High-temperature type viscoelastic body corrosion-preventing sealing adhesive tape and preparation method thereof

A technology of sealing tape and viscoelastic body, applied in chemical instruments and methods, non-polymer adhesive additives, adhesives, etc., can solve the problems of insufficient resistance to mechanical external forces, etc., and achieve long-term protection and high shear strength , Unique cold flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

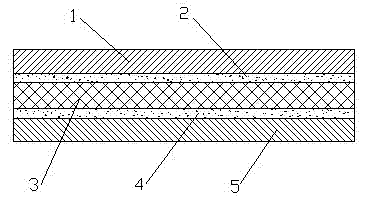

Image

Examples

Embodiment 1

[0036] Raw material ratio of viscoelastic rubber layer:

[0037] 5 kg of low molecular weight polyisobutene; 40 kg of medium molecular weight polyisobutene; 10 kg of high molecular weight polyisobutene; 44.7 kg of talcum powder; 0.2998 kg of 1010 antioxidant; 0.0002 kg of titanium cyanine blue.

[0038] The number average molecular weight of the low molecular weight polyisobutene is 2500; the viscosity average molecular weight of the medium molecular weight polyisobutene is 90000; the viscosity average molecular weight of the high molecular weight polyisobutene is 200000.

[0039] The preparation method of high temperature type viscoelastic anticorrosion sealing tape is as follows:

[0040] Step 1: Add low-molecular-weight polyisobutene, medium-molecular-weight polyisobutene, high-molecular-weight polyisobutene and antioxidant into a kneader for 30-60 minutes; the temperature of the kneader is controlled at 120-160°C.

[0041] Step 2, adding inorganic filler to the kneader to...

Embodiment 2

[0046] Raw material ratio of viscoelastic rubber layer:

[0047] 3 kg of low molecular weight polyisobutene; 41 kg of medium molecular weight polyisobutene; 7 kg of high molecular weight polyisobutene; 48.7 kg of precipitated barium sulfate; 0.5 kg of 1010 antioxidant; 0.0004 kg of titanium cyanine blue.

[0048] The number average molecular weight of the low molecular weight polyisobutene is 3000; the viscosity average molecular weight of the medium molecular weight polyisobutene is 30000; the viscosity average molecular weight of the high molecular weight polyisobutene is 400000.

[0049] The method of Example 1 was used to prepare the high-temperature type viscoelastic anti-corrosion sealing tape of the present invention.

Embodiment 3

[0051] Raw material ratio of viscoelastic rubber layer:

[0052] 4 kg of low molecular weight polyisobutene; 42 kg of medium molecular weight polyisobutene; 8 kg of high molecular weight polyisobutene; 23 kg of precipitated barium sulfate; 22.7 kg of talcum powder; 0.2997 kg of 1010 antioxidant; 0.0003 kg of titanium cyanine blue.

[0053]The number average molecular weight of the low molecular weight polyisobutene is 2800; the viscosity average molecular weight of the medium molecular weight polyisobutene is 50000; the viscosity average molecular weight of the high molecular weight polyisobutene is 300000.

[0054] The method of Example 1 was used to prepare the high-temperature type viscoelastic anti-corrosion sealing tape of the present invention.

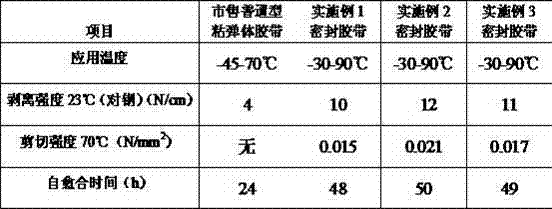

[0055] The difference in performance between the high temperature type viscoelastic anti-corrosion sealing tape prepared by the present invention and the common type viscoelastic adhesive tape is as follows in Table 1:

[0056]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com