Patents

Literature

255 results about "Medium molecular weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medium molecular weight polyisobutylene is used to adjust properties such as flexibility, elongation, cohesive strength, and gas barrier performance of a product. They have an average molecular weight, Mw, of from 40,000 to 120,000 g/mol.

Reversible pegylated drugs

ActiveUS20060171920A1Prolonged Circulatory Half-LifeProvide benefitsAntibacterial agentsOrganic active ingredientsPhosphate9-fluorenylmethoxycarbonyl

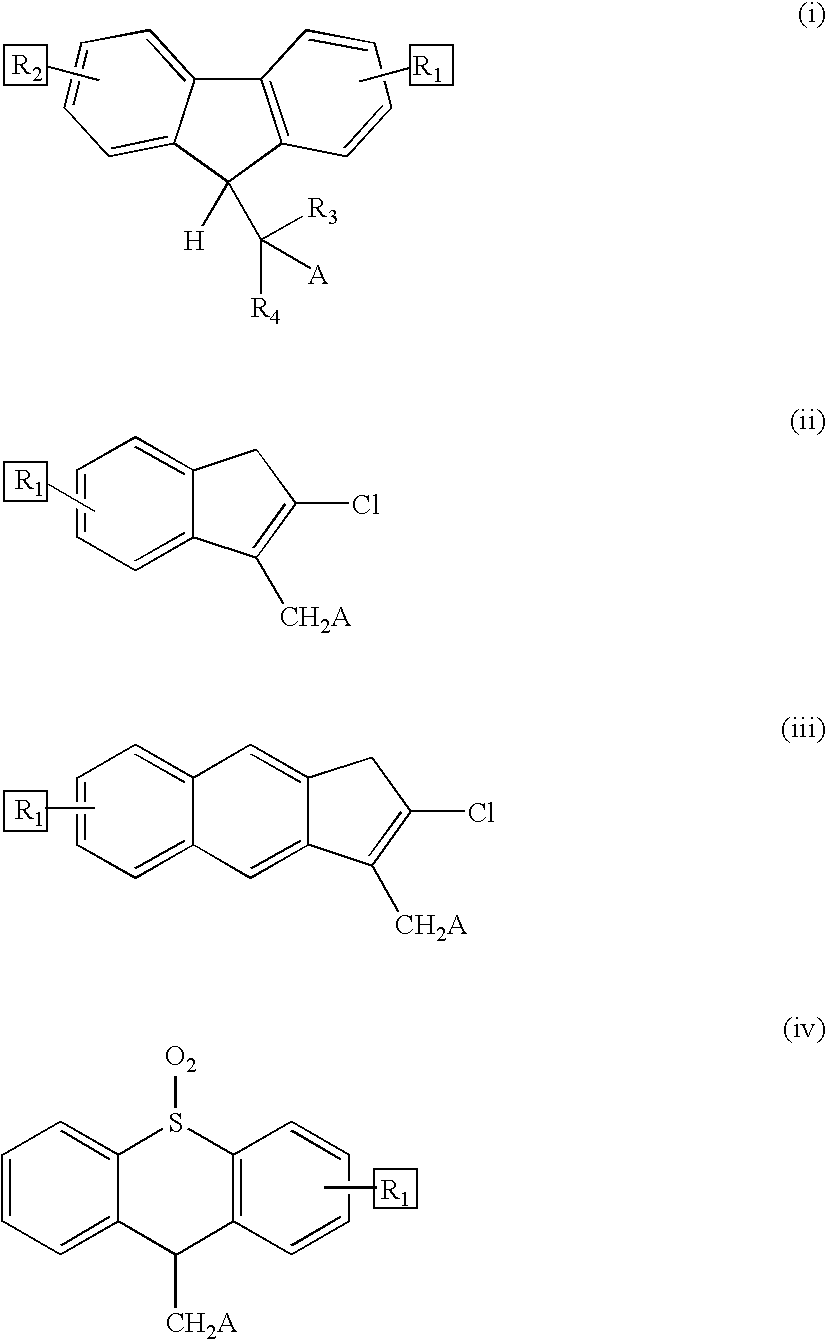

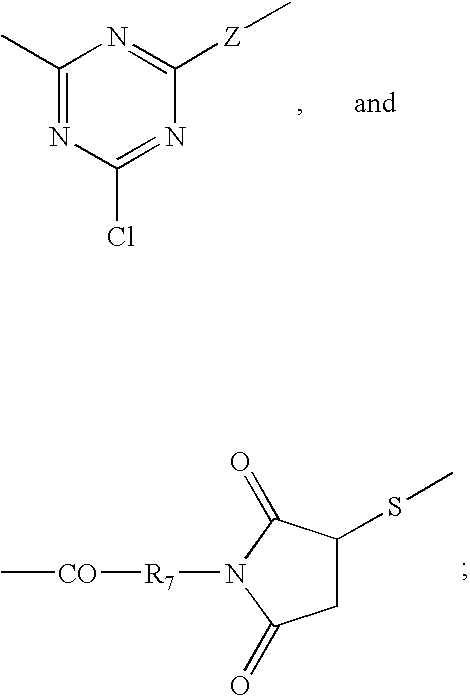

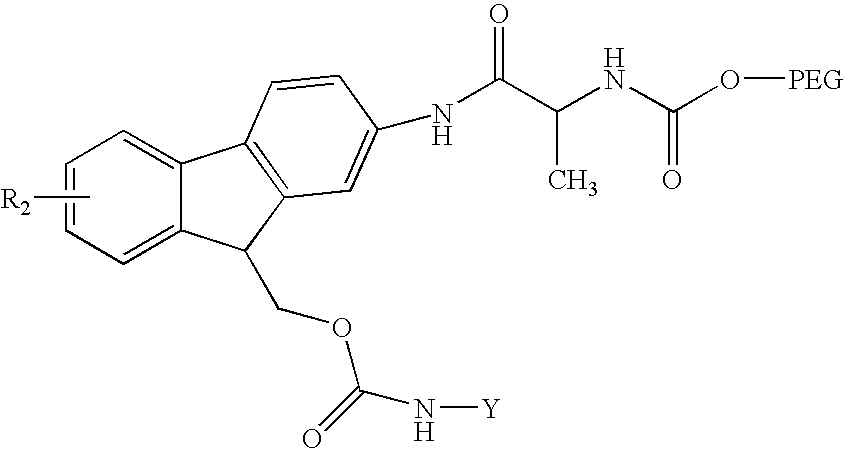

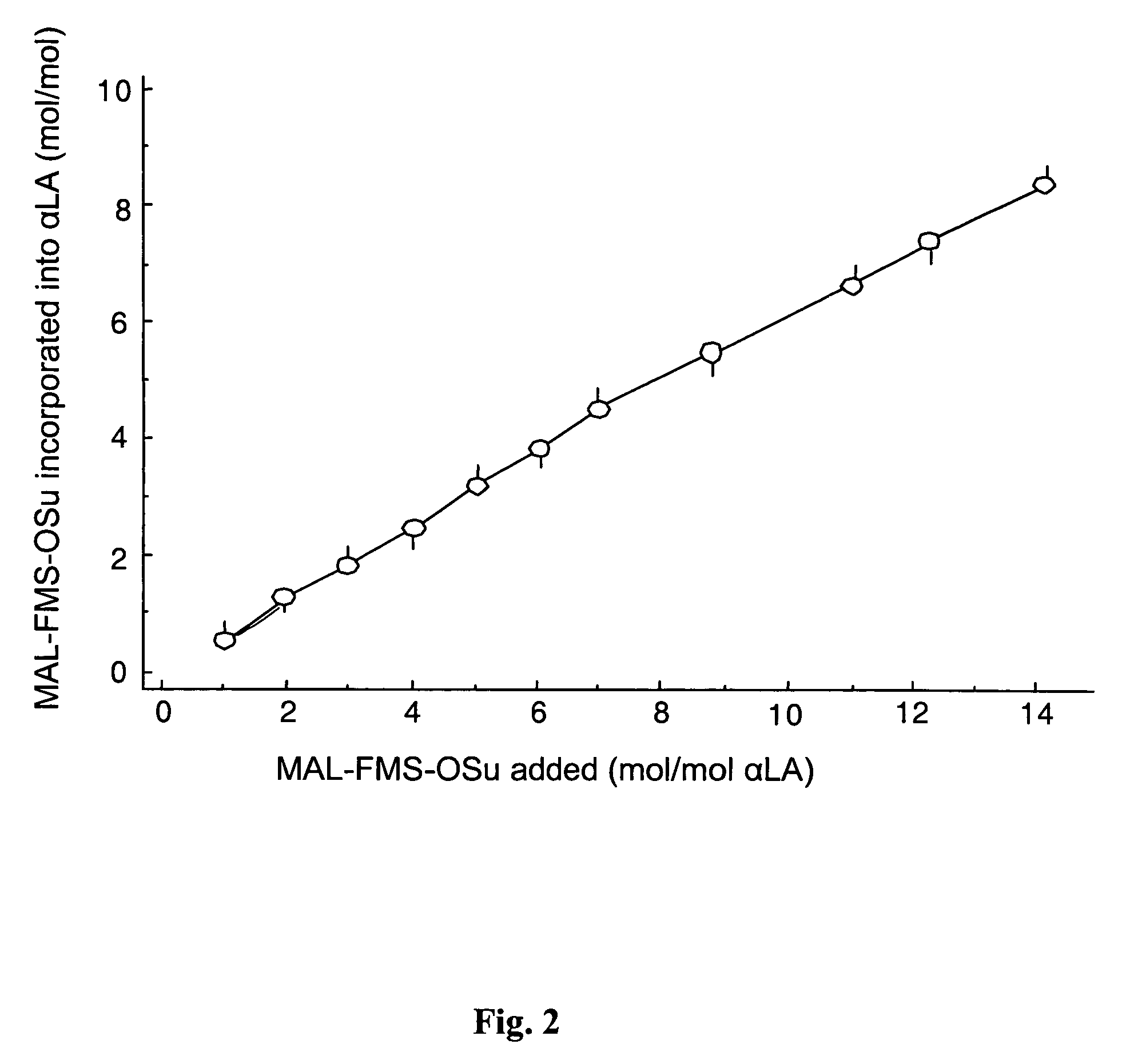

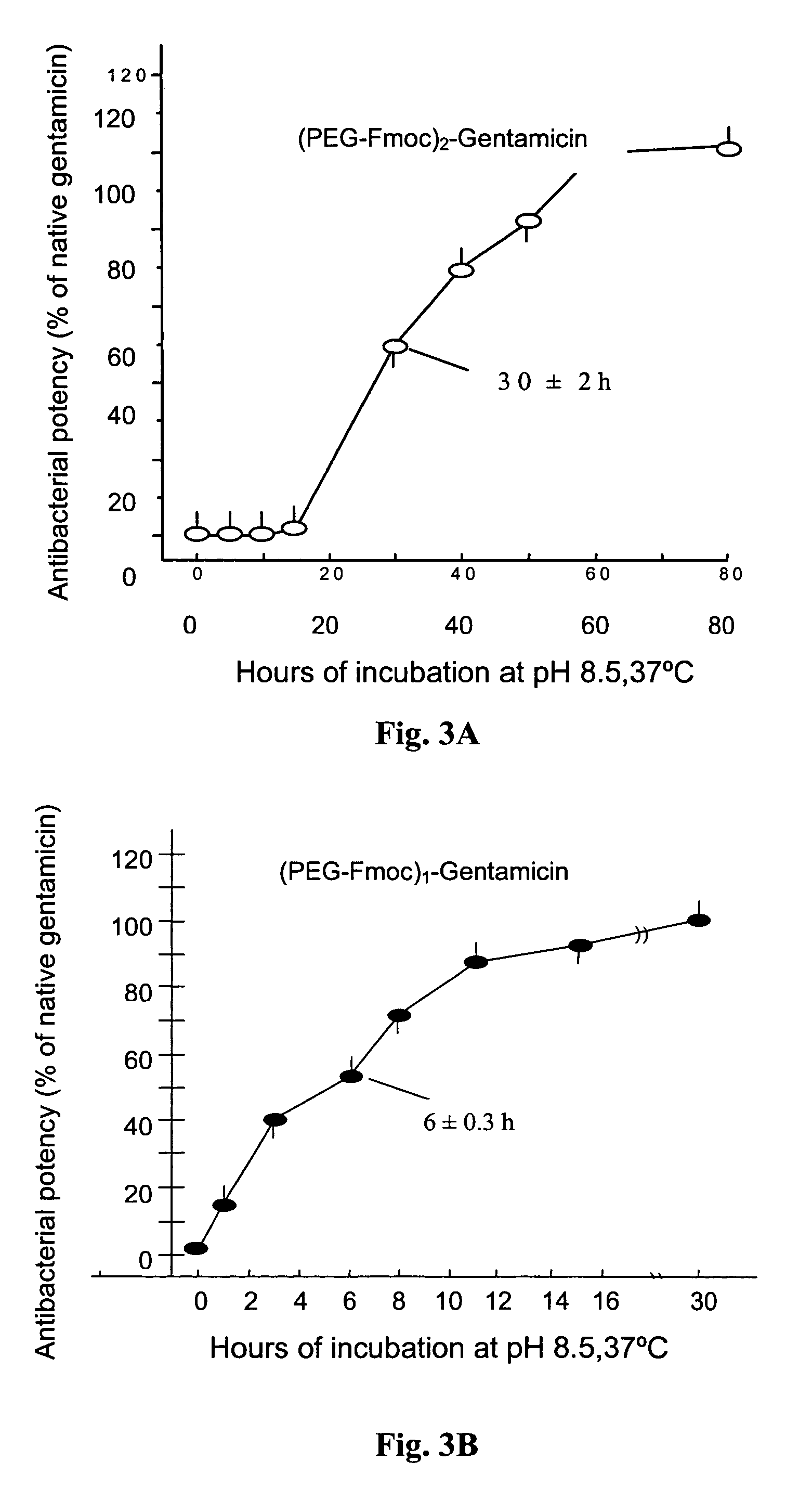

Reversible pegylated drugs are provided by derivatization of free functional groups of the drug selected from amino, hydroxyl, mercapto, phosphate and / or carboxyl with groups sensitive to mild basic conditions such as 9-fluorenylmethoxycarbonyl (Fmoc) or 2-sulfo-9-fluorenylmethoxycarbonyl (FMS), to which group a PEG moiety is attached. In these pegylated drugs, the PEG moiety and the drug residue are not linked directly to each other, but rather both residues are linked to different positions of the scaffold Fmoc or FMS structure that is highly sensitive to bases and is removable under physiological conditions. The drugs are preferably drugs containing an amino group, most preferably peptides and proteins of low or medium molecular weight. Similar molecules are provided wherein a protein carrier or another polymer carrier replaces the PEG moiety.

Owner:YEDA RES & DEV CO LTD

Reversible pegylated drugs

ActiveUS7585837B2Prolonged Circulatory Half-LifeLoss of biological and pharmacological potenciesAntibacterial agentsOrganic active ingredientsPhosphate9-fluorenylmethoxycarbonyl

Reversible pegylated drugs are provided by derivatization of free functional groups of the drug selected from amino, hydroxyl, mercapto, phosphate and / or carboxyl with groups sensitive to mild basic conditions such as 9-fluorenylmethoxycarbonyl (Fmoc) or 2-sulfo-9-fluorenylmethoxycarbonyl (FMS), to which group a PEG moiety is attached. In these pegylated drugs, the PEG moiety and the drug residue are not linked directly to each other, but rather both residues are linked to different positions of the scaffold Fmoc or FMS structure that is highly sensitive to bases and is removable under physiological conditions. The drugs are preferably drugs containing an amino group, most preferably peptides and proteins of low or medium molecular weight. Similar molecules are provided wherein a protein carrier or another polymer carrier replaces the PEG moiety.

Owner:YEDA RES & DEV CO LTD

Methods for converting linear polyesters to macrocyclic oligoester compositions and macrocyclic oligoesters

InactiveUS6525164B2Low viscosityCost-effectivePreparation by ester-hydroxy reactionOrganic compound preparationPolyesterDicarboxylic acid

Owner:LIQUID THERMO PLASTICS

Preparation method for self-emulsified cationic epoxy emulsion

InactiveCN103497617ANarrow molecular weight distributionGood flexibilityPolyurea/polyurethane coatingsPaints for electrolytic applicationsEmulsionCarbon chain

The invention discloses a preparation method for self-emulsified cationic epoxy emulsion. The method mainly comprises: using bisphenol A, dodecylphenol and ethoxylatedbisphenol A to perform chain extension on low-molecular-weight epoxy resin to obtain medium-molecular-weight chain-extended epoxy resin; using diethanolamine and N, N-dimethylpropylamine to perform ring-opening amination on chain-extended epoxy resin; and taking a totally-enclosed modified MDI as a curing agent, neutralizing with lactic acid, and emulsifying in deionized water to obtain the self-emulsified cationic epoxy emulsion. According to the epoxy emulsion, tertiary / quaternary amine cationic epoxy resin is taken as the resin main body, and the molecules of the tertiary / quaternary amine cationic epoxy resin have both hydrophobic carbon chains and hydrophilic cationic chain segments, so that the resin molecules have self-emulsifying function, and can be stably emulsified in water without the help of emulsifiers. The provided self-emulsified cationic epoxy emulsion is applicable to preparation of cathodic electrophoretic coatings which has excellent coating performance.

Owner:ZHAOQING UNIV

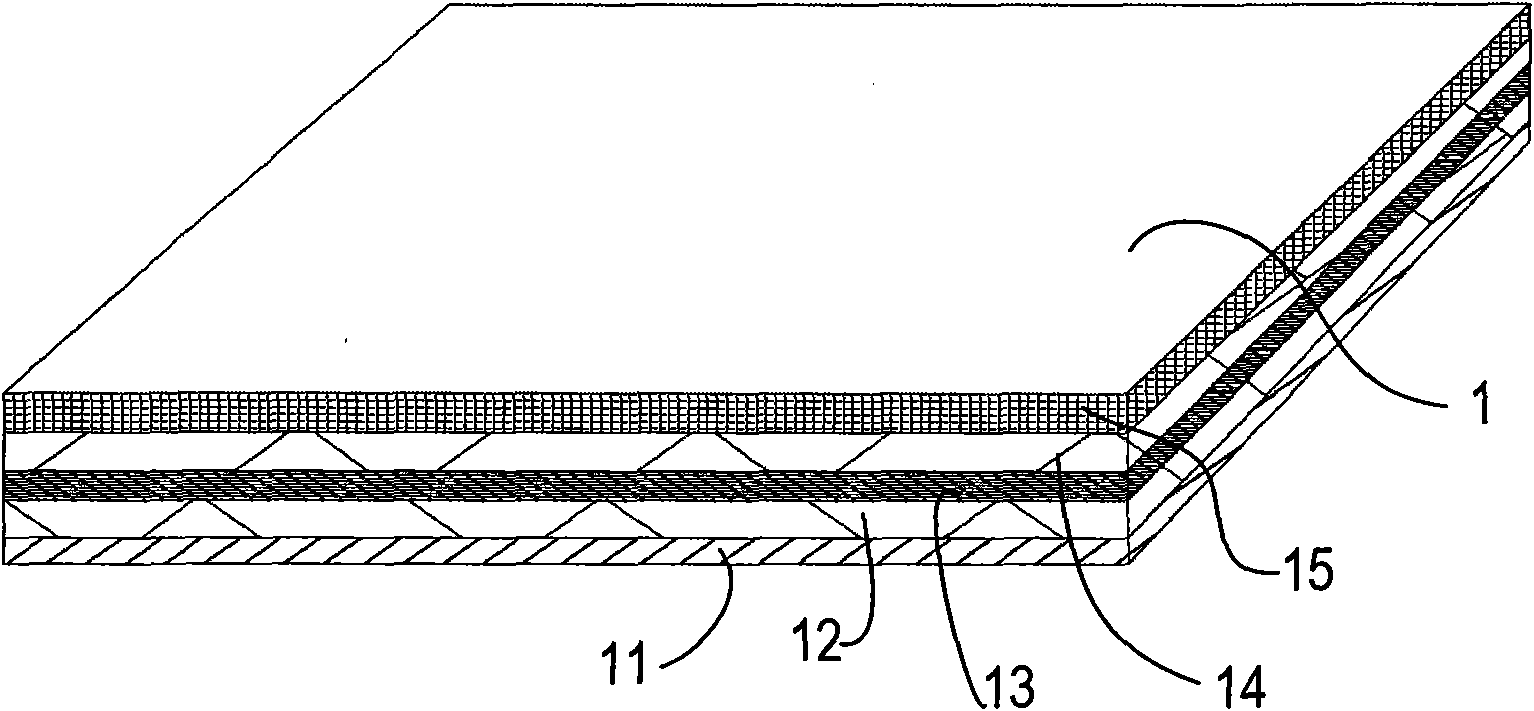

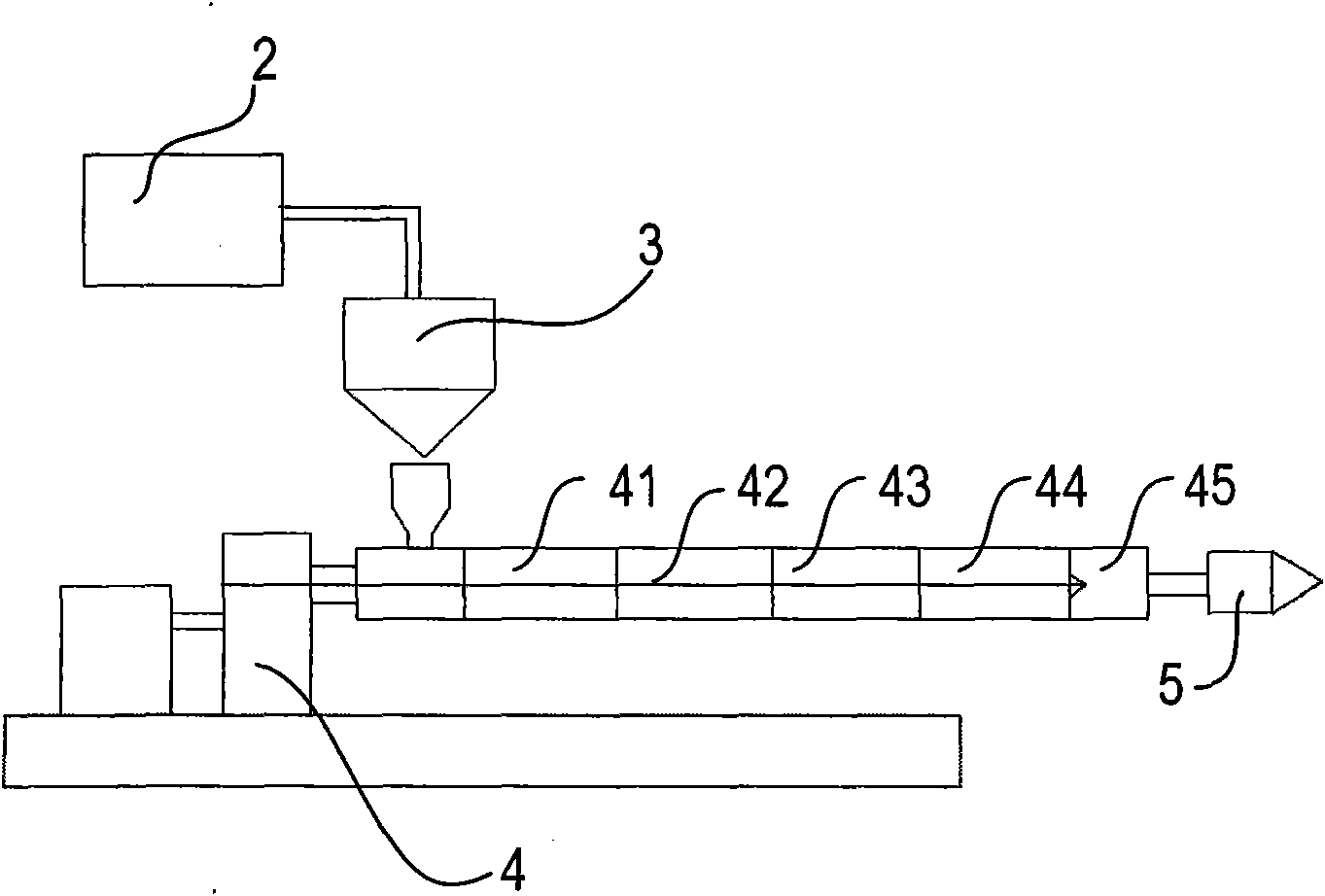

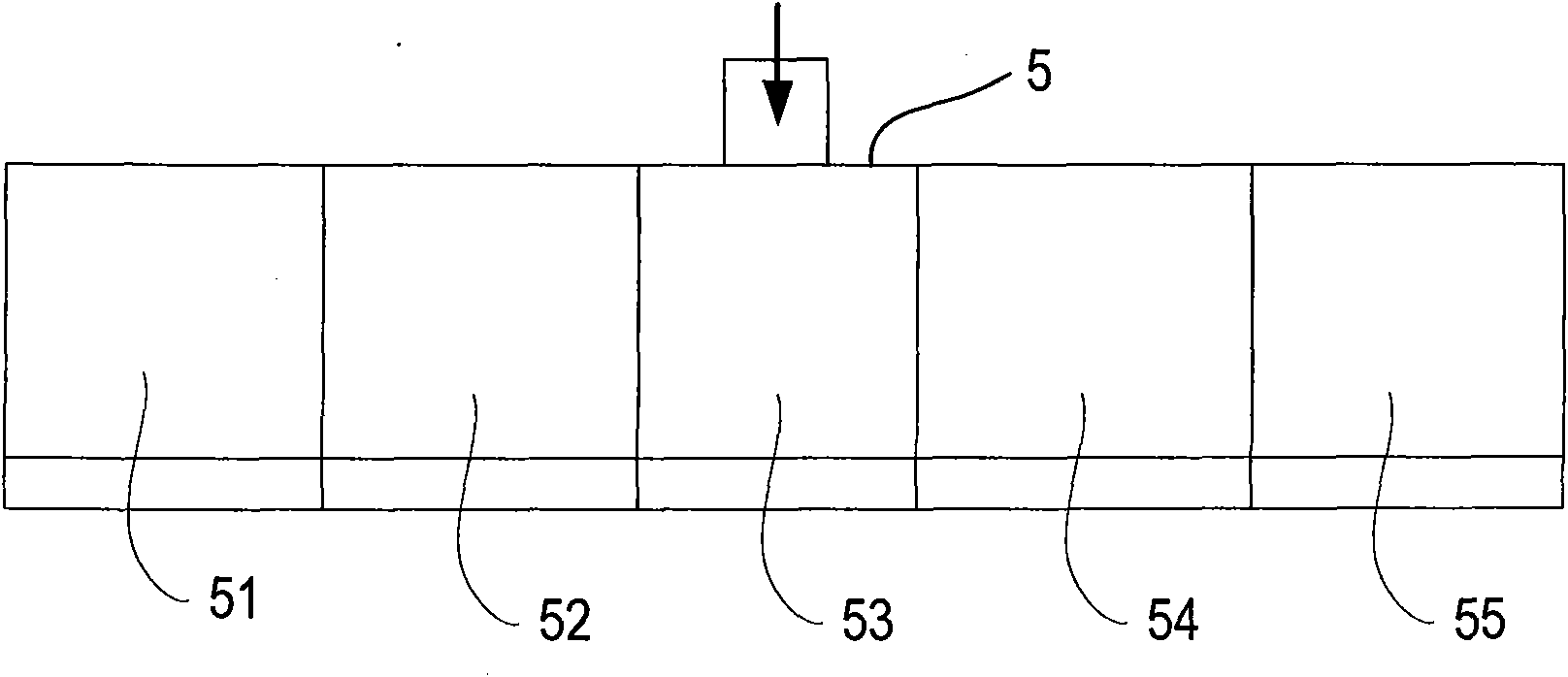

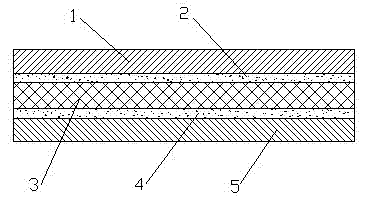

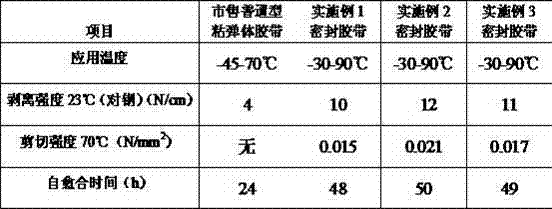

Anticorrosive viscoelastic body rubber belt and preparation method thereof

ActiveCN101935500AImprove adhesionUnique cold flow characteristicsNon-macromolecular adhesive additivesFilm/foil adhesivesCompound aWhole body

The invention relates to an anticorrosive viscoelastic body rubber belt, which comprises a protective film layer, a first viscoelastic body rubber belt, an enhanced network layer, a second viscoelastic body rubber layer and a release film layer arranged in turn, wherein the protective film layer is bonded with the first viscoelastic body rubber layer, the first viscoelastic body rubber layer is bonded with the enhanced network layer, and the enhanced network layer is bonded with the second viscoelastic body rubber layer to compound a whole body; and the release film layer is adhered to the second viscoelastic body rubber layer, wherein the viscoelastic body rubber is prepared from the following raw materials in percentage by weight: 3 to 10 percent of butyl rubber, 5 to 10 percent of highmolecular weight polyisobutylene, 25 to 35 percent of medium molecular weight polyisobutylene, 10 to 15 percent of low molecular weight polyisobutylene, 30 to 45 percent of inorganic enhanced powder,0.5 to 1.0 percent of antioxidant, 0.5 to 1.0 percent of anti-aging agent, and 0 to 1.0 percent of colorant. The viscoelastic body rubber belt has a self-healing function, is not brushed with a primer when used, and can be directly used for corrosion protection of irregular components. The invention also relates to a preparation method of the anticorrosive viscoelastic body rubber belt.

Owner:CYG CHANGTONG NEW MATERIAL

Temperature-resistant water-soluble copolymer, preparation and use thereof

InactiveCN101274974AImprove solution performanceImprove rigidityDrilling compositionSolubilityPersulfate

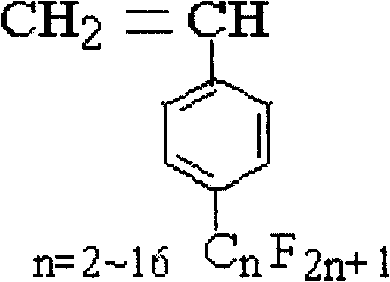

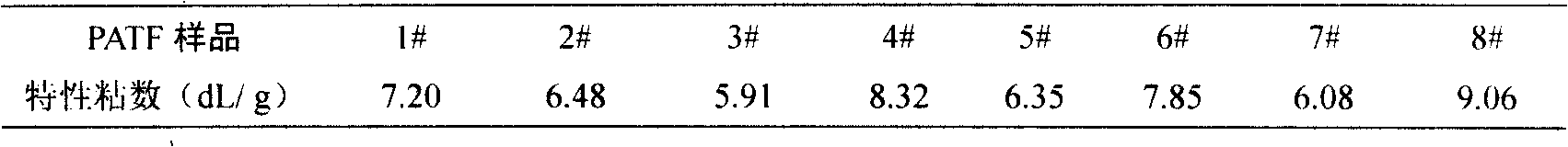

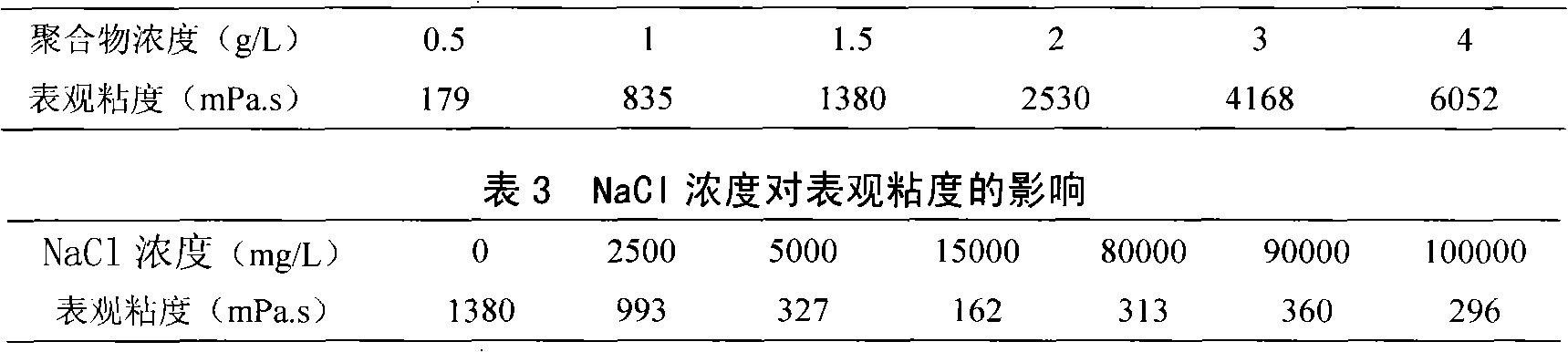

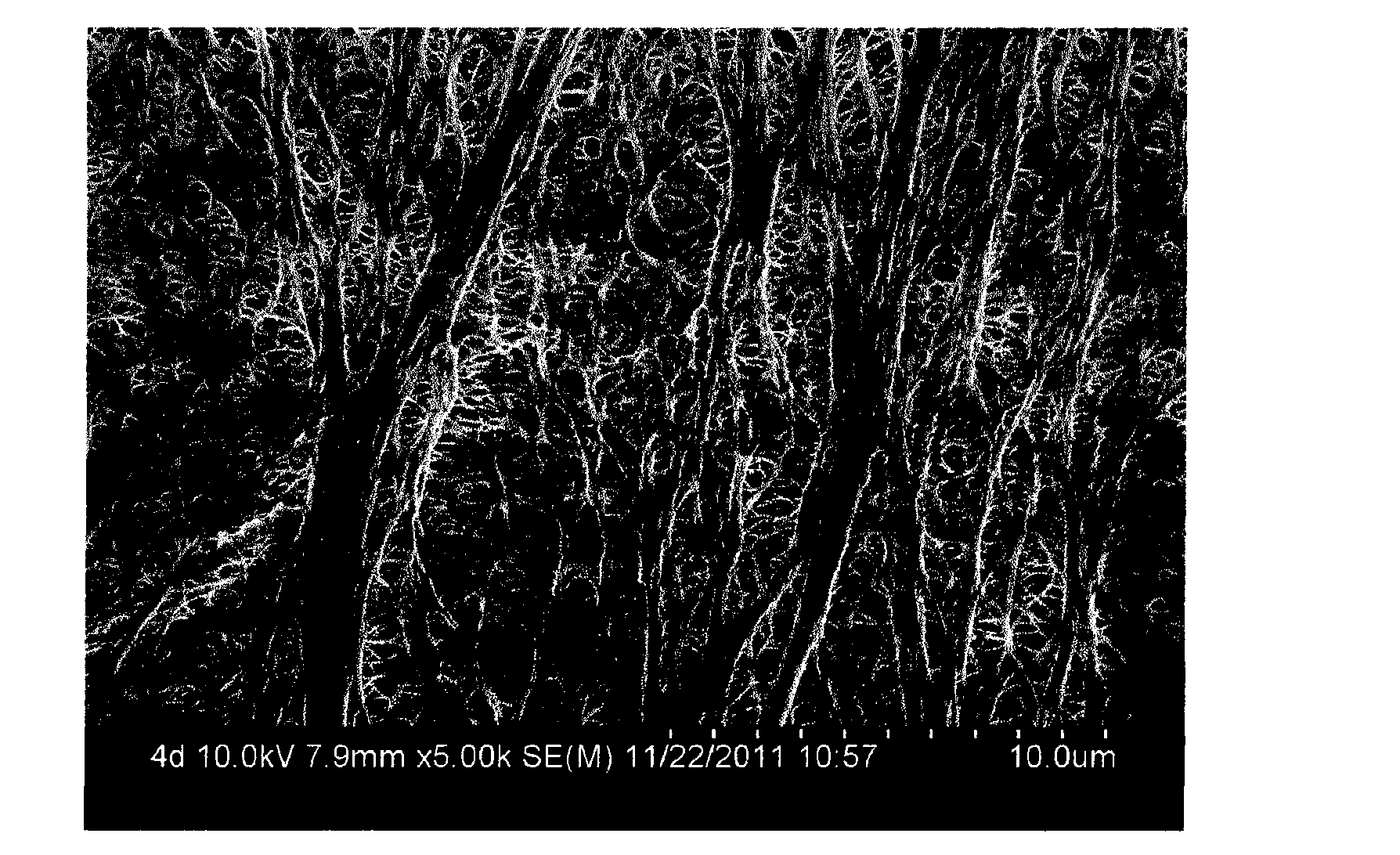

The invention discloses a copolymer with temperature resistance and water solubility and the preparation method and application thereof, which is characterized in that: 20 portions of acrylic amide, 0.1 to 10 portions of anion monomer or / and cation monomer, 0.05 to 3 portions of fluorine-containing styrene or / and perfluoroalkyl styrene hydrophobic monomer, 0.5 to 60 portions of surface active agent and 50 to 700 portions of deionized water are put into a three-necked reaction bulb; after the solution pH is regulated to be equal to 2.5 to 9 and N2 is connected for 30 minutes, 0.001 to 0.2 portion of an evocating agent of persulfate is added under temperature of 20 to 70 DEG C, reacting for 6 to 36 hours, and PATF is prepared. Then water is used for diluting so as to prepare PATF concentrated solution, thus obtaining a copolymer that has medium molecular weight and water solubility, is high-temperature resistant, has an ability of molecular association and can be used in high temperature and high salinity reservoir. The copolymer is prepared into aqueous solution with a mass concentration of 0.3 to 3g / L and a surface-active-agent concentration of 0.01 to 4mmol / L, which is put in a blending container with a dasher and is stirred even at room temperature to prepare a polymer oil-displacing agent which is high-temperature resistant, high tackifying and anti-sharing and has excellent aging resistance under high salinity and the temperature of 110 DEG C. The prepared oil-displacing polymer has excellent solution properties owing to the supermolecular structure formed by the association between molecules of fluorine-containing cinnamene or / and alkylbenzene hydrophobic groups, thus having favorable application prospects in high temperature and high salinity reservoir exploitation.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Polyethylene having faster crystallization rate and improved environmental stress cracking resistance

InactiveUS20100105839A1Fast crystallizationAdditional stress crackCrystallization rateMedium molecular weight

Disclosed is a polyethylene composition having faster crystallization rate and improved environmental stress cracking resistance. The polyethylene composition comprises a multimodal polyethylene and a nucleating agent. The multimodal polyethylene comprises from 25 to 50 wt % of a low molecular weight ethylene homopolymer component, from 25 to 50 wt % of a medium molecular weight ethylene copolymer component and from 25 to 50 wt % of a high molecular weight ethylene copolymer component. The polyethylene composition has an environmental stress cracking resistance (ASTM D1693, Condition B in 100% Igepal) greater than or equal to 40 days and a crystallization half time less than or equal to 70% of the crystallization half time of the multimodal polyethylene without nucleating agent.

Owner:EQUSR CHEM LP

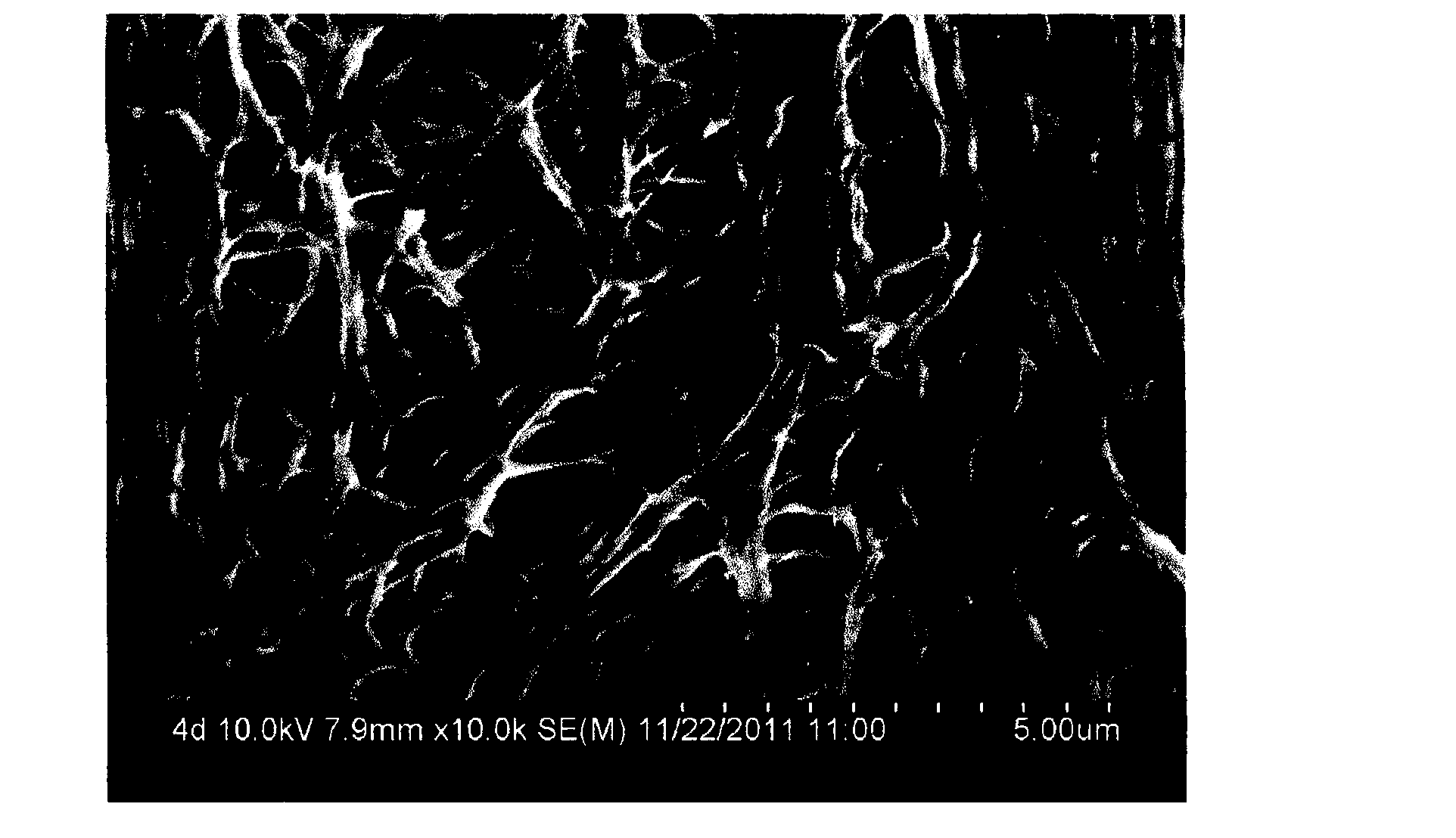

Polyethylene based composite material microporous diaphragm with hot-pressing adhesive characteristic

InactiveCN103178227AInhibit heat shrinkageImprove securityMembranesSemi-permeable membranesPolymer scienceWhole body

The invention relates to a polyethylene based composite material microporous diaphragm with a hot-pressing adhesive characteristic. According to the polyethylene based composite material microporous diaphragm, ethylene propylene monomer and polyisobutene rubbers with medium molecular weights are adopted to modify high-crystallinity high-density polyethylene, and fatty series dibasic acid ester of which the flashing point is more than 210DEG C is adopted as a process solvent and a pore forming agent of a diaphragm to obtain the diaphragm with the hot-pressing adhesive characteristic. The diaphragm with the hot-pressing adhesive characteristic and a positive pole piece are adhered into a whole body after hot-pressing lamination, so that the thermal contraction of the diaphragm is inhibited. The composite material diaphragm has high strength and high-temperature resistance, and can be applied to lithium ion power batteries with high safety and long cycle lives.

Owner:TIANJIN DG MEMBRANE

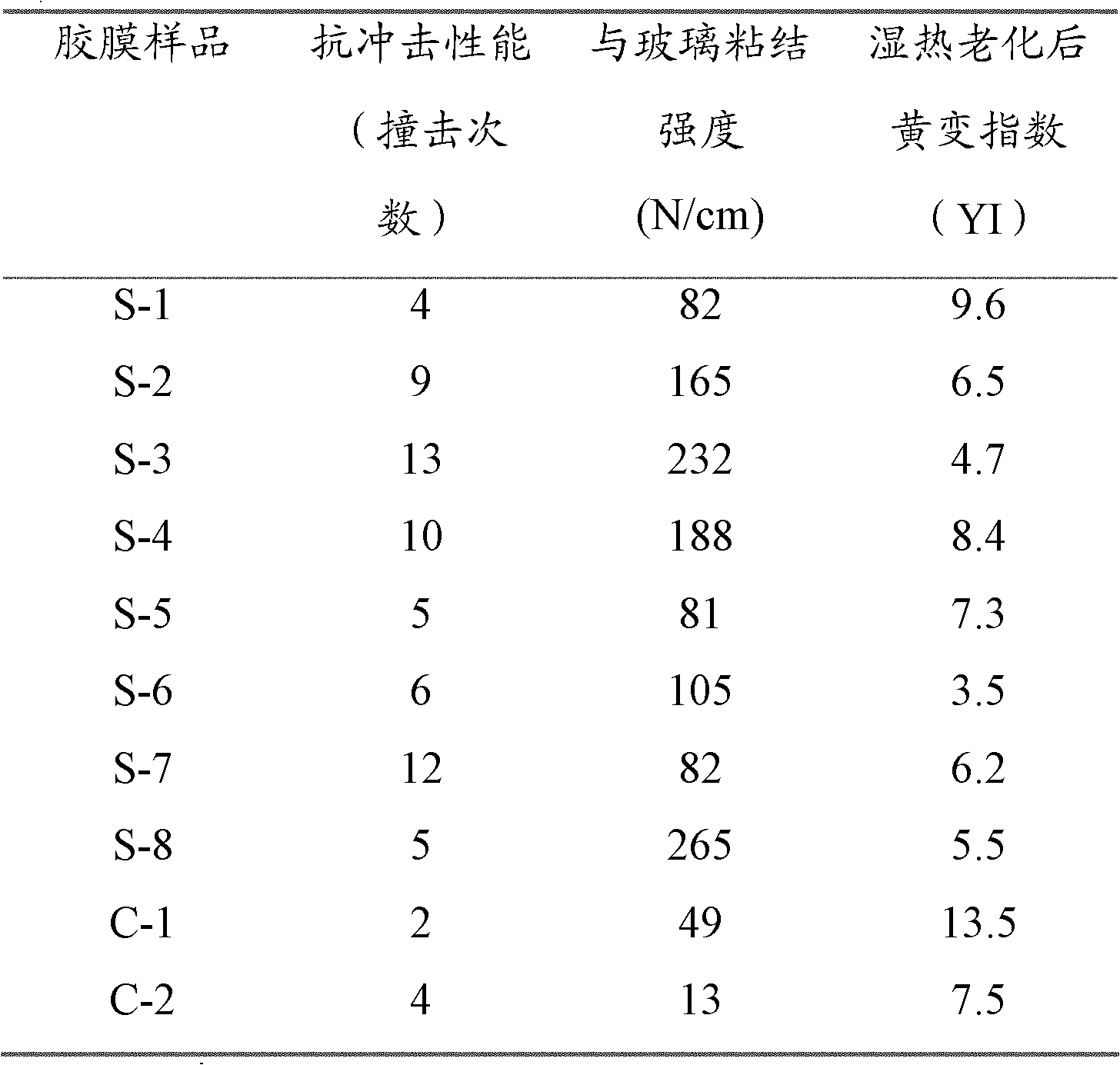

Packaging adhesive film composition and application thereof

ActiveCN101942145AGood aging resistanceHigh impact modulusPhotovoltaic energy generationSemiconductor devicesHindered amine light stabilizersCarvacryl acetate

The invention relates to a packaging adhesive film composition and application thereof. The composition mainly comprises the following components in parts by mass: 65-95 parts of ethylene-vinyl acetate copolymer, 2-20 parts of ethylene-octylene copolymer, 2-15 parts of medium molecular weight polyisobutylene, 0.1-3 parts of cross-linking agent, 0.05-2 parts of ultraviolet stabilizer and 0.05-2 parts of hindered amine antioxidant. The composition has the advantages of excellent aging resistance, high bonding strength with glass, high impact resistance modulus and easy processing, and is suitable for packaging a double-layer glass solar battery pack of BIPV or double-layer glass of decorative buildings in the aspects of tear strength and impact resistance modulus.

Owner:SUZHOU FIRST PV MATERIAL CO LTD

Technique for extracting and separating rare earth elements from non-saponification system

ActiveCN101050488AReduce residual acidReduce acid consumptionProcess efficiency improvementRare-earth elementSulfate

This invention provides a process for extracting and separating rare earth elements by using non-saponification extractant. The process comprises: utilizing rare earth sulfate solution containing two or more rare earth elements obtained by treating rare earth ore as the raw material, performing Nd / Sm multi-stage fractionation and extraction by using non-saponification extractant P507 to obtain Sm / Eu / Gd enriched product and La / Ce / Pr / Nd extraction raffinate, and further extracting and separating rare earth compounds with non-saponification extractant. The process has such advantages as no emulsification under low-acidity extraction, easy back extraction of medium-molecular-weight rare earth elements, low acid consumption, and high productivity.

Owner:GRIREM ADVANCED MATERIALS CO LTD

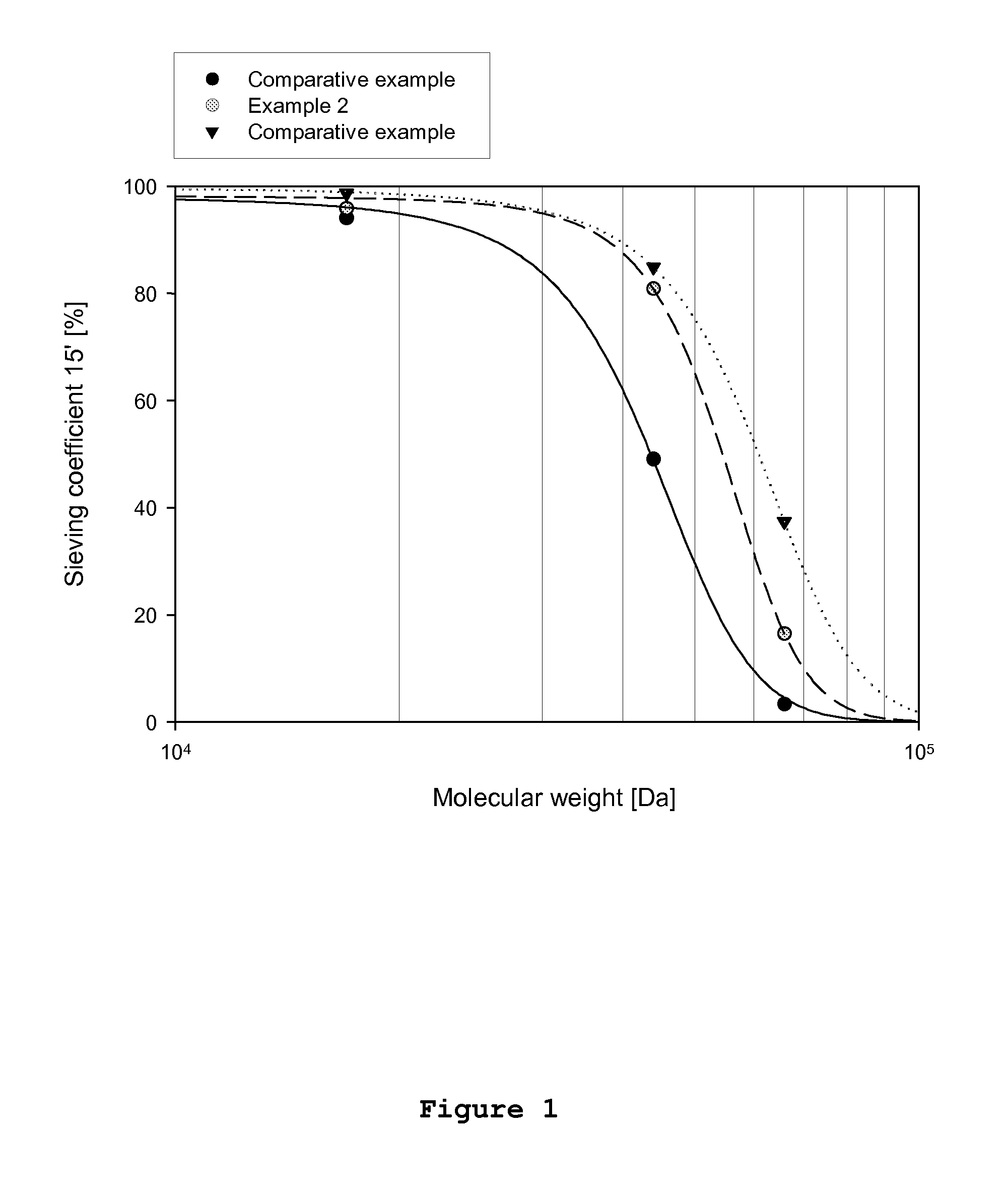

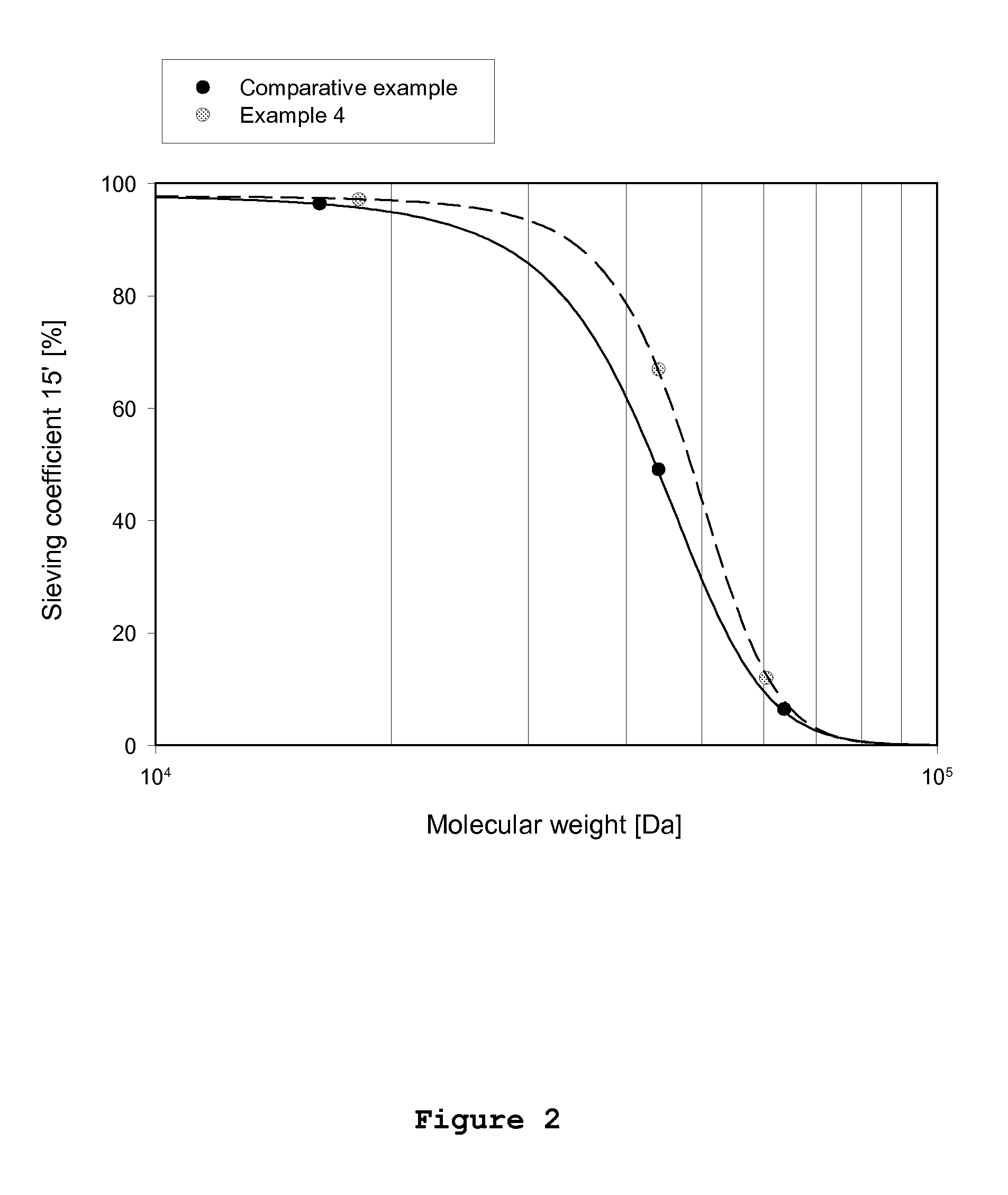

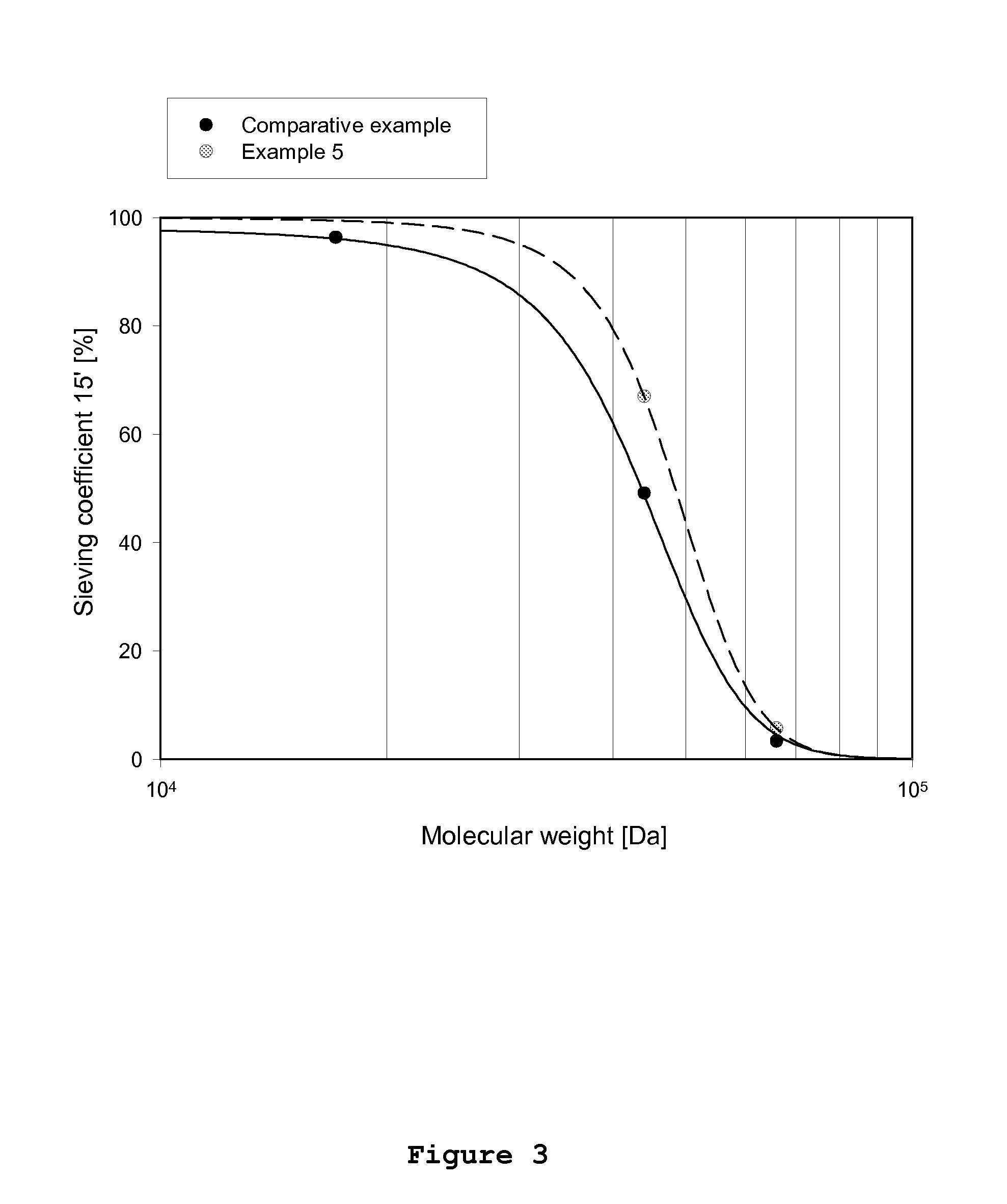

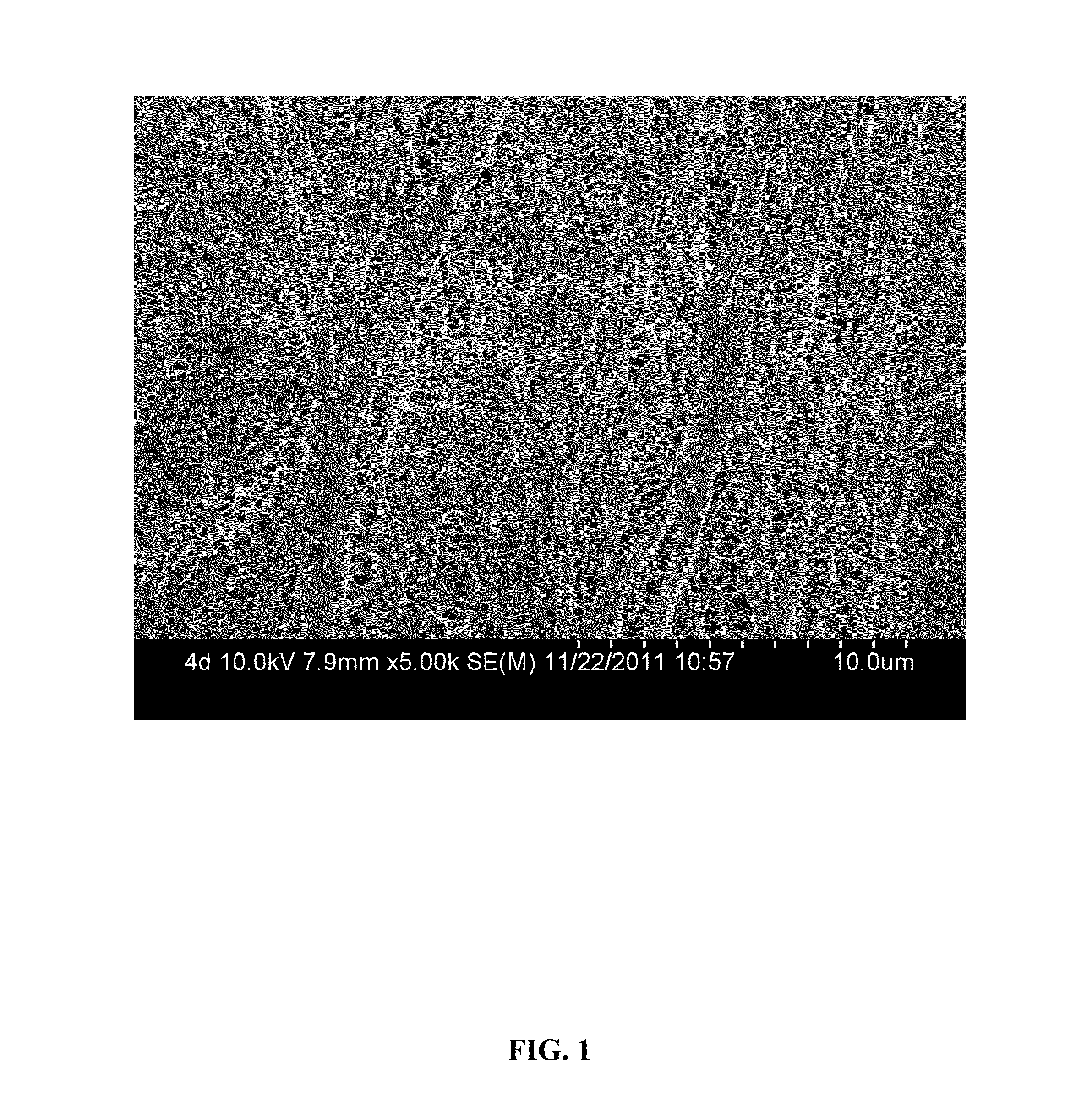

Membranes having improved performance

ActiveUS20120074063A1Improve performanceInflammatory mediatorSolvent extractionDialysisPhosphoryl cholineProtein solution

Permselective asymmetric membranes suitable e.g. for hemodialysis, hemodiafiltration and hemofiltration of blood, and having improved sieving characteristics providing enhanced removal of middle molecular weight substances, e.g. inflammatory mediators having a molecular weight between 20 and 40 kDa. The membranes comprise polyethersulfone and polyvinylpyrrolidone and are coated with hyaluronic acid or copolymers of 2-methacryloyloxyethyl phosphoryl choline and other vinyl polymerizable monomers. Processes for the preparation of these membranes, devices comprising these membranes, and the use of these membranes in hemodialysis, hemodiafiltration and hemofiltration of blood, as well as in bioprocessing, plasma fractionation and the preparation of protein solutions.

Owner:GAMBRO LUNDIA AB

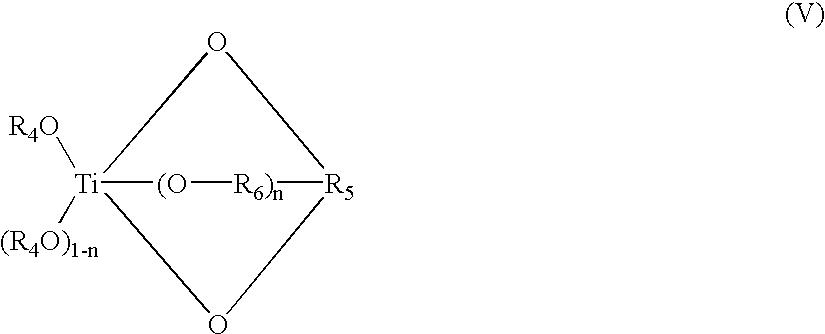

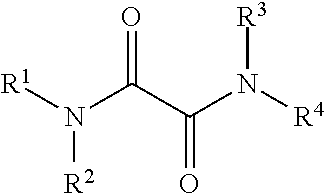

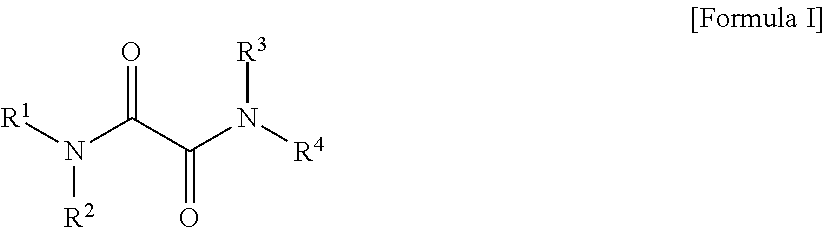

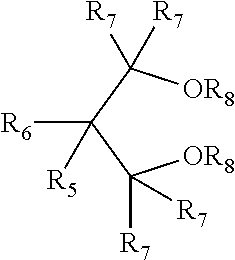

Catalyst System for Olefin Polymerization and Method for Producing Olefin Polymer

ActiveUS20170240667A1High activityEnhanced hydrogen responseOrganic-compounds/hydrides/coordination-complexes catalystsElectron donorPolymer chemistry

A phthalate-free catalyst component for olefin polymerization comprising titanium, magnesium, a halogen, diether, and oxalic acid diamides represented by the following formula (I):and an olefin polymerization catalyst system consisting of the solid catalyst component, an organoaluminum compound, and an optional external electron donor compound. The present catalyst compositions improve diether-based catalyst selectivity while maintaining excellent catalyst activity and hydrogen response. An olefin polymer that has a moderate molecular weight distribution while maintaining higher stereoregularity (isotacticity) over diether-based catalyst, and better than or equal to phthalate-based catalyst can be produced by utilizing the inventive catalyst component.

Owner:FORMOSA PLASTICS USA

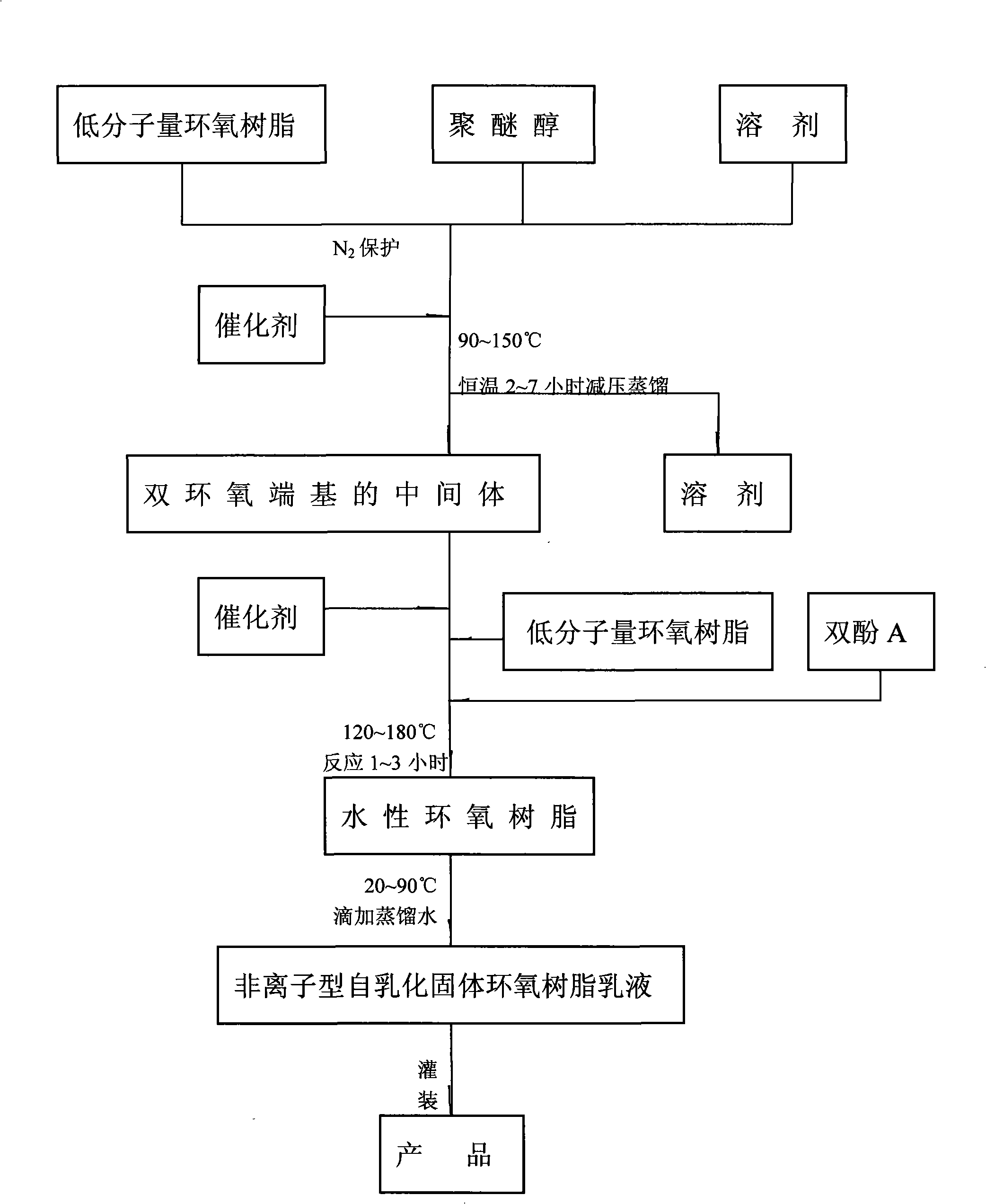

Non-ionic self-emulsification solid epoxy resin and preparation method for emulsion thereof

The invention relates to a non-ionic self-emulsifying solid epoxy resin and a preparation method of the emulsion of the resin, belonging to the coating material chemical manufacturing industry. The preparation method adopts a 'two-step method' principle during preparation: step one: under the protection of nitrogen, the reaction of 5 to 25 percent of low-molecular weight epoxy resin, 40 to 70 percent of polyether alcohol, 1 to 10 percent of solvent and 0.01 to 0.1 percent of catalyst is carried out at 90 to 150 DEG C, and then a constant temperature is kept for 2 to 7 hours before intermediate is obtained through the vacuum distillation of the solvent; step two: 10 to 25 percent of intermediate, 40 to 70 percent of low-molecular weight epoxy resin, 5 to 25 percent of bisphenol A and 0.02 to 0.1 percent of catalyst are heated up to 120 to 180 DEG C, and then a constant temperature is kept for 1 to 3 hours before non-ionic self-emulsifying solid epoxy resin with medium molecular weight and high molecular weight is obtained; and finally, at the temperature of 20 to 90 DEG C, distilled water is dripped in to dilute the solution to a degree with solid content ranging between 30 and 80 percent of through violent stirring, thereby obtaining non-ionic self-emulsifying solid epoxy resin emulsion. The preparation method has convenient operation, stable manufacturing technique, energy conservation and moderate preparation process. Moreover, the water-based epoxy emulsion is exquisite and has uniform particle diameter and high product quality.

Owner:中山大桥化工集团有限公司

Polyethylene having faster crystallization rate and improved environmental stress cracking resistance

InactiveUS9187627B2Fast crystallizationIncrease weightEthylene HomopolymersEnvironmental stress cracking

Disclosed is a polyethylene composition having faster crystallization rate and improved environmental stress cracking resistance. The polyethylene composition comprises a multimodal polyethylene and a nucleating agent. The multimodal polyethylene comprises from 25 to 50 wt % of a low molecular weight ethylene homopolymer component, from 25 to 50 wt % of a medium molecular weight ethylene copolymer component and from 25 to 50 wt % of a high molecular weight ethylene copolymer component. The polyethylene composition has an environmental stress cracking resistance (ASTM D1693, Condition B in 100% Igepal) greater than or equal to 40 days and a crystallization half time less than or equal to 70% of the crystallization half time of the multimodal polyethylene without nucleating agent.

Owner:EQUSR CHEM LP

Implantable paste and its use

ActiveUS20120276164A1Simple and safe operationDesired propertyBiocideOrganic active ingredientsPolymer scienceBioactive glass

The present invention relates to an implantable paste comprising bioactive glass spheres having a size distribution of 50-425 μm, low molecular weight polyethylene glycol having a molecular weight range of 200-700 g / mol, medium molecular weight polyethylene glycol having a molecular weight range of 700-2500 g / mol and high molecular weight polyethylene glycol having a molecular weight range of 2500-8000 g / mol, with the proviso that the molecular weight of the low molecular weight polyethylene glycol and of the medium molecular weight polyethylene glycol differ from each other by at least 80 g / mol and that the molecular weight of the medium molecular weight polyethylene glycol and of the high molecular weight polyethylene glycol differ from each other by at least 300 g / mol.

Owner:BONALIVE BIOMATERIALS

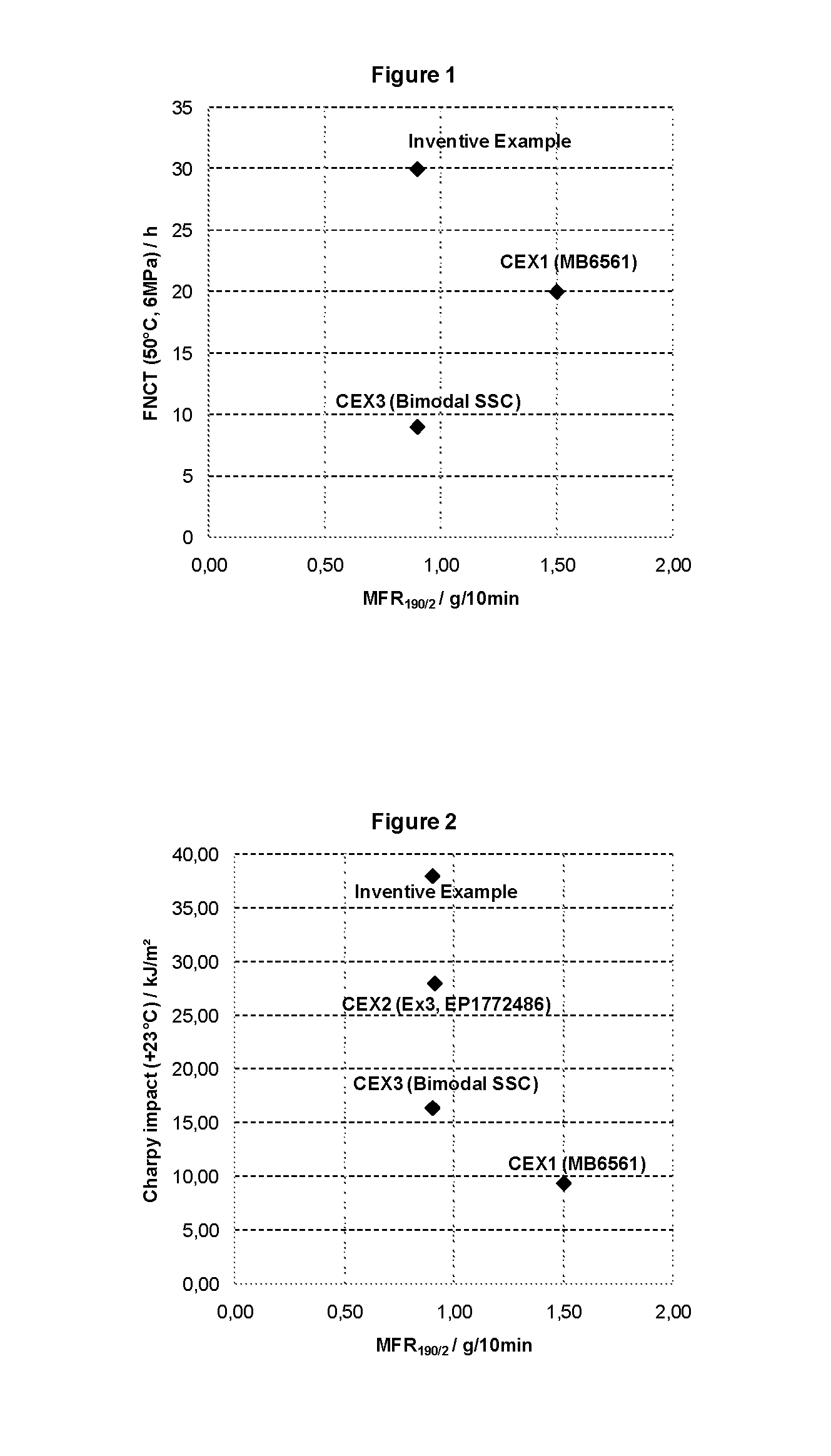

Polyethylene moulding composition with improved stress crack/stiffness relationship and impact resistance

ActiveUS8759448B2Improve performanceImprove mechanical propertiesPolymer scienceEthylene Homopolymers

A high density polyethylene moulding composition having a multimodal molecular weight distribution, having a density according to ISO 1183 at 23° C. in the range of 945 to 965 kg / m3 and an MFR190 / 2 according to ISO 1133 in the range of 0.05 to 25 g / 10 min, said polyethylene moulding composition comprising at least three ethylene polymer fractions having distinct molecular weights: A) 15 to 50 wt % of a low molecular weight ethylene homopolymer fraction with a weight average molecular weight Mw in the range of 15 to 40 kg / mol; B) 15 to 50 wt % of a medium molecular weight ethylene homopolymer fraction with a weight average molecular weight Mw in the range of 70 to 180 kg / mol; and C) 15 to 50 wt % of a high molecular weight ethyleve copolymer fraction with a weight average molecular weight Mw in the range of 200 to 400 kg / mol; and wherein the composition has: a tensile modulus according to ISO 527-2: 1993 measured on compression moulded samples of at least 800 MPa; a Charpy impact strength CIS (23° C.) according to ISO 179:2000 measured on V- notched samples produced by compression moulding of at least 30 kJ / m2; and an environmental stress crack resistance ESCR measured as FNCT full notch creep test according to ISO / DIS 16770.3 at 50° C. and 6 MPa of at least 20 h.

Owner:BOREALIS AG

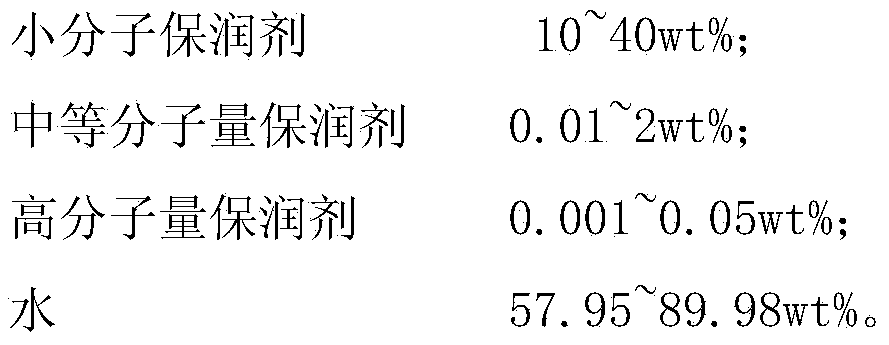

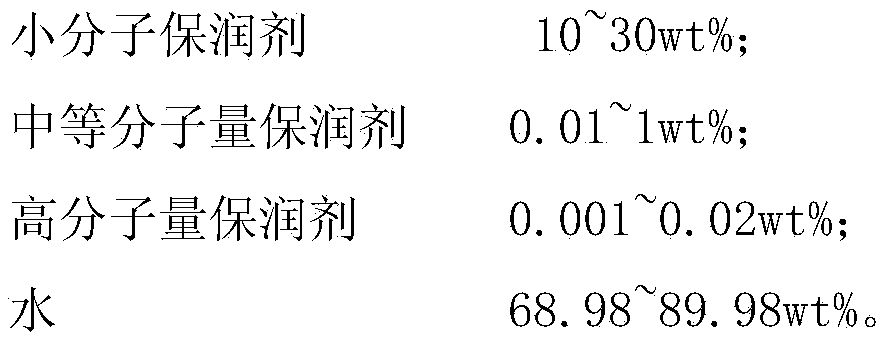

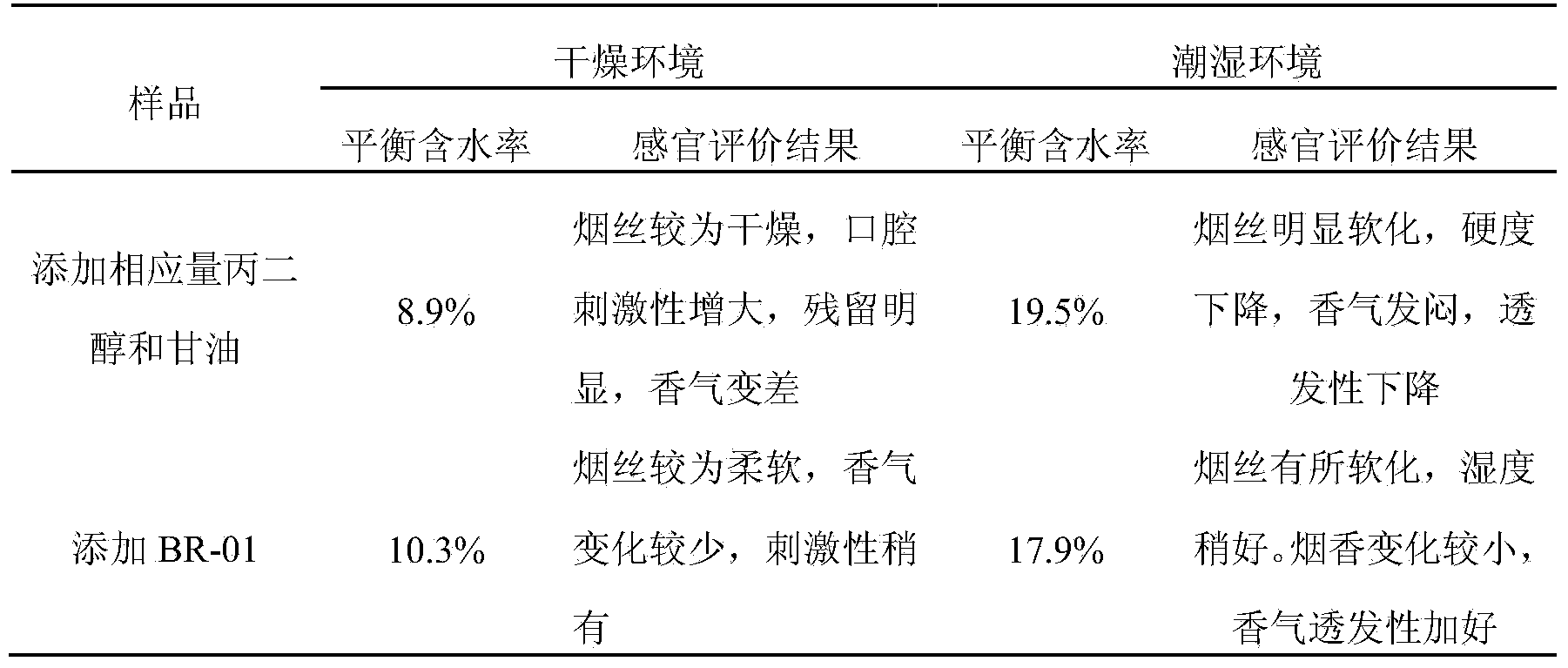

Tobacco humectant achieving gradient distribution of molecular weights

The invention discloses a tobacco humectant achieving gradient distribution of molecular weights. Raw materials of the tobacco humectant are distributed in a gradient mode according to the magnitudes of the molecular weights, and the tobacco humectant is composed of, by weight, 10%-40% of micromolecule humectants, 0.01%-2% of medium-molecular-weight humectants, 0.001%-0.05% of high-molecular-weight humectants and 57.95%-89.98% of water. According to the sequence from high molecular weights to low molecular weights, the raw materials of the tobacco humectant are sequentially dissolved in the water so as to form a homogeneous phase solution, and the tobacco humectant is obtained. The tobacco humectant is added to cigarette feeding liquid or expanded cut tobacco feeding liquid or cut stem feeding liquid or papermaking-method slice coating liquid according to the ratio of 1%-50%, the tobacco humectant is applied to cigarettes in a fed mode, and functions of the tobacco humectant are given into play.

Owner:CHINA TOBACCO ANHUI IND CO LTD +1

Preparation method of high-heat-resistance and high-wear-resistance polyesterimide enameled wire insulating paint

The invention relates to a preparation method of a high-heat-resistance and high-wear-resistance polyesterimide enameled wire insulating paint, which takes 100 parts of reacted polyesterimide enameled wire insulating paint by weight with medium molecular weight as a basal body. At least the following components in parts by weight are added: 1-20 parts of amino resin, 1-20 parts of thermoplastic phenolic resin and 0.5-5 parts of siloxane. Enameled wires which are made by using the paint has the advantages that the paint film adhesiveness is excellent, the stripping and twisting K value of the enameled wires can reach more than 155 and the K value is higher than the K value (which is 110) of the existing conventional products by more than two grades; the scratch resistance is excellent and the unidirectional scratch resistance can reach more than 2000g when the wire is combined with the polyesterimide paint; the heat resistance can reach 200 while the heat resistance of the conventional polyesterimide enameled wires is 180; and the process redundancy is wide and the realization of stable process production is facilitated.

Owner:艾仕得绝缘材料(安徽)有限公司

Pressure-sensitive type self-adhesive waterproof adhesive

ActiveCN105925214AMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesElastomerPetroleum resin

The invention discloses a self-adhesive waterproof adhesive. The self-adhesive waterproof adhesive is characterized by being prepared from, by weight, 30-40 parts of butyl rubber with the high molecular weight, 10-20 parts of polyisobutene with the medium molecular weight, 20-30 parts of polyisobutene with the low molecular weight, 10-20 parts of petroleum resin, 1-10 parts of ethylene vinyl acetate (EVA) elastomers, 20-30 parts of naphthenic oil, 0.5-1 part of an antioxidant and 0.5-1 part of an ultraviolet absorbent.

Owner:南京臻致新材料科技有限公司 +2

Sodium hyaluronate mixture and application thereof

InactiveCN107582424ASmall molecular weightTo achieve the purpose of moisturizingCosmetic preparationsToilet preparationsAging resistanceSodium hyaluronate

The invention relates to a sodium hyaluronate mixture which comprises high molecular weight sodium hyaluronate, medium molecular weight sodium hyaluronate and low molecular weight sodium hyaluronate in a ratio of 1:(1-1.2):(2-2.2), wherein the molecular weight of the high molecular weight sodium hyaluronate is 1800000-2200000 Dalton; the molecular weight of the medium molecular weight sodium hyaluronate is 1300000-1500000 Dalton; the molecular weight of the low molecular weight sodium hyaluronate is 4000-6000 Dalton. The invention further discloses application of the sodium hyaluronate mixturein cosmetics. The sodium hyaluronate mixture has the advantages that by compounding sodium hyaluronate of different molecular weights, a relatively good moistening effect is achieved, and meanwhile functions of aging resistance, skin repairing and the like are achieved.

Owner:广州青葱贸易有限公司

High-density high-temperature heat-shrinkable pressure-sensitive tape and preparation method thereof

ActiveCN103087385AImprove installation efficiencySimplify the installation processFilm/foil adhesivesHigh densityAntioxidant

The invention provides a high-density high-temperature heat-shrinkable pressure-sensitive tape and a preparation method thereof. The high-density high-temperature heat-shrinkable pressure-sensitive tape comprises the following components in percentage by weight: 6-12% of butyl rubber, 8-15% of high-molecular-weight polyisobutylene, 14-19% of medium-molecular-weight polyisobutylene, 8-12% of low-molecular-weight polyisobutylene, 9-15% of tackifying resin, 30-45% of inorganic reinforcing powder, 0.5-1% of antioxidant, 0.5-1% of anti-aging agent and 0.5-1% of black color master batch. The heat-shrinkable pressure-sensitive adhesive tape provided by the invention is a novel material for pipeline joint coating, and is a high-performance butyl rubber modified pressure-sensitive adhesive. When being applied to onto a radiation crosslinking polyethylene substrate to form a heat-shrinkable pressure-sensitive joint coating material, the problems of in-service pipeline joint coating overhaul and new pipeline joint coating corrosion resistance can be simultaneously solved.

Owner:CYG CHANGTONG NEW MATERIAL

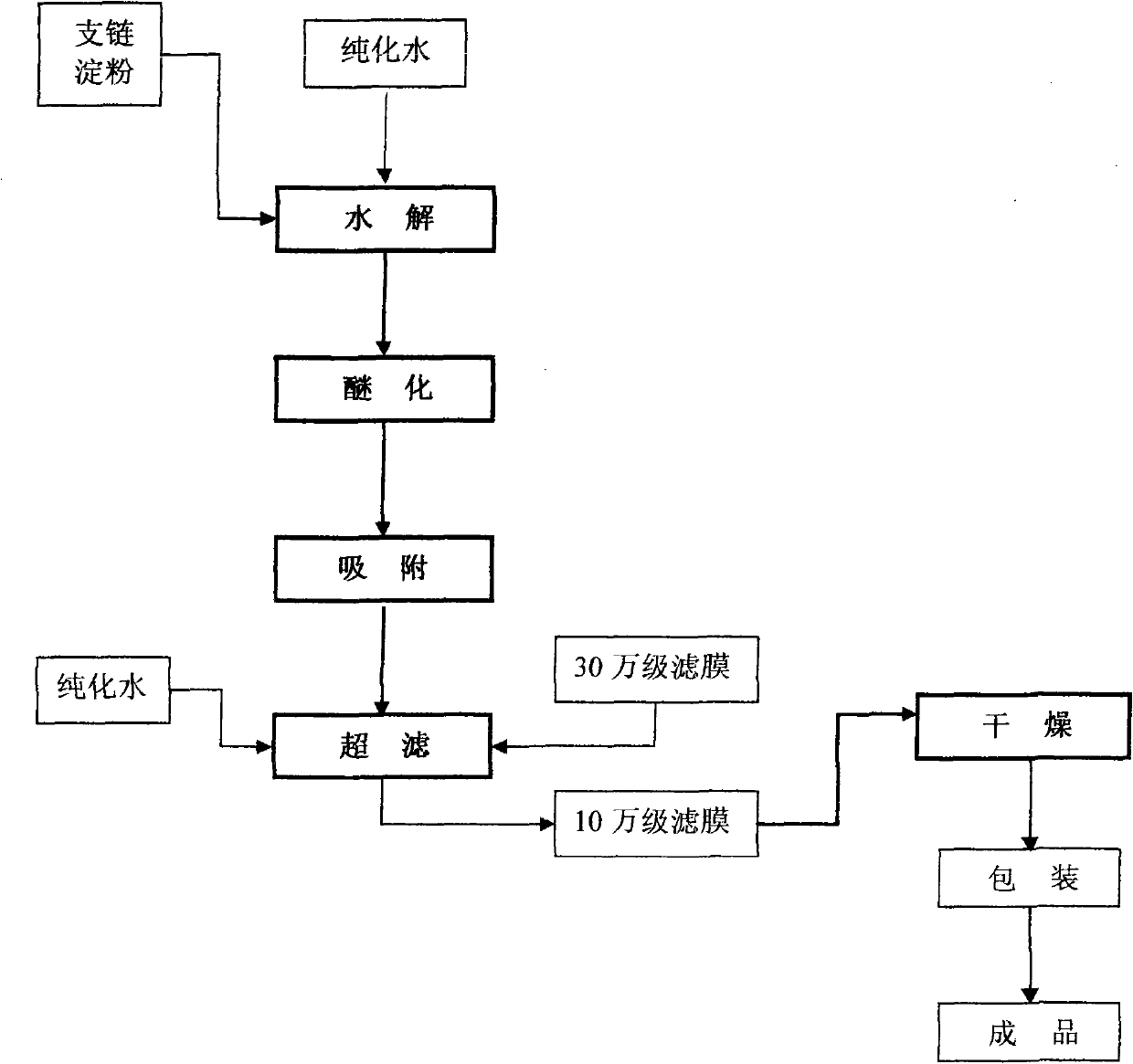

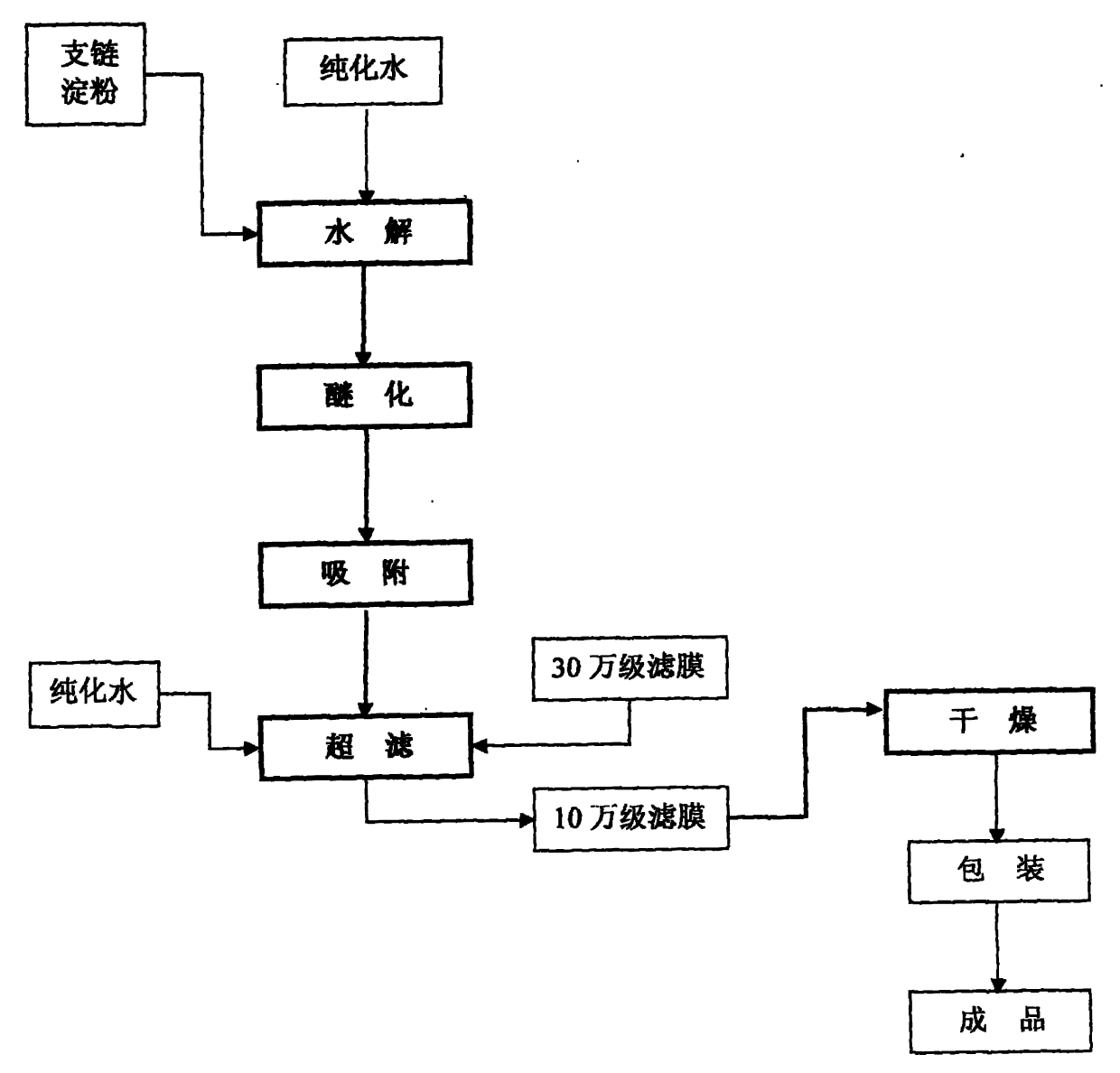

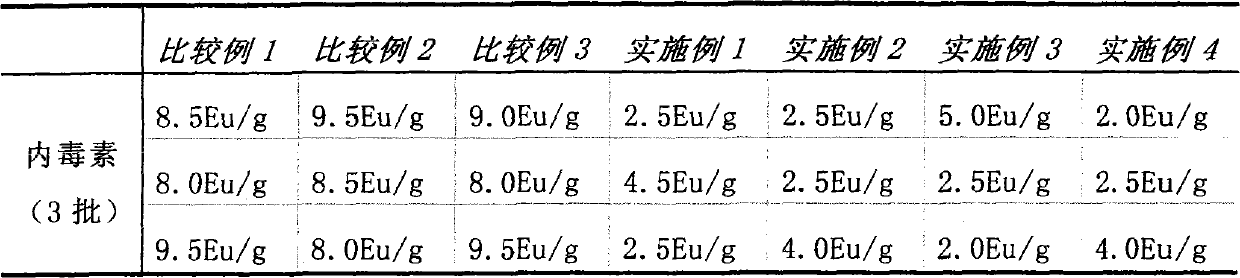

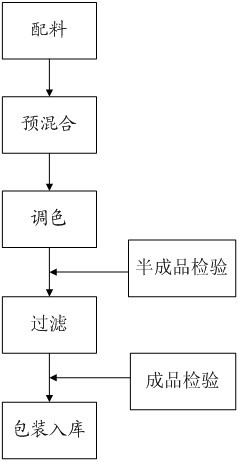

Preparation method for improving quality of medium molecular weight hydroxyethyl starch

The invention provides a new process for preparing medium molecular weight hydroxyethyl starch materials. In the ultrafiltration step of the production process flow, a filter membrane with the molecular mass cut-off of 300,000 and a filter membrane with the molecular mass cut-off of 100,000 are used in turn for ultrafiltration, and an ultrafiltration process of only using a filter membrane with the molecular mass cut-off of 100,000 is replaced, so that the content of endotoxin in the hydroxyethyl starch is effectively reduced, the molecular weight of the hydroxyethyl starch is more concentrated in a medium molecular weight range, the safety and quality of the product are improved, and the produced medium molecular weight hydroxyethyl starch (including hydroxyethyl starch 130 / 0.4 and hydroxyethyl starch 200 / 0.5) materials and preparations meet the standard of state pharmacopoeia.

Owner:CHONGQING DAXIN PHARMA +1

Epoxy polyurethane anticorrosive coating capable of resisting light aging and preparation method

InactiveCN101597455AImproves photoaging performanceEffectively adjust viscosityAnti-corrosive paintsEpoxy resin coatingsEpoxyPhosphate

The invention discloses an epoxy polyurethane anticorrosive coating capable of resisting light aging and a preparation method; A component is prepared by mixing, stirring and grinding epoxy resin with medium molecular weight, hydroxyl-containing polyester resin, dimethylbenzene, butyl acetate, titanium pigment, ultraviolet absorber, talcum powder, mica powder, organosiloxane, isopropyl tri (dioctylpyrophosphato) titanate, poly-organic phosphate and the like; B component is prepared by mixing and stirring diphenylmethane diisocyanate and biuret. A component and B component are uniformly mixed according to weight ratio of 4:1 to be used. The epoxy polyurethane anticorrosive coating is capable of resisting light aging and has excellent corrosion resistance against acid, alkali and salt and salt fog resistance. The invention is external anticorrosive preferential coating for steel structures under severe environment such as chemical factories, refineries and the like.

Owner:CNPC RES INST OF ENG TECH

Epoxy anti-corrosive finish paint and preparation method thereof

InactiveCN102604513AStrong adhesionGood flexibilityAnti-corrosive paintsEpoxy resin coatingsEpoxyPliability

The invention discloses epoxy anti-corrosive finish paint, which is a double-component epoxy finish paint consisting of component A and component B; the component A consists of the following ingredients: 35 to 45 percent by weight of medium-molecular weight epoxy resin, 8 to 10 percent by weight of dimethylbenzene, 3 to 5 percent by weight of n-butyl alcohol, 1.0 to 1.4 percent by weight of anti-settling agent, 8.5 to 10.5 percent by weight of filler, 10 to 20 percent by weight of pigment, 0.5 to 1.5 percent by weight of dispersant, 0.2 to 0.4 percent by weight of defoaming agent and 0.5 to 1.5 percent of multifunctional auxiliary; the component B consists of the following ingredient: 8 to 12 percent by weight of epoxy curing agent; and the weight ratio of the component A to the component B is (2 to 6):1. By the manner, the invention provides the epoxy anti-corrosive finish paint and a preparation method thereof, the method is simple, the production cost is low, thick film type epoxy finish paint can be produced, and the paint film has excellent physical properties, such as adhesive force, flexibility, wear resistance and impact resistance, and also has excellent corrosion resistance and weather fastness.

Owner:CHANGSHU FANGTA COATING CHEM

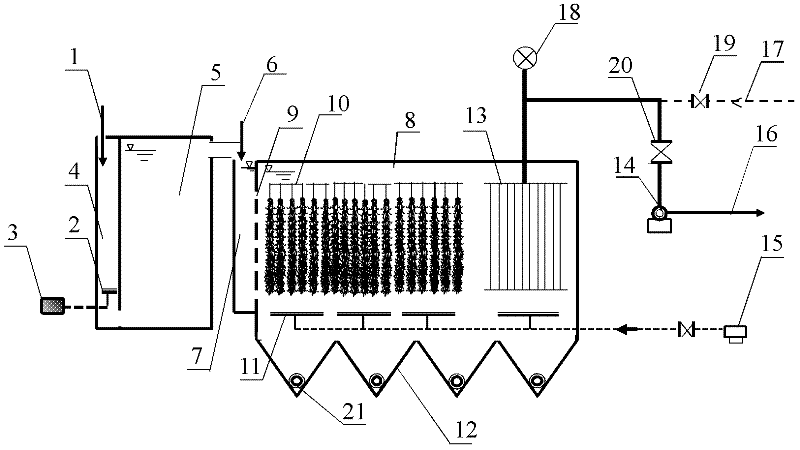

Reactor for deep purification of drinking water and deep purification method of drinking water

ActiveCN102351371AEnsure safetyGood removal effectMultistage water/sewage treatmentPurification methodsUltrafiltration

The invention relates to a reactor for deep purification of drinking water and a deep purification method of drinking water. The reactor comprises a main ozone oxidation unit, a biological oxidation unit and an ultrafilter membrane filtration unit, wherein the biological oxidation unit is positioned between the main ozone oxidation unit and the ultrafilter membrane filtration unit; and the biological oxidation unit and the ultrafilter membrane filtration unit are disposed in a same reaction tank. Ozone oxidizes and destroys hardly degraded pollutants and converts high molecular weight organicmatters into intermediate and low molecular weight organic matters. After ozonization, an effluent respectively enters into the reaction tank fixed with a biological filling material and an ultrafilter membrane assembly. When the pollution of the water source is severe, powdered active carbon can be also added. The active carbon is used to absorb intermediate molecular weight or volatile organic compounds; microorganisms on the surface of the biological filling material and on the surface of the powdered active carbon are used to remove ammonia nitrogen and low molecular weight organic matters; and the security of the microorganisms is guaranteed by ultrafiltration. The reactor provided by the invention can be used for deep purification of polluted water sources, and also can be applied for deep processing of urban sewage treatment plants and reclaimed water.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Microporous membrane of polyethylene-based composite material and preparation method thereof

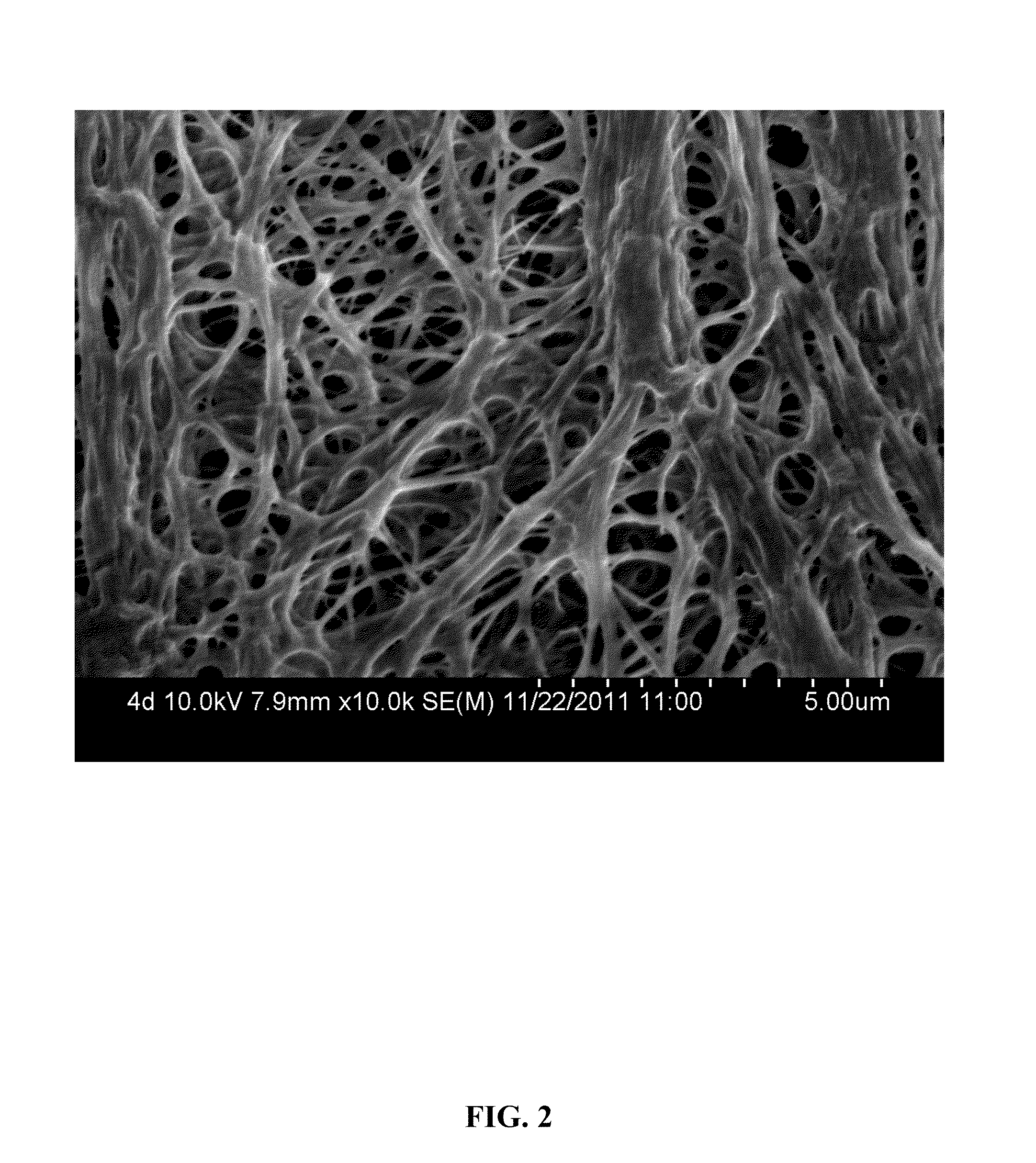

ActiveUS20140335421A1Improve cycle lifeImprove uniformityMembranesSemi-permeable membranesHigh densityPolymer science

A microporous membrane of a polyethylene-based composite material, including high density and high crystallinity of polyethylene as a base material. The polyethylene is modified by a modifying agent accounting for 10-25 wt. % of the membrane and including a moderate molecular weight of rubber selected from polyisobutylene (PIB), ethylene-propylene methylene copolymer (EPM), or a mixture thereof, the rubber having a dynamic viscosity of between 50 and 2000 Pa·S at 100° C. and a weight average molecular weight of between 90,000 and 250,000. The modified polyethylene is dissolved in a solvent and a pore-forming agent for pore formation.

Owner:TIANJIN DG MEMBRANE

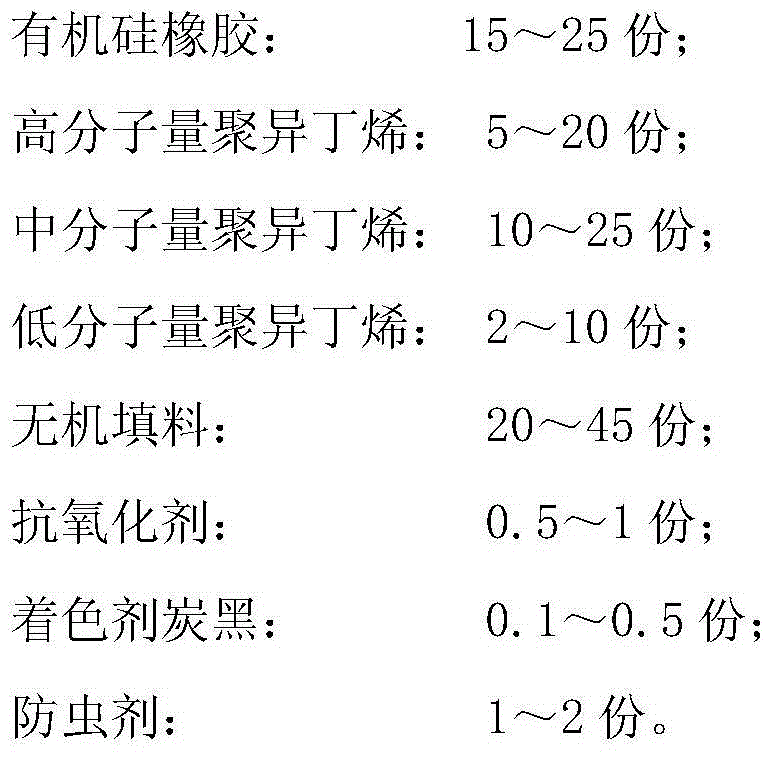

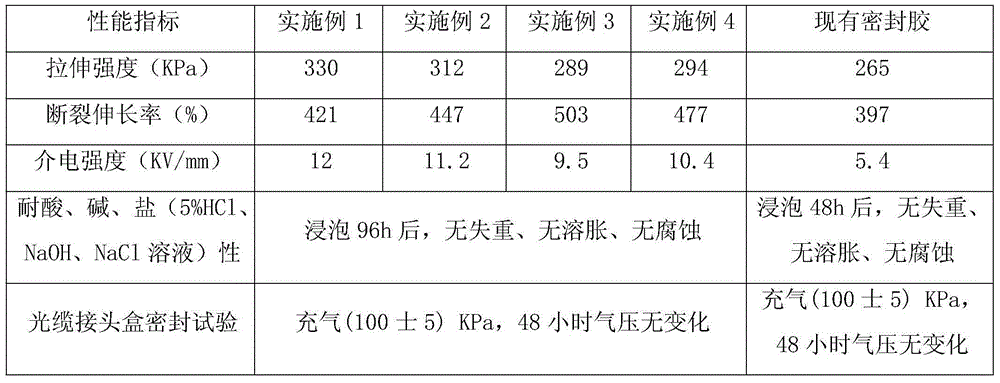

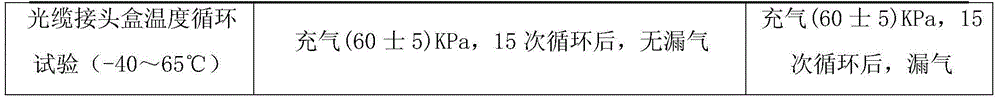

Sealing adhesive for cable joint box and preparation method thereof

ActiveCN104559912AImprove thermal stabilityStrong chemical resistanceNon-macromolecular adhesive additivesAdhesiveBound property

The invention discloses a sealing adhesive for a cable joint box and a preparation method thereof, and belongs to the technical field of preparation of the sealing adhesive. The sealing adhesive comprises organic silicone rubber, high-molecular weight polyisobutene, medium-molecular weight polyisobutene, low-molecular weight polyisobutylene, inorganic filler, an antioxidant, carbon black as a coloring agent and a mothproofing agent. The preparation method comprises the following steps of: S1. weighing: weighing raw materials; S2. kneading: adding the raw materials for kneading; S3. blending: blending the kneaded sizing materials; S4. extruding: extruding the blended sizing materials, and then cooling and cutting to prepare the sealing adhesive for the cable joint box. The sealing adhesive disclosed by the invention has the advantages of excellent binding property, filling property, sealing property, water resistance, high-low temperature resistance, acid resistance, alkali resistance, salt resistance and dielectric property. The preparation method disclosed by the invention has the characteristics of health, environmental friendliness, simple production process, no solvent, time and energy conservation, low cost and suitability for industrial large-scale production.

Owner:SICHUAN TIANYI COMHEART TELECOM

Gradient hyaluronic acid dressing and preparation method thereof

InactiveCN108578747APromote healingPrevent and reduce scar formationAbsorbent padsBandagesMedicineSkin Injury

The invention discloses a gradient hyaluronic acid dressing and a preparation method thereof. The gradient hyaluronic acid dressing contains a packing material, a base material and a dressing medicament, wherein the dressing medicament is prepared from the following raw materials: high-molecular-weight hyaluronic acid, medium-molecular-weight hyaluronic acid, low-molecular-weight hyaluronic acid,oligomeric hyaluronic acid, EGF, KGF, FGF, glycerin, hydroxyethyl cellulose, collagen, alginate, chitosan, phenoxyethanol, plant extract and water. The invention also discloses a preparation method ofthe gradient hyaluronic acid dressing. The scar-preventing repair dressing made by adopting the gradient hyaluronic acid has the remarkable effects of promoting healing and preventing and reducing scar formation on skin injuries and can be used for treatment and nursing of various body surface injuries and problematic skin.

Owner:广州芬森医学科技有限公司

Inorganic whisper reinforced polyolefin composite material in-situ filled polymerization preparing method

The invention relates to a kind of insitu filling polymerization-manufacturing method of inorganic whisker intensification polyolefin composite material. Load olefinic polymerization catalyst in the surface of inorganic whisker with preliminary stirring-dispersing treatment, and then take alkene monomer polymerization in its surface in order to get polyolefin / whisker composite material. The composite material is composed with 3-80% inorganic mineral whisker and 20-97% polyolefin polymer. The manufacturing method in the invention is convenient. The composite material manufactured by the method has high filling extent of whisker, retentive slenderness ratio of whisker, and also the whisker has well distribution in matrix polymer and fine adhesion with matrix interface, so that it can give full play to intensification characteristic of whisker, in order to get polyolefin / inorganic whisker composite material with the advantages such as easiness to formation and processing, fine cleanliness of product, and excellent mechanical property. Plastics matrix can be manufactured into polyolefin from low molecular weight, middle molecular weight, and high molecular weight to superhigh molecular weight, such as polypropylene or polythene. The material acquired can be used not only as structural material by direct injection formation, but also as masterbatch after having crossblend with commercial polyolefine.

Owner:INST OF CHEM CHINESE ACAD OF SCI

High-temperature type viscoelastic body corrosion-preventing sealing adhesive tape and preparation method thereof

InactiveCN102382593AUnique cold flowPrevent intrusionNon-macromolecular adhesive additivesOther chemical processesPolymer sciencePolyethylene terephthalate glycol

The invention discloses a high-temperature type viscoelastic body corrosion-preventing sealing adhesive tape and a preparation method thereof. The high-temperature type viscoelastic body corrosion-preventing sealing adhesive tape is in a layer-shaped structure and is sequentially composed of a polyethylene film, a first viscoelastic body sizing layer, a polyethylene net layer, a second viscoelastic body sizing layer and a polyethylene terephthalate (PET) adhesion-preventing film. The first viscoelastic body sizing layer and the second viscoelastic body sizing layer are both composed of the following materials including, by weight, 2 to 5 parts of low molecular weight polyisobutene, 35 to 45 parts of medium molecular weight polyisobutene, 5 to 10 parts of high molecular weight polyisobutene, 40 to 50 parts of inorganic filler, 0.2 to 0.5 part of antioxidant and 0.0001 to 0.0005 part of pigment. The high-temperature type viscoelastic body corrosion-preventing sealing adhesive tape can be used for corrosion-preventing protection of oil and gas pipelines and abnormal devices, has unique cold flow property, can achieve a self-repairing function in the corrosion-preventing process, can thoroughly prevent moisture from invading simultaneously, thoroughly avoids microorganism corrosion, and has good long-acting protection.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com