Multifunctional ball-milling device capable of manufacturing nanopowder or slurry efficiently and manufacturing process of multifunctional ball-milling device

A nano-powder, high-efficiency technology, applied in grain processing, etc., can solve the problems of long action time, difficulty in large-scale application, serious environmental pollution, etc., and achieve the effect of increasing uniformity and increasing the speed of nanometerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

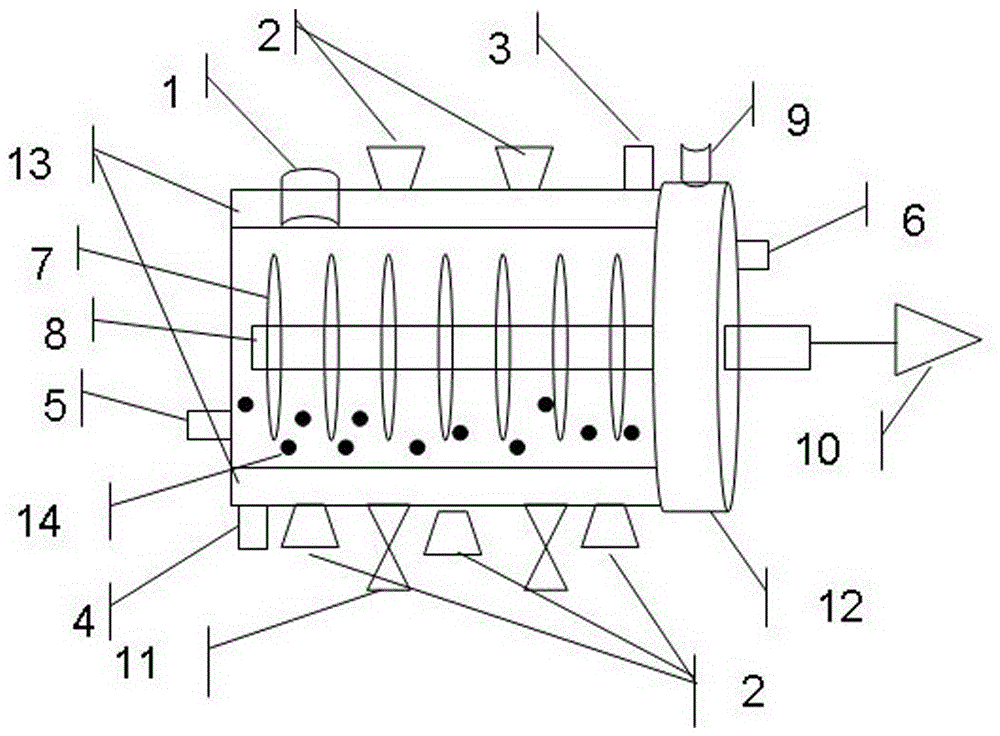

[0022] Please refer to figure 1 As shown, it shows the specific structure of the preferred embodiment of the present invention, a multifunctional ball milling device for preparing nano powder or slurry with high efficiency. device, atmosphere protection assembly and support 11; the grinding drum includes a stirring rod 8, a grinding disc 7, a material and grinding medium inlet 1, a filter and separation device 12, and a discharge port 9; the grinding drum is provided with a circulating cooling device, The circulating cooling device includes a circulating cooling jacket 13, a cooling liquid inlet 4 and a cooling liquid outlet 3; the functional auxiliary component 2 is at least one of a microwave generating device, an ultrasonic generator, a discharge device or a magnetic field generating device; An atmosphere protection assembly, the atmosphere protection assembly includes a shielding gas inlet 5, a shielding gas outlet 6 and vacuum equipment.

[0023] The circulating cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com