Fe-based amorphous nano-coating powder and its argon atomization production

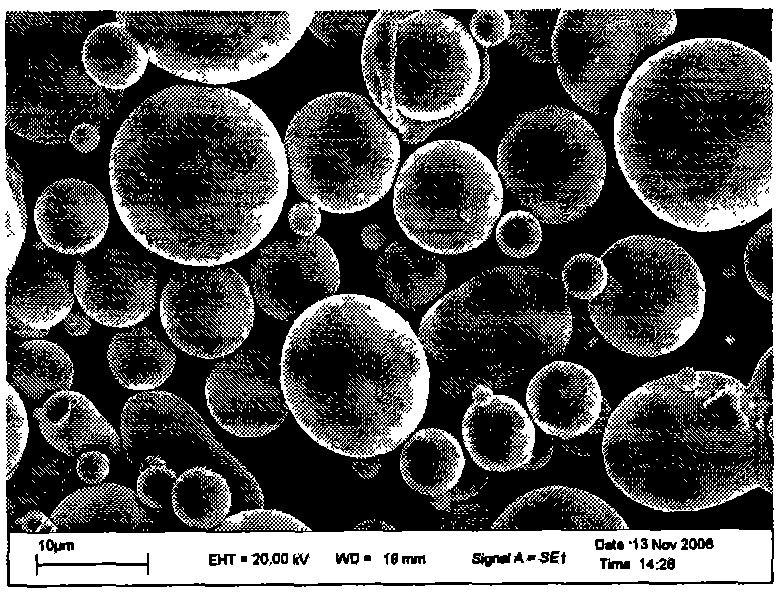

An amorphous nanocrystalline and spraying powder technology is applied in the field of Fe-based amorphous nanocrystalline spraying powder and its argon atomization preparation, and achieves the effects of reasonable powder particle size distribution, good sphericity and good fluidity

Inactive Publication Date: 2007-09-05

UNIV OF SCI & TECH BEIJING

View PDF0 Cites 31 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Login to View More

Abstract

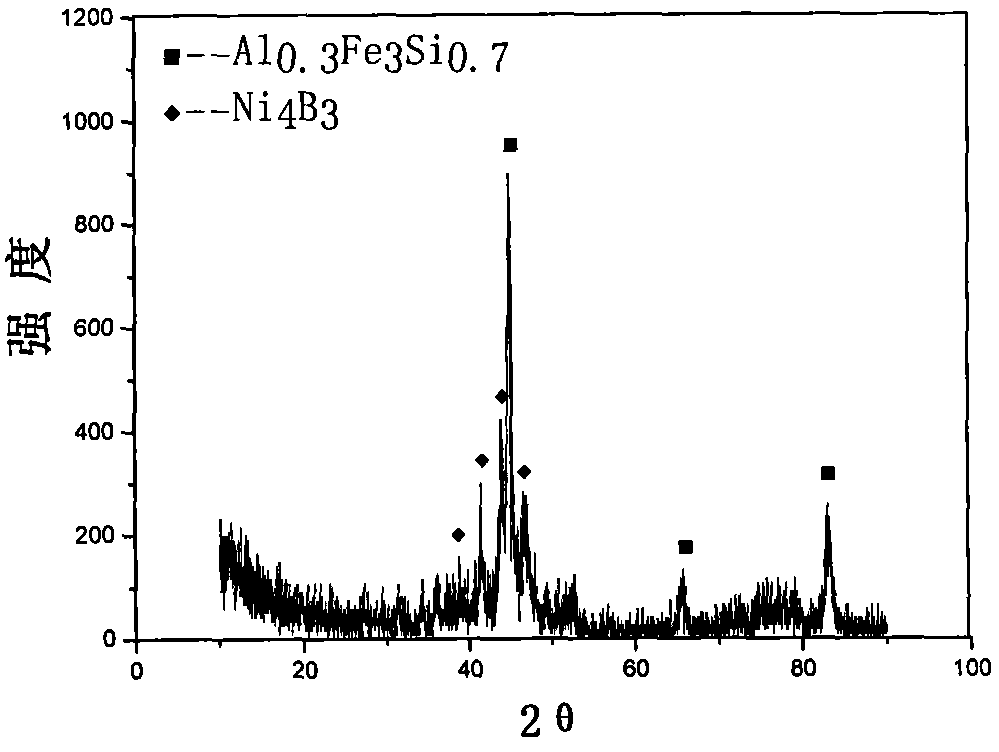

A Fe-based amorphous nano-crystal spraying powder and its argon atomizing production are disclosed. The spraying powder consists of Cr 8-15wt%, Ni 8-16wt%, Si 2.8-5.7wt%, B 2.8-5wt%, W 2-8wt%, Mo 2-8wt%, Co 0.5-1wt%, Al 1-4wt% and Fe residues. The process is carried out by proportioning for ingredients, vacuum smelting, atomizing and screening powders. It has excellent fluidity and stability.

Description

technical field The present invention relates to the technical field of amorphous and nanocrystalline powders, in particular to a Fe-based amorphous and nanocrystalline spray powder and an argon atomization preparation method thereof. Background technique Amorphous-nanocrystalline materials have more unique and excellent properties than traditional materials, and are promising new materials. However, in practice, until now, these materials have not been widely used. The main factor is that their preparation process is difficult to control, and their applications are mainly limited to low-dimensional shapes such as thin strips, filaments, and powders. Relatively speaking, the preparation process of amorphous and nanocrystalline coatings is relatively easy to realize. Among many methods of preparing coatings, thermal spraying technology is a very competitive technology, and it is also a very promising technology. The use of thermal spraying technology to obtain amorphous-nan...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C45/02C22C24/00C22C33/04B22F9/08

Inventor 樊自拴王勇张丽娜孙冬柏孟惠民俞宏英王旭东

Owner UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com