Method of using tin-and-iron-containing stone sawing mud with high efficient

A stone and high-efficiency technology, applied in the field of stone sawing mud resource recycling, can solve the problems of low whiteness of ceramic raw materials and no comprehensive recycling process, and achieve the effects of protecting the environment, reducing waste and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

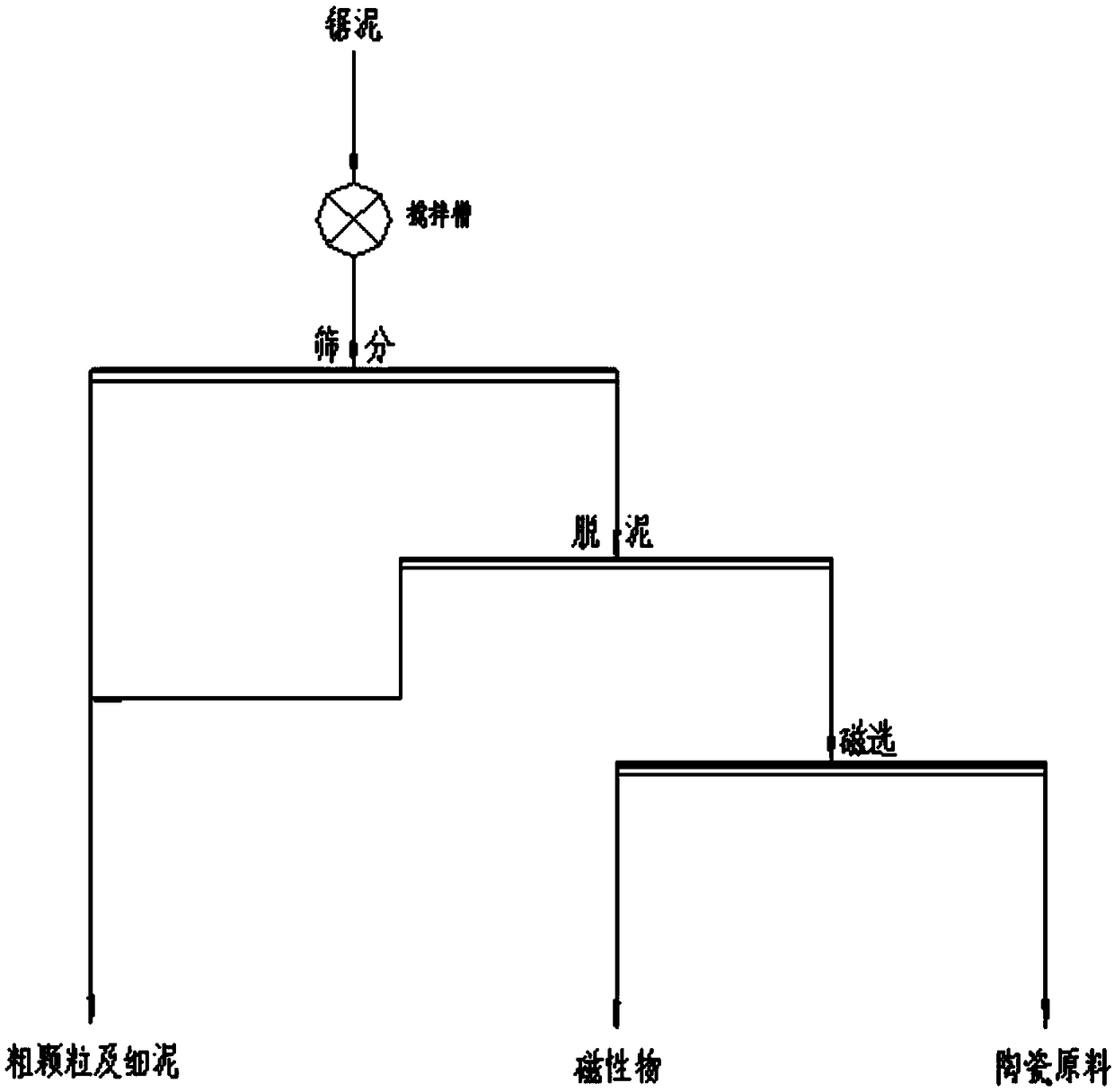

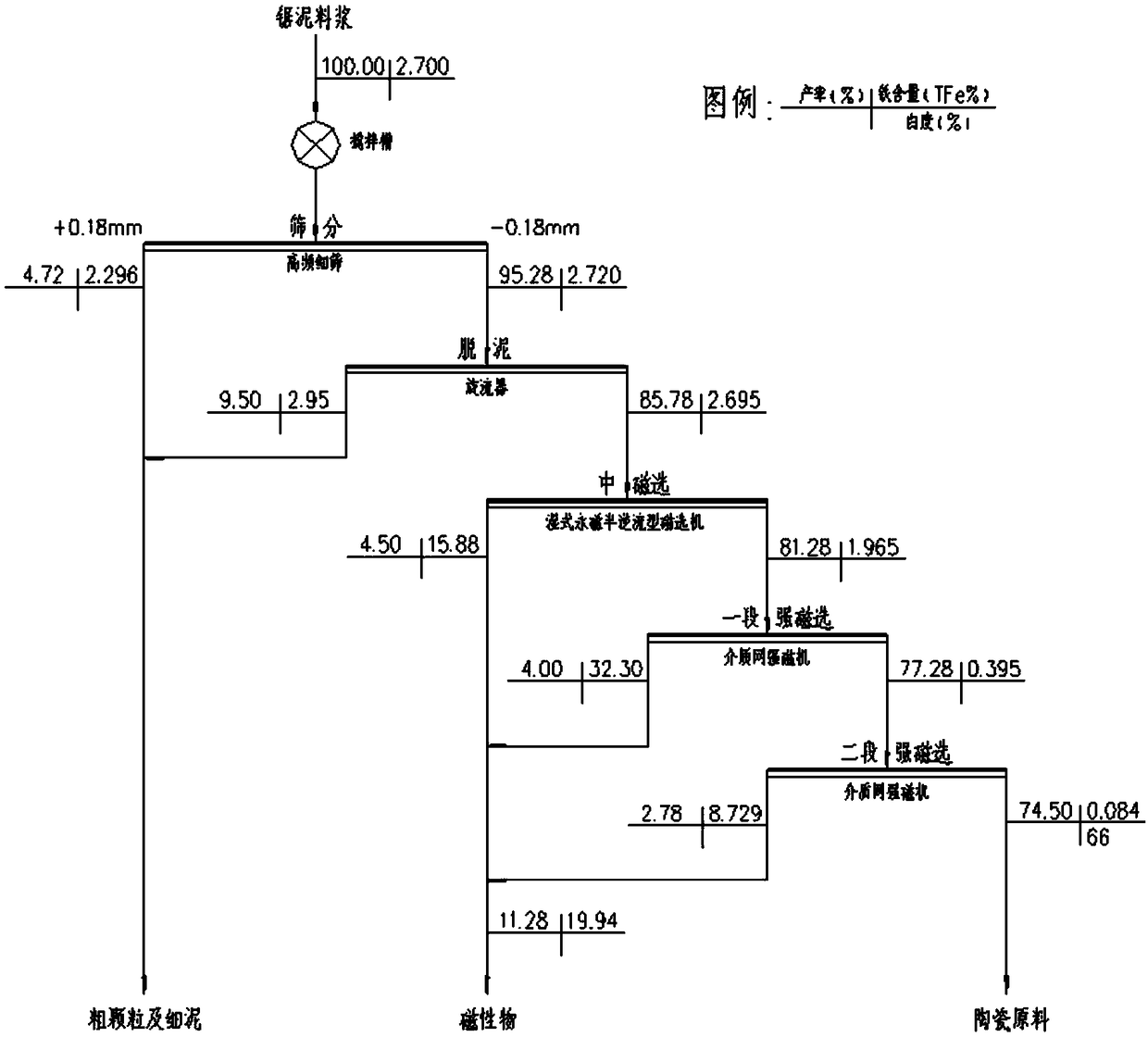

[0073] Such as figure 1 As shown, a method for efficient utilization of stone sawing mud, the method comprises the following steps:

[0074] 1) Screening: Stir 60kg of stone sawing mud slurry containing tin and iron evenly, and then use the grading particle size (cut-off size) as S 分 The sieve is sieved to obtain the sieved coarse particles (P0) and the sieved fine particles (P1) under the sieve, where S 分 is 0.18mm (i.e. cut-off size); wherein: the particle size of the sieved coarse particles is greater than 0.18mm, and the particle size of the sieved fine particles (P1) is less than or equal to 0.18mm;

[0075] 2) Desliming: The sieved fine particles (P1) obtained in step 1) are deslimed using a cyclone to obtain fine mud and sieved fine particles (P2) after desliming; wherein: cyclone sorting The lower limit of particle size is +0.005mm. The particle size of the screened fine particles (P2) after desliming is greater than 0.005mm, and the particle size of the fine mud is...

Embodiment 2

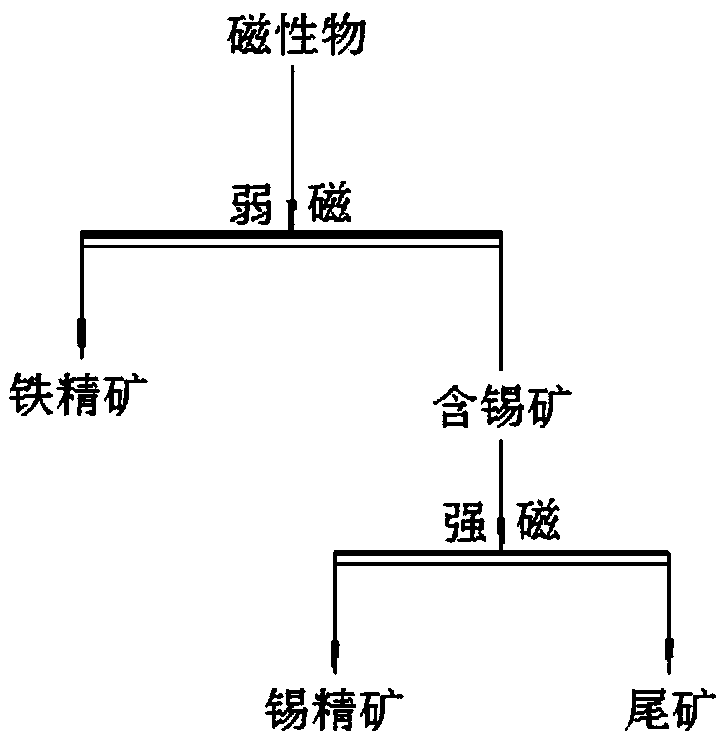

[0079] Repeat embodiment 1, just this method further comprises:

[0080] 4) Iron concentrate recovery: the magnetic material (W) obtained in step 3) is subjected to a weak magnetic concentration to obtain iron concentrate (W1) and remaining iron tailings respectively;

[0081] 5) Tin concentrate recovery: the iron-selected tailings obtained in step 4) are subjected to a strong magnetic separation to obtain primary tin concentrate and strong magnetic separation tailings, and then the primary tin concentrate is subjected to a shaker concentration to obtain Tin concentrate (W2) and gravity separation tailings.

Embodiment 3

[0083] Repeat embodiment 2, just step 3) strong magnetic sweeping comprises a strong magnetic sweep and secondary strong magnetic sweep, wherein a strong magnetic sweep obtains a strong magnetic sweep concentrate (i.e. magnetic material) and The remaining primary tailings materials are then subjected to secondary strong magnetic scavenging to obtain secondary strong magnetic scavenging concentrates (that is, magnetic materials) and remaining fine materials.

[0084] Among them: the wet permanent magnet semi-countercurrent magnetic separator is used for the medium magnetic rough separation, and the surface magnetic induction of the wet permanent magnet semi-countercurrent magnetic separator is 1.0T. The strong magnetic scanning adopts the medium net strong magnetic machine, and the surface magnetic induction of the medium net strong magnetic machine is 3.2T.

[0085] The whiteness of the obtained ceramic raw material can reach 65% by processing the stone material sawing mud thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com