Processing method for curved black tea

A processing method, Quhao technology, applied in tea treatment before extraction, etc., can solve the problems of green taste, poor moisturization, old aroma, etc., and achieve the effect of beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1 A kind of processing method of koji-shaped black tea

[0017] The raw material of fresh leaves used is: 50 kg of fresh leaves of Fuding Dabai variety tea mainly with 1 bud 1 leaf - 1 bud 2 leaves first developed.

[0018] The specific implementation is as follows:

[0019] (1) Place the mat with fresh leaves in the sun for 20 minutes at about 8:00 in the morning, turn it once during the period, then move it to a cool place for 30 minutes; then place it in the sun again for 20 minutes, remove To a cool place for 30 minutes, repeat this 4 times until the moisture content of fresh leaves is around 66-68%.

[0020] (2) Put the sun-dried green leaves in a withering room at 22°C-24°C / RH80-90% (using the green air-handling unit produced by Yuyao Yao Jiangyuan Tea Machine Co., Ltd. to adjust the ambient temperature and humidity) for airing, until The moisture content is 62%-64%.

[0021] (3) Put the finished product into the kneading machine (6CR-35 kneading machi...

Embodiment 2

[0026] Example 2 A kind of processing method of koji-shaped black tea

[0027] The raw material of fresh leaves used is: 50 kg of fresh leaves of Yingshuang variety tea with 1 bud and 1 leaf - 1 bud and 2 leaves for the first development.

[0028] The specific implementation is as follows:

[0029] (1) Place the mat with fresh leaves in the sun for 30 minutes at around 5 p.m., turn it once during the period, then move it to a cool place for 30 minutes; then place it in the sun again for 30 minutes, remove To a cool place for 30 minutes, repeat this 3 times until the moisture content of fresh leaves is around 66-68%.

[0030] (2) Put the sun-dried green leaves in a withering room at 22°C-24°C / RH80-90% (using the green air-handling unit produced by Yuyao Yao Jiangyuan Tea Machine Co., Ltd. to adjust the ambient temperature and humidity) for airing, until The moisture content is 62%-64%.

[0031] (3) Put the finished product into the kneading machine (6CR-35 kneading machine...

Embodiment 3

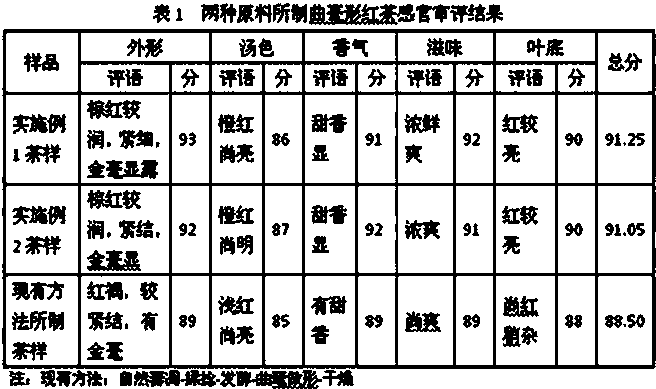

[0036] Example 3 Sensory evaluation of Quhao black tea made from two raw materials

[0037] The Quhao-shaped black tea prepared in Example 1 and Example 2 was subjected to sensory evaluation, and compared with the Quhao-shaped black tea prepared by the existing method, the results are shown in Table 1.

[0038]

[0039] It can be seen from the review results of the tea samples that the present invention achieves a better flavor endoquality through the organic integration and integrated innovation of sun-drying technology / aerobic fermentation / shaping of bent hair / cold wind color protection / manual assisted forming technology. At the same time, it can also make the appearance of the finished tea with a unique shape, which is obviously better than the tea samples made by the existing method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com