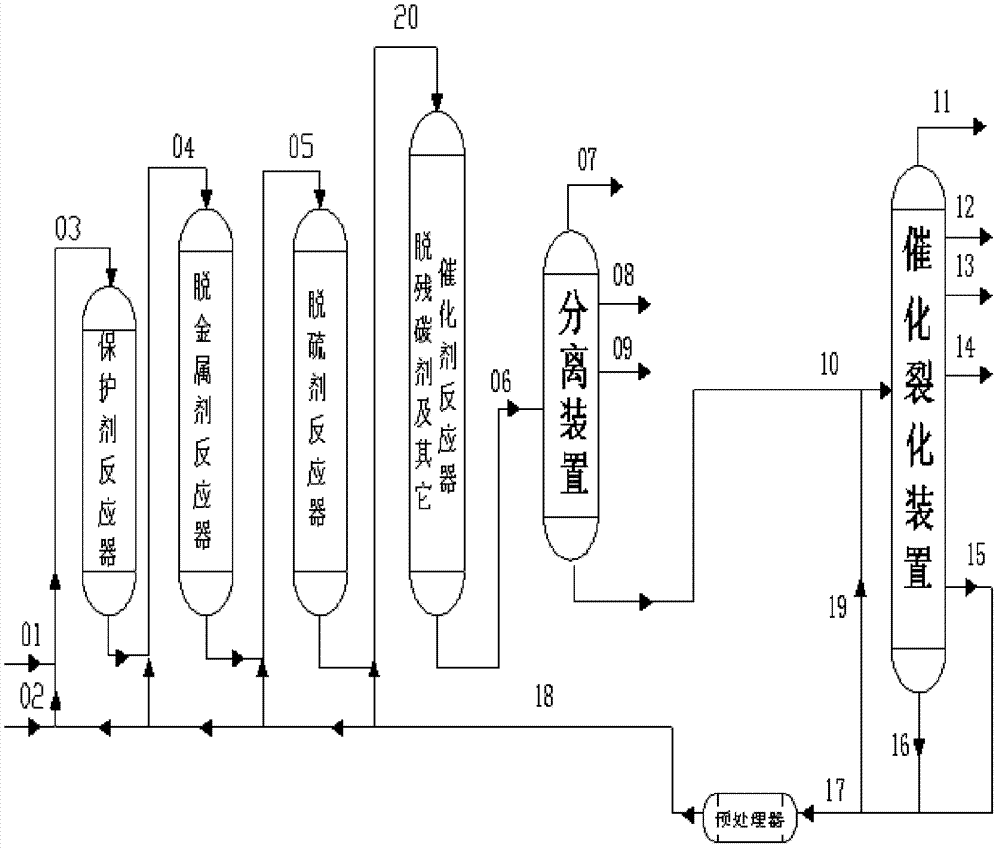

Residuum hydrotreatment-catalytic cracking combination technology

A technology for catalytic cracking and residual oil hydrogenation, which is applied in hydrotreating process, petroleum industry, processing of hydrocarbon oil, etc., can solve problems such as inconvenient adjustment of oil properties, reduce the amount of cold hydrogen used, and achieve flexible combination methods. Improve fluid flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

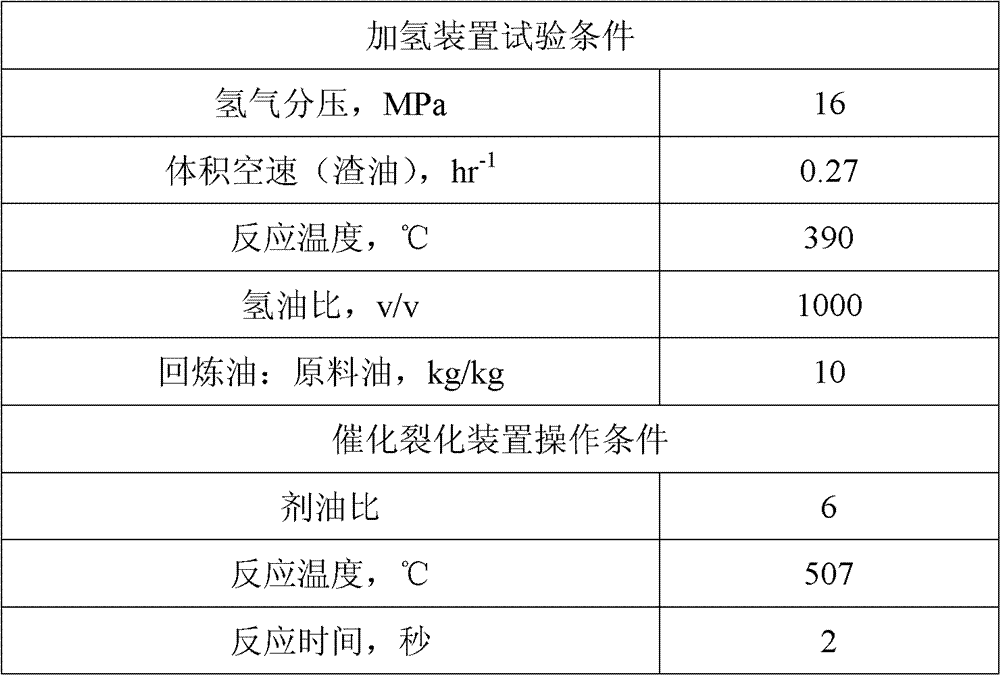

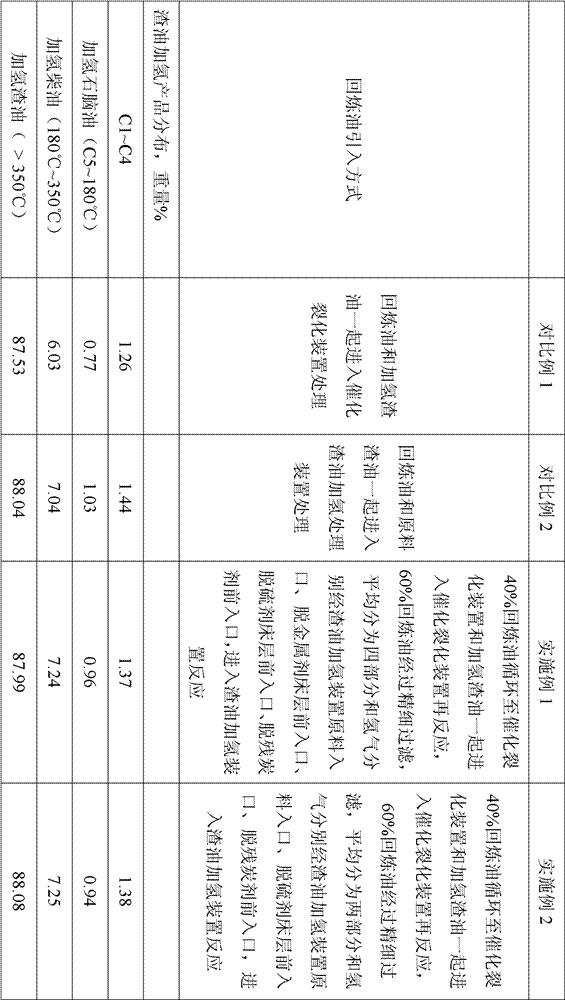

[0043] Kuwaiti residual oil and hydrogen enter the residual oil hydrogenation pilot plant together, after residual oil hydrogenation treatment, the reaction is carried out according to the conditions in Table 1, and the reaction products are separated into gas, hydrogenated naphtha, hydrogenated diesel oil, and hydrogenated residue oil; hydrogenated residual oil enters the catalytic cracking unit, and reacts according to the conditions in Table 1. The catalytic cracking products are divided into dry gas, liquefied gas, catalytic gasoline, catalytic diesel oil, catalytic cracking heavy cycle oil and oil slurry, and the refining oil adopts For heavy cycle oil, 40% of the recycled oil is recycled to the catalytic cracking unit and the hydrogenated residual oil enters the catalytic cracking unit for re-reaction. 60% of the recycled oil is finely filtered and divided into four parts on average and the hydrogen is respectively passed through the raw material inlet of the residual hydr...

Embodiment 2

[0045] Kuwaiti residual oil and hydrogen enter the residual oil hydrogenation pilot plant together, after residual oil hydrogenation treatment, the reaction is carried out according to the conditions in Table 1, and the reaction products are separated into gas, hydrogenated naphtha, hydrogenated diesel oil, and hydrogenated residue oil; the hydrogenated residual oil enters the catalytic cracking unit and reacts according to the conditions in Table 1. The catalytic cracking products are divided into dry gas, liquefied gas, catalytic gasoline, catalytic diesel, catalytic cracking heavy cycle oil and oil slurry. For circulating oil, 40% of the recycled oil is recycled to the catalytic cracking unit and the hydrogenated residual oil enters the catalytic cracking unit for re-reaction. 60% of the recycled oil is finely filtered and divided into two parts on average. The front inlet of the desulfurizer bed and the front inlet of the carbon removal catalyst bed enter the residual oil h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com