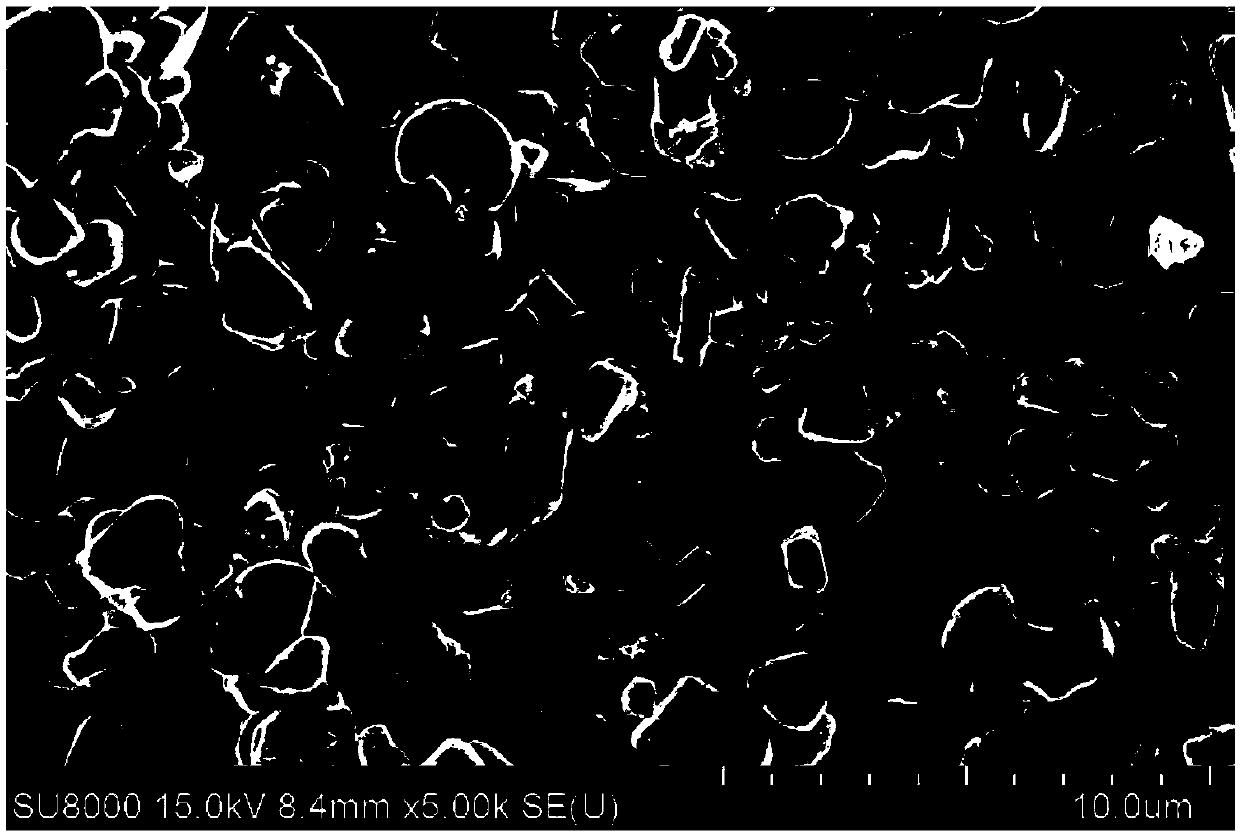

High-nickel ternary positive electrode material with monocrystal morphology and preparation method of high-nickel ternary positive electrode material

A positive electrode material and morphology technology, which is applied in the field of single-crystal high-nickel ternary positive electrode materials and its preparation, can solve the problems of strict requirements in the cell preparation process, poor high-temperature storage performance, and limited energy density, and achieve increased Effect of coating process, improvement of processability, improvement of particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

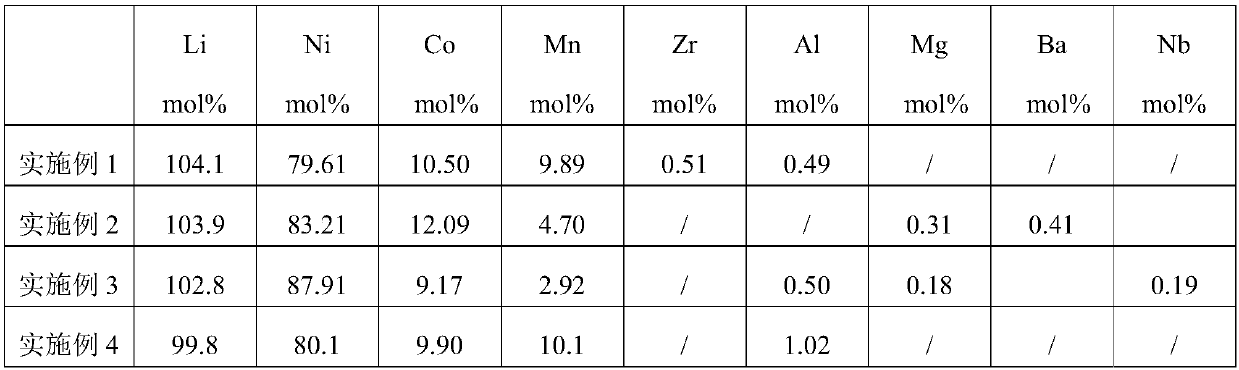

Embodiment 1

[0064] (1) preparation is by Ni: Co: solution A of Mn molar ratio 8.0: 1.0: 1.0, metal ion concentration is 1.5mol / L, preparation concentration is the NaOH solution of 5mol / L; Preparation concentration is the ammoniacal solution of 9mol / L; Put solution A (flow rate 30ml / min), NaOH solution (flow rate 10ml / min), and ammonia solution (flow rate 8ml / min) into the reaction kettle at the same time, control the pH to 11.5-12.5, and react at a temperature of 50°C. After 20 hours, After the reaction is completed, after aging, washing and drying, the precursor Ni with a D50 of 3 μm is obtained. 0.8 co 0.1 mn 0.1 (OH) 2 ;

[0065] (2) the precursor described in step (1), and lithium hydroxide, ZrO 2 Mixing, wherein, the molar ratio of lithium:transition metal (Ni+Co+Mn) is 1.04, the amount of Zr added is 0.005 of the amount of (Ni+Co+Mn) substances, and sintered in an oxygen atmosphere at 840°C for 15 hours. After cooling and crushing, the base material is obtained;

[0066] (3) A...

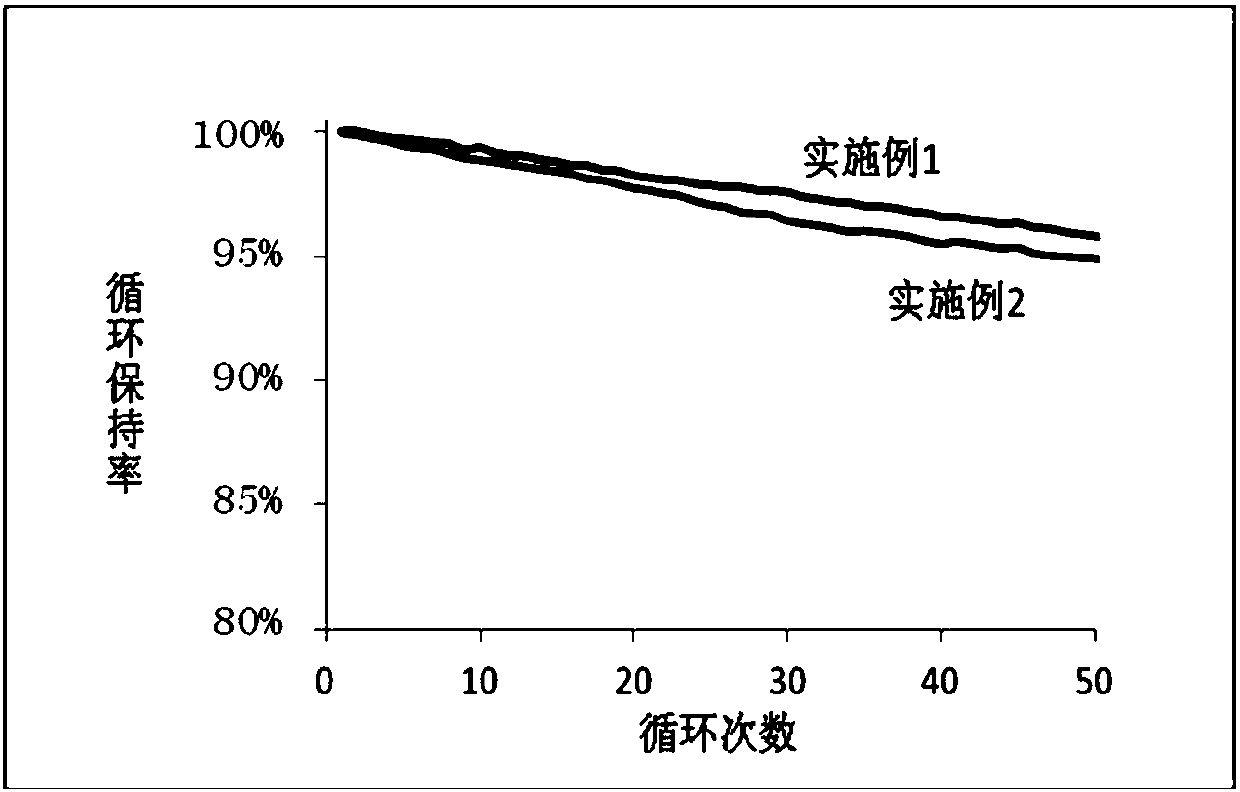

Embodiment 2

[0072] (1) The preparation method of the precursor is similar to Example 1, except that the molar ratio of Ni:Co:Mn is changed to 8.3:1.2:0.5, and the precursor Ni with a D50 of 3 μm is obtained. 0.83 co 0.12 mn 0.05 (OH) 2 ;

[0073] (2) Mix the precursor described in step (1) with lithium hydroxide and additive MgO. Among them, the molar ratio of lithium:transition metal (Ni+Co+Mn) is 1.04, the amount of Mg added is 0.003 of the amount of (Ni+Co+Mn) material, and sintered in an oxygen atmosphere at 840 ° C for 12 hours. After cooling, The base material is obtained after pulverization;

[0074] (3) After washing and drying the substrate described in step (2), uniformly mix it with barium nitrate, the amount of Ba added is 0.004 of the amount of (Ni+Co+Mn) substance, and then sintering at 400° C. in an oxygen atmosphere, The sintering time is 12h, and the single-crystal high-nickel ternary positive electrode material is obtained, and the base material is LiNi 0.832 co 0...

Embodiment 3

[0080] (1) The preparation method of the precursor is similar to Example 1, except that the molar ratio of Ni:Co:Mn is changed to 8.8:1.2:0.5, and the precursor Ni with a D50 of 3 μm is obtained. 0.88 co 0.18 mn 0.05 (OH) 2 ;

[0081] (2) the precursor described in step (1), and lithium hydroxide, additive Nb 2 o 5 Mixing, wherein, the molar ratio of lithium:transition metal (Ni+Co+Mn) is 1.03, the amount of Nb added is 0.002 of the amount of (Ni+Co+Mn) substance, sintering in an oxygen atmosphere at 830 ° C, sintering time 12h, after After cooling and crushing, the base material is obtained;

[0082] (3) Wash and dry the base material obtained above, and evenly mix it with nano-sized alumina. The amount of Al added is 0.005 of the amount of (Ni+Co+Mn) substance; then sintered at 750°C in an oxygen atmosphere, and the sintering time For 12h, the high-nickel ternary positive electrode material with single crystal morphology is obtained, and its base material is LiNi 0.87...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com