Patents

Literature

87results about How to "Achieve effective use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wet separation method for valuable metals in purified liquid cobalt slags of wet zinc smelting system

ActiveCN101838736AReduce pollutionAchieve effective useProcess efficiency improvementPregnant leach solutionZinc smelting

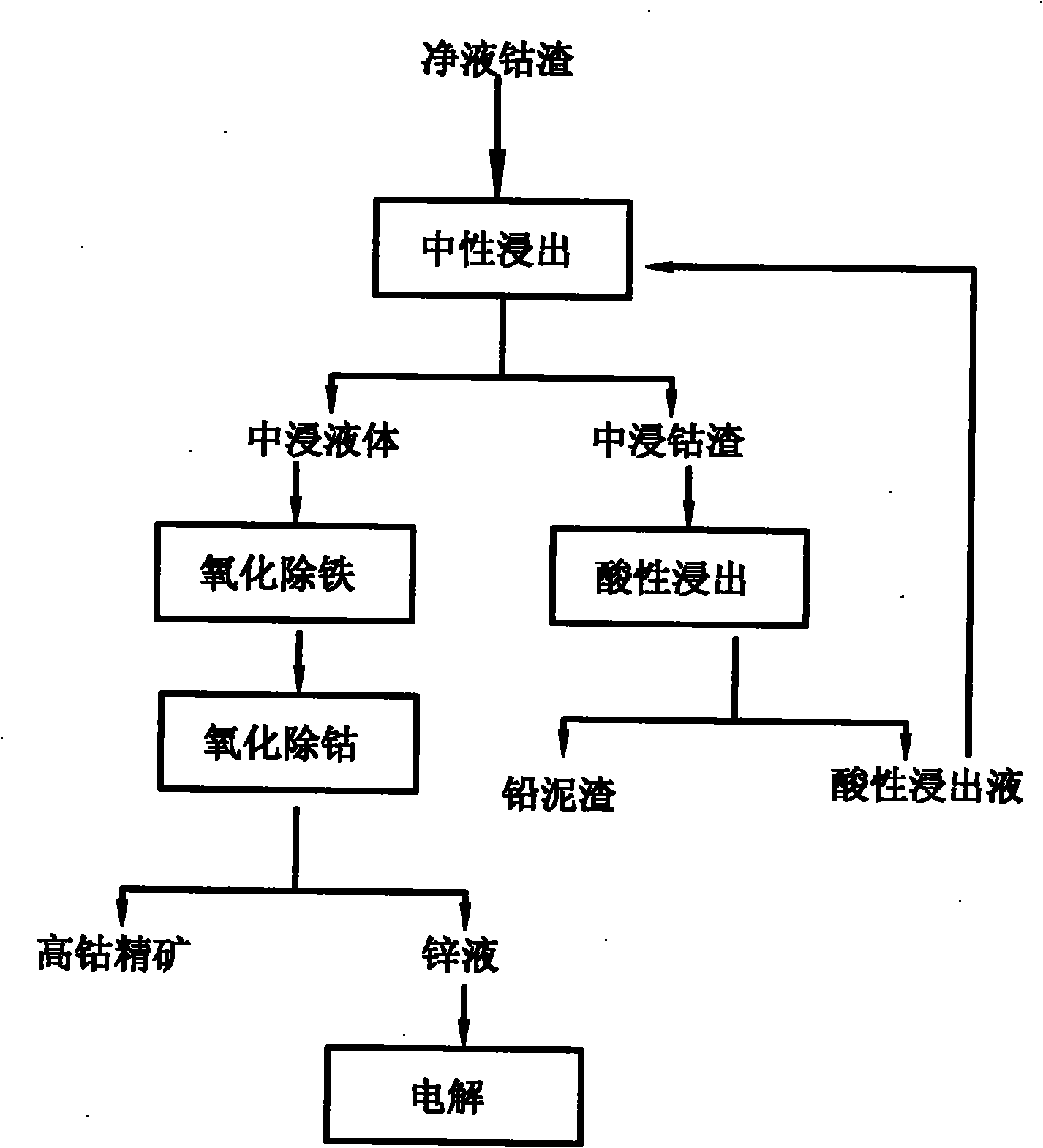

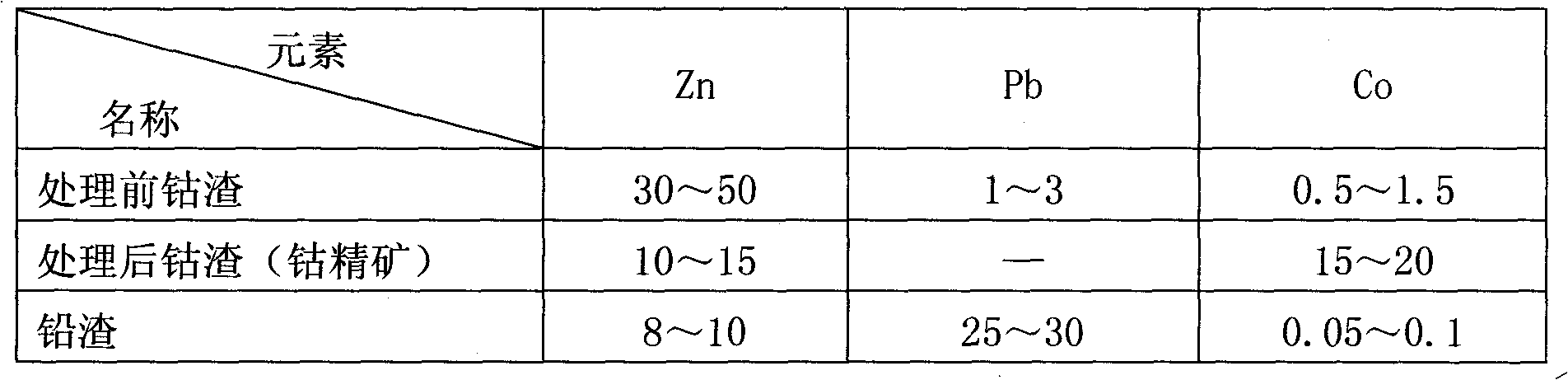

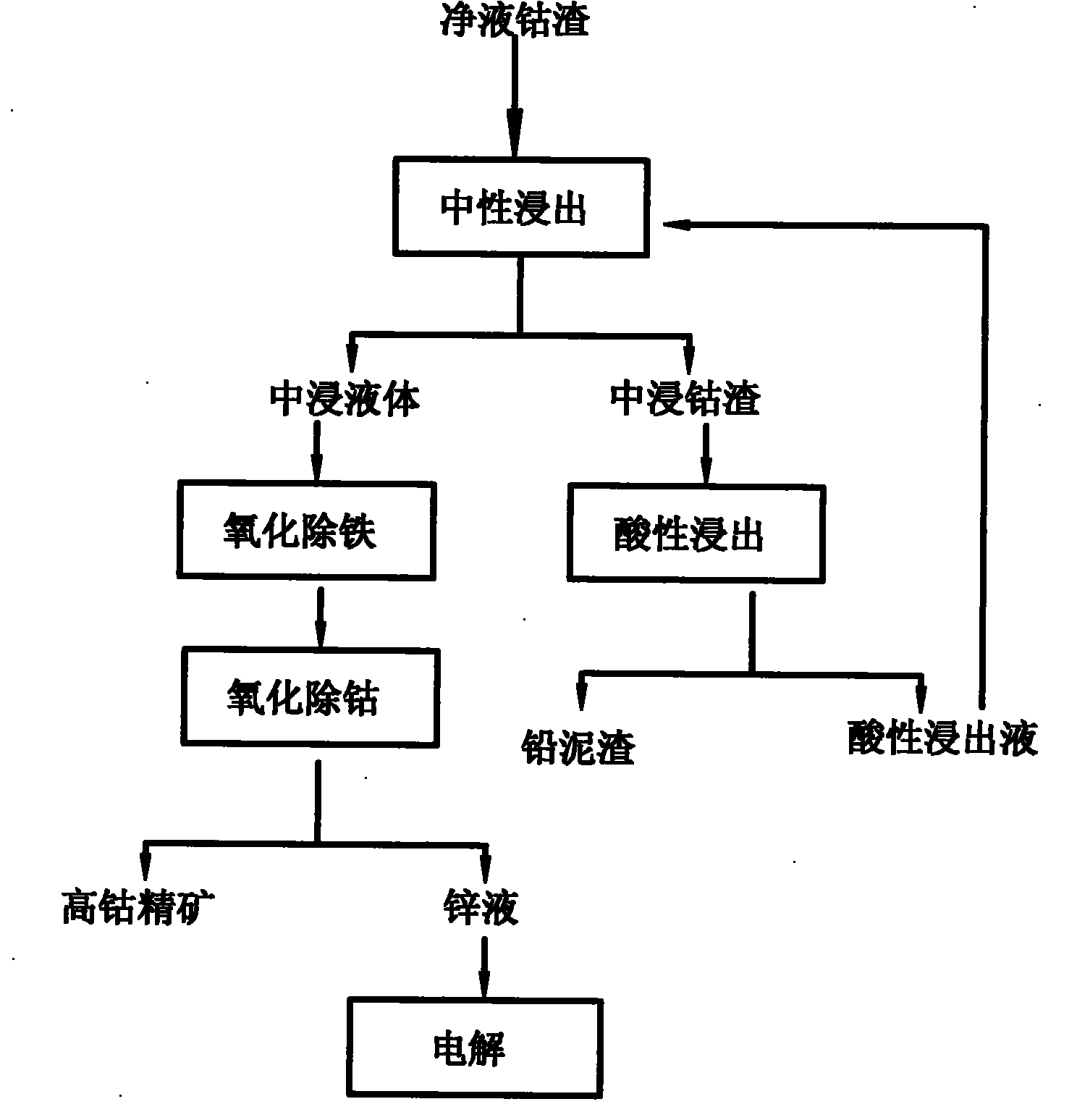

The invention relates to a wet separation method for valuable metals in purified liquid cobalt slags of a wet zinc smelting system, which comprises the processes of neutral leaching of cobalt slags, acid leaching of the cobalt slag, removal of iron in neutrally leached liquid, removal of cobalt in the neutrally leached liquid and the like and concretely comprises the following steps: firstly, sieving and crushing the purified liquid cobalt slags in the wet zinc smelting process; carrying out segmented leaching in a sulfuric acid system; separating leached ore pulp to obtain lead slags; treating impurities in the leached liquid; and adding oxidant into the treated leached liquid for separating Fe and Co to obtain high cobalt concentrate with the cobalt content more than 15%, wherein the high cobalt concentrate can be used as a cobalt smelting raw material to be sold. The invention can effectively recover the valuable metals such as cobalt, zinc, lead and the like in the purified liquid cobalt slags, outputs the lead slags, the high cobalt concentrate and electrolytic zinc, realizes the effective utilization of waste slags, solves the problem of treatment of the waste slags in the wet zinc smelting process, and achieves the purpose of comprehensively recycling resources.

Owner:HENAN YUGUANG ZINC IND

Method for producing 2,3-butanediol by using starch raw materials

InactiveCN101565721AWide variety of sourcesLow priceMicroorganism based processesFermentationK pneumoniaeAlpha-amylase

The invention discloses a method for producing 2,3-butanediol by using starch raw materials, which comprises the following steps: subjecting the starch raw materials to treatment by alpha-amylase and maltogenic amylase; and producing the 2,3-butanediol by carrying out separate hydrolysis and fermentation or simultaneous sacchrification and fermentation under an aseptic condition, using saccharification liquid or liquefaction liquid as a fermentable substrate and using Klesiella pneumoniae as a fermentable strain. Finally the concentration of the 2,3-butanediol reaches 43 to 112g / L, and the final concentration of acetoin and the final concentration of the 2,3-butanediol reach 45 to 121g / L. The method has the advantages of using the starch raw materials to produce a high-value platform compound by fermentation, reducing the raw material cost of the production of the 2,3-butanediol by the fermentation and establishing the optimal fermentation condition for the production of the 2,3-butanediol by the sacchrification and fermentation of the starch raw materials. The production of the 2,3-butanediol by the simultaneous sacchrification and fermentation of the invention can save energy and equipment investment, reduce fermentation period and improve production efficiency.

Owner:SHANDONG UNIV

Complex microbial agent for fast decaying straws to produce organic fertilizer as well as preparation method and application

InactiveCN104357362AShorten corrosion cycleEfficient decompositionFungiBacteriaCelluloseMicrobial agent

The invention relates to a complex microbial agent mainly used for fast decaying straws to produce an organic fertilizer as well as a preparation method and the application. The complex microbial agent for fast decaying the straws to produce the organic fertilizer is characterized by being prepared from 15-20% of bacillus subtilis, 16-20% of aspergillus niger, 18-22% of trichoderma reesei, 10-15% of white rot fungi, 10-15% of aspergillus oryzae, 5-7% of alkalophilic bacteria, 5-8% of thermophilic cellulose decomposition bacteria and 5-10% brewer's yeast in percentage by mass, as well as an accelerant accounting for 0.01-0.03% of the total mass of the bacillus subtilis, the aspergillus niger, the trichoderma reesei, the white rot fungi, the aspergillus oryzae, the alkalophilic bacteria, the thermophilic cellulose decomposition bacteria and the brewer's yeast. The complex microbial agent is capable of shorting the straw decaying period; the decayed straw is combined with pig manure to produce the organic fertilizer, and therefore, the straws can be utilized effectively and practically.

Owner:WUHAN UNIV OF TECH

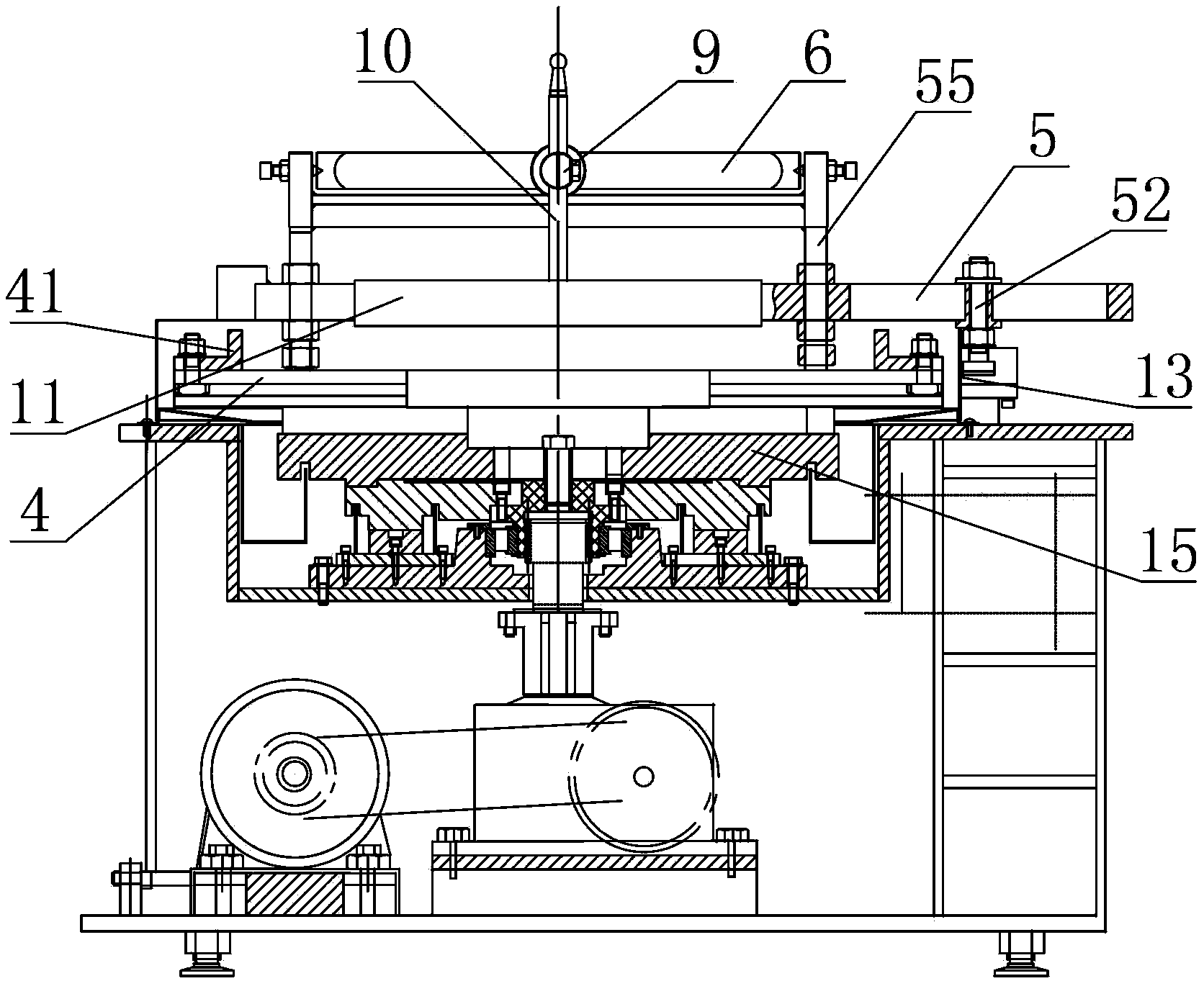

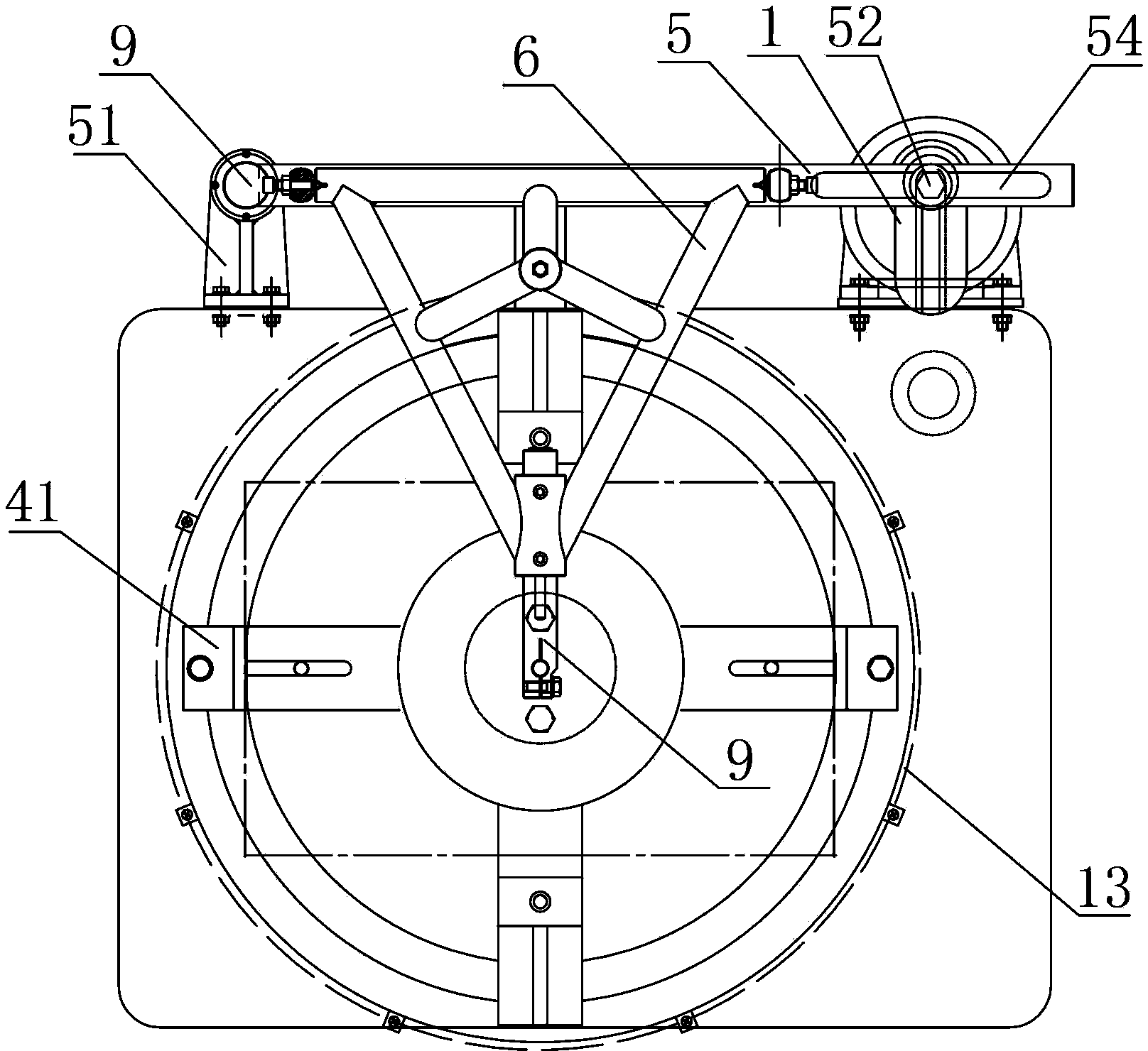

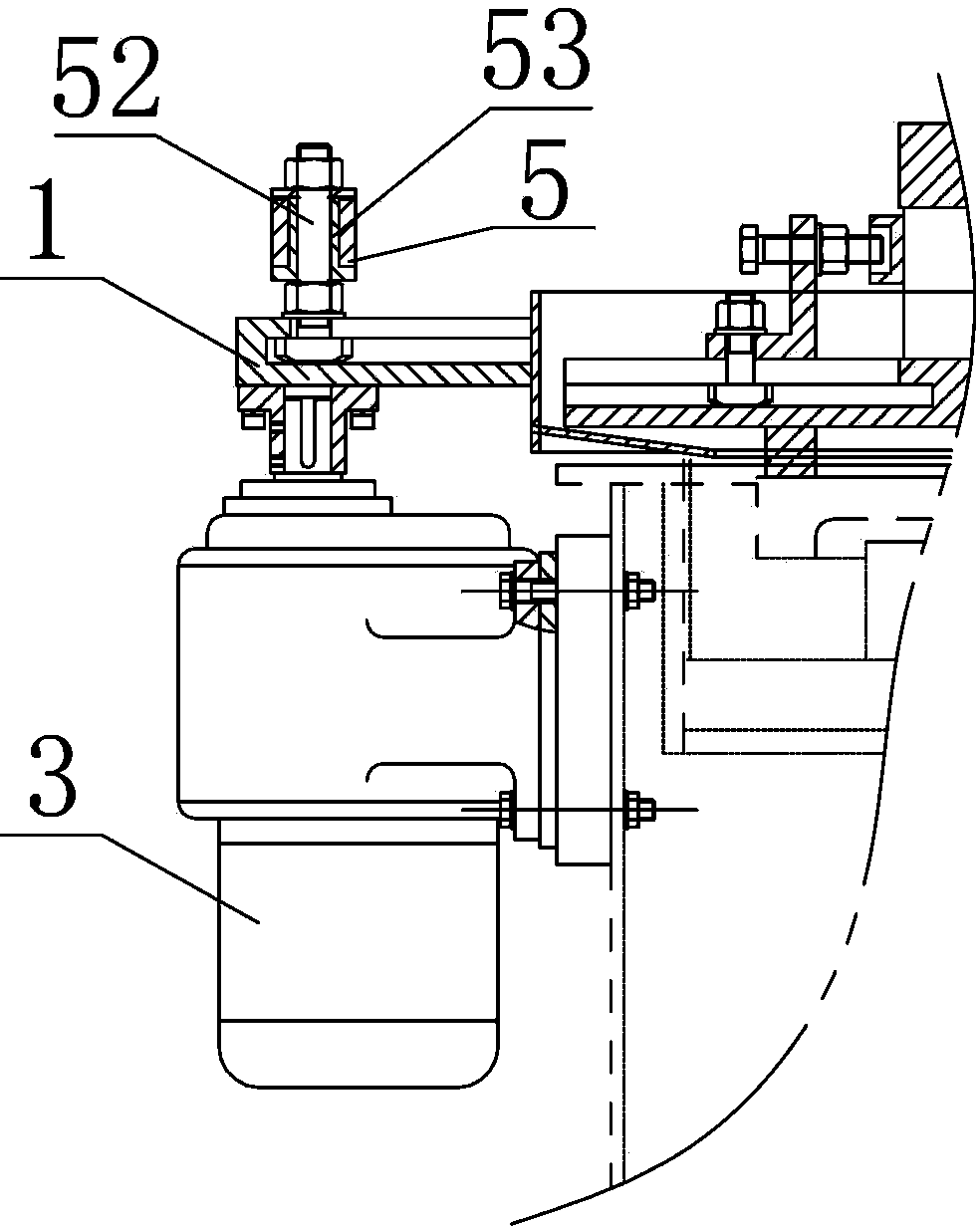

Swing arm continuous polishing machine

ActiveCN103350394APowerfulExpand the scope of processingPolishing machinesGrinding work supportsReciprocating motionResource utilization

The invention discloses a swing arm continuous polishing machine which comprises a machine frame, a location chuck and a first grinding tool. The location chuck is horizontally arranged on the machine frame and used for locating a workpiece to be machined, the first grinding tool is arranged on the machine frame through a swing arm structure, and the first grinding tool is located above the location chuck. The swing arm structure comprises a swing rod, one end of the swing rod is arranged on the machine frame in a hinged mode, the first grinding tool is located on the swing rod through a supporting arm, and the other end of the swing rod is driven by the rotation of an eccentric swing disc to perform the reciprocating motion. The swing arm structure is designed based on the prior art, and when the machine frame is a machine frame of an existing continuous polishing machine, the swing arm structure is arranged on the existing continuous polishing machine to achieve the powerful functions of the swing arm continuous polishing machine. The cost of a manufacturer for buying new equipment can be greatly reduced, the effective utilization on original equipment can be achieved, and the resource utilization rate is improved. The swing arm continuous polishing machine uses a millstone of the continuous polishing machine to serve as a workpiece carrier, the machining scope of the continuous polishing machine is greatly expanded, the machining accuracy is improved, and the market competitiveness of the swing arm continuous polishing machine is improved.

Owner:成都川威机械制造厂

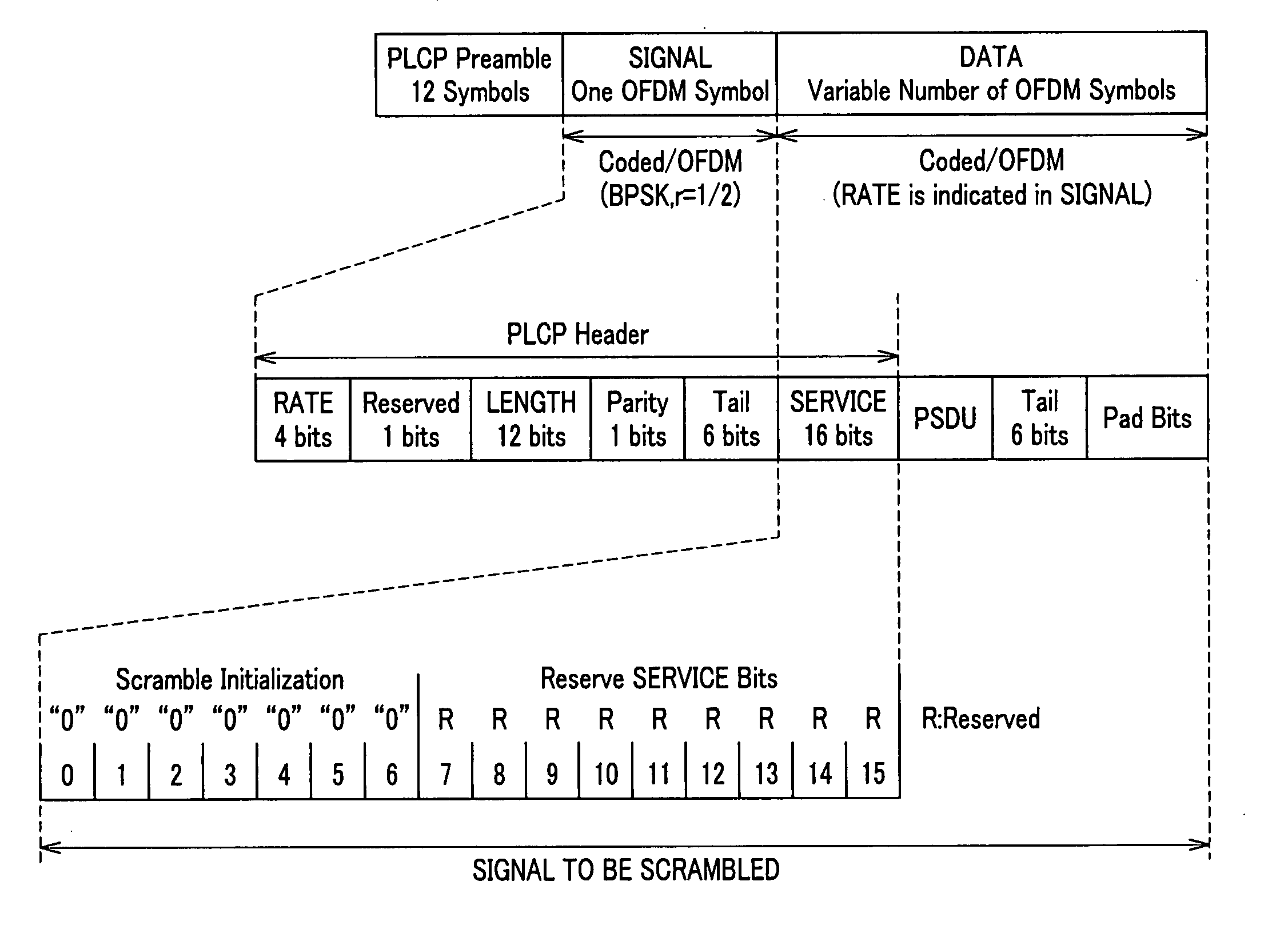

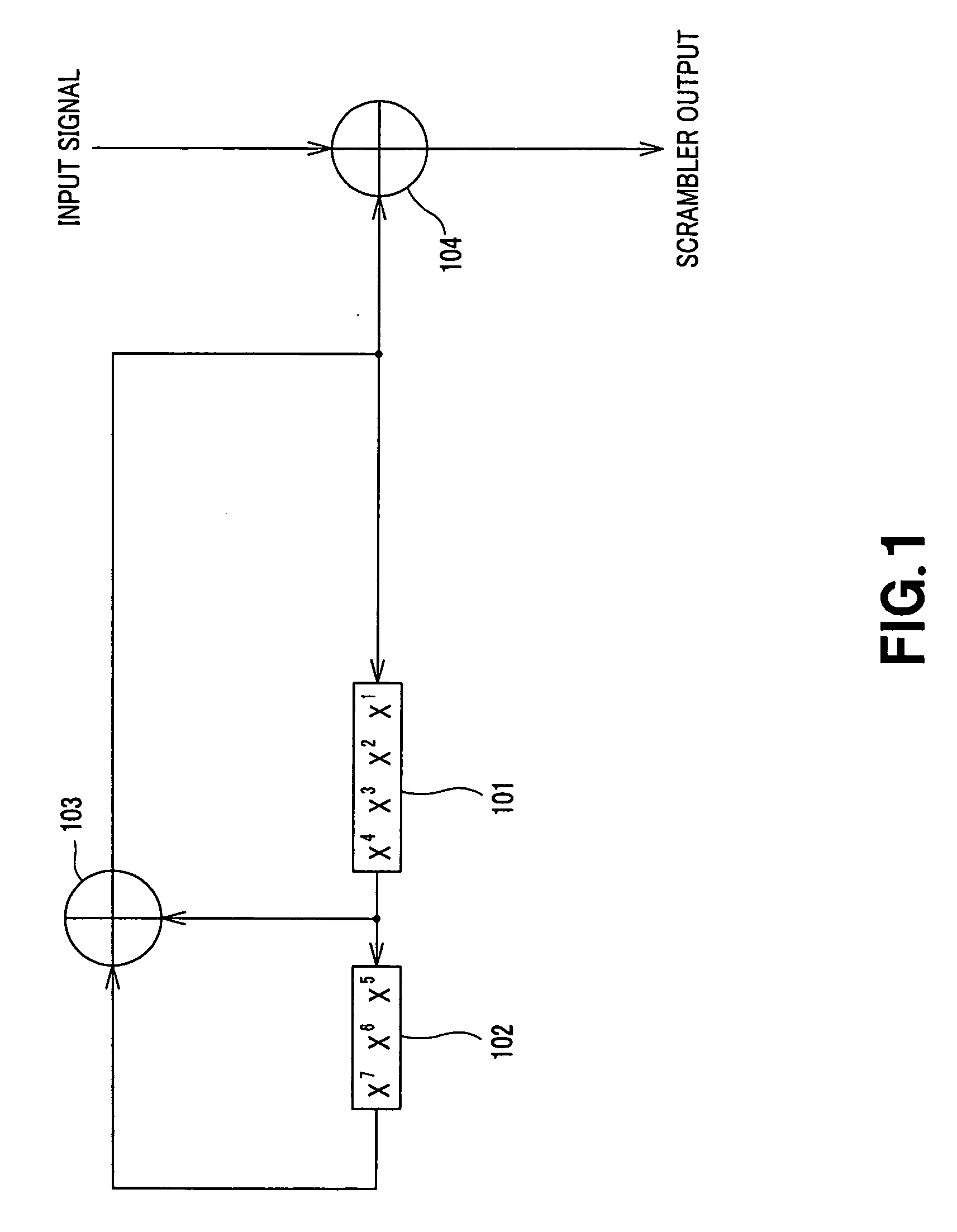

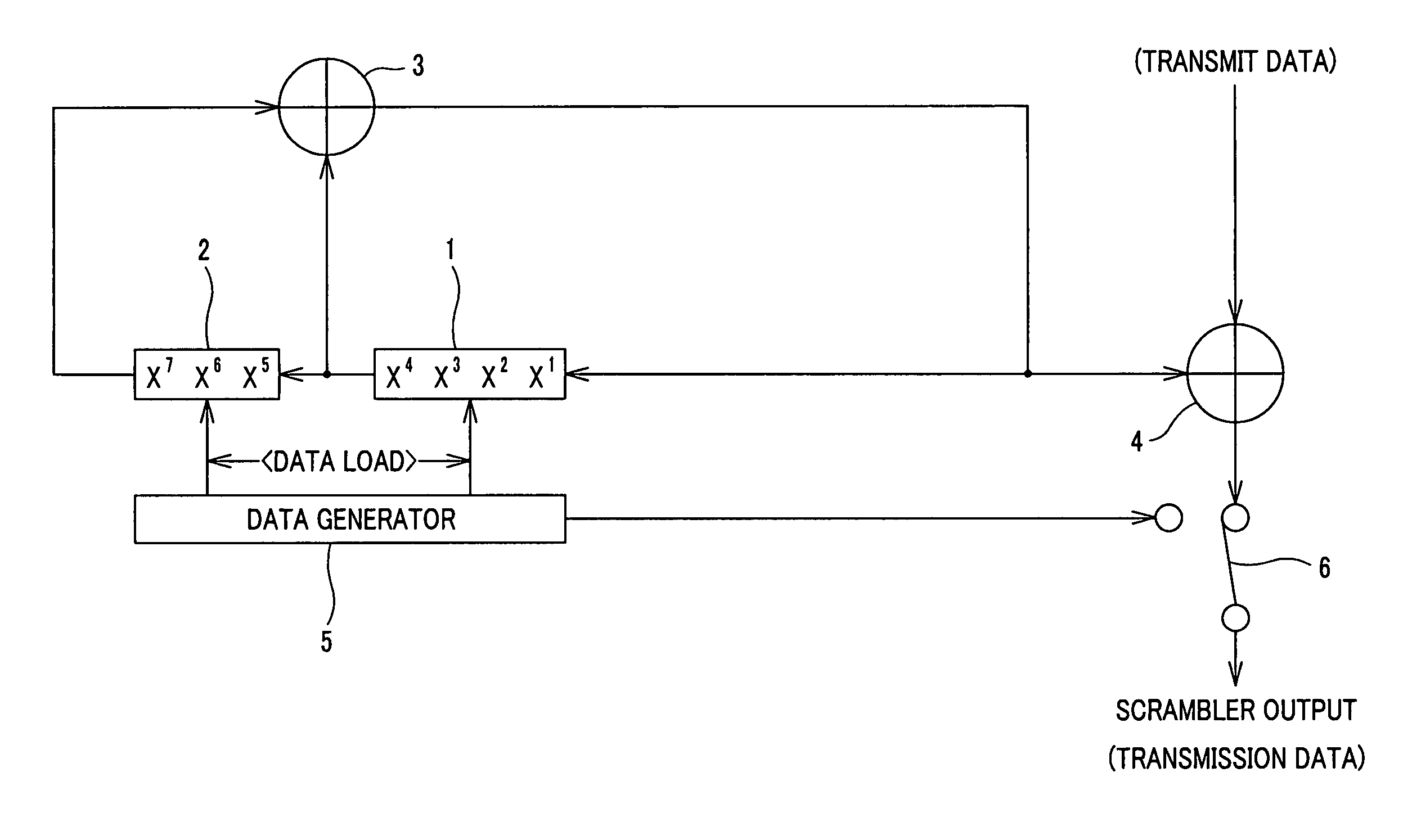

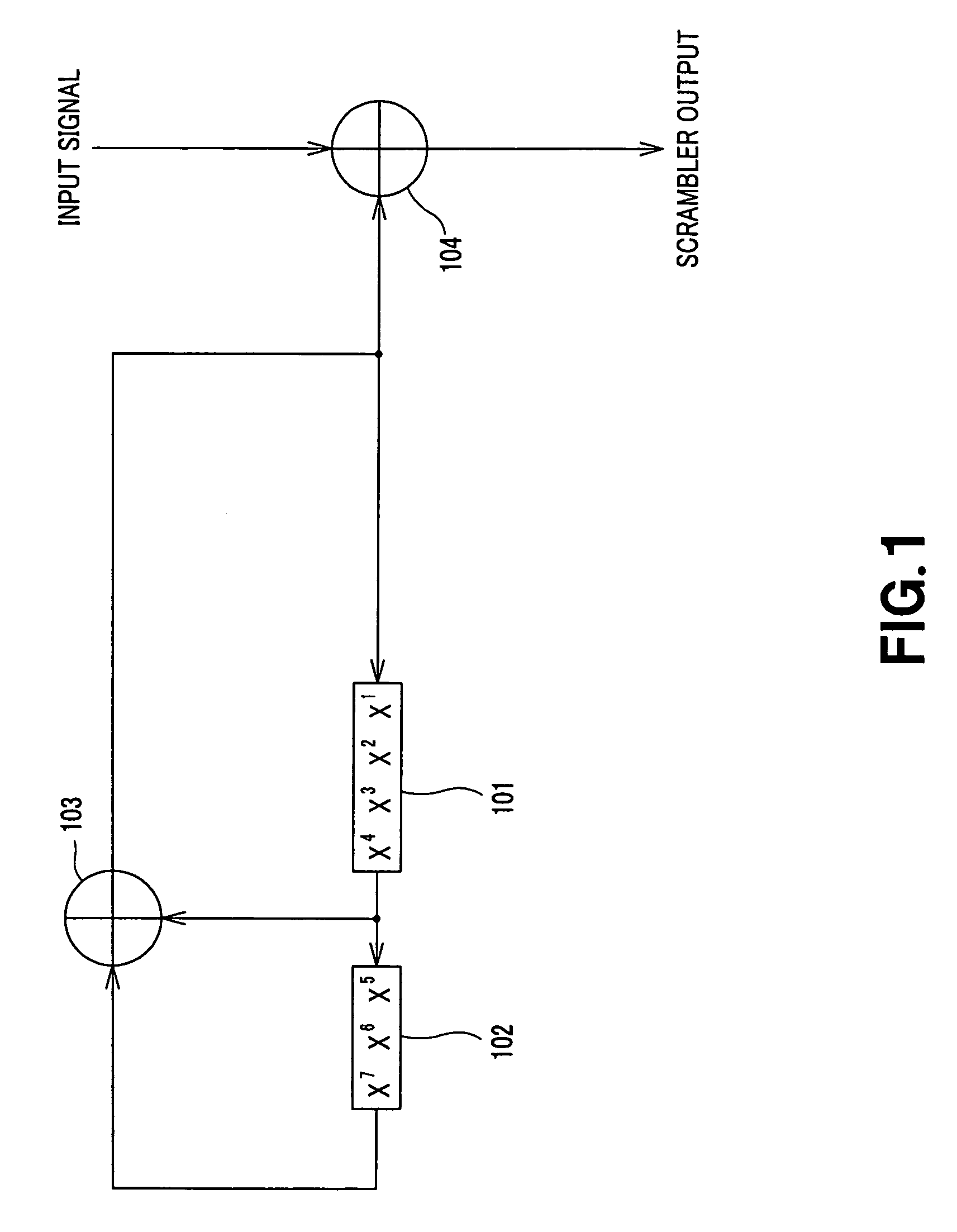

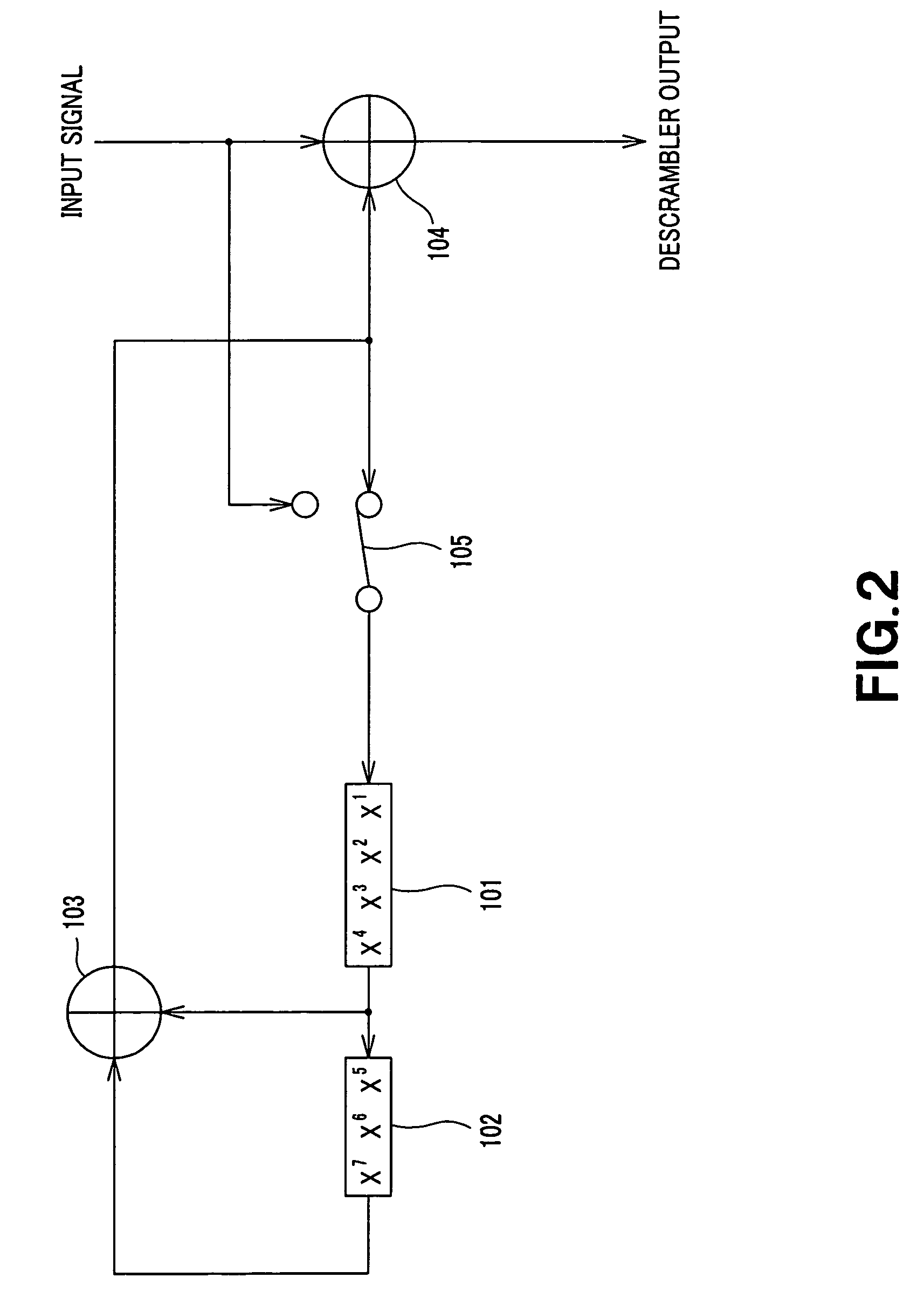

Data processsing deviceand data reception processing device

InactiveUS20060041576A1Solve problemsEfficient comprehensive utilizationData stream serial/continuous modificationDigital data processing detailsComputer hardwareComputer science

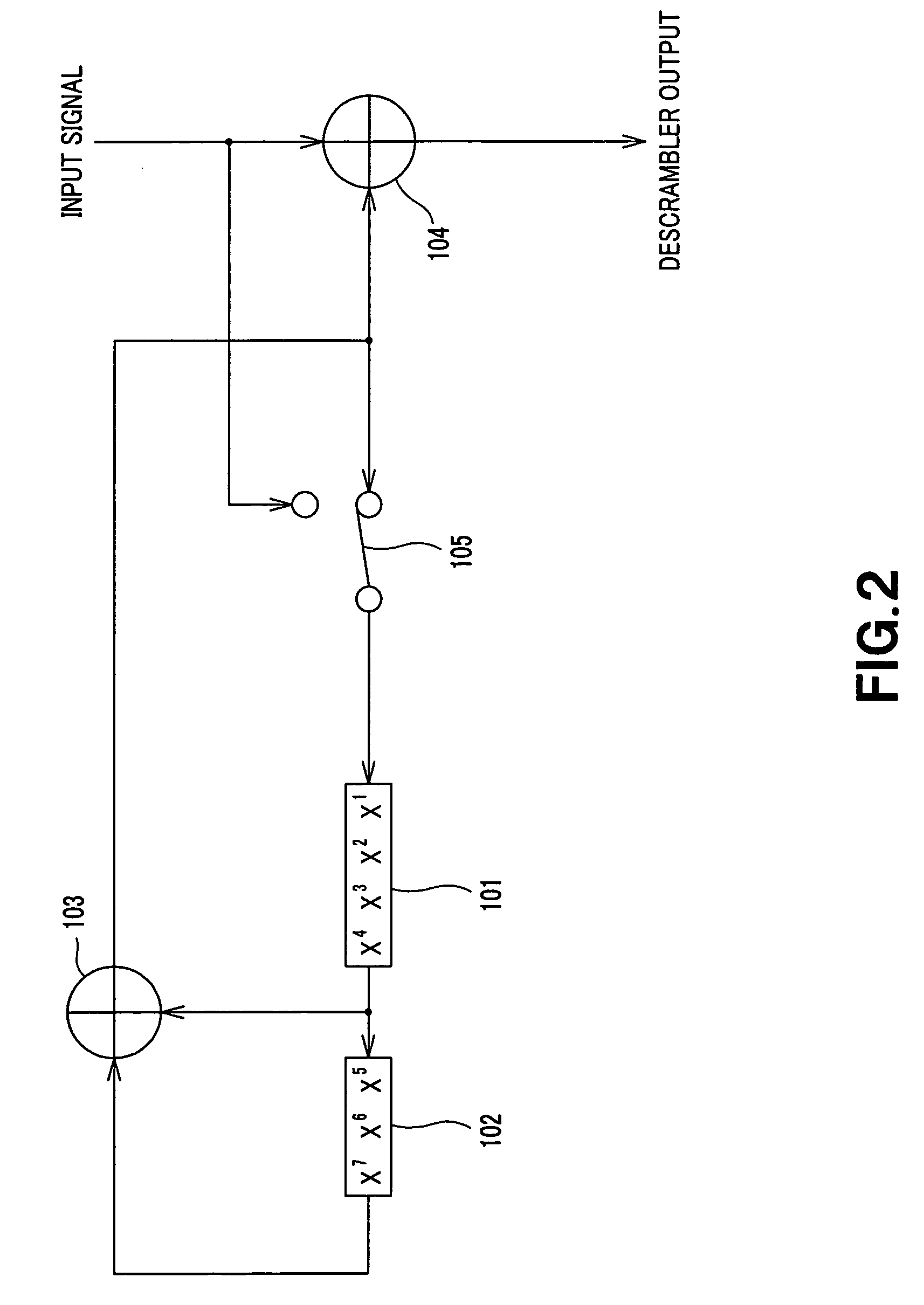

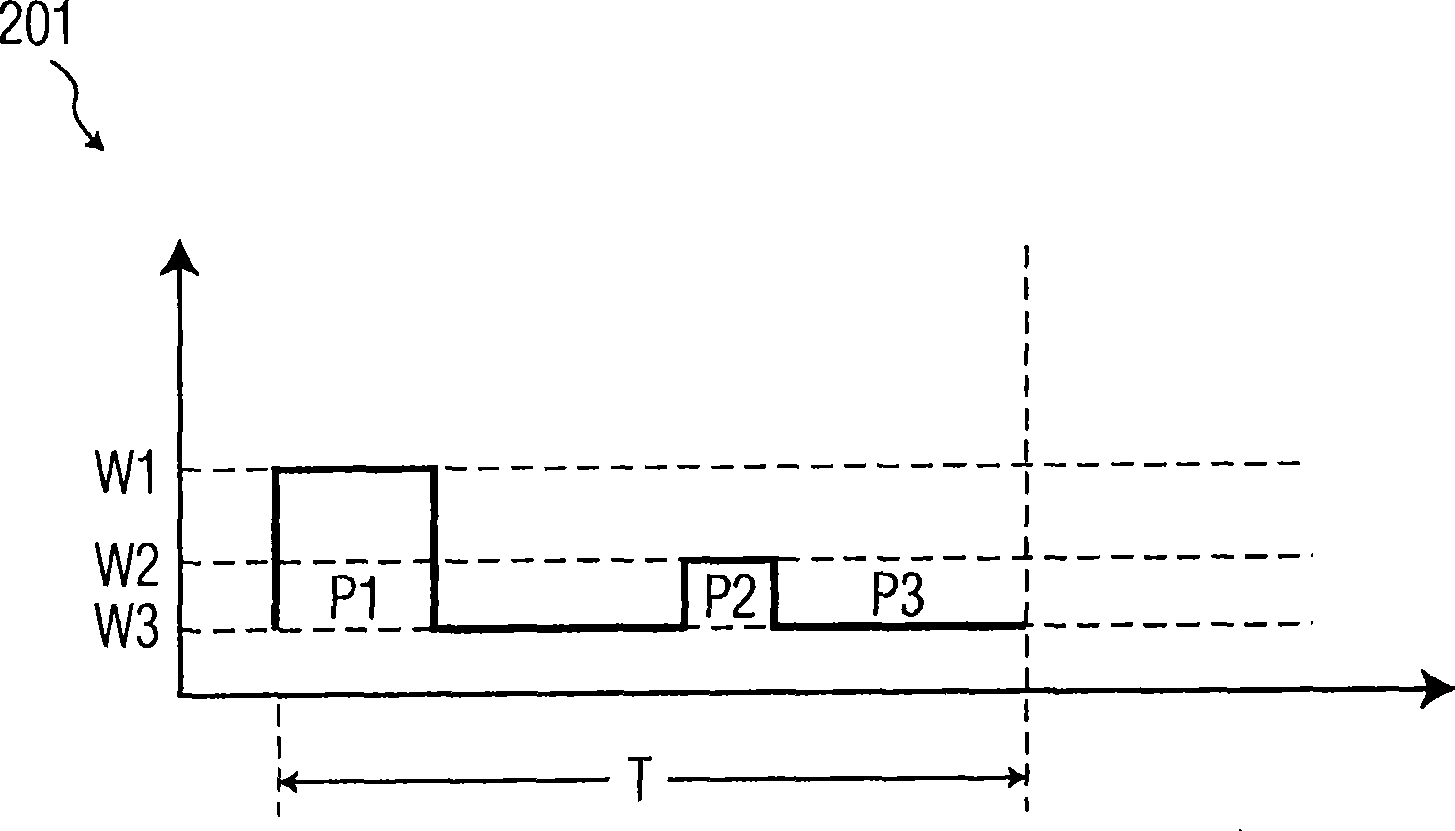

The present invention is directed to a data processing apparatus adapted for performing scramble processing of transmit data, which comprises cyclic code generating means for generating cyclic bit data train of a predetermined period, EXOR operation means for sequentially performing EXOR operation of the cyclic bit data train with respect to the transmit data to output scramble-processed data, data generating means for generating bit data of a predetermined pattern, and switching means supplied with the scramble-processed data and the bit data of the predetermined pattern generated by the data generating means to select the bit data of the predetermined pattern at the time of synchronization processing of the transmit data, and to select the scramble-processed data when synchronization processing of transmit data is not performed to output the data thus selected as scrambler output data.

Owner:SONY CORP

Method and apparatus for dynamic resizing of cache partitions based on the execution phase of tasks

InactiveCN101395586AAvoid reservationAchieve effective useMemory architecture accessing/allocationMemory adressing/allocation/relocationMulti processorWorking set

The present invention proposes a method and a system for dynamic cache partitioning for application tasks in a multiprocessor. An approach for dynamically resizing cache partitions based on the execution phase of the application tasks is provided. The execution phases of the application tasks are identified and updated in a tabular form. Cache partitions are resized during a particular instance of the execution of application tasks such that the necessary and sufficient amount of cache space is allocated to the application tasks at any given point of time. The cache partition size is determined according to the working set requirement of the tasks during its execution, which is monitored dynamically or statically. Cache partitions are resized according to the execution phase of the task dynamically such that unnecessary reservation of the entire cache is avoided and hence an effective utilization of the cache is achieved.

Owner:NXP BV

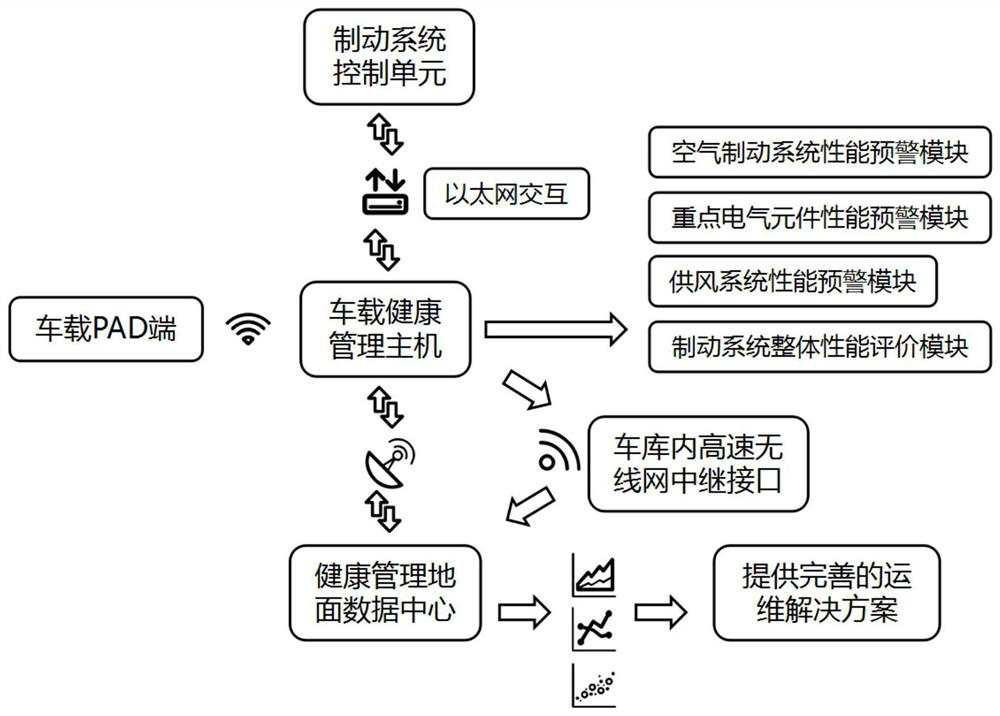

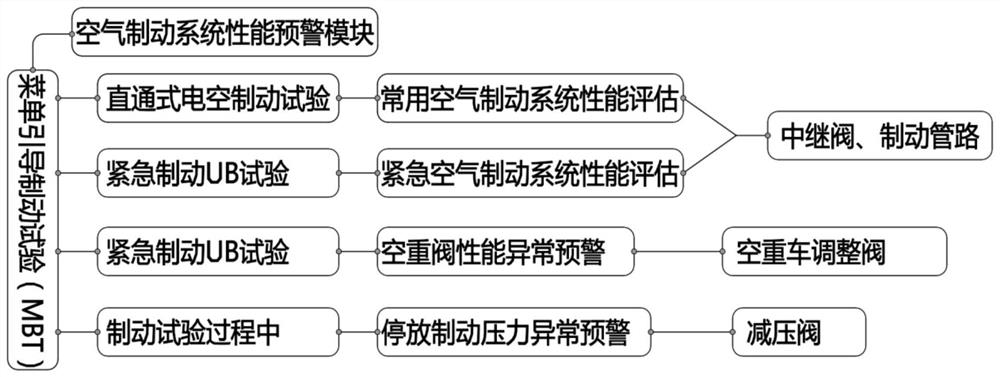

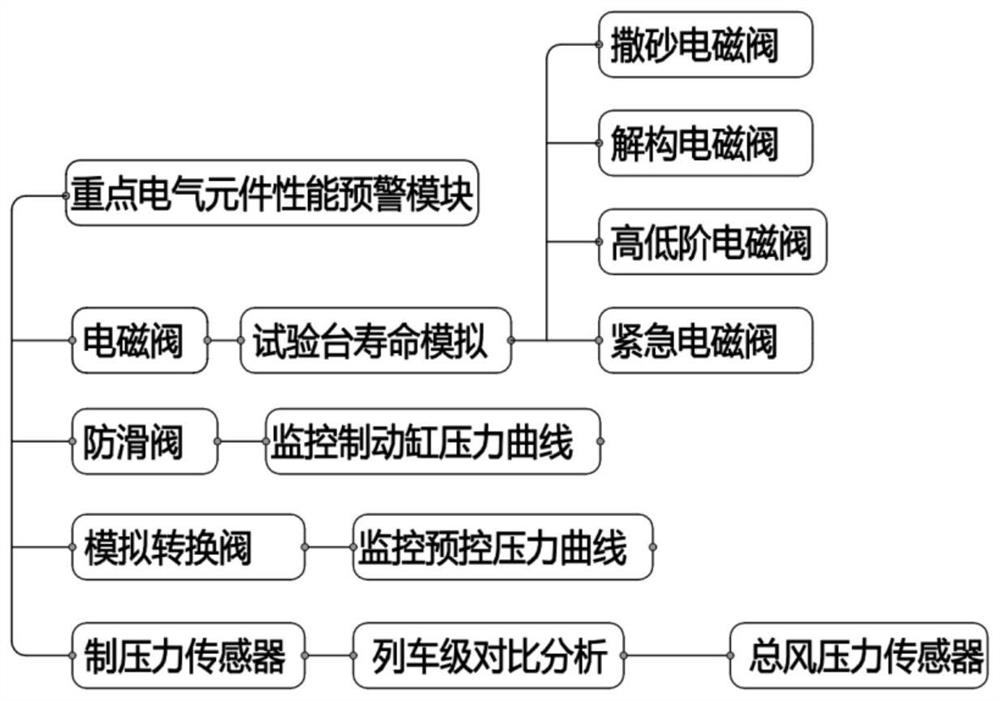

Health management system of braking and air supply system for motor train unit

ActiveCN112141069AAchieve effective useRealize comprehensive utilizationBrake safety systemsOriginal dataThe Internet

The invention provides a health management system of a braking and air supply system for a motor train unit, and relates to the field of braking of a rail transit system. The health management systemaims to solve the problems that a health management system of an air supply system is long in data updating period, original data cannot be stored and accumulated, and therefore, early warning of faults cannot be achieved in advance and preventive maintenance suggestions cannot be provided before the faults occur. A braking system control unit and a train-mounted health management host are in datainteraction through the Ethernet, and the train-mounted health management host forms intelligent driving information according to an early warning result of an early warning module and feeds back theintelligent driving information to a train-mounted PAD end; the train-mounted health management host and a health management ground data center achieve real-time transmission of train in-transit states and fault information through the Internet, and after a train returns to a motor train unit maintenance depot, all original data of the train on the current running day are sent to the health management ground data center through a high-speed wireless network relay interface in the depot and used for data deep analysis and screening. According to the system, manpower, logistics and storage costs are reduced.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

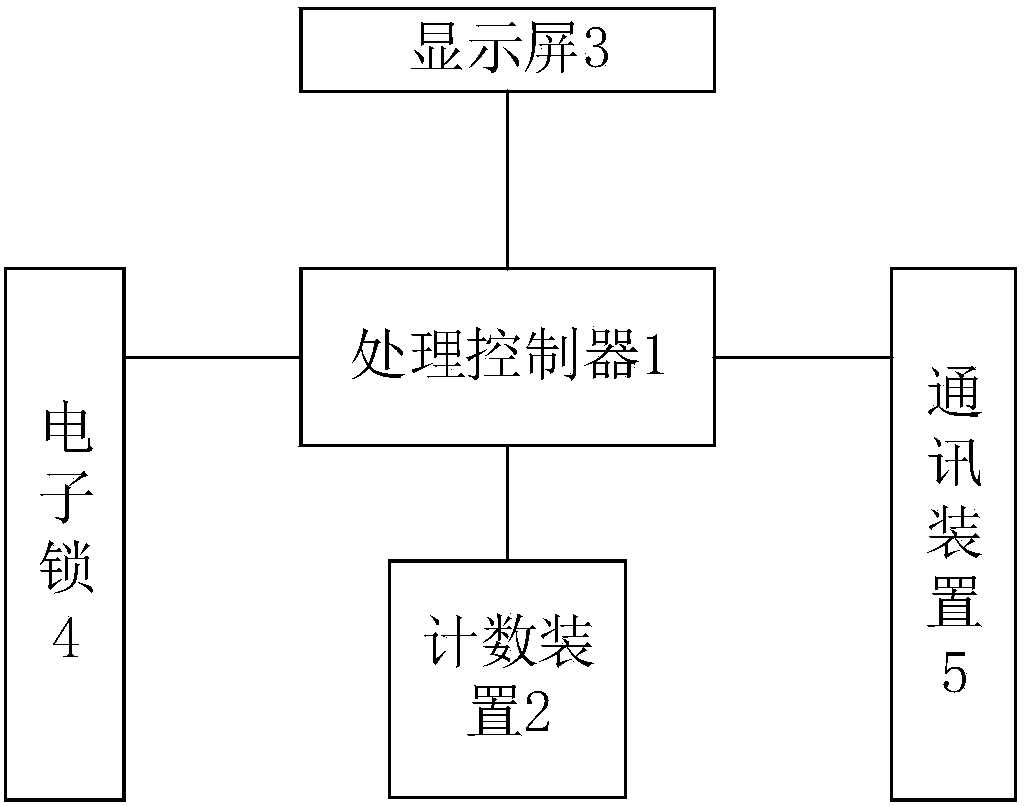

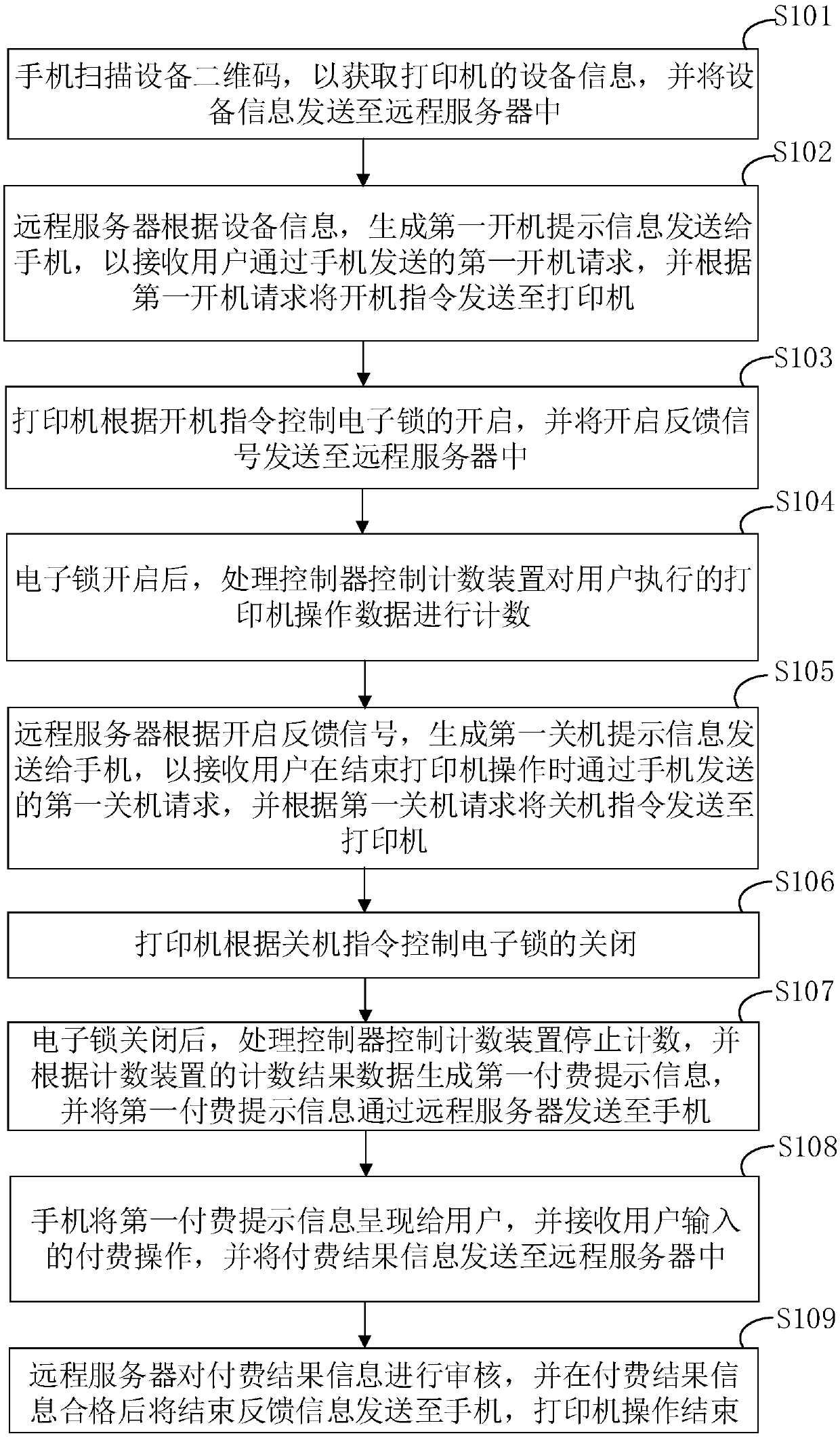

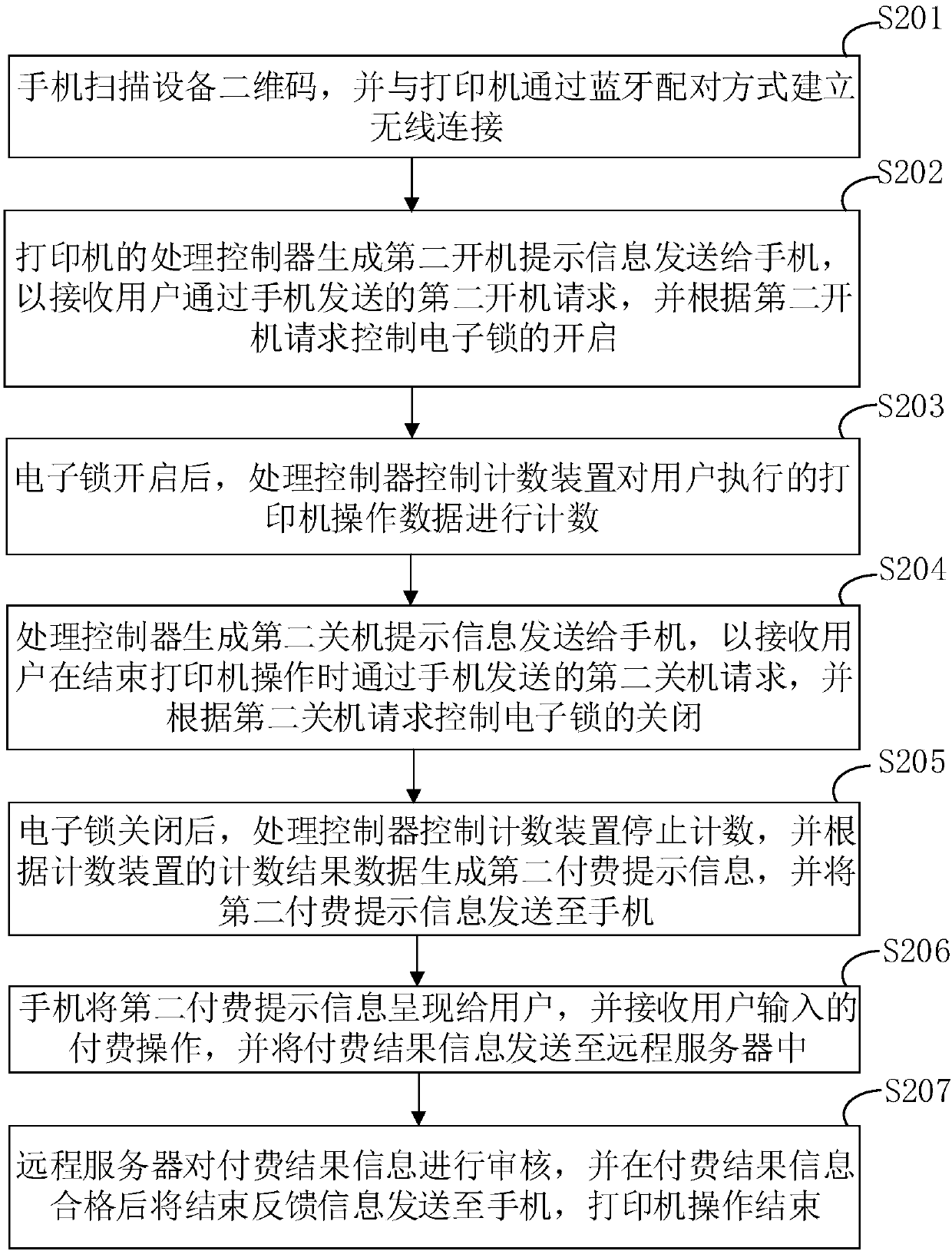

Sharable printer and printer sharing method

InactiveCN107665548ARealize resource sharingAchieve effective useApparatus for meter-controlled dispensingSubstation equipmentEmbedded systemMobile phone

The invention provides a sharable printer and a printer sharing method. The printer comprises a printer body, a processing controller, a counting device, an electronic lock, a communication device anda display screen, wherein the processing controller, the counting device, the electronic lock and the communication device are fixedly arranged in the printer body, the display screen is fixedly arranged on the body, and the processing controller is connected with the counting device, the display screen, the electronic lock and the communication device separately. The communication device is usedfor making the printer body communicate with a remote server and / or a mobile phone; the counting device is used for recording the printing amount, the copy amount and the scanning amount; the electronic lock is used for controlling the printer to be turned on or off; the display screen is used for displaying the unique device two-dimensional code corresponding to the printer body; the processingcontroller is used for processing and storing data. According to the sharable printer and the printer sharing method, when the printer is shared, resource sharing can be achieved, and moreover, it also can be achieved that the printer is effectively utilized.

Owner:邵林

Method for preparing mesophase pitches or mesophase microspheres through coal and oil co-liquified residues

The invention provides a method for preparing mesophase pitches or mesophase microspheres through coal and oil co-liquified residues. The coal and oil co-liquified residues and a first-level extracting solvent are subjected to positive extraction, first-level extract liquor and first-level raffinate are obtained, remaining substances obtained after the first-level extracting liquid solvent is recycled are a mixture of asphaltene and heavy oil, the mixture of the asphaltene and the heavy oil and a second-level extracting solvent are subjected to position extraction, and second-level extract liquor and second-level raffinate are obtained; the second-level raffinate is processed, and asphaltene is obtained; heavy oil is obtained after the second-level extracting liquid solvent is recycled; the asphaltene and the heavy oil are mixed according to a certain proportion and evenly placed in a reactor to be subjected to co-carbonization thermal polycondensation, and thermal polycondensation products containing the mesophase pitches or thermal polycondensation products containing the mesophase microspheres are generated; the thermal polycondensation products containing the mesophase microspheres are washed through quinoline, filtered and dried, and the mesophase microspheres are obtained. The method has the advantages of being simple in technology and low in production cost.

Owner:TAIYUAN UNIV OF TECH +1

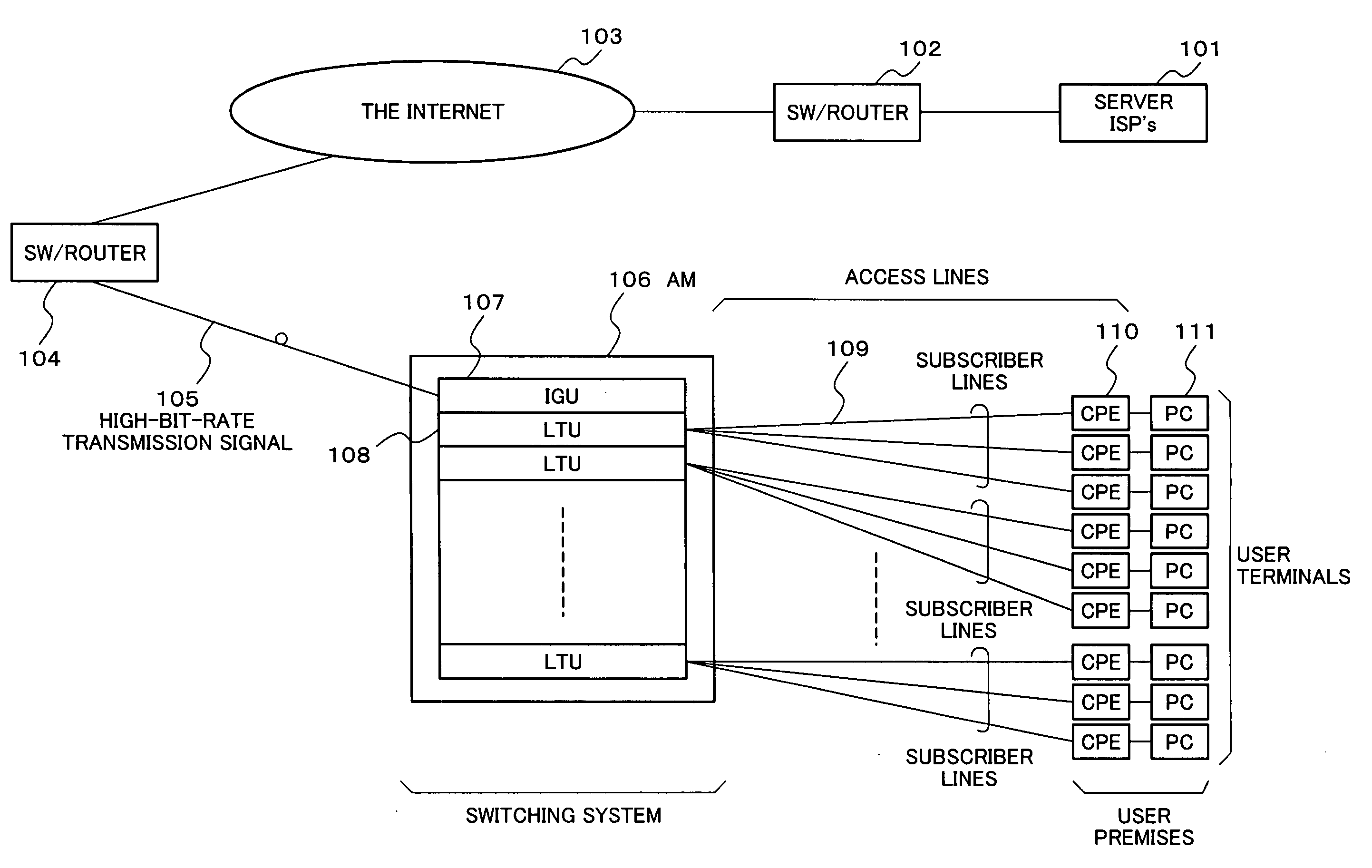

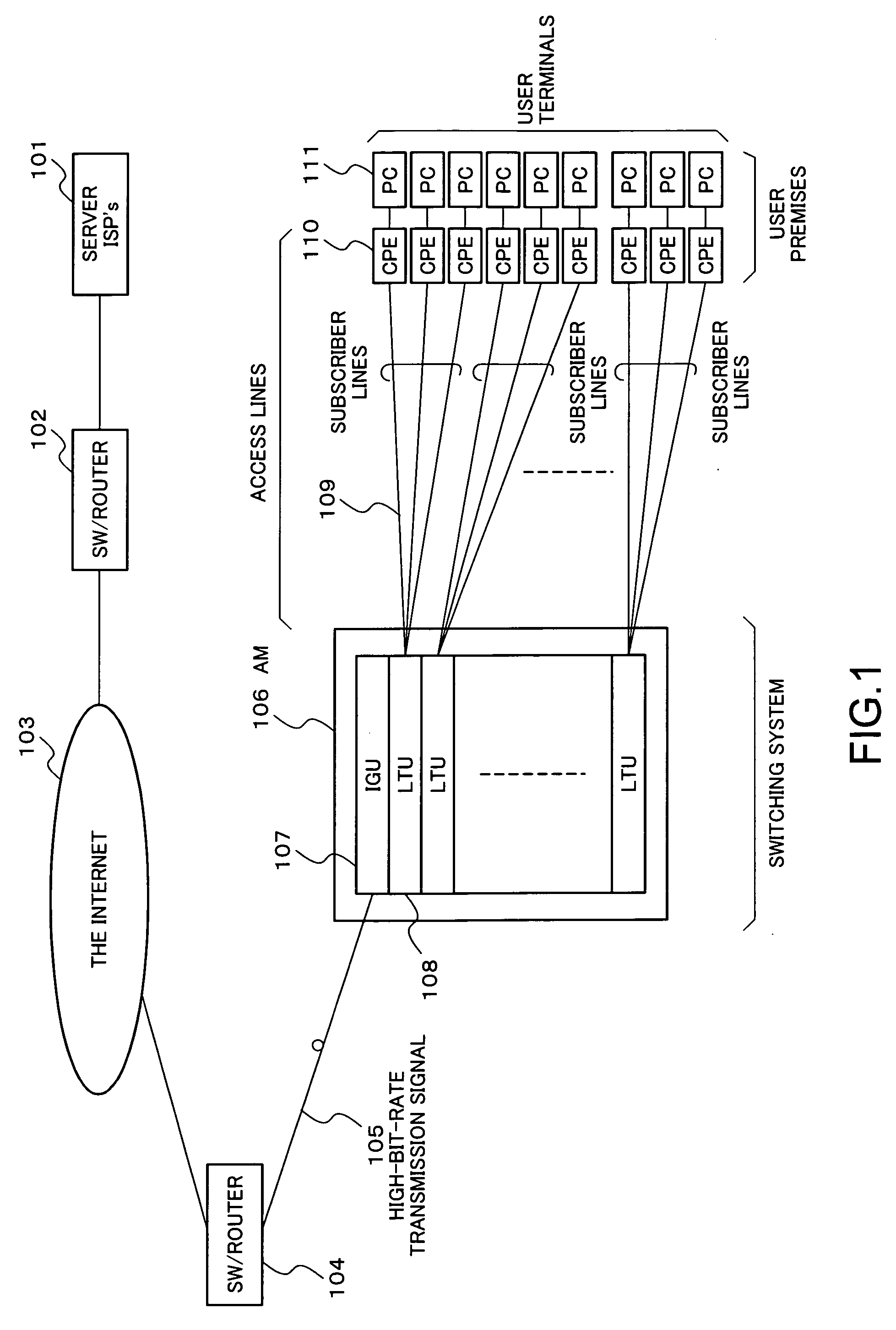

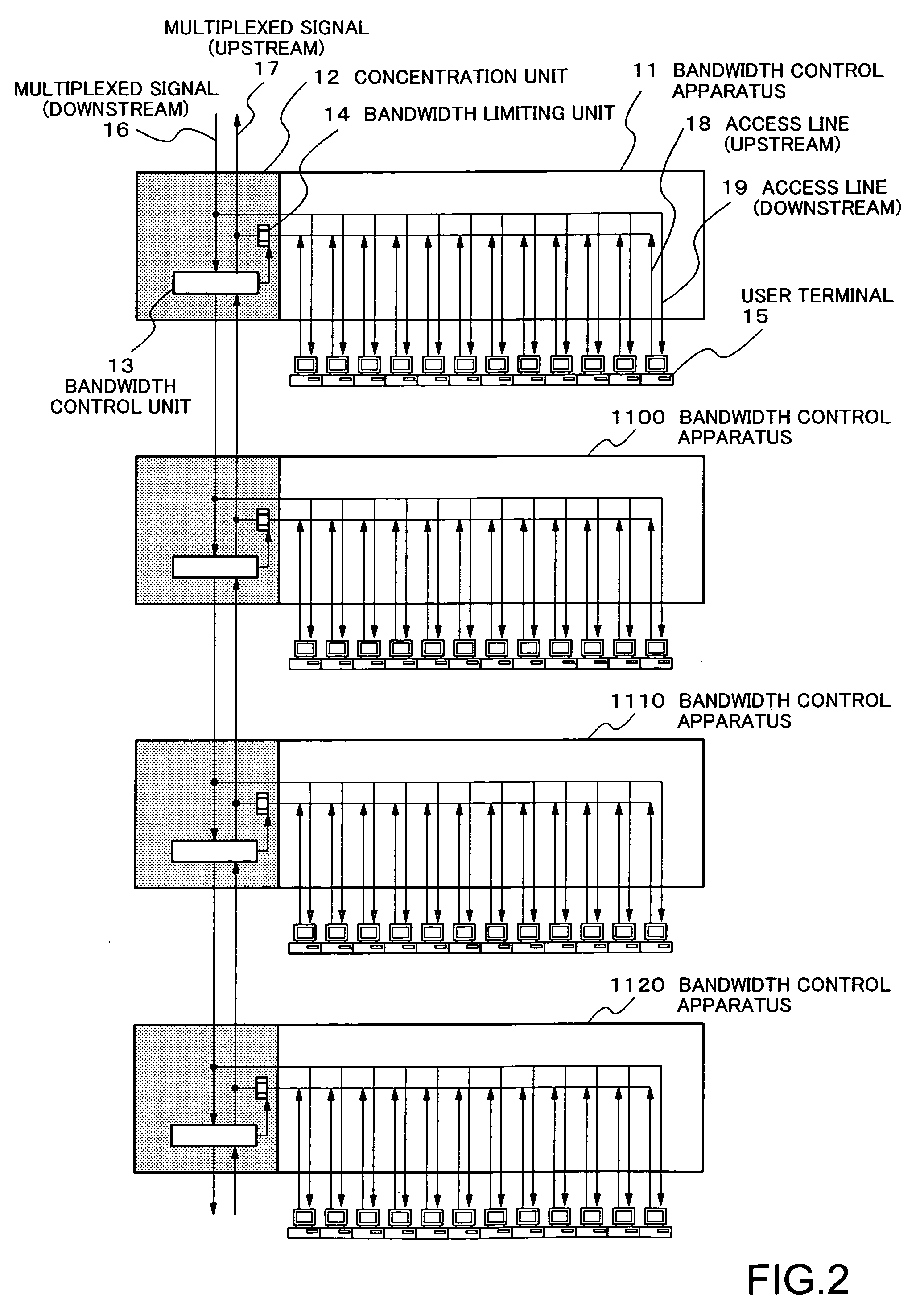

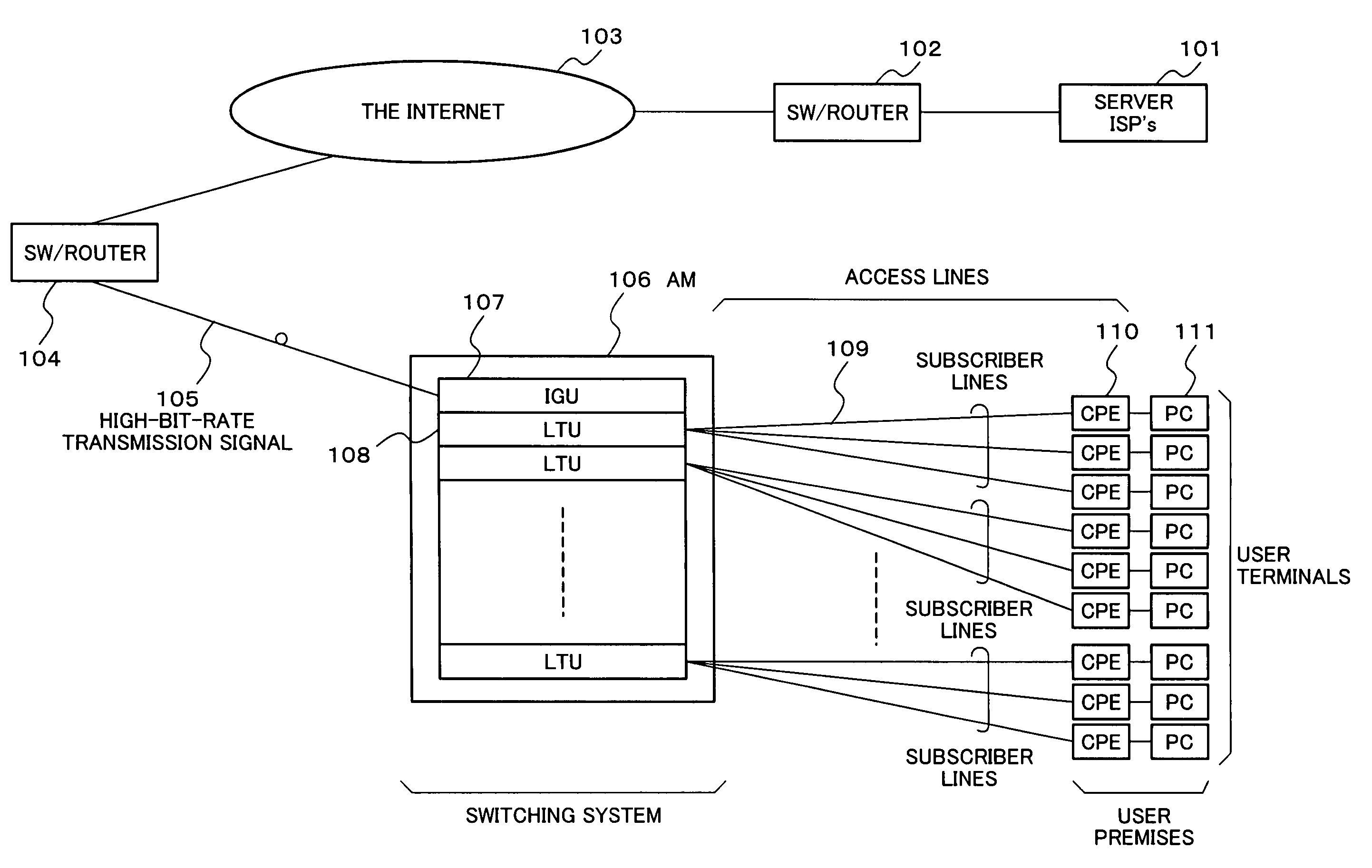

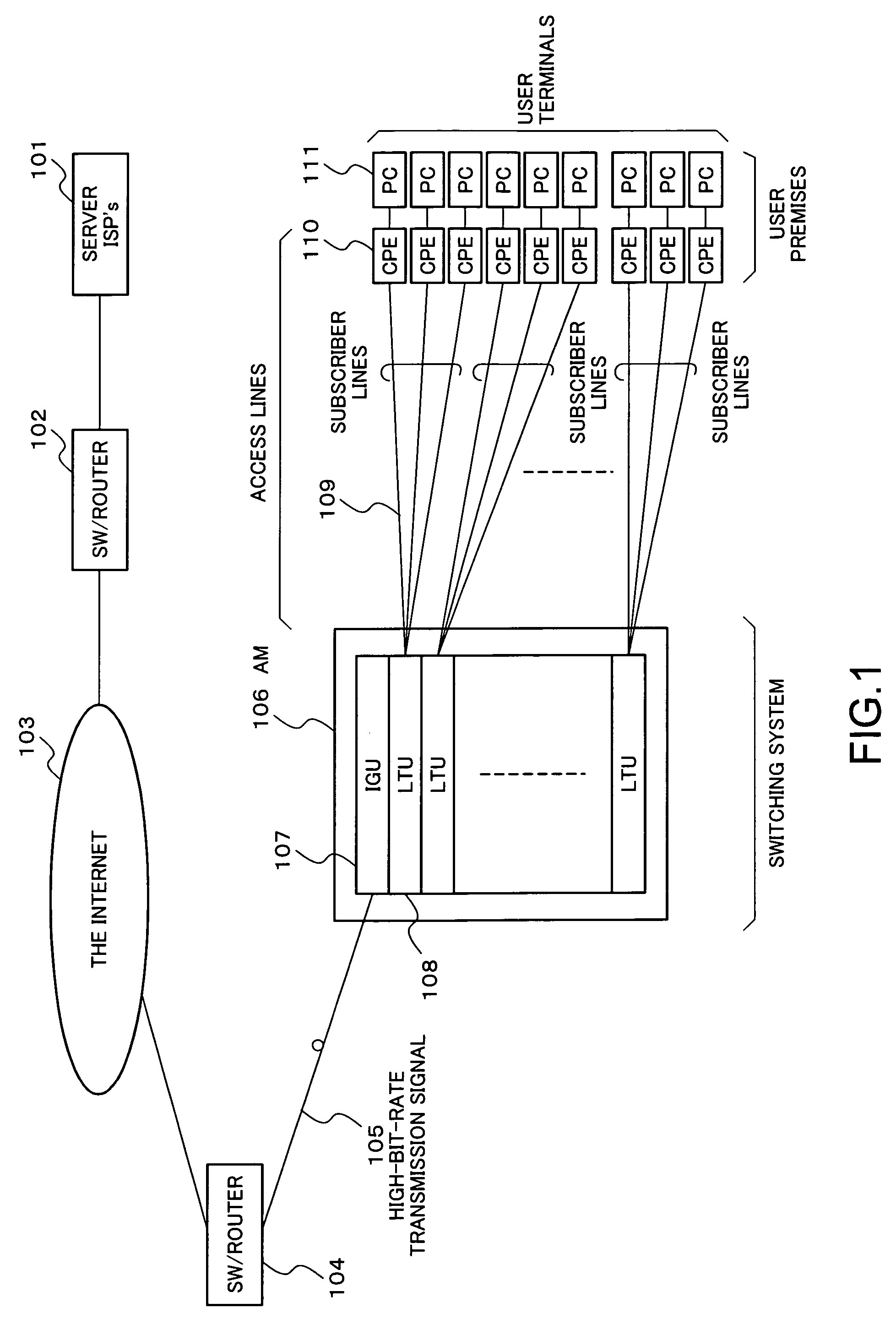

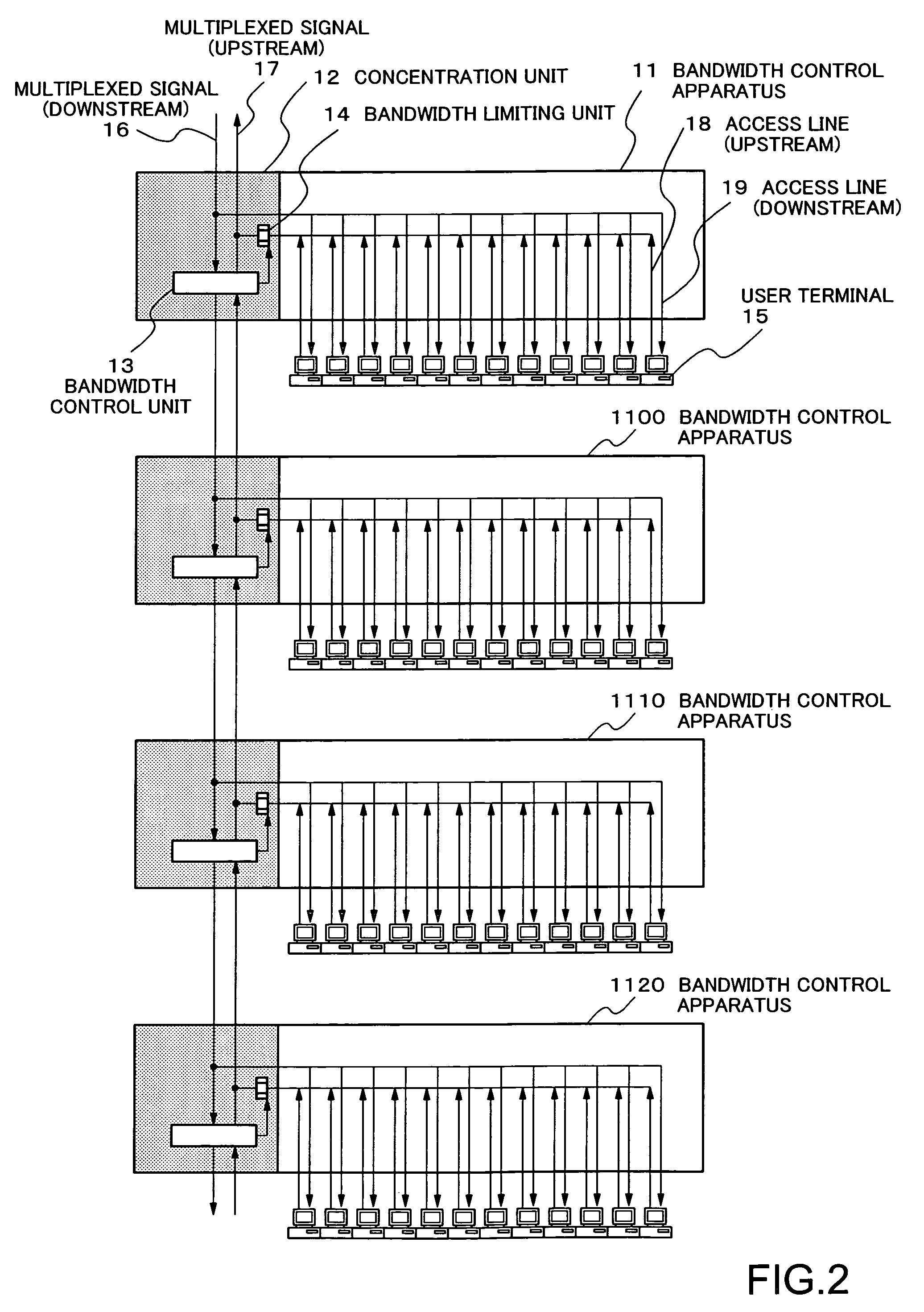

Bandwidth control apparatus, bandwidth control method, bandwidth control system, and bandwidth allocating apparatus

InactiveUS20060280123A1Efficient comprehensive utilizationAchieve effective useMultiplex system selection arrangementsData switching detailsMultiplexingControl system

A bandwidth control apparatus which can reflect current operation states or effective rates of the access lines on bandwidth distribution is realized for effective utilization of bandwidths in a subscriber data transmission system. In a plurality of bandwidth control apparatuses accommodating a plurality of access lines in a bandwidth control system, multiplexed signal lines of respective bandwidth control apparatuses are connected to one another in cascade. Each bandwidth control apparatus acquires a bandwidth state of the access lines in the own apparatus and-notifies the other apparatuses of the bandwidth state of the own apparatus having been acquired. Therefore, the bandwidth control apparatus can allocate a transmission bandwidth to be controlled in the own apparatus using a ratio of the bandwidth state occupied by the own apparatus to a total bandwidth states occupied in the bandwidth control system, and can control transmission bandwidths of the respective access lines accommodated in the own apparatus.

Owner:NEC CORP

Method for extracting proteins from vitamin C fermented mash

The invention discloses a method for extracting proteins from vitamin C fermented mash, which comprises the following steps: ultrafiltering the vitamin C fermented mash via an ultrafiltering membrane, and collecting the intercepted components; adding water into the intercepted components so as to uniformly mix, quickly freezing the intercepted component solution via an ultralow temperature quick-freezing technology, and then crushing the quick-frozen intercepted component solution via a high-pressure homogenizer; adding a compound protease into the crushed suspension, extracting the protein components via enzymolysis, centrifugally separating enzymatically decomposed solution obtained by enzymolysis, and collecting liquid supernatant; adjusting the pH value of the liquid supernatant, and carrying out flocculating settling for the proteins; and drying the precipitate to obtain the albumen powder. According to the invention, the albumen powder is extracted by a vitamin C fermented by-product, a wide variety of amino acid in the extracted proteins is capable of being taken as feed proteins and raw materials for deeply processing the proteins, thereby realizing comprehensively and effectively utilizing the vitamin C fermented by-product, increasing a new channel of the resource of the feeding albumen powder, and saving the resources and protecting the environment.

Owner:SHANDONG TIANLI PHARMA

Bandwidth control apparatus, bandwidth control method, bandwidth control system, and bandwidth allocating apparatus

InactiveUS7778251B2Efficient comprehensive utilizationAchieve effective useMultiplex system selection arrangementsData switching detailsMultiplexingControl system

A bandwidth control apparatus which can reflect current operation states or effective rates of the access lines on bandwidth distribution is realized for effective utilization of bandwidths in a subscriber data transmission system. In a plurality of bandwidth control apparatuses accommodating a plurality of access lines in a bandwidth control system, multiplexed signal lines of respective bandwidth control apparatuses are connected to one another in cascade. Each bandwidth control apparatus acquires a bandwidth state of the access lines in the own apparatus and notifies the other apparatuses of the bandwidth state of the own apparatus having been acquired. Therefore, the bandwidth control apparatus can allocate a transmission bandwidth to be controlled in the own apparatus using a ratio of the bandwidth state occupied by the own apparatus to a total bandwidth states occupied in the bandwidth control system, and can control transmission bandwidths of the respective access lines accommodated in the own apparatus.

Owner:NEC CORP

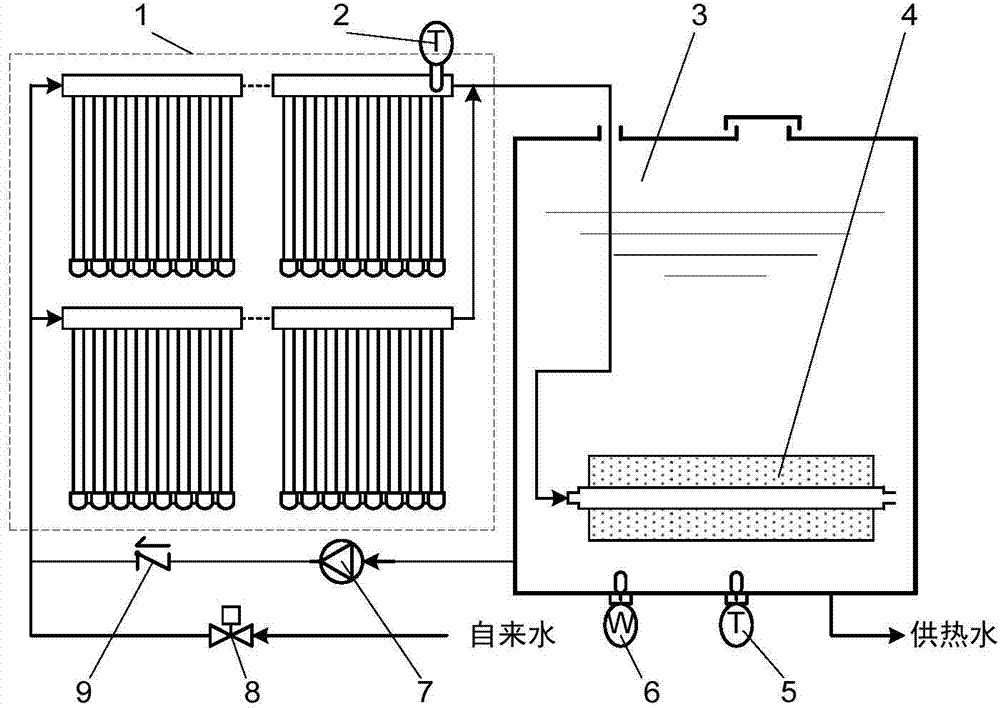

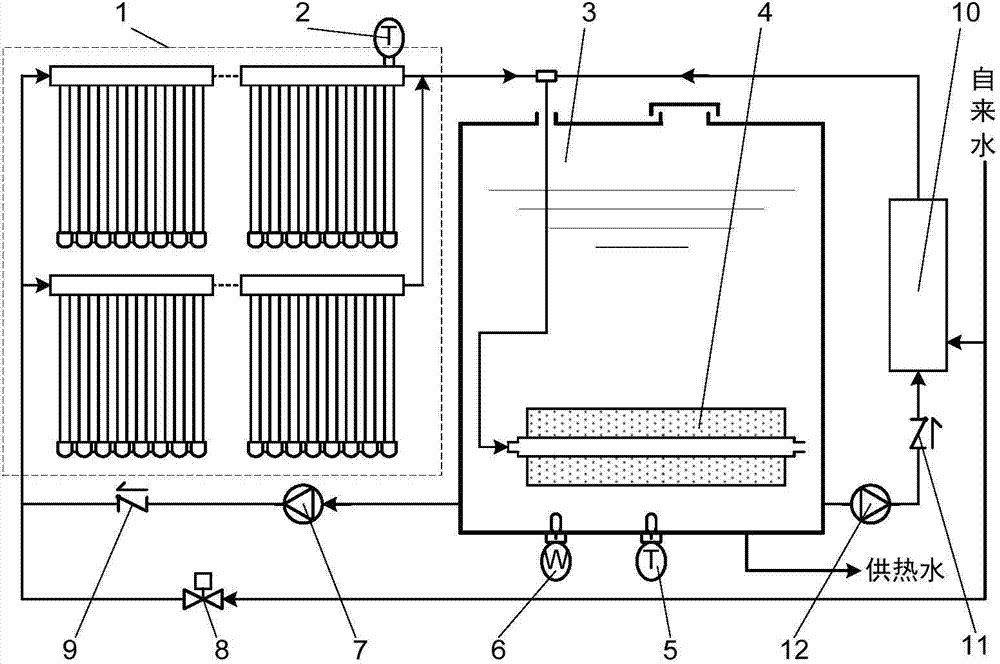

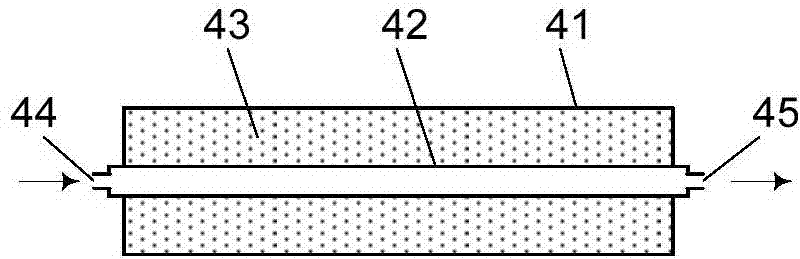

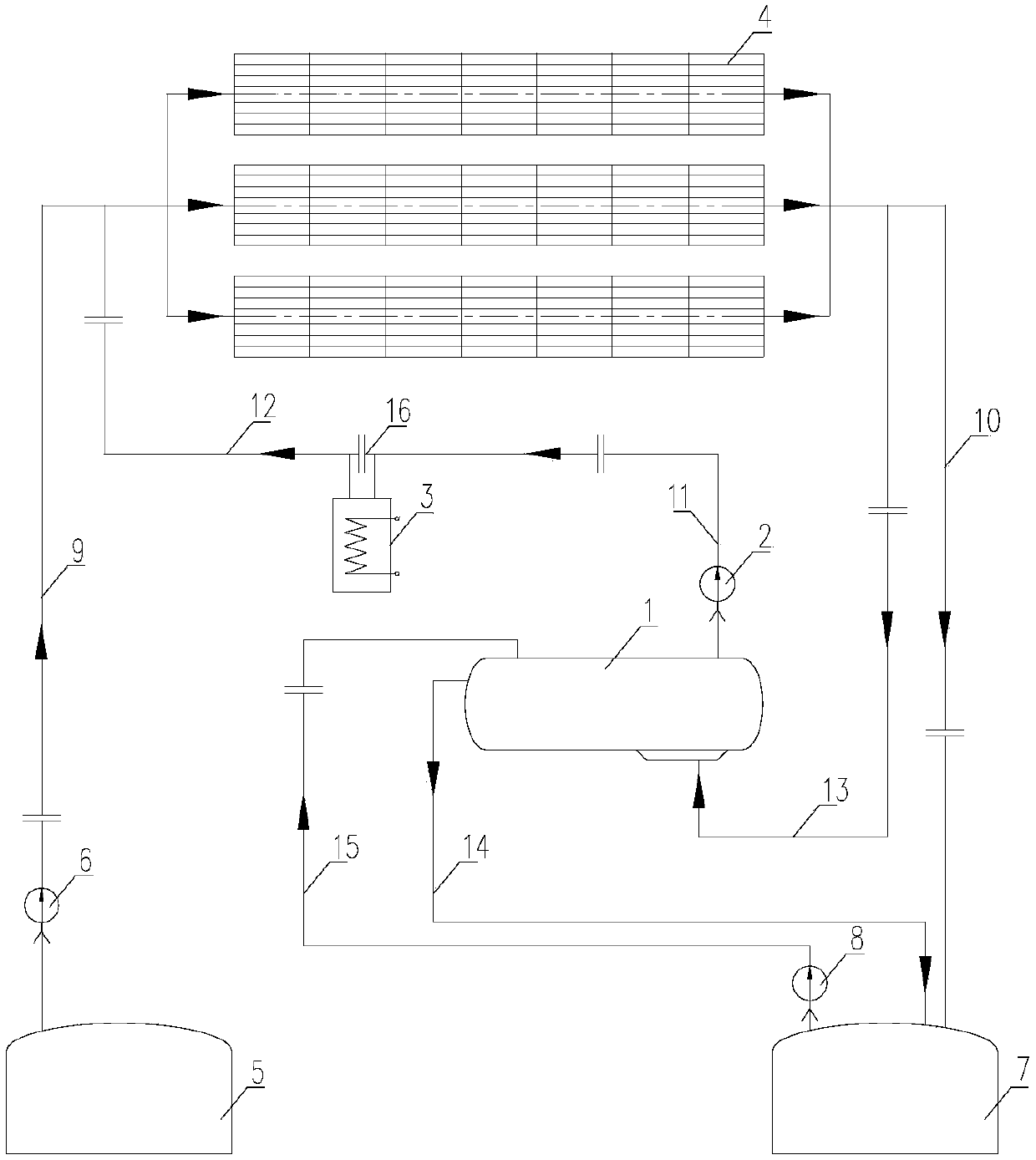

Solar central water heating system with heat accumulation function

ActiveCN103697607AReduce energy consumptionAchieve effective useSolar heat devicesSolar thermal energy generationSolar thermal collectorPhase change temperature

The invention discloses a solar central water heating system with a heat accumulation function, which comprises a solar thermal collector array, a water tank, a collector circulating pump, a check valve, an electromagnetic valve and other parts. A heat accumulator filled with phase-change heat accumulation medium is arranged on the bottom in the water tank, and the interior of a heat accumulator core tube is a water passage. A heat accumulator water passage inlet is connected with the outlet of the solar thermal collector array, a heat accumulator outlet is directly open in the hot water storage tank, and the inlet of the solar thermal collector array is connected with the bottom of the hot water storage tank sequentially through the check valve and the collector circulating pump and connected with a tap water supply pipeline through the water-lifting electromagnetic valve. Both hot water heated by the solar thermal collectors and cold water replenished into the water tank first flow through the heat accumulator core tube and exchange heat with the heat accumulator. When the water temperature in the water tank is higher or lower than the phase change temperature of the heat accumulation medium in the heat accumulator, heat is released to the heat accumulator or heat is absorbed from the heat accumulator. By means of the heat absorption and release of the heat accumulator, energy consumption can be reduced, and solar radiation energy can be effectively utilized by the way of peak load shifting.

Owner:RES INST OF XIAN JIAOTONG UNIV & SUZHOU

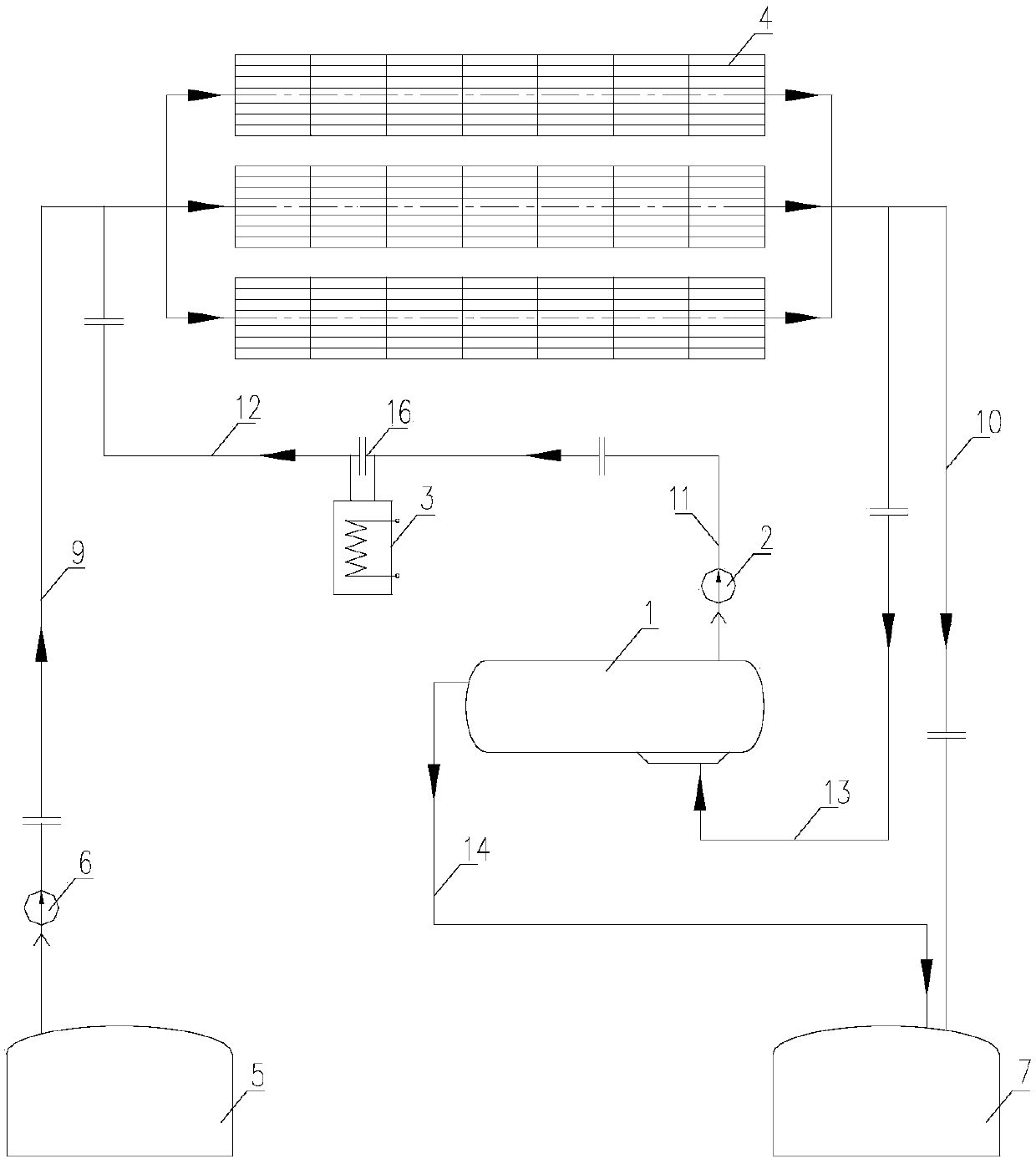

Fused salt linear Fresnel heat collecting field anti-condensing system and method thereof

InactiveCN110068155AAchieve effective useLow energy consumptionSolar heating energySolar heat storageProcess engineeringStart up

The invention discloses a fused salt linear Fresnel heat collecting field anti-condensing system. The fused salt linear Fresnel heat collecting field anti-condensing system comprises a fused salt expanding tank which is arranged at a high position, a linear Fresnel heat collecting field, a low-temperature fused salt tank, a high-temperature fused salt tank and a fused salt heating unit, wherein afused salt outlet of the fused salt expanding tank communicates with a fused salt inlet of the fused salt heating unit through an outlet pipeline of the expanding tank; and a fused salt outlet of thefused salt heating unit communicates with a fused salt inlet of the linear Fresnel heat collecting field through an outlet pipeline of a heater. The fused salt linear Fresnel heat collecting field anti-condensing system has the advantages that the source of the heat collecting field anti-condensing device is flexibly selected according to break-down length of the heat collecting field, start-up preheating time of a light-focusing heat collecting sub system, an energy storage sub system and a steam generating sub system is shortened, and system start-up flexibility is improved; and meanwhile, manufacturing difficulty of electrifying heat-tracing related equipment is further avoided, and safety reliability of the system is ensured.

Owner:内蒙古电力勘测设计院有限责任公司

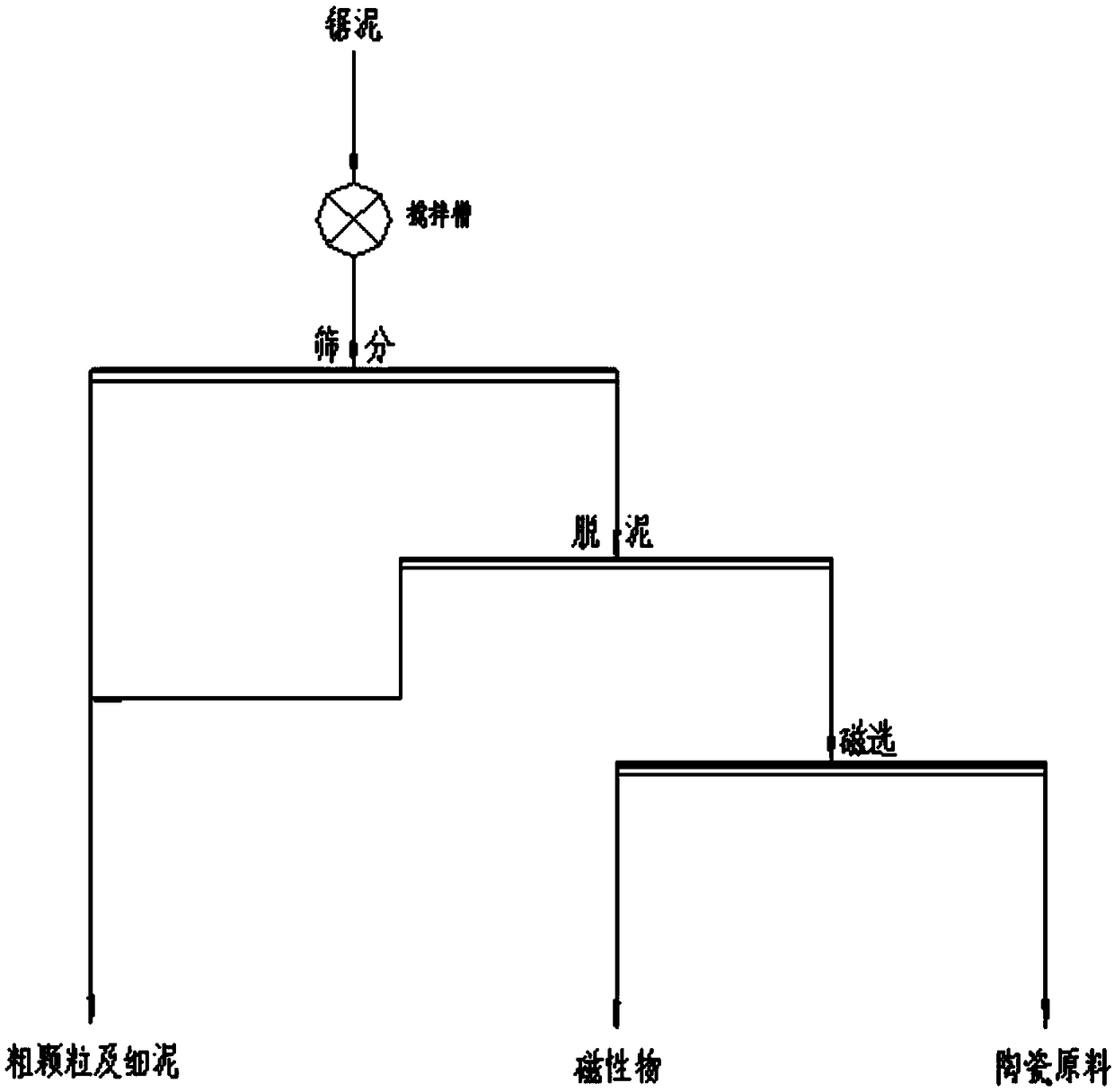

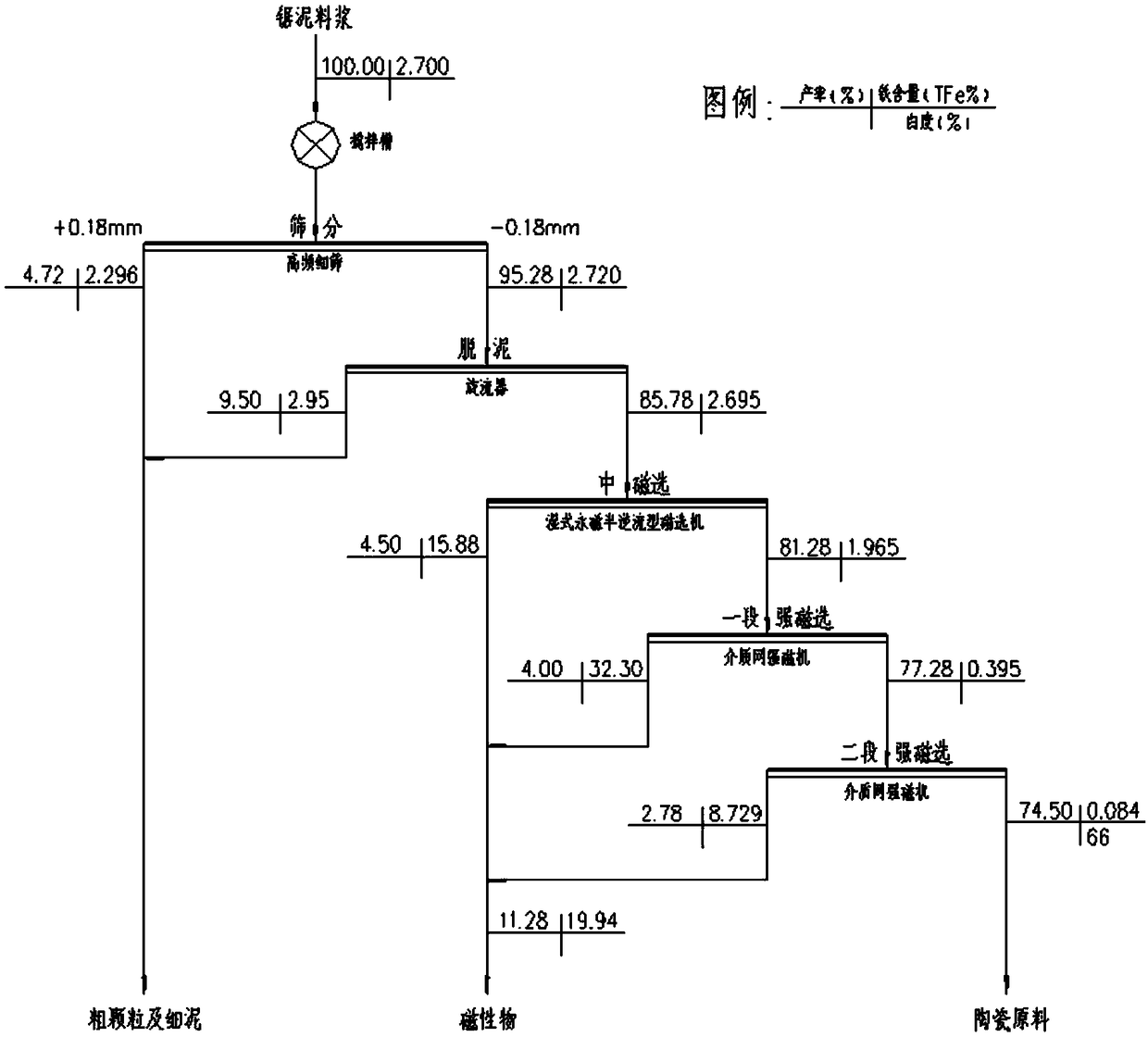

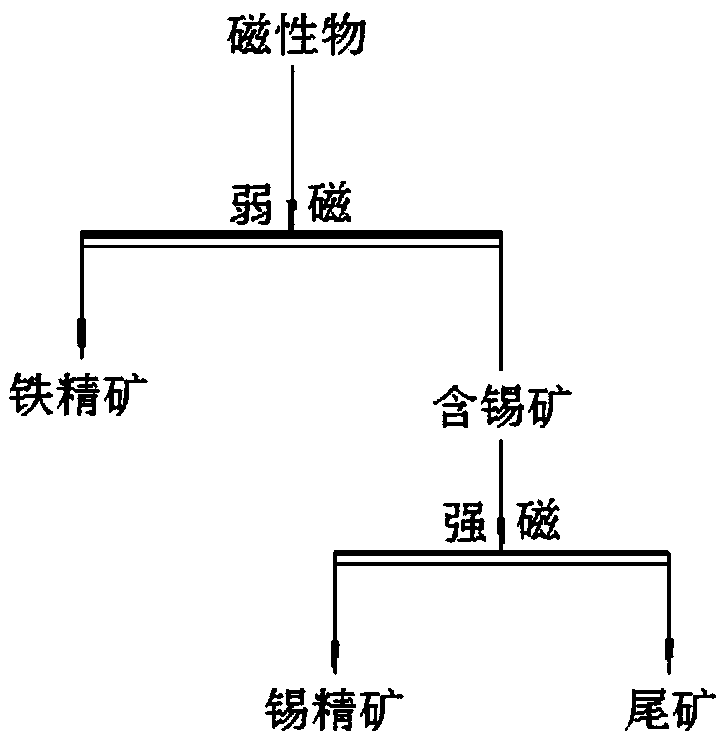

Method of using tin-and-iron-containing stone sawing mud with high efficient

ActiveCN109453892AHigh yieldHigh whitenessSolid separationMechanical material recoverySlurryCoarse particle

The invention discloses a method of using tin-and-iron-containing stone sawing mud with high efficient. The method comprises the following steps that 1 ) screening is carried out, stone sawing mud powder slurry is uniformly stirred and then screening is carried out, and screened coarse particles and screened fine particles are obtained; desliming is carried out, the obtained screened fine particles in the step 1 ) are subjected to the desliming treatment so as to obtain coarse particles and fine mud after the desliming; and 3 ) magnetic separation is carried out, the deslimed coarse particlesobtained in the step 2 ) are subjected to the magnetic separation, and magnetic materials and ceramic raw materials are obtained. According to the method, the stone sawing mud is processed through processes such as the screening, the desliming, the magnetic separation and the like, a high-whiteness ceramic raw material is recycled, the valuable metal tin and iron in the high-whiteness ceramic rawmaterial can further be recycled, so that effective utilization of waste resources and comprehensive recovery of metal resources are realized, waste of the resources is reduced, emission is reduced, and the environment is protected.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

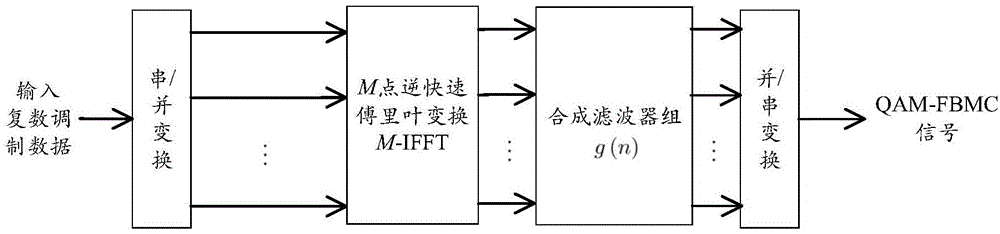

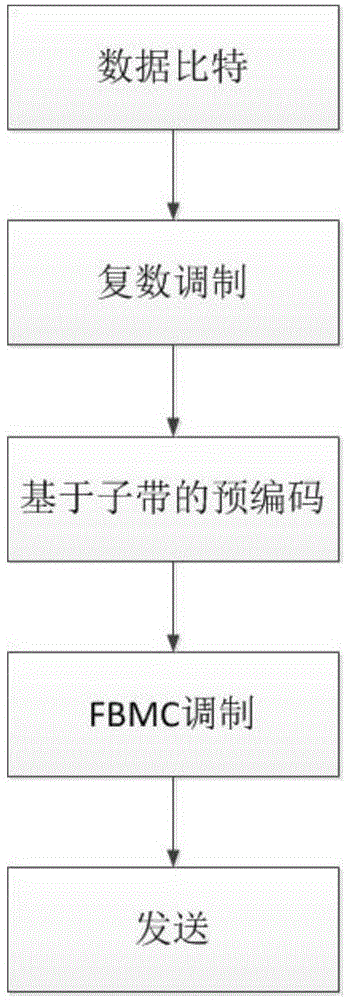

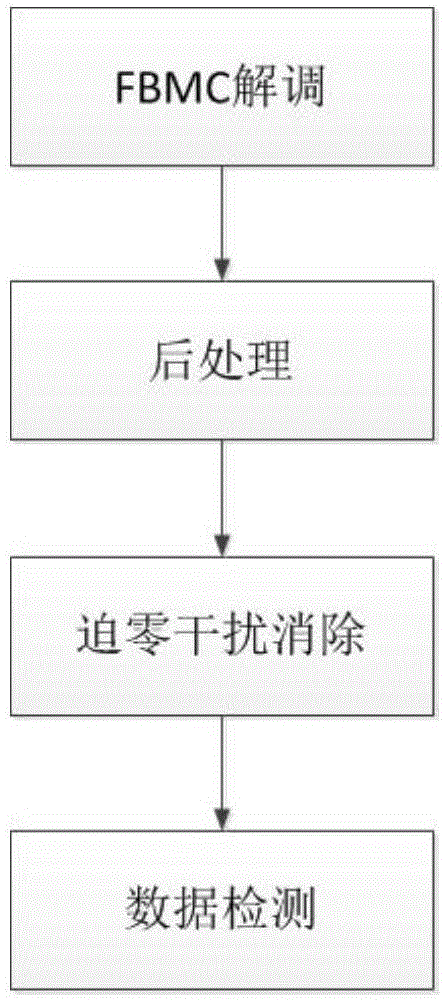

Complex modulation based FBMC signal sending and receiving methods and devices thereof

InactiveCN106302301AAchieve effective useEfficient use ofMultiple carrier systemsCarrier signalIntercarrier interference

The invention discloses a complex modulation based FBMC signal sending method. The method is characterized by comprising that a complex signal a is pre-coded to obtain X=Ta, and T represents a precoding matrix, and serves as conjugated transposition of a right singular-value matrix of an interference matrix I; and an FBMC based modulation manner is used to send X. The invention also discloses a corresponding complex modulation based FBMC signal receiving device, an emitter and a receiver. The problem that inter-carrier interference occurs when the FBMC modulation manner is applied to a radio communication system is solved.

Owner:BEIJING SAMSUNG TELECOM R&D CENT +1

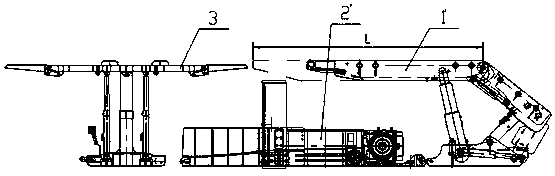

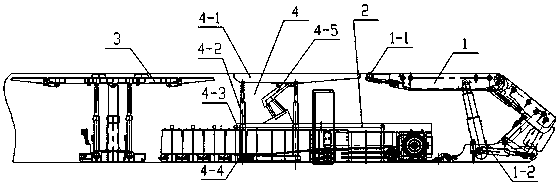

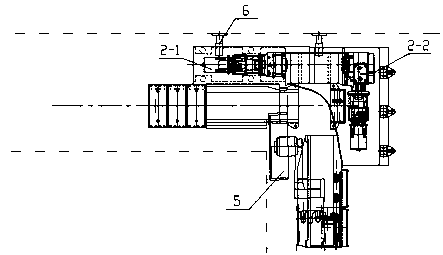

Fully mechanized mining face end conveying and supporting integrated supporting device

ActiveCN111396104AAchieve effective useDecrease control top distanceMine roof supportsProcess engineeringCoal

The invention discloses fully mechanized mining face end supporting equipment and specifically relates to a conveying and supporting integrated end supporting device collaboratively designed with a scraper conveyor. The integrated supporting device is composed of a top beam, a base, stand columns, a middle supporting frame and a stabilizing mechanism. The base is connected with the end of the scraper conveyor into a whole. The force bearing points of the stand columns are locally reinforced at the base. The middle supporting frame is arranged between the top beam and the base and serves as a cover plate of a driving part, and space utilization of intensive devices is realized. According to the conveying and supporting integrated supporting device arranged at the end, the constraint and adjustment functions are added to the head or the tail of the scraper conveyor, and the tendency of upward moving and downward sliding is slowed down; a three-level collaborative supporting mode of an end hydraulic support, an end conveying and supporting integrated supporting device and a fore support is formed at the end of a fully mechanized mining face. The problem of ineffective supporting of asuperlong top beam of a traditional end hydraulic support is solved. The mining face end surrounding rock control capability is improved. The fully mechanized mining face end supporting equipment provides a device support for high-yield and high-efficiency mining of complicated coal seams.

Owner:TIANDI SCI & TECH CO LTD +1

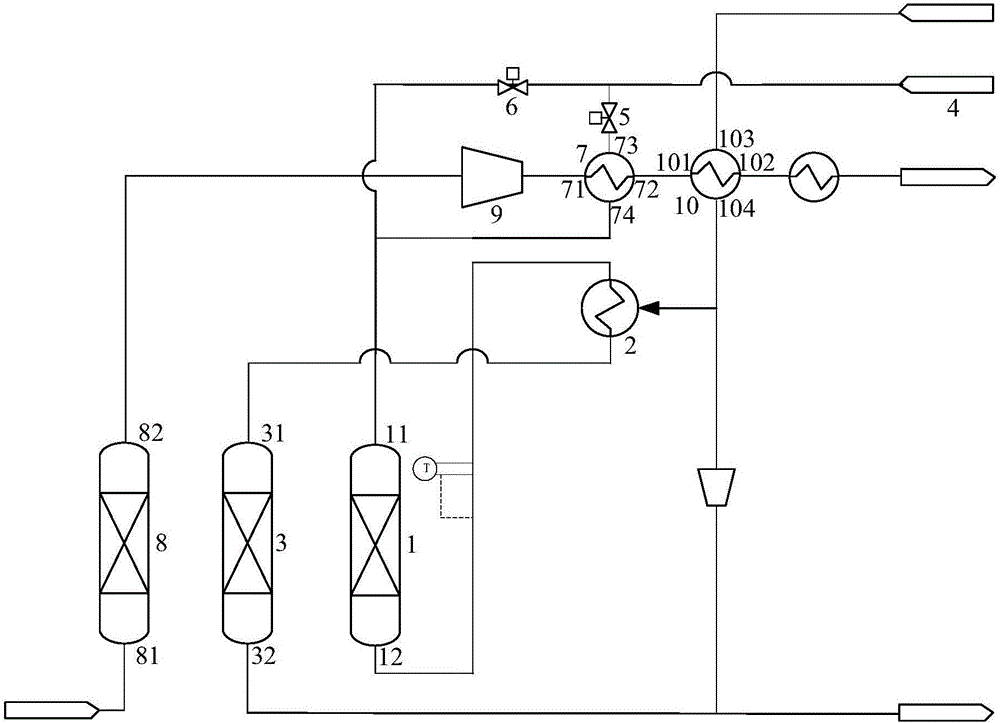

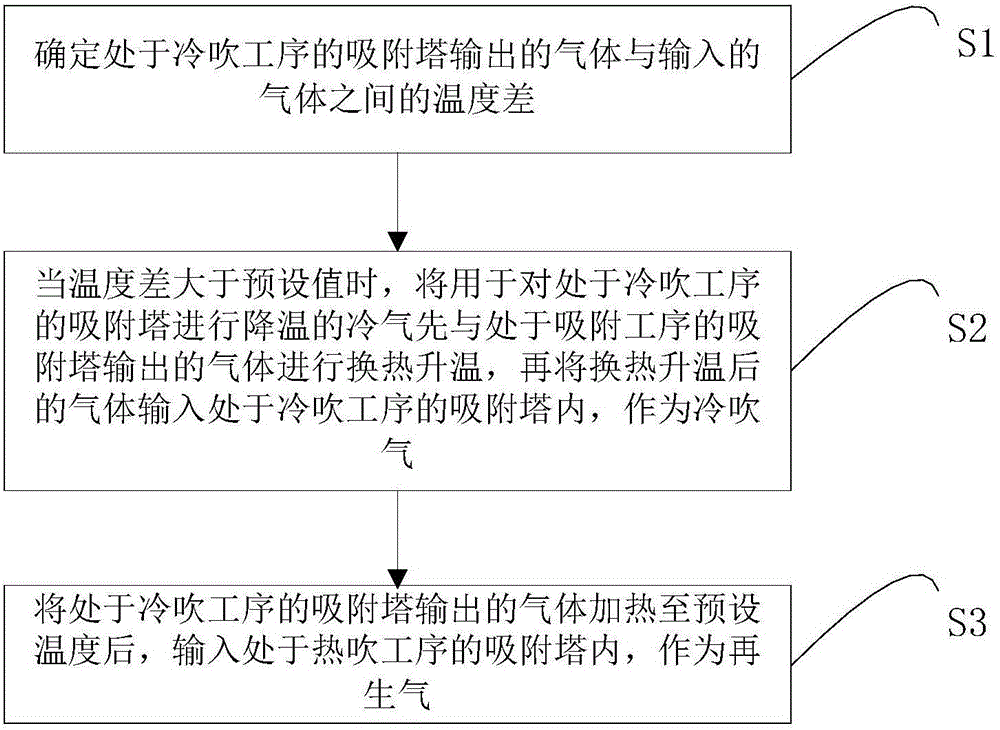

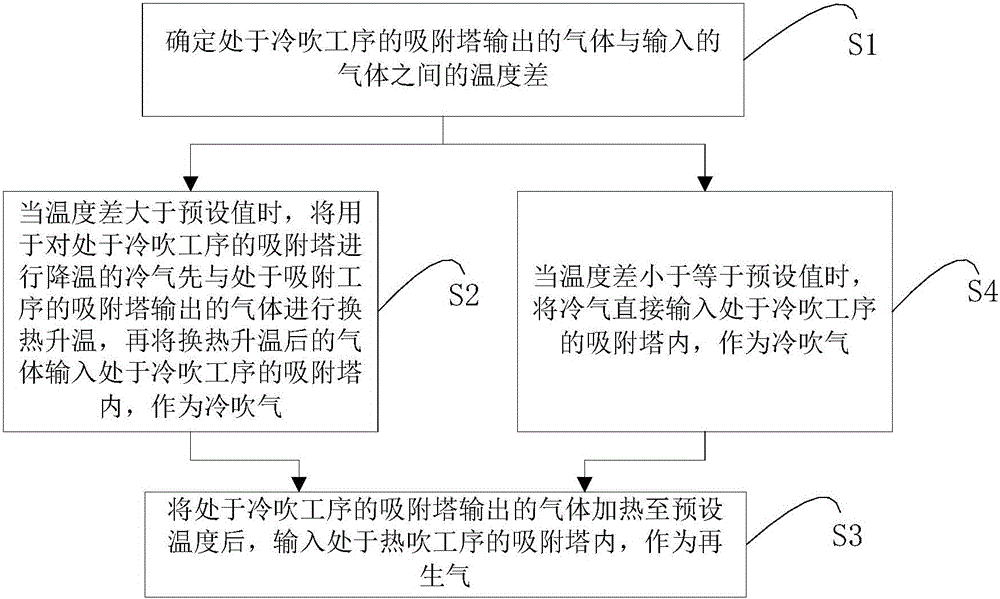

Natural gas purification device, purification system, treatment system and adsorbent regeneration method

ActiveCN105126536AAchieve effective useIncrease profitGaseous fuelsDispersed particle separationProcess engineeringUtilization factor

The invention provides a natural gas purification device, a purification system, a treatment system and an adsorbent regeneration method. Specifically, the natural gas purification device comprises a first adsorption tower, a second adsorption tower, a pre-heating unit and a heating unit. The inlet of the pre-heating unit is connected to a cold air source to receive the cold air provided by the cold air source, the outlet of the pre-heating unit is in connection with a cold blowing section inlet of the first adsorption tower, a cold blowing section outlet of the first adsorption tower is connected to a hot blowing section inlet of the second adsorption tower, and a hot blowing section outlet of the second adsorption tower is used for outputting the gas in the second adsorption tower. The heat of the gas output by the cold blowing section outlet of the first adsorption tower is reutilized, effective utilization of energy is realized, the utilization rate of energy is greatly improved, the energy consumption of the heating unit is reduced, and further energy is saved. In addition, the first adsorption tower is also effectively protected.

Owner:ENN SCI & TECH DEV

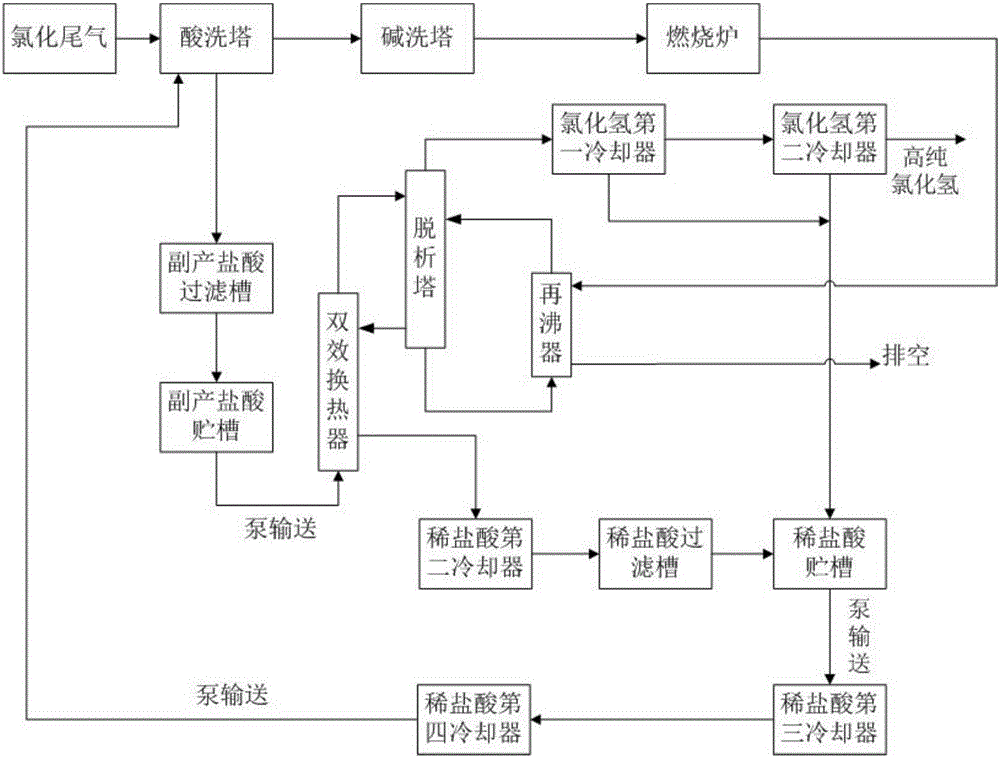

Method for comprehensively utilizing chlorination tail gas in chlorination-process titanium dioxide powder production procedures

ActiveCN106044708AAvoid wastingAchieve effective useChlorine/hydrogen-chloride purificationPreparation from chloridesDischarge pressureExhaust gas

The invention relates to a method for treating chlorination tail gas in chlorination-process titanium dioxide powder production procedures. Carbon monoxide in the chlorination tail gas can be used as a heat source, and byproduct hydrochloric acid which is obtained after the chlorination tail gas is subjected to acid pickling can be desorbed to obtain high-purity hydrogen chloride by the aid of the method. The method includes carrying out acid pickling and alkali washing on the chlorination tail gas, then combusting the chlorination tail gas in a combustion furnace, feeding generated hot flue gas into a reboiler and ultimately venting the flue gas; filtering the byproduct hydrochloric acid obtained after the chlorination tail gas is subjected to acid picking, carrying out heat exchange on the byproduct hydrochloric acid, then feeding the byproduct hydrochloric acid into a desorption tower, continuously heating and evaporating the byproduct hydrochloric acid by the aid of a reboiler to obtain hydrogen chloride gas, exhausting the hydrogen chloride gas from the top of the desorption tower and draining evaporated diluted hydrochloric acid from the bottom of the desorption tower; carrying out heat exchange on the diluted hydrochloric acid by the aid of a double-effect heat exchanger and cooling the diluted hydrochloric acid until the temperature of the diluted hydrochloric acid reaches the normal temperature; condensing the hydrogen chloride gas to obtain high-purity hydrogen chloride gas. The method has the advantages that carbon resources can be effectively utilized; the recycled hydrochloric acid can be converted into the high-purity hydrogen chloride, and accordingly the resource utilization rate can be increased; the desorbed diluted hydrochloric acid is used as acid pickling absorption liquid, accordingly, the recycling rate of the byproduct hydrochloric acid can be increased, discharge pressures can be relieved, and the production cost can be lowered.

Owner:YIBIN TIANYUAN GRP CO LTD +1

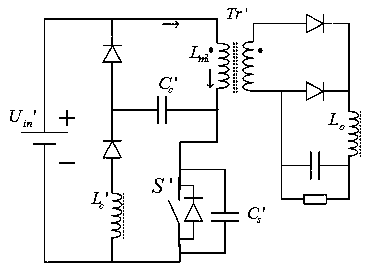

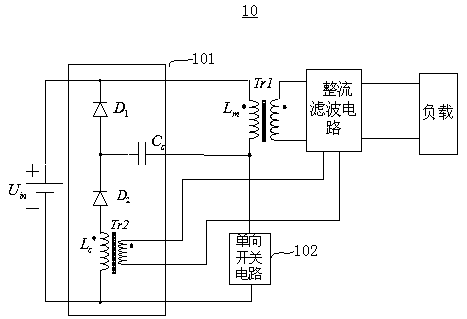

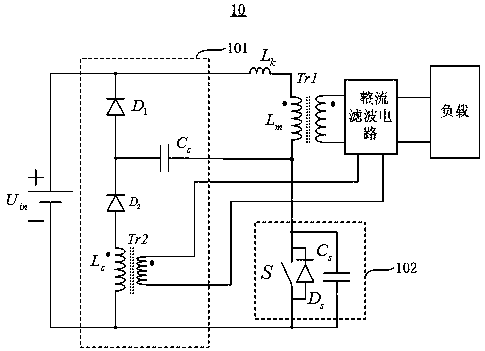

LCD clamping single-tube forward converter and electronic equipment

InactiveCN110829843AAchieve effective useEliminate reverse surge current interferenceApparatus with intermediate ac conversionPhysicsCapacitance

The invention relates to an LCD clamping single-tube forward converter and electronic equipment. The LCD clamping single-tube forward converter comprises a forward transformer, a one-way switching circuit and a clamping magnetic reset circuit, wherein the clamping magnetic reset circuit comprises a coupling capacitor, a first diode and a flyback transformer, the negative electrode of the first diode is connected with the positive electrode of a preset power supply, the positive electrode of the first diode is connected with the first end of a primary winding of the flyback transformer and is connected with the second end of a primary winding of the forward transformer through the coupling capacitor, the second end of the primary winding of the flyback transformer is connected with the negative electrode of the preset power supply, and a secondary winding of the flyback transformer is used for connecting a load. According to the invention, the effective utilization of magnetic reset energy of the forward transformer can be realized, and the reverse impact current interference to the input power supply end is eliminated. The secondary side of the forward transformer outputs to the load during the conduction period of the one-way switching circuit, so that the output voltage ripple of the converter is small, the filtering parameter is small, and the voltage stabilization regulation and modular design are easy.

Owner:东莞南方半导体科技有限公司

Data processing apparatus and data reception processing apparatus

InactiveUS7760881B2Efficient comprehensive utilizationAchieve effective useData stream serial/continuous modificationSecret communicationComputer hardwareCyclic code

The present invention is directed to a data processing apparatus adapted for performing scramble processing of transmit data, which comprises cyclic code generating means for generating cyclic bit data train of a predetermined period, EXOR operation means for sequentially performing EXOR operation of the cyclic bit data train with respect to the transmit data to output scramble-processed data, data generating means for generating bit data of a predetermined pattern, and switching means supplied with the scramble-processed data and the bit data of the predetermined pattern generated by the data generating means to select the bit data of the predetermined pattern at the time of synchronization processing of the transmit data, and to select the scramble-processed data when synchronization processing of transmit data is not performed to output the data thus selected as scrambler output data.

Owner:SONY CORP

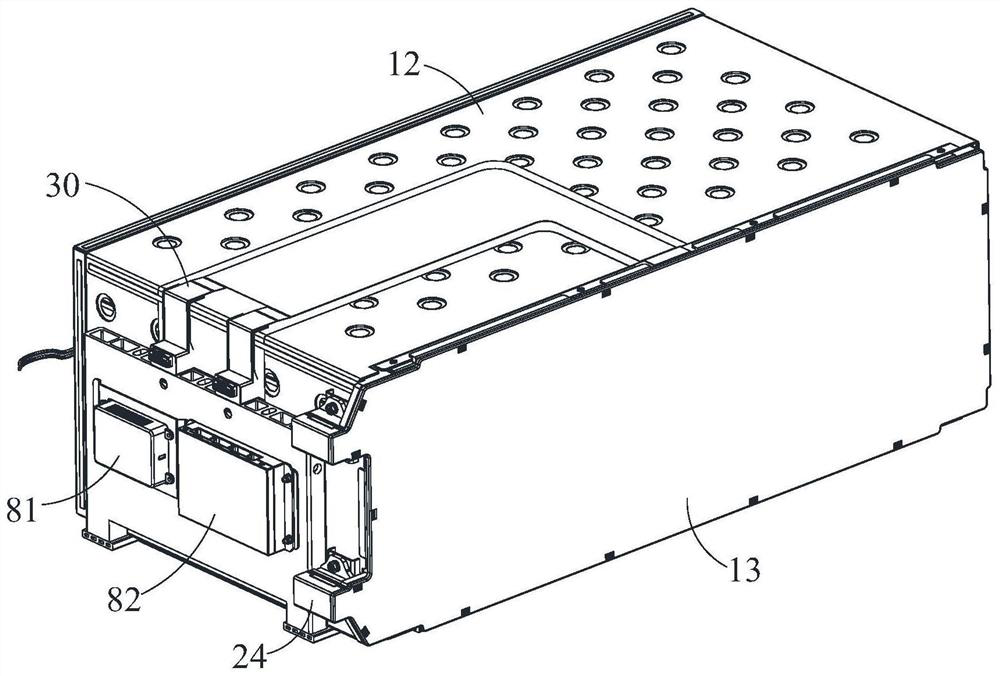

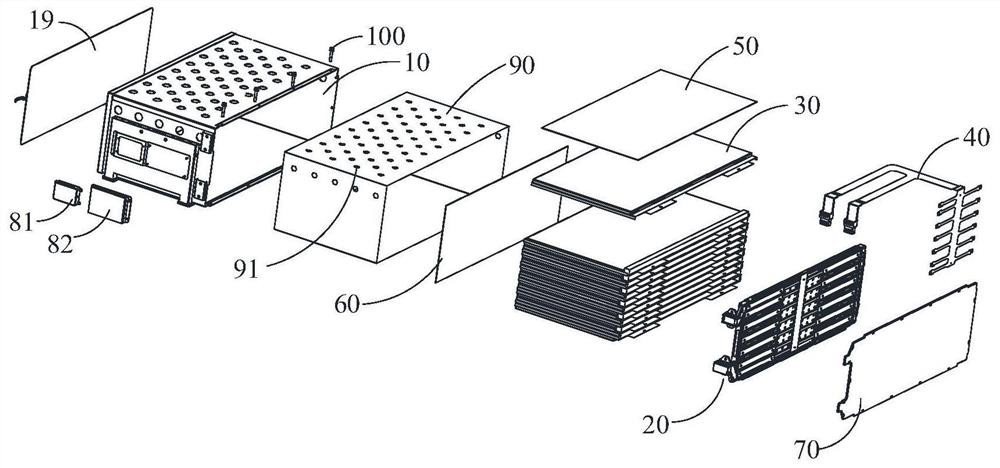

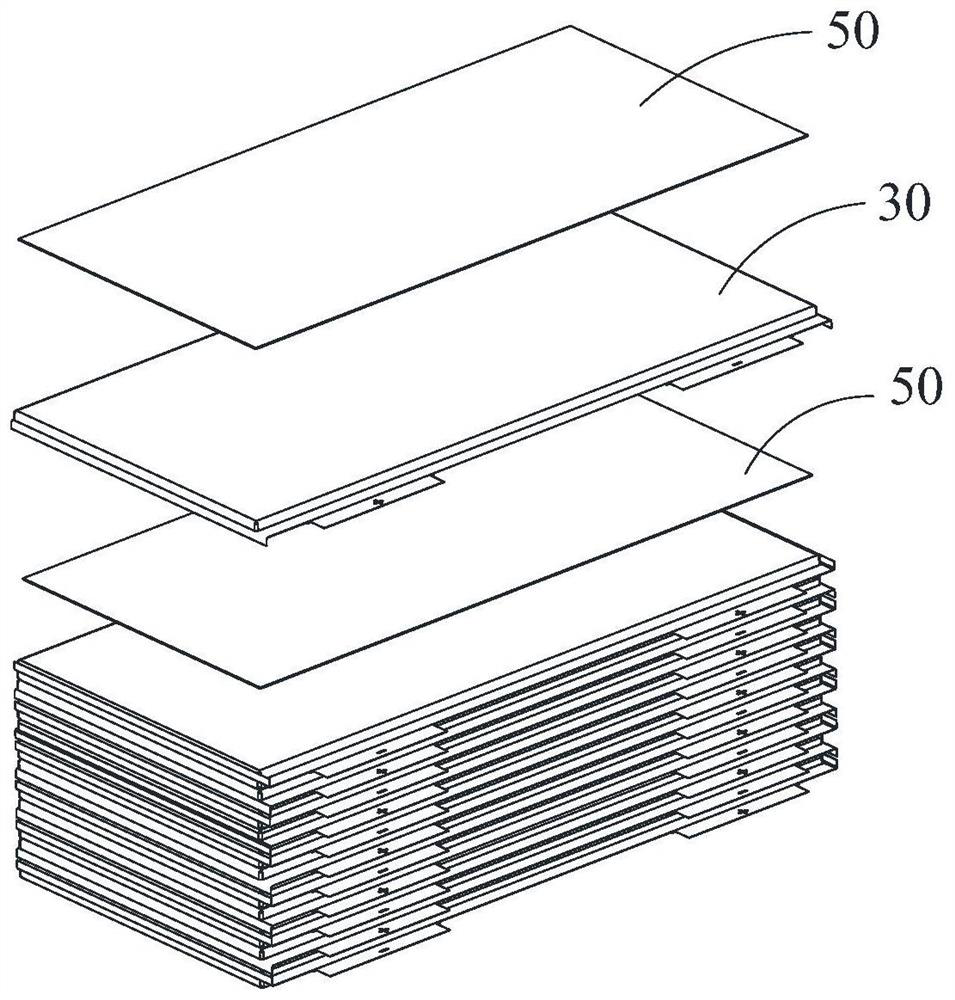

Large soft package battery module, assembly method, power battery and electric vehicle

InactiveCN111933852AAchieve effective useBig room for expansionFinal product manufactureCells structural combinationElectric vehiclePower battery

The invention provides a large soft package battery module, an assembly method, a power battery and an electric vehicle. The large soft package battery module comprises a shell, buffer pads, a copperbar assembly, battery cells, a flexible circuit board and a heat-conducting fin, wherein the shell is provided with an opening in one side; the multiple layers of battery cells are stacked and then accommodated in the shell, the shell comprises a shell main body, an upper cover and a rear cover, the shell main body comprises a bottom plate and two side plates fixed at two opposite ends of the bottom plate, the upper cover covers the top of the multiple layers of battery cells and is fixedly connected with the two side plates, the rear cover covers one sides of the two side plates, and the heat-conducting fin is arranged between the rear cover and the multiple layers of battery cells; each buffer pad is arranged between two adjacent battery cells, the copper bar assembly comprises a plasticsupport and a copper bar fixed to the plastic support, and a guide groove is formed in the side, which deviates from the copper bar, of the plastic support; a tab of the battery cell penetrates through the plastic support and is connected with the copper bar, the flexible circuit board is buckled on the shell and is electrically connected with the copper bar, and a plastic cover plate fixedly connected with the shell covers the outer side of the copper bar. The large soft package battery module is high in energy density.

Owner:领航国创新能源电池技术研究院(北京)有限公司

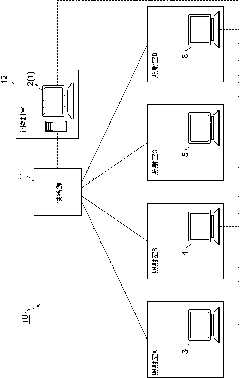

Beam scheduler and beam distribution method thereof

ActiveCN102188777AAchieve effective useEfficient use ofX-ray/gamma-ray/particle-irradiation therapyParticle beamDistribution method

The invention discloses a beam scheduler and a beam distribution method of the beam scheduler. The invention aims to realize the effective utilization of a particle beam irradiation facility. When an irradiation request is received from one of a plurality of irradiation chambers (A-D) , the beam scheduler (1) in the invention adds maximum allowable waiting time at the end of beam distribution to the irradiation request, adds the irradiation request to the end of a waiting list, judges whether prediction waiting time at the end of distributing beam to one irradiation chamber is beyond the maximum allowable waiting time, brings forwardly the irradiation request in the waiting list when the prediction waiting time is beyond the maximum allowable waiting time, and distributes beam to the irradiation chamber corresponding to the highest-level irradiation request in the waiting list.

Owner:SUMITOMO HEAVY IND LTD

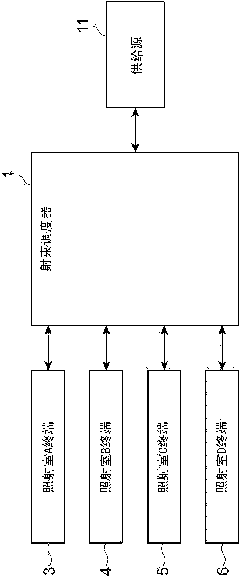

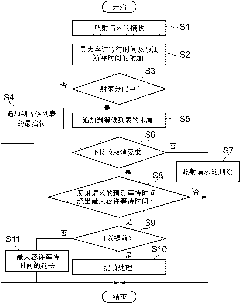

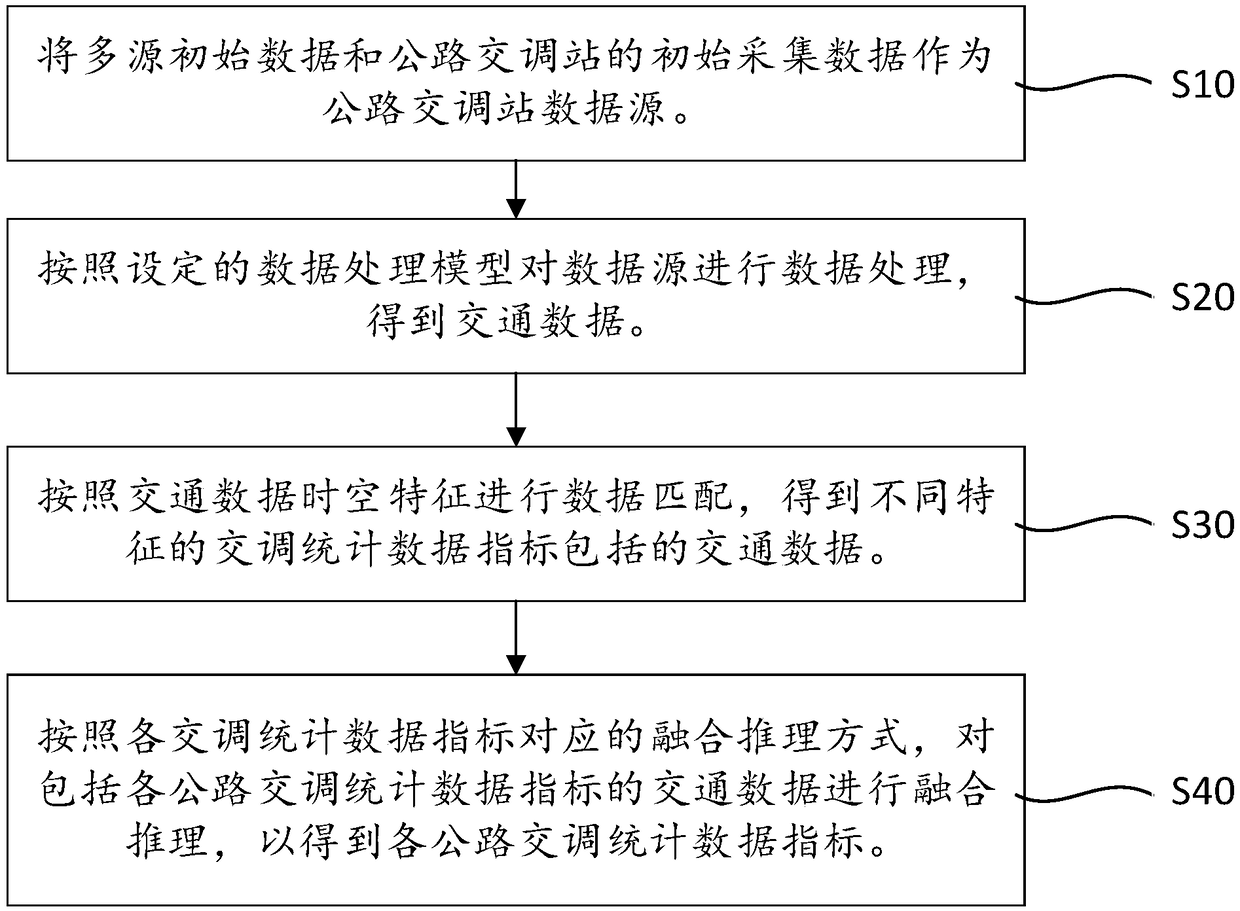

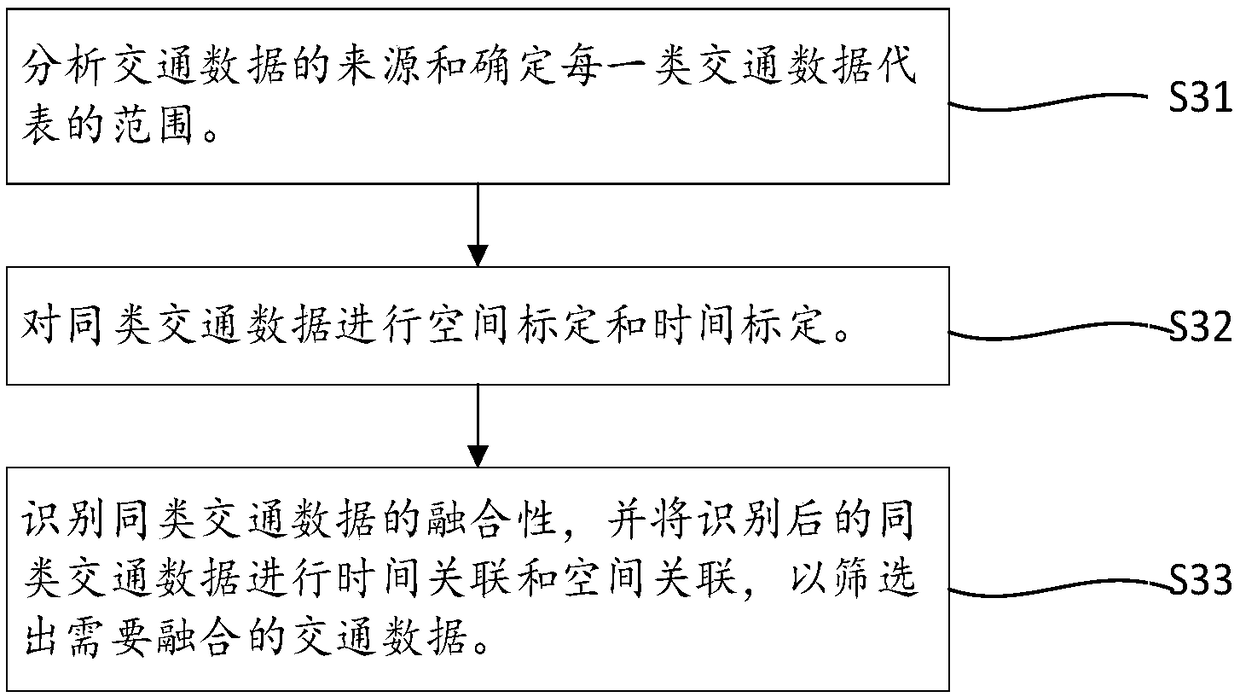

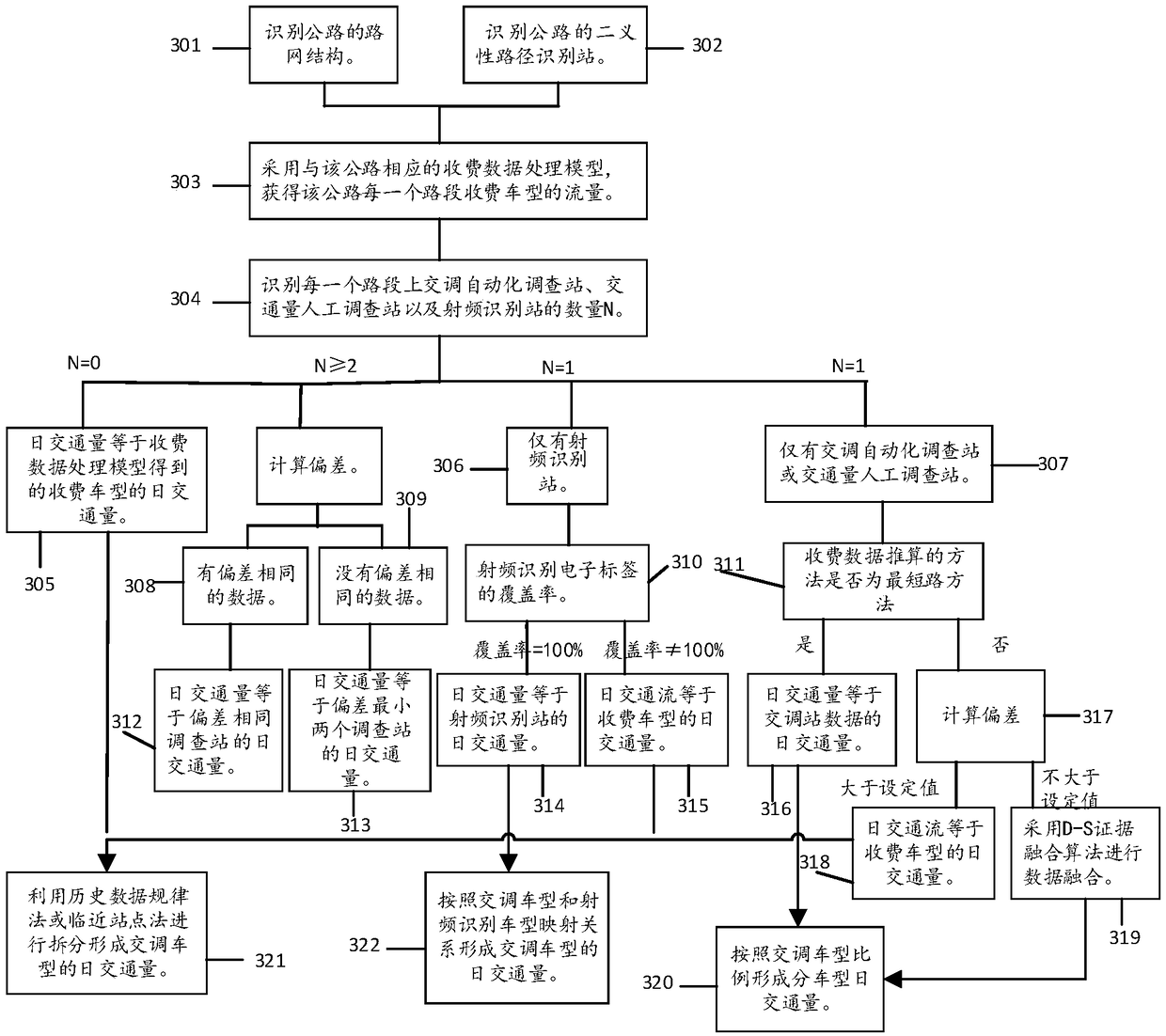

Multi-source data fusion method and device for highway traffic investigation stations

ActiveCN109118789AAchieve effective useRich survey methodsRoad vehicles traffic controlData matchingCollection system

The invention provides a multi-source data fusion method for highway traffic investigation stations, including the following steps: taking multi-source initial data and the initial collected data of ahighway traffic investigation station as the data sources of the highway traffic investigation station; processing the data of the data sources according to a set data processing model to obtain traffic data; carrying out data matching according to the spatial and temporal characteristics of the traffic data to obtain traffic data having different characteristics and including traffic investigation statistical data indicators; and carrying out fusion reasoning on the traffic data including the highway traffic investigation statistical data indicators according to a fusion reasoning mode corresponding to the traffic investigation statistical data indicators to obtain the highway traffic investigation statistical data indicators. According to the invention, different multi-source data is fused through data fusion to form required highway traffic investigation statistical data indicators, and thus, a technical basis is provided for the construction of a new traffic investigation information collection scheme and collection system. Effective utilization of existing resources in the industry is realized, the traffic investigation mode is enriched, and the quality of traffic investigation data and the work efficiency are improved.

Owner:TRANSPORT PLANNING & RES INST MINIST OF TRANSPORT

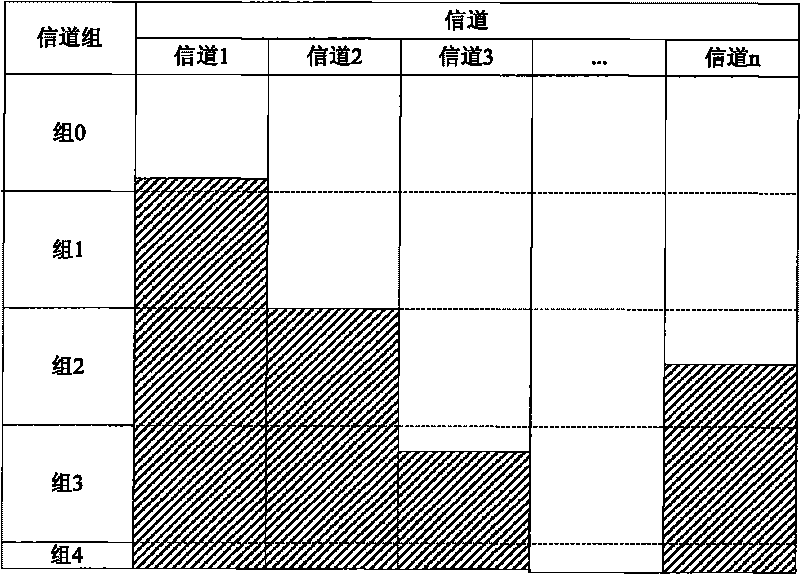

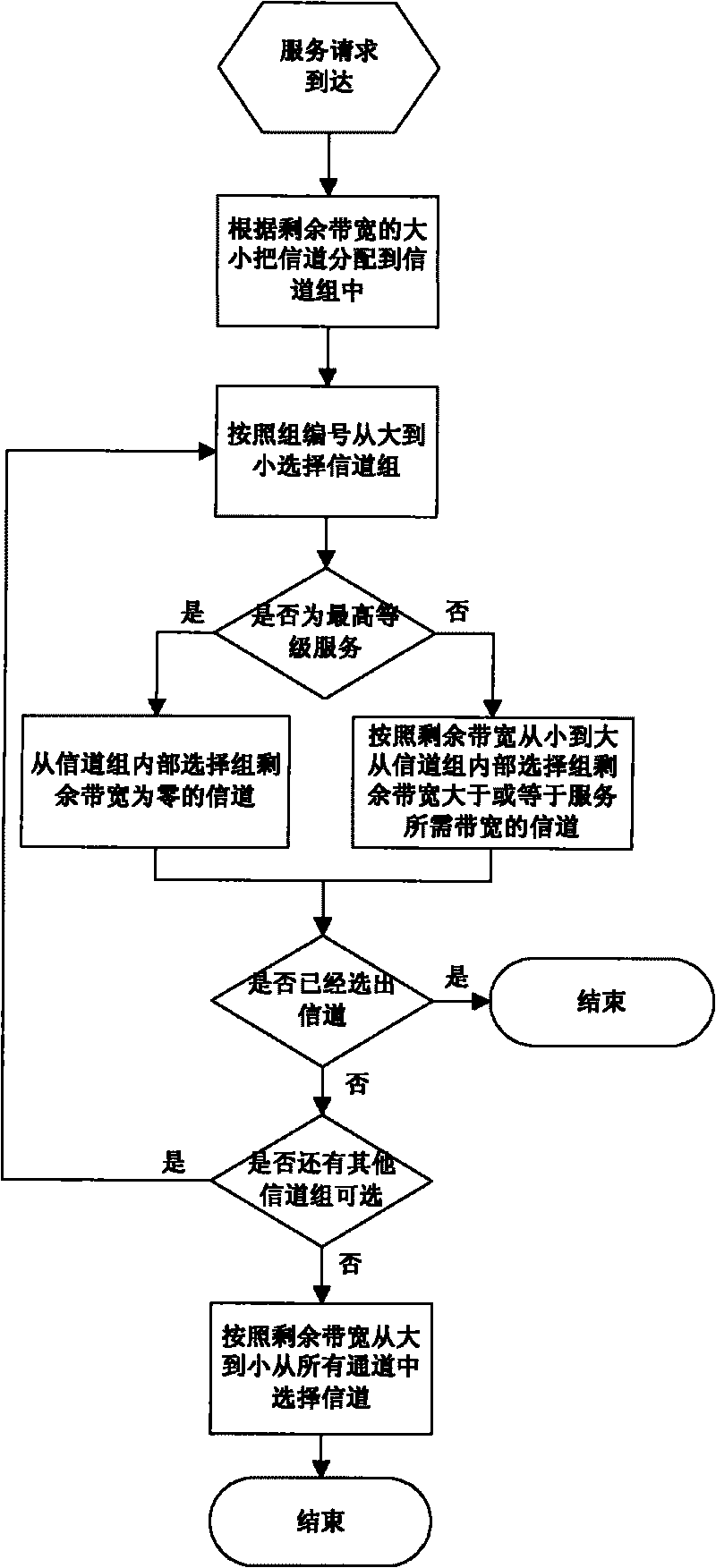

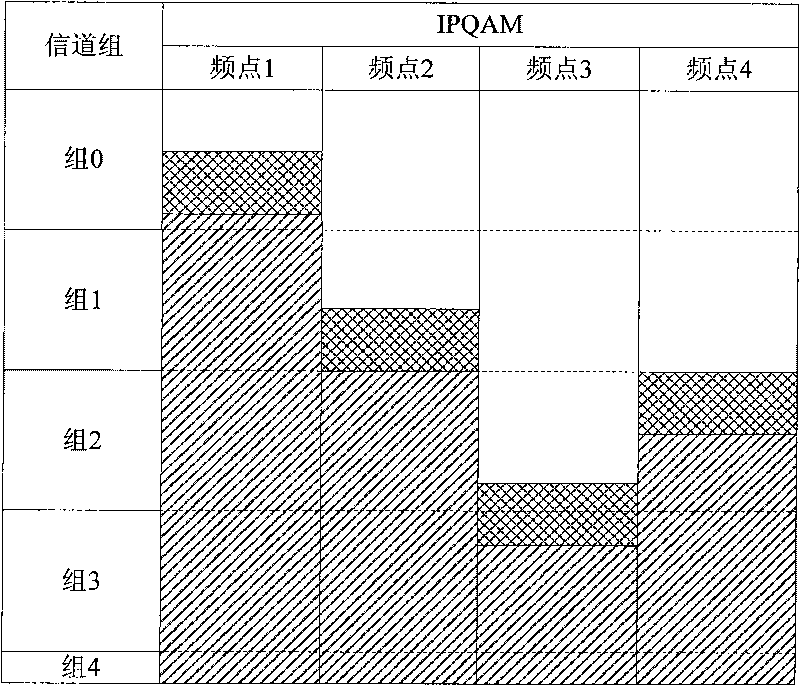

Channel bank-based bandwidth allocation method

InactiveCN101742566AAchieve effective useGuaranteed load balancingNetwork traffic/resource managementTelecommunicationsBandwidth allocation

The invention discloses a channel bank-based bandwidth allocation method, which comprises the following steps: determining the service request level; allocating all channels to a plurality of channel banks according to the size of residual bandwidth of each channel; selecting a channel bank from the plurality of channel banks, judging whether the selected channel bank has a proper channel for allocation until a proper bandwidth is allocated for the service, wherein all the channels are allocated to the channel banks according to the size of the residual bandwidth of the channels; the channel bank has a serial number; the serial number of the channel bank to which a certain channel belongs is equal to a value that the residual bandwidth of the channel divides exactly the needed bandwidth of the highest-level service. Firstly, a channel bank is selected from the larger one to the smaller one according to the serial number of the channel banks, and then, a channel is selected from the interior of the channel bank. When the channel is selected from the interior of the channel bank, the channel with the residual bandwidth of zero is selected for the high-level service, and the channel with the residual bandwidth of more than or equal to the needed bandwidth of the service is selected for the low-level service according to the order from the smaller residual bandwidth to the larger residual bandwidth.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

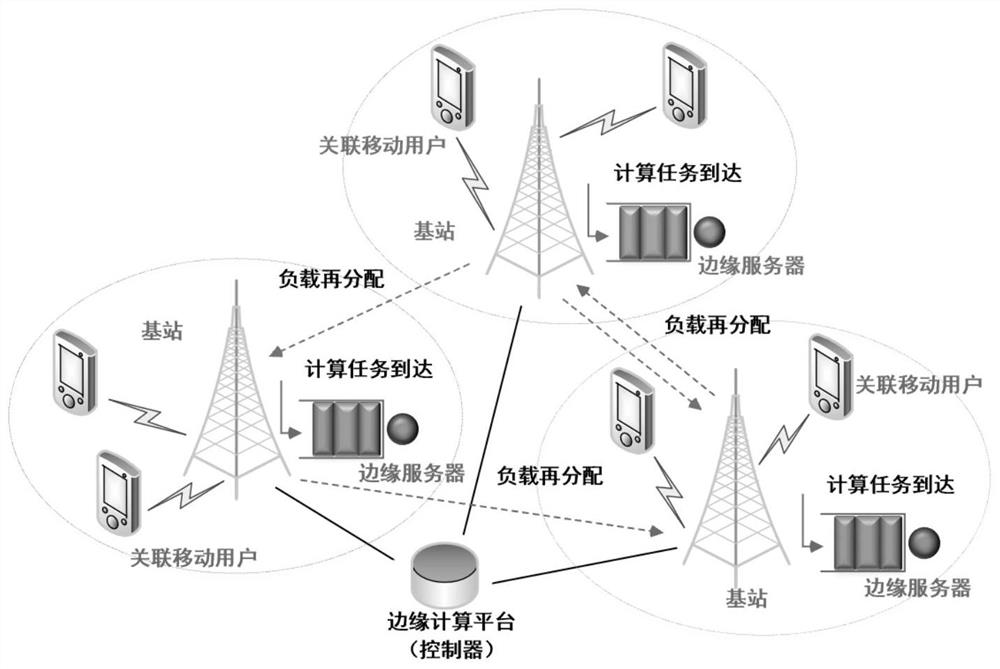

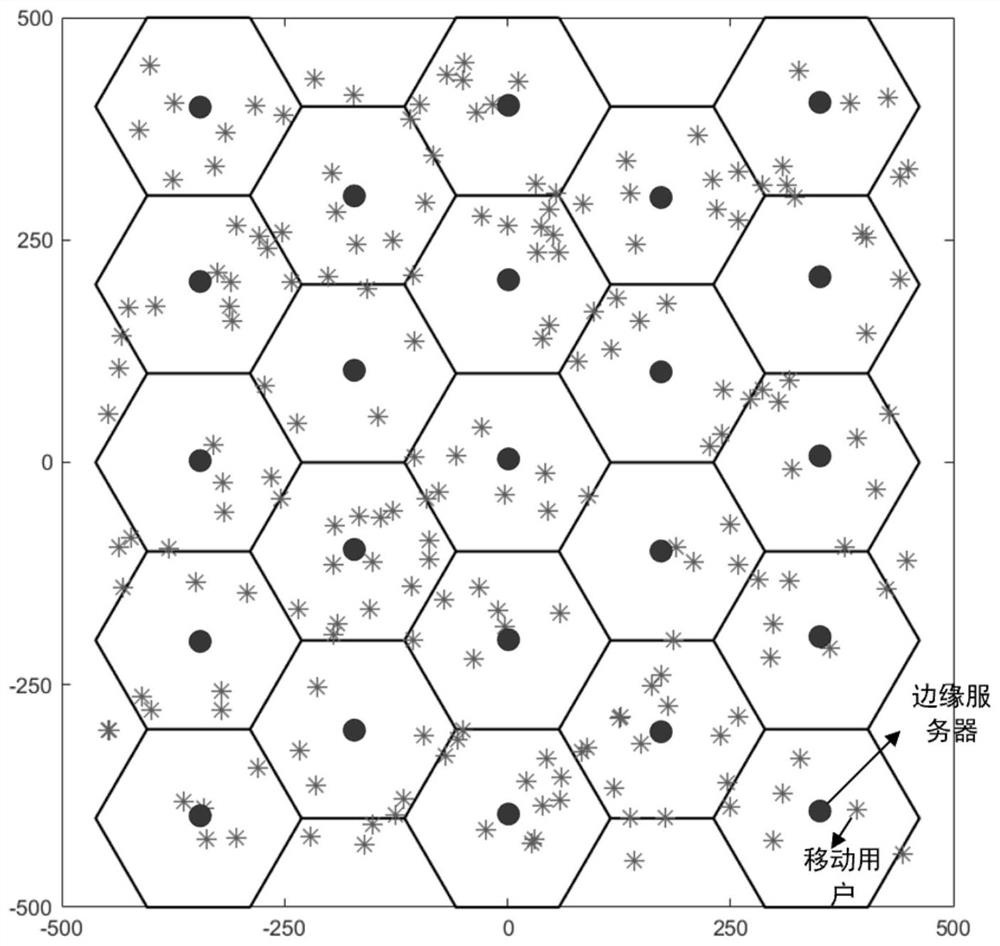

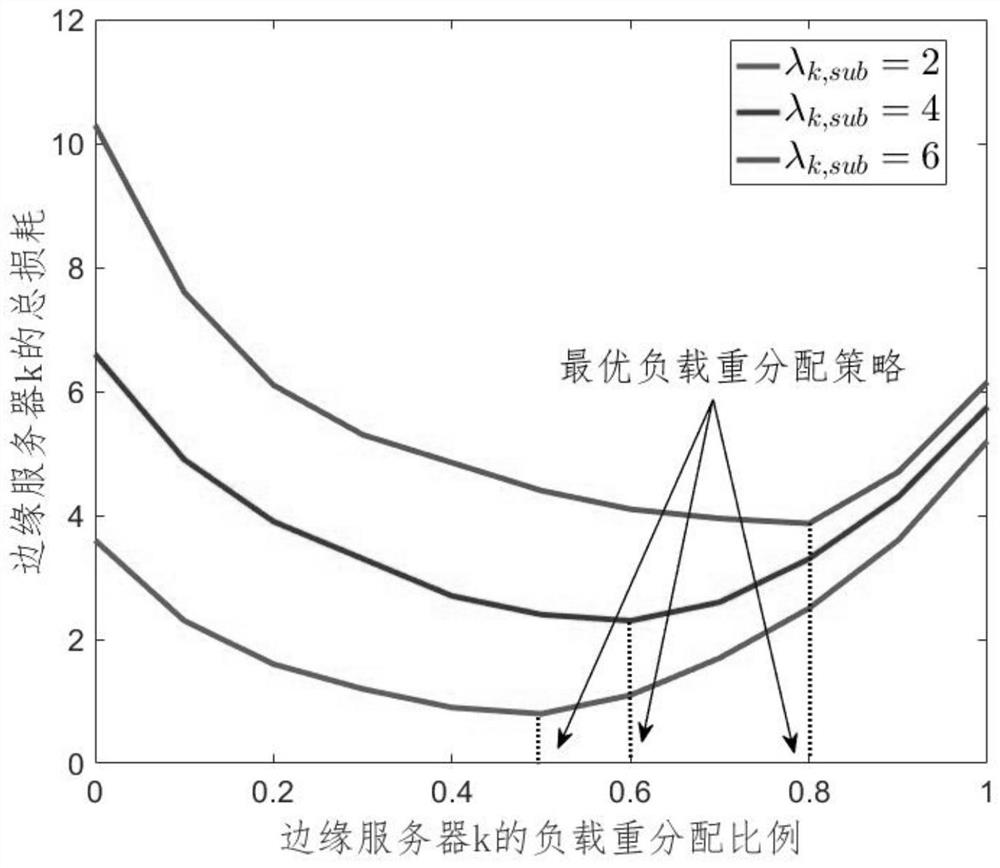

Task unloading distribution method in edge computing network based on cooperative queue game

ActiveCN113613261AAchieve effective usePricing strategy balanceNetwork traffic/resource managementData switching networksEngineeringDistribution method

The invention discloses a task unloading allocation method in an edge computing network based on a cooperative queue game. The method is based on a cooperative queue game between edge servers, and comprises the following steps: establishing an edge server network platform; setting the aim of achieving balance when the expected cost of each edge server is minimized as a target, dynamically and centrally unloading the computational intensive tasks of mobile users to edge servers associated therewith, and then enabling each edge server to decide whether to participate in edge server cooperation to achieve redistribution of loads. According to the method, combined optimization is constructed to determine the load borne by the edge server, the compensation cost received from other edge servers, the willingness to transfer tasks which are not wanted to be processed and the adopted calculation speed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

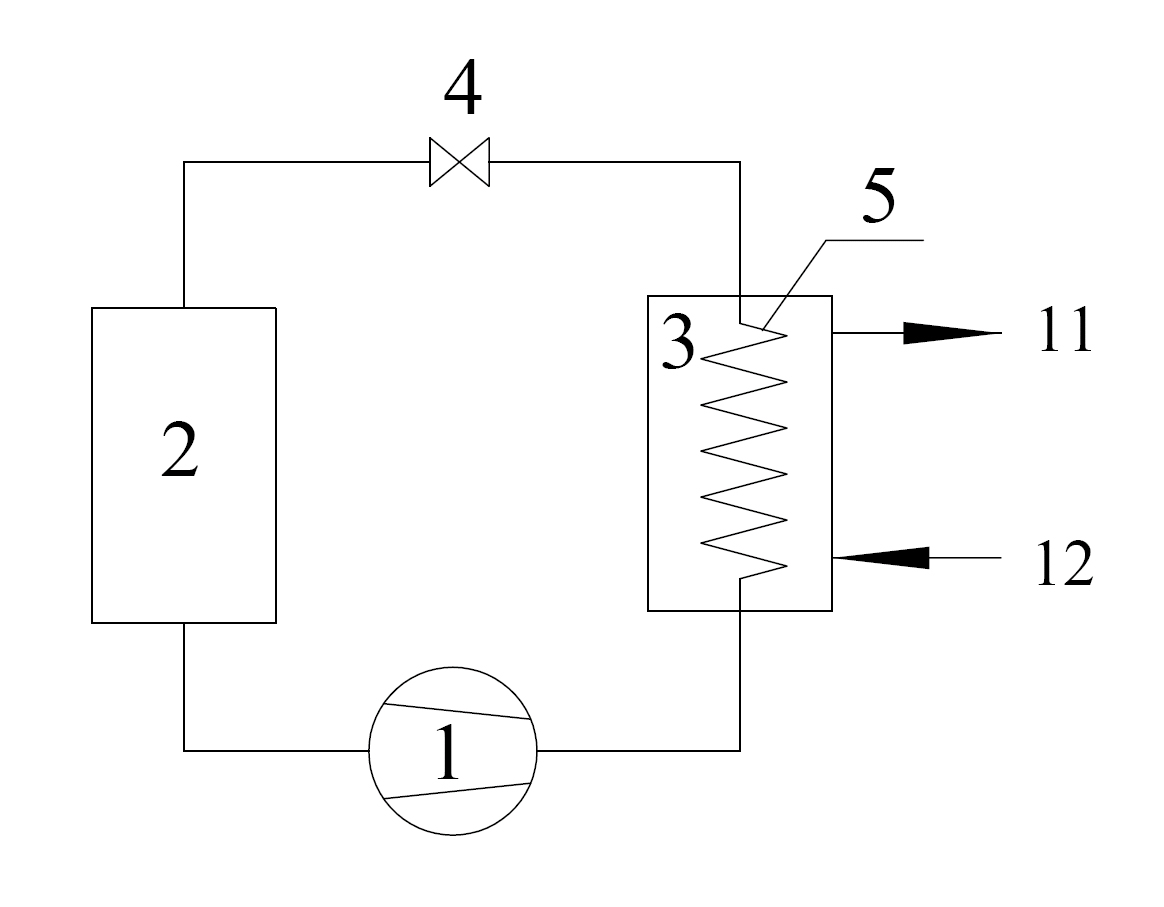

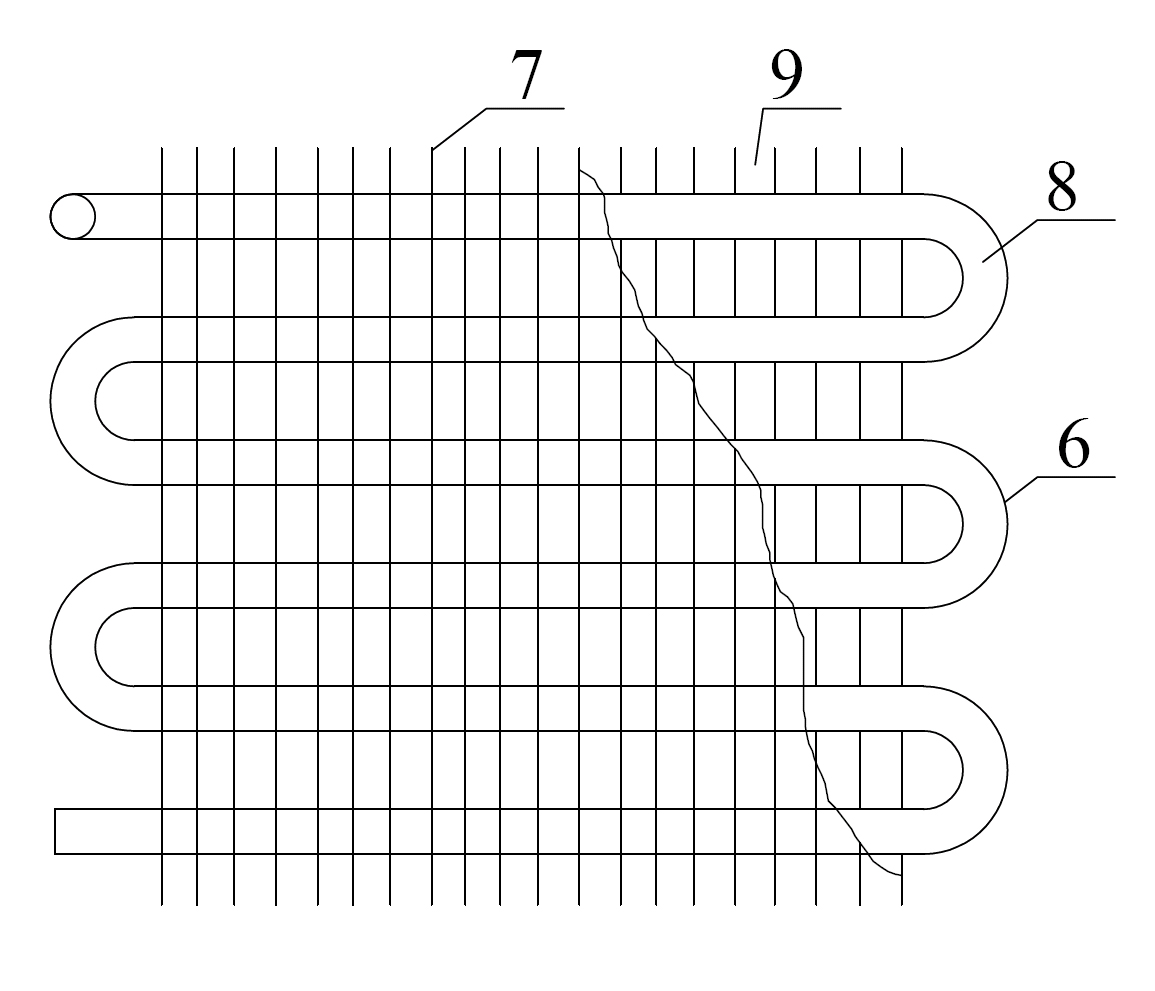

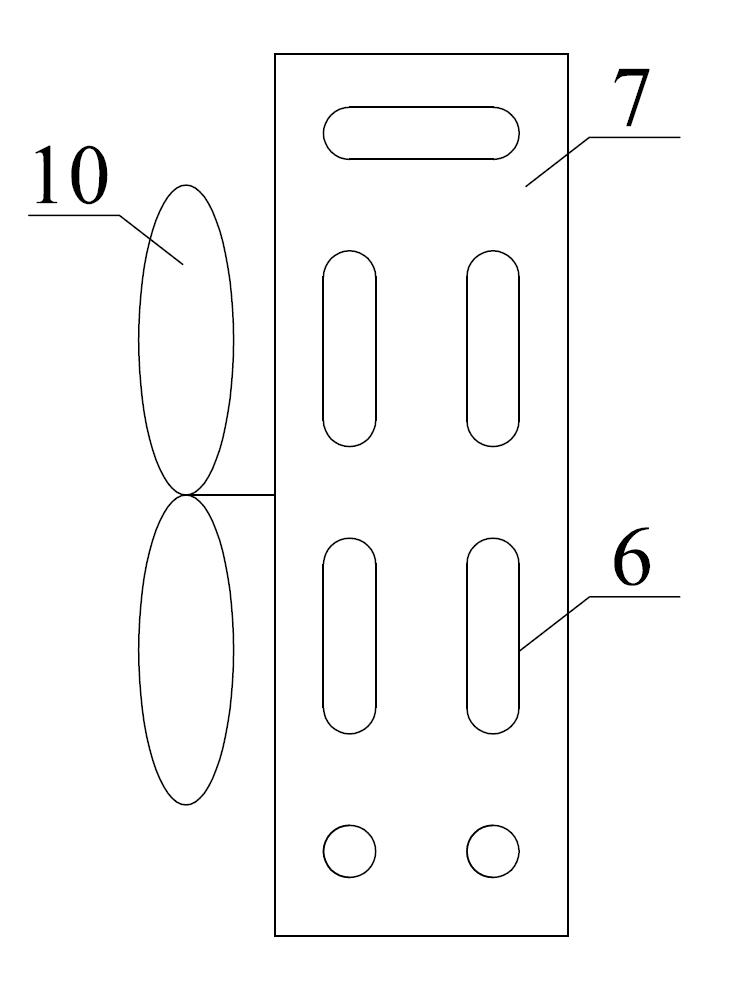

Solar-air dual-heat-source heat pump water heater

InactiveCN101929734ASimplify the structure of the heat exchangerSimplify pipeline structureFluid heatersSolar heat devicesHeat pump water heaterEngineering

The invention discloses a solar-air dual-heat-source heat pump water heater. The water heater comprises a compressor, a heat exchanger, a hot water storage tank, a throttle valve, a hot water heat exchanging coil pipe and a connecting pipeline, wherein the heat exchanger is a solar-air dual-heat-source heat exchanger; one port of the solar-air dual-heat-source heat exchanger is connected with one port of the hot water heat exchanging coil pipe through the compressor, while the other port is connected with the other port of the hot water heat exchanging coil pipe through the throttle valve; the hot water heat exchanging coil pipe is arranged in the hot water storage tank; and the solar-air dual-heat-source heat exchanger comprises a heat exchanging pipe, fins combined with the outer wall of the heat exchanging pipe, and a solar radiation absorbing coating on the external surfaces of the heat exchanging pipe and the fins. The water heater can obviously improve the heating coefficient of performance (COP) and the running stability thereof and simplify the system composition by simultaneously using the air source and the solar radiation energy as the heat pump heat source.

Owner:ZHONGYUAN ENGINEERING COLLEGE

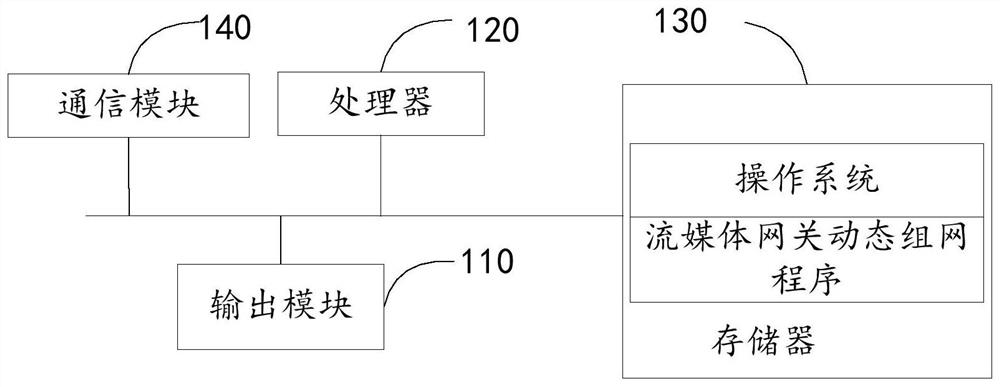

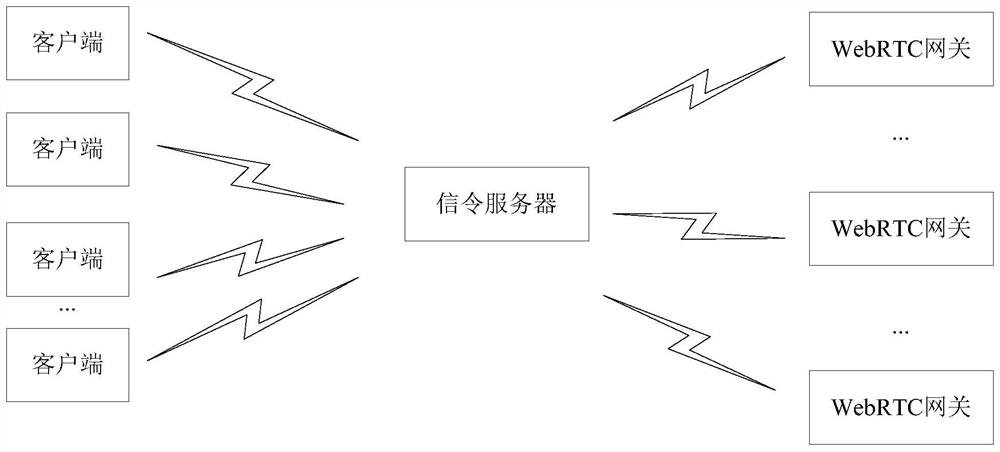

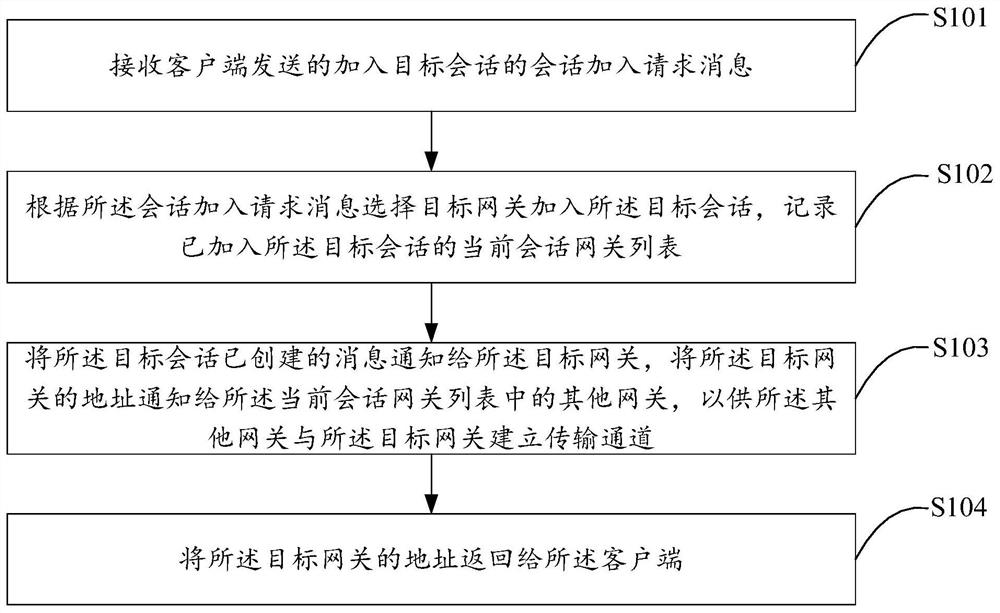

Streaming media gateway dynamic networking method, device and system, terminal equipment and medium

PendingCN112367309AFine Scheduling ManagementAchieve effective useSpecial service provision for substationEngineeringWeb resource

The invention discloses a streaming media gateway dynamic networking method, device and system, terminal equipment and a medium. The method comprises the following steps: receiving a session joining request message for joining a target session sent by a client; selecting a target gateway to join the target session according to the session joining request message, and recording a current session gateway list which joins the target session; notifying the target gateway of the message that the target session has been created, and notifying other gateways in the current session gateway list of theaddress of the target gateway, so that the other gateways establish transmission channels with the target gateway; and returning the address of the target gateway to the client. According to the scheme, the networking topology of the streaming media gateway can be dynamically adjusted according to the session joining or leaving of the client, the forwarding of invalid flow in the gateway clusteris reduced, and the effective utilization of network resources is realized.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

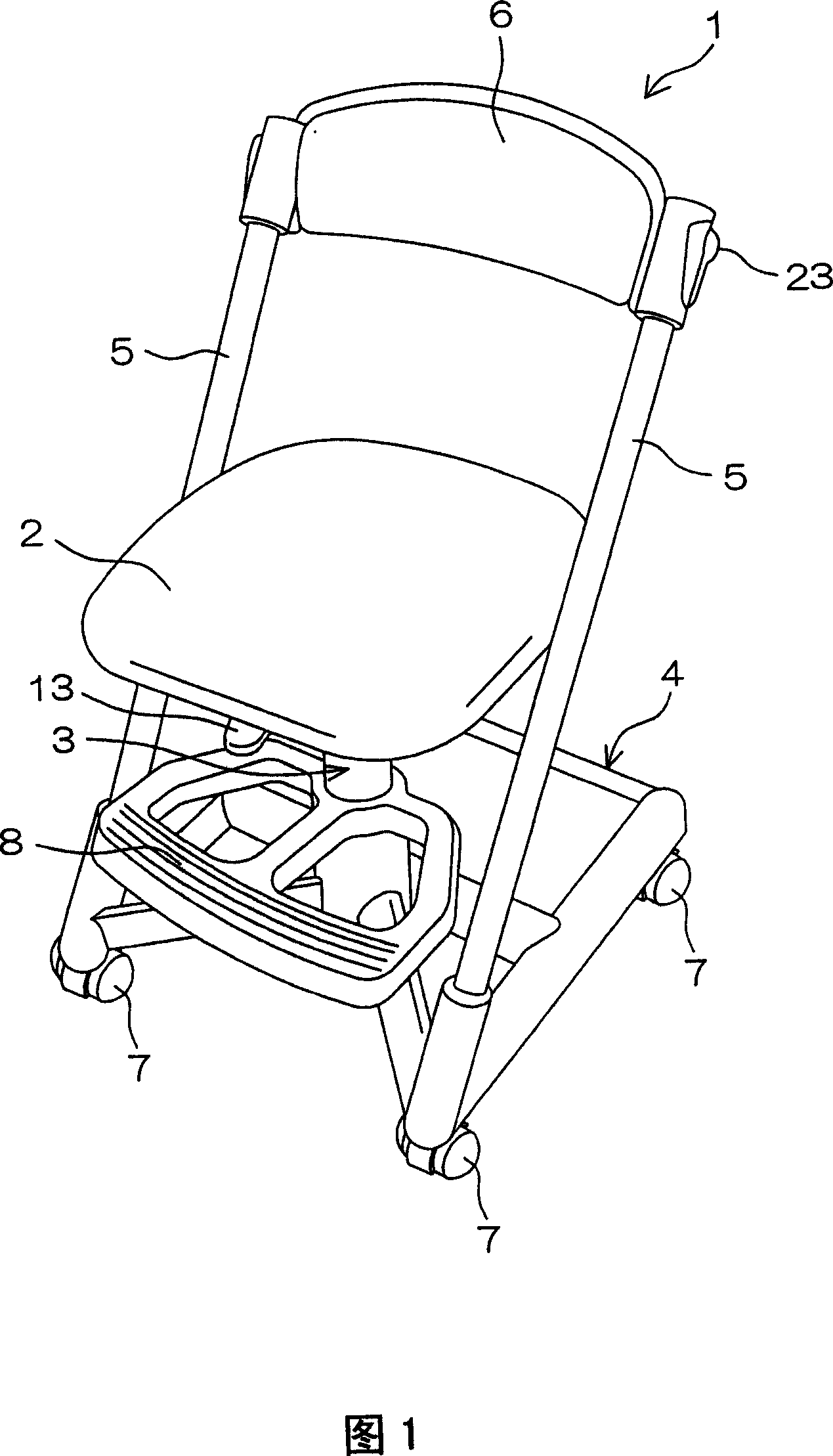

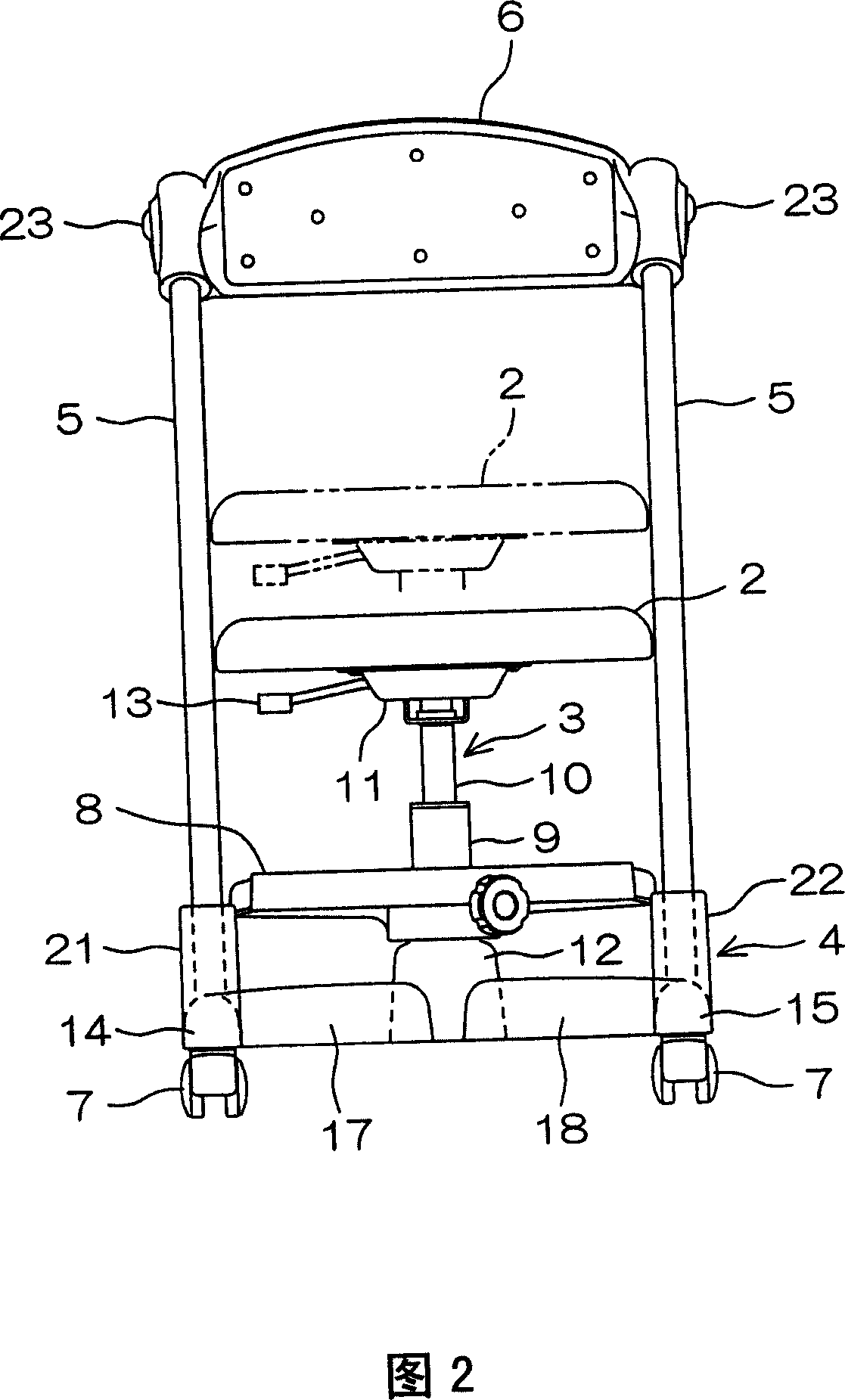

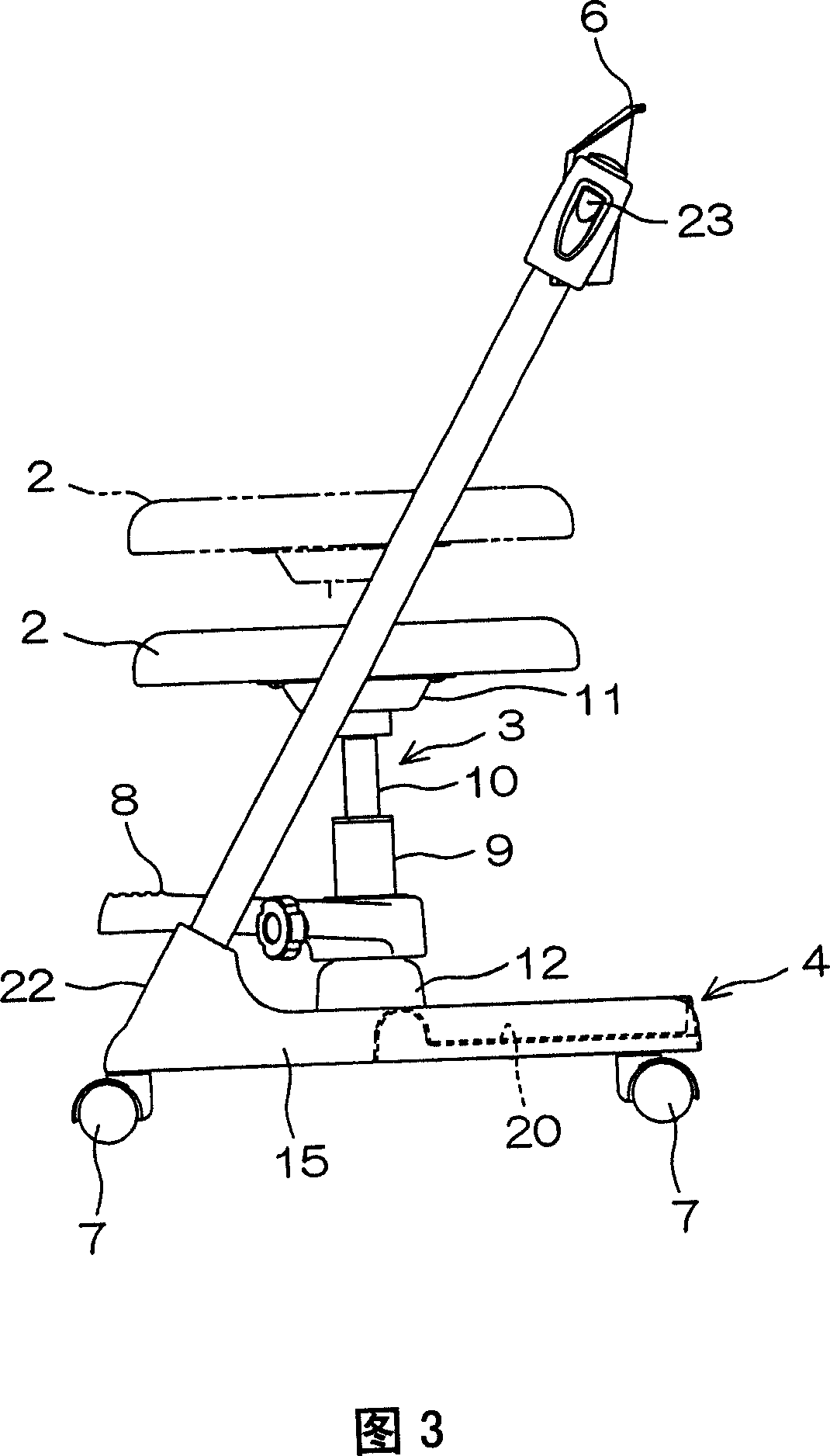

Mixed chair

The present invention provided a hybrid chair for children which has advantages of both a swivel chair and a wooden seat. In a hybrid chair 1, a seat 2 is supported by a support rod 3. The height of the seat 2 can be easily adjusted by operation of a gas-cylinder through operation of an operation handle 13. While, a leg base 4, a pair of bars 5 and a back plate 6 are structured in a conventional wooden seat style to achieve a totally stable organization. Then, the hybrid chair 1 has a new structure with an advantage of the conventional swivel chair and an advantage of a wooden chair.

Owner:KOIZUMI EQUIP TECH

Data storage method and device

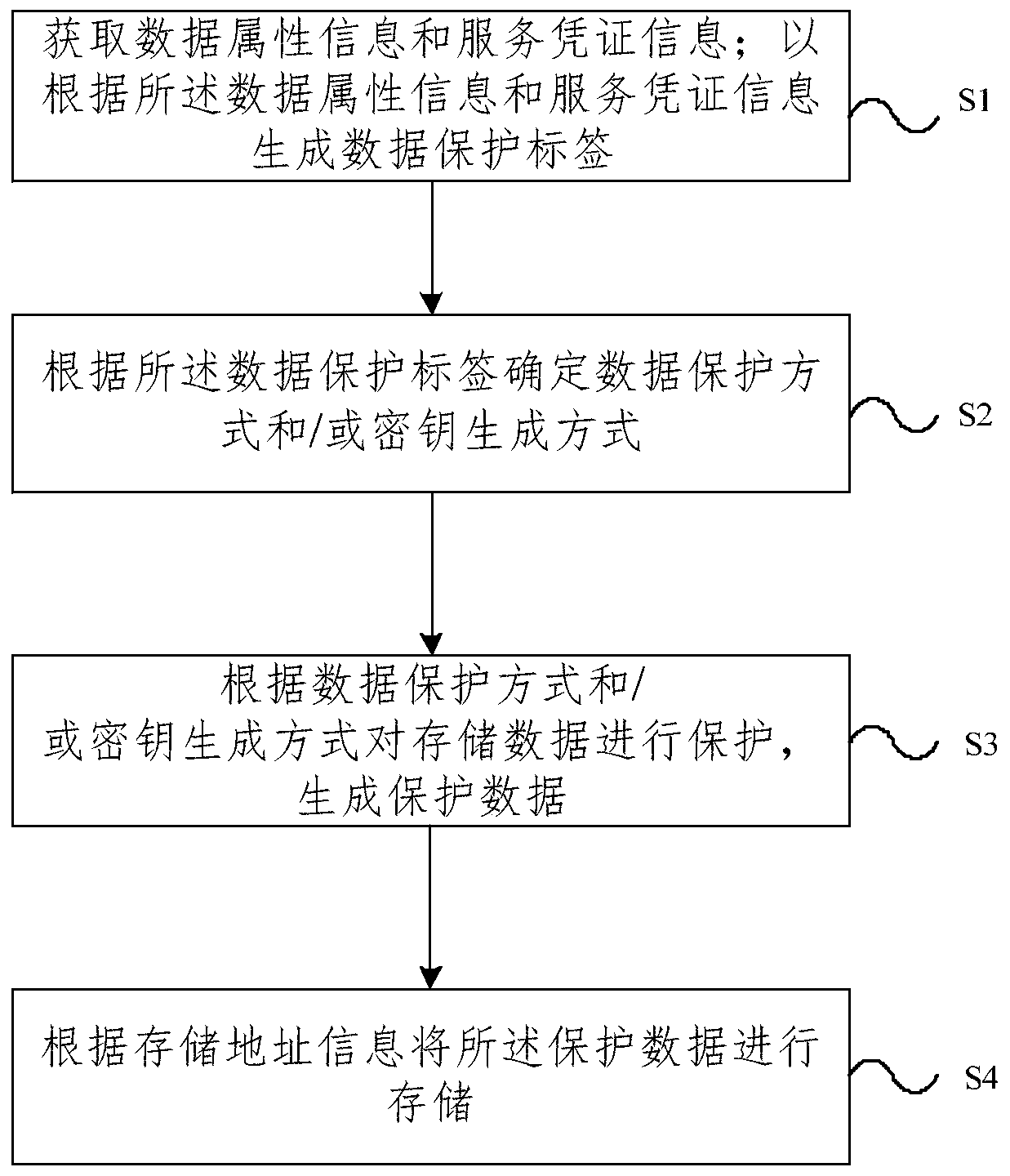

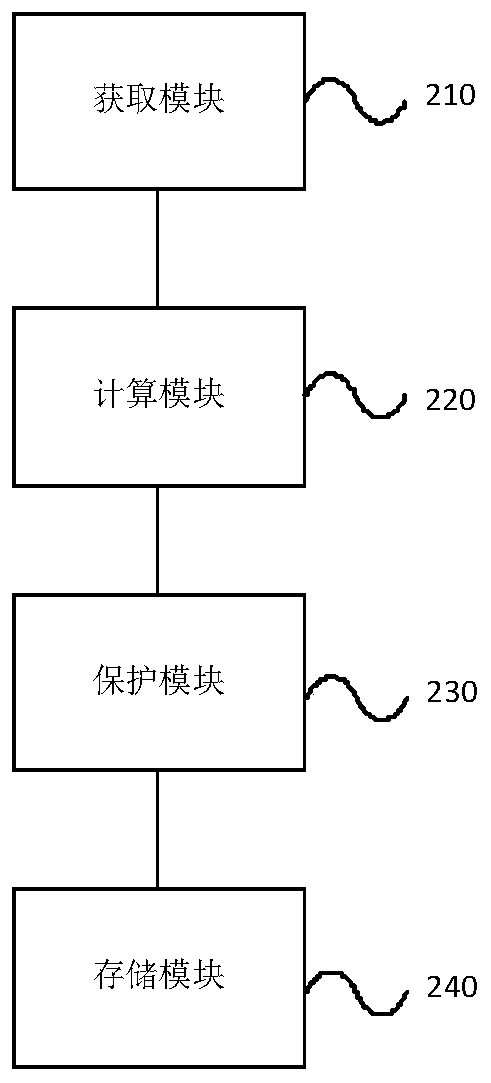

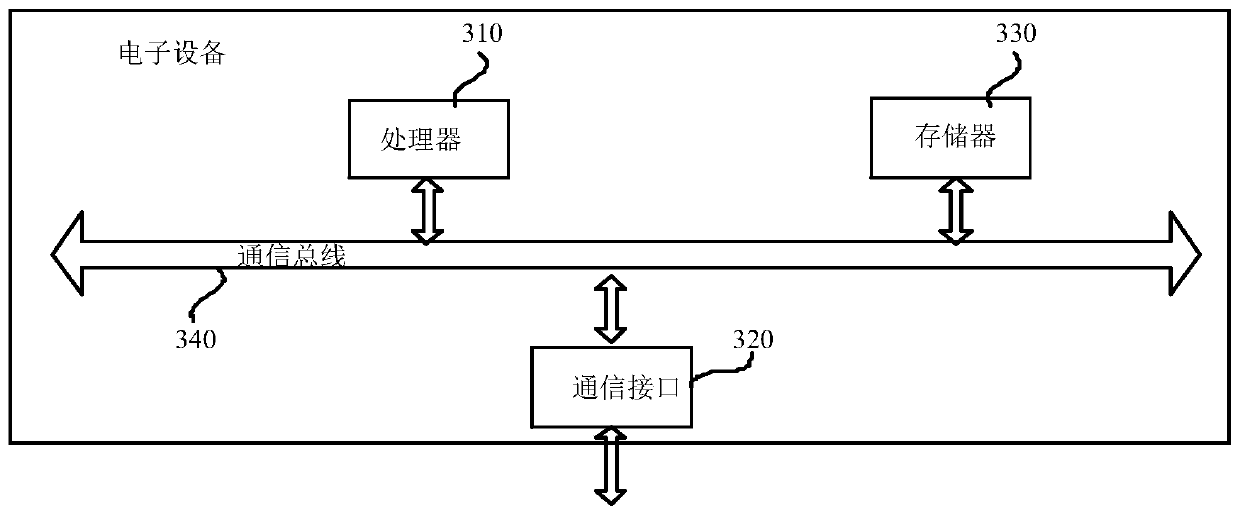

ActiveCN110110551AAchieve effective useWays to avoid uniform protectionDigital data information retrievalDigital data protectionKey generationComputer security

The embodiment of the invention provides a data storage method and device. The method comprises: acquiring data attribute information and service certificate information; generating a data protectionlabel according to the data attribute information and the service certificate information; determining a data protection mode and / or a key generation mode according to the data protection label; protecting the stored data according to the data protection mode and the key generation mode to generate protection data; and storing the protection data according to the storage address information. Through determining the data protection label, protection key generation and data protection mode determination are carried out according to different security requirements. And a safer and more complex protection mode is provided for the client with higher safety requirements, and a simpler protection mode is provided for the client with lower safety requirements, so that a unified protection mode isprevented from being adopted for all user data, and effective utilization of storage system resources is realized.

Owner:中共中央办公厅电子科技学院

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com