Patents

Literature

44 results about "Isotropic pitch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The mesophase pitch forms a thermotropic crystal, which allows the pitch to become organized and form linear chains without the use of tension. Mesophase pitch is made by polymerizing isotropic pitch to a higher molecular weight. The melting point for the mesophase pitch is roughly 300 °C.

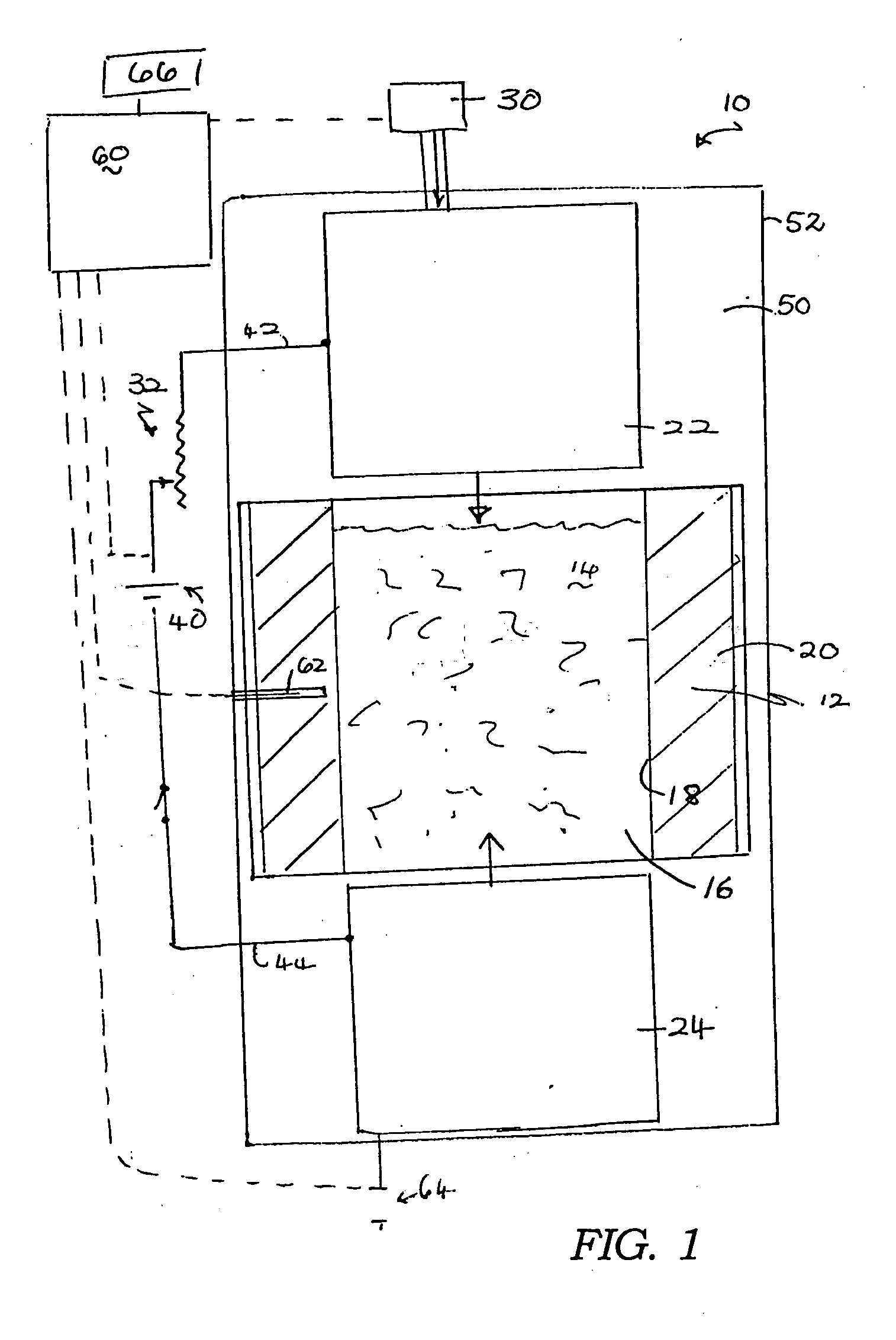

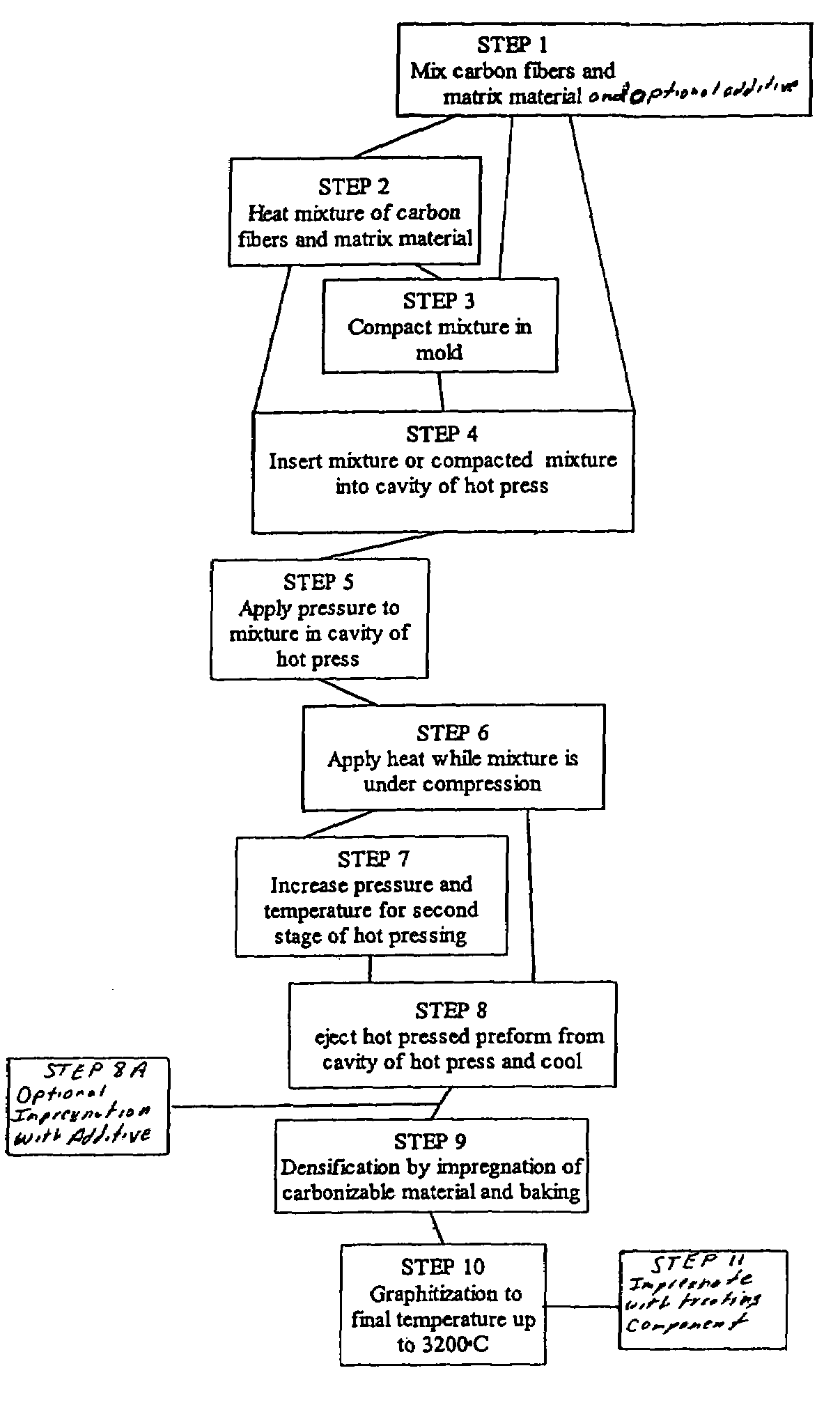

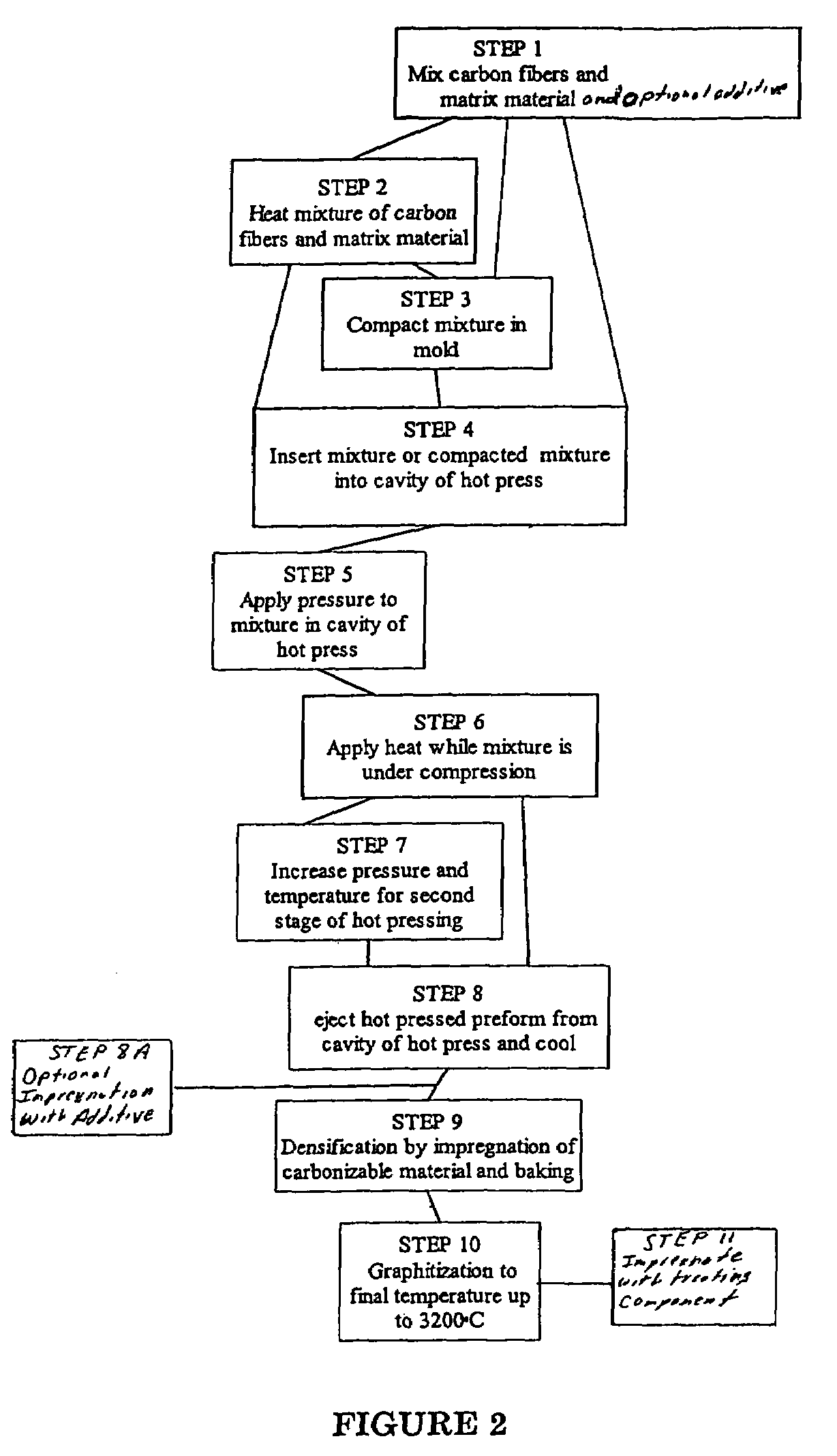

Manufacture of carbon composites by hot pressing

InactiveUS6878331B2Increase coefficient of frictionElectric discharge heatingLaminationFiberCarbon composites

A mixture of carbon-containing fibers, such as mesophase or isotropic pitch fibers, a suitable matrix material, such as a milled pitch is compressed while resistively heating the mixture to form a carbonized composite material. Preferably, the carbonized material has a density of at least about 1.30 g / cm3. Preferably, the composite material is formed in less than ten minutes. This is a significantly shorter time than for conventional processes, which typically take several days and achieve a lower density material. A treating component may be impregnated into the composite. Consequently, carbon composite materials having final densities of about 1.6-1.8 g / cm3 or higher are readily achieved with one or two infiltration cycles using a pitch or other carbonaceous material to fill voids in the composite and rebaking.

Owner:GRAFTECH INT HLDG INC

Method for preparing pitch-based carbon fiber

The invention discloses a method for preparing a pitch-based carbon fiber, relates to the carbon fiber and a preparation method thereof, and provides the method for preparing the pitch-based carbon fiber which has the advantages of high mechanical performance, simple production process, low cost, stable product performance and the like. The method comprises the following steps of: heating anisotropic pitch and isotropous pitch under the protection of inert gas; mechanically stirring in a molten state at a constant temperature; cooling to obtain a mixed pitch raw material; placing into a spinning barrel of a melt spinning machine; loading in a pitch carbon fiber forming device; heating under the protective gas to a melt spinning temperature to obtain a precursor fiber at a spinning nozzle;placing on a sample carrying table; placing in a high temperature furnace; setting a heating program; performing oxidation treatment and naturally cooling to obtain an oxidized fiber; and placing a cross-linked oxidized fiber on the sample carrying table, placing in the high temperature furnace, setting a heating program, introducing the inert gas for protection, performing carbonization treatment and then naturally cooling to obtain the pitch-based carbon fiber.

Owner:XIAMEN UNIV

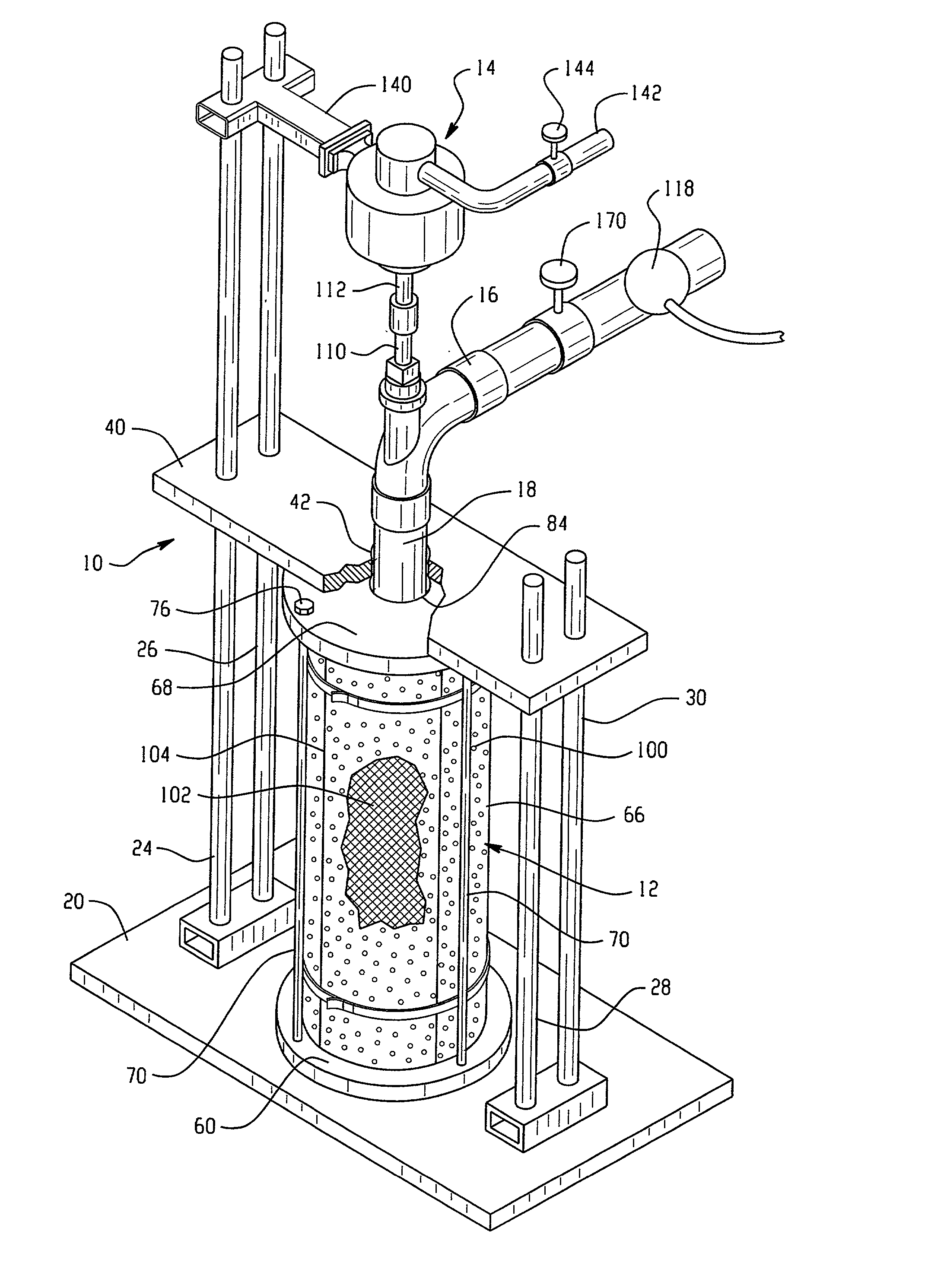

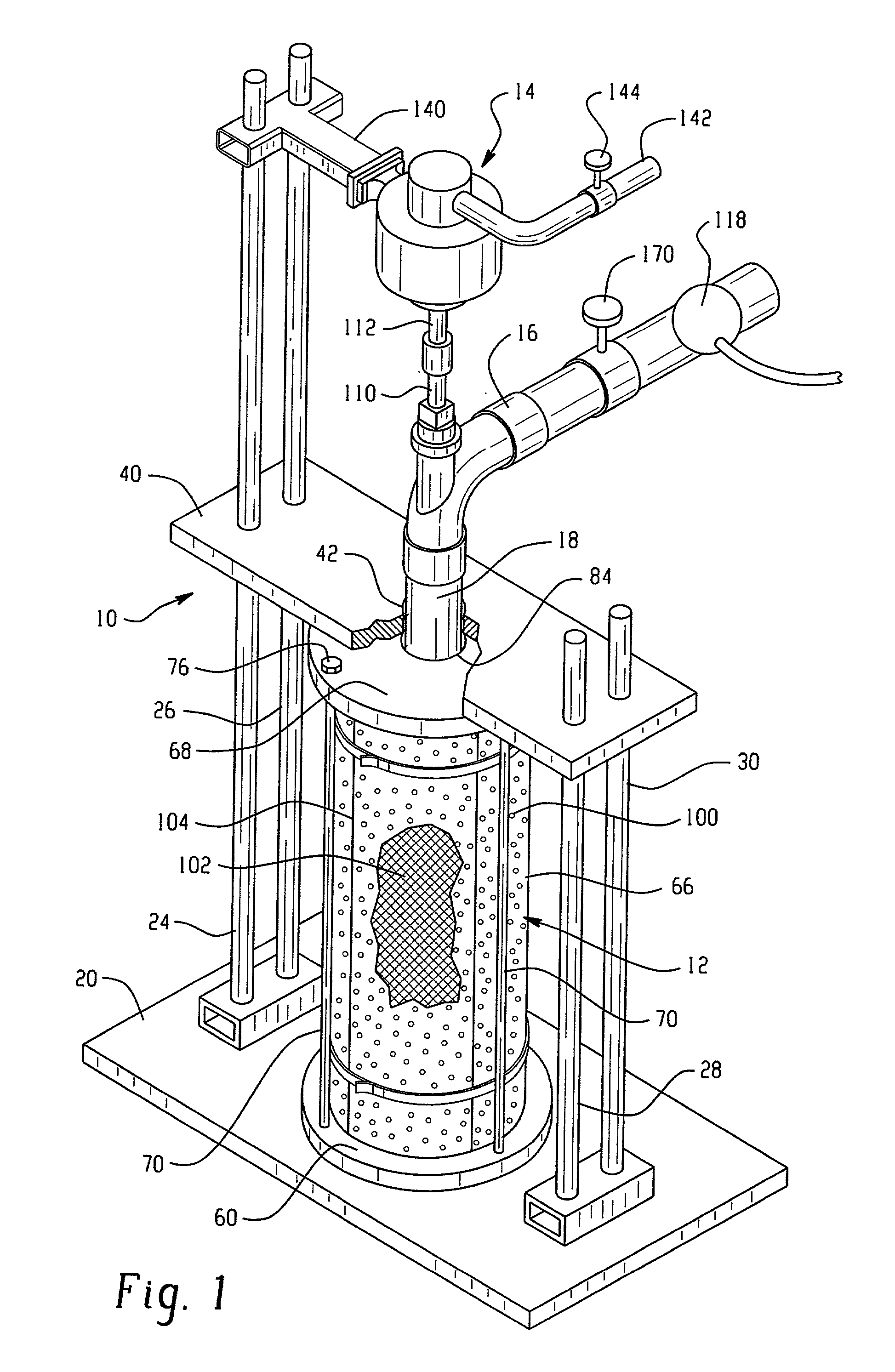

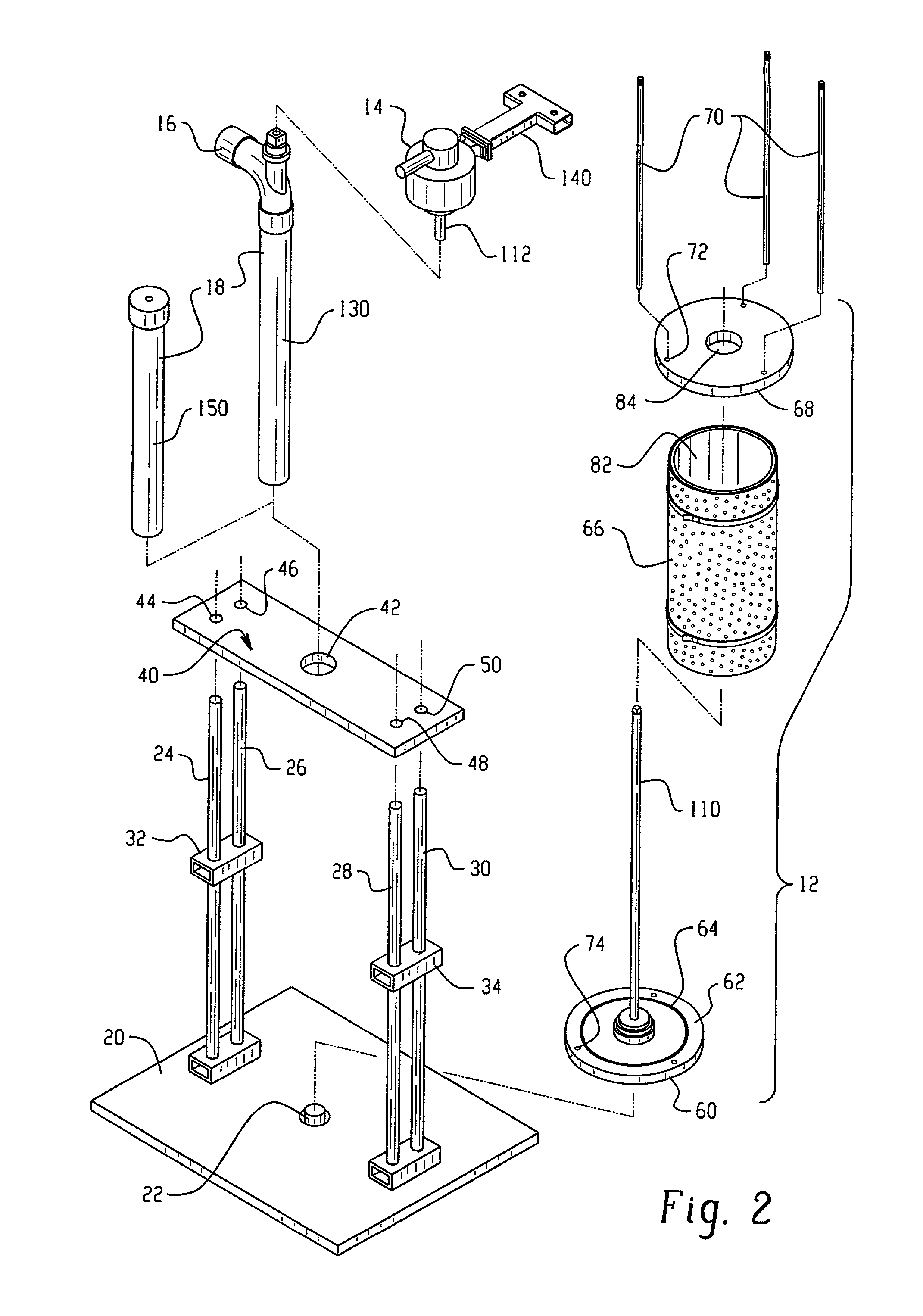

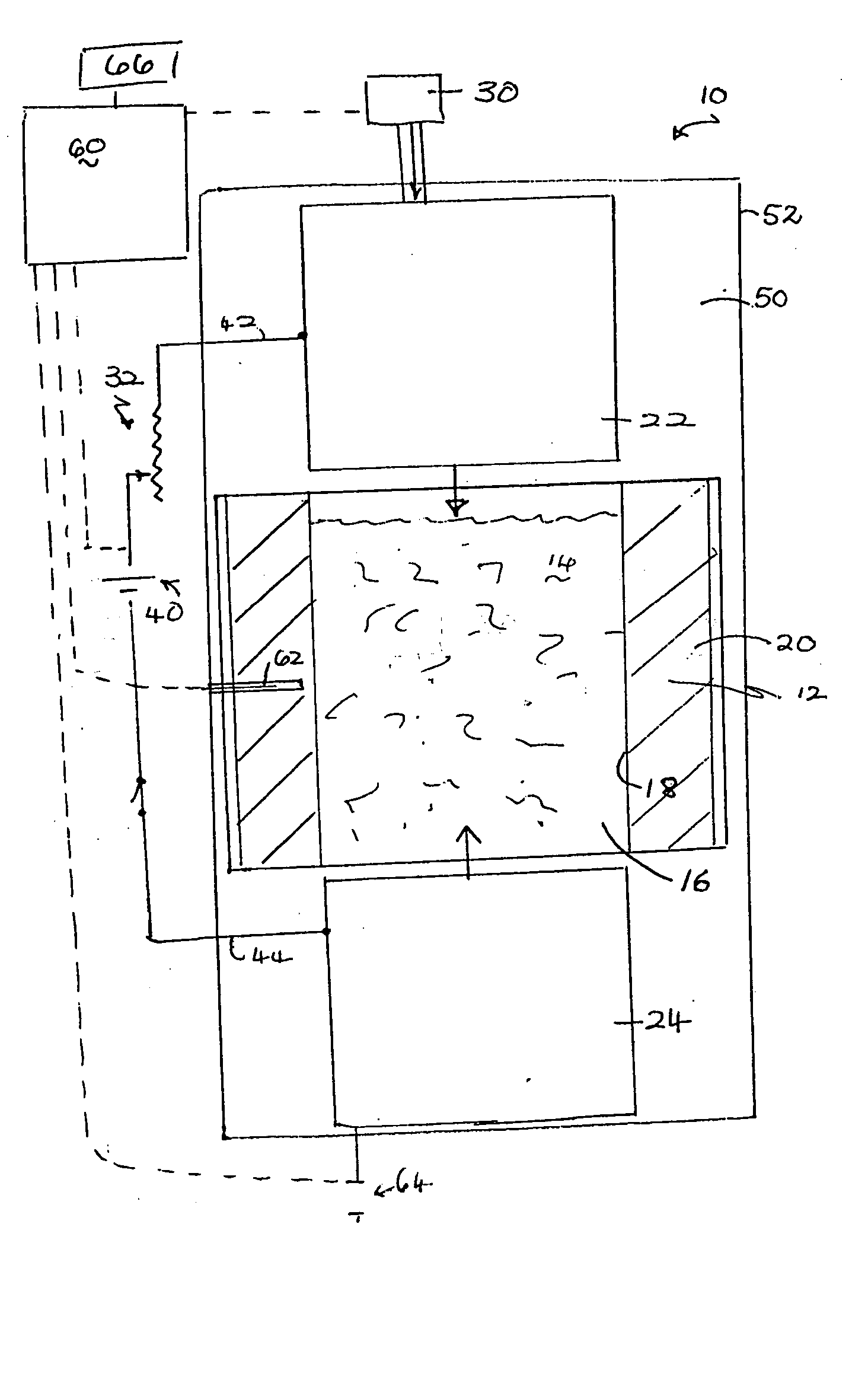

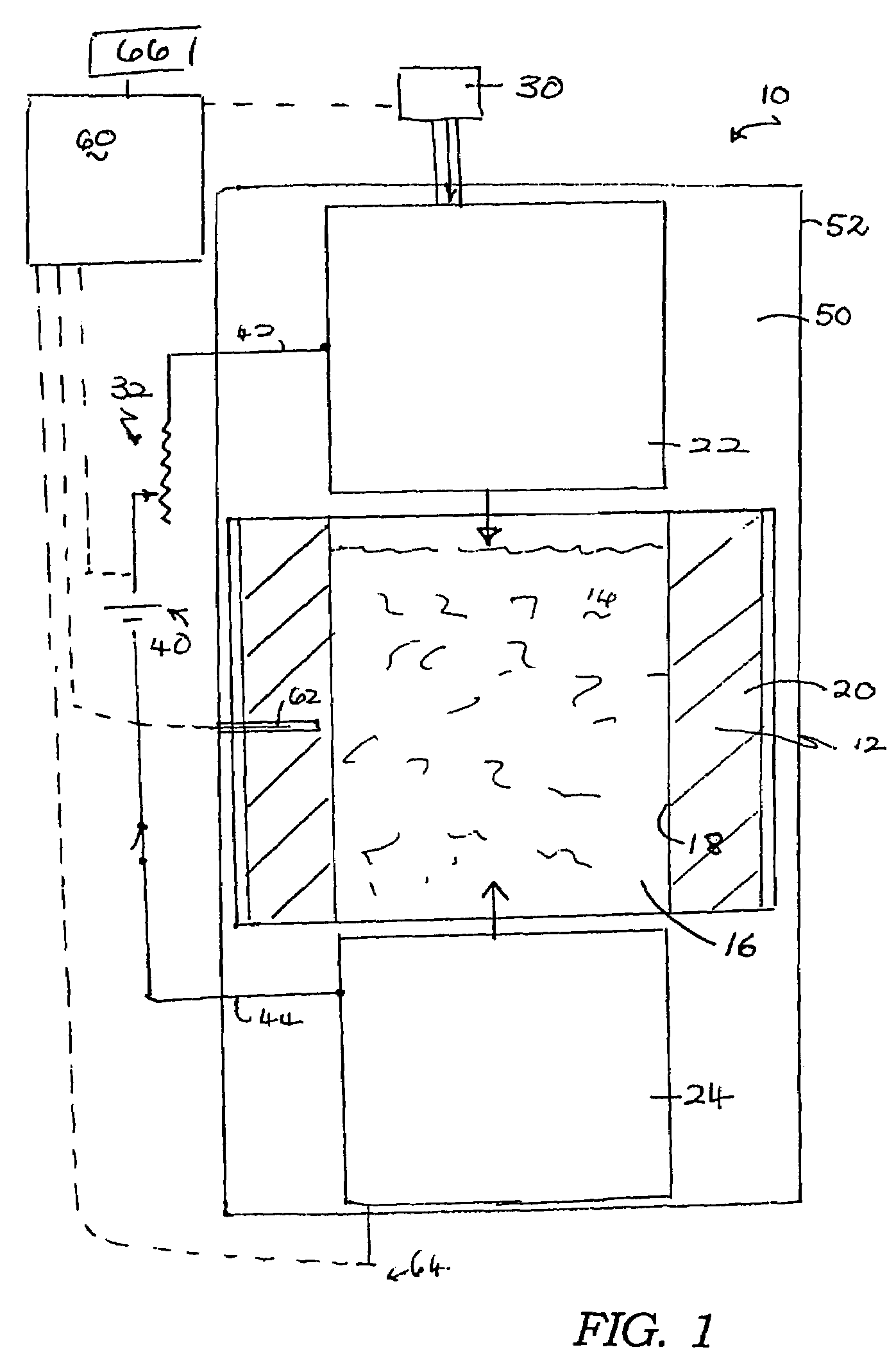

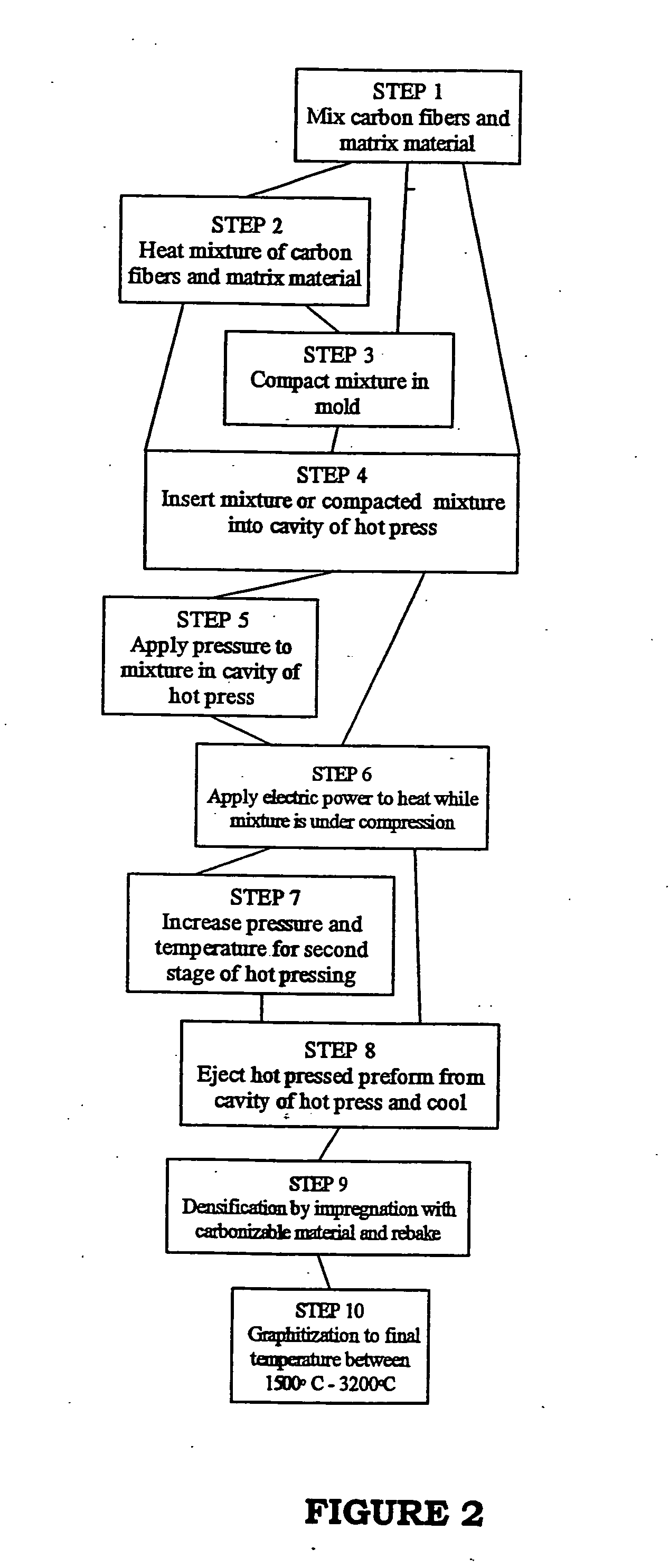

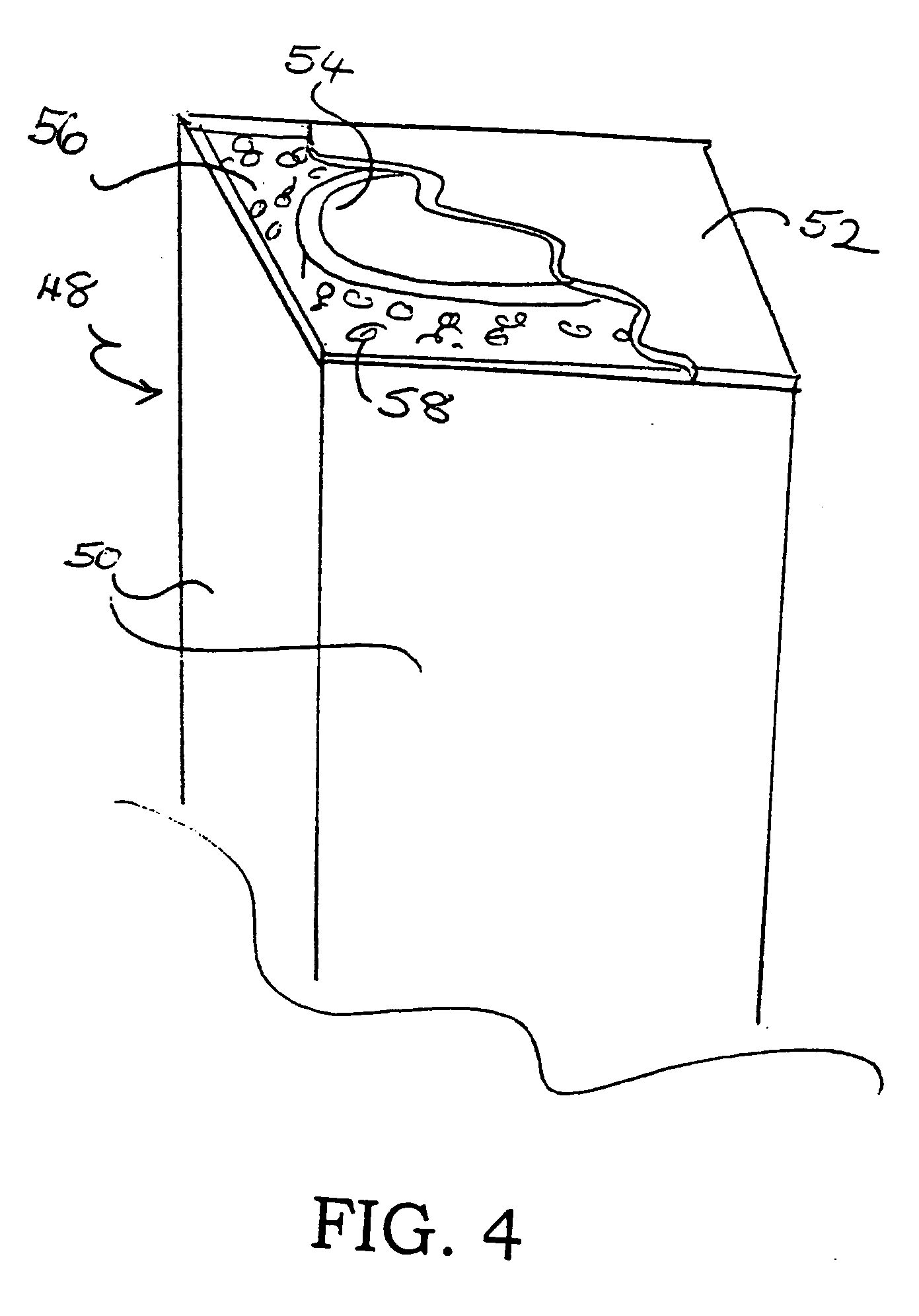

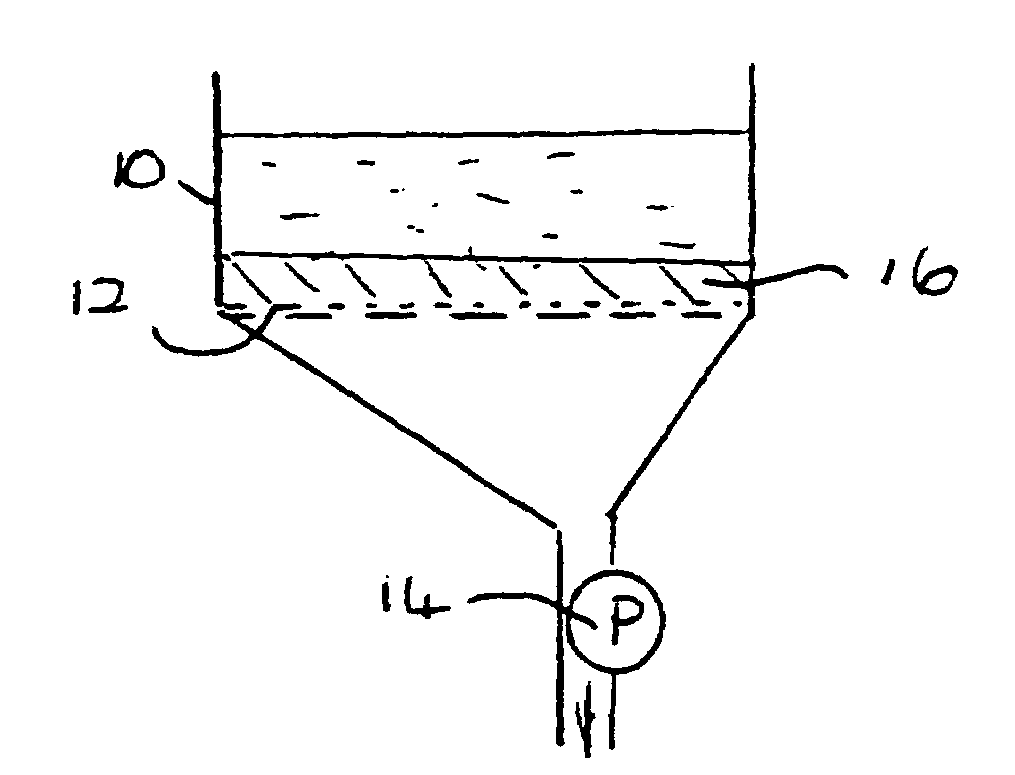

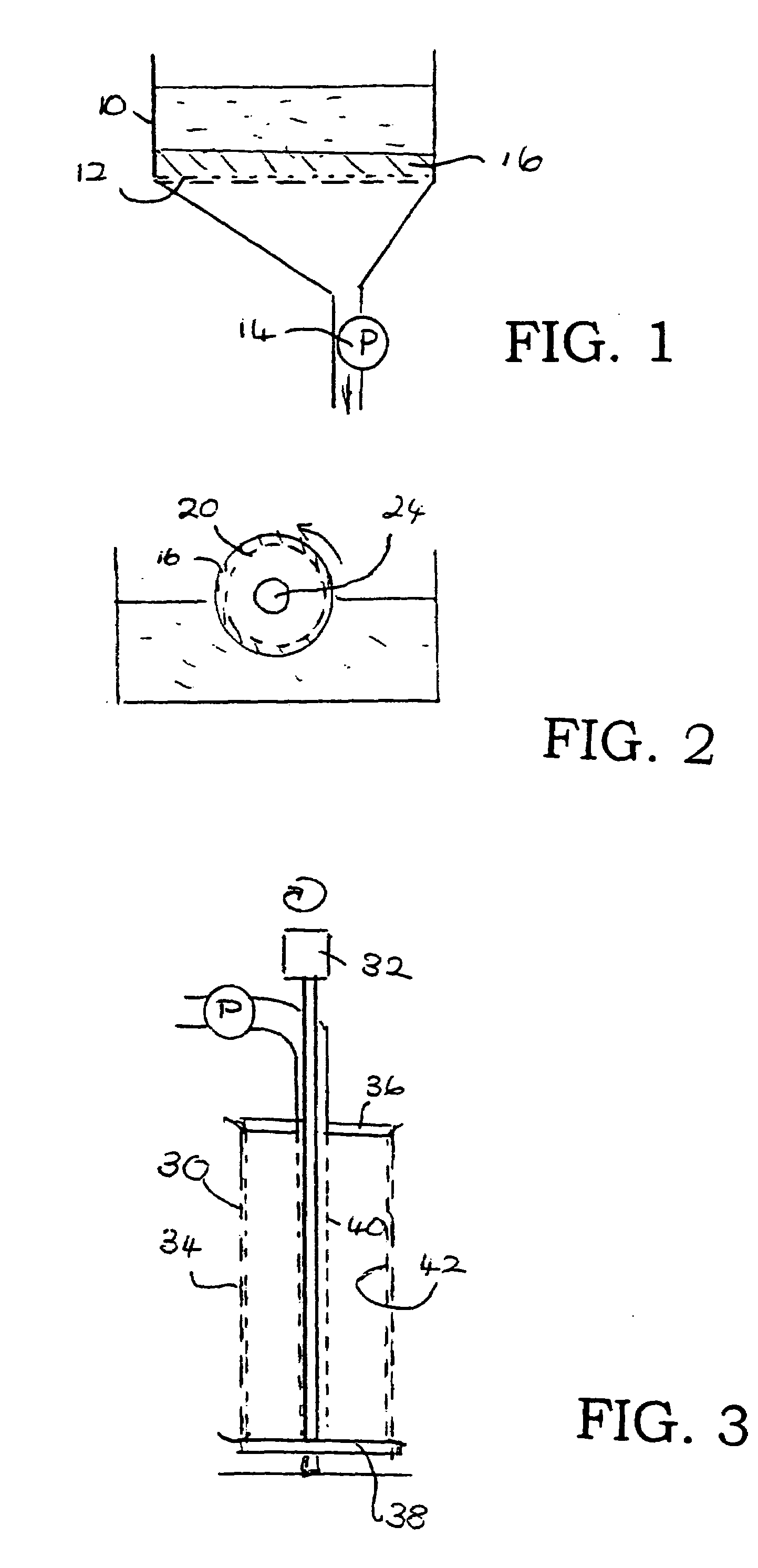

Centrifugal casting of graphite for rigid insulation

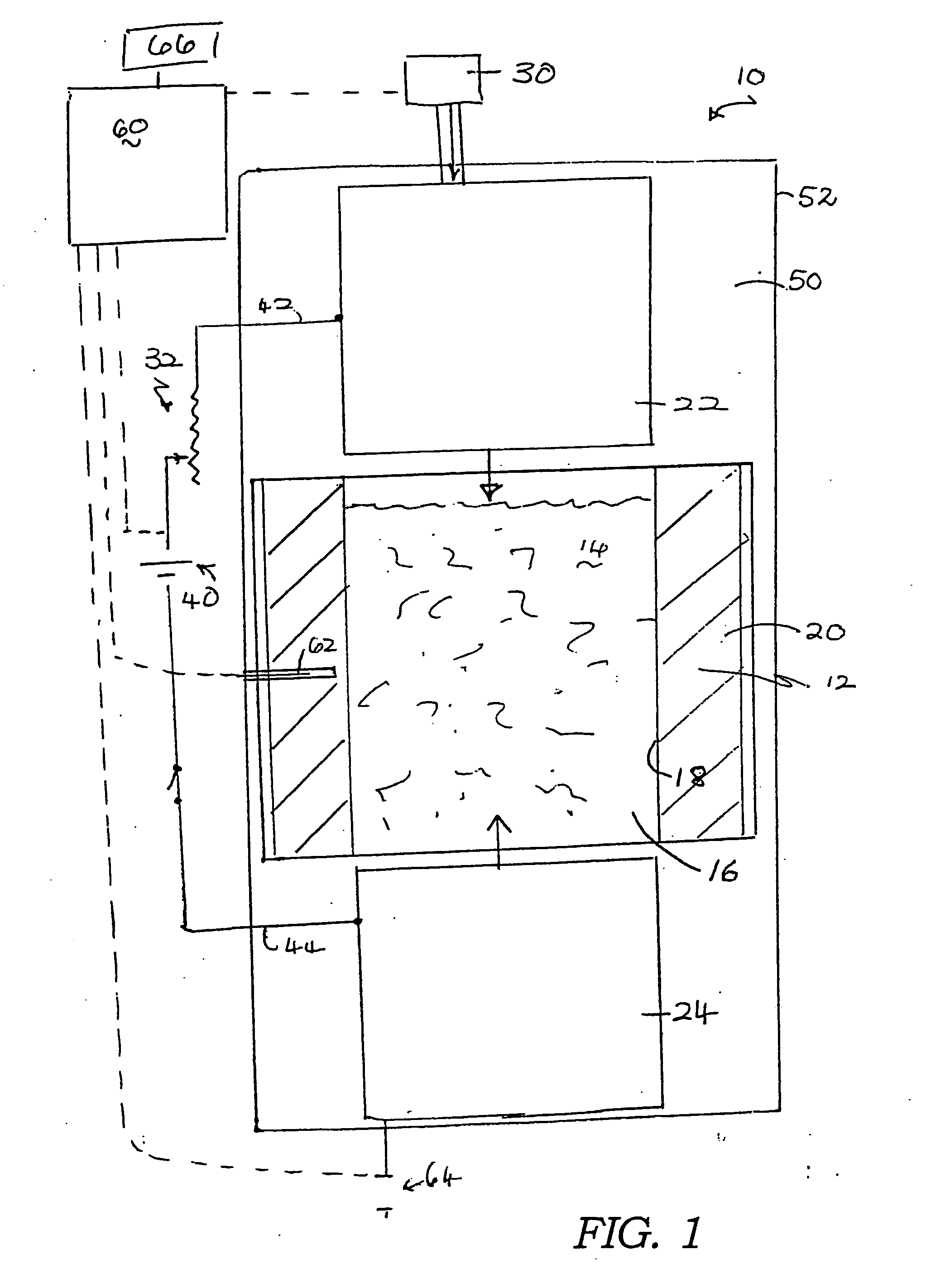

InactiveUS20040000734A1Low thermal conductivityReduce variationConfectionerySweetmeatsFiberThermal insulation

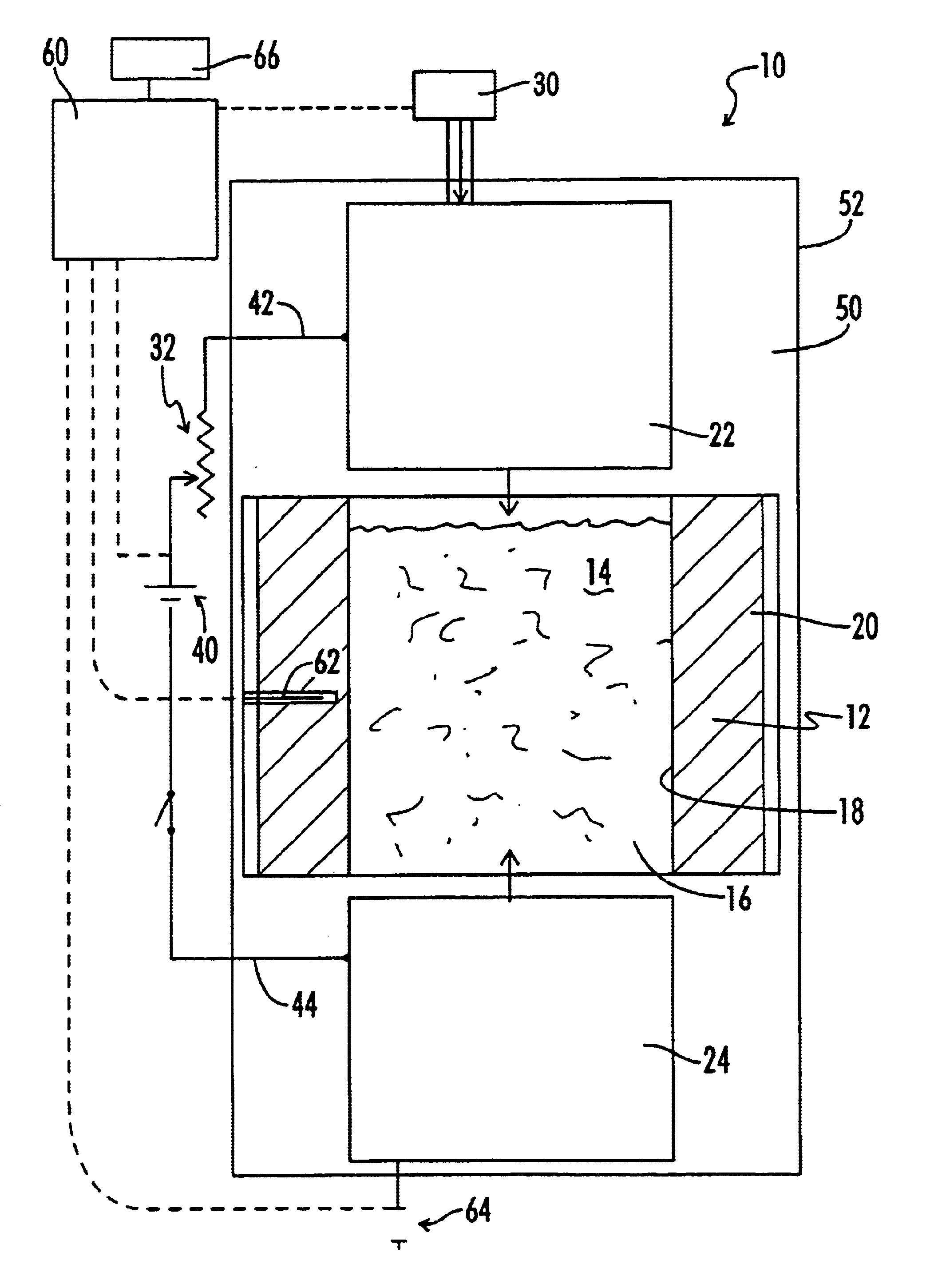

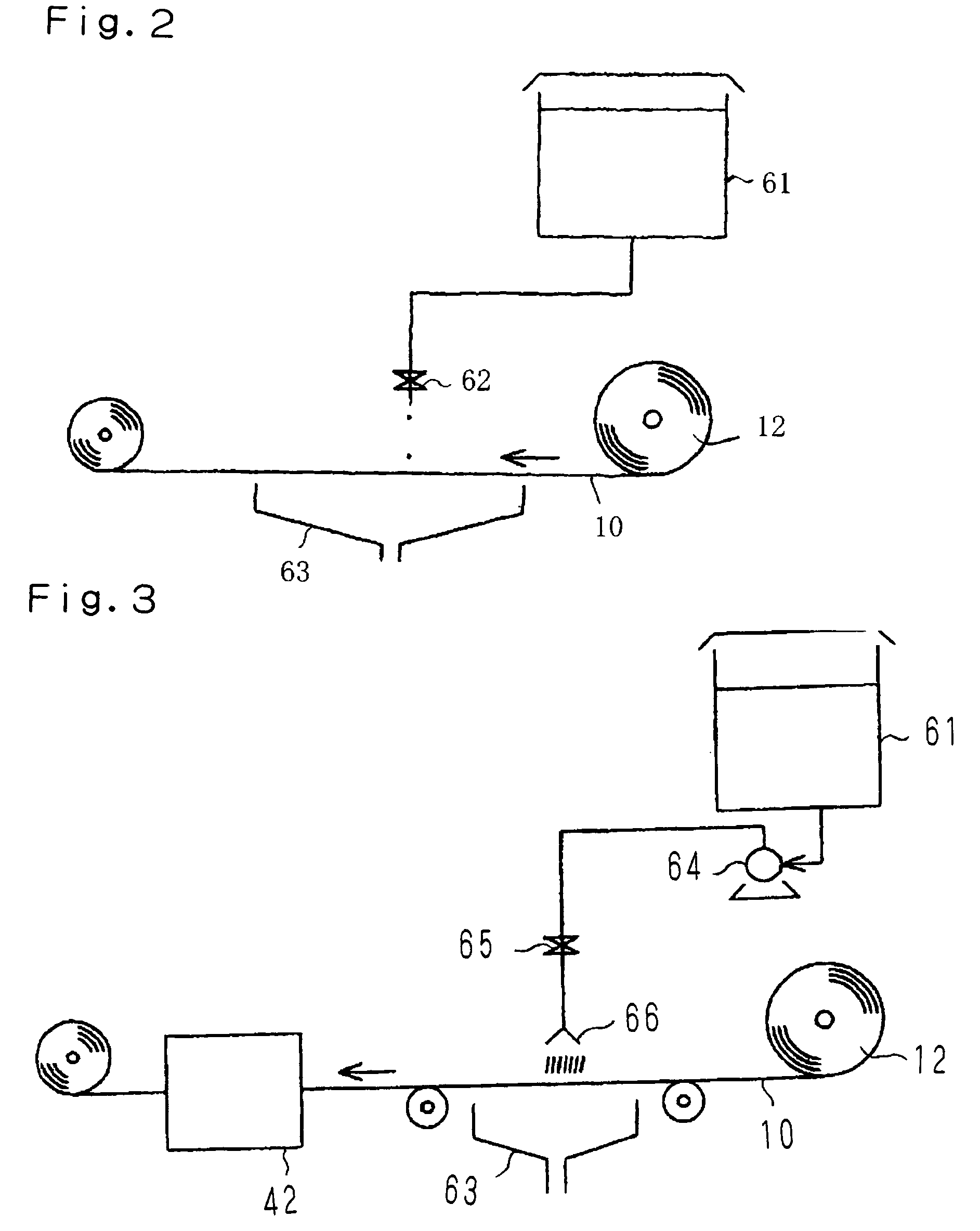

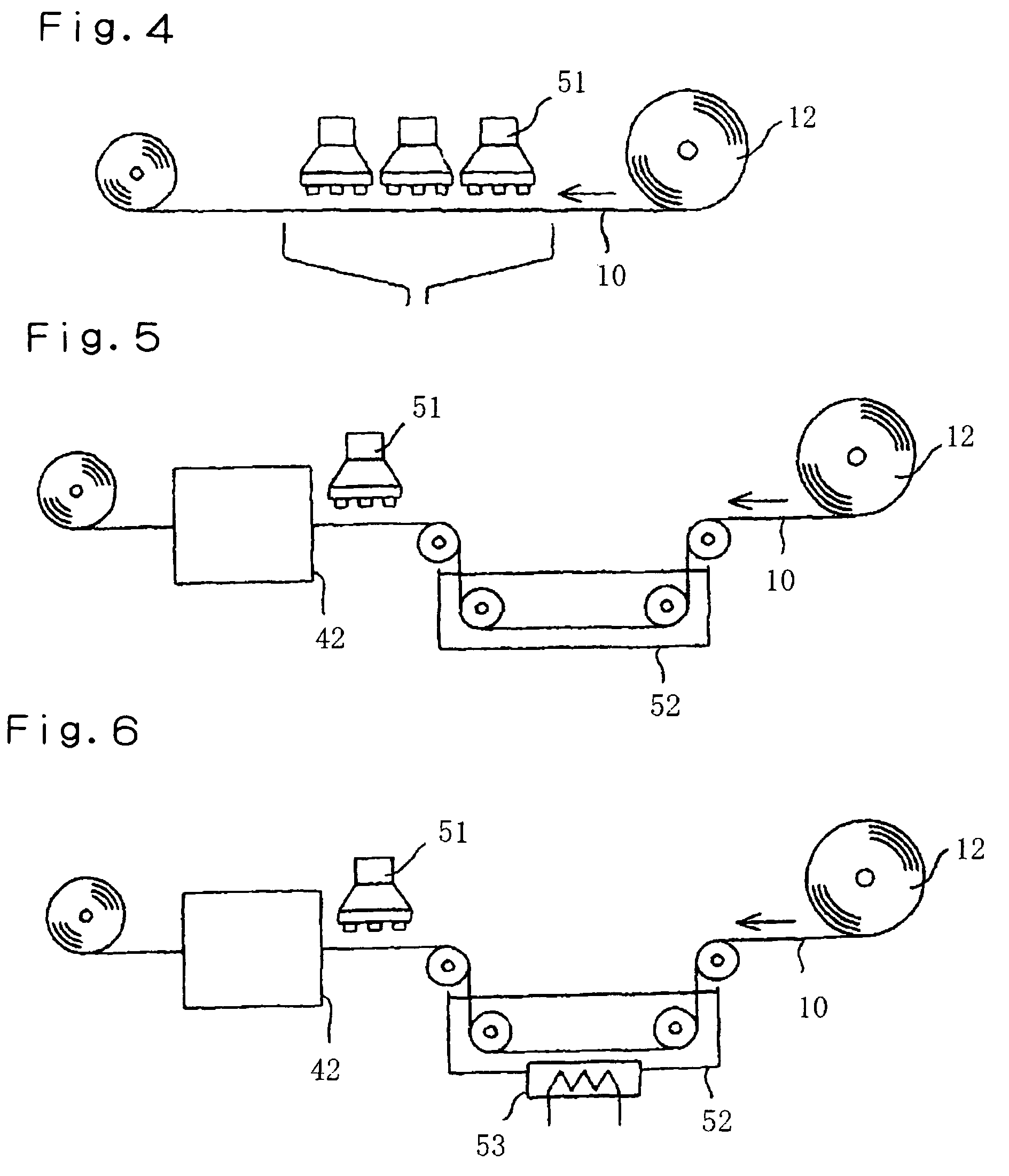

Cylindrical castings (174), suited to thermal insulation applications at high temperatures, are formed by a centrifugal casting process. A mixture of carbon-containing fibers, such as isotropic pitch fibers, and a suitable aqueous binder, such as a sugar solution, is supplied to a rotating drum (12). The mixture is supplied via a feed pipe (18) concentrically aligned with a screen (66) of the drum. The fibers and binder collect on a filter cloth (102) supported by an inner surface of the screen. Excess binder flows through the filter cloth and passes through adjacent apertures (100) in the screen. When a cylindrical preform of sufficient thickness has built up, the drum is disassembled. The preform is dried, to drive off excess water, and heated to a temperature of about 900° C.-2000° C. to form the casting.

Owner:UCAR CARBON TECH

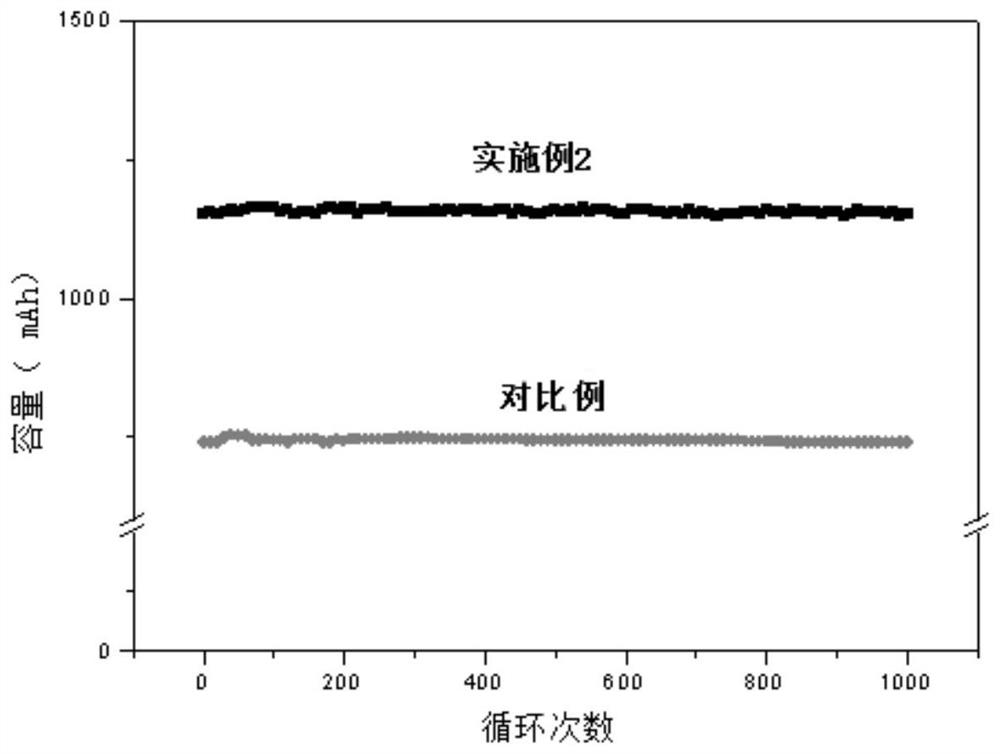

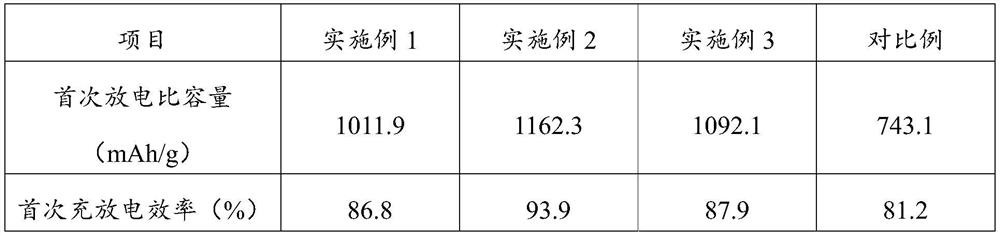

High softening point bitumen used as lithium ion battery negative pole coating layer material and manufacture thereof

ActiveCN101108918AImprove discharge capacityPromote circulationActive material electrodesNon-aqueous electrolyte accumulator electrodesPetroleumLithium electrode

The invention discloses an asphalt with high softening point for the clad material of the negative electrode of lithium ion battery, which is characterized in that the asphalt is the isotropic asphalt with content of fixed carbon more than 80 per cent, content of quinoline insolubles of 10 per cent to 30 per cent, content of toluene insolubles of 60 per cent to 90 per cent and softening point of 240 DEG C. to 300 DEG C.. The invention realizes the process solution of the clad material-asphalt with high softening point of the lithium ion battery prepared by cheap mid-temperature coal asphalt or petroleum asphalt and adopts the material as the lithium ion secondary battery modification graphite negative electrode materials, which has high discharge capacity, good cycle performance, lower production cost, simple process of the invention and easy industrialization.

Owner:ZHANJIANG JUXIN NEW ENERGY

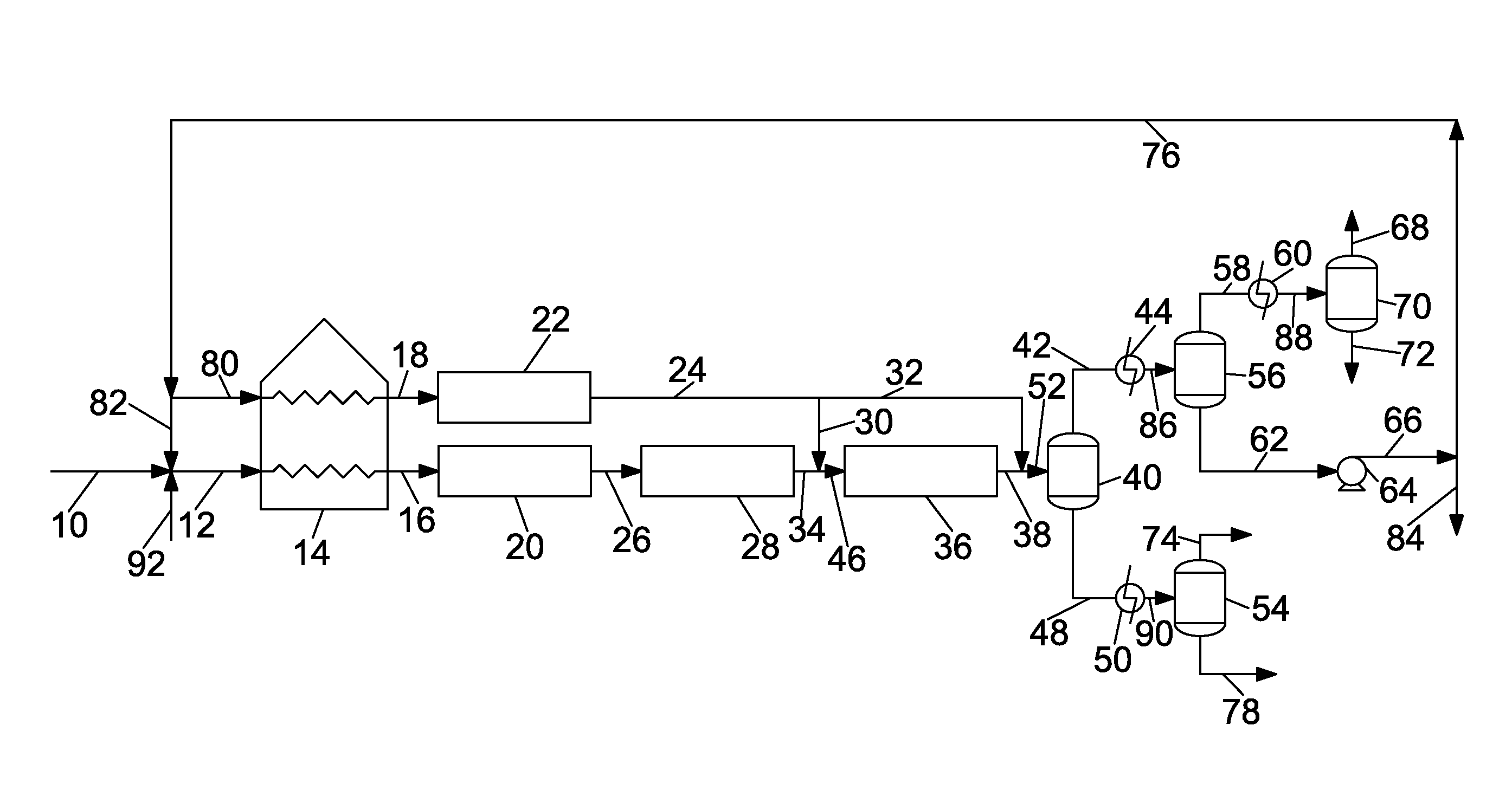

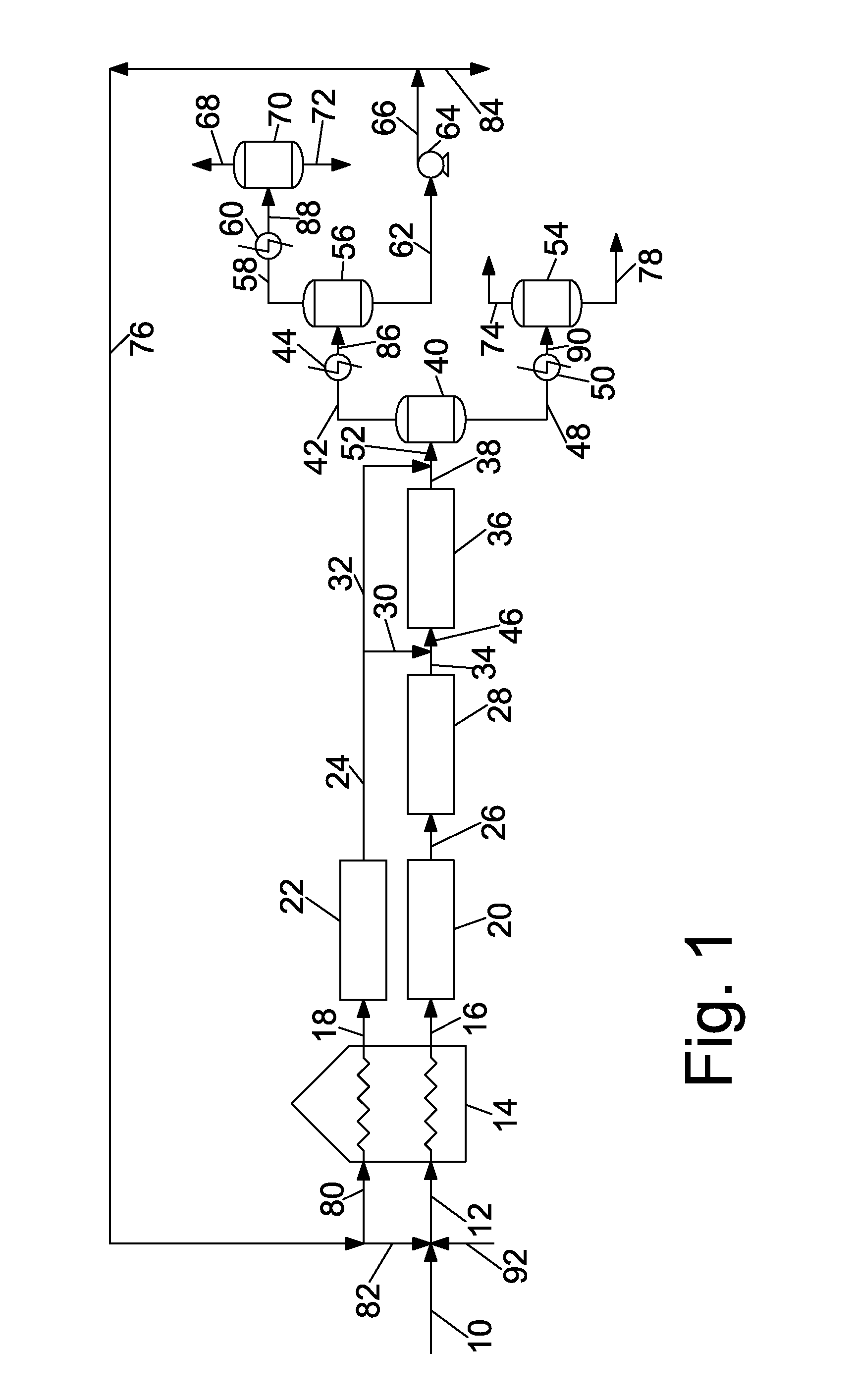

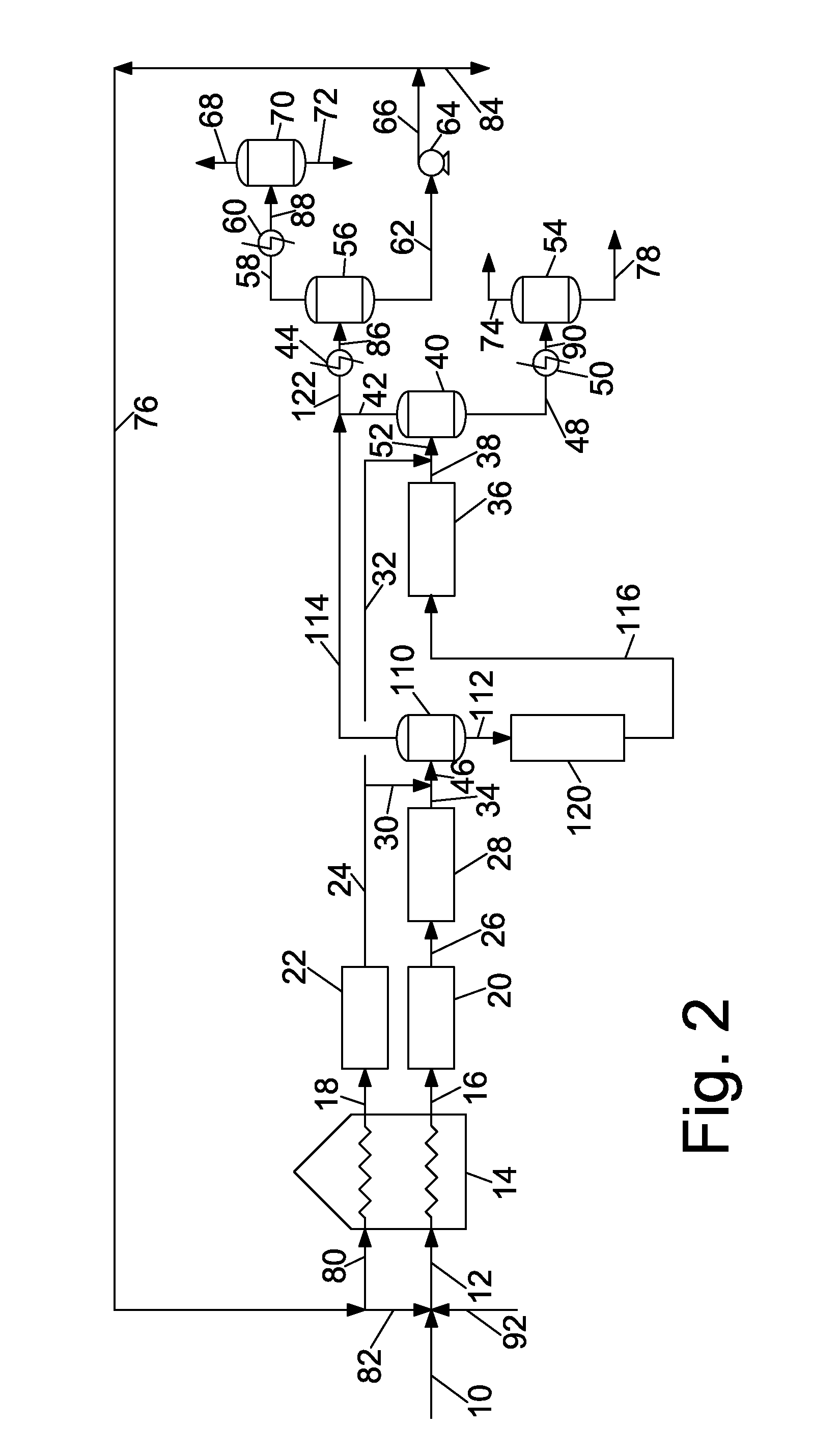

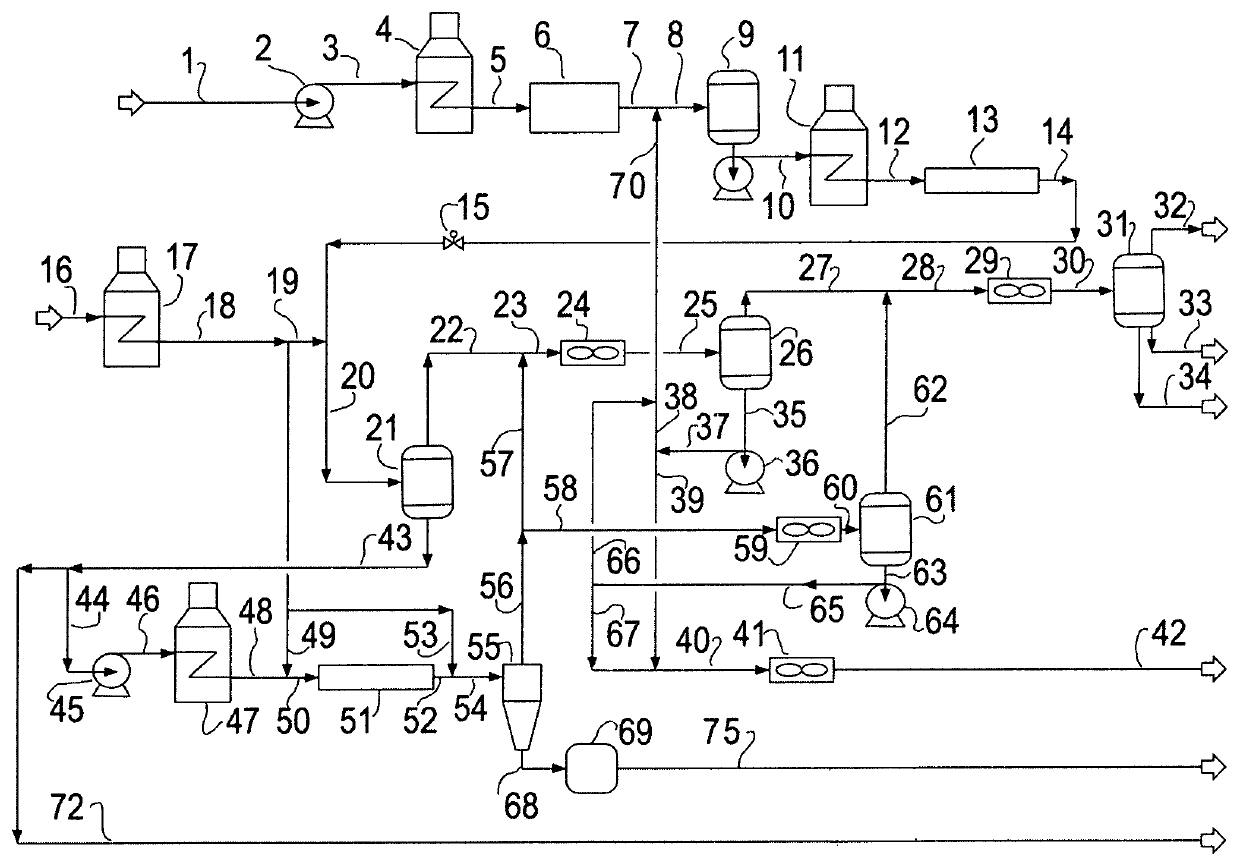

Single stage pitch process and product

ActiveUS9222027B1Suppress mesophase formationSimple materialThermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by chemical meansEngineeringHigh pressure

A process and apparatus for making isotropic pitch are disclosed. A tubular reactor operating at high velocity and pressure converts aromatic rich liquid feed to pitch within minutes. Reactor is heated by electric resistance or inductance, a salt or molten metal bath, or fired heater. Reactor effluent flashes and isotropic pitch recovered from the flash drum. Softening point is affected by flash drum pressure or stripping steam. Unconverted feed may be recycled. Process makes little gasoline, simple condensation of flash drum vapor may produce gas oil and gasoline fractions. Isotropic pitch is made in a single step with a coking value of 50 to 55 wt %. Time and temperature in the reactor convert at least 20 wt % of feed and any recycle material present to isotropic pitch. Pressure is preferably above 500 psig, to suppress mesophase formation and produce isotropic pitch with less than 0.5 wt % mesophase.

Owner:ACP TECH LLC

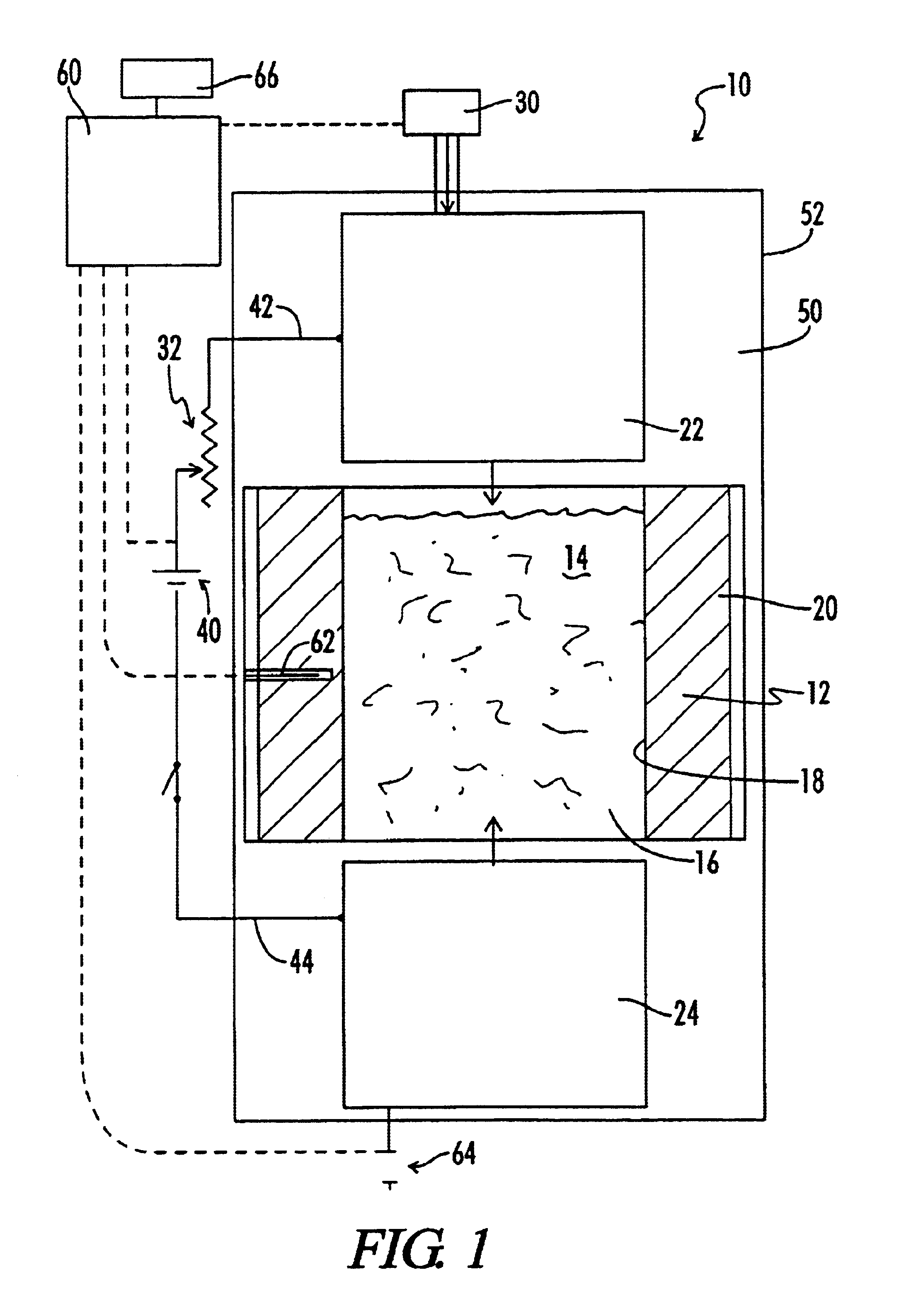

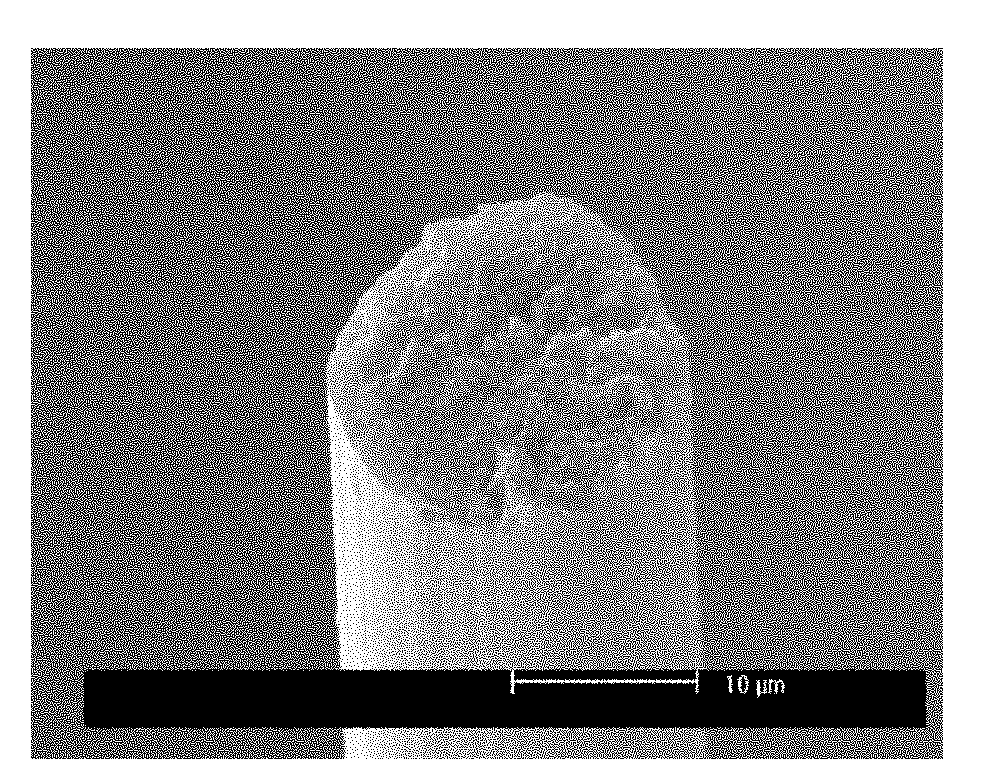

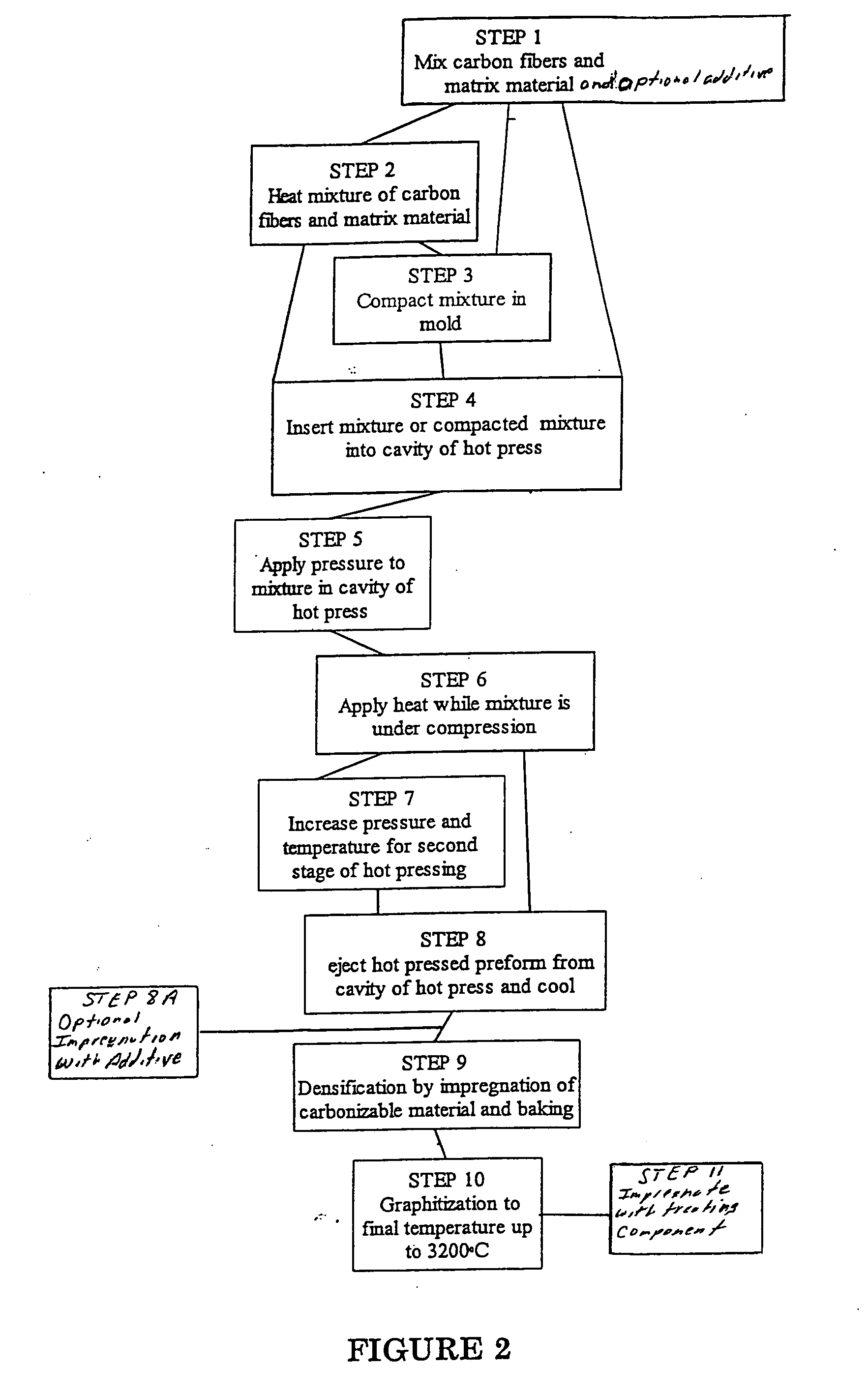

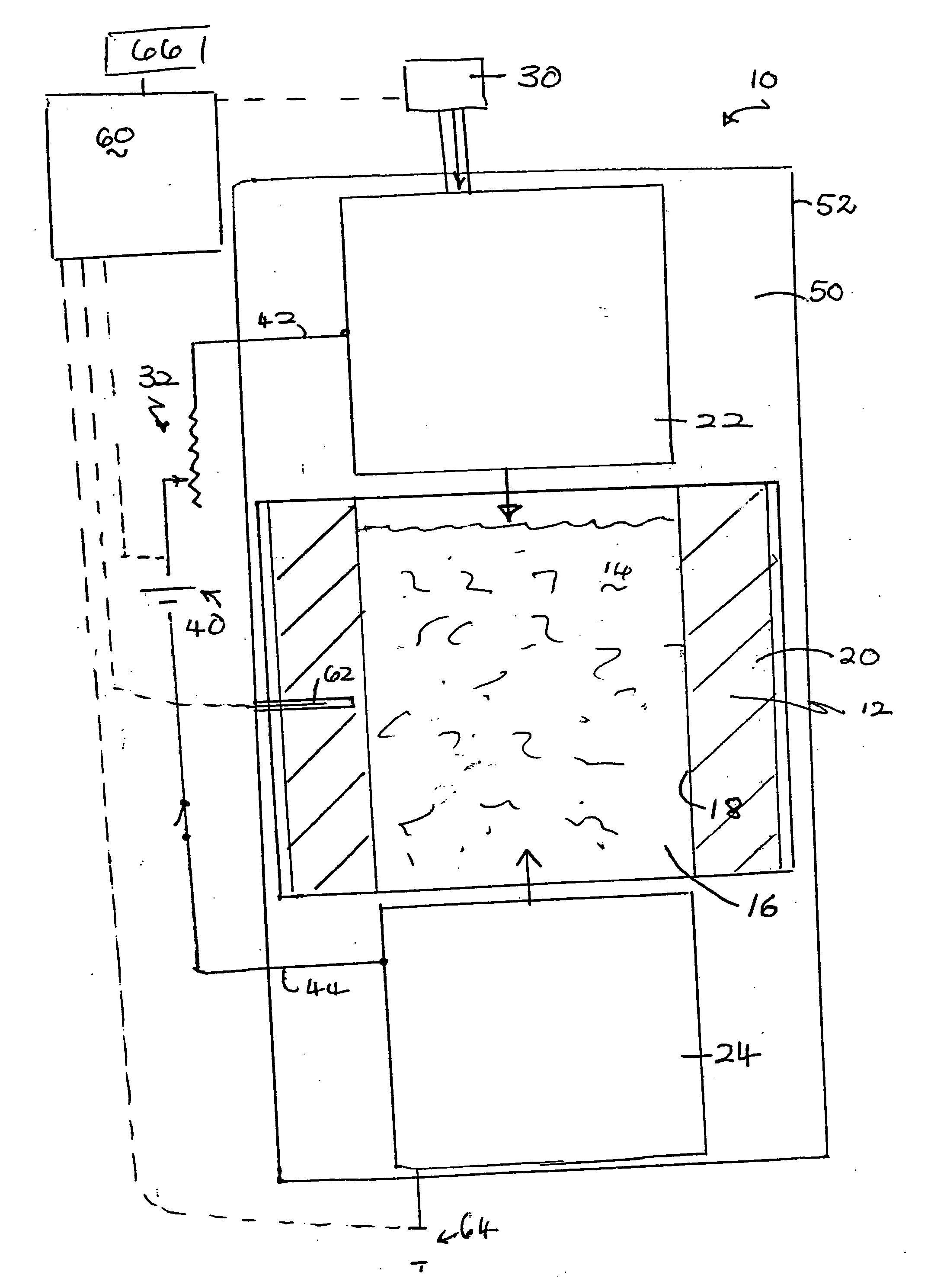

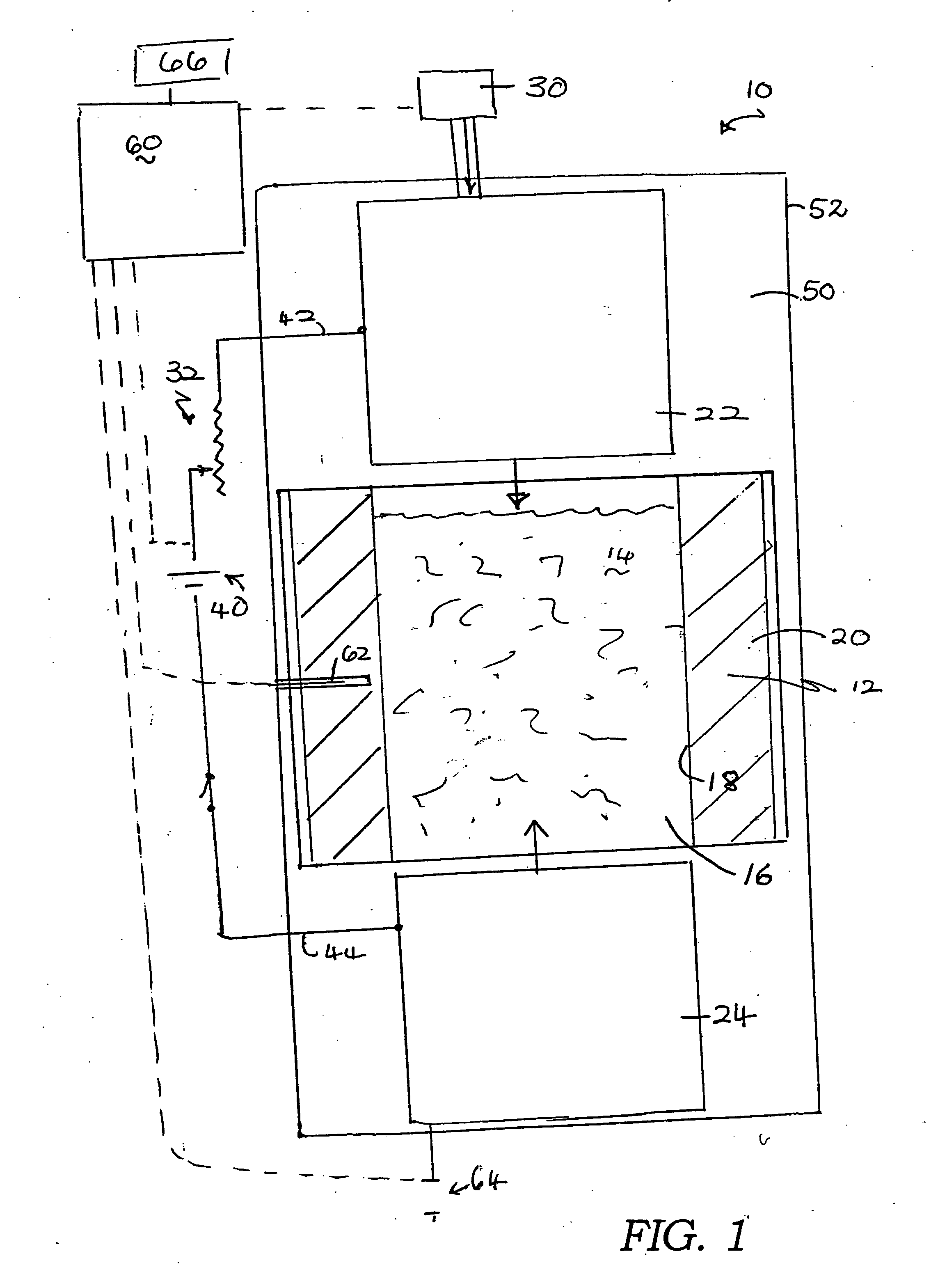

Manufacture of carbon/carbon composites by hot pressing

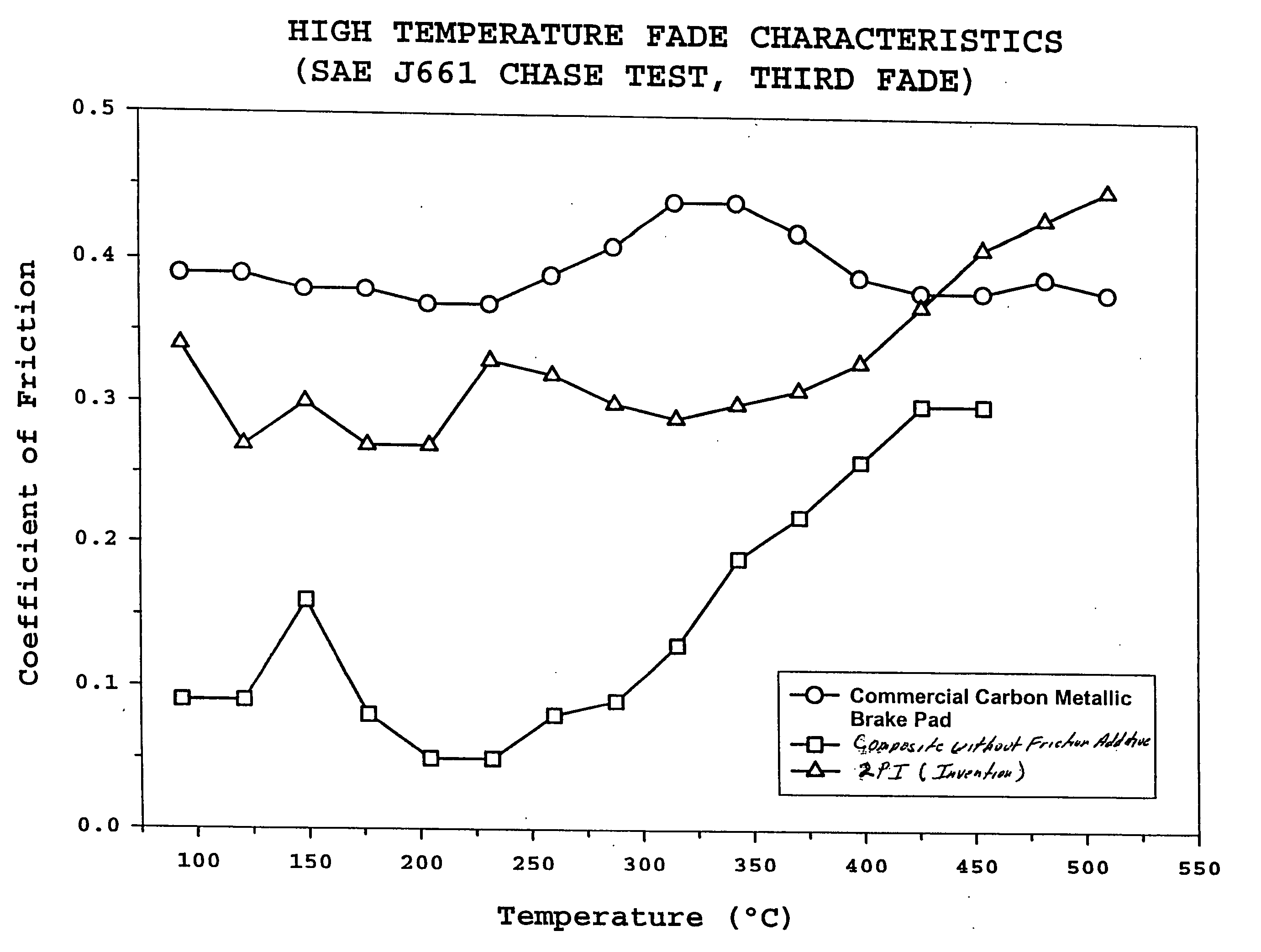

InactiveUS20050051394A1Increase coefficient of frictionImprove Oxidation StabilityMaterial nanotechnologyLaminationFiberCarbon composites

A mixture of carbon-containing fibers, such as mesophase or isotropic pitch fibers, a suitable matrix material, such as a milled pitch is compressed while resistively heating the mixture to form a carbonized composite material. Preferably, the carbonized material has a density of at least about 1.30 g / cm3. Preferably, the composite material is formed in less than ten minutes. This is a significantly shorter time than for conventional processes, which typically take several days and achieve a lower density material. A treating component may be impregnated into the composite. Consequently, carbon / carbon composite materials having final densities of about 1.6-1.8 g / cm3 or higher are readily achieved with one or two infiltration cycles using a pitch or other carbonaceous material to fill voids in the composite and rebaking.

Owner:GRAFTECH INT HLDG INC

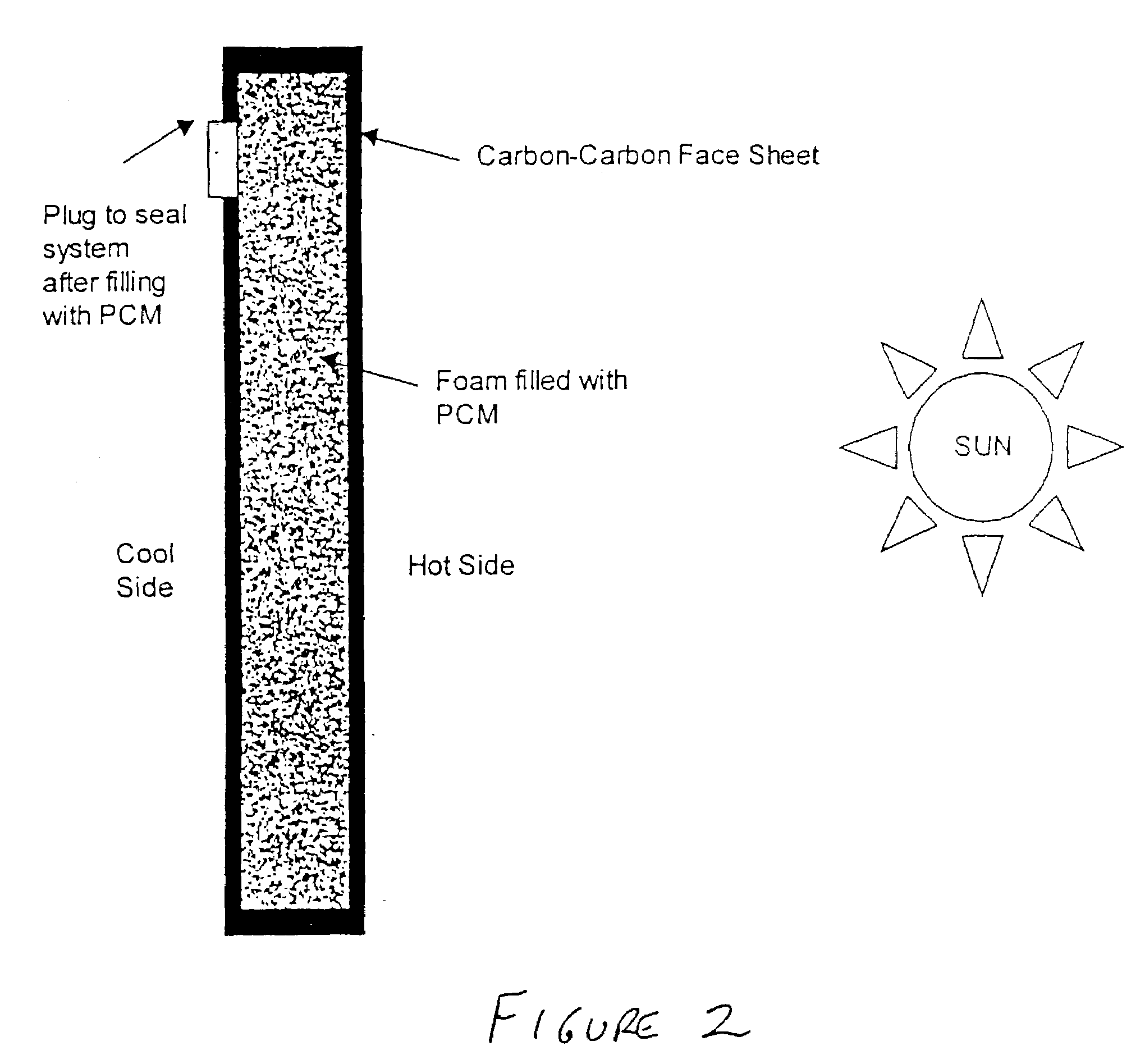

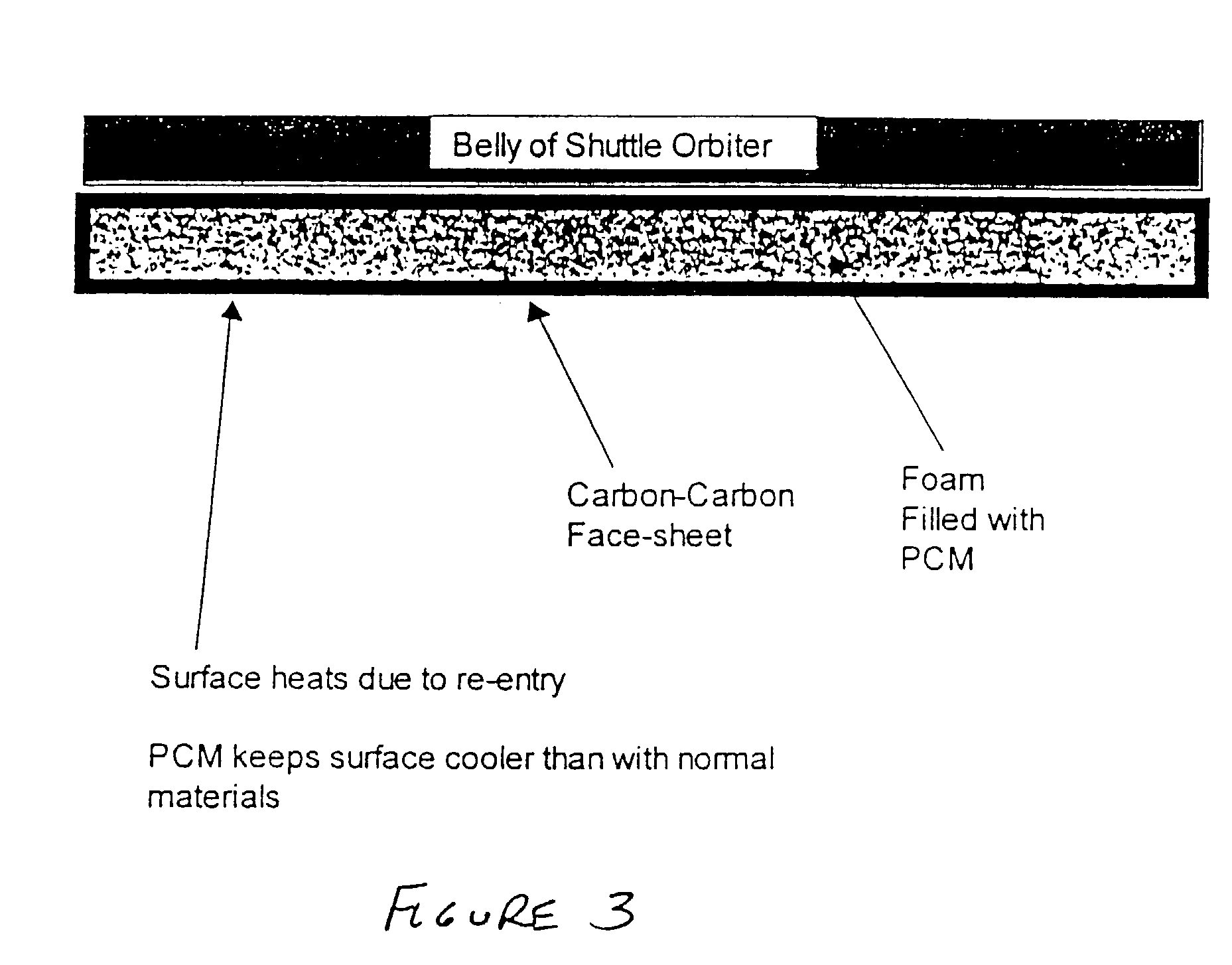

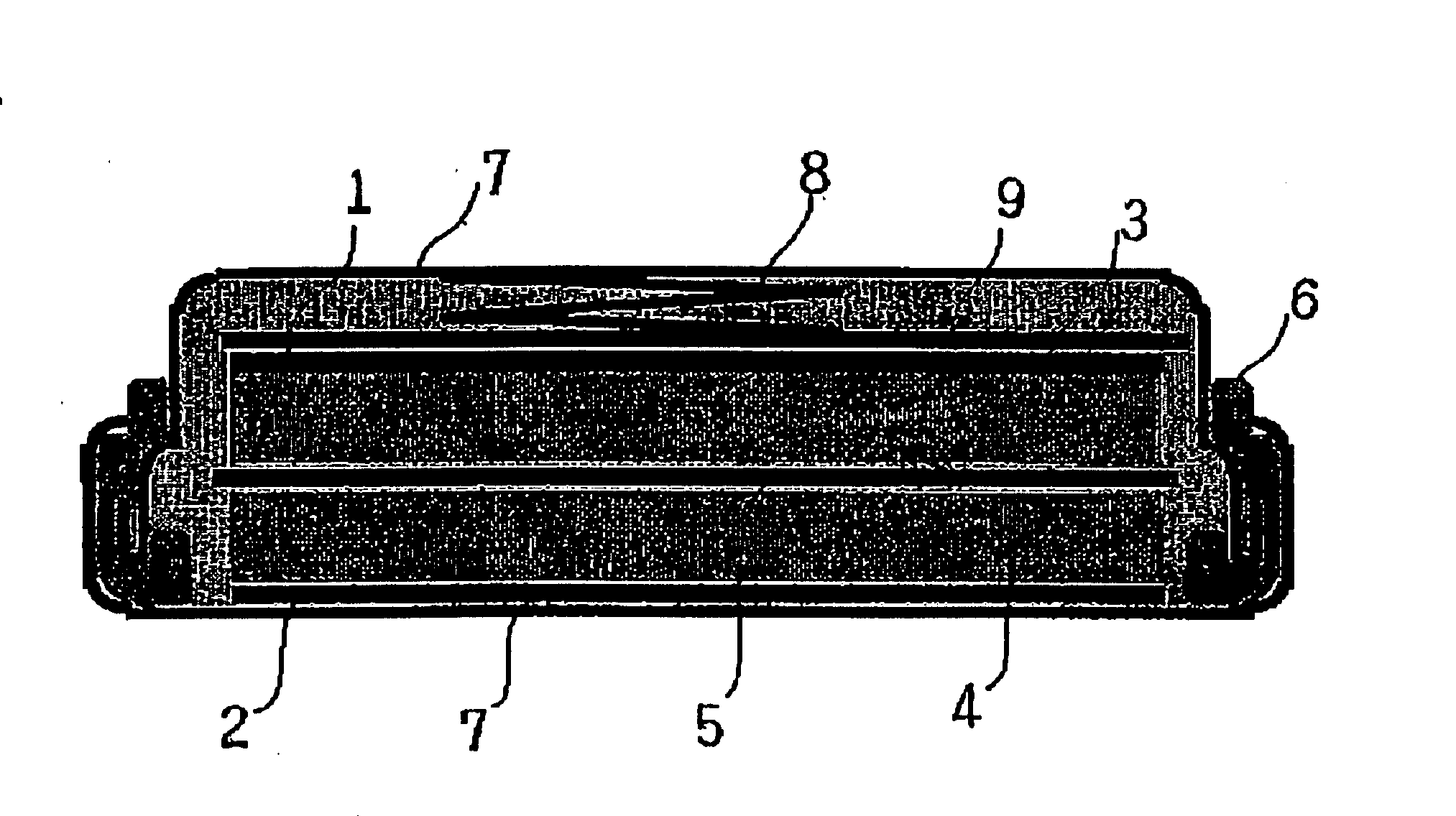

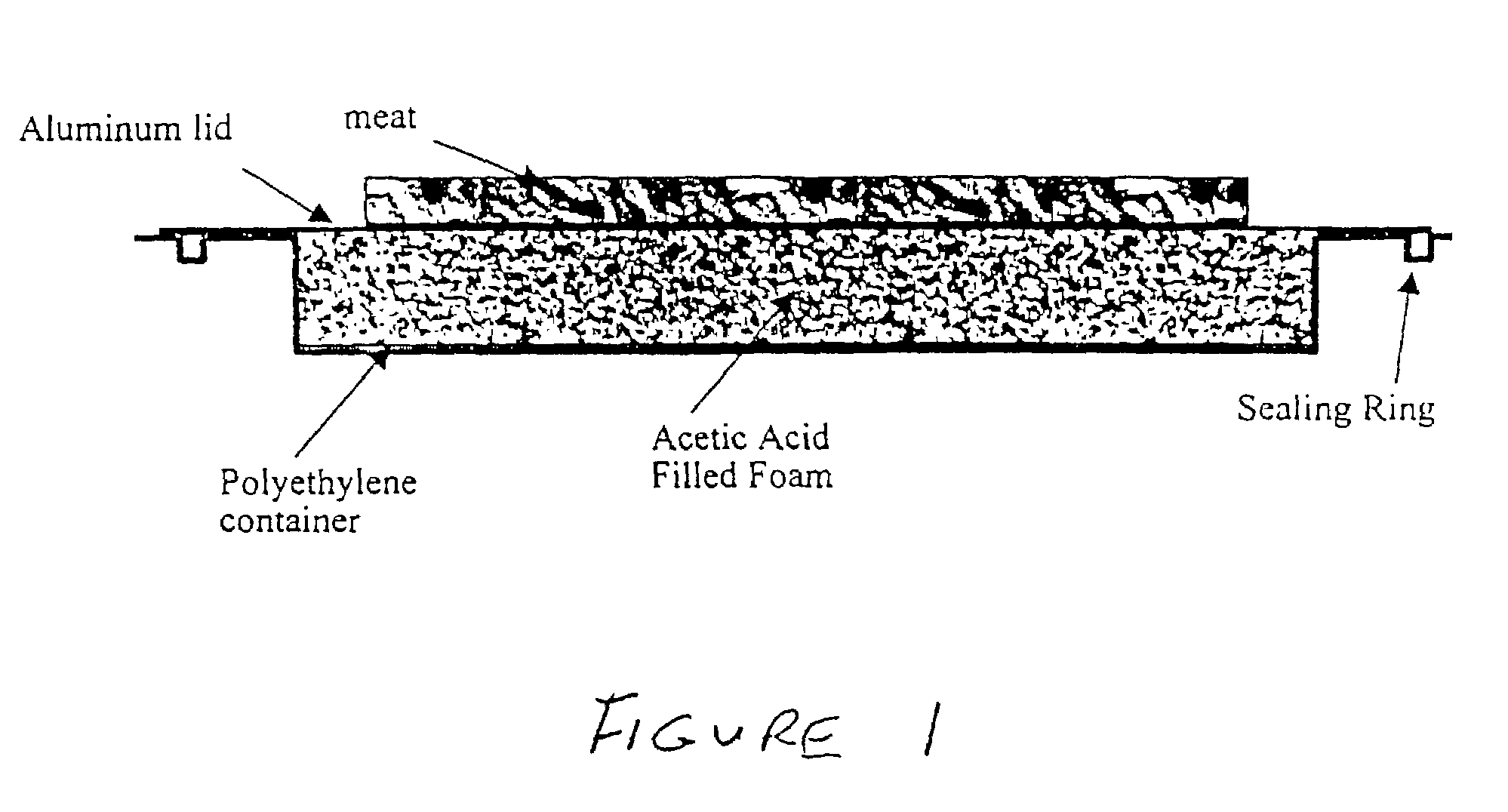

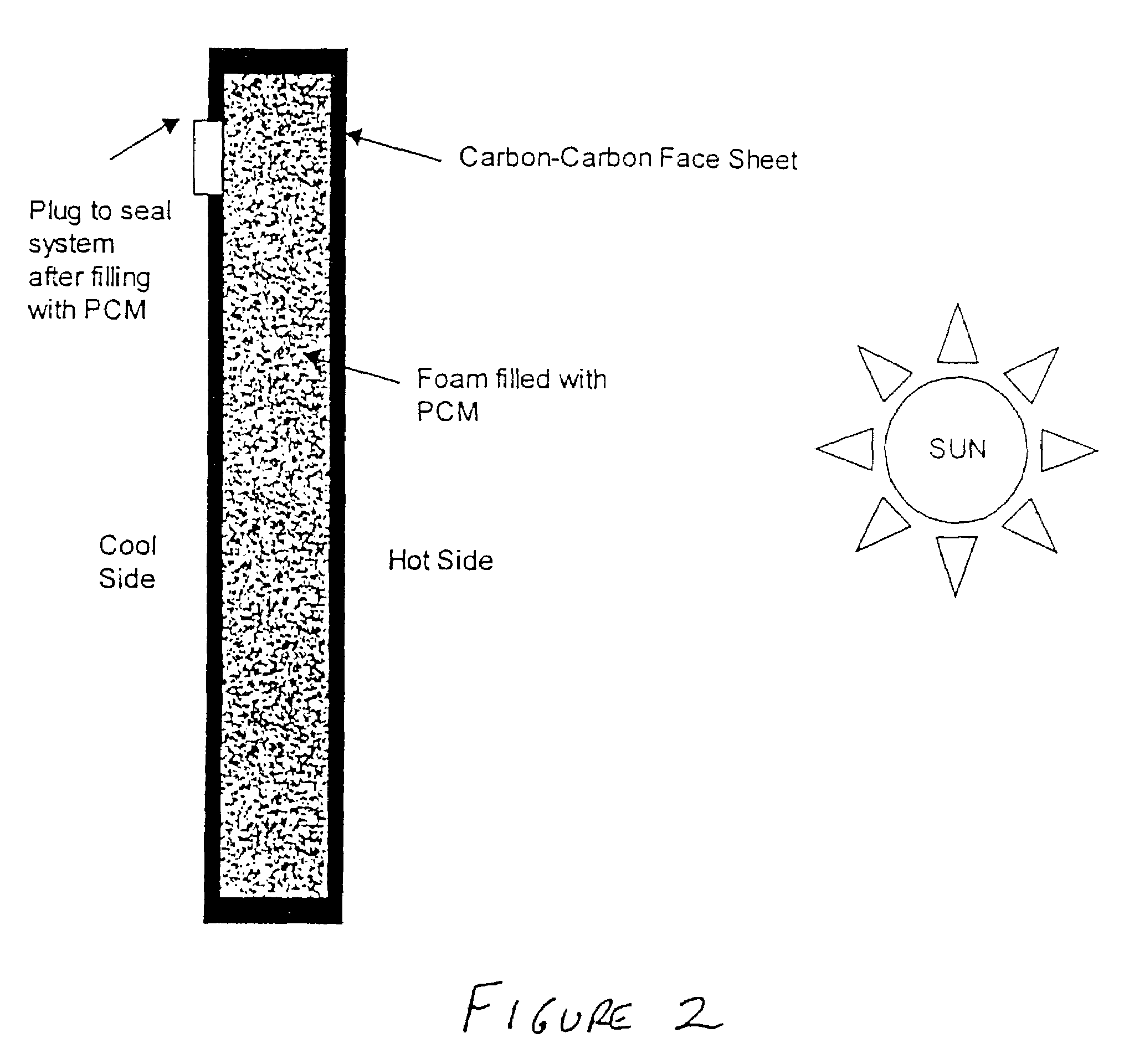

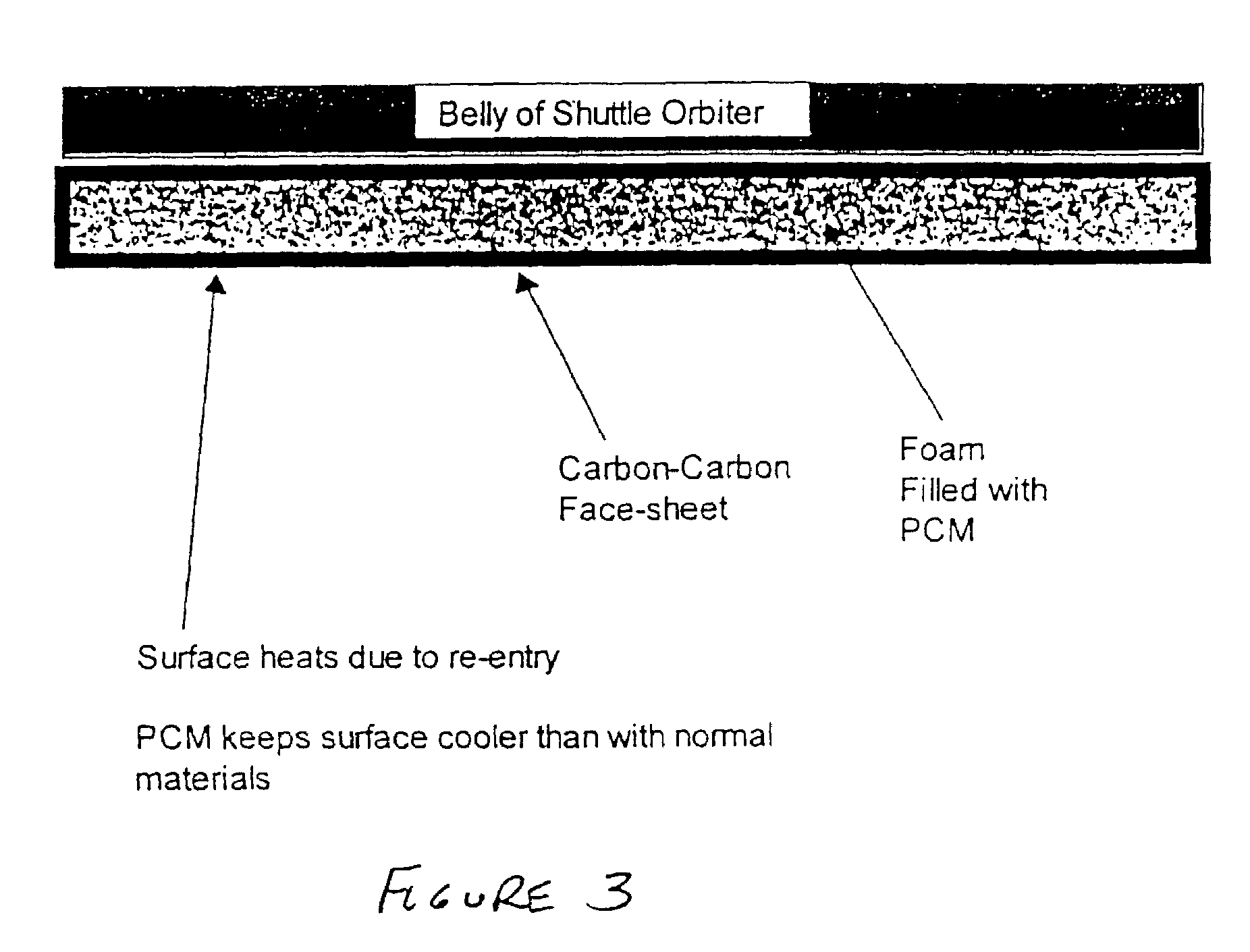

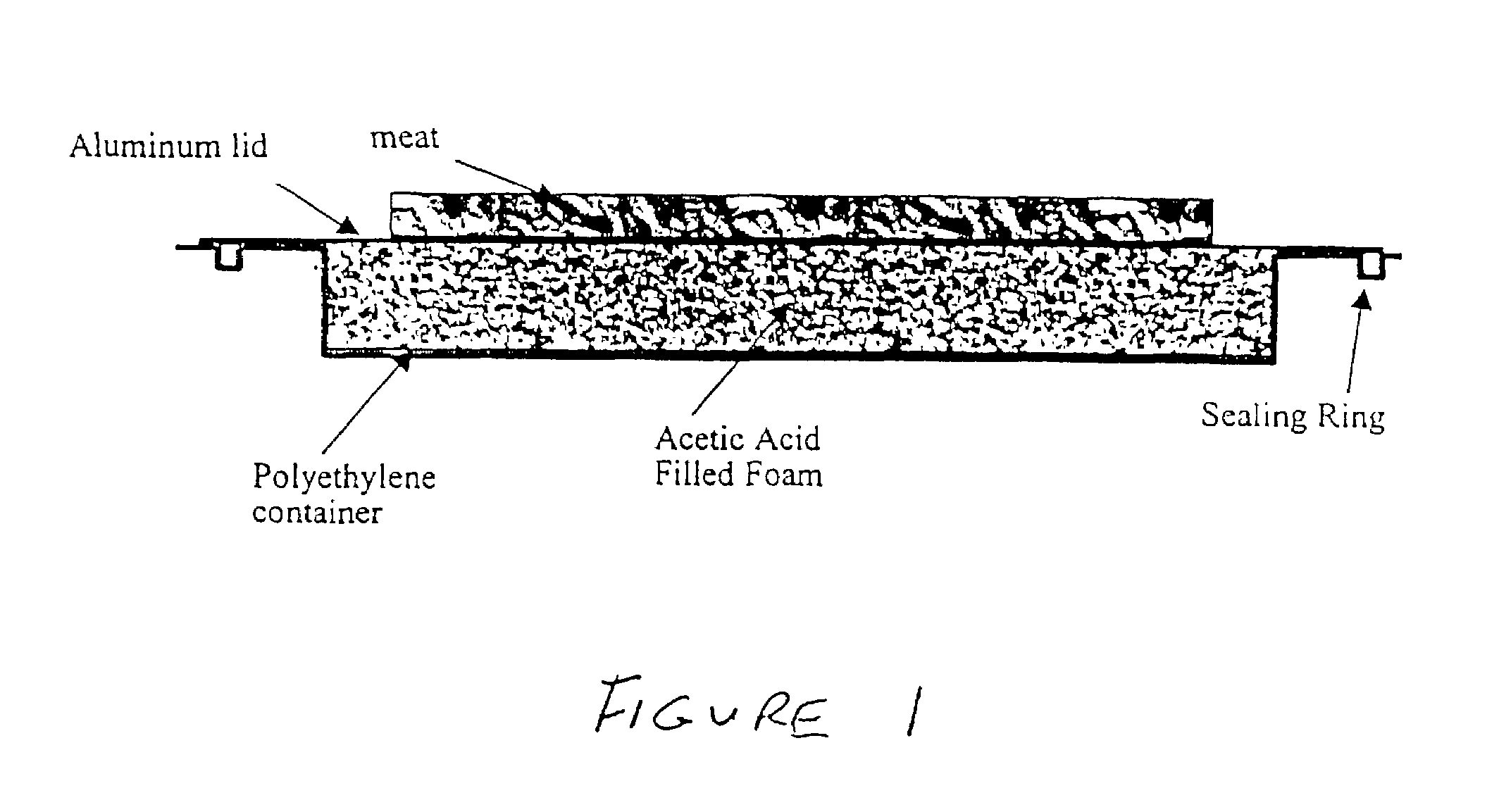

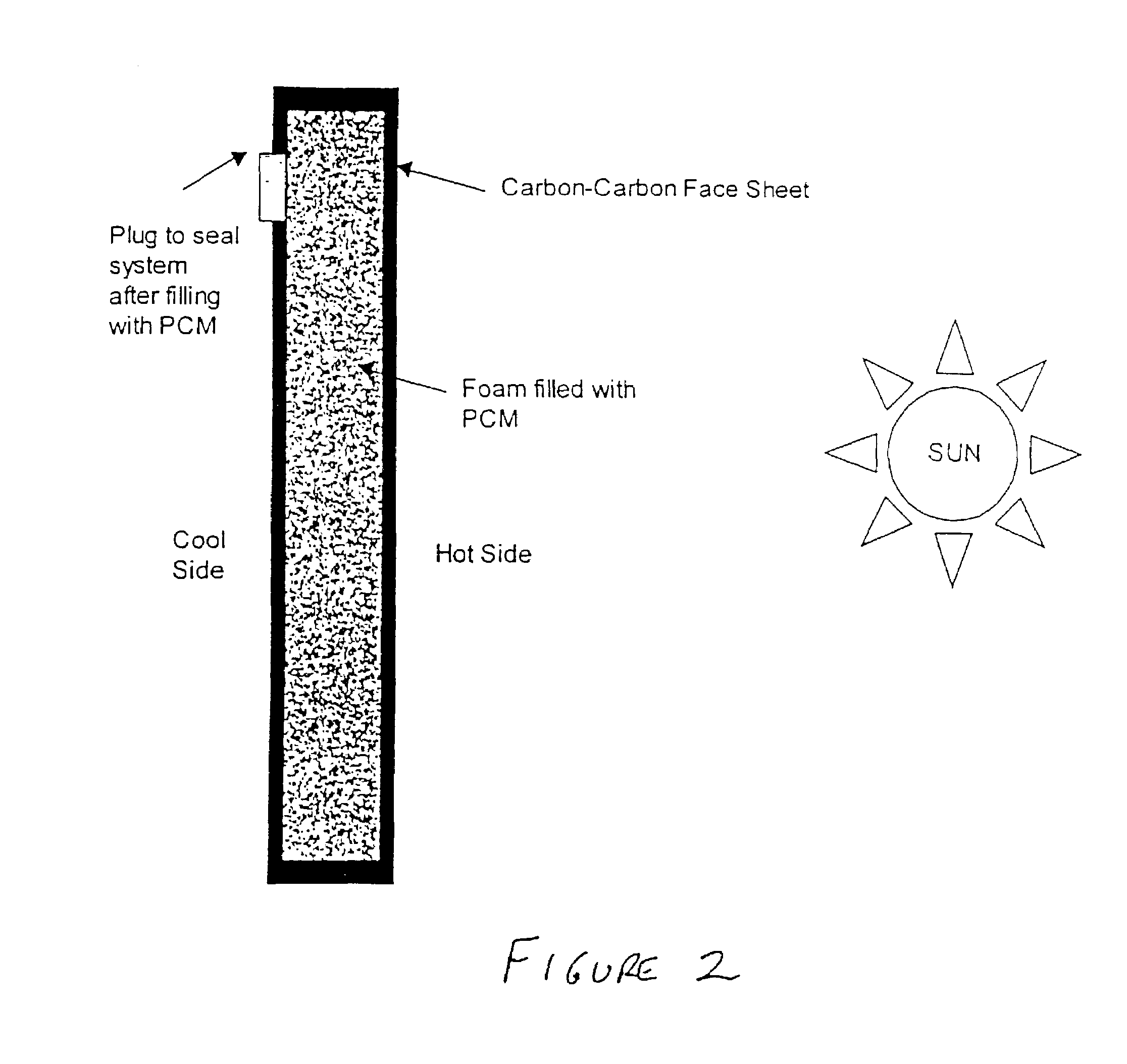

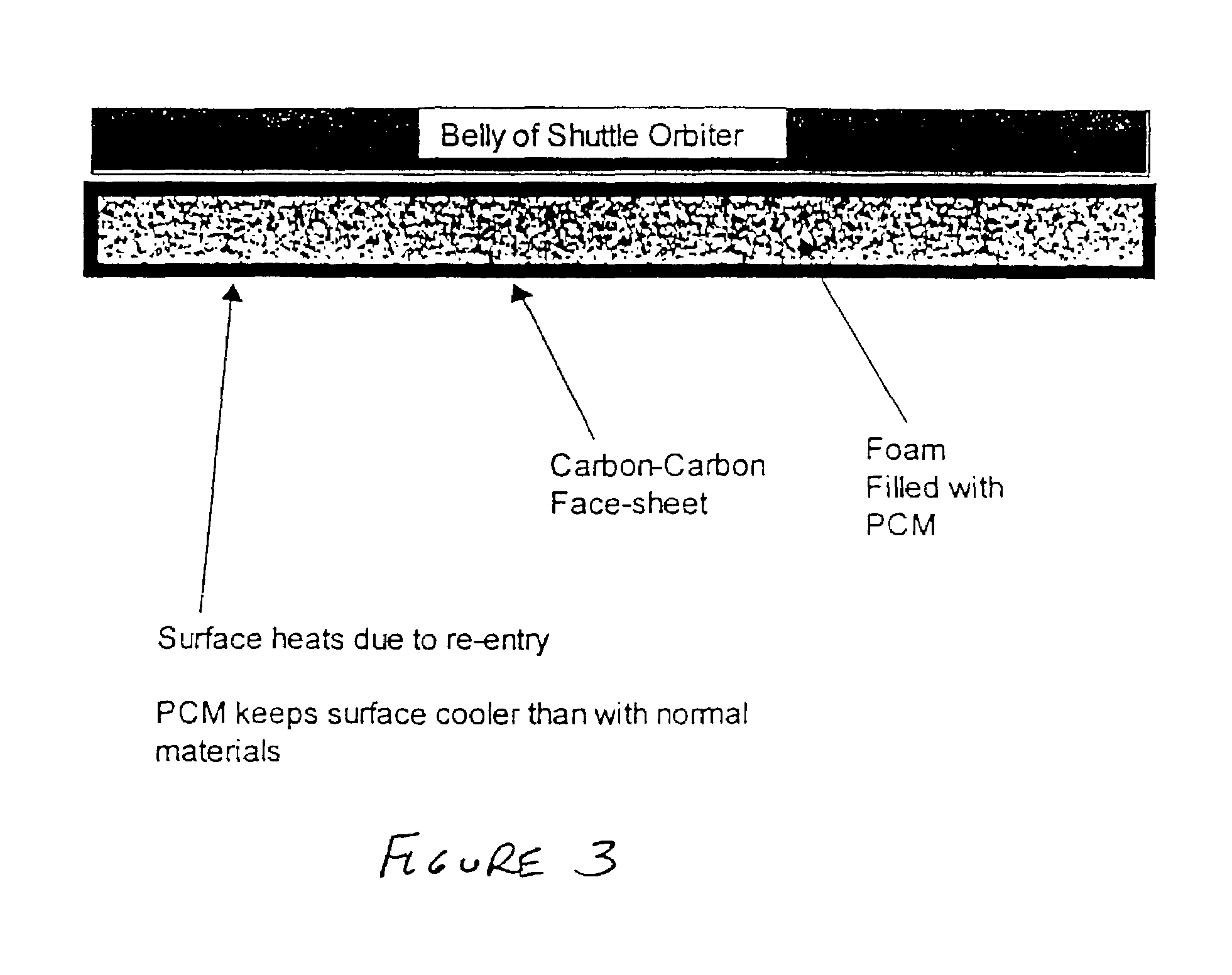

Pitch-based carbon foam heat sink with phase change material

InactiveUS7166237B2Improve thermal conductivityEmitted very rapidlyLayered productsHeat storage plantsPhase-change materialSandwich panel

A process for producing a carbon foam heat sink is disclosed which obviates the need for conventional oxidative stabilization. The process employs mesophase or isotropic pitch and a simplified process using a single mold. The foam has a relatively uniform distribution of pore sizes and a highly aligned graphic structure in the struts. The foam material can be made into a composite which is useful in high temperature sandwich panels for both thermal and structural applications. The foam is encased and filled with a phase change material to provide a very efficient heat sink device.

Owner:UT BATTELLE LLC

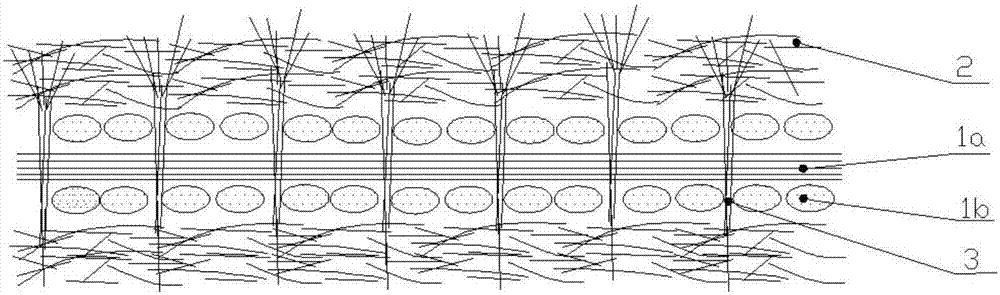

Method for manufacturing high thermal conductivity pitch-based carbon fiber composite material prefabricated body

ActiveCN107059242AEasy to bring inImprove thermal conductivityHeating/cooling textile fabricsNon-woven fabricsPunchingViscose

The invention discloses a method for manufacturing high thermal conductivity pitch-based carbon fiber composite material prefabricated body. The method includes: alternatively stacking pre-oxidized or low-temperature carbonized high thermal conductivity pitch-based carbon fiber continuous layers and viscose glue-based or polyacrylonitrile-based or isotropy pitch-based or high thermal conductivity pitch-based short carbon fiber webs; inducing Z-directional reinforcing fibers in the axial direction of the continuous layers and the web layers through a needle punching technology; the Z-directional reinforcing fibers can get through a Z-directional heat conduction channel, Z-directional dredging and conduction of heat is facilitated, the needle punching density is controlled in 10-50 / cm<2>, and the volume density of a three-directional structure prefabricated blank is 0.25-0.75 g / cm<3>; and carbonization and graphitization treatment is performed on the prefabricated blank. The method can form a large-diameter high thermal conductivity pitch-based carbon fiber special-shaped blank, and the forming size and shape are not limited; and the method can manufacture high thermal conductivity pitch-based carbon fiber composite materials, and is suitable for batch industrial production.

Owner:HUNAN UNIV

Manufacture of carbon/carbon composites by hot pressing

InactiveUS7207424B2Increase coefficient of frictionImprove Oxidation StabilityMaterial nanotechnologyBraking discsElectrical resistance and conductanceCarbon composites

A mixture of carbon-containing fibers, such as mesophase or isotropic pitch fibers, a suitable matrix material, such as a milled pitch is compressed while resistively heating the mixture to form a carbonized composite material. Preferably, the carbonized material has a density of at least about 1.30 g / cm3. Preferably, the composite material is formed in less than ten minutes. This is a significantly shorter time than for conventional processes, which typically take several days and achieve a lower density material. A treating component may be impregnated into the composite. Consequently, carbon / carbon composite materials having final densities of about 1.6–1.8 g / cm3 or higher are readily achieved with one or two infiltration cycles using a pitch or other carbonaceous material to fill voids in the composite and rebaking.

Owner:GRAFTECH INT HLDG INC

Activated carbon, process for producing the same, polarizable electrode, and electric double layer capacitor

Owner:KURARAY CO LTD

Method for reinforcing steel structure through FRP (Fiber Reinforced Polymer)

InactiveCN104695720AHigh specific strengthHigh strengthBuilding repairsBridge erection/assemblyPolymer scienceRapid construction

The invention discloses a method for reinforcing a steel structure through FRP (Fiber Reinforced Polymer). The FRP adopted in the invention is carbon fibre reinforced polymer (CFRP), specifically, mesophase pitch (MP) based carbon fiber is used as raw material, the mesophase pitch based carbon fiber is the fiber obtained by spinning processing of pitch obtained through thermal polymerization of isotropic pitch with high aroma content, and having a mesophase or liquid-crystal structure, and the stress performance of the fiber is improved, so that a reinforcing effect is realized. The method has the characteristics that since the fiber reinforced polymer (FRP) has the characteristics of being high in specific strength and specific stiffness, and corrosion-resistant, the fiber reinforced polymer (FRP) is widely applied to reinforcing of a concrete structure, and the steel structure reinforced through the fiber reinforced polymer (FRP) has a good effect. The method for reinforcing the steel structure through the fiber reinforced polymer (FRP) has the characteristics that the specific strength is high, rapid construction is achieved, and bearing capacity of the structure is obviously improved after construction.

Owner:QINGDAO PINGDU JIUDIAN GOLD MINE

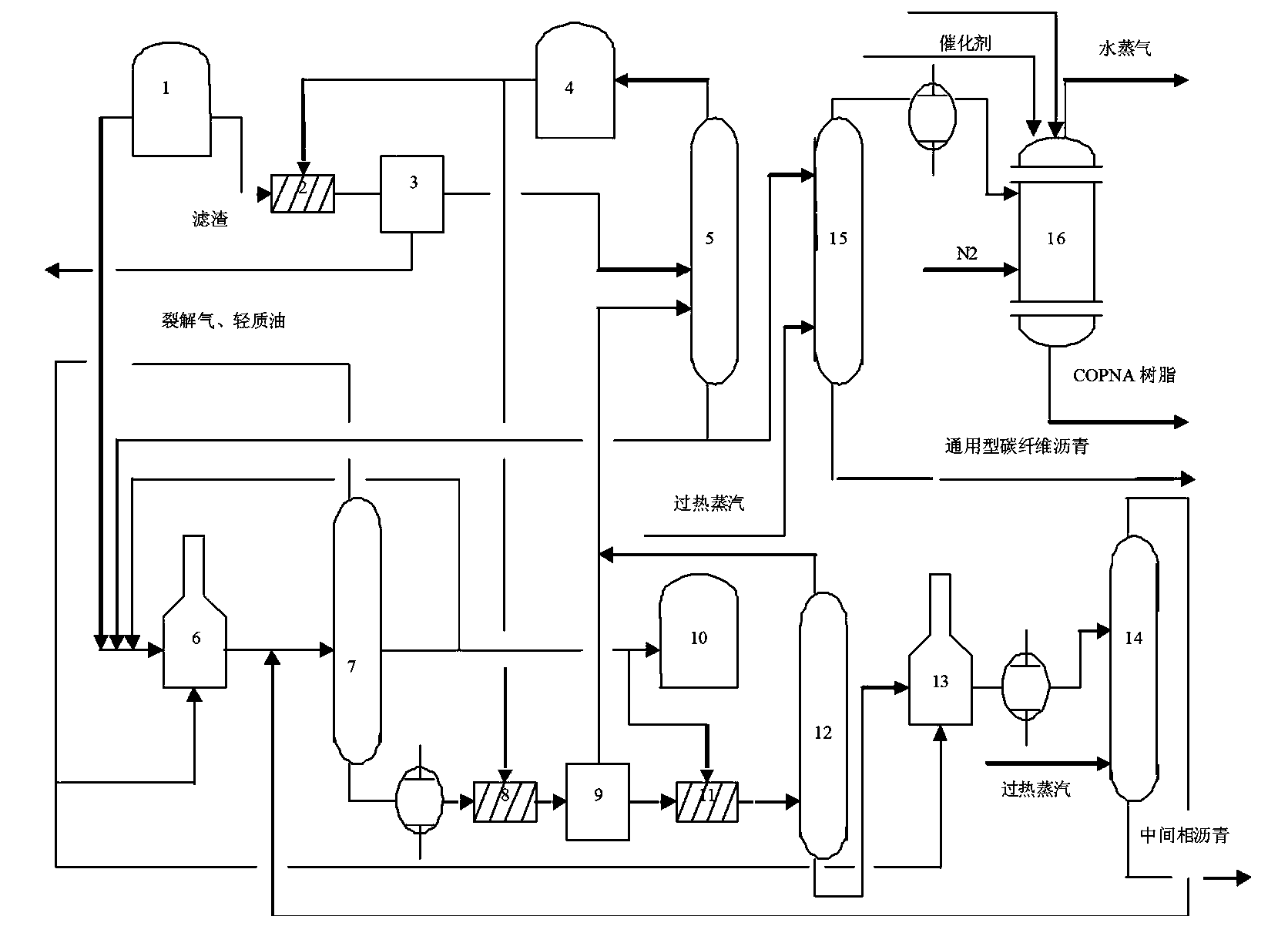

Method for preparing carbon material by use of heavy oil

InactiveCN103865558AImprove uniformityHigh content of mesophaseWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansCondensation processSolvent

The invention discloses a method for preparing a carbon material by use of heavy oil. The method adopts the heavy oil as a raw material to produce intermediate-phase spun asphalt, isotropic spun asphalt and COPNA resin through the following steps: 1, pretreating the heavy oil, and removing free carbon granules and dimethyl benzene insoluble substances from the heavy oil to obtain refined heavy oil; 2, treating the refined heavy oil through a proper thermal poly-condensation process to obtain pyrolysis heavy oil; 3, dissolving, washing and separating the pyrolysis heavy oil by use of dimethyl benzene to obtain a dimethyl benzene soluble component and a dimethyl benzene insoluble component; 4, dissolving the dimethyl benzene insoluble component by use of a hydrogenated heavy solvent and performing a hydrogenation and co-carbonization reaction to obtain hydrogenated asphalt; 5, thermally treating the hydrogenated asphalt to obtain intermediate-phase asphalt; 6, separating the solvent from the dimethyl benzene soluble component obtained in the step 3 and removing the dimethyl benzene solvent to obtain the soluble component; 7, recycling a part of the soluble component in the step 2 and making the part have thermal poly-condensation with the refined heavy oil, and thermally treating the other part to obtain the isotropic spun asphalt; and 8, letting distillate oil which is at a temperature lower than 350 DEG C and obtained by separation during the thermal treatment in the step 7 have a cross-linkage reaction with a cross-linking agent to obtain the CNPNA resin.

Owner:广州万熹龙新材料科技有限公司

High-strength and high-density graphite material and preparation method

The invention relates to a high-strength and high-density graphite material and a preparation method. The preparation method includes the steps of S1, using an organic solvent to dissolve soft asphalt to obtain a soft asphalt solution, using the soft asphalt solution to spray calcined fine coke powder, and mechanically mixing into isotropic asphalt powder to obtain a mixture; S2, performing compression molding on the mixture to obtain a green body, calcining the green body once, using impregnation asphalt to perform density increasing, and performing second calcining and graphitizing to obtain the high-density graphite material. The preparation method has the advantages that the surface of the calcined coke powder can be moistened and even in soft asphalt coating by the liquid spraying technology, and the interface compatibility and isotropic degree of the coke powder are increased; the isotropic asphalt can be evenly decomposed during the calcining, the calcined isotropic asphalt and the coke powder aggregate are consistent in shrinkage, material internal stress is relieved, and yield is increased evidently; the high-strength and high-density graphite material is prepared by one impregnation, two calcinations and one graphitizing, and the method is simple in process, low in cost, good in repeatability and short in production cycle.

Owner:江西宁新新材料股份有限公司 +1

Manufacture of carbon composites by hot pressing

InactiveUS20050274581A1Increase coefficient of frictionImprove Oxidation StabilityBraking drumsFriction liningFiberCarbon composites

A mixture of carbon-containing fibers, such as mesophase or isotropic pitch fibers, a suitable matrix material, such as a milled pitch is compressed while resistively heating the mixture to form a carbonized composite material. Preferably, the carbonized material has a density of at least about 1.30 g / cm3. Preferably, the composite material is formed in less than ten minutes. This is a significantly shorter time than for conventional processes, which typically take several days and achieve a lower density material. A treating component may be impregnated into the composite. Consequently, carbon composite materials having final densities of about 1.6-1.8 g / cm3 or higher are readily achieved with one or two infiltration cycles using a pitch or other carbonaceous material to fill voids in the composite and rebaking.

Owner:HUANG DAI +3

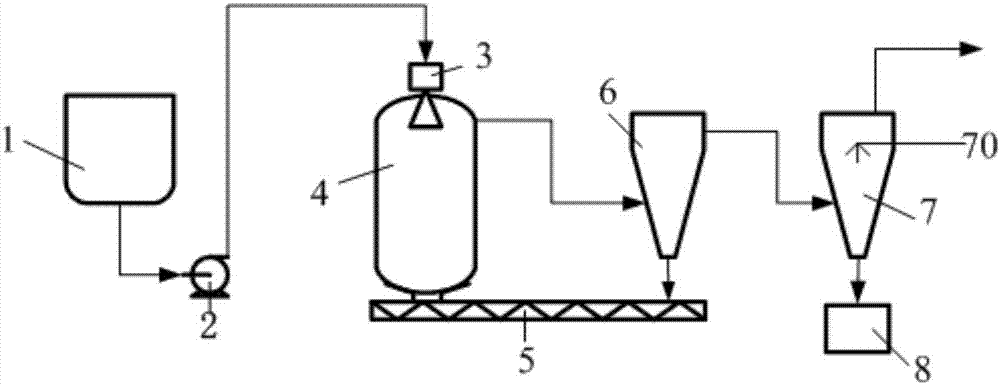

Preparation method and preparation device of isotropic pitch coke

InactiveCN106987262AReduce porosityHigh strengthCarbon compoundsWorking-up pitch/asphalt/bitumenPorosityRetention time

The invention provides a preparation method and a preparation device of isotropic pitch coke. The preparation method includes the steps of S1, subjecting molten pitch to atomization to obtain atomized pitch; S2, pyrolyzing the atomized pitch by contacting with high-temperature gas to obtain isotropic pitch coke, wherein the temperature of the high-temperature gas ranges from 500 DEG C to 1400 DEG C. The molten pitch is atomized and carbonized, the retention time for high-temperature carbonizing stage of pitch is short, and the intermediate phase process is omitted so that the isotropic pitch coke is obtained directly; further, the isotropic pitch coke can be utilized directly for producing isotropic graphite, the procedure of grinding and fining is omitted, the technique is simplified, and the lengthiness of processing flow is avoided; in addition, the isotropic pitch coke has low porosity which is favorable for improving strength of graphite.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Pitch-based carbon foam heat sink with phase change material

InactiveUS7014151B2Improve thermal conductivityEmitted very rapidlyCosmonautic vehiclesHeat storage plantsPhase-change materialSandwich panel

A process for producing a carbon foam heat sink is disclosed which obviates the need for conventional oxidative stabilization. The process employs mesophase or isotropic pitch and a simplified process using a single mold. The foam has a relatively uniform distribution of pore sizes and a highly aligned graphic structure in the struts. The foam material can be made into a composite which is useful in high temperature sandwich panels for both thermal and structural applications. The foam is encased and filled with a phase change material to provide a very efficient heat sink device.

Owner:UT BATTELLE LLC

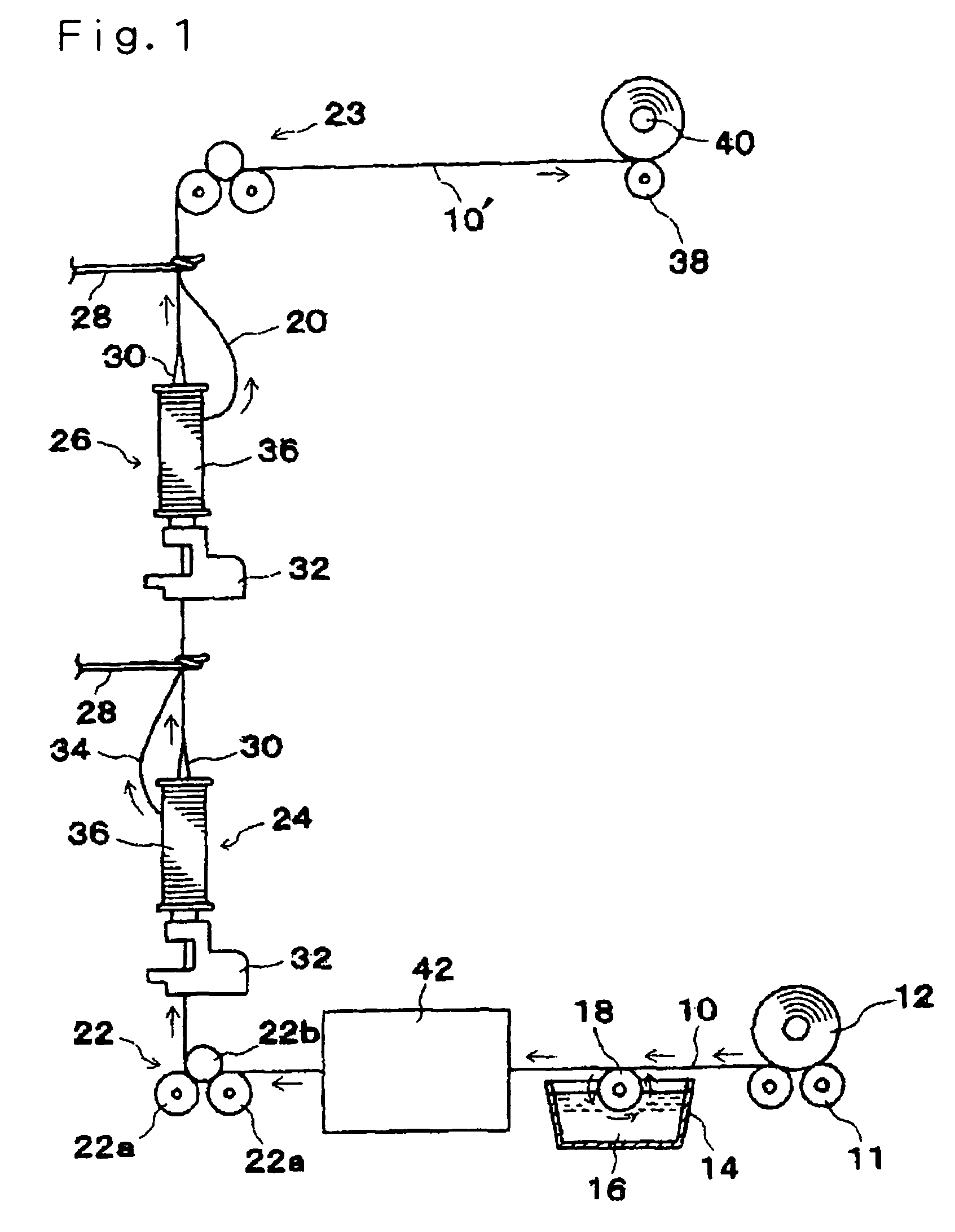

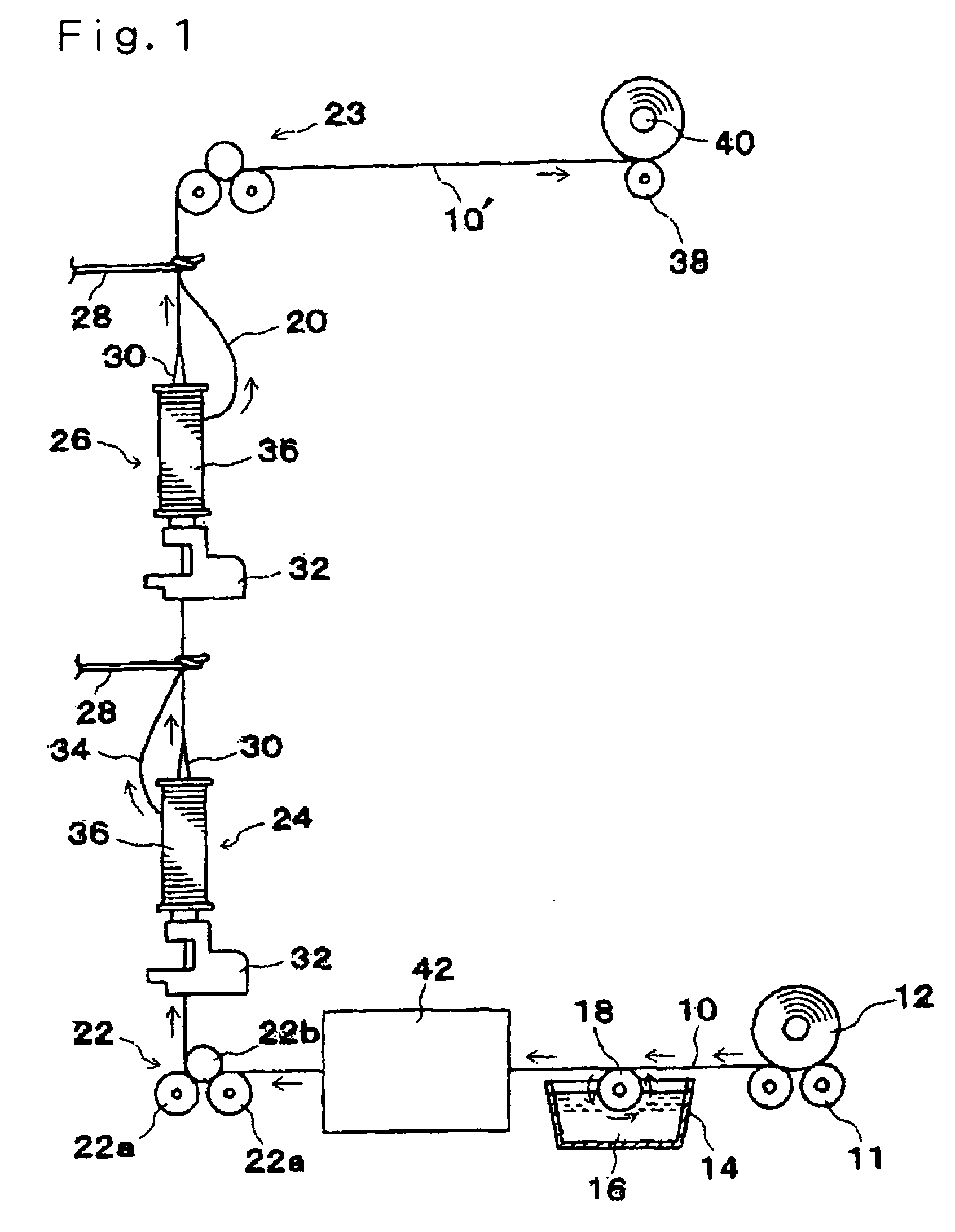

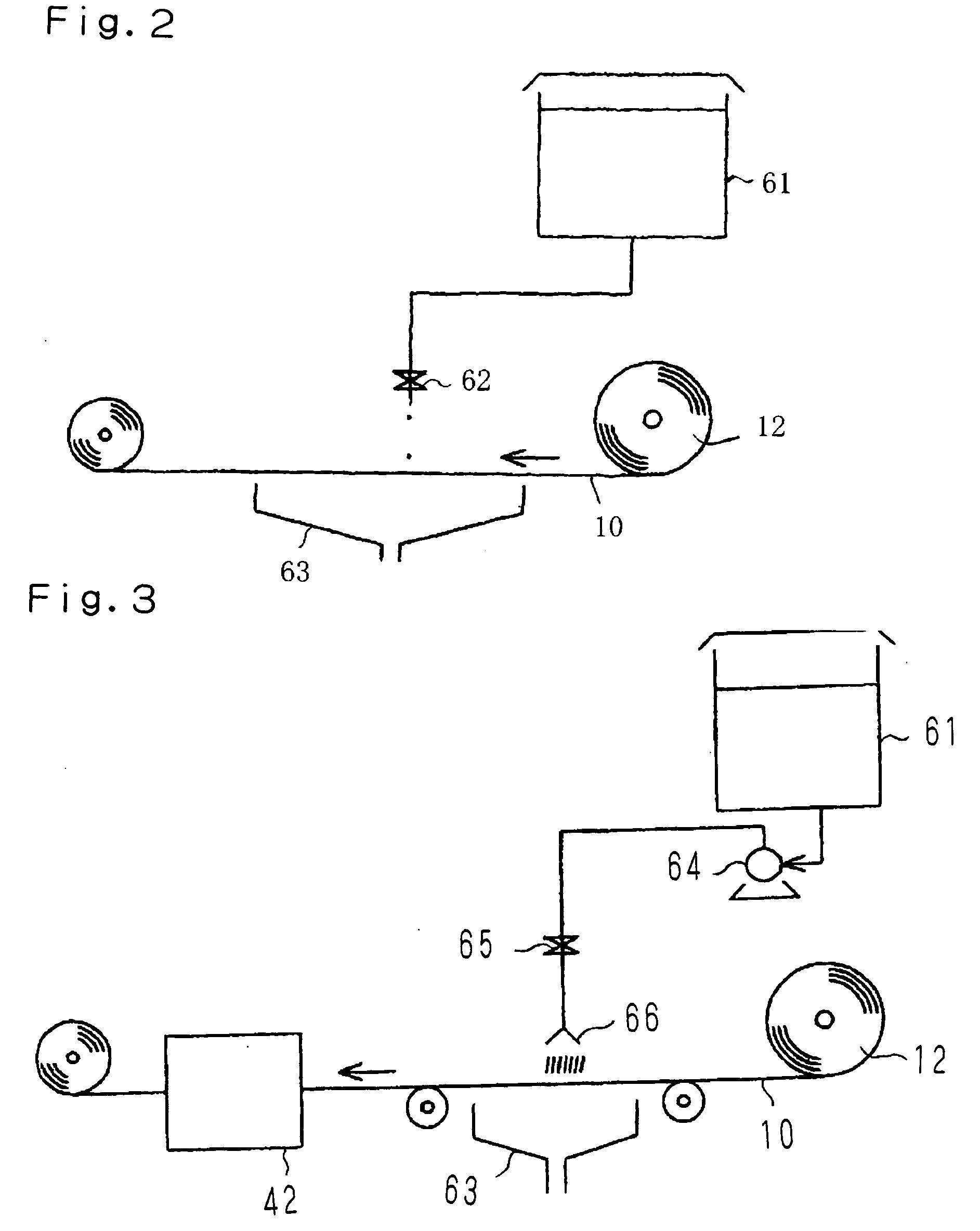

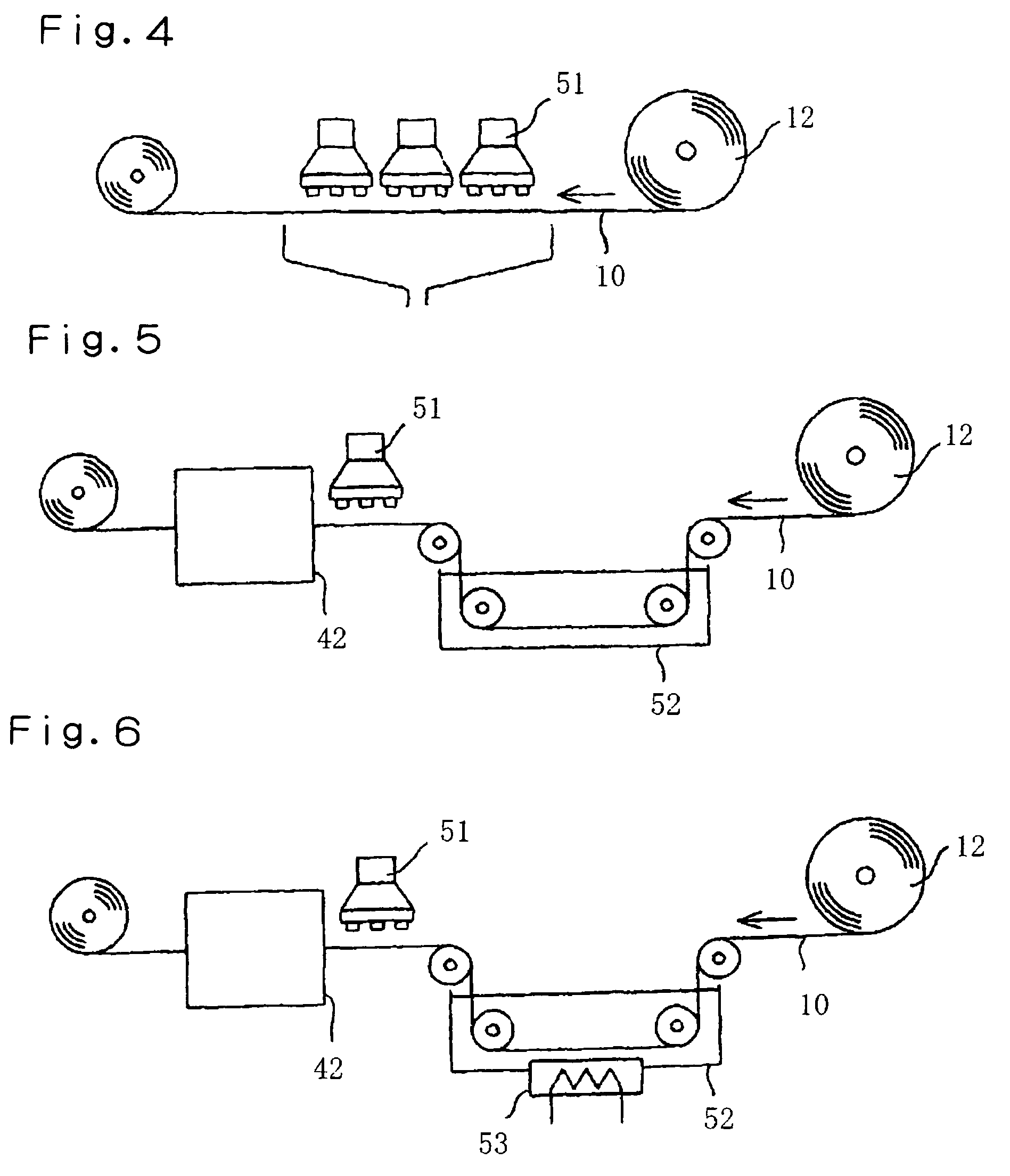

Isotropic pitch-based carbon fiber spun yarn, composite yarn and fabric using the same, and manufacturing methods thereof

InactiveUS7807590B2Avoid generatingAvoid it happening againEngine sealsSynthetic resin layered productsYarnPolymer science

A method of manufacturing an isotropic pitch-based carbon fiber spun yarn fabric includes the following steps of: obtaining composite yarn by winding a water-soluble polymer fiber around a surface of isotropic pitch-based carbon fiber spun yarn; obtaining a composite yarn fabric by weaving the composite yarn; and obtaining the isotropic pitch-based carbon fiber spun yarn fabric by dissolving and removing the water-soluble polymer fiber from the composite yarn fabric.

Owner:KUREHA KAGAKU KOGYO KK

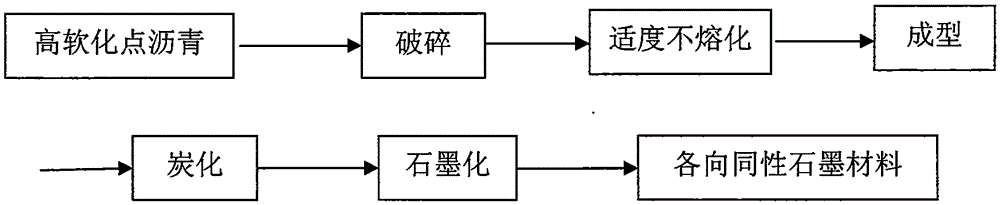

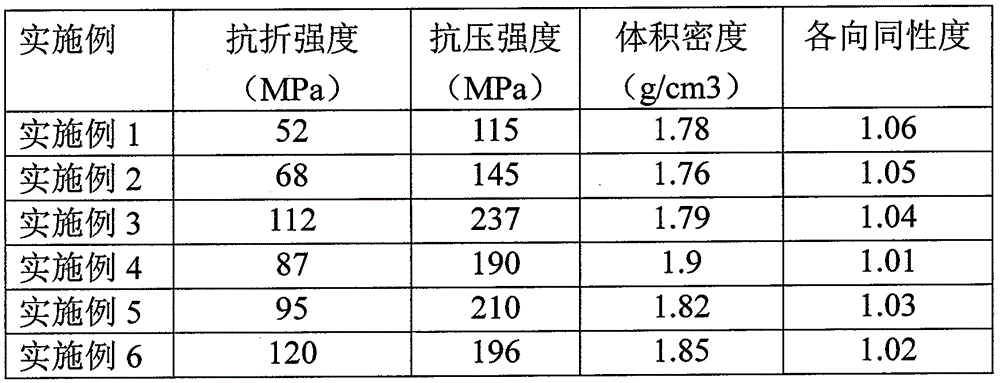

Method for preparing isotropic graphite from isotropic asphalt with high softening point through self-sintering

The invention discloses a method for preparing isotropic graphite from isotropic asphalt with a high softening point through self-sintering. According to the method, isotropic asphalt with a softening point of 200 to 330 DEG C is taken as the raw material, then isotropic asphalt is grinded into particles with a particle size of 5 to 30 [mu]m; the particles are oxidized in the air for 1.5 to 15 hours at a temperature of 200 to 400 DEG C to reach a proper non-melt degree so as to obtain a primary raw material; and then the primary raw material is moulded, carbonized, and graphitized to obtain the graphite having advantages of high strength, high density, and good isotropic property. The preparation method is simple, and the prepared graphite has a good isotropic property.

Owner:TIANJIN POLYTECHNIC UNIV

Pitch-based carbon foam heat sink with phase change material

InactiveUS7157019B2Improve thermal conductivityEmitted very rapidlyLayered productsHeat storage plantsPhase-change materialSandwich panel

A process for producing a carbon foam heat sink is disclosed which obviates the need for conventional oxidative stabilization. The process employs mesophase or isotropic pitch and a simplified process using a single mold. The foam has a relatively uniform distribution of pore sizes and a highly aligned graphic structure in the struts. The foam material can be made into a composite which is useful in high temperature sandwich panels for both thermal and structural applications. The foam is encased and filled with a phase change material to provide a very efficient heat sink device.

Owner:UT BATTELLE LLC

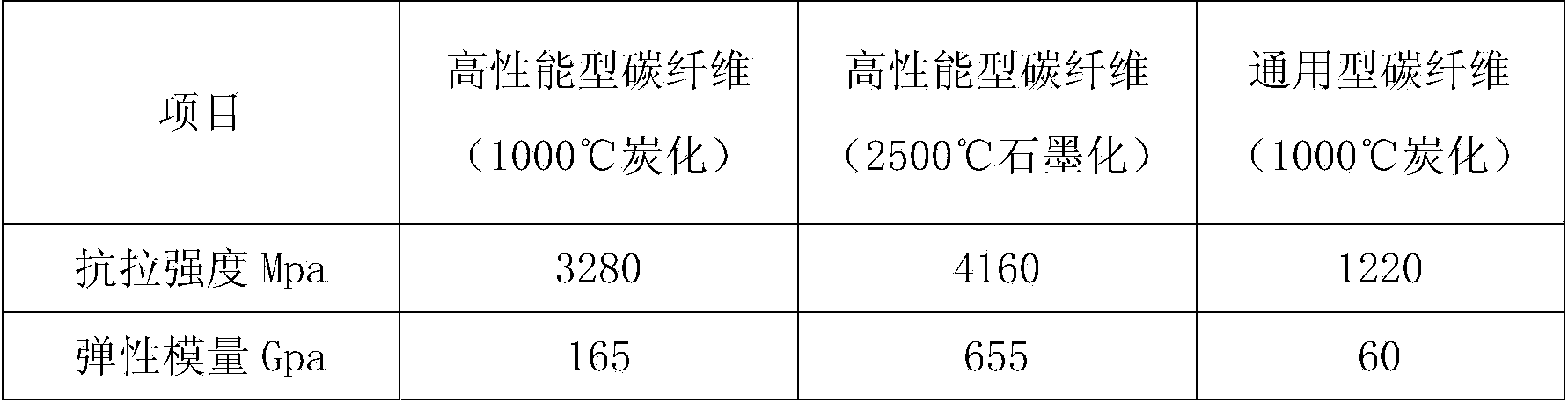

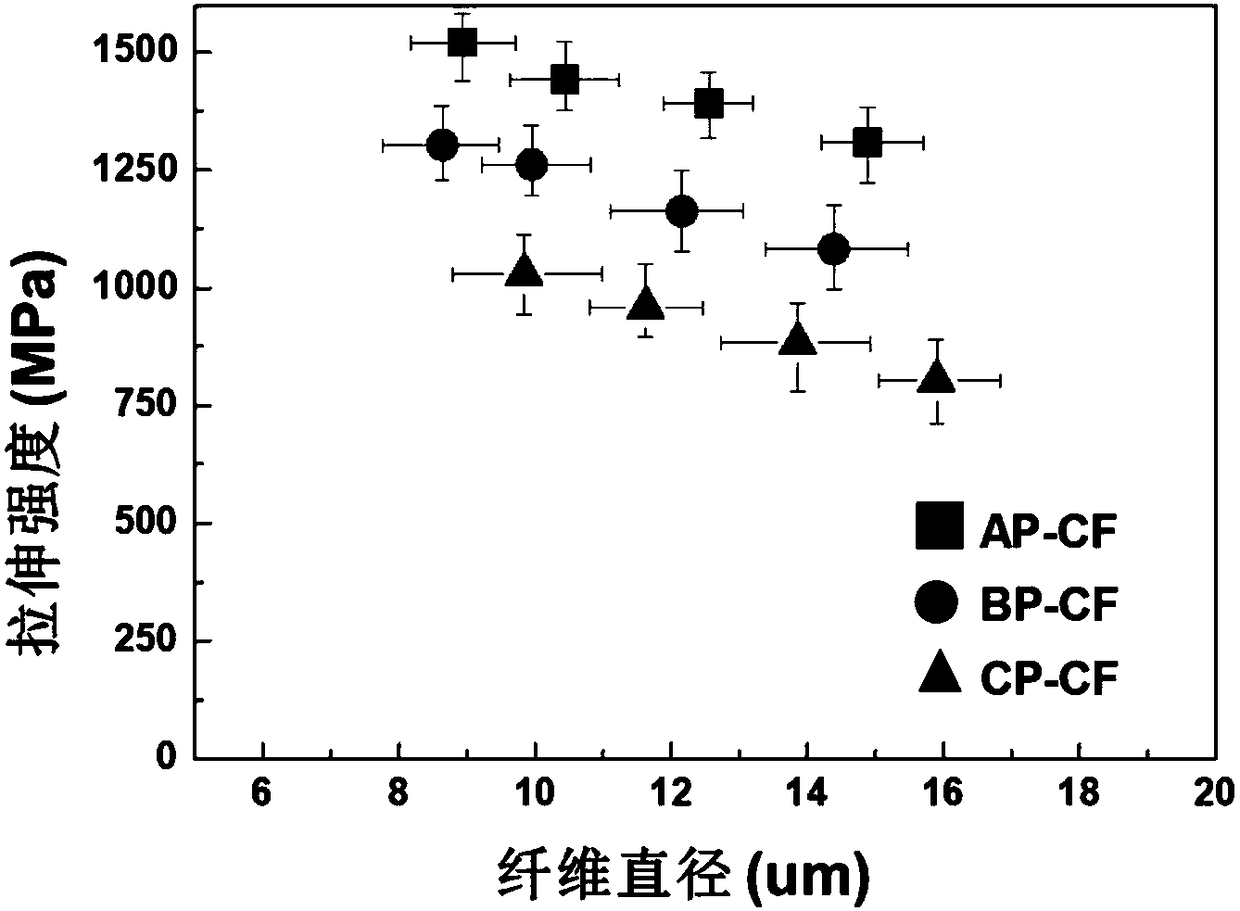

Preparation method of high-strength coal series isotropic asphalt base carbon fiber

ActiveCN108560082AExcellent performance indexImprove performanceFibre chemical featuresCarbon fibersEvaporation

The invention discloses a production method of a high-strength coal series isotropic asphalt base carbon fiber. The production method comprises the following steps: taking ashless coal as an asphalt precursor, removing volatile components of the ashless coal by adopting a thin layer evaporation method, and controlling a softening point of asphalt at a temperature of 180 to 260 DEG C to obtain spinning alphalt; then obtaining a carbon fiber by a melt spinning technology, a preoxidizing technology, a carbonization technology and the like; mixing coal with 1-methylnaphthalene according to the ratio of 1-2 to 1-10, carrying out solvent extraction reaction at the temperature of 350 to 410 DEG C and the pressure of 1 to 5MPa, and then carrying out solid-liquid separation, hot press filtering andsolvent recovery to obtain the ashless coal; finally, preparing the carbon fiber of the ashless coal by the melt spinning technology, the preoxidizing technology, the carbonization technology and thelike. According to the production method disclosed by the invention, coal is used as a raw material for producing a general asphalt base carbon fiber with excellent performance indexes; tensile strength of the general asphalt base carbon fiber is as high as 1500MPa; the general asphalt base carbon fiber has a broader market prospect and economic benefits.

Owner:HUNAN UNIV

Isotropic pitch-based carbon fiber spun yarn, composite yarn and fabric using the same, and manufacturing methods thereof

InactiveUS20070190883A1Improve working environmentAvoid generatingEngine sealsSynthetic resin layered productsYarnPolymer science

A method of manufacturing an isotropic pitch-based carbon fiber spun yarn fabric includes the following steps of: obtaining composite yarn by winding a water-soluble polymer fiber around a surface of isotropic pitch-based carbon fiber spun yarn; obtaining a composite yarn fabric by weaving the composite yarn; and obtaining the isotropic pitch-based carbon fiber spun yarn fabric by dissolving and removing the water-soluble polymer fiber from the composite yarn fabric.

Owner:KUREHA KAGAKU KOGYO KK

Manufacture of carbon/carbon composites by hot pressing

InactiveUS20050003037A1Short timeFew densificationFurnaces without endless coreConfectioneryFiberCarbon composites

A mixture of carbon-containing fibers, such as mesophase or isotropic pitch fibers, and a suitable matrix material, such as a milled pitch, is compressed while resistively heating the mixture to form a carbonized composite material having a density of about 1.5 g / cm3, or higher. The composite material is formed in under ten minutes. This is a significantly shorter time than for conventional processes, which typically take several days and achieve a lower density material. Consequently, carbon / carbon composite materials having final densities of about 1.6-1.8 g / cm3, or higher are readily achieved with one or two infiltration cycles using a pitch or other carbonaceous material to fill voids in the composite and rebaking.

Owner:GRAFTECH INT HLDG INC

Organometallic containing mesophase pitches for spinning into pitch carbon fibers

InactiveUS6270652B1Improve stabilitySuitable for useLiquid crystal compositionsWorking-up pitch/asphalt/bitumen by selective extractionFiberCarbon fibers

An improved process is disclosed for producing a unique metals-containing anisotropic pitch suitable for carbon fiber manufacture. Soluble, aromatic-organometallic compounds are added to a carbonaceous feedstock which is substantially free of mesophase pitch and the resulting composition is heat soaked to produce an isotropic pitch product containing mesogens and soluble, aromatic-organometallic compounds. Next, the pitch product is solvent fractionated to separate mesogens which contain metals from the organometallic compounds. The metals-containing mesogens are heated to a temperature sufficient to cause fusion to produce a metals-containing mesophase pitch.In another method, the carbonaceous feedstock is heat soaked to produce an isotropic pitch product containing mesogens and high molecular weight, soluble, aromatic-organometallic compounds are added to the mesogen containing isotropic pitch product prior to solvent fractionation. Metals-containing carbon fibers produced from the mesophase pitch exhibit enhanced stabilization, tensile strength and modulus properties.Alternatively, the solvent fractionation or separation is conducted under supercritical extraction conditions to produce a metals-containing mesophase pitch. Organometallic compounds may be added to the carbonaceous feedstock either prior to or after the heat soak step.

Owner:CONOCO INC

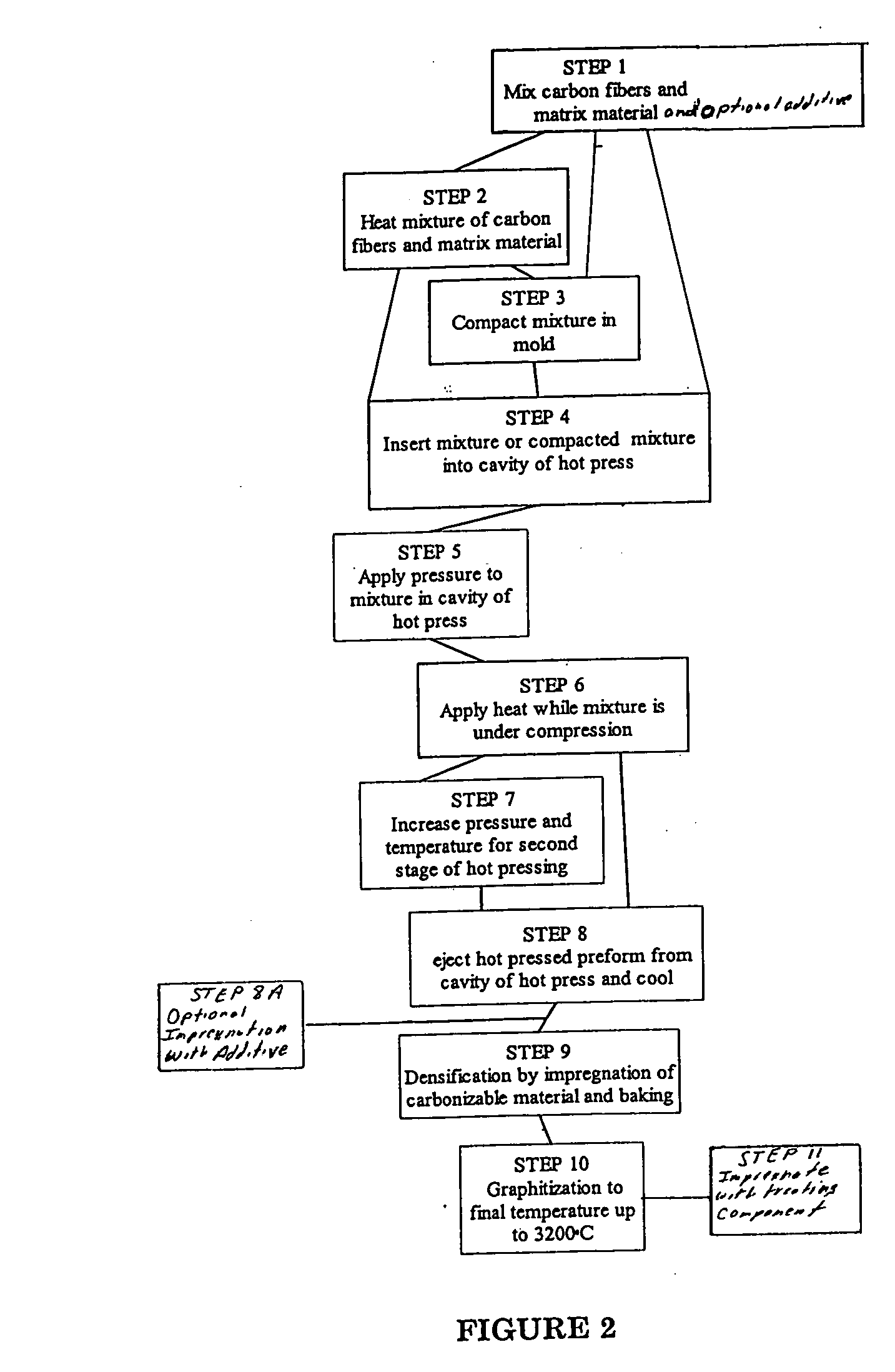

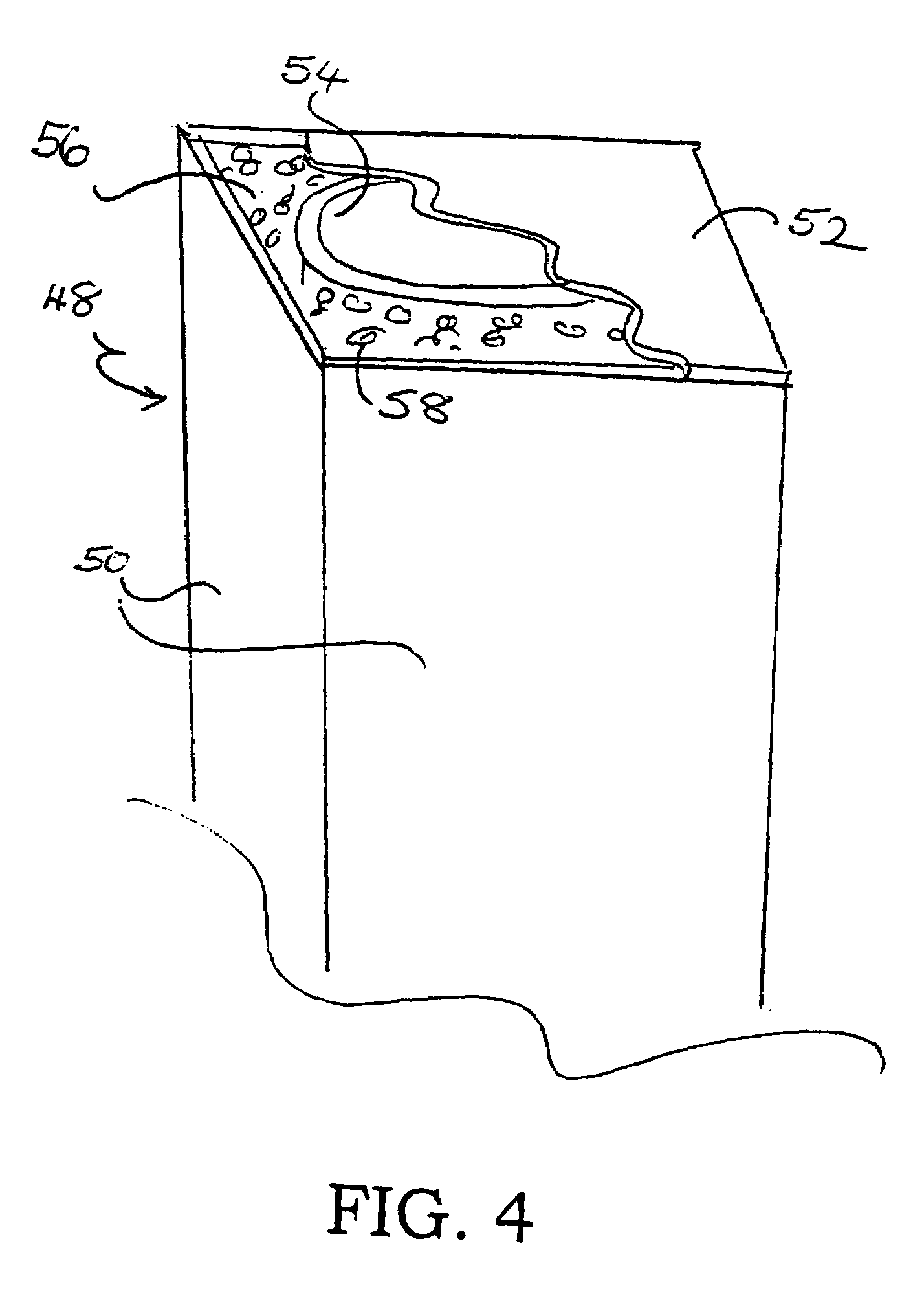

Isotropic pitch-based materials for thermal insulation

InactiveUS20050029487A1Improve flexural strengthLow thermal conductivityWorking-up pitch/asphalt/bitumenWorking-up tarFiberCarbon fibers

Insulation materials suited to high temperature applications, such as the insulation of furnaces, are formed from a mixture of pitch carbon fibers, such as isotropic pitch carbon fibers, and a binder comprising a solution of sugar in water. The sugar solution is preferably at a concentration of from 20-60% sucrose to yield a low density material having high flexural strength and low thermal conductivity when carbonized to a temperature of about 1800° C.

Owner:ADVANCED ENERGY TECH

A kind of preparation method of mesophase pitch

ActiveCN110272757BEasy to purifyWill not polluteWorking-up pitch/asphalt/bitumen by chemical meansFiberCarbon fibers

Owner:湖南东映碳材料科技股份有限公司

Isotropic pitch-based materials for thermal insulation

InactiveUS7150837B2Improve flexural strengthLow thermal conductivityCeramic layered productsBuilding constructionsFiberCarbon fibers

Insulation materials suited to high temperature applications, such as the insulation of furnaces, are formed from a mixture of pitch carbon fibers, such as isotropic pitch carbon fibers, and a binder comprising a solution of sugar in water. The sugar solution is preferably at a concentration of from 20–60% sucrose to yield a low density material having high flexural strength and low thermal conductivity when carbonized to a temperature of about 1800° C.

Owner:ADVANCED ENERGY TECH

Preparation method of mesophase pitch continuous filaments

InactiveCN105177766AGuaranteed decentralizationIncrease surface areaFibre chemical featuresOperabilityStatic mixer

The invention relates to a preparation method of mesophase pitch continuous filaments. A small amount of incompatible isotropic pitch with similar softening points is added to mesophase pitch, and after the isotropic pitch is subjected to melt blending through twin screws, the isotropic pitch passes a static mixer, and is metered, spun and wound to obtain the mesophase pitch continuous filaments. The obtained mesophase pitch continuous filaments are large in elongation at break, low in brittleness and good in operability, and particularly meet the requirements of high-speed spinning, and an oiling process and a filament collecting process are greatly simplified.

Owner:DONGHUA UNIV

Nitrogen-doped mesonphase carbosphere as well as preparation method and application thereof

InactiveCN112811408AImprove uniformityHigh charge and discharge capacitySecondary cellsNegative electrodesMicrospherePhysical chemistry

The invention belongs to the technical field of lithium ion battery materials, and discloses a nitrogen-doped mesonphase carbosphere and a preparation method and application thereof. The nitrogen-doped mesonphase carbosphere comprises a mesonphase carbosphere body and nitrogen, wherein the nitrogen is doped in a lamellar structure of the mesonphase carbosphere body. The preparation method comprises the following steps: heating asphalt to a semi-solidified state, then introducing naphthalene steam to obtain isotropic pitch, carrying out a thermal polycondensation reaction on the isotropic pitch, then conducting cooling, carrying out extracting, subjecting an aqueous extract to filtering, cleaning and drying so as to obtain the mesonphase carbosphere body, uniformly mixing the mesonphase carbosphere body, a defect introducing agent and a polar solvent, successively conducting drying and sintering to obtain a mesonphase carbosphere body with defects, mixing the mesonphase carbosphere body with defects with ammonia water, carrying out a heating reaction, conducting filtering, and cleaning filter residues to obtain the nitrogen-doped mesonphase carbosphere. According to the nitrogen-doped mesonphase carbosphere synthesized by using the method, the uniformity of the nitrogen-doped mesonphase carbosphere can be greatly improved, and the nitrogen-doped mesonphase carbosphere has excellent charge-discharge capacity and structural stability.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

Pitch process

ActiveUS11319491B1Pressurized chemical processWorking-up pitch/asphalt/bitumen by chemical meansFluid phaseVapor phase

A process for making mesophase and / or isotropic pitch. An aromatic rich liquid is charged at high temperature and pressure to a first thermal polymerization reactor to produce an effluent stream which is flashed to remove unconverted or partially converted feed as a vapor yielding a liquid phase enriched in isotropic pitch. The enriched isotropic pitch liquid is charged to a second thermal reactor and reactor effluent flashed to produce mesophase pitch and a vapor phase. The vapor phases from both flashing steps are condensed and combined for recycle of a liquid aromatic rich stream to the first reactor. Flashing from the first reactor cools the liquid phase which is enriched in isotropic pitch. This enriched stream is mixed with a superheated fluid, preferably steam, upstream of the second reactor.

Owner:ACP TECH LLC

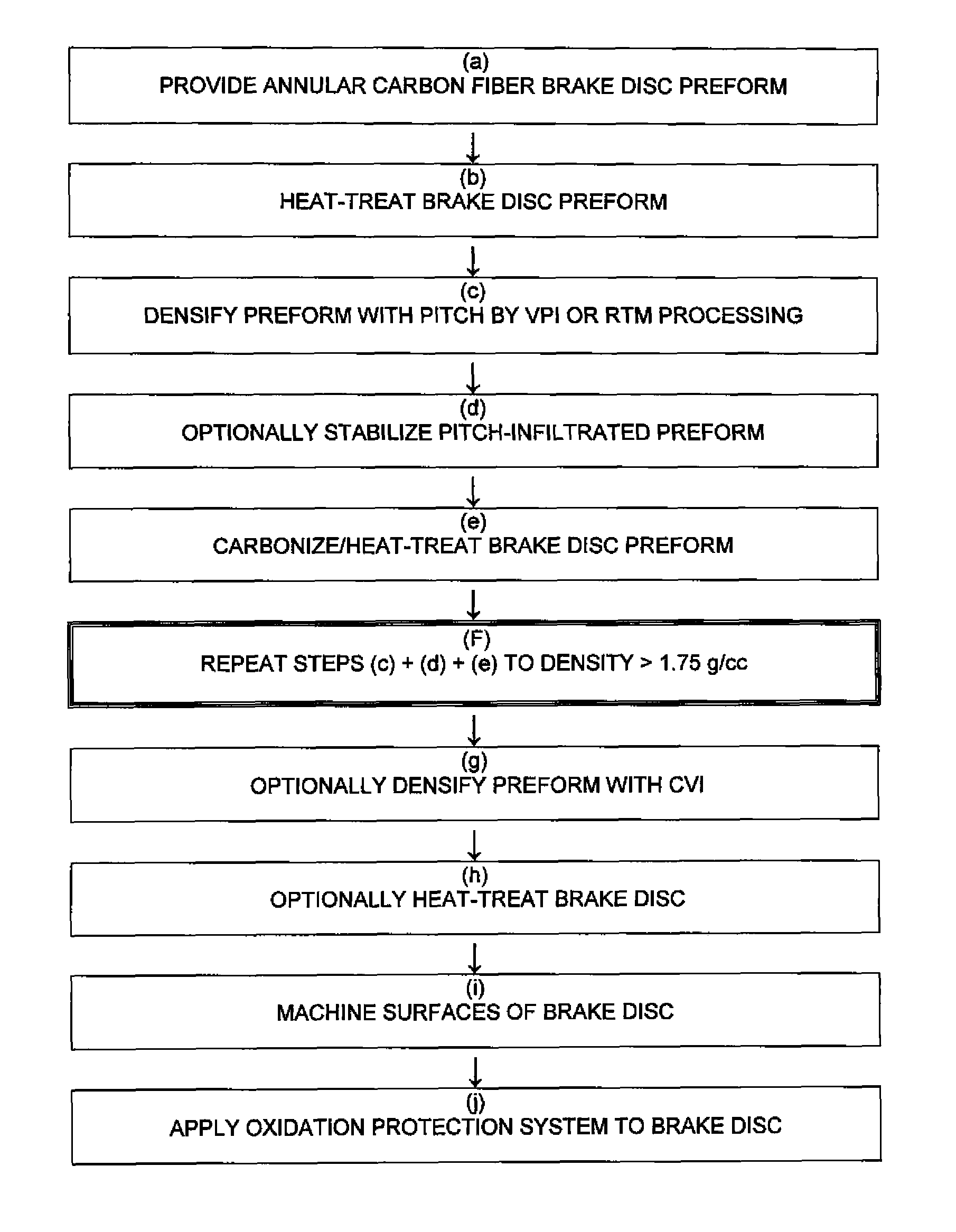

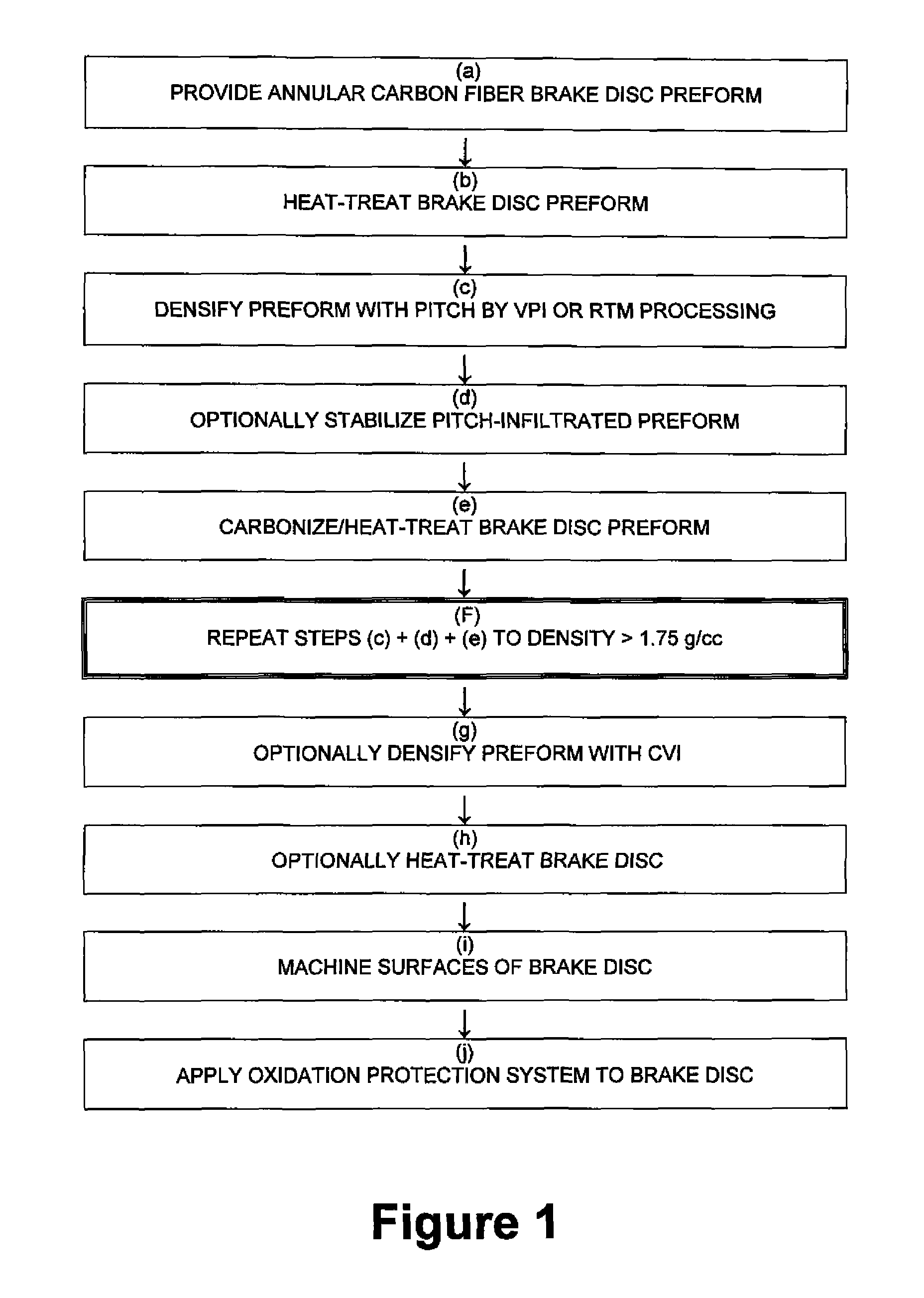

Pitch-only densification of carbon-carbon composite materials

ActiveUS8003026B2Reduce variationLower density carbon-carbonTextiles and paperFriction liningCarbon compositesFiber

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com