Preparation method of rare-earth bonding magnet

A technology of bonded magnets and rare earth magnetic powders, applied in the manufacture of inductors/transformers/magnets, adhesives, electrical components, etc. The effect of fluidity and magnetic powder loading, improving the oxidation resistance of magnetic powder and reducing the viscosity of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

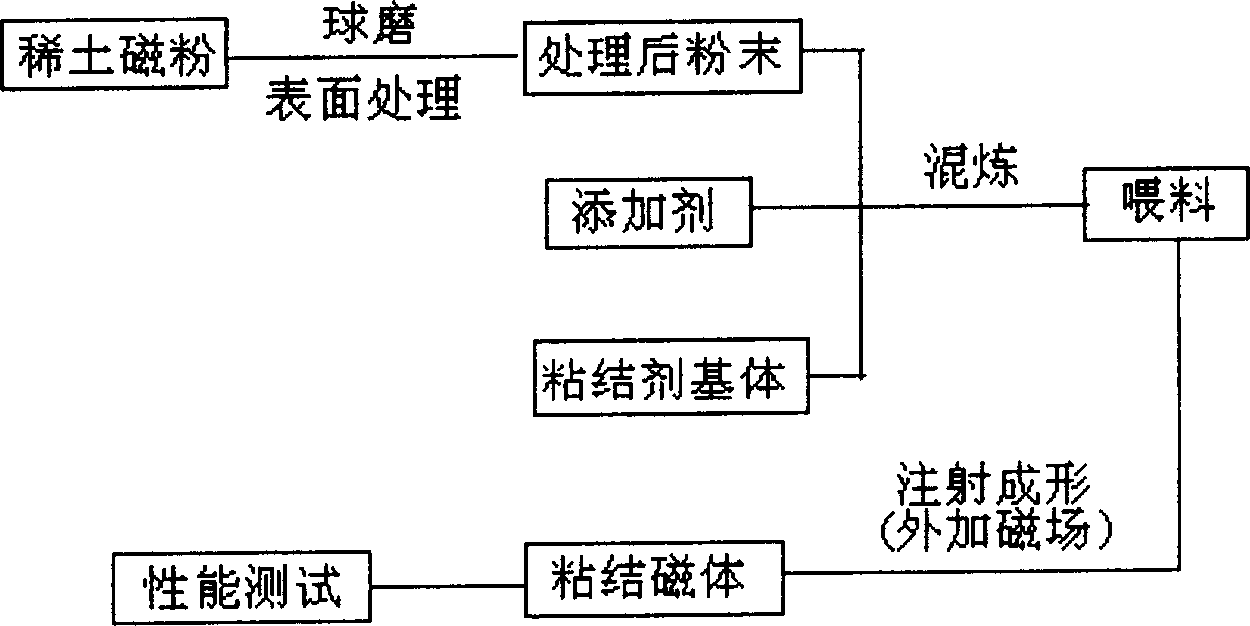

Method used

Image

Examples

Embodiment 1

[0018] Sieve the raw magnetic powder of anisotropic NdFeB magnet produced by hydrogen explosion method, the result is +75μm:-75μm=1:1. Re-optimize the batch combination according to the ratio of +75μm:-75μm=7:3, and then put 2.5g / mL into the acetone phosphate solution with a concentration of 0.1mol / L and stir it in a stirring ball mill at a speed of 20 rpm After 30 minutes, filter and dry in vacuum at 110°C. It is 67VOL% and binder to mix 40min with temperature 235 ℃, rotating speed 30rpm in the kneader with loading subsequently, to obtain uniform feeding, and measure it with capillary rheometer at 300 ℃ temperature and 10 5 the s -1 Viscosity value η at shear rate. Wherein the composition of the adhesive is as follows: the matrix component is nylon 12 (melting point is 178° C., solubility parameter is 19.6), and the amount accounts for 78.6 wt% of the total adhesive; the coupling agent is KH550 silane, and the amount is 3 wt%. Lubricant is " 50wt% stearylamide (solubility ...

Embodiment 2

[0021] Sieve the raw magnetic powder of anisotropic NdFeB magnet produced by hydrogen explosion method, the result is +75μm:-75μm=1:1. Re-optimize the batch combination according to the ratio of +75μm:-75μm=8:2, and then put 3.5g / mL into the acetone phosphate solution with a concentration of 0.1mol / L and stir it in a stirring ball mill at a speed of 25 rpm After 60 minutes, filter and dry in vacuum at 90°C. It is 72VOL% and binder to mix 60min with temperature 235 ℃, rotating speed 40rpm in the kneader with loading subsequently, to obtain uniform feeding, and measure it with capillary rheometer at 300 ℃ temperature and 10 5 the s -1 Viscosity value η at shear rate. The composition of the binder is as follows: the base component is nylon 12, and the amount accounts for 73.9wt% of the total binder; the coupling agent is NDZ-201 titanate, and the amount is 4wt%; the lubricant is "70wt% Stearamide + 30wt% methyl silicone oil" compound, the dosage is 12wt%; the plasticizer is o-...

Embodiment 3

[0024] Sieve the raw magnetic powder of anisotropic NdFeB magnet produced by hydrogen explosion method, the result is +75μm:-75μm=1:1. Re-optimize the batch combination according to the ratio of +75μm:-75μm=7:2, and then put 2.5g / mL into the acetone phosphate solution with a concentration of 0.1mol / L and stir it in a stirring ball mill at a speed of 25 rpm 50min, filtered and dried in vacuum at 80°C. Then be that 65VOL% and binder mix 40min with temperature 215 ℃, rotating speed 30rpm in the kneader with loading capacity, to obtain uniform feeding, and measure its temperature at 300 ℃ and 10 with capillary rheometer 5 the s -1Viscosity value η at shear rate. The composition of the binder is as follows: the matrix component is nylon 12, and the dosage accounts for 81.5wt% of the total binder; the grade of the coupling agent is titanate, and the dosage is 3wt%; the lubricant is "60wt% stearic acid Zinc + 40wt% methyl silicone oil" compound, the dosage is 8wt%; the plasticizer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com