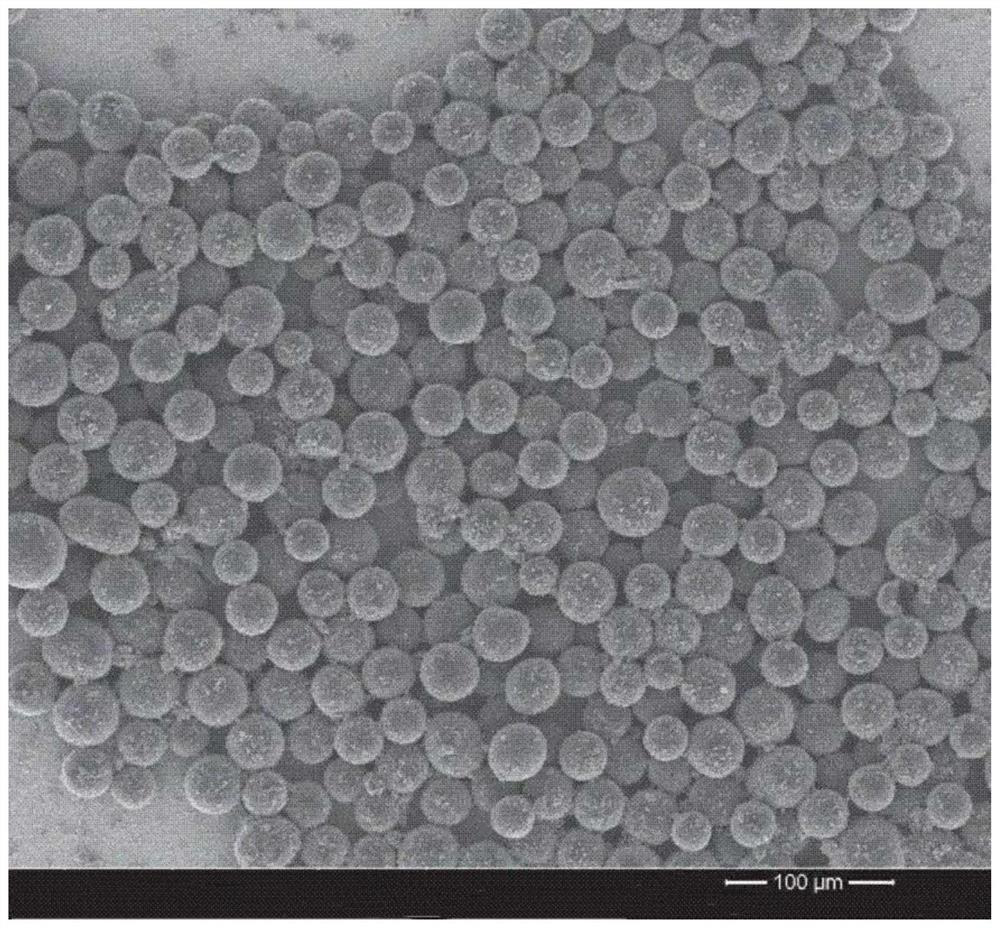

Nitrogen-doped mesonphase carbosphere as well as preparation method and application thereof

A technology of mesophase carbon microspheres and reaction, which is used in the preparation/purification of carbon, active material electrodes, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

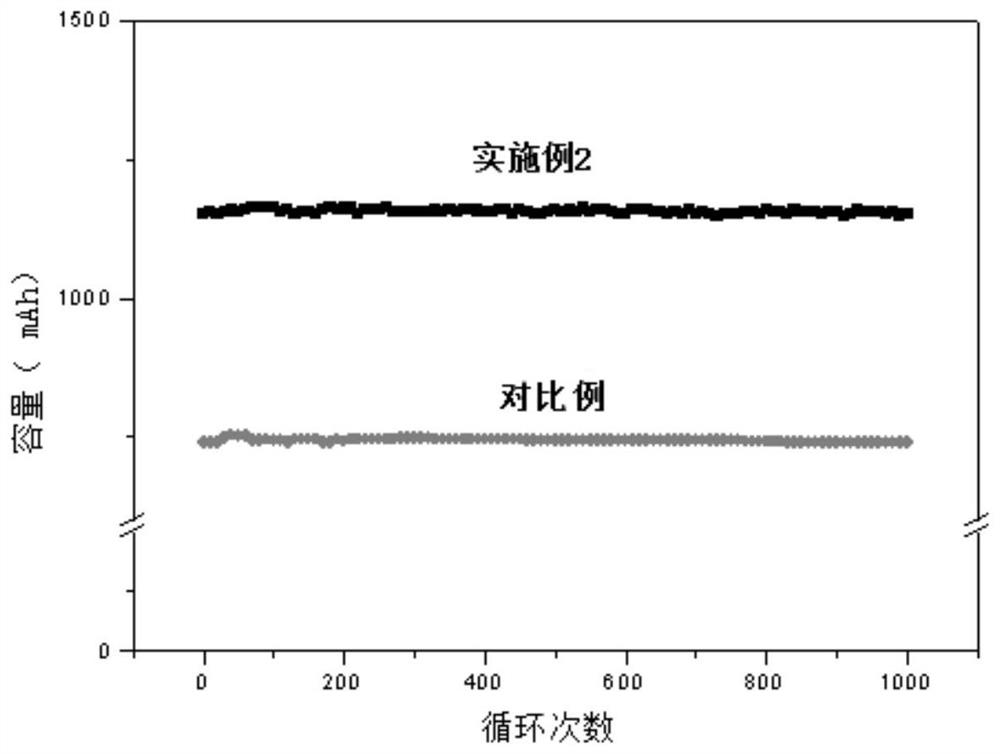

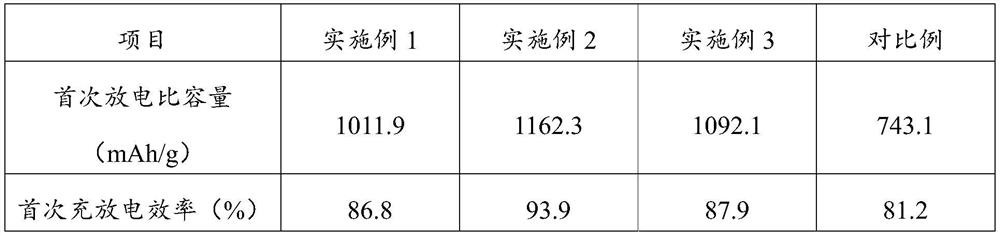

Examples

Embodiment 1

[0037] A preparation method of nitrogen-doped mesophase carbon microspheres, comprising the following specific steps:

[0038] (1) Heat naphthalene to 210°C at a heating rate of 5°C in a closed reactor A with nitrogen gas, place pitch in reactor B with nitrogen gas, and heat it to 85°C at a heating rate of 2°C, wherein, naphthalene The molar ratio of asphalt and asphalt is 1:0.1, reactor A and reactor B are connected by a conduit, and the air duct has a valve control switch. Reactor B has a long inlet and a short outlet, and the outlet is connected with tetrahydrofuran absorption liquid. When the reactor When the temperature of A reaches 210°C and the reactor B reaches 85°C, open the valve between reactor A and reactor B, let the naphthalene vapor pass into the semi-condensed asphalt to fully absorb, and when the naphthalene evaporates, the reactor A Heating is stopped, and isotropic pitch is obtained in reactor B;

[0039] (2) Feed nitrogen gas into reactor B, raise the temp...

Embodiment 2

[0045] A preparation method of nitrogen-doped mesophase carbon microspheres, comprising the following specific steps:

[0046] (1) Heat naphthalene in a closed reactor A with nitrogen to 220°C at a heating rate of 7°C, place the pitch in reactor B with nitrogen, and heat it to 90°C at a heating rate of 4°C, wherein, naphthalene The molar ratio of asphalt to asphalt is 1:0.5. Reactor A is connected to reactor B by a conduit, and the air duct has a valve control switch. Reactor B has a long inlet and a short outlet, and the outlet is connected with tetrahydrofuran absorption liquid. When the reactor When the temperature of A reaches 220°C and the reactor B reaches 90°C, open the valve between reactor A and reactor B, let the naphthalene vapor pass into the semi-condensed asphalt to fully absorb, and when the naphthalene evaporates, the reactor A Heating is stopped, and isotropic pitch is obtained in reactor B;

[0047] (2) Feed nitrogen into reactor B, raise the temperature to 41...

Embodiment 3

[0054] A preparation method of nitrogen-doped mesophase carbon microspheres, comprising the following specific steps:

[0055] (1) Heat naphthalene to 230°C at a heating rate of 10°C in a closed reactor A with nitrogen gas, place pitch in reactor B with nitrogen gas, and heat it to 95°C at a heating rate of 5°C, wherein, naphthalene The molar ratio of asphalt and asphalt is 1:1. Reactor A and reactor B are connected by a conduit, and the air duct has a valve control switch. Reactor B has a long inlet and a short outlet, and the outlet is connected with tetrahydrofuran absorption liquid. When the reactor When the temperature of A reaches 230°C and the reactor B reaches 95°C, open the valve between reactor A and reactor B, let the naphthalene vapor pass into the semi-condensed asphalt for full absorption, and when the naphthalene evaporates, the reactor A Heating is stopped, and isotropic pitch is obtained in reactor B;

[0056] (2) Feed nitrogen gas into reactor B, raise the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com