Preparation method of catalyst for removing tritium in tritium-containing air

A catalyst and air technology, applied in the field of catalyst preparation, can solve the problems of increased air resistance of the tritium removal system, and achieve the effects of convenient high dispersion, convenient preparation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

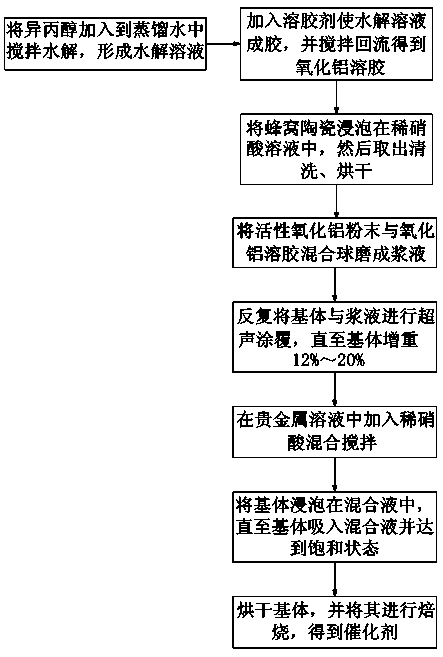

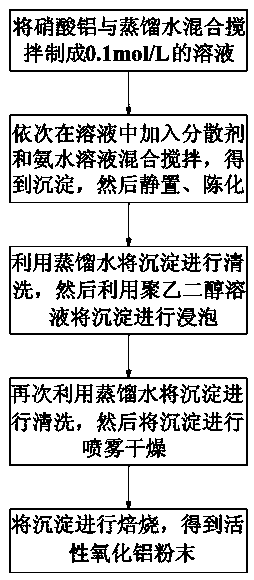

[0041] Such as figure 1 As shown, the present invention provides a kind of processing method of preparing the catalyst of tritium-containing air detritium, and the catalyst that it makes is made of active component, carrier and substrate three parts, and wherein, substrate is the ceramic carrier block of regular structure, and The active component and the carrier are loaded on the inner surface of the inner channel wall of the substrate in the form of a coating structure. The substrate acts as a support for the coated catalyst; the carrier uses activated alumina powder to increase the surface area, disperse and support the activity of the catalyst. The role of components. The process of preparing catalyst of the present invention is as follows:

[0042] (1) Aluminum isopropoxide is added to distilled water and stirred for hydrolysis to form a hydrolysis solution, and then the alcohol produced by hydrolysis is removed;

[0043] (2) adding a peptizer to make the hydrolyzed sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com