Mesophase pitch and preparation method thereof

A technology of mesophase pitch and asphalt, which is applied in the field of mesophase pitch and its preparation, to achieve the effects of moderate carbon-hydrogen ratio, improved economy, and high aromaticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] (1) First, the above-mentioned coal direct liquefaction residue and the IBP-110°C liquefied oil produced during the coal direct liquefaction process were subjected to primary extraction at a volume ratio of 1:3 for 50 minutes; the mixture obtained by the primary extraction was separated into solid and liquid, The obtained solid part and the 220-260 ℃ liquefied oil produced during the direct coal liquefaction process were subjected to secondary extraction for 60 minutes at a volume of 1:3, and the soluble part obtained from the two-stage extraction was recovered to obtain the extracted pitch.

[0078](2) Take 200g coal direct liquefaction residue to extract asphalt (volume about 195ml) and mix it with 600mL n-hexane, put it in a mixing tank, dissolve it with n-hexane at 40°C for 30min, then separate it by filtration, and recover the insoluble matter (about 160g ). Then mix the insoluble matter with 550mL tetrahydrofuran, fully dissolve it in the mixing tank for 30 minute...

Embodiment 2

[0082] (1) and (2): Take 156g of refined asphalt obtained by step (1) and step (2) in Example 1.

[0083] (3) Put the above-mentioned refined asphalt in a high-temperature and high-pressure reactor, rapidly raise the temperature to 250°C within 25 minutes, and keep the constant temperature under normal pressure for 30 minutes. Then, the temperature was raised to 415° C. at a rate of 5° C. / min, the pressure was maintained at 3 MPa, and the reaction was performed at a constant temperature for 10 hours.

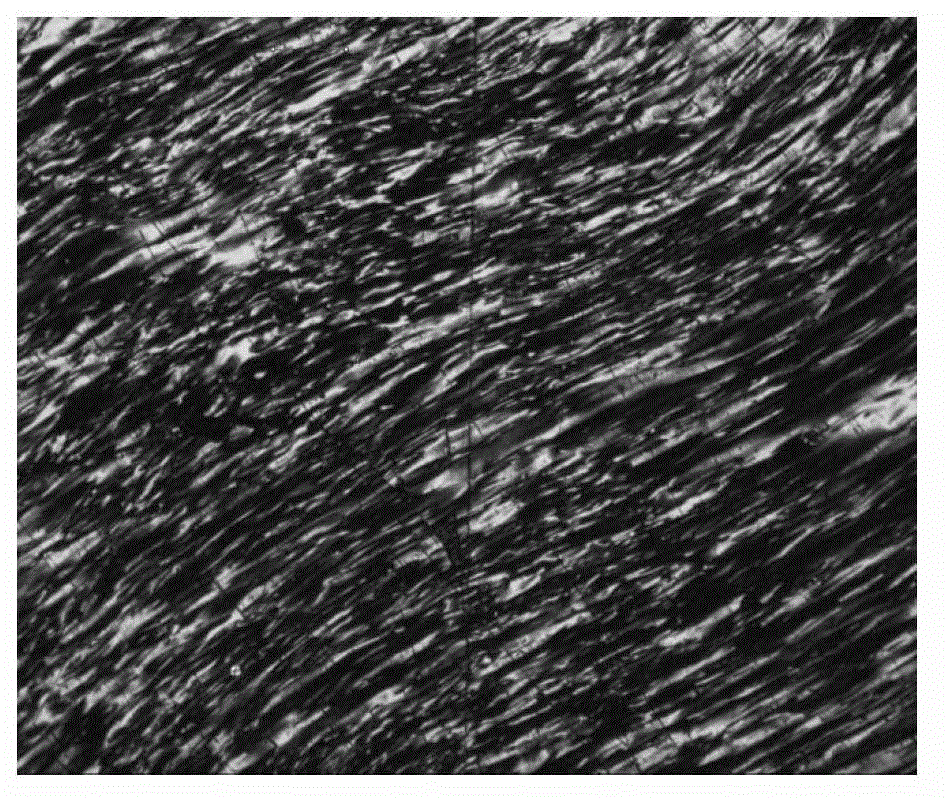

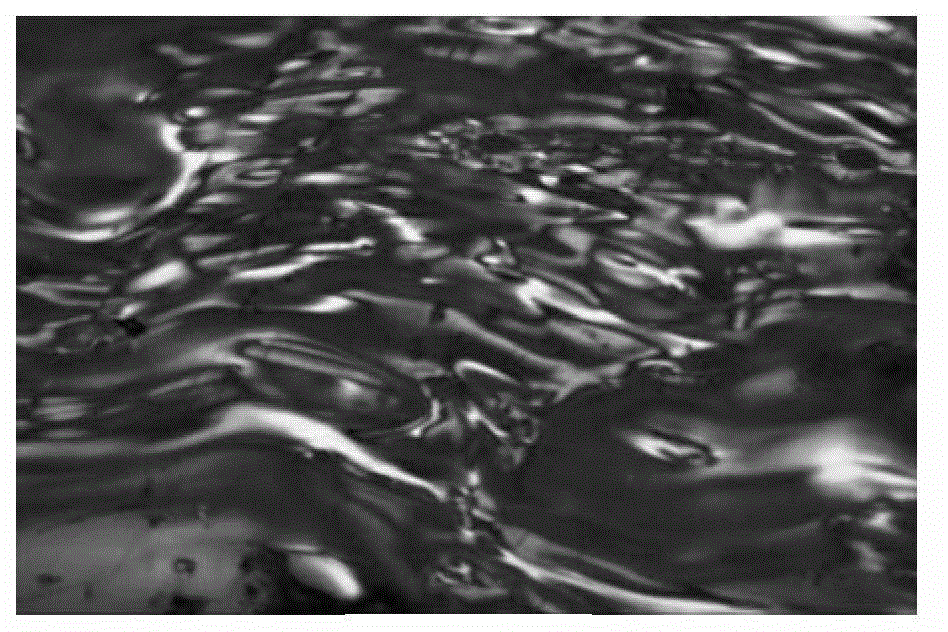

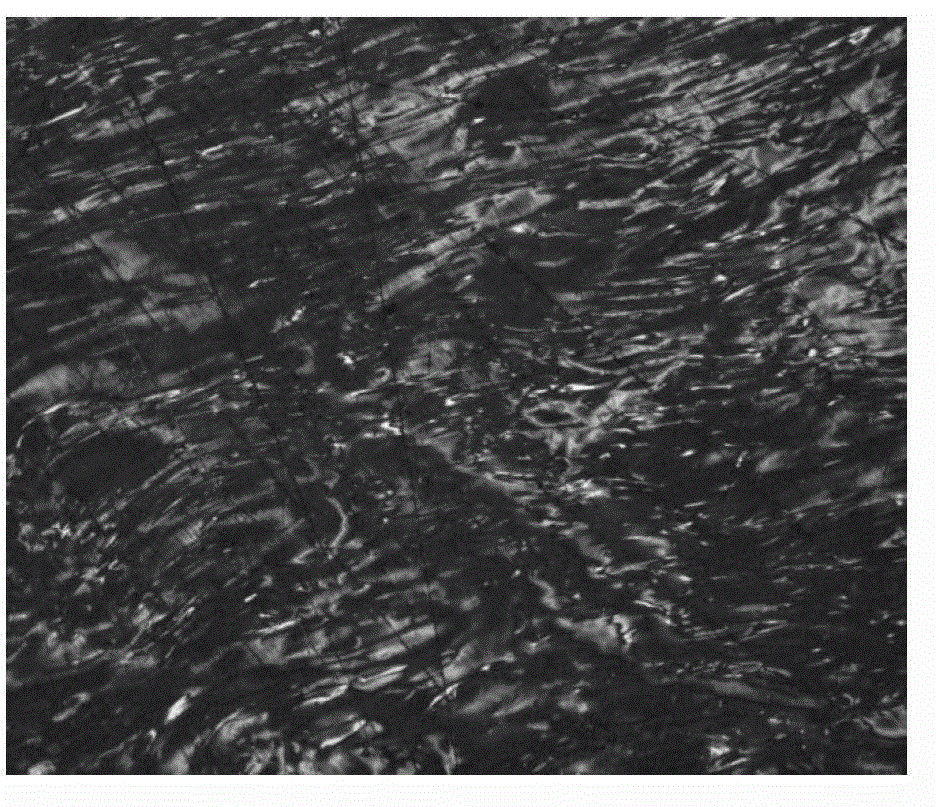

[0084] (4) Then, cool down to 370°C at a rate of 5°C / min, evacuate to 80mbar (absolute pressure), and maintain for 150min. Naturally cool down to room temperature to obtain mesophase pitch 115g (yield 57.5%), the analysis data is as shown in Table 1 and Figure 1 (b), the mesophase pitch of the present invention has a very high aromatic carbon rate, and its mesophase is Ideal wide-area fusion form.

Embodiment 3

[0086] (1) Using the step (1) in Example 1 to obtain the extracted pitch.

[0087] (2) Mix 1000g of extracted bitumen (volume about 976ml) with 4000mL of n-hexane, put it in a mixing tank, dissolve it with n-hexane at 40°C for 30min, then separate by filtration and recover the insoluble matter (about 795g). Then mix the insoluble matter with 2800mL tetrahydrofuran, fully dissolve in the mixing tank for 30 minutes, filter to remove the insoluble matter, and distill the obtained soluble matter to recover tetrahydrofuran. The two-step extraction operation was repeated successively to obtain 750 g of refined pitch with a softening point of 130°C, an ash content of 0.06%, a sulfur content of 0.03%, and a hydrocarbon molar ratio of 1.28.

[0088] (3) Put the above-mentioned refined asphalt in a high-temperature and high-pressure reaction kettle, rapidly raise the temperature to 330°C within 35 minutes, keep the constant temperature under normal pressure for 30 minutes, and dry the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com