Method for preparing carbon material by use of heavy oil

A technology of carbon materials and heavy oil, which is applied in the processing of tar pitch/petroleum pitch/natural pitch, chemical processing of tar pitch/petroleum pitch/natural pitch, and the petroleum industry, and can solve problems such as inability to adjust flexibly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

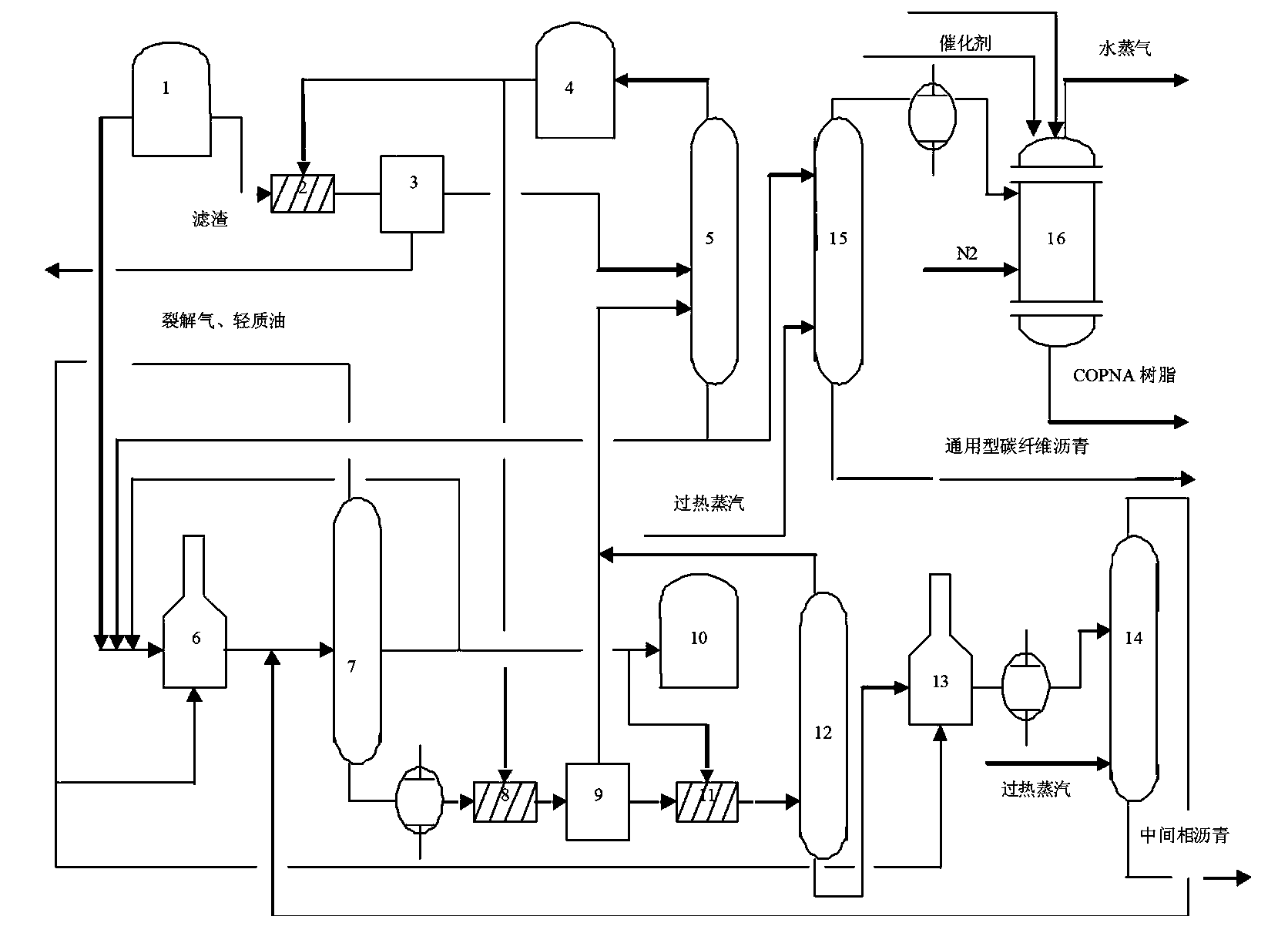

Method used

Image

Examples

Embodiment 1

[0068] Certain heavy oil, its property is as follows table 1,

[0069] Table 1

[0070] project

[0071] 1 part of heavy oil was mixed and dissolved in 2 parts of xylene, and the insoluble fraction thus formed was separated and removed using a continuous filter. Remove xylene from the filtrate by distillation to obtain refined heavy oil, the properties of which are shown in Table 2

[0072] Table 2

[0073] project

[0074] Refined heavy oil, xylene soluble components produced in subsequent processes, and hydrogenated heavy solvent (residue) are placed at a temperature of 450-550°C and a pressure of 1.0-5.0Mpa. Carry out heat treatment in the thermal polycondensation furnace, and send the processed product to the distillation tower for fractional distillation at the top temperature of 250-290°C and the top pressure of 0-0.3Mpa, remove cracked gas and lighter fractions from the top of the tower, and use it as fuel for the device. Take out pyrolysis heav...

Embodiment example 2

[0102] The properties of a certain heavy oil are shown in Table 11

[0103] Table 11

[0104] project

[0105] Repeat the implementation of Case 1 to obtain the following products at each stage:

[0106] Table 12

[0107] project

[0108] Table 13: Xylene Insoluble Components

[0109] project

[0110] Table 14: Mesophase pitch properties

[0111] project

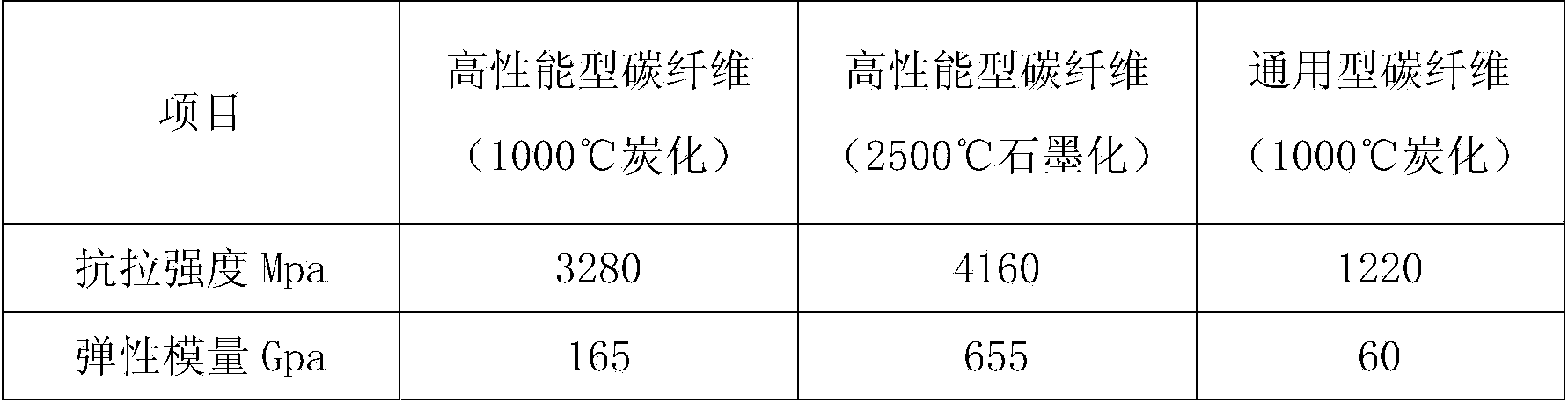

[0112] Table 15: High Performance Carbon Fiber

[0113] project

[0114] Table 16: Isotropic Bitumen

[0115] project

[0116] Table 17: General purpose carbon fiber

[0117] project

[0118] COPNA resin is the same as embodiment 1

Embodiment 3

[0120] Repeat embodiment 1, take following heavy oil as raw material, each step implementation data is as follows:

[0121] Table 18 Heavy oil

[0122] project

heavy oil

Refined heavy oil

Pyrolysis of heavy oil

Soluble components

density 3 g / cm 3

1.163

1.182

1.194

1.189

Viscosity (cst100℃)

5.2

28.5

23.6

19.2

Xylene insoluble matter (wt%)

4.7

1.9

6.1

2.1

Quinoline insoluble matter (wt%)

0.6

<0.1

<0.1

<0.1

Distillation (°C)

IBP

189

221

223

219

10% (vol)

221

304

253

250

30% (vol)

322

373

345

342

50% (vol)

402

439

428

405

[0123] Table 19: Asphalt

[0124] project

Xylene insoluble components

Isotropic asphalt

Xylene insoluble matter (wt%)

73.5

92.9

61.8

Quinoline insolu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com