Gradient hyaluronic acid dressing and preparation method thereof

A technology of hyaluronic acid and oligomeric hyaluronic acid, which is applied in medical science, absorbent pads, bandages, etc., can solve problems that do not involve the prevention and reduction of scars, affect the appearance, and severe itching, and achieve prevention and scar formation, Reduces scar formation and promotes healing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] The preparation method of this gradient hyaluronic acid dressing comprises the following steps:

[0070] 1) Pack the base material into the packaging material, sterilize, and set aside;

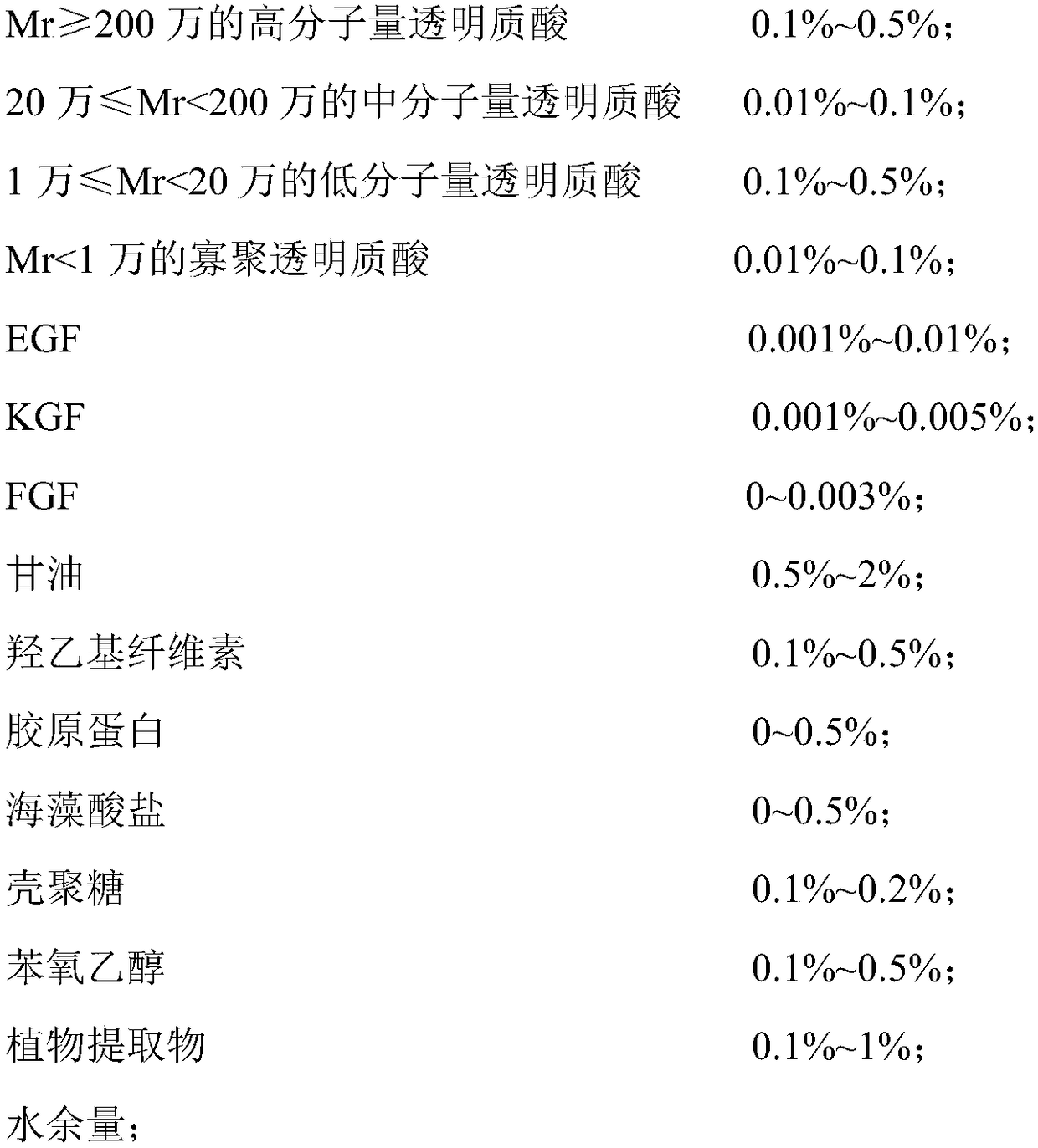

[0071] 2) Mix high-molecular-weight hyaluronic acid, medium-molecular-weight hyaluronic acid, low-molecular-weight hyaluronic acid, oligomeric hyaluronic acid and water, stir and dissolve to obtain liquid A;

[0072] 3) Mix EGF, KGF, FGF, glycerin and water, and stir evenly to obtain liquid B;

[0073] 4) Mix hydroxyethyl cellulose, collagen, alginate, chitosan, phenoxyethanol, plant extracts and water, and stir evenly to obtain liquid C;

[0074] 5) mixing liquid A, liquid B and liquid C to obtain a dressing agent;

[0075] 6) Fill the dressing agent into the packaging material obtained in step 1) and fully infiltrate it to obtain a gradient hyaluronic acid dressing.

[0076] Preferably, in step 2) of the preparation method, the total content of hyaluronic acid in liquid A is 0.1 w...

Embodiment 1

[0081] The preparation method of embodiment 1 gradient hyaluronic acid dressing, comprises the following steps:

[0082] 1) Fold the non-woven fabric into an aluminum foil bag, sterilize it, and set it aside;

[0083] 2) Take 50 grams of hyaluronic acid (including: 25 grams of high molecular weight hyaluronic acid, 5 grams of medium molecular weight hyaluronic acid, 15 grams of low molecular weight hyaluronic acid, and 5 grams of oligomeric hyaluronic acid), add 1000 mL of ultrapure water , heated and stirred to dissolve to obtain liquid A;

[0084] 3) Mix 0.5gEGF, 0.25gKGF, 0.25gFGF, 100g glycerin and 1000mL ultrapure water, and stir evenly to obtain liquid B;

[0085] 4) 20g hydroxyethyl cellulose, 10g sodium alginate, 15g chitosan, 20g phenoxyethanol, 5g witch hazel extract, 20g scutellaria root extract, 10g raspberry extract, 5g Burnet extract, Mix 10g of onion extract with 8000mL of ultrapure water, and stir evenly to obtain liquid C;

[0086] 5) mixing liquid A, liqui...

Embodiment 2

[0089] The preparation method of embodiment 2 gradient hyaluronic acid dressing, comprises the following steps:

[0090] 1) Fold the non-woven fabric into an aluminum foil bag, sterilize it, and set it aside;

[0091] 2) Take 50 grams of hyaluronic acid (including: 25 grams of high molecular weight hyaluronic acid, 5 grams of medium molecular weight hyaluronic acid, 15 grams of low molecular weight hyaluronic acid, and 5 grams of oligomeric hyaluronic acid), add 1000 mL of ultrapure water , heated and stirred to dissolve to obtain liquid A;

[0092] 3) Mix 0.5gEGF, 0.25gKGF, 100g glycerin and 1000mL ultrapure water, and stir evenly to obtain liquid B;

[0093] 4) 20g hydroxyethyl cellulose, 10g sodium alginate, 10g collagen, 15g chitosan, 20g phenoxyethanol, 5g witch hazel extract, 20g scutellaria baicalensis root extract, 10g raspberry extract, 5g ground Mix elm extract, 10g onion extract and 8000mL ultrapure water, and stir evenly to obtain liquid C;

[0094] 5) mixing li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com