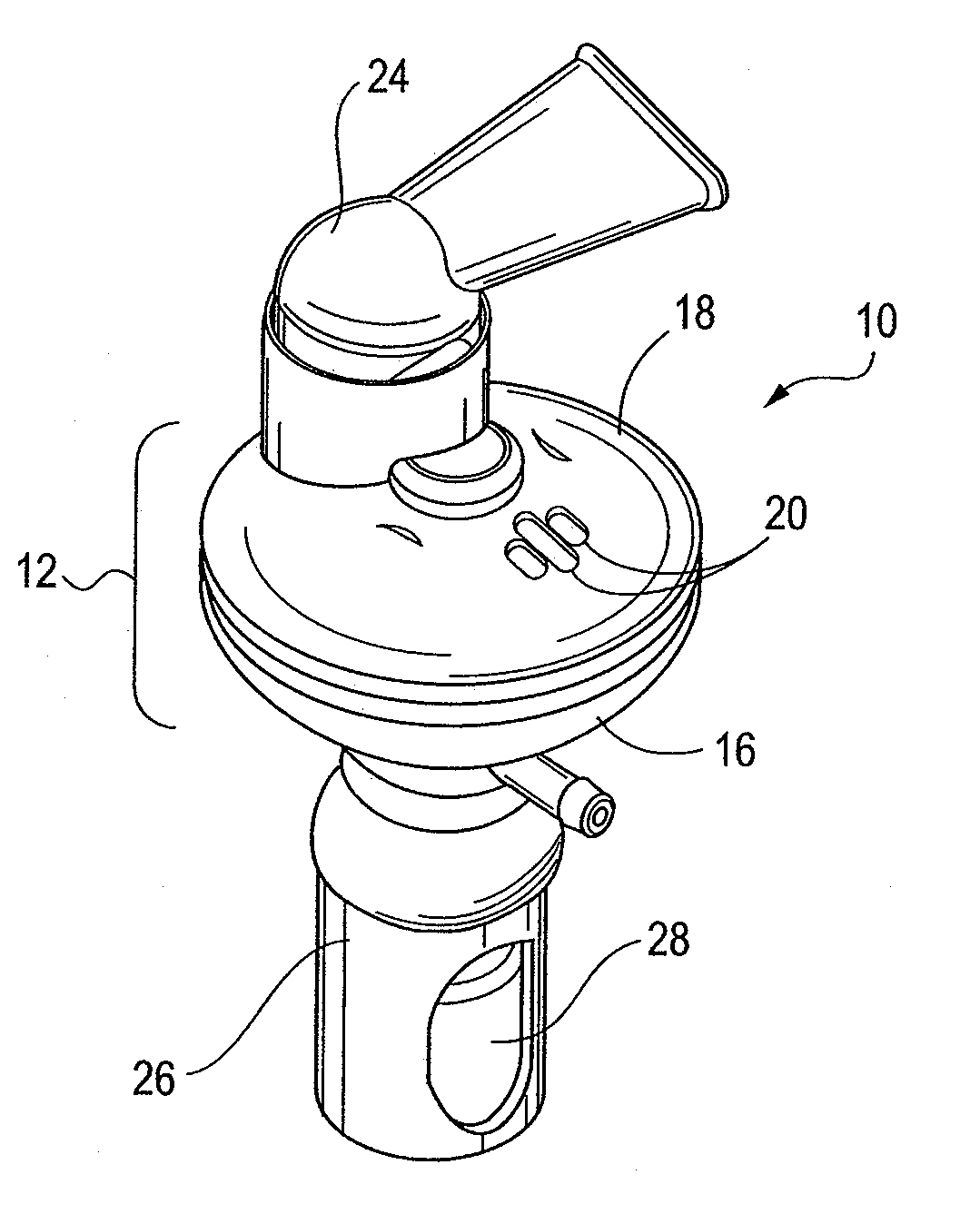

Nebulizer Apparatus And Method

ActiveUS20080083407A1Reduce impactImprove particle size distributionRespiratorsSpray nozzlesNebulizerInlet valve

A nebulizer for efficiently and reliably delivering aerosolized fluid to an inhaling patient is disclosed. The nebulizer, in one embodiment, includes a fluid channel air inlet and fluid channel air inlet valve responsive to either a manual force external of the nebulizer, or a patient's breathing, to begin the nebulization process. The nebulizer also includes a fluid return channel to a fluid source, such as a removable vial, containing fluid to be aerosolized.

Owner:TRUDELL MEDICAL INT INC

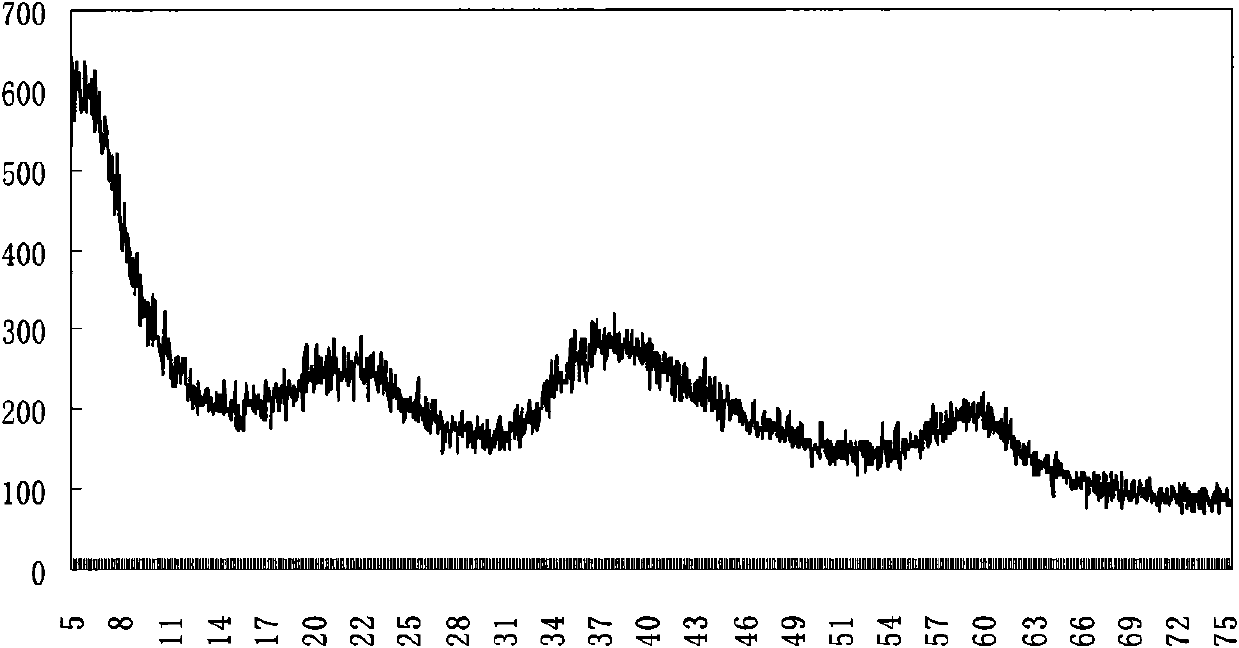

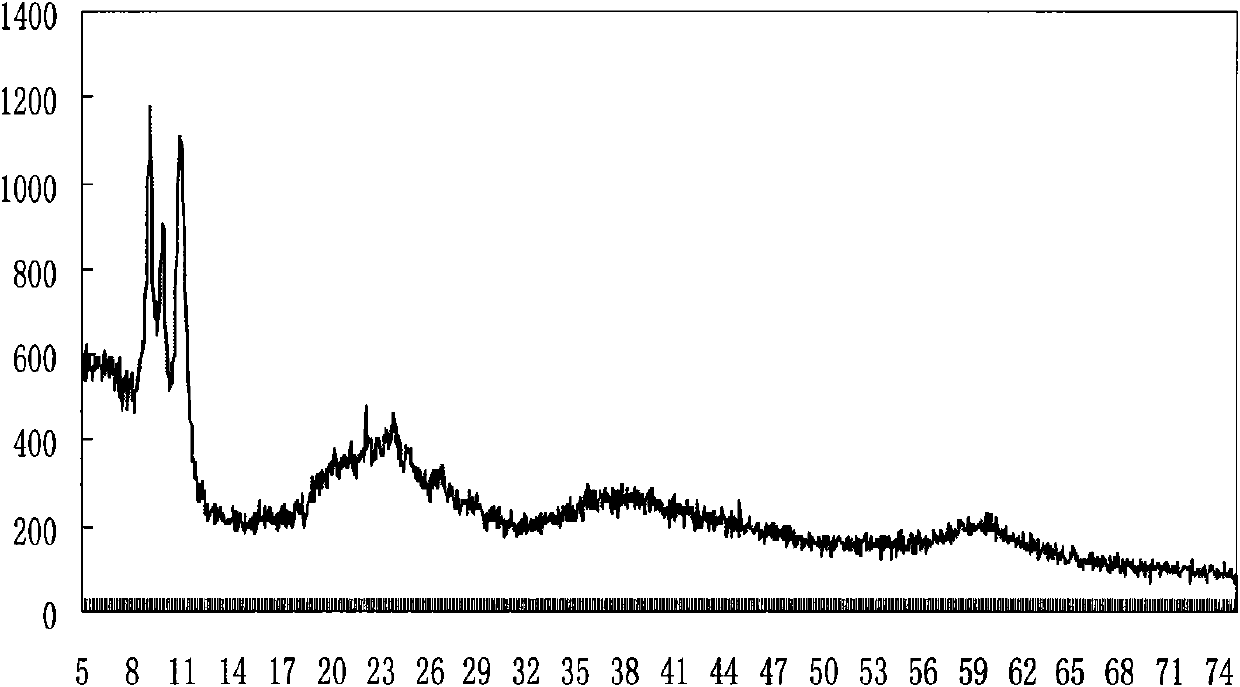

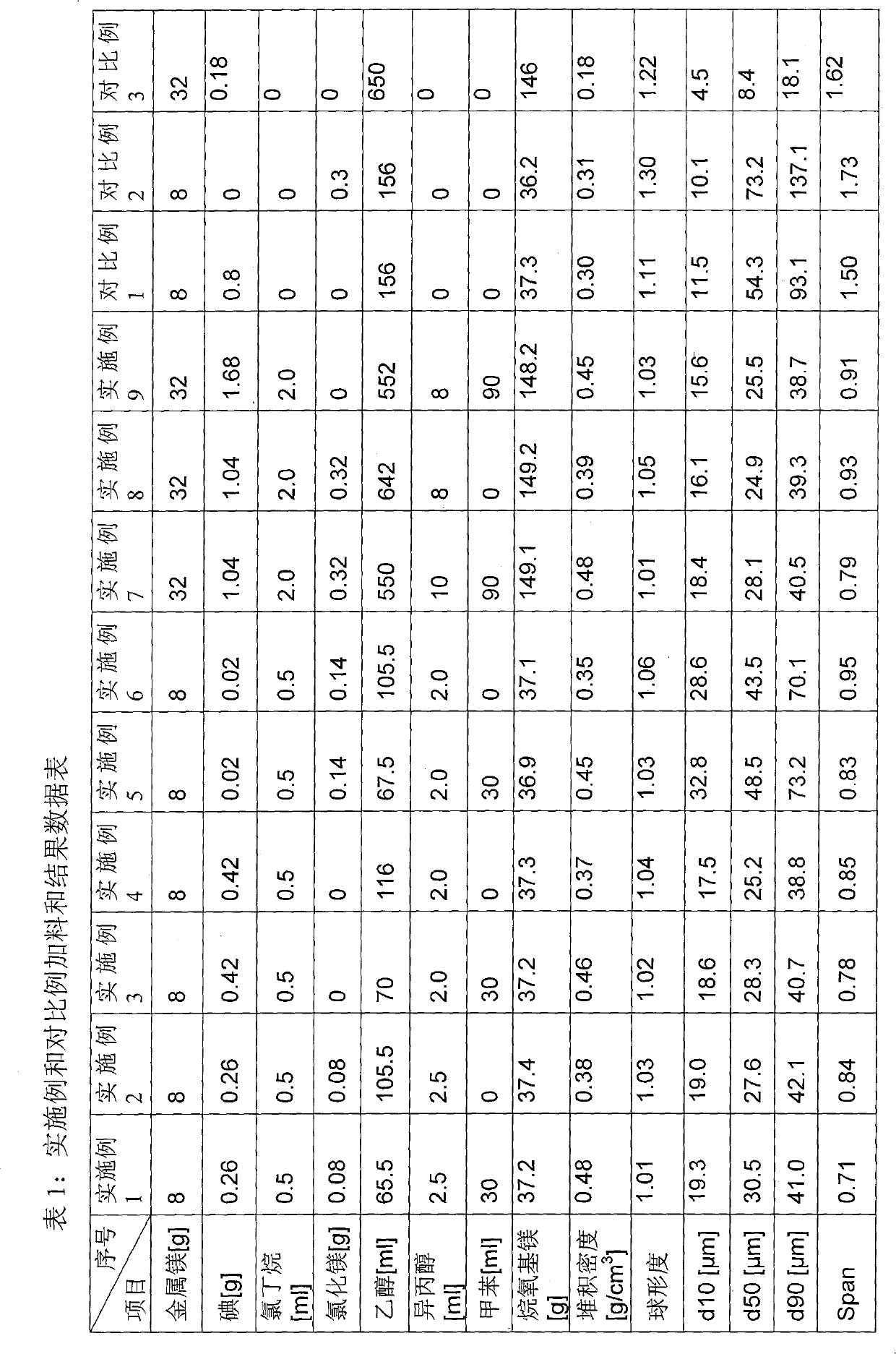

Method for preparing amorphous alkoxy magnesium

ActiveCN102020534AReduce dosageReduce manufacturing costPreparation of metal alcoholatesBulk chemical productionGas phasePolypropylene

The invention provides a method for preparing amorphous spherical particle alkoxy magnesium. In the method for preparing the amorphous spherical particle alkoxy magnesium, magnesium powder and mixed alcohol are used as raw materials, halogen monomer and / or inorganic halide are / is used as a halogenating agent, an organic halogen-containing compound is used as a modifier, and one or more inertial organic solvents are used as a dispersing agent; and the obtained spherical particle alkoxy magnesium has higher stacking density, more perfect particle shape and higher particle size distribution uniformity. The alkoxy magnesium is particularly suitable to be used as an olefin polymerization catalyst carrier. The obtained catalyst has high activity, higher stacking density, good particle shape and uniform distribution and is suitable for devices for producing polypropylene by gas-phase processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation process of catalyst for ethylene polymerization

InactiveCN1861650AHigh titanium contentImprove particle size distributionPolymer scienceZiegler–Natta catalyst

A process for preparing a Ziegler-Natta catalyst used for the sludge polymerization of ethene features that in its preparing procedure the ultrasonic wave technique is used for increasing the content of Ti and improving the granularity distribution of polymer.

Owner:北京燕化高新催化剂有限公司

Preparation method of high-light-resistant titanium dioxide pigment for laminated paper

ActiveCN109705630AImprove retentionGood dispersant effectInorganic compound additionPigment treatment with non-polymer organic compoundsALUMINUM PHOSPHATESlurry

The invention provides a preparation method of a high-light-resistant titanium dioxide pigment for laminated paper. The method comprises the following steps: preparing titanium dioxide slurry from a rutile-type titanium dioxide initial product prepared by adopting a chlorination process method, and adjusting the pH value to 8.5-10.5; adding a citric acid radical-containing organic substance as a dispersing agent, and performing grinding treatment; performing heating to 55-65 DEG C for coating treatment, performing coating by using a dense aluminum phosphate coating layer, performing coating byusing a loose silicon aluminum compound coating layer, and performing coating by using a loose boehmite-type hydrated aluminum oxide coating layer; performing washing by using deionized water until conductivity of a filter cake is greater than 15000 omega*cm, and performing drying; and adding amino-containing organic matter in the steaming powder process, and performing organic coating treatmentto obtain the titanium dioxide pigment for the decorative laminated paper. The method provided by the invention has the advantages that the titanium dioxide pigment prepared by the method has the characteristics of high light performance, good whiteness and a high retention rate in the laminated decorative paper, and the prepared titanium dioxide pigment has a medium color bottom phase and the advantage of easy color matching, and can be widely used in the field of the high-end laminated decorative paper.

Owner:中信钛业股份有限公司

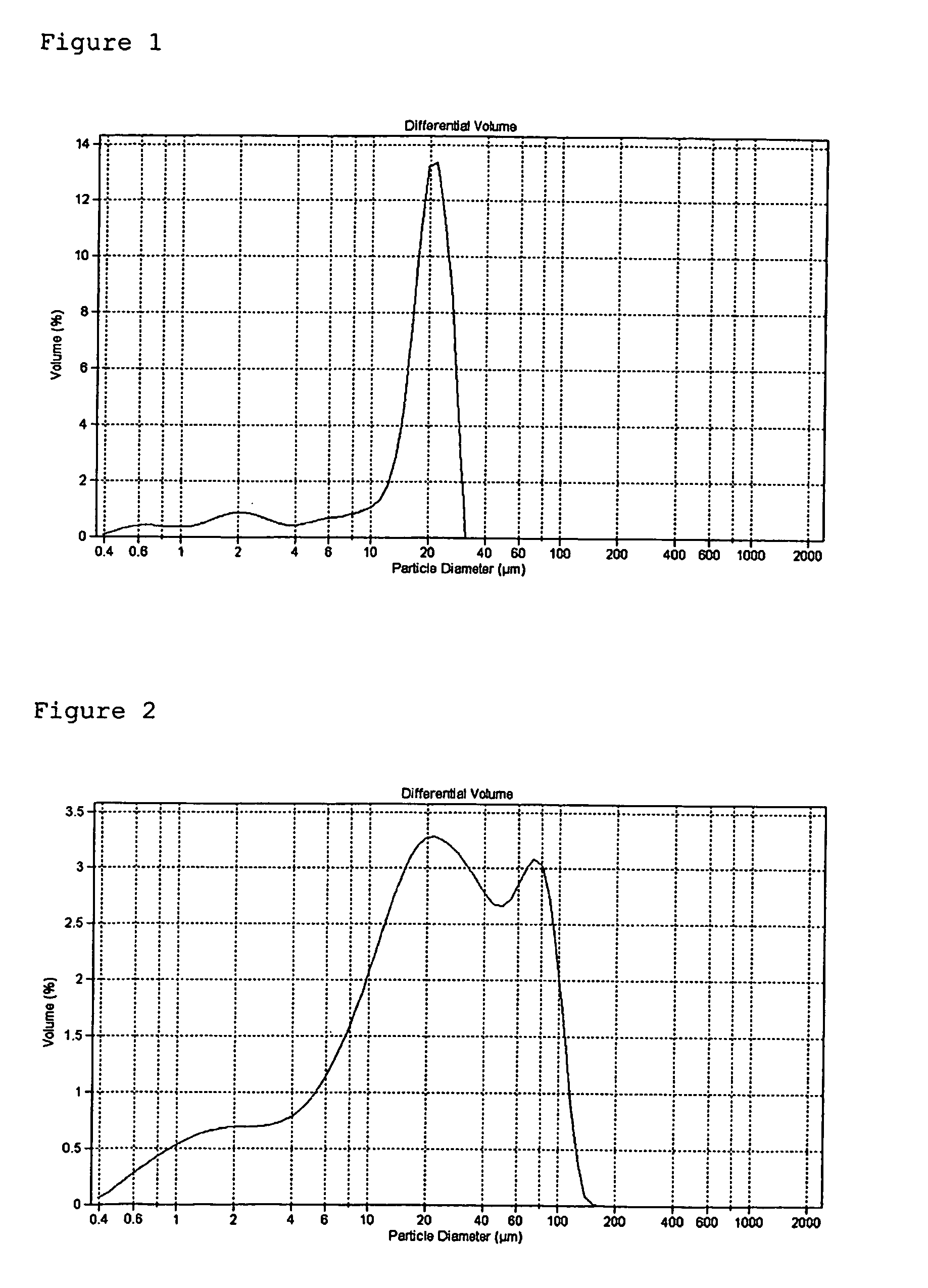

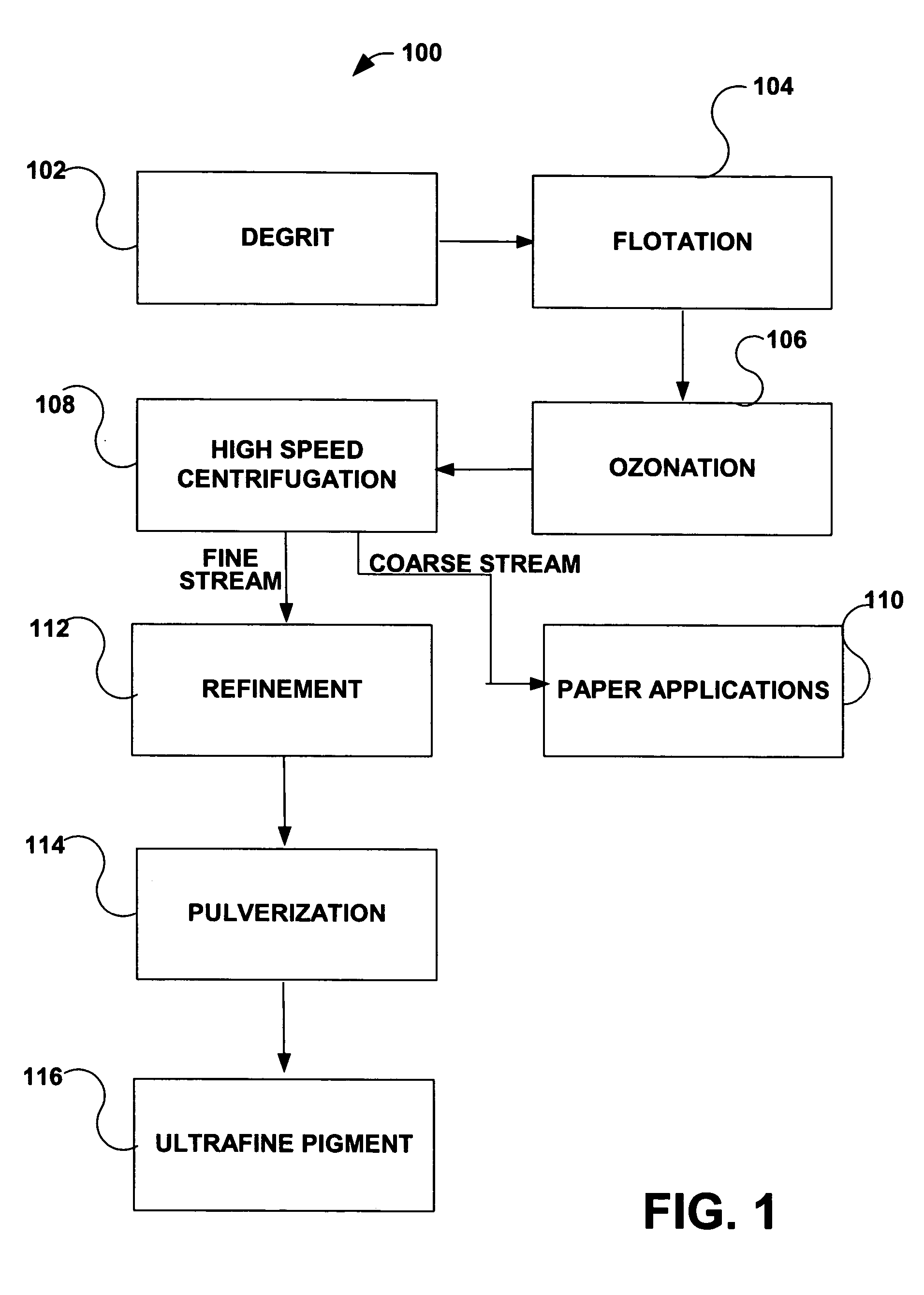

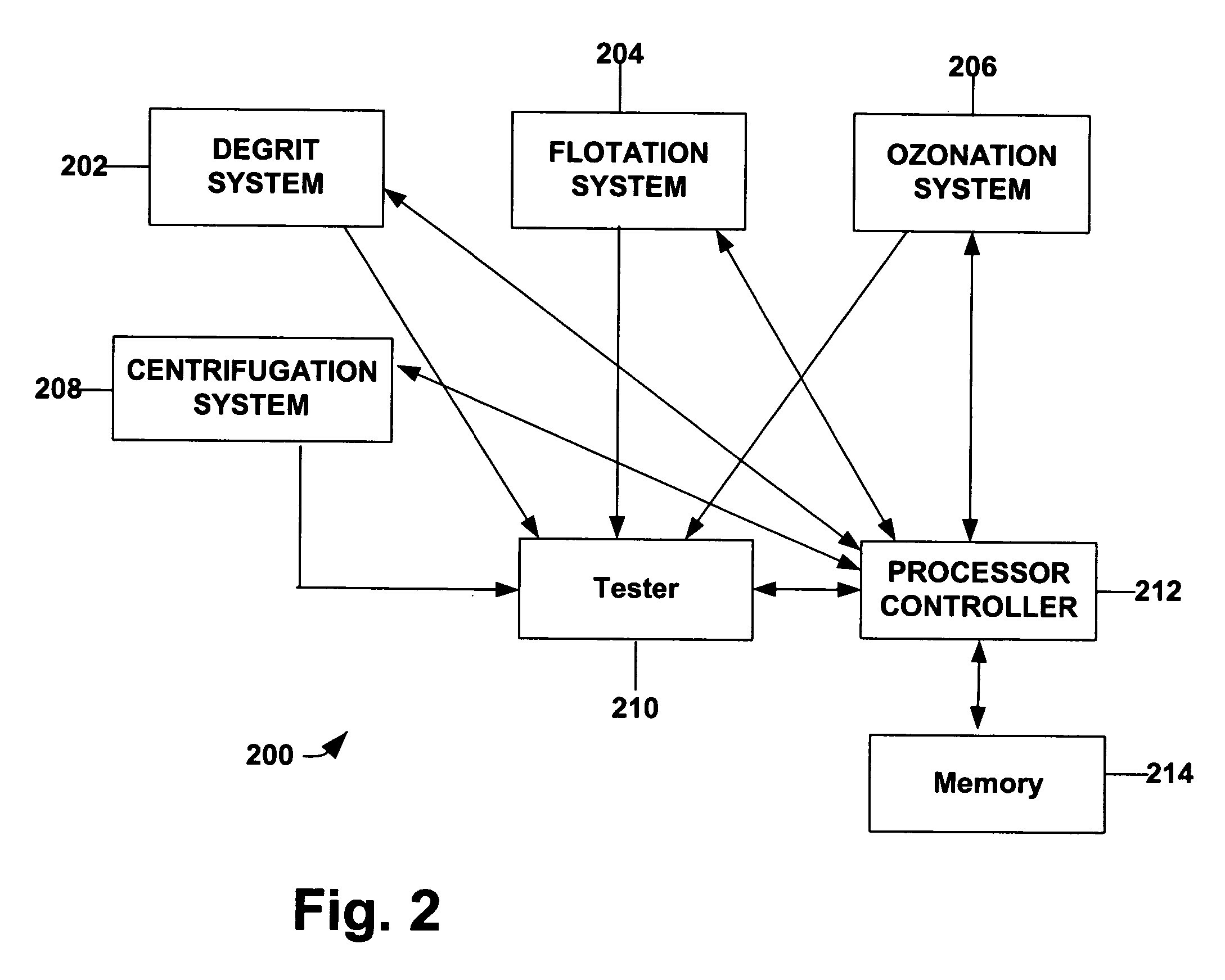

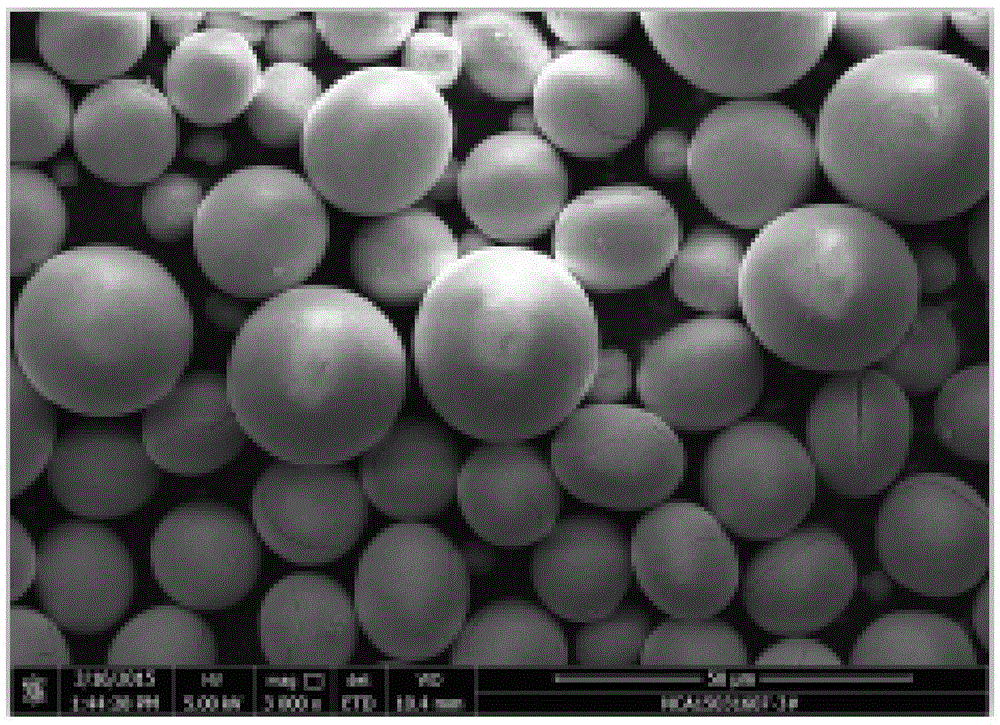

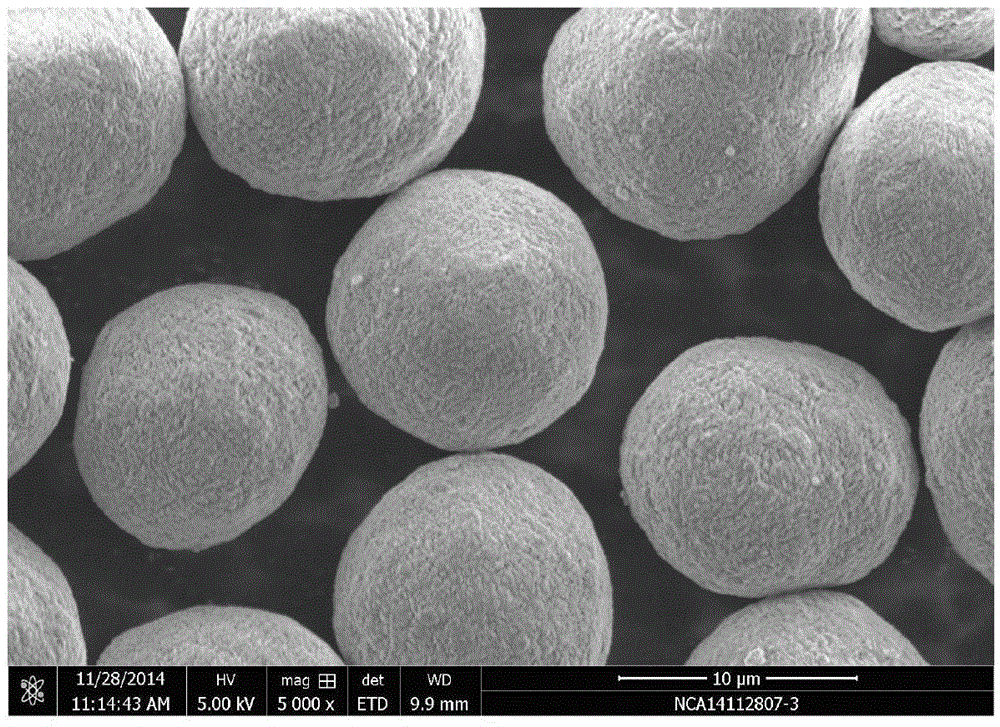

Ultrafine hydrous kaolin pigments, methods of making the pigments, and methods of using the pigments in gloss paint formulations

InactiveUS20060047047A1Large specific surface areaLow oil absorptionMaterial nanotechnologyInorganic pigment treatmentPigmentChemistry

Disclosed are methods of processing kaolin to produce ultrafine hydrous kaolin. The methods involve processing gray crude kaolin by subjecting the kaolin crude to flotation and then centrifuging the kaolin to provide a fine stream that is subject to refinement. Also disclosed are systems for the automated processing of gray crude kaolin to produce the ultrafine hydrous kaolin and paint compositions that contain the ultrafine hydrous kaolin.

Owner:BASF CORP

Positive electrode material precursor of lithium ion battery and preparation method thereof

InactiveCN105552361AAvoid shufflingEasy to spreadCell electrodesSecondary cellsLithium-ion batteryCobalt

The invention provides a positive electrode material precursor of a lithium ion battery. The positive electrode material precursor is a core-shell structure, and comprises an inner core and a shell, the inner core is [Ni(OH)2]<x>.[Co(OH)2]<y> with constant constituents, and the shell is [Ni(OH)2].[Co(OH)2].[Al(OH)3]<c> with gradually changing constituents, wherein x is greater than or equal to 0.7 and less than 1, y is greater than 0 and not greater than 0.3, and x+y is equal to 1; a is greater than 0.55 and less than 1, b is greater than 0 and less than 0.3, c is greater than 0 and not greater than 0.15, a+b+c is equal to 1, and x / y is equal to a / b; from an interface between the inner core and the shell to the surface of the shell, content of nickel and content of cobalt both decrease gradually, and content of aluminum increases gradually. The positive electrode material precursor has the advantages of high specific capacity of the inner core and high stability of the shell, and also can avoid generation of a gap between the inner core and the shell after discharging many times. The invention also provides a preparation method of the positive electrode material precursor.

Owner:JINGMEN GEM NEW MATERIAL

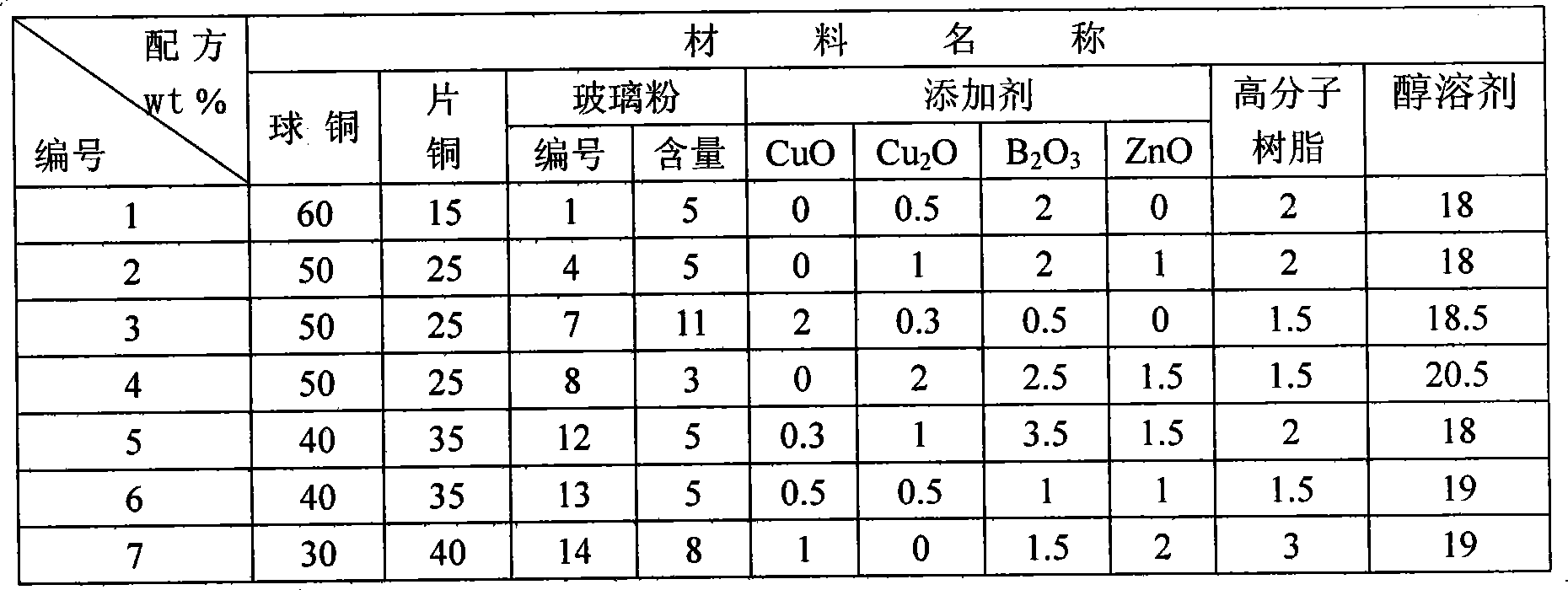

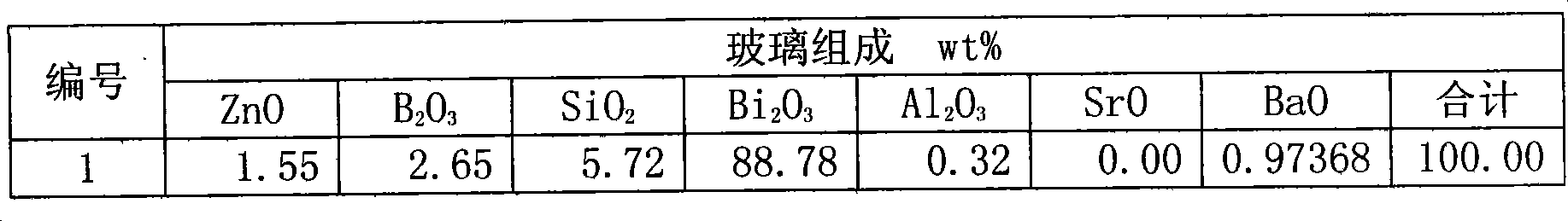

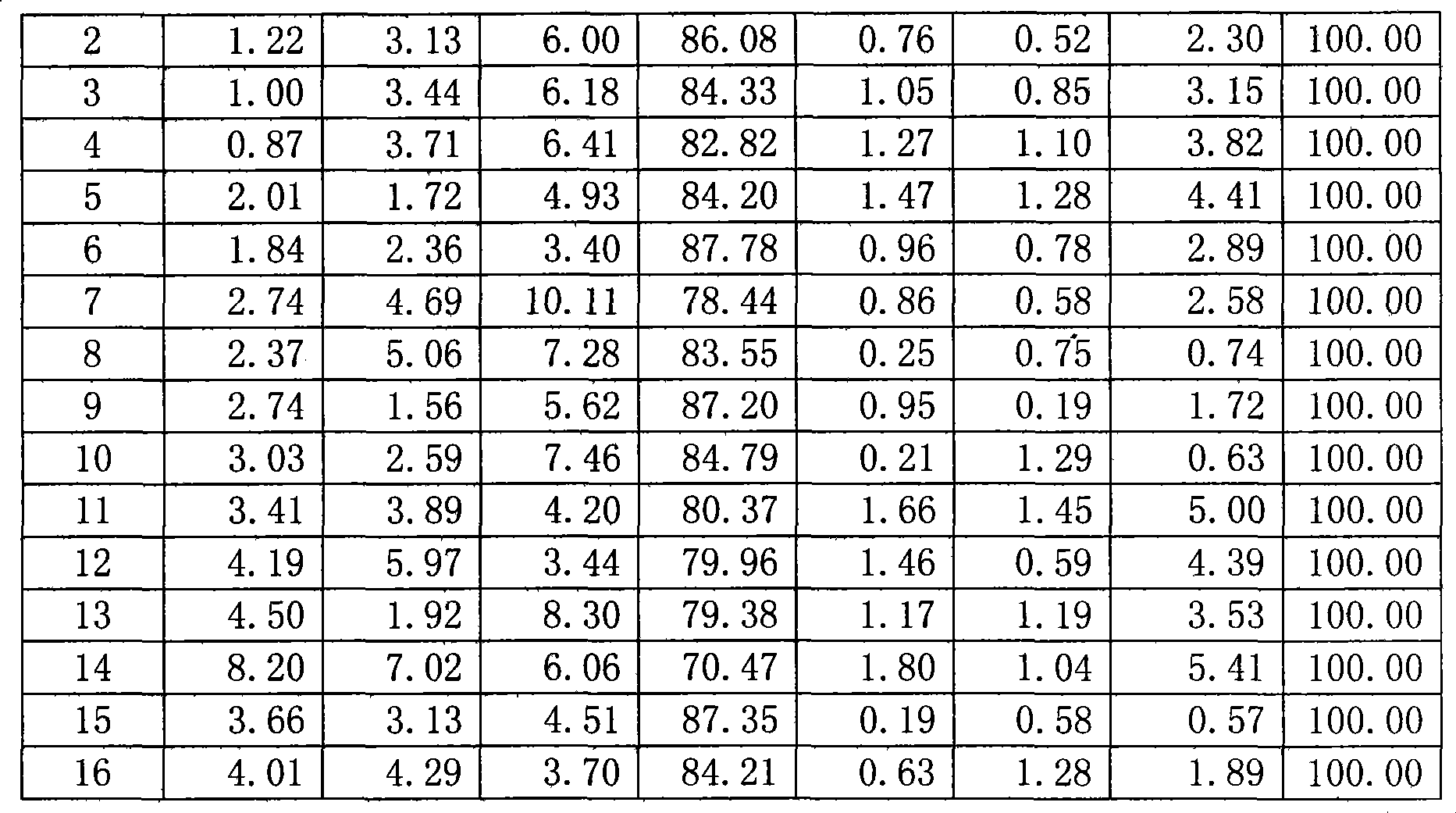

Base metal copper electrode paste and preparation of obtained capacitor

ActiveCN101364455APromote crystallizationImprove uniformityFixed capacitor electrodesConductive materialPolymer resinCopper electrode

The invention relates to base metal copper electrode slurry and a preparation method of a capacitor from the same. The base metal copper electrode slurry comprises the following components (wt%): 30-65 wt% of spherical copper, 10-30 wt% of sheet copper, 1.52-10 wt% of glass powder, 2-15 wt% of inorganic non-metallic additive, and 10.5-24 wt% of organic carrier, wherein the glass powder is a ZnO-B2O3-SiO2-Bi2O3 glass system; the inorganic non-metallic additive is one or more selected from CuO, Cu2O, ZnO and B2O3; and the organic carrier is polymer resin and a solvent. The base metal copper electrode slurry can be used in a ceramic disc capacitor and a semiconductor disc ceramic capacitor chip, the sintering temperature is 600-800 DEG C, and after sintering, the copper electrode slurry is converted to a copper electrode. The base metal copper electrode slurry has the characteristics of low cost, uniform material, uniform particle size distribution, high dispersibility, good forming process, and environmental friendliness.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Silver particle composite powder and process production thereof

InactiveUS20100025639A1Improve adhesionLow viscosityMaterial nanotechnologyTransportation and packagingSilver particlesFatty acid

A silver particle composite powder produced by mixing a silver particle powder (A) which bears on the surface of each silver particle, an organic protective layer comprising an amine compound having at least one unsaturated bond in one molecule and having a molecular weight of from 100 to 1000, and has a mean particle diameter DTEM, as determined by TEM, of at most 50 nm and a silver particle powder (B) which bears on the surface of each silver particle, an organic protective layer comprising a fatty acid having a molecular weight of from 100 to 1000 and an amine compound having a molecular weight of from 100 to 1000 with at least any one of the fatty acid and the amine compound having at least one unsaturated bond in one molecule, and has a mean particle diameter DTEM of at most 50 nm, in a blend ratio by mass, A / B of from 3 / 1 to 1 / 3 in terms of silver.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

Manufacturing Method of Antimicrobial Fiber Using Nano Silver Powder

InactiveUS20090214771A1Easily synthesizeExcellent antimicrobial and bactericidal activityLiquid surface applicatorsCoatingsSolventSpray nozzle

Disclosed is a method for manufacturing a method for manufacturing antimicrobial fiber using nano silver powder, which can greatly increase the antimicrobial and bactericidal activities of fiber by preparing nano silver particles with high dispersibility and high purity in a continuous and easy manner and allowing fiber yarn to contain the prepared nano silver particles in an optimal manner. The method the steps of: dissolving a silver precursor in solvent; spraying the precursor solution in the form of fine droplets by any one technique selected from ultrasonic spraying, air-assist spray nozzle spraying and pressure nozzle spraying; transferring the sprayed droplet precursor into a thermal reactor or a flame reactor by carrier gas; decomposing the transferred precursor by heating at a temperature of 400-2,000° C. to prepare nano silver particles; collecting the prepared nano silver particles in a collector while cooling with cooling fluid of less than 200° C.; preparing master batch chips using the prepared nano silver particles; and mixing yarn raw material with the master batch chips to manufacture fiber yarn.

Owner:SHIN HYUNKYUNG +1

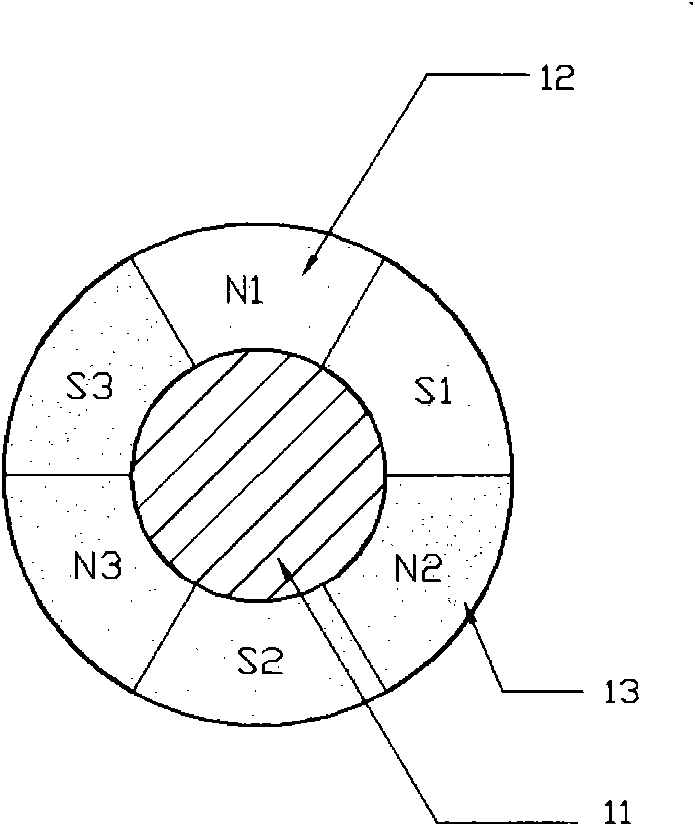

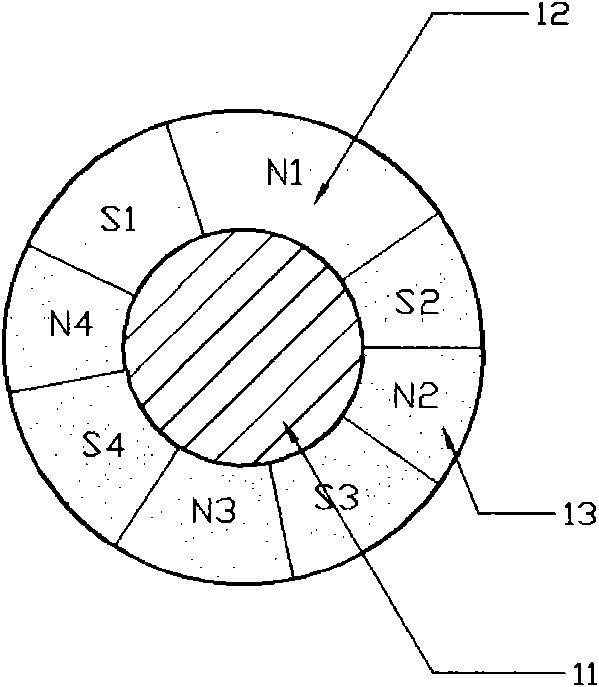

Isotropic bonded NdFeB magnet and magnetic roller consisting of same

ActiveCN101673606AHigh energy productImprove remanencePermanent magnetsInorganic material magnetismMetallurgyRare earth

The invention relates to a magnetic roller used in a laser printer and a copier. An isotropic bonded NdFeB magnet used by the magnetic roller contains rare earth permanent magnetic powder and adhesive resin, wherein the rare earth permanent magnetic powder is a mixture of NdFeB magnetic powder and ferrit magnetic powder, and the formed magnet has the length of between 210 and 910mm. When the isotropic bonded NdFeB magnet is used to replace one or more ferrit permanent magnet poles in the magnetic roller, because the bonded NdFeB magnet has stronger magnetic performance than ferrit magnets, a strong magnetic filed can be formed on an outer surface taking the bonded NdFeB magnet as a pole so as to provide stronger magnetic filed adsorptive power, contribute to the size distribution of multiple kinds of color matching powder, and reduce the grey back of copying and printing to contribute to clear imaging.

Owner:上海三环磁性材料有限公司 +1

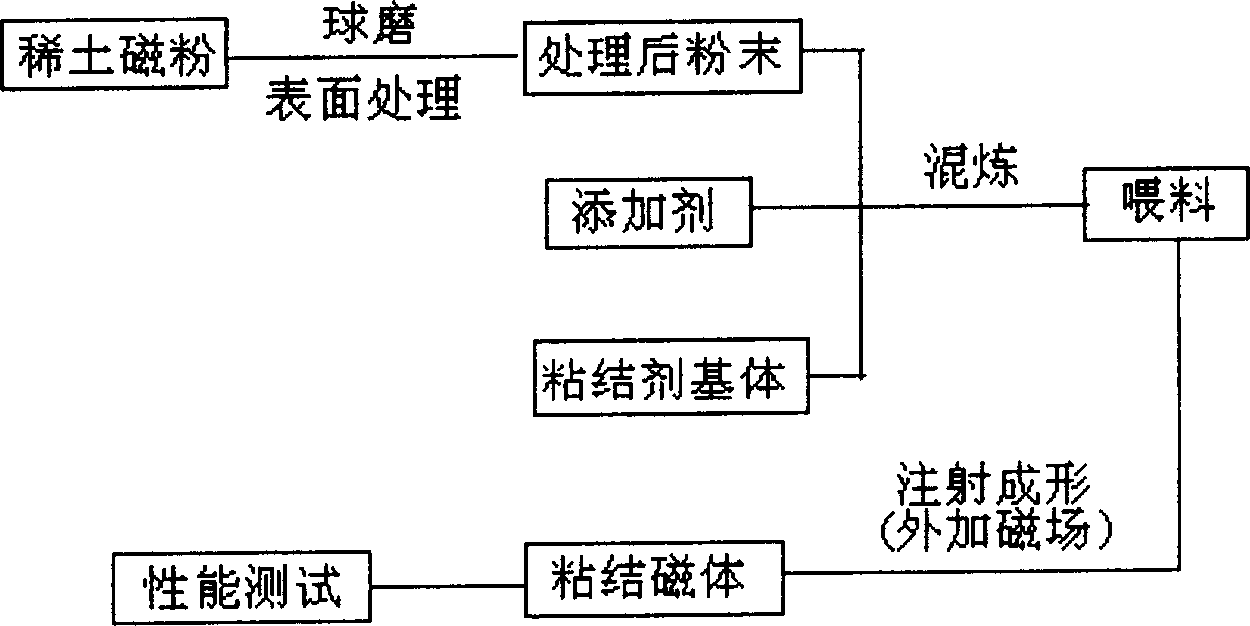

Preparation method of rare-earth bonding magnet

InactiveCN1808648AImprove antioxidant capacityIncrease loading capacityInductances/transformers/magnets manufactureAdhesivesRare earthOxidation resistant

This invention provides one rare earth binding magnet process method, which comprises the following steps: optimizing the magnetic powder distribution; matching the magnetic powder as proportion of 6 to 4 or 8 to 2; adopting non-water binderies process to process the anti-oxidation on the powder surface; mixing the rare powder as 55í½74VOLúÑ with binding agent to process injection materials; Injecting to shape to get the needed final product.

Owner:UNIV OF SCI & TECH BEIJING

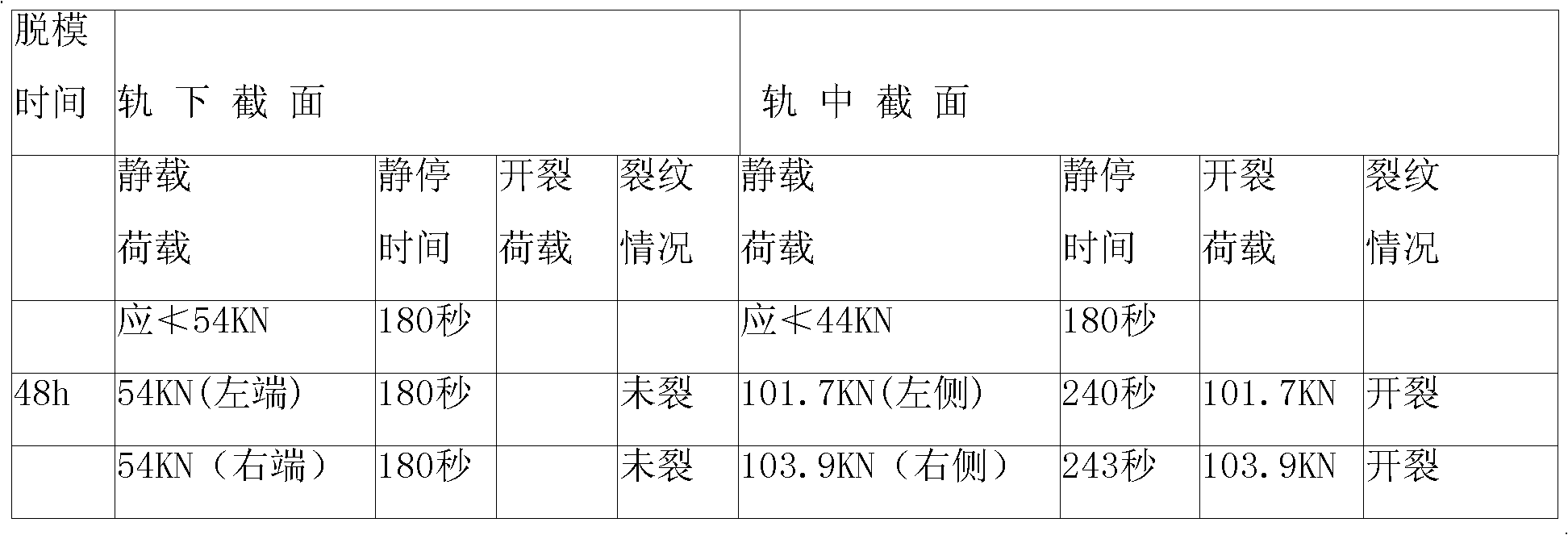

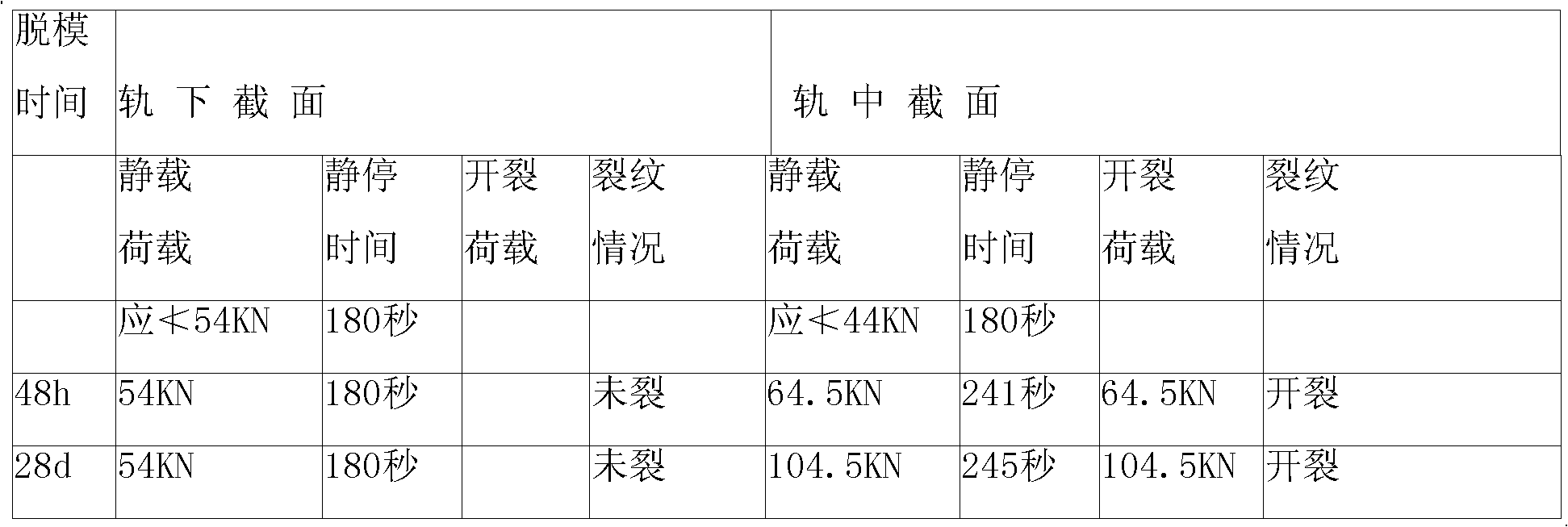

High-performance concrete material for prestressed component of ballastless track and method for preparing same

InactiveCN101289302ALow costSolve insufficient resourcesSolid waste managementSuperplasticizerWater reducer

The invention relates to a high performance concrete material used in prestressed components of non-ballasted tracks and a preparation method thereof. The gel material is cement, the aggregate is sand and stone, the admixture is complex mineral powder, and then high efficiency water reducing agent and water are added, stirred and vibrated, thus preparing the material. The components of the complex admixture are aluminosilicate, carbonate and sulfate, and the relative weight ratios are as follows: 15 to 80 percent of the aluminosilicate, 15 to 80 percent of the carbonate and 5 to 20 percent of the sulfate, and the total weight is 2 to 6 percent of the total weight of the concrete component. The material can ensure that the early strength of the concrete can achieve the required technical indexes of the prestressed concrete component used in non-ballasted tracks, thus obviously increasing the comprehensive properties, the workability and the durability of the concrete component. By using ordinary portland cement instead of superfine cement with deficient material source and exorbitant price, the product quality in mass production can be increased and the problem of high production cost of the prestressed concrete preformed component used in non-ballasted tracks can be solved.

Owner:CHINA RAILWAY SHISIJU GROUP CORP +2

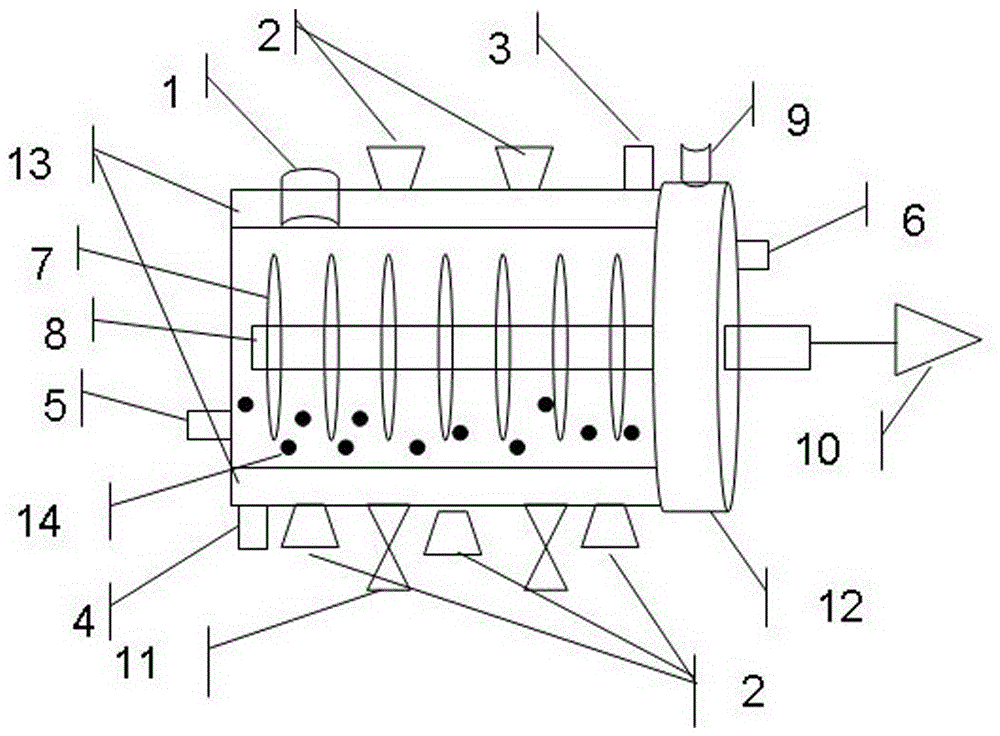

Multifunctional ball-milling device capable of manufacturing nanopowder or slurry efficiently and manufacturing process of multifunctional ball-milling device

InactiveCN105921222ANanoization speed increasedImprove particle size distributionGrain treatmentsMicrowaveHigh energy

The invention discloses a multifunctional ball-milling device capable of manufacturing nanopowder or slurry efficiently and a manufacturing process of the multifunctional ball-milling device. The high-energy ball-milling device comprises a motor, a grinding cylinder, functional auxiliary assemblies, a circulating cooling device, a protecting atmosphere assembly and a support. The grinding cylinder comprises a stirring rod, grinding discs, a material and grinding medium feeding opening, a filtering and separating device and a discharging opening. The circulating cooling device is arranged on the grinding cylinder and comprises a circulating cooling jacket, a cooling liquid inlet and a cooling liquid outlet. The functional auxiliary assemblies are at least one of a microwave generation device, an ultrasonic generator, a discharging device and a magnetic field generation device. The protecting atmosphere assembly is arranged on the grinding cylinder and comprises a protecting gas inlet, a protecting gas outlet and vacuumizing equipment. The functional auxiliary assemblies have the functions and beneficial effects of microwaves, ultrasound, discharging, magnetic fields, temperature fields and the like, so that the device meets the requirements on different conditions, and the operability of the device is improved.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

Preparation method of coated copper-silver metal powder

InactiveCN101664803AIncrease contact areaImproves antioxidant propertiesLiquid/solution decomposition chemical coatingNitrogen gasCopper

The invention discloses a preparation method of coated copper-silver metal powder which contains the pretreatment of copper powder, the preparation of silver solution and the preparation of copper-silver metal powder, wherein the preparation method of copper-silver metal powder comprises the following steps: dropwise adding dilute nitric acid in the sol of copper powder to adjusting the pH value to 3.0-5.0, adding ionic masking agent with the dosage of 1-30g / L, fully stirring, injecting inert protective gas such as nitrogen, argon or the like to remove the air in a reactor for protection, thenslowly dropping silver nitrate solution in the sol of copper powder while stirring to fully react for 30min, then dropping dilute ammonia water to adjusting the pH value to 7.0-11.0, continuously reacting for 30min, washing the reaction solution with deionized water, 5% of dilute sulphuric acid and ethanol solution for several times after the reaction and drying the obtained copper-silver metal powder at 60-80 DEG C to obtain the finished product. The product obtained by the method of the invention has excellent high temperature oxidation resistance and conductivity and narrow particle size distribution.

Owner:GUIZHOU INST OF METALLURGY & CHEM ENG

Highly crystalline silver powder and process for production of the same

InactiveCN101218051AExcellent heat shrinkage resistanceSmooth surface roughnessTransportation and packagingMetal-working apparatusFiltrationMicroparticle

The invention aims at providing a process for the production of highly crystalline silver powder which comprises silver particles falling within the fine particle region and has an excellent particle size distribution and highly crystalline silver powder obtained by the process. The aim is attained by a process for the production of highly crystalline silver powder which is characterized by preparing the first aqueous solution containing gelatin, silver nitrate and nitric acid and having a temperature of 45 to 55 C and the second aqueous solution containing erythorbic acid and / or ascorbic acid and a water-soluble organic acid, adding the second aqueous solution mildly to the first aqueous solution, stirring the mixed solution after the completion of the addition to form silver particles through particle growth, allowing the resulting system to stand to settle the silver particles, removing the supernatant, and then subjecting the remainder to filtration and washing to recover the silver particles.

Owner:MITSUI MINING & SMELTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com