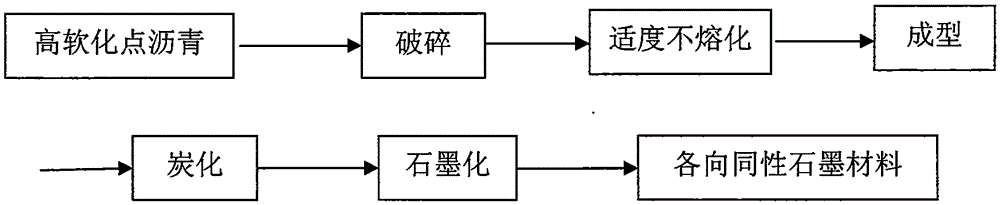

Method for preparing isotropic graphite from isotropic asphalt with high softening point through self-sintering

A technology for isotropic and graphite materials, which is applied in the field of preparing isotropic graphite materials with isotropic asphalt with high softening point, can solve the problems of reduced graphite performance, easy generation of voids, and easy cracking of products, and achieves stable product quality and various Good isotropy and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

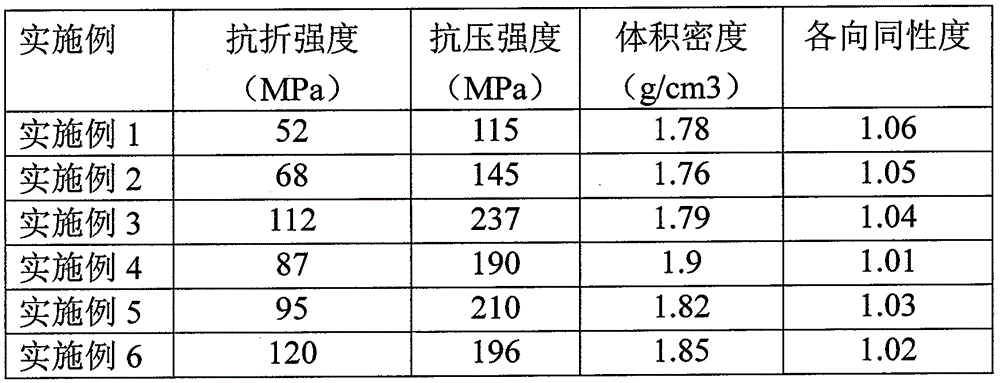

[0020] The high softening point isotropic pitch with a softening point of 200°C was crushed to 30 μm, raised to 200°C in air at 2°C / min, and the non-melting time at 200°C was 15 hours for "moderate" non-melting to obtain Powdered primary raw material. The above-mentioned powdery primary raw materials are molded, and then carbonized at 800°C under normal pressure and inert atmosphere protection, and kept at a constant temperature for 1 hour to obtain a carbon product; graphitization is carried out at 2800°C under normal pressure and inert atmosphere protection to obtain Target product; the product has a flexural strength of 52MPa, a compressive strength of 115MPa, and a bulk density of 1.78g / cm 3 , the degree of isotropy is 1.06.

Embodiment 2

[0022] The high softening point isotropic asphalt with a softening point of 220°C is crushed to 20 μm, raised to 250°C at 2°C / min in air, and the non-melting time at 250°C is 12 hours, and "moderate" non-melting is carried out to obtain Powdered primary raw material. The above-mentioned powdery primary raw materials are formed by vibration, and then carbonized at 1000°C under normal pressure and inert atmosphere protection, and kept at constant temperature for 1 hour to obtain a carbon product; graphitization is carried out at 2600°C under normal pressure and inert atmosphere protection to obtain Target product; the product has a flexural strength of 68MPa, a compressive strength of 145MPa, and a bulk density of 1.76g / cm 3 , the degree of isotropy is 1.05.

Embodiment 3

[0024] The high-softening-point isotropic asphalt with a softening point of 250°C was crushed to 15 μm, raised to 300°C at 2°C / min in air, and the non-melting time at 300°C was 10 hours for "moderate" non-melting to obtain Powdered primary raw material. The above-mentioned powdery primary raw materials are formed by vibration, and then carbonized at 900°C under normal pressure and inert atmosphere protection, and kept at constant temperature for 1 hour to obtain carbon products; graphitization is carried out at 2400°C under normal pressure and inert atmosphere protection to obtain Target product; the product has a flexural strength of 112MPa, a compressive strength of 237MPa, and a bulk density of 1.79g / cm 3 , the degree of isotropy is 1.04.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com