Pressure-sensitive type self-adhesive waterproof adhesive

A self-adhesive waterproof, butyl rubber technology, applied in the direction of adhesives, adhesive types, oil/grease/wax adhesives, etc., can solve the problems of excellent self-adhesive waterproof adhesives, no performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The embodiment of the present invention also provides a preparation method of self-adhesive waterproof glue. The method comprises the steps of:

[0044] (1) Cut the high molecular weight butyl rubber into small pieces and put them into a mixer for stirring; for example, the size of the small pieces can be a 1-2cm square; the mixer can be, for example, a double planetary mixer.

[0045] (2) Put naphthenic oil and antioxidant into the mixer, evacuate to 0.05-0.09MPa, keep the pressure, heat up to 120-130°C, start stirring, and stir at low speed for 60 minutes; the mixer can be, for example, a double planetary Stirrer; the evacuation to 0.05-0.09MPa can prevent the oxygen in the air from being mixed into the oxide material in the material system to cause performance degradation; the speed of the low-speed stirring is, for example, 30-50 rpm.

[0046] (3) Put medium-molecular-weight polyisobutylene, low-molecular-weight polyisobutylene, petroleum resin, EVA elastomer, and ...

Embodiment 1

[0048] Embodiment 1, the preparation method of self-adhesive waterproof glue comprises the following steps:

[0049] (1) Cut high-molecular-weight butyl rubber into thumb-cap-sized fritters and put them into a double planetary mixer;

[0050] (2) Put the naphthenic oil and antioxidant into the double planetary mixer, evacuate to 0.05-0.09MPa, keep the pressure, raise the temperature to 120-130°C, start stirring, and stir at a low speed for 60 minutes;

[0051] (3) Put medium-molecular-weight polyisobutylene, low-molecular-weight polyisobutylene, petroleum resin, EVA elastomer, and ultraviolet absorber into the double planetary mixer, vacuumize to 0.05-0.09MPa, keep the pressure, and keep the temperature of the material at 120-130°C , start stirring, stir at a low speed for 60 minutes, turn on the high-speed disperser, set the speed to 100 rpm, keep it for 20 minutes, adjust the speed to 300 rpm, keep it for 20 minutes, adjust the speed to 600 rpm, keep it for 20 minutes, adjus...

Embodiment 2

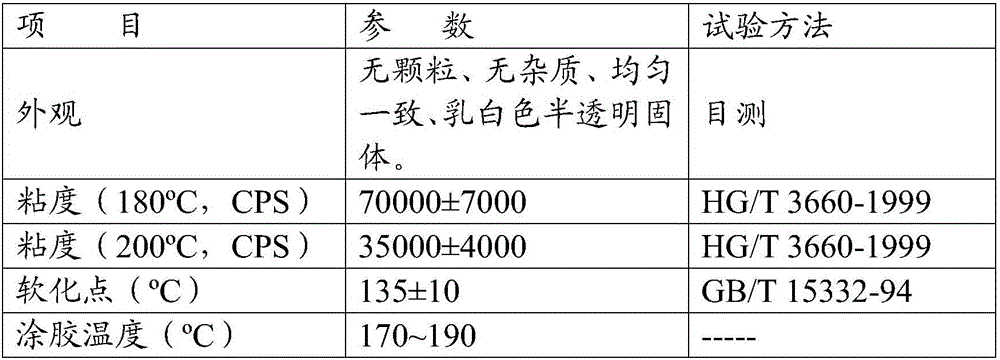

[0053] Example 2, the physical performance test results of the self-adhesive waterproof adhesive prepared by the method of the above-mentioned Example 1 are shown in the following table.

[0054] Table 1, the physical property test result of the self-adhesive waterproof glue prepared by the embodiment of the present invention 1

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com