Patents

Literature

156results about How to "High aroma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting heavy liquefaction oil and intermediate-phase bitumen matter from coal liquefaction residuals and application thereof

ActiveCN101885976ARealize rationalityRealization of high value-added utilizationThermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by selective extractionEvaporationOil water

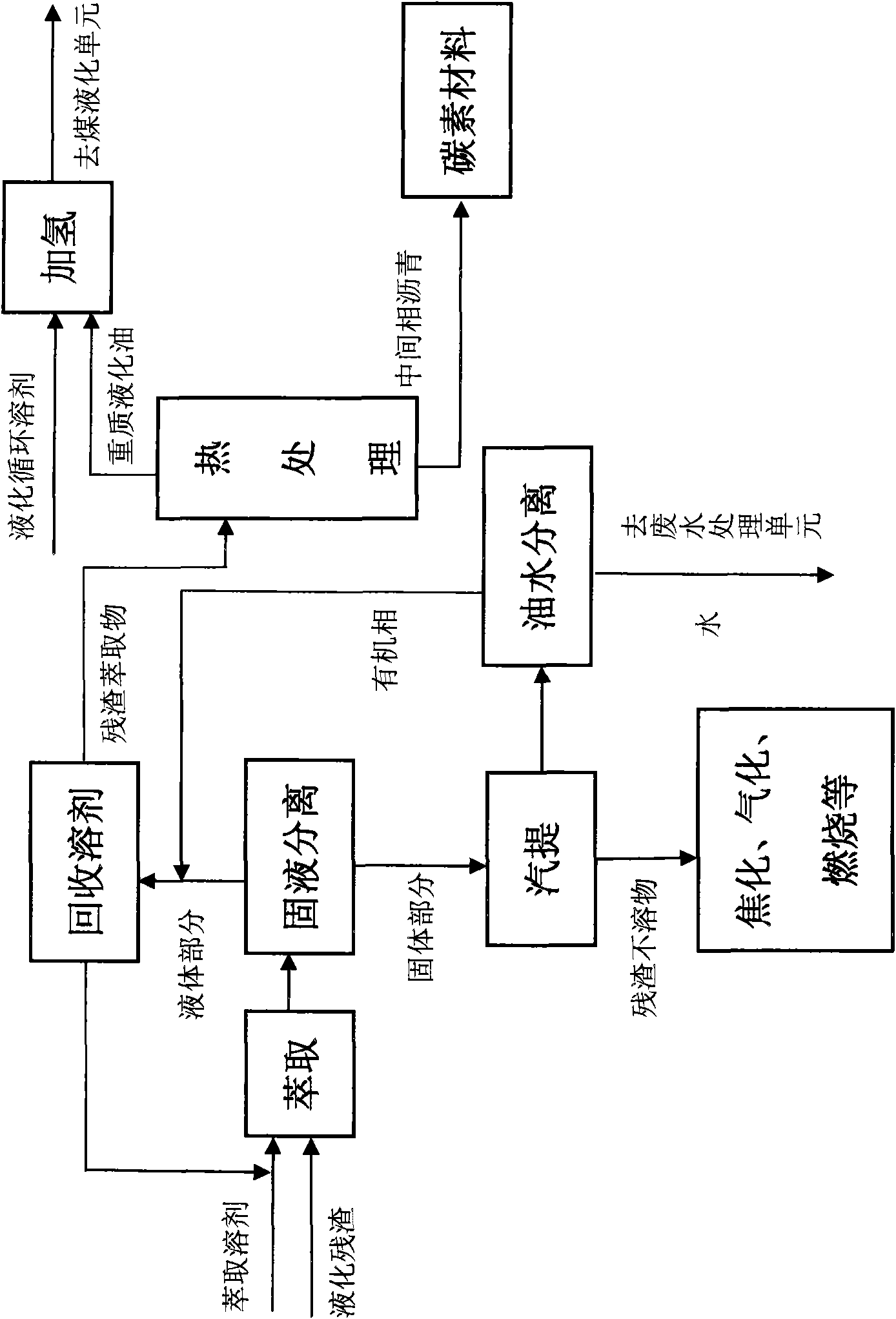

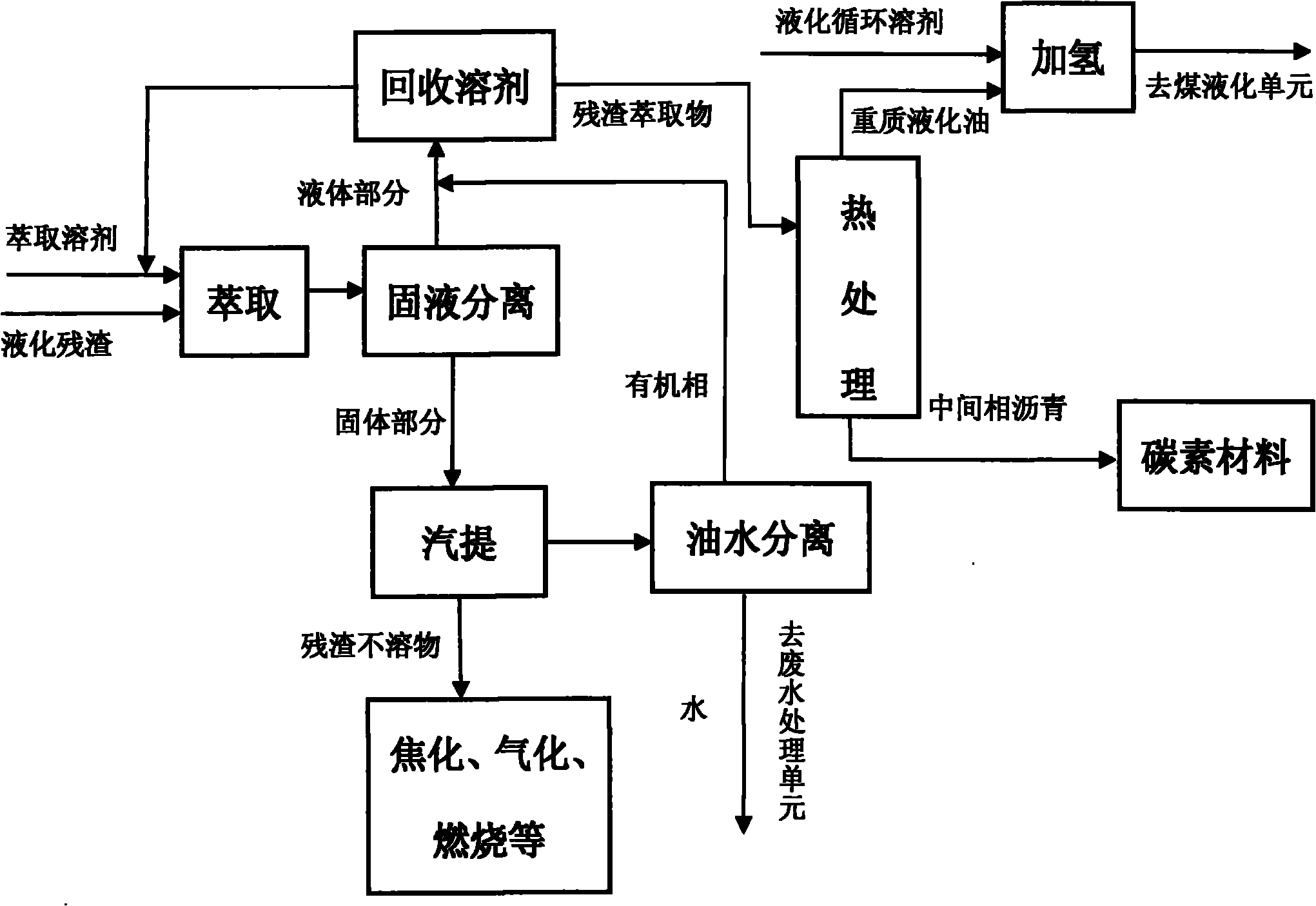

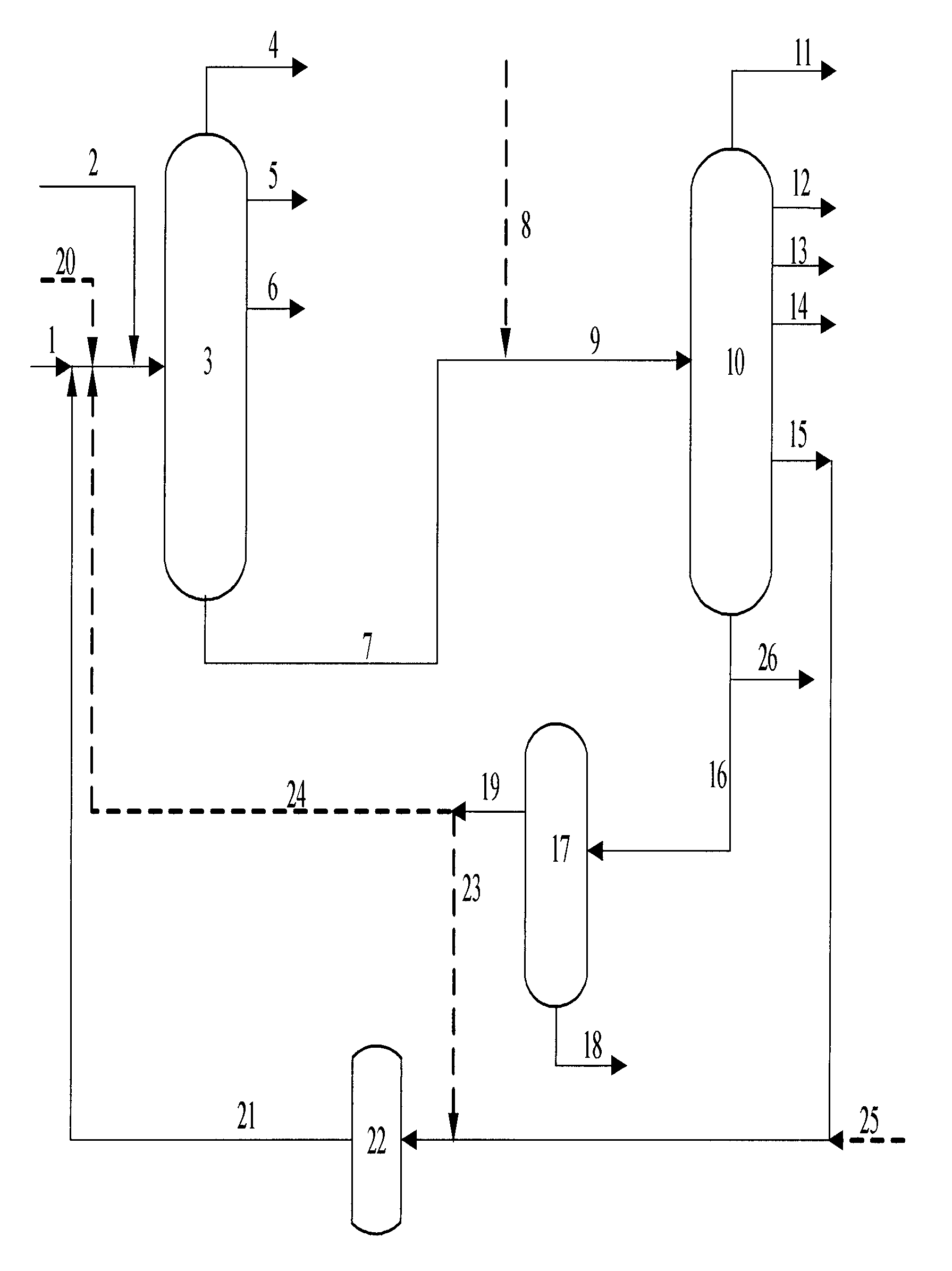

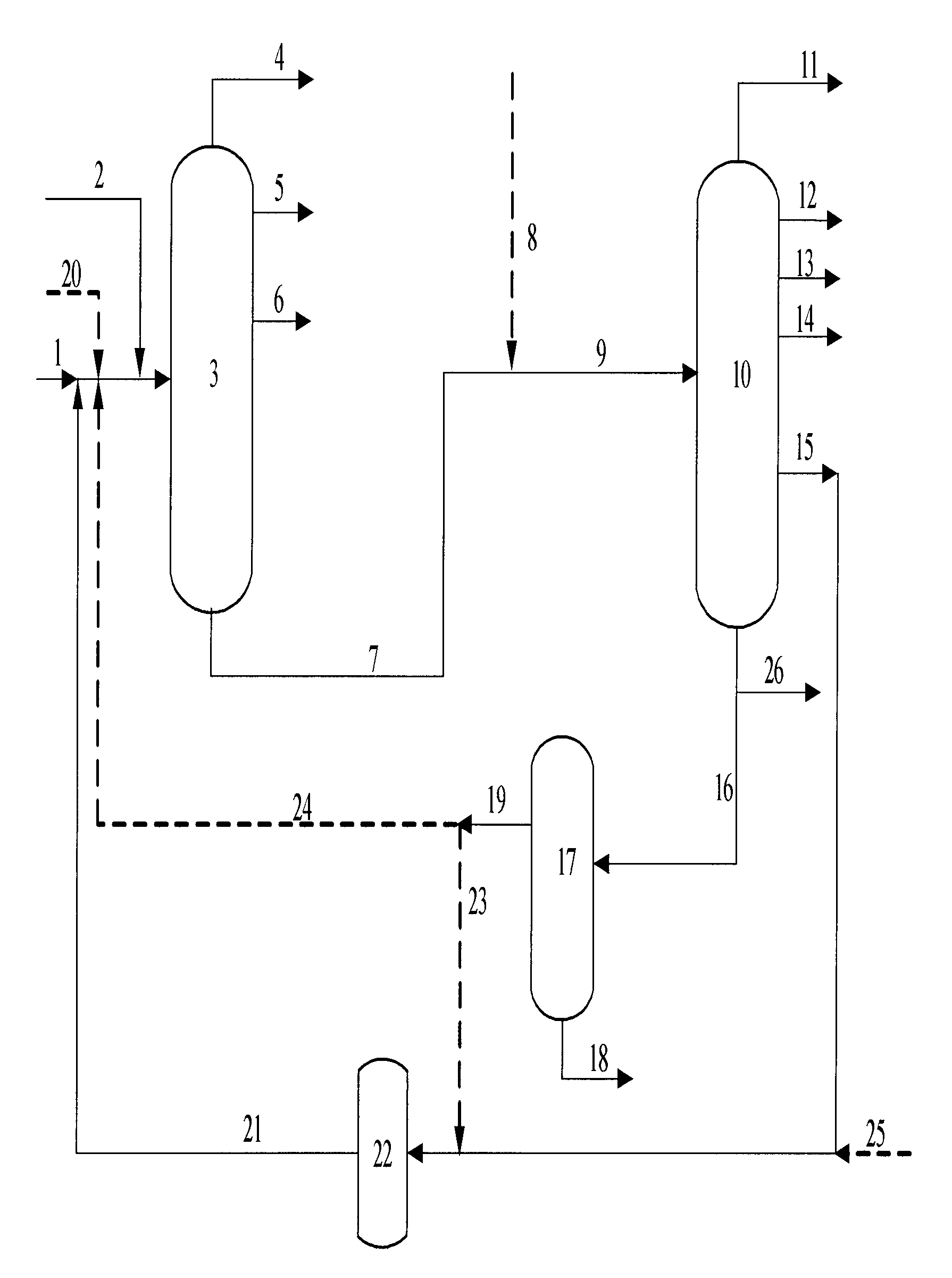

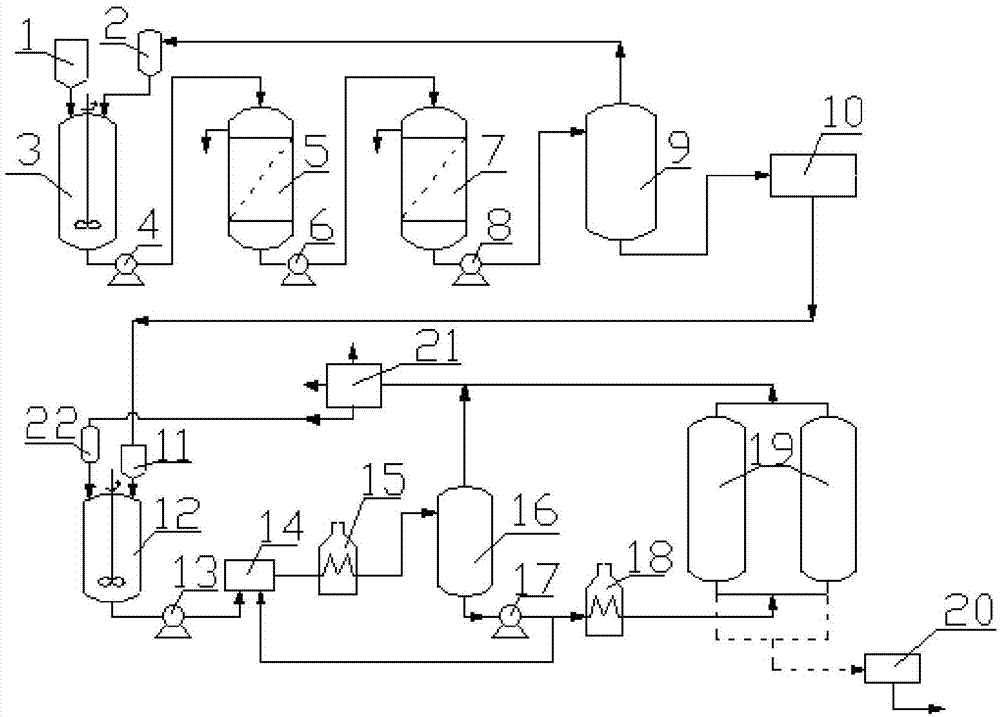

The invention provides a method for extracting heavy liquefaction oil and an intermediate-phase bitumen matter from coal liquefaction residuals and application thereof. The method comprises the following steps of: adding coal liquefaction residual powder and an extraction solvent to a stirring kettle together for extraction to obtain extraction liquid and extraction residues; carrying out solid-liquid separation on the obtained extraction liquid and extraction residues; carrying out steam stripping on the obtained extraction residues, and recovering an organic phase after oil-water separation; mixing the extraction liquid with the organic phase, and then delivering into a solvent recovery unit; recovering the extraction solvent for recycling use or being returned to a liquefaction productprocessing unit by using a distillation method and / or an evaporation method, wherein residuals obtained after the extraction solvent is recovered are liquefaction residual extractives; delivering theobtained liquefaction residual extractives into a heat treatment unit, and separating the heavy liquefaction oil from the intermediate-phase bitumen matter by using a heating dry distillation method;and adding the obtained heavy liquefaction oil and other recycling solvents in a direct liquefaction process to a coal liquefaction solvent hydrogenation unit together.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Extraction method of direct coal liquefaction residues and application of extracts

ActiveCN101962561AMake full use ofSimple processWorking-up pitch/asphalt/bitumen by selective extractionLiquid hydrocarbon mixture productionSolventThermal treatment

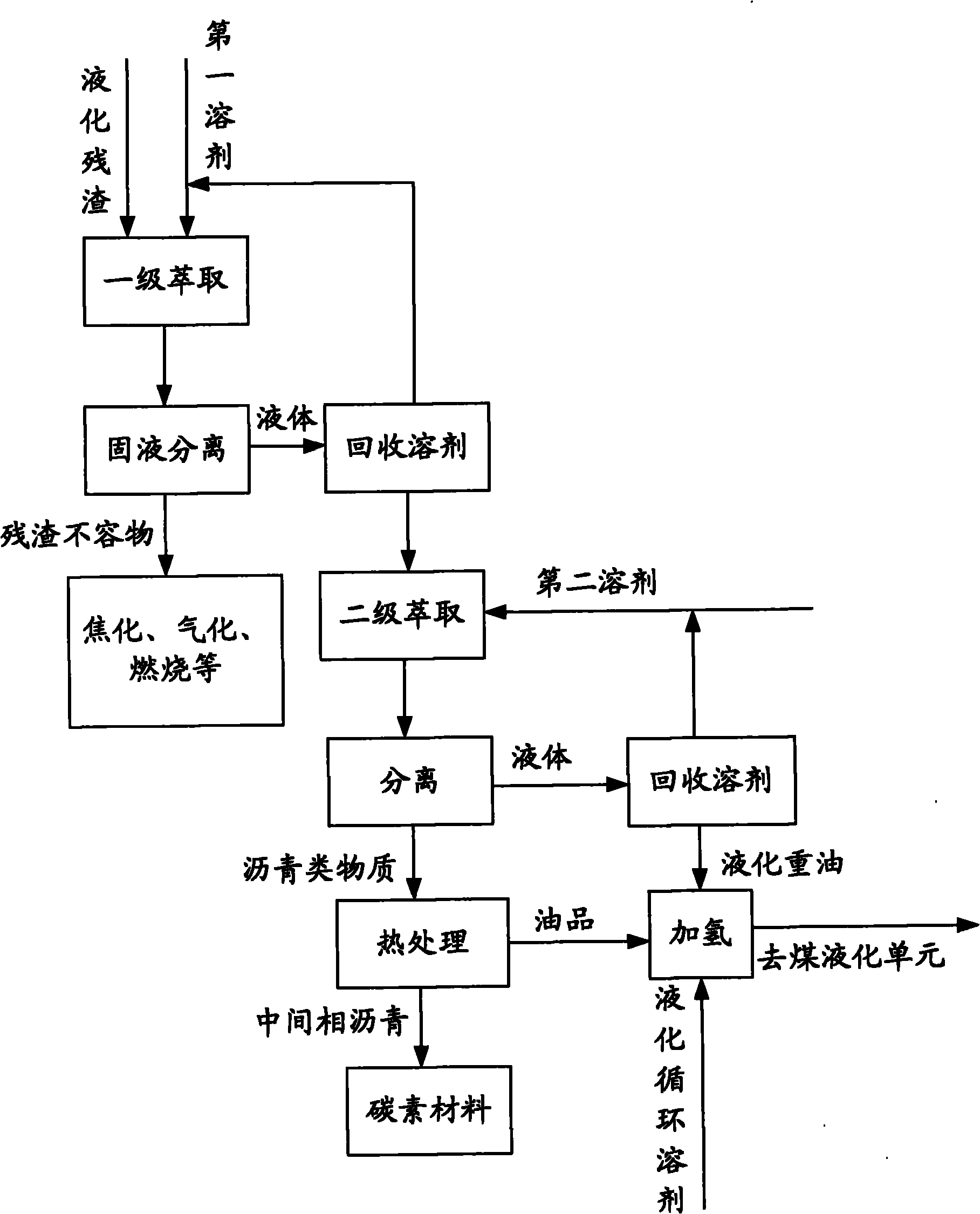

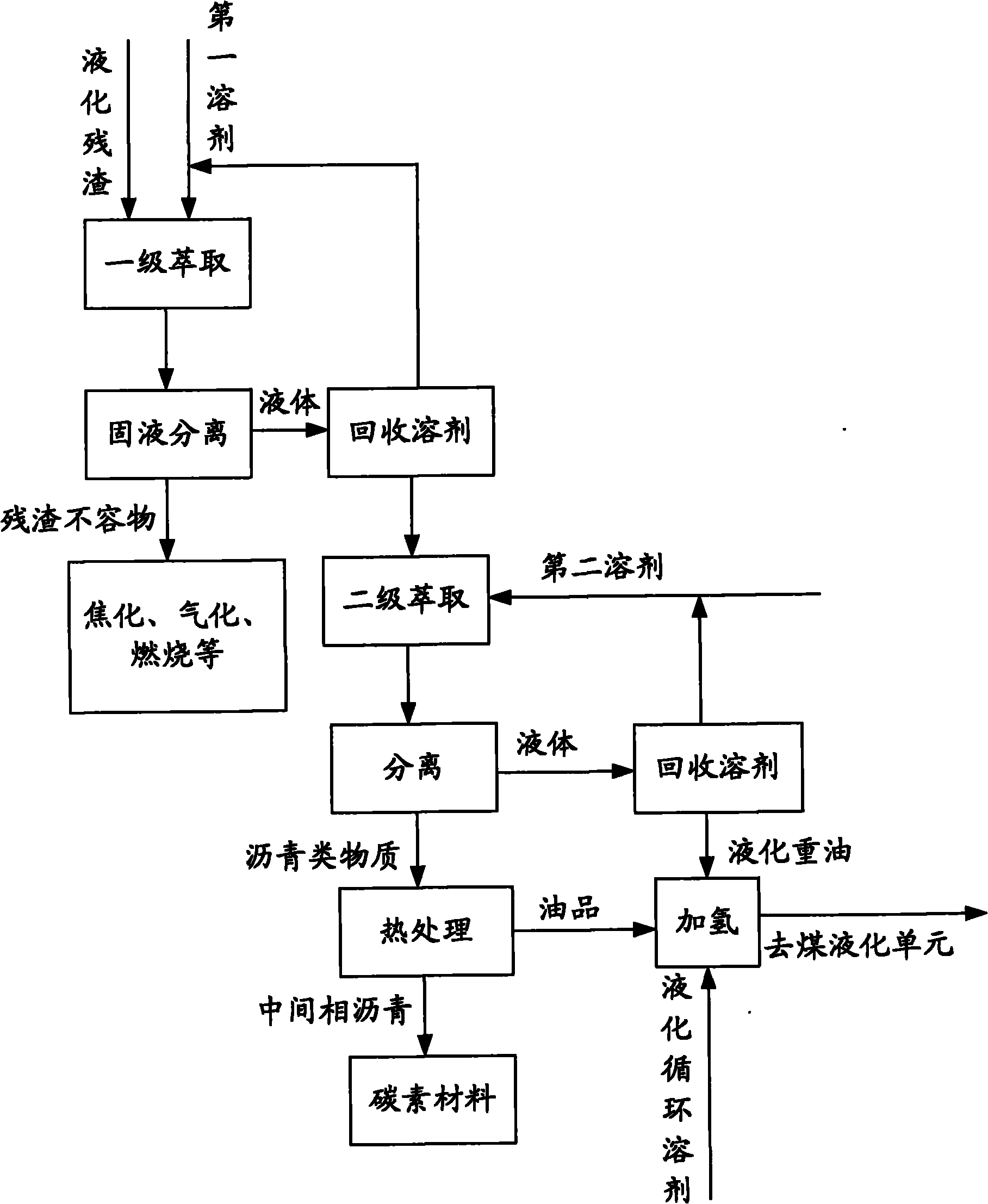

The invention relates to an extraction method of direct coal liquefaction residues and application of extracts. The extraction method comprises the following steps: a) adding coal liquefaction residue powder and a first extraction solvent to a stirred tank to undergo primary extraction; b) carrying out solid-liquid separation on the extracted mixture obtained in the step a) and recovering the first extraction solvent from the obtained liquid in a solvent recovery unit and recycling the first extraction solvent; c) obtaining extracts after recovering the first solvent and mixing the extracts with a second extraction solvent to undergo secondary extraction; d) carrying out solid-liquid separation on the extracted mixture obtained in the step c), obtaining heavy liquefied oil after recovering the second extraction solvent from the obtained liquid in the solvent recovery unit and then carrying out moderate hydrogenation on the heavy liquefied oil and other recycled solvents in a coal liquefaction solvent hydrogenation unit and using the product as the recycled solvent in the coal liquefaction process; and e) carrying out heat treatment on the asphaltic substances obtained in the step d) by heating and carbonizing to obtain mesophase asphalt and oils.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Combined process for hydrotreating and catalytic cracking of residue

ActiveUS8529753B2Improve efficiencyLow costThermal non-catalytic crackingCatalytic crackingSlurryImpurity

Owner:CHINA PETROCHEMICAL CORP +1

Intermediate phase asphalt and preparation method thereof

InactiveCN103194254AHas a streamlined structureHigh aromaWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansResource utilizationDistillation

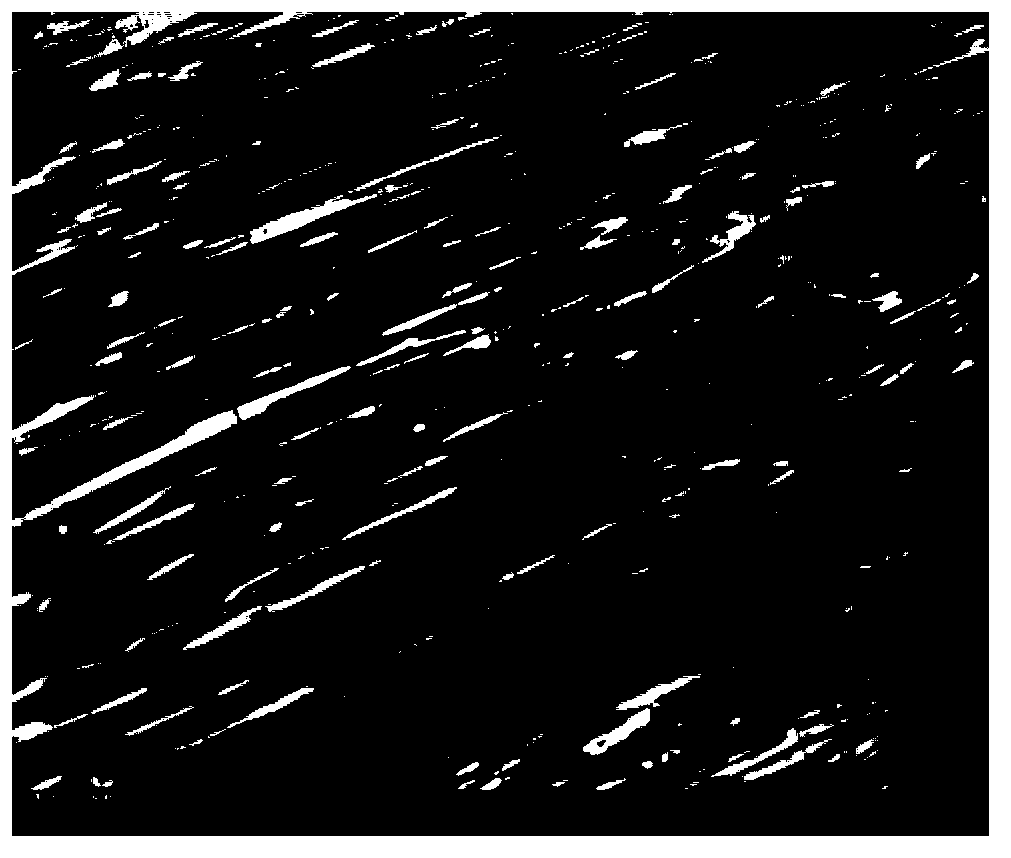

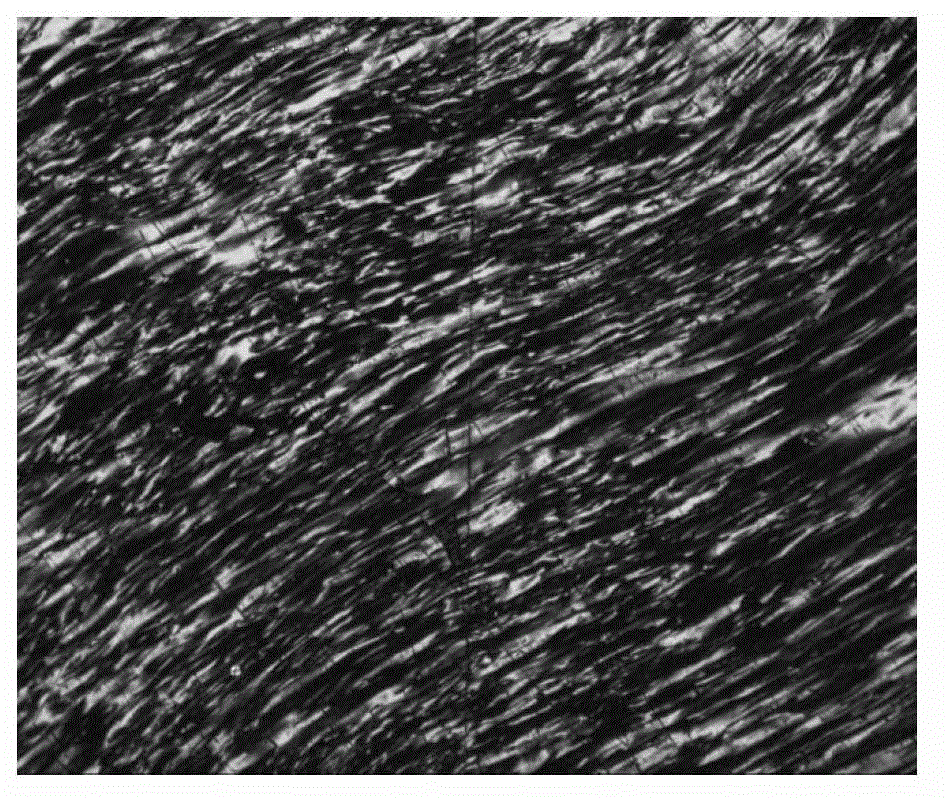

The invention provides intermediate phase asphalt and a preparation method thereof. The preparation method comprises the following steps that A, mixing coal liquefaction residuals with an extraction solvent, stirring, extracting, and carrying out centrifugal separation to form an extraction liquid; B, carrying out atmospheric or reduced pressure distillation on the extraction liquid to form an extraction refined substance; and C, carrying out a polymerization reaction on the extraction refined substance at constant 400-450 DEG C and at constant 0.1-3.0MPa in an inert gas atmosphere for 5-16 hours to form the intermediate phase asphalt. According to the preparation method, under the condition that no catalyst is added, the intermediate phase asphalt in a good streamline structure is prepared, and serves as a carbon precursor for further preparing various carbon materials; the flow of a whole technical process is relatively simple; operation is convenient and safe; utilization potential of asphalt substances in the coal liquefaction residuals is fully exerted; the application field of the coal liquefaction residuals is expanded; and the resource utilization ratio is increased.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Mesophase pitch and preparation method thereof

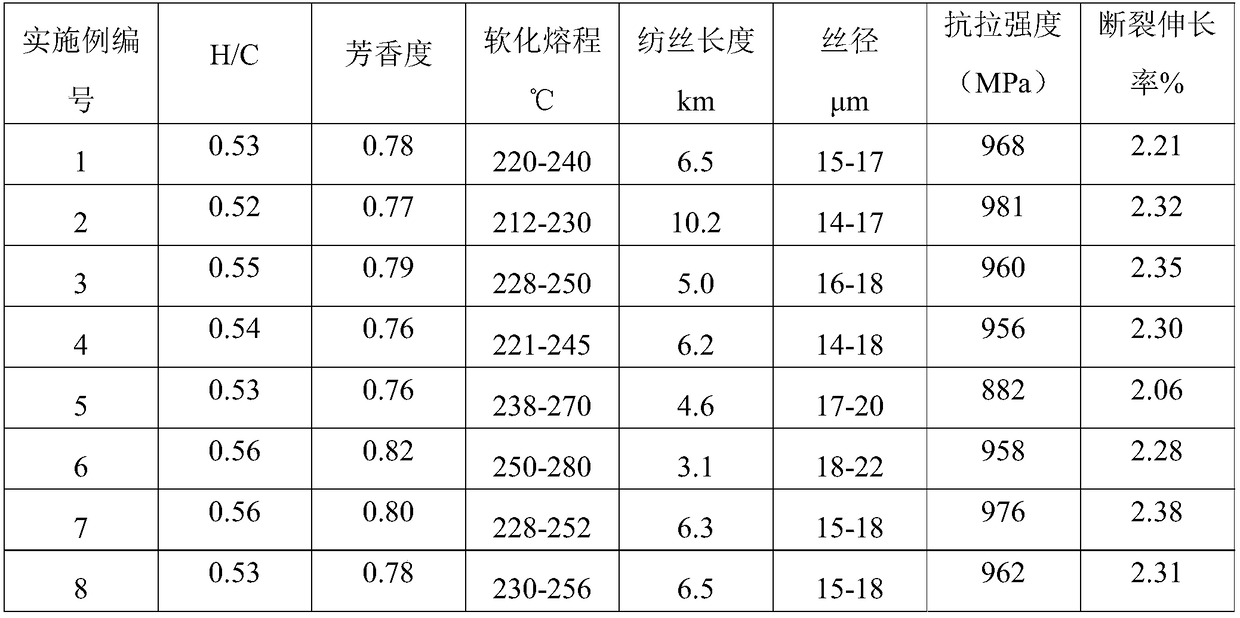

ActiveCN104004536AHigh carbon contentModerate carbon-hydrogen ratioWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionOrganic solventSolvent

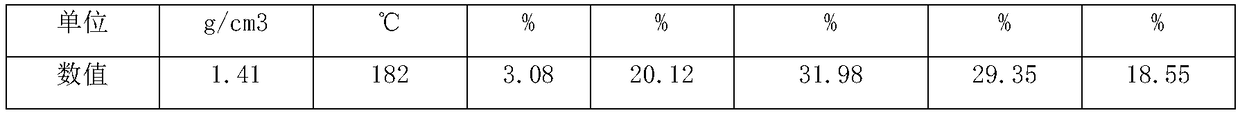

The invention provides a method for preparing mesophase pitch from direct coal liquefaction residues. The method mainly comprises the following steps: 1, extracting the direct coal liquefaction residues by using an organic solvent I to obtain extracted pitch; 2, dissolving the extracted pitch by using a polar organic solvent II, and carrying out solvent recovery on the soluble part to obtain refined pitch; 3, carrying out thermal polycondensation on the obtained refined pitch at a high temperature to obtain a thermal polycondensation product; and 4, carrying out reduced pressure flash evaporation on the thermal polycondensation product to obtain the mesophase pitch. The invention also provides the mesophase pitch. The spinnable indexes of the mesophase pitch are characterized in that the softening point, the aromatic carbon rate and the quinoline insoluble substance content of the mesophase pitch are 250-280DEG C, not lower than 0.9 and 35-45% respectively.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

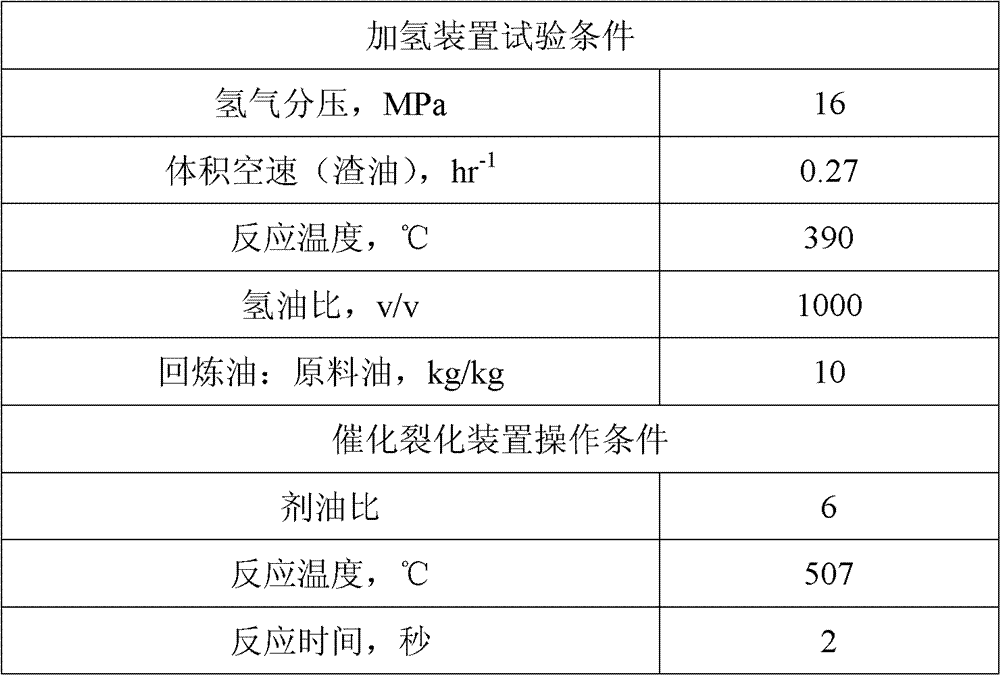

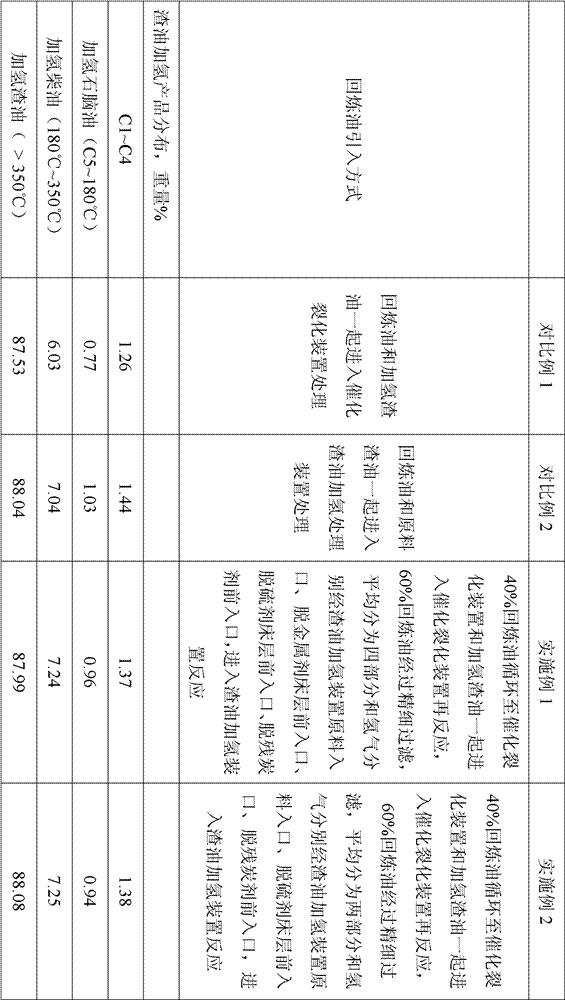

Improved integrated process for hydrogenation and catalytic cracking of hydrocarbon oil

ActiveUS20110062054A1Improve conversion depthIncrease productionCatalytic crackingTreatment with plural parallel cracking stages onlyQuantum gasNatural gas

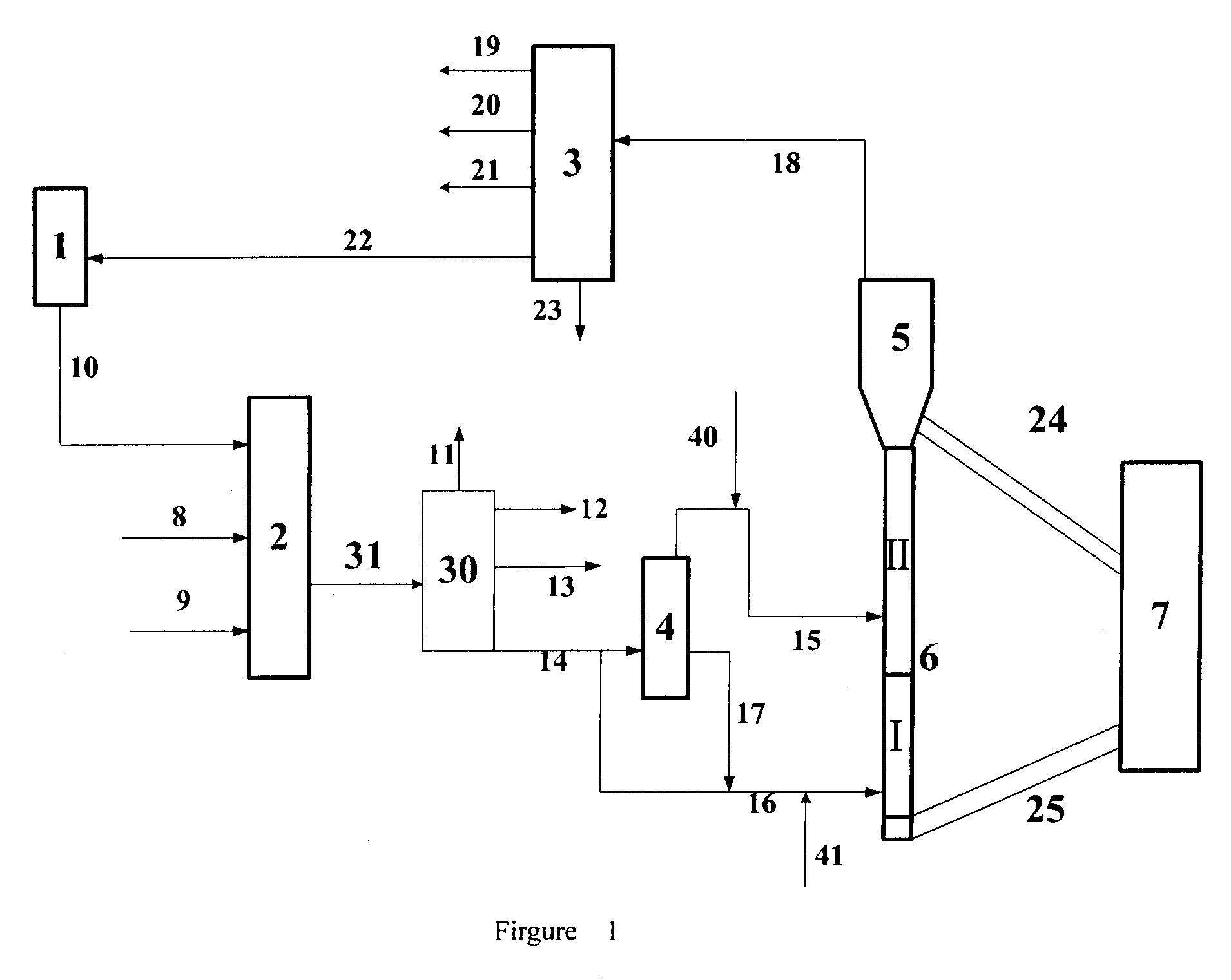

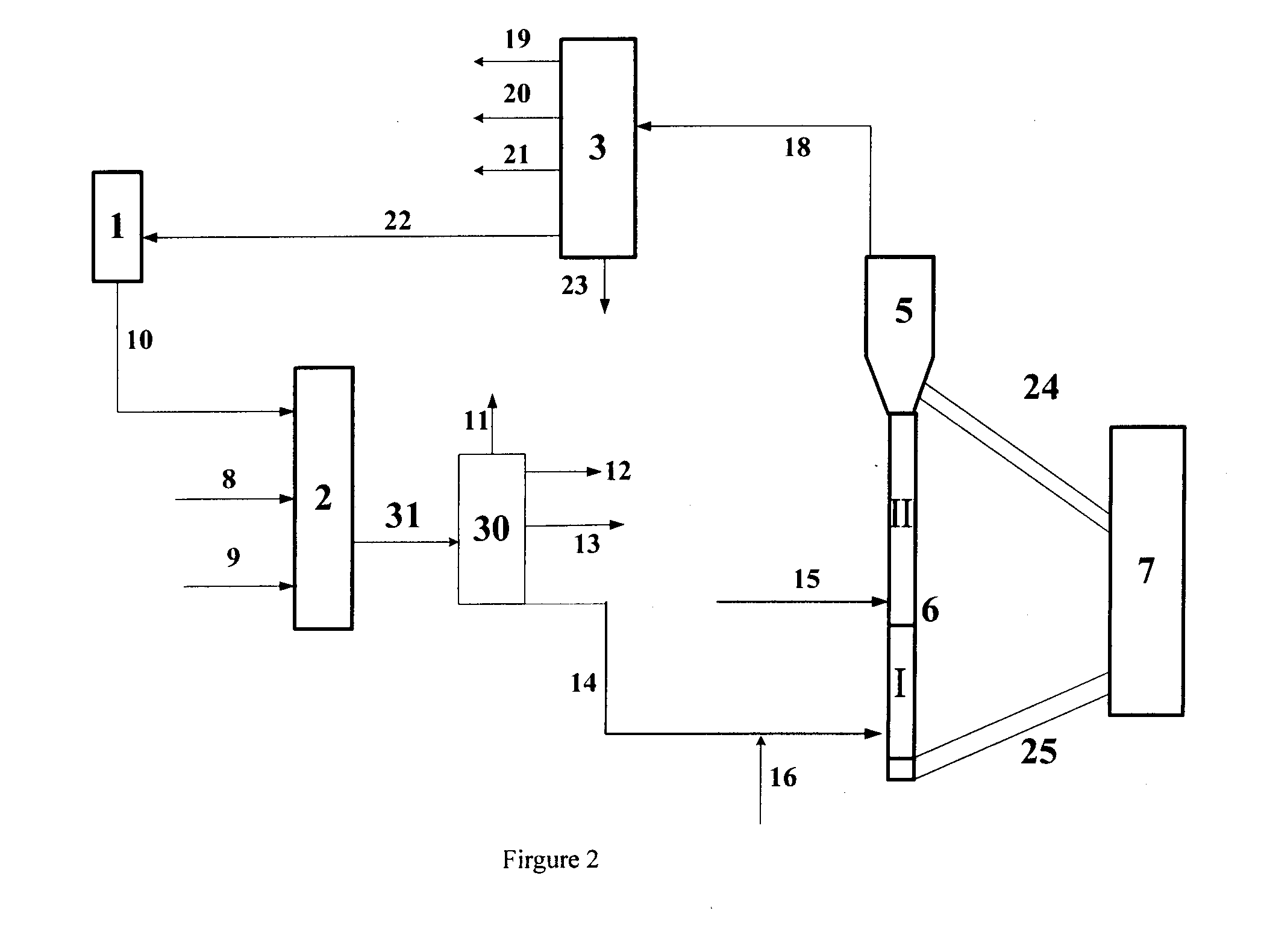

Disclosed is a combination process for improved hydrotreating and catalytic cracking of hydrocarbon oils, including: contacting residual oil, catalytic cracking cycle oil, and optional distillate oil with a hydrotreating catalyst under hydrotreating conditions in the presence of hydrogen followed by separation of the reaction products to obtain gas, hydrogenated naphtha, hydrogenated diesel oil, and hydrogenated tail oil; contacting the hydrogenated tail oil and optional normal catalytic cracking feedstock oil with a cracking catalyst under catalytic cracking conditions followed by separation of the reaction products to obtain dry gas, hydrogenated naphtha, liquefied petroleum gas, catalytic cracked gasoline, catalytic cracked diesel oil, and catalytic cracking cycle oil; wherein the hydrogenated tail oil and / or normal catalytic cracking feedstock oil are separated into at least two fractions, the light and the heavy fractions or normal catalytic cracking heavy feedstock oil and normal catalytic cracking light feedstock oil, prior to contacting the hydrogenated tail oil and / or normal catalytic cracking feedstock oil with the cracking catalyst. The process according to the present invention is especially suitable for conversion of hydrocarbon oils to produce more products of gasoline or diesel oil.

Owner:CHINA PETROCHEMICAL CORP +1

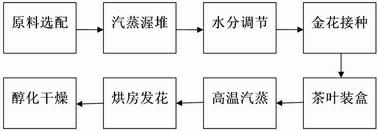

Improved manufacture process of golden flower loose tea

ActiveCN102640815ALow skill level requiredSimple production processPre-extraction tea treatmentOperational costsEngineering

The invention relates to an improved manufacture process of golden flower loose tea. The method comprises the following processing steps of raw material selection and matching, steam steaming pile fermentation, moisture regulation, golden flower inoculation, tea boxing, high temperature steam steaming, baking room flowering and alcoholization and drying. The manufacture process breaks through thelimitation that the industrialized production cannot be realized in the existing loose tea flowering technology. The manufacture process has the advantages that the production process flow process issimple, the operation is convenient, the technical level requirement on workers is not high, the operation cost is low, the production period is short, and the like. Compared with other loose tea products, the golden flower loose tea produced by using the improved manufacture process has the advantages that the growth of eurotium cristatum is more uniform and stronger, and the golden flower particles are greater.

Owner:XIANYANG JINGWEI EIGHT TEA CO LTD

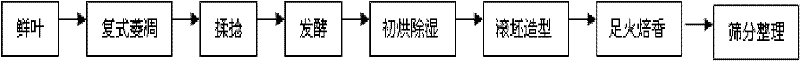

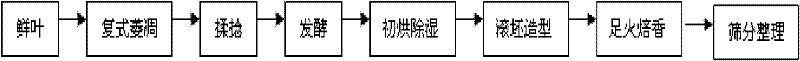

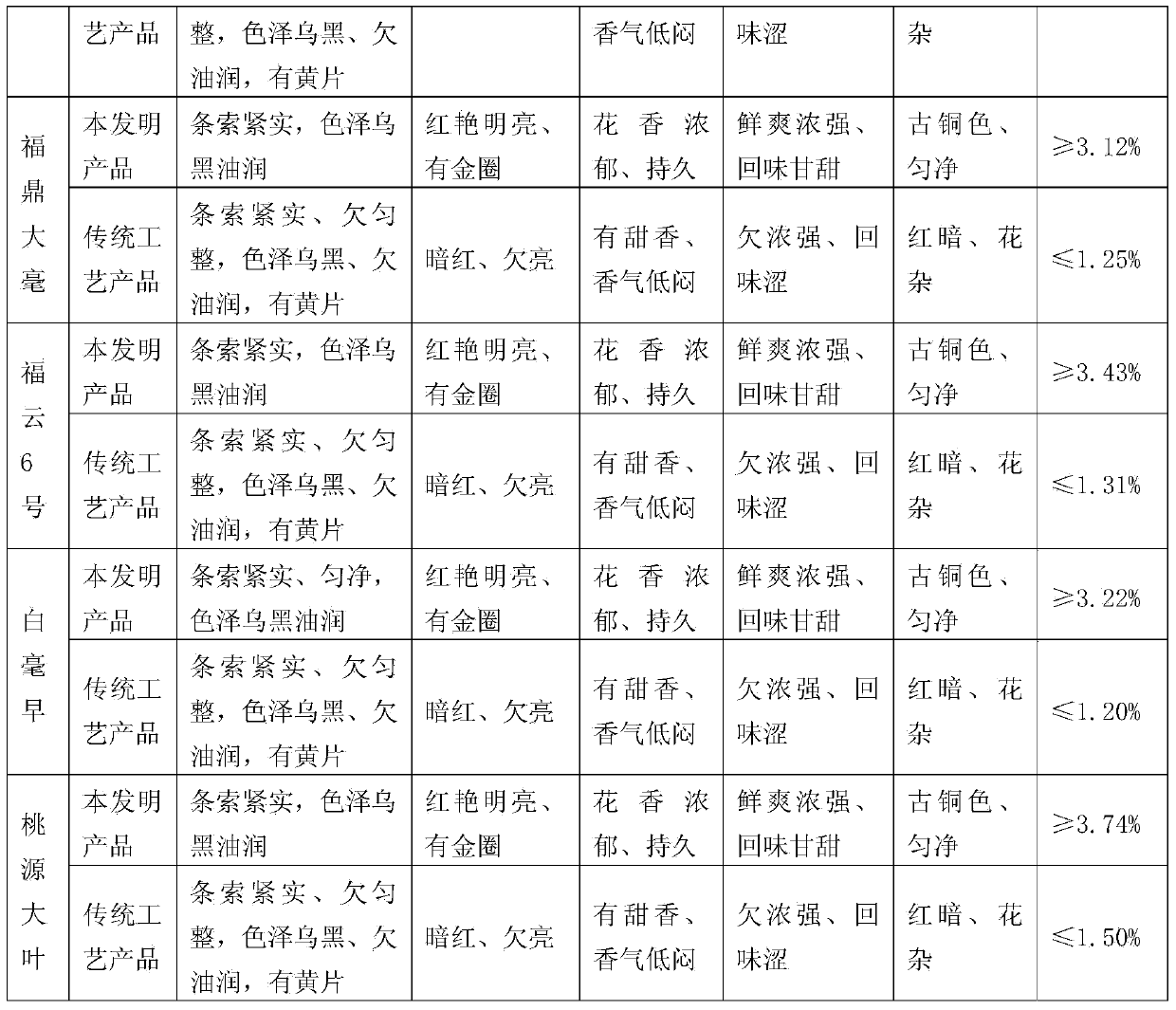

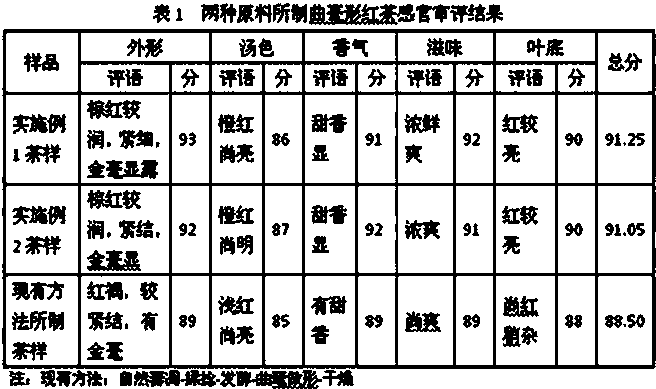

Method for processing high-fragrance curly black tea

InactiveCN102511572ARapid termination of enzyme activityOvercome the defect of not being brightPre-extraction tea treatmentBlack teaHot Temperature

The invention discloses a method for processing high-fragrance curly black tea. The method comprises the following steps of: selecting a fresh one-bud two-leaf raw material of black tea, sequentially performing composite withering, twisting, fermenting, primary drying for dehumidifying, rolling, shaping, baking for getting fragrance over complete fire, screening, finishing, and thus obtaining thehigh-fragrance curly black tea. By adopting composite withering, high-temperature quick drying for dehumidifying and low-temperature slow baking treatment over the complete fire, the fragrance of theblack tea is remarkably improved, and the finished tea is compact and curly as snails and has black, bright and gold color; by sensory change of water losing weight parameter and leaf phase of the tea blank of each processing stage, the processing procedure of the black tea is controlled; and the method is easy and convenient to operate and easy to master, and is a black tea processing method convenient to popularize and apply.

Owner:TEA RES INST ANHUI ACAD OF AGRI SCI

Preparation method of polycondensed asphalt, preparation method of needle coke and needle coke

ActiveCN103614153AHigh aromaHigh carbon contentWorking-up pitch/asphalt/bitumenCoking carbonaceous materialsHigh carbonQuinoline

The invention provides a preparation method of polycondensed asphalt, a preparation method of needle coke and a needle coke. The preparation method of polycondensed asphalt comprises the following steps: S1. extracting asphalt in coal liquefication residues with an extraction solvent to obtain refined asphalt, wherein the extraction solvent is composed of one or more of 120-300 DEG C distillate segment coal liquefied oil, N-methylpyrrolidone, tetrahydrofuran, quinoline, pyridine and anthracene oil; and S2. carrying out polycondensation reaction on the refined asphalt to form the polycondensed asphalt. The refined asphalt is separated from the coal liquefication residues in an extraction mode, and such process can adopt the currently common extraction technique having high operability; the obtained refined asphalt is mainly composed of polycyclic condensed aromatics, has the characteristics of high aromaticity, high carbon content and high polymerization or crosslinking tendency, and is suitable to be used as a precursor of a polycondensed asphalt raw material for preparing needle coke; and the invention finds out a new application direction for coal liquefication residues.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Processing method of green tea

ActiveCN102960482APromote sustainable developmentImprove tree down ratePre-extraction tea treatmentGreen teasProcess engineering

The invention provides a processing method of green tea, which is used for solving the problem of bitter taste of a large amount of green tea produced in Sichuan province. The processing method of the green tea is characterized by comprising the following steps of: picking fresh leaf, tedding green leaves, deactivating enzymes, rolling, conducting first-step roasting, conducting secondary rolling, conducting deblocking, conducting second-step roasting, spreading and airing, roasting to be dry, spreading and airing, and drying and extracting flavor, wherein twice rolling processes are carried out by hot rubbing. According to the processing method of the green tea, the bitter taste of the large amount of the green tea produced in the Sichuan province can be effectively reduced, the quality of tea leaves can be improved, and the heavy, mellow, fresh and brisk degrees can be increased; and the good foundation is established for expanding the tea markets of Sichuan and promoting the export of the tea in Sichuan.

Owner:YIBIN CHUANHONG TEA IND GRP

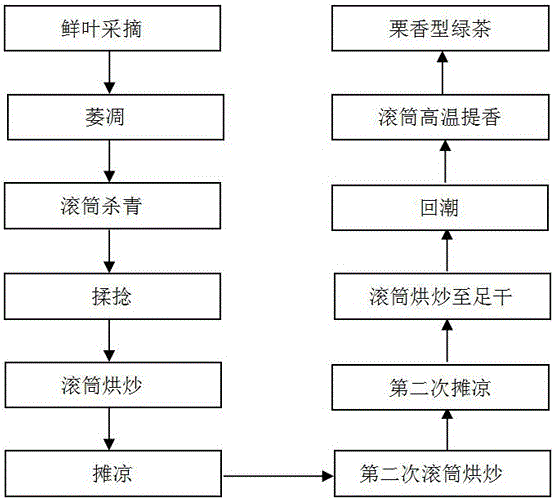

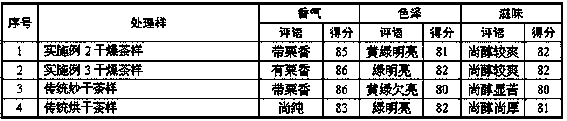

Simple process method of chestnut-flavor-type roasted green tea

ActiveCN106172905AImprove qualityBright yellow-green soupPre-extraction tea treatmentFlavorGreen tea

The invention belongs to the field of tea leaf processing and particularly relates to a simple process method of chestnut-flavor-type roasted green tea. The method employs fresh leaves of six tea varieties including Long Jing 43, Wuniu early tea, Mei Zhan, Fuding Dahao and Fuyun 6. The method includes the steps of: picking fresh leaves, withering the leaves, performing de-enzyme, rolling the tea leaves, dry-frying the tea leaves in a cylinder, spreading the tea leaves, dry-frying the tea leaves in the cylinder again, spreading the tea leaves again, completely drying the tea, performing moisture regaining, performing fragrance enhancing to the tea leaves in a cylinder, and packaging the tea. The tea processing devices in the method are simple and are easy to operate. The method is low in cost. The chestnut-flavor-type roasted green tea has the following characters: dry tea is fine, tight and slightly-twisted, has a grey-green color with white fur, and has a significant chestnut flavor by smelling the tea while dry; when being brewed, the tea has a yellow and green color and is clear, has a strong fragrance and significant chestnut flavor and is refreshing and has a slight sweet taste; the tea is refreshing and has an sweet after taste. The tea residue has a deep-green and bright color and is uniform. The tea has durable taste when being brewed. The tea has excellent comprehensive quality and excellent economic beneifit.

Owner:福建省香入林茶业有限公司

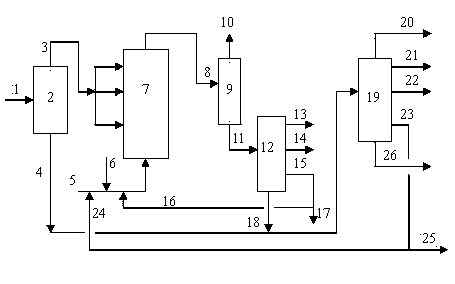

Combined process of hydrotreating and catalytic cracking of hydrocarbon oils

ActiveUS20130062250A1Big ratioIncrease productionCatalytic crackingTreatment with plural parallel cracking stages onlyHydrogenResidual oil

Disclosed is a combination process for improved hydrotreating and catalytic cracking of hydrocarbon oils, including: contacting residual oil, catalytic cracking cycle oil, and optional distillate oil with a hydrotreating catalyst under hydrotreating conditions in the presence of hydrogen followed by separation of the reaction products to obtain hydrogenated tail oil and other products; contacting the hydrogenated tail oil and optional normal catalytic cracking feedstock oil with a cracking catalyst under catalytic cracking conditions followed by separation of the reaction products; wherein the hydrogenated tail oil and / or normal catalytic cracking feedstock oil are separated into at least two fractions prior to contacting the hydrogenated tail oil and / or normal catalytic cracking feedstock oil with the cracking catalyst.

Owner:CHINA PETROCHEMICAL CORP +1

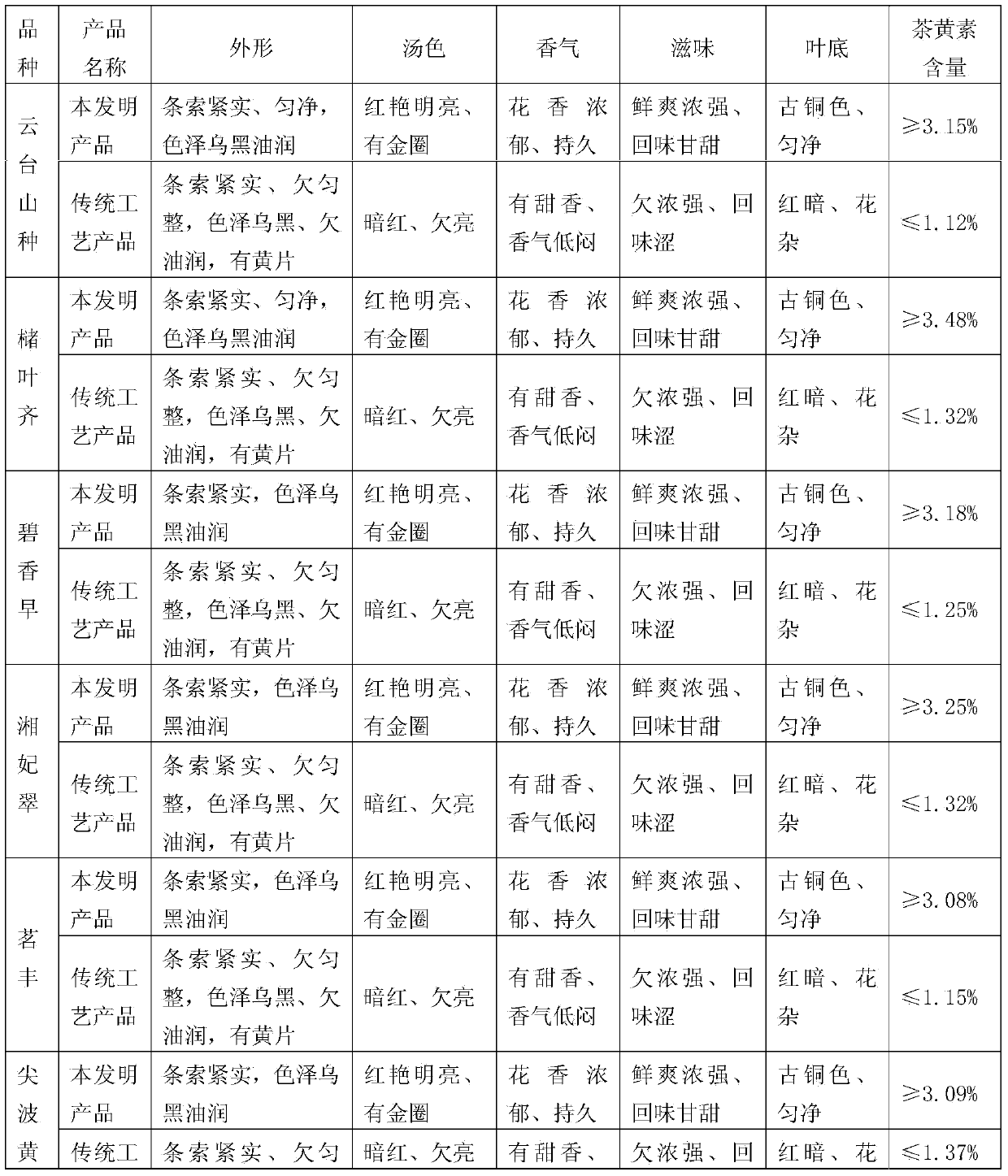

Processing method capable of improving quality of Hunan medium/small leaf Congou black tea

InactiveCN104186738AFully fermentedMellow tastePre-extraction tea treatmentTea flavoringBlack teaBud

The invention relates to a processing method capable of improving the quality of Hunan medium / small leaf Congou black tea. The processing method comprises the following steps: by adopting one of Yuntai Mountain tea, camellia sinensis, Zhuyeqi, Fuding large vellus, Baihaozao, Fuyun No.6, Bixiangzao, Xiangfucui, Mingfeng and Taoyuan large leaf tea which are widely planted in tea areas in Hunan, sequentially selecting tea leaves of one bud with two or three leaves or symmetric leaves with same tenderness, then performing ultraviolet irradiation, withering, making green, kneading, fermenting, drying, and enriching the fragrance on the selected leaves, wherein green making tea juice is respectively sprayed in the kneading and fermentation processes. By adopting the processing method, the defects that the leaves are not green, the taste is thin, the fragrance is poor, the color of tea soup is dark, the concentration intensity is poor, and the astringency is poor when a conventional fermentation process is adopted are overcome, the techniques of the process steps are all improved, the Congou black tea processed by using the processing method is uniform in fermentation, the leaf is bronze, the taste is mellow and fresh, the fragrance is heavy and long-lasting, the tea soup is red and right, and the astringency is high; the quality and the competitiveness of the Hunan medium / small leaf Congou black tea in the domestic and international black tea markets are remarkably improved.

Owner:HUNAN AGRICULTURAL UNIV

Method for producing fragrant and fruity persimmon leaf tea

The invention belongs to the field of comprehensive utilization of horticultural products and relates to a method for producing fragrant and fruity persimmon leaf tea. The method comprises the following steps: 1) picking the fresh tender emerald green leaves of the persimmon tree without diseases and insect pests; 2) placing the fresh leaves into a tea kneading and cutting machine to be kneaded and cut, and repeating kneading and cutting twice to prepare the leaves into grains, thus obtaining the kneaded and cut leaves; 3) placing the kneaded and cut leaves with thickness of 15-20cm into a fermenting tray to be fermented under the conditions of temperature of 30-35 DEG C, relative humidity of 50-70% and stacking fermentation time of 12h to obtain fermented leaves; and 4) placing the fermented leaves into a dryer to be dried twice to obtain the finished persimmon leaf tea, wherein the first drying temperature is 100-120 DEG C and the water content of the persimmon leaves is 10-15%; and the second drying temperature is 80-90 DEG C and the water content of the persimmon leaves is 3-5%. The persimmon leaf tea is characterized in that the tea is strongly fragrant and fruity, the liquor is orange red or orange yellow, the taste is mellow sweet, etc. The persimmon leaf tea is suitable for mechanized production.

Owner:HUAZHONG AGRI UNIV

Terpolymer oil soluble viscosity reducer for thick oil exploration and transportation and preparation method thereof

InactiveCN101824314AGood viscosity reduction effectImprove universalityDrilling compositionMethacrylateSolvent

The invention relates to a terpolymer oil soluble viscosity reducer for thick oil exploration and transportation and a preparation method thereof. The terpolymer oil soluble viscosity reducer for thick oil exploration and transportation is characterized in that the viscosity reducer is prepared from methacrylate ester, N, N'- 2 (methacryloyloxyethyl) diamine, styrene, azobisisbutyronitrile and toluene, and the molar ratio of all the raw materials is as follows: methacrylate ester: N, N'- 2 (methacryloyloxyethyl) diamine: styrene is (4 to 5): (2 to 3): (2 to 4), the added amount of the azobisisbutyronitrile is 0.5 to 2 percent of the total mass of the methacrylate ester, the N, N'- 2 (methacryloyloxyethyl) diamine and the styrene, and toluene serves as the solvent; the methacrylate ester is prepared from acrylic acid, C16 to C22 higher alcohols, sulfoacid catalyst and phenolic inhibitor; and the N, N'- 2 (methacryloyloxyethyl) diamine is prepared from methyl acrylate and diamine. The oil soluble viscosity reducer has the advantages of good effect, strong universality, no pollution and relaxed use conditions, and can simultaneously meet the needs of thick oil exploration and transportation.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method for preparing spinnable pitch from coal tar pitch

ActiveCN109181733AHigh yieldHigh overall yield (27-32%), softening pointWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansFiltrationNitrogen

A method for preparing spinnable pitch from coal tar pitch comprises the following steps: crushing medium-low-temperature coal tar pitch to 20 meshes or below, performing extracting by using tetrahydrofuran, performing filtration to obtain a medium-low-temperature coal tar pitch soluble component, and recovering the tetrahydrofuran solvent from the soluble component to obtain refined pitch; and mixing the refined pitch with petrolatum, adding the obtained mixture into a reactor, introducing nitrogen under normal pressure, heating the reactor to 180-220 DEG C at a heating rate of 1-10 DEG C / min, switching to air, introducing the air into the reactor at a rate of 10-60 mL / min.g, heating the reactor to 280-350 DEG C at a heating rate of 1-10 DEG C / min, and allowing the obtained mixture to stay for 1-10 h to obtain the spinnable pitch. The method has the advantages of high yield, low price and moderate thermal polycondensation temperature.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Pu'er tea yeast fermentation technology

InactiveCN104304531AEnhanced cell membrane permeabilityIncrease quality ingredient contentPre-extraction tea treatmentBiotechnologyCell membrane

The invention discloses a Pu'er tea yeast fermentation technology. The technology comprises the following steps: (1) cleaning, (2) fermentation, (3) tea overturning, (4) stacking, (5) natural drying and (6) refining. According to the invention, Pu'er tea leaves are fermented in a fermentation room with the assistance of yeast, so that the cell membrane permeability of the Pu'er tea is increased, the enzymatic oxidation of polyphenols substances is promoted, the quality of the Pu'er tea is enhanced and the contents of water extracts, tea pigment, amino-acid and the like of the Pu'er tea are increased; as the Pu'er tea is produced through the adoption of the yeast fermentation technology, the fermentation time is distinctly shortened and the production efficiency is improved. The Pu'er tea, produced by adopting the yeast fermentation technology, is bright in color, full in shape, attractive in appearance, rich and strong in scent and rich in nutrition; the Pu'er tea water has a sweet and faint fragrance and is palatable; color, fragrance, taste, shape and nutrition of the original tea leaves are kept.

Owner:YUNNAN DIANBOER BIOTECH

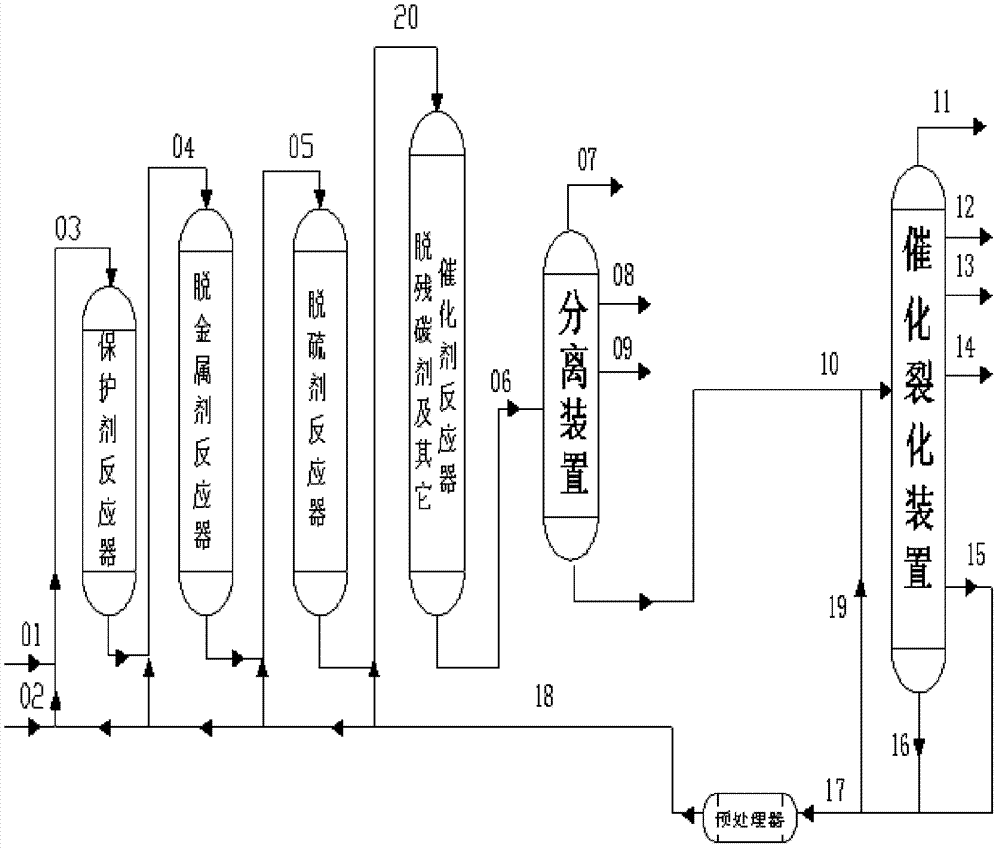

Residuum hydrotreatment-catalytic cracking combination technology

ActiveCN102816595ACombination methods are flexibleLarge amount of processingTreatment with hydrotreatment processesProlongationResidual carbon

A residuum hydrotreatment-catalytic cracking combination technology of catalytic cracking recycle oil is characterized in that a material inlet is arranged in front of a metal removal agent bed layer, a desulfurizer bed layer, and a residual carbon removal agent bed layer of a device respectively, residuum and hydrogen enter the device to react through a device raw material port, hydrogenated residuum enters a catalytic cracking device and continuously reacts, one part of the recovery oil of the catalytic cracking device enters a hydrogenation device to react through one or more of four material inlets of a hydrotreatment device, and the residual recovery oil of the catalytic cracking device is cycled to the catalytic cracking device and enters the catalytic cracking device together with the hydrogenated residuum. The technology enables the operations of the residuum hydrotreatment-catalytic cracking combination technology to be flexible and efficient, and has the advantages of prolongation of the operation period of the residuum hydrotreatment device, improvement of the impurity removal rates of residuum hydrogenation products, reduction of the application amount of cold hydrogen, and increase of the yield of light oil having high added values.

Owner:PETROCHINA CO LTD

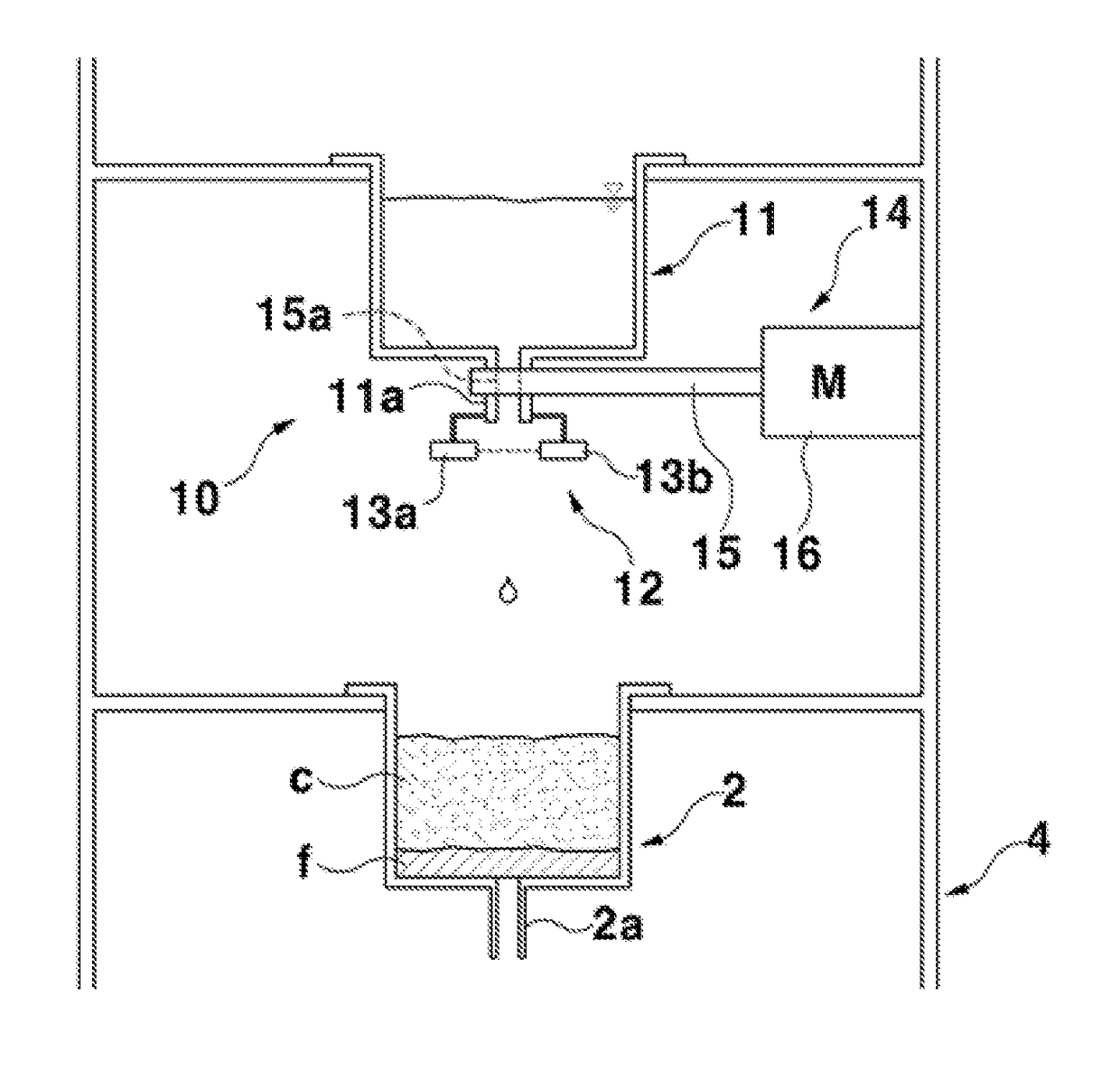

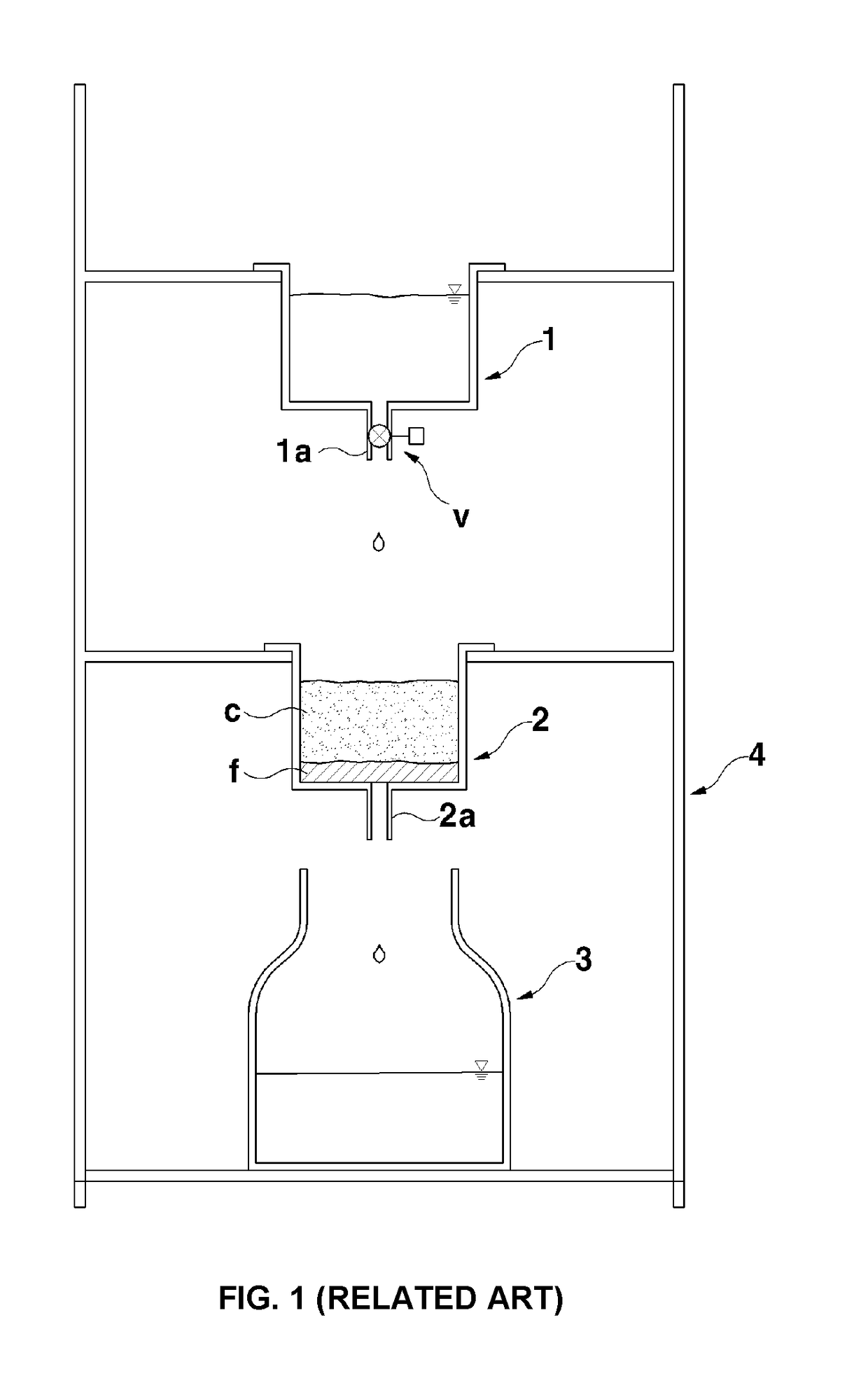

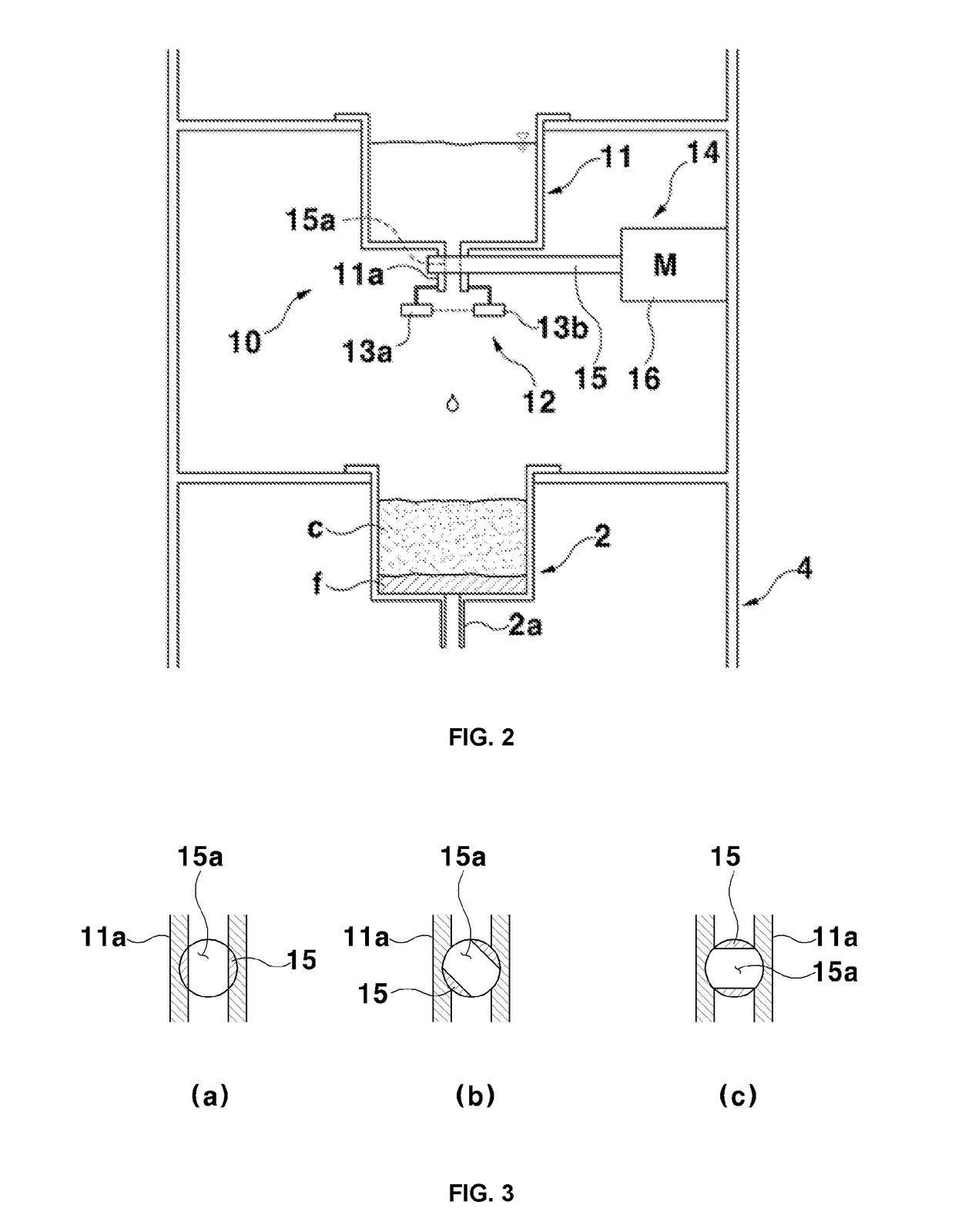

Cold brew coffee maker with water drip supply unit and coffee extraction guide member

InactiveUS20180168388A1Quality improvementUniform tasteBeverage vesselsEngineeringGreen coffee extract

A cold brew coffee maker includes a water drip supply unit for dripping drops of water through a water dispensing port; a coffee container configured to steep the ground coffee in the coffee container to produce coffee extract using the water dripped from the water drip supply unit; a collecting container disposed below the coffee container and configured to collect the drops of the coffee extract dripping through a coffee extract dispensing port; and a collection guide member configured to guide the drops of the coffee extract to flow downward along the inner wall surface of the collecting container to fill the coffee extract collecting container. The water drip supply unit further includes a control unit configured to control an electric valve based on the water drop detection signal from a sensor unit so that the water drops can drip from the water dispensing port at a preset supply rate.

Owner:KIM SEO RYOUNG

Compressed tea flower and white tea cake and preparation method thereof

InactiveCN105815477AEfficient bindingGreat tastePre-extraction tea treatmentAdditive ingredientPolyphenol

The invention relates to the technical field of white tea cake preparation, in particular to a compressed tea flower and white tea cake and a preparation method thereof .The preparation method includes the steps of tea flower preparation, white tea preparation and mixing forming .After tea flowers and white tea are mixed at the mass ratio of 0.7:1.3, stream-pressure softening treatment is carried out with a steam machine, and roasting treatment is carried out multiple times, so that nutritional ingredients in tea flowers and nutritional ingredients in white tea are effectively combined, it is ensured that tea cake leaves are oily, and inlaid with golden yellow tea flowers, the tea cake is strong and refreshing in aroma, obvious in flowery fragrance, sweet and tasty .Loss of the aroma, the beneficial substance tea polyphenol and the like in the processing process is reduced, and dehydration is uniform; the taste of the tea cake is improved.

Owner:贵州湄潭兰馨茶业有限公司

Tea making process for stale flavor orchid-flavored Danchongcha

The invention discloses a tea making process for stale flavor orchid-flavored Danchongcha. The tea making process comprises the following steps: (1) fresh leaf picking; (2) sun-withering; (3) leaf cooling; (4) green leaf making; (5) de-enzyming; (6) rolling; (7) roasting; (8) aging; and (9) packaging. According to the stale flavor orchid-flavored Danchongcha prepared by the tea making process disclosed by the invention, the strip shape of the tea is robust and bead-shaped, the tea is olivine in color and luster, pure and lofty in fragrance, the fragrance of the tea is slightly like fragrance of gardenia, the tea is stale flavored and mellow in taste, strong in sweetness after taste, golden and bright in tea soup and smooth and heavy in taste.

Owner:饶平县金利香生态茶叶有限公司

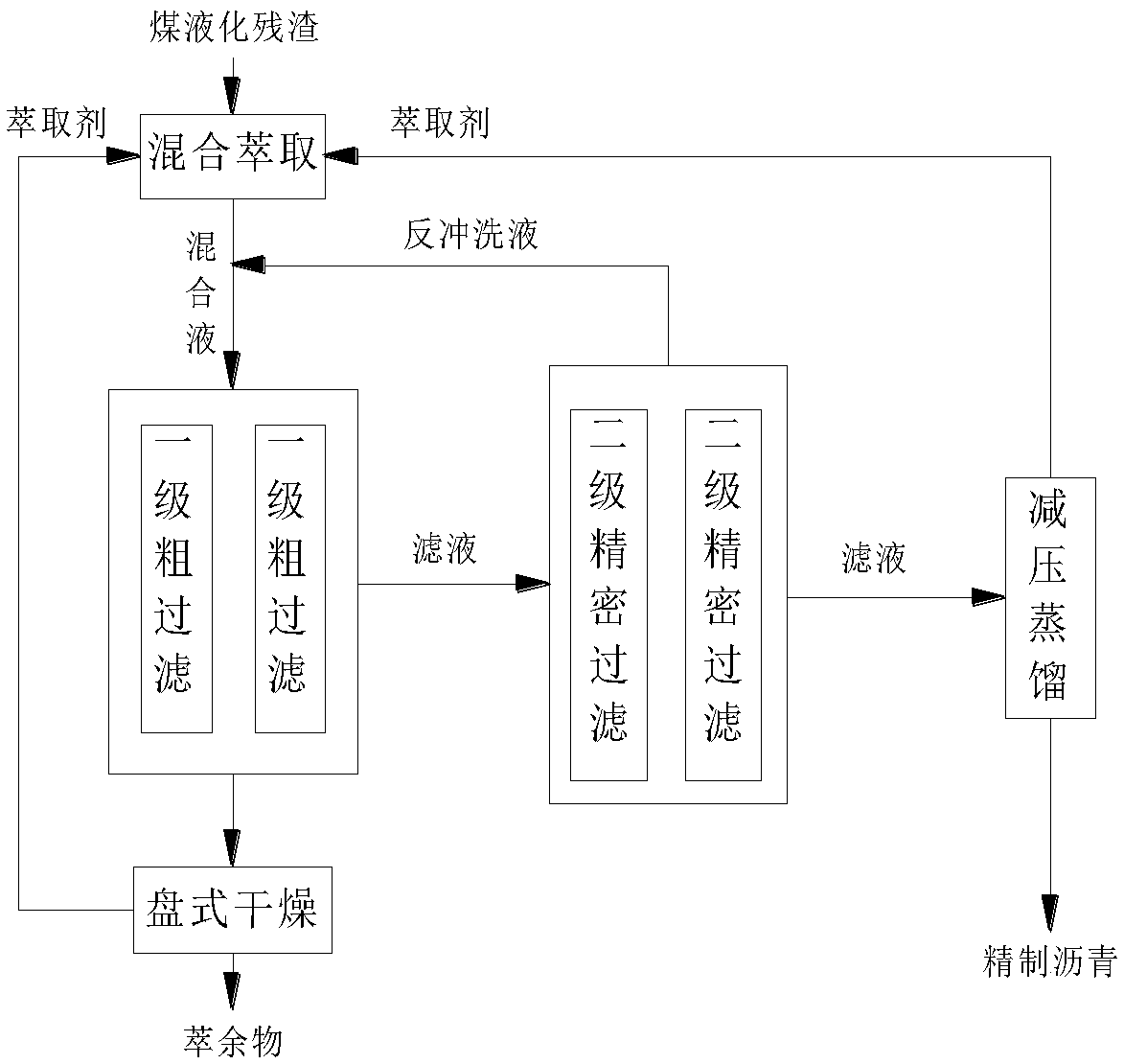

Method for preparing mesophase pitches or mesophase microspheres through coal and oil co-liquified residues

The invention provides a method for preparing mesophase pitches or mesophase microspheres through coal and oil co-liquified residues. The coal and oil co-liquified residues and a first-level extracting solvent are subjected to positive extraction, first-level extract liquor and first-level raffinate are obtained, remaining substances obtained after the first-level extracting liquid solvent is recycled are a mixture of asphaltene and heavy oil, the mixture of the asphaltene and the heavy oil and a second-level extracting solvent are subjected to position extraction, and second-level extract liquor and second-level raffinate are obtained; the second-level raffinate is processed, and asphaltene is obtained; heavy oil is obtained after the second-level extracting liquid solvent is recycled; the asphaltene and the heavy oil are mixed according to a certain proportion and evenly placed in a reactor to be subjected to co-carbonization thermal polycondensation, and thermal polycondensation products containing the mesophase pitches or thermal polycondensation products containing the mesophase microspheres are generated; the thermal polycondensation products containing the mesophase microspheres are washed through quinoline, filtered and dried, and the mesophase microspheres are obtained. The method has the advantages of being simple in technology and low in production cost.

Owner:TAIYUAN UNIV OF TECH +1

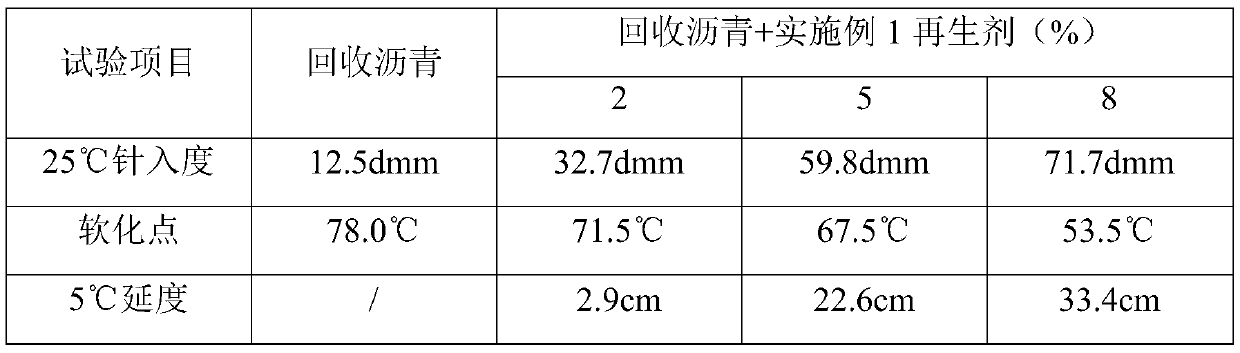

Slow-release asphalt modified regenerant and preparation method thereof

ActiveCN110669345AImprove performanceStrong environmental protectionBuilding insulationsPlasticizerProcess engineering

The invention discloses a slow-release asphalt modified regenerant and a preparation method thereof. The regenerant comprises the following components in parts by mass: 30-80 parts of modified base oil, 30-50 parts of matrix asphalt, 10-30 parts of an added oil, 1-5 parts of a plasticizer, 1-5 parts of an anti-aging agent, 1-5 parts of a modifier and 1-10 parts of a capsule modifier. The regenerant provided by the invention is capable of adjusting the viscosity of new and old asphalt and mixture systems, enhancing the anti-stripping performance of systems, slowly releasing light components, realizing lasting regeneration, saving the dosage of new asphalt, increasing the compatibility of the new and old asphalt through active points, improving the performance of the asphalt, resisting agingand the like. In addition, the regenerant provided by the invention can realize waste recycling, and solve the problems of single performance and poor long-term regeneration effect of traditional regenerants. In addition, the regenerant is simple in preparation process and convenient for industrial production.

Owner:山西交通科学研究院集团有限公司 +1

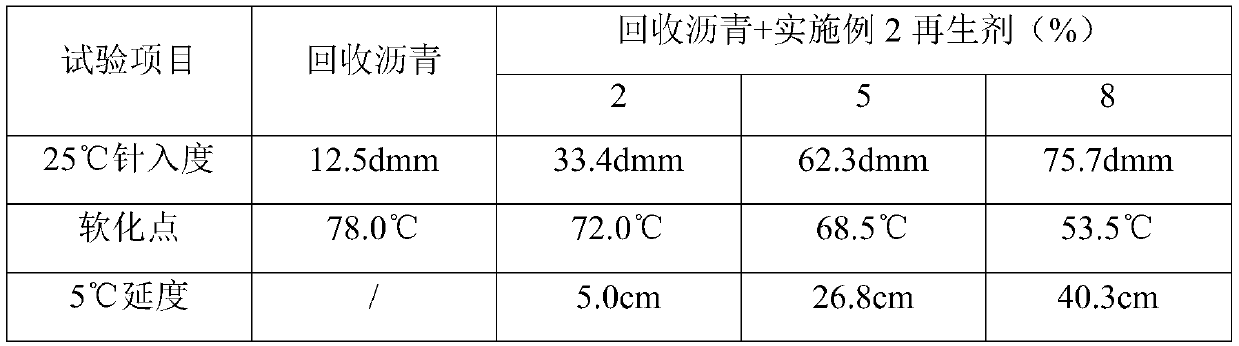

Method and system to prepare asphalt with coal liquefaction residue

InactiveCN108410491AThe type is not limitedAdaptableWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionProcess engineeringAsphalt

The invention relates to a method and system to prepare asphalt with coal liquefaction residue. The system comprises a mixing extracting device, a first filter unit, a second filter unit, a drying device and a distilling device; the mixing extracting device is communicated with the first filter unit; the first filter unit is communicated with the drying device; the first filter unit is communicated with the second filter unit, and the second filter unit is communicated with the distilling device, wherein the first filter unit at least includes a first filter and a second filter; the second filter unit at least includes a third filter and a fourth filter. Each of the two filter units in the system includes two filters arranged in alternate manner, so that continuous production of asphalt isachieved.

Owner:CCTEG CHINA COAL RES INST +1

Processing method for curved black tea

ActiveCN103404629ABeautiful appearanceRuddy colorPre-extraction tea treatmentProcess engineeringBlack teas

The invention provides a processing method for curved black tea. The processing method comprises the following steps of carrying out sunning treatment on fresh leaves, naturally withering and lightly rolling; then introducing oxygen and fermenting; then drying a product to be with a certain water content by using a drying machine; then putting the product on a curve frying machine to be shaped; and finally, putting the product on drying equipment to be shaped by handwork and drying. According to the processing method provided by the invention, foundations are laid for flavor quality by processes of sunning, withering, introducing the oxygen, fermenting and the like; foundations are laid for appearance quality by processes of shaping by curves, protecting the color by cold air, manually assisting and the like; finally, the specially-produced curved black tea which is beautiful in appearance, high in color and aroma and mellow in taste is obtained.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

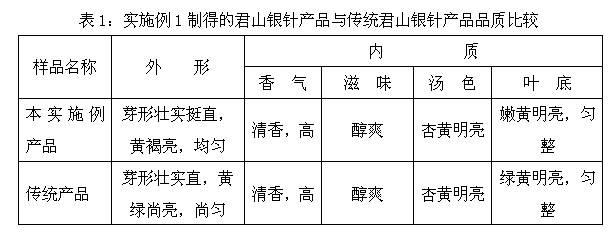

Method for killing out yellow Junshan needle tea

ActiveCN102630773ABuds are strong and straightBright yellowish brownPre-extraction tea treatmentAgroforestryRaw material

The invention relates to a method for killing out yellow Junshan needle tea, which comprises the following steps: (1) collecting fresh leaves of raw materials; (2) dewatering the leaves; (3) killing out the leaves with a food oven; (4) airing the leaves to dissipate heat by wind; (5) preliminarily drying the leaves; (6) primarily packing the dried leaves; (7) drying the leaves for the second time; (8) packing the leaves for the second time; and (9) completely drying the leaves. The dry Junshan needle tea prepared with the method disclosed by the invention has the advantages of strong and straight shape of tea leaves, russet brown, bright and even color of the tea leaves, light aroma of the tea leaves, mellow taste of the tea leaves, apricot yellow and bright soup, bright yellow, bright and uniform Securinega and stable quality.

Owner:HUNAN JUSN YINZHEN TEA IND

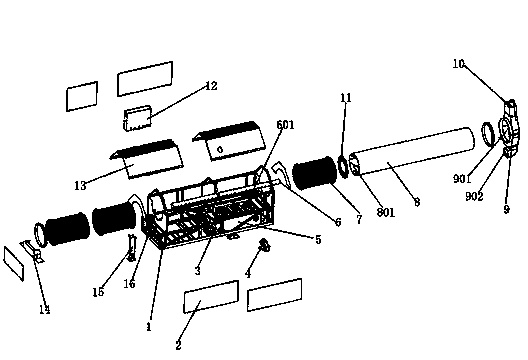

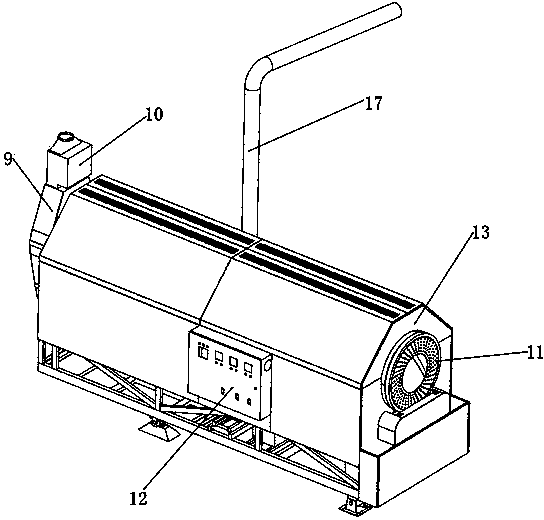

Roller drying machine

InactiveCN104186732AHas completedWith tumblePre-extraction tea treatmentPulp and paper industryElectromagnetic heating

The invention discloses a roller drying machine, and belongs to the technical field of tea processing devices. The roller drying machine comprises a main frame, wherein a side plate and a top plate are fixedly arranged on the main frame, a roller is arranged in the main frame, and driven by a transmission mechanism arranged on the main frame, a heat source exchange chamber is arranged below the roller, an axial flow fan is arranged on one side of the heat source exchange chamber, a hot air pipe is arranged in the roller, the roller is sheathed with an electromagnetic heating jacket, a perforated closed plate is fixedly arranged at the feed end of the roller, a wet exhaust hood is sheathed at the discharging end of the roller, a wet exhaust fan is arranged at the upper end of the wet exhaust hood, a hot air inlet is formed in the lower end of the wet exhaust hood, the hot air pipe is connected with a hot air pipe interface arranged in the wet exhaust hood, the hot air pipe interface is communicated with the hot air inlet, and the hot air inlet faces to the axial flow fan. The roller drying machine disclosed by the invention simultaneously has the functions of green removing, roll drying and stir-frying, a product obtained by using the roller drying has jade green color and high fragrance which are better than that of the traditional stir-frying product and higher than that of a hot air dried product respectively.

Owner:宁波市姚江源机械有限公司

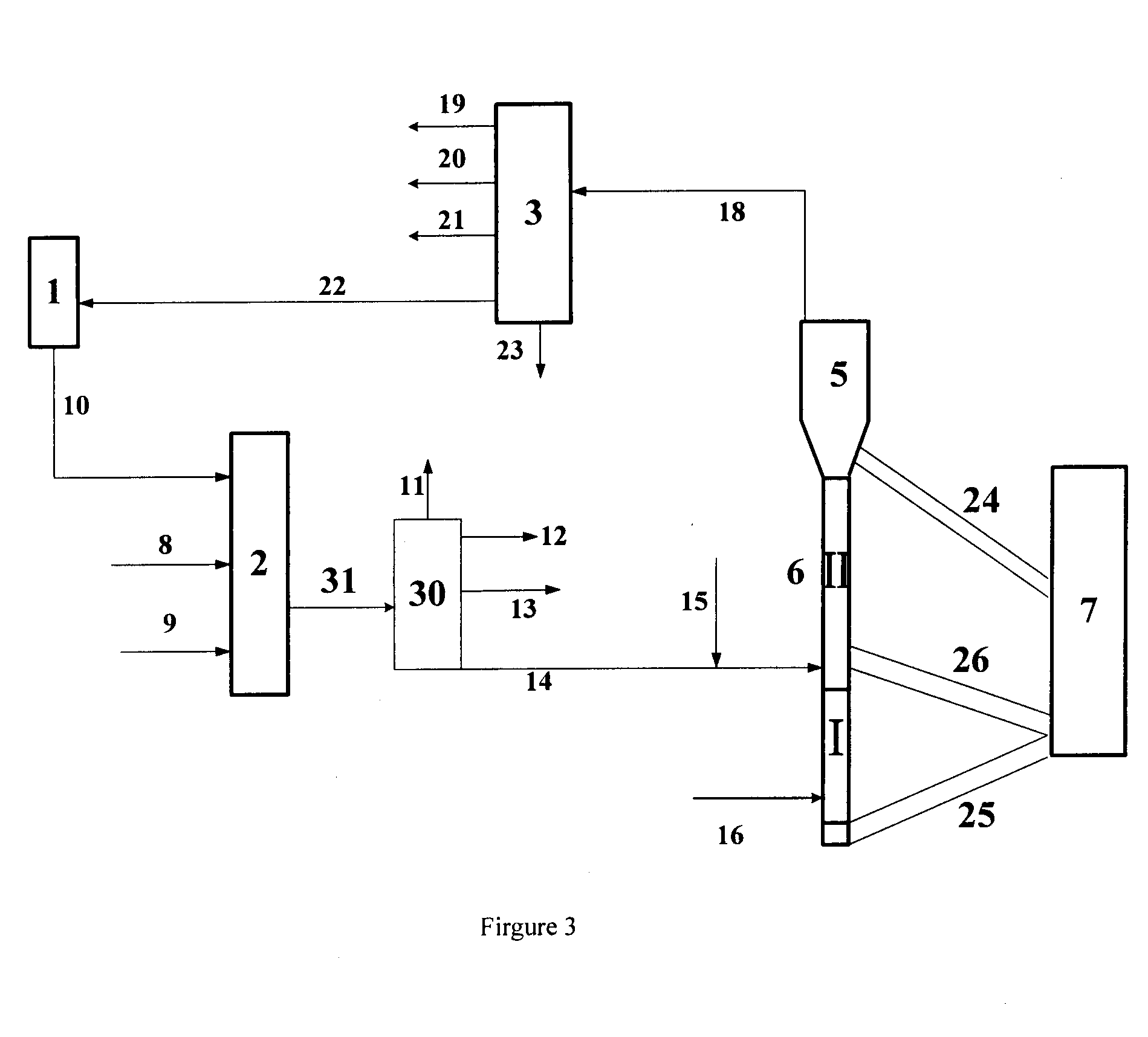

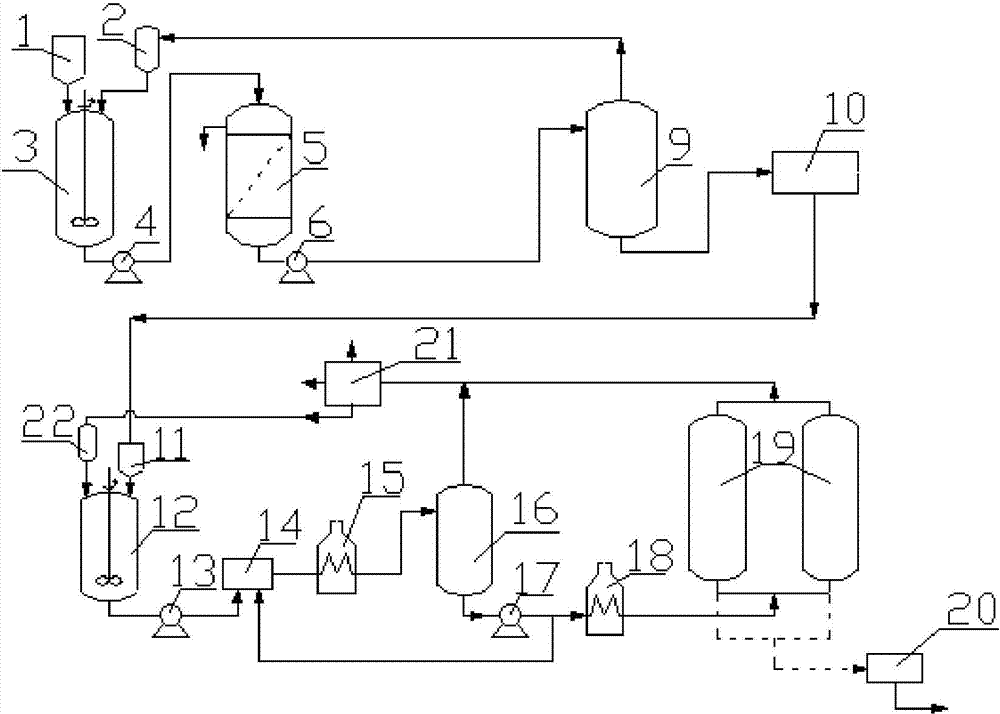

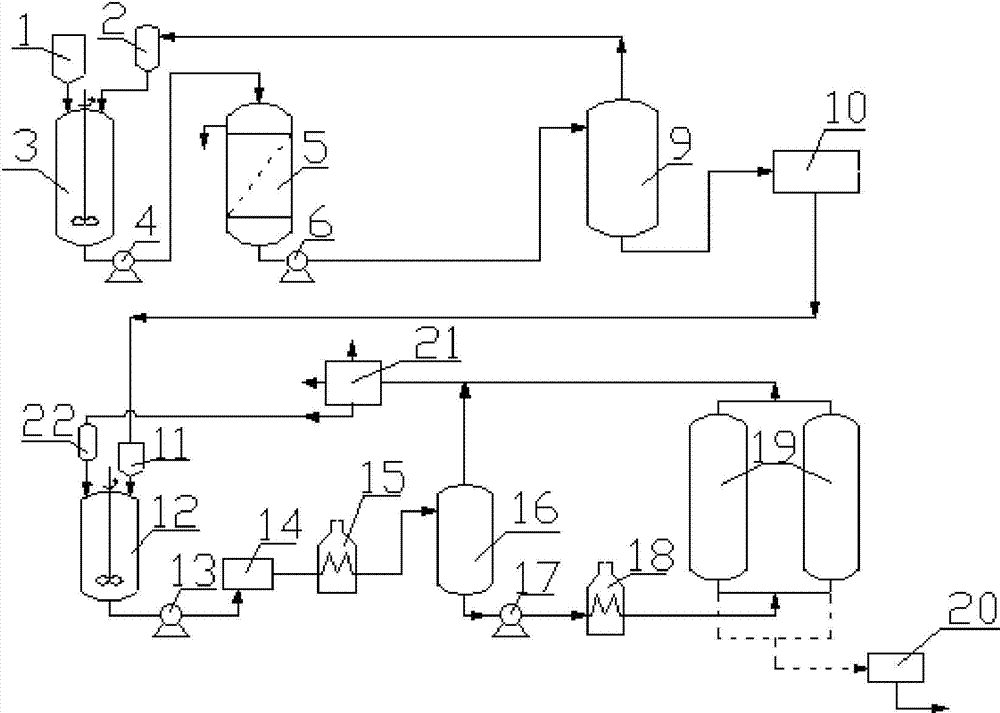

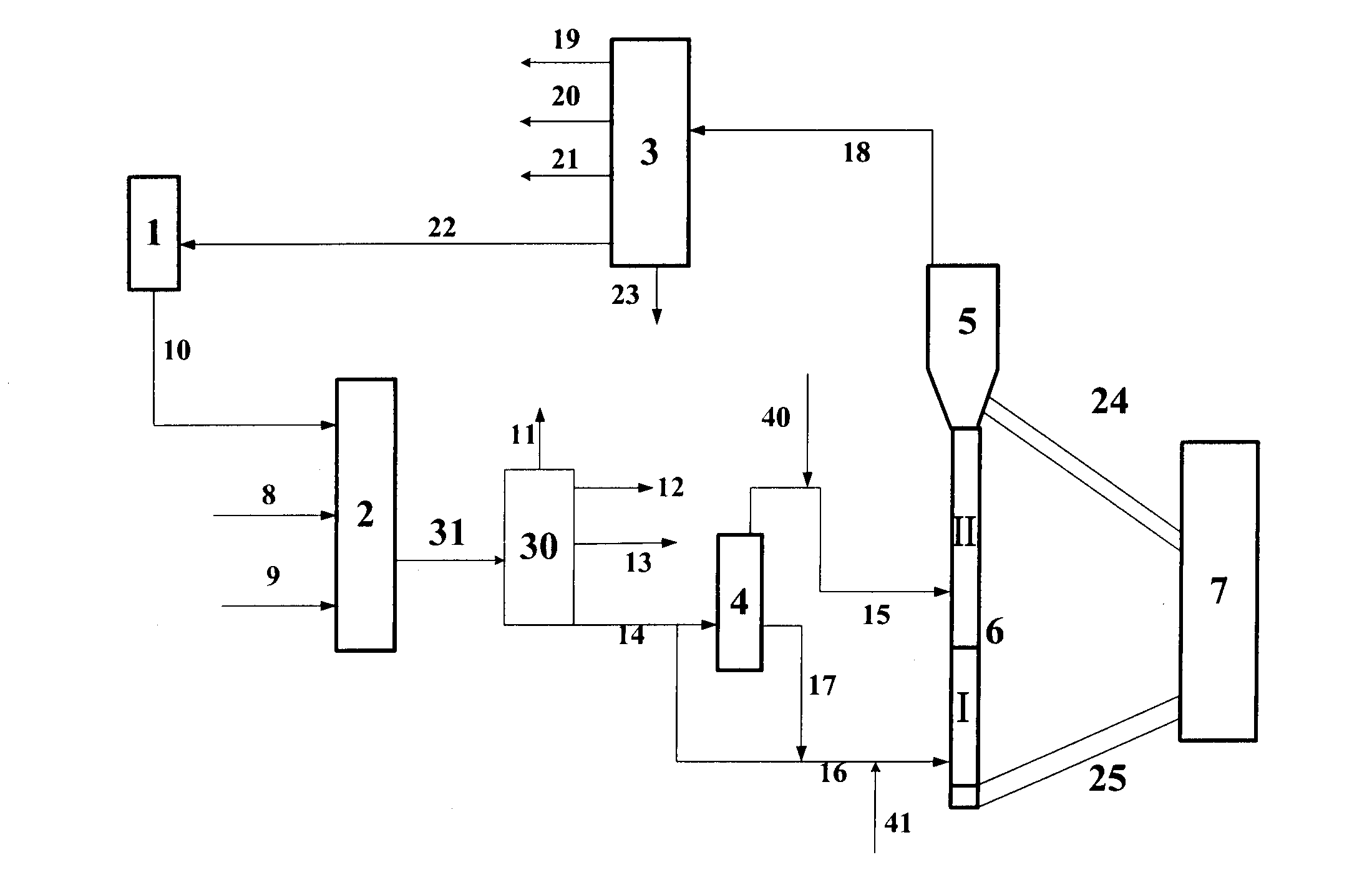

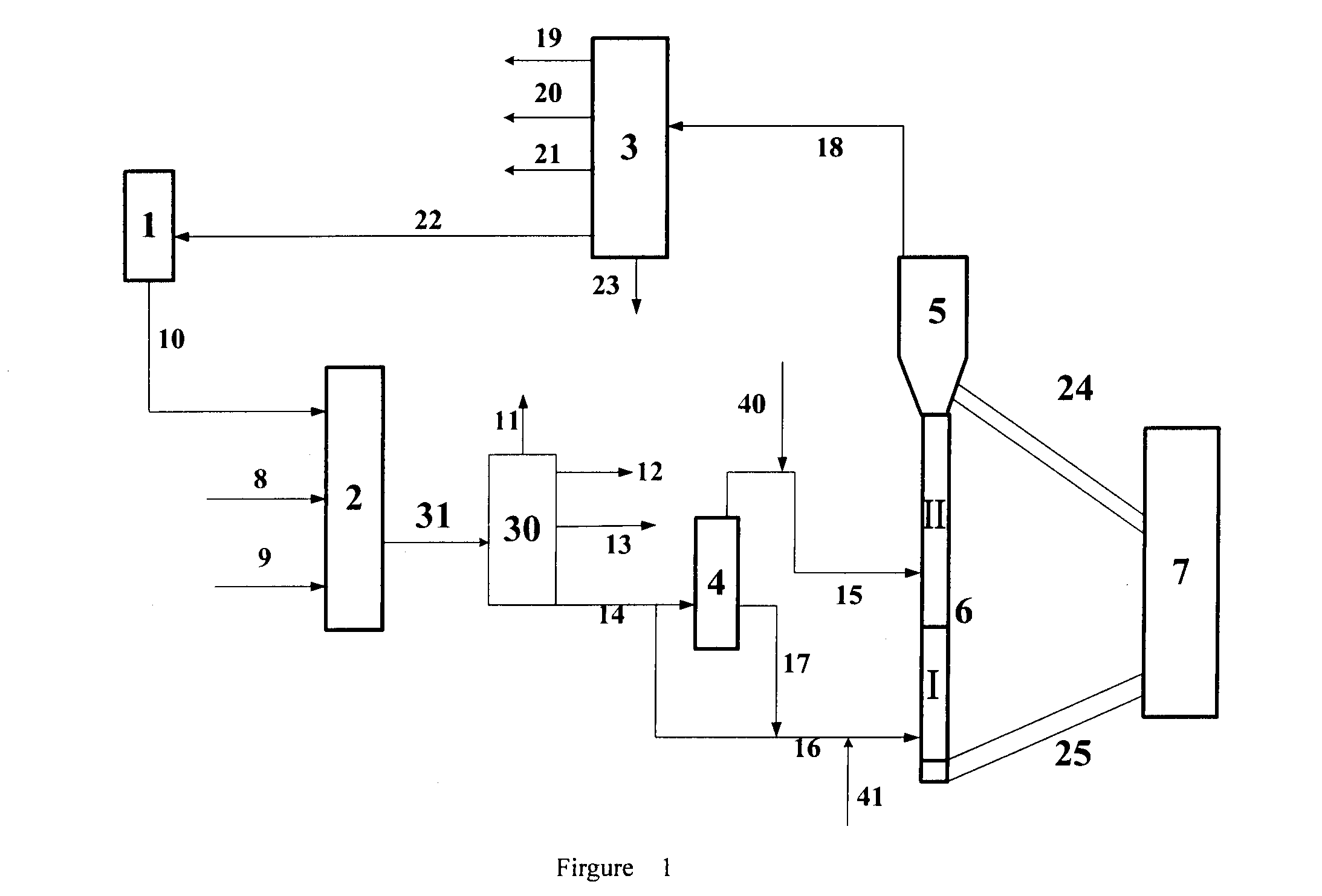

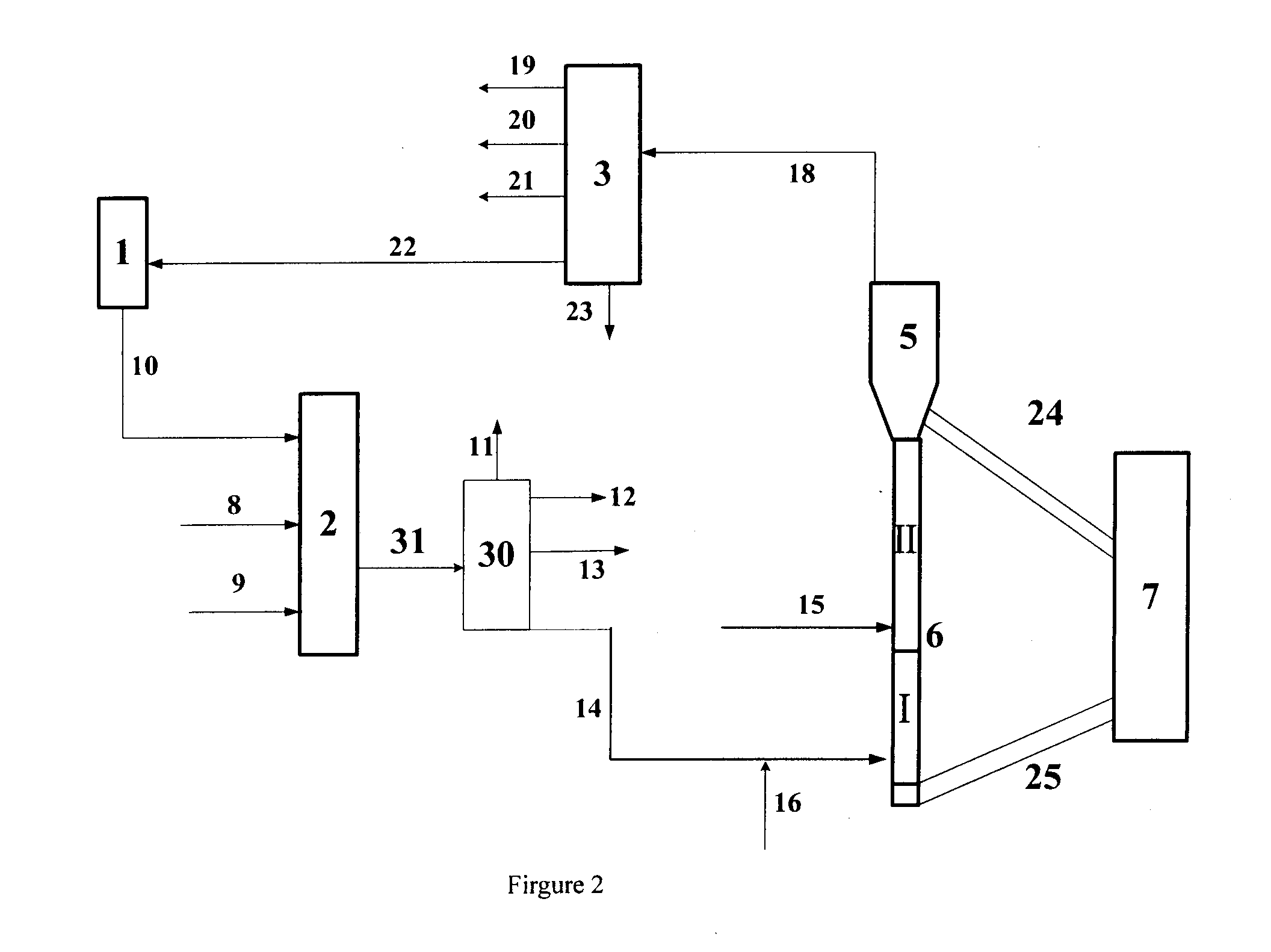

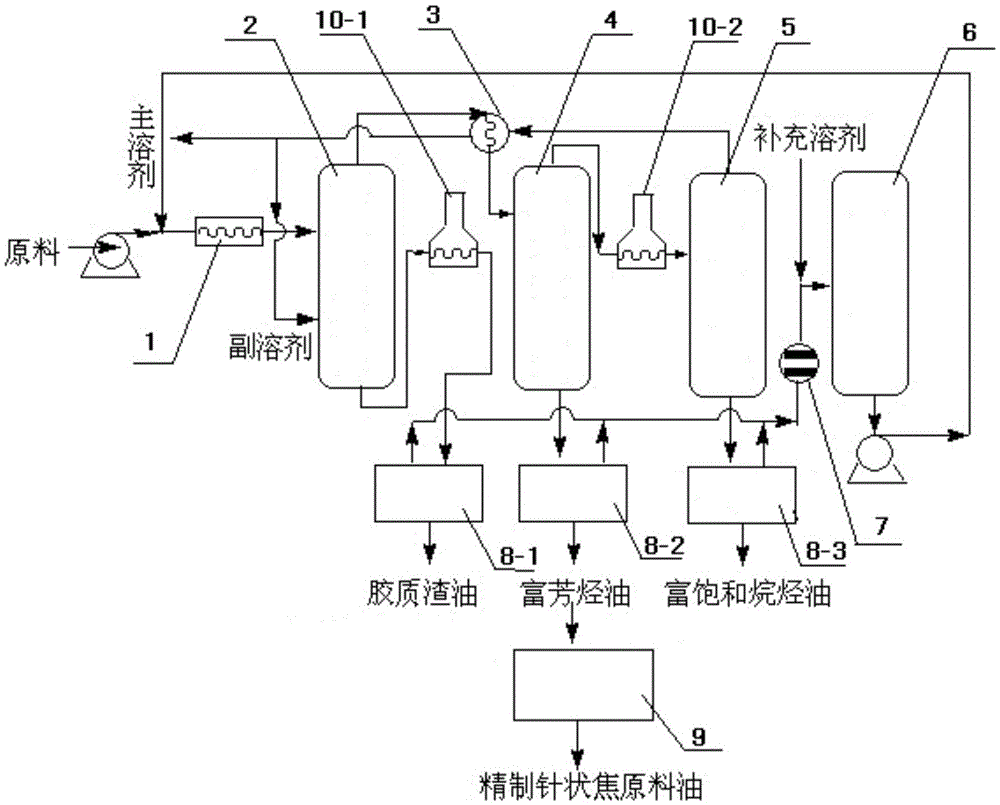

System device for producing needle coke crude oil through catalytic slurry oil

InactiveCN105482850AHigh aromaShort recycling processTreatment with hydrotreatment processesHydrocarbon oils treatment productsAlkaneThermodynamics

The invention belongs to the field of catalytic slurry oil deep processing and particularly relates to a system device for producing needle coke crude oil through catalytic slurry oil. According to the device, a mixer 1, the top of a catalytic slurry oil extraction tower 2, the top of an aromatic-hydrocarbon-rich oil separation tower 4 and the top of an aromatic-alkane-rich oil separation tower 5 are sequentially connected through pipelines. The bottom of the catalytic slurry oil extraction tower 2 is connected with a gas stripping tower A8-1. The bottom of the aromatic-hydrocarbon-rich oil separation tower 4 is directly connected with a gas stripping tower B8-2. The bottom of the aromatic-alkane-rich oil separation tower 5 is connected with a gas stripping tower C8-3. A gas outlet of the gas stripping tower A8-1, a gas outlet of the gas stripping tower B8-2 and a gas outlet of the gas stripping tower C8-3 are sequentially connected and then connected with a condenser 7 and a solvent tank 6, and the bottom of the gas stripping tower B8-2 is connected with a hydrofining reactor 9. The device fully utilizes petroleum resources and turns waste into wealth, the catalytic slurry oil can be utilized at high value, and the produced needle coke crude oil can serve as needle coke raw materials high-additional-value products.

Owner:GUANGXI HONGDA BIO ENERGY TECH

Coal tar and residuum hydrocracking-delayed coking combination processing method

ActiveCN103773477AImprove conversion rateImprove stabilityTreatment with hydrotreatment processesHydrogenFluidized bed

The invention discloses a coal tar and residuum hydrocracking-delayed coking combination processing method which is as follows: light and heavy coal tar are obtained by reduced pressure distillation of coal tar; the light coal tar is mixed with and residuum, and enters a fluidized bed reactor together with hydrogen to contact a hydrocracking catalyst for hydrocracking reaction, a hydrocracked effluent is separated to obtain a gas and a liquid phase product, gasoline, diesel, vacuum gas oil and tail oil are obtained by fractionation of the liquid phase product; the tail oil and the heavy coal tar together enter a delayed coking unit for thermal cracking reaction to obtain coker dry gas, coker gasoline, coker diesel oil, coker gas oil and coke. The process method can improve the conversion rate of raw materials, reduce coking, increase the yield of light oil, and prolong the device operation cycle, and provides a processing method for low-added-value coal tar and residuum to improve the economical efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

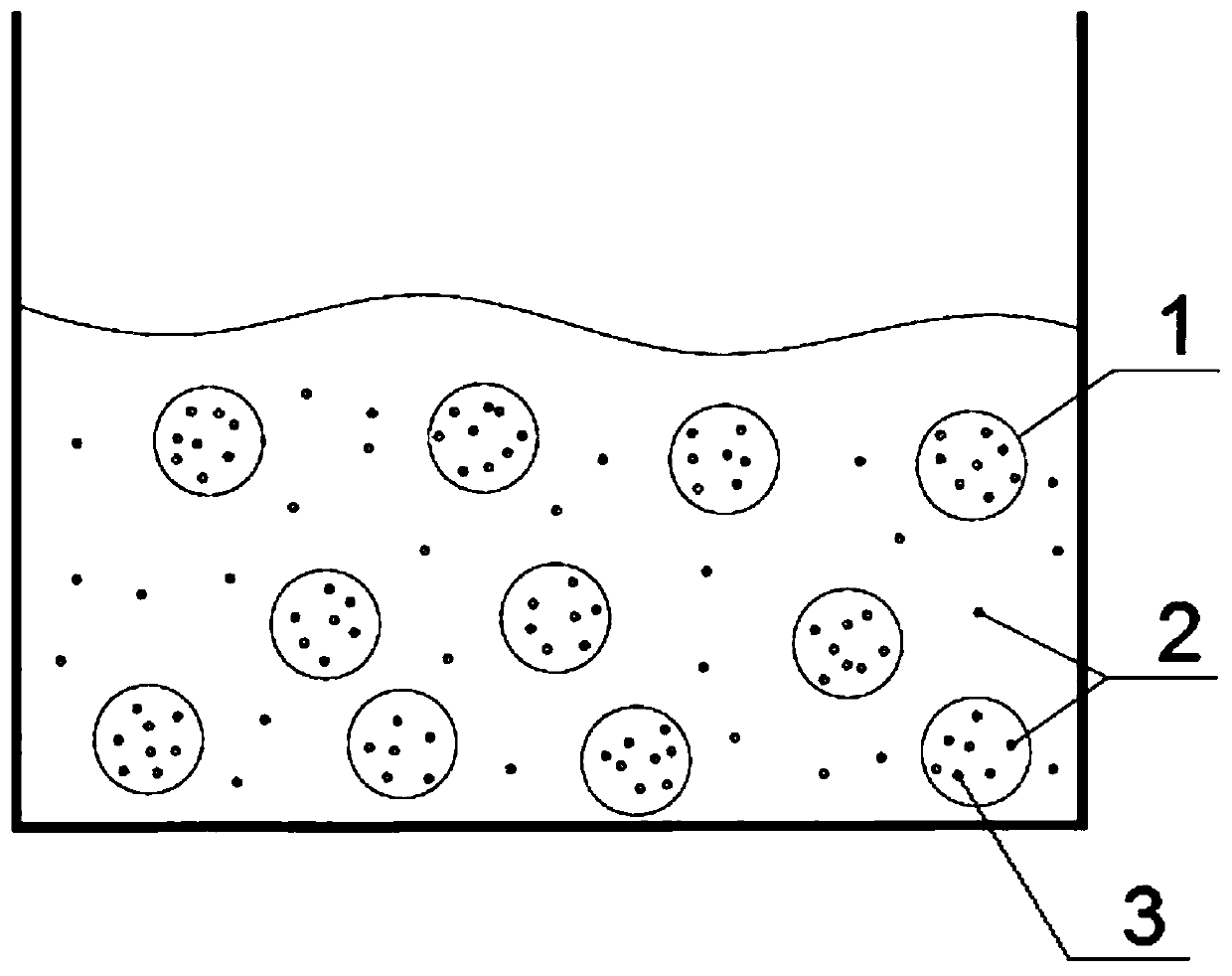

Method for efficiently preparing petroleum asphalt-based mesocarbon microbeads

The invention discloses a method for efficiently preparing petroleum asphalt-based mesocarbon microbeads. The method comprises the following steps: firstly, carrying out full mixing and preheating treatment on petroleum asphalt and an additive under a certain temperature, a certain N2 flow and a certain stirring speed, thus removing a small molecule compound which is difficult to polymerize; secondly, carrying out thermal polymerization reaction by keeping constant temperature for 2 to 6 hours under N2 protection and under the conditions that the pressure is 0.5 to 2.0 MPa and the temperatureis 380 to 420 DEG C, thus obtaining polymerized asphalt containing mesocarbon microbeads; finally, carrying out hot melting and filtration on the polymerized asphalt by using wash oil of which the boiling range is 245 to 290 DEG C, and carrying out vacuum drying after extracting filter cake by organic solvents of pyridine, methylbenzene and the like, thus obtaining the petroleum asphalt-based mesocarbon microbeads. According to the method disclosed by the invention, the petroleum asphalt and the additive which are used in the invention are rich in sources and lower in cost; by controlling themass percentage of the additive, the mesocarbon microbeads which are uniform in particle size distribution, controllable in size and relatively higher in yield can be prepared, and the mesocarbon microbeads can be used as lithium ion battery cathode materials after the mesocarbon microbeads are carbonized and graphitized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com