Tobacco humectant achieving gradient distribution of molecular weights

A technology of gradient distribution and molecular weight, applied in the direction of tobacco, tobacco processing, application, etc., can solve the problems of difficult to form a film on the surface of cut tobacco, affecting the moisturizing effect of moisturizing agent, and difficult to infiltrate the moisturizing agent, so as to reduce the dryness of the mouth. , The effect of reducing irritation and reducing the rate of moisture change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

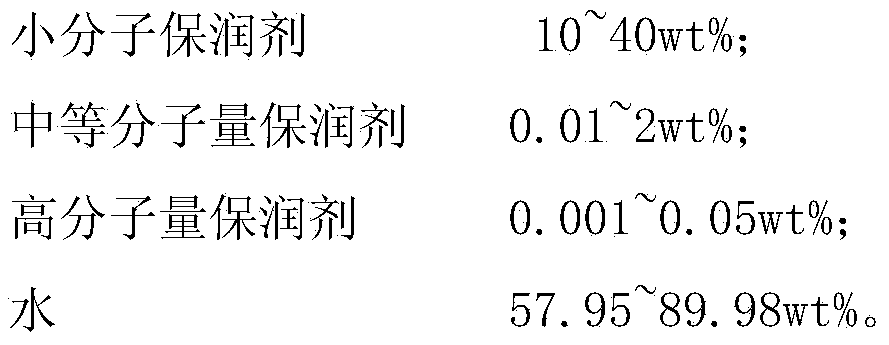

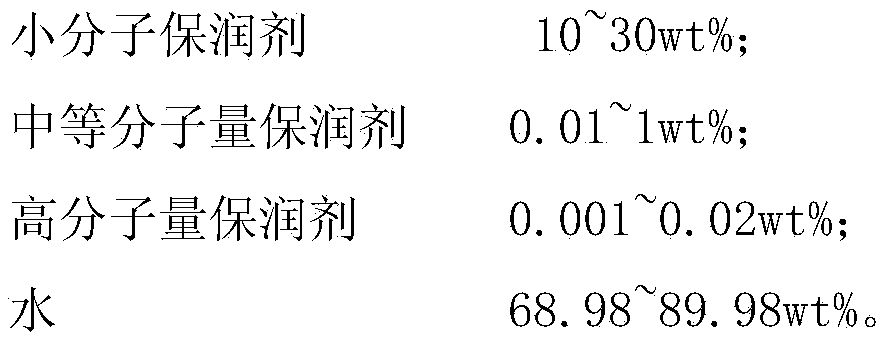

Method used

Image

Examples

Embodiment

[0018] Example: The tobacco humectant with molecular weight gradient distribution in this example, its formulation is calculated by weight percentage, and includes the following substances: 20 wt% of propylene glycol with a molecular weight ranging from 100 to 1000, 10% of glycerin, and 0.2 wt% of dextran with a molecular weight of 50000D , with a molecular weight in the range of 10 5 ~10 6 The guar gum is 0.01wt%, and the balance is water and accounts for 69.79wt%.

[0019] Dissolve guar gum and dextran in water in sequence, then add corresponding amount of propylene glycol and glycerin, stir and dissolve to obtain humectant BR-01.

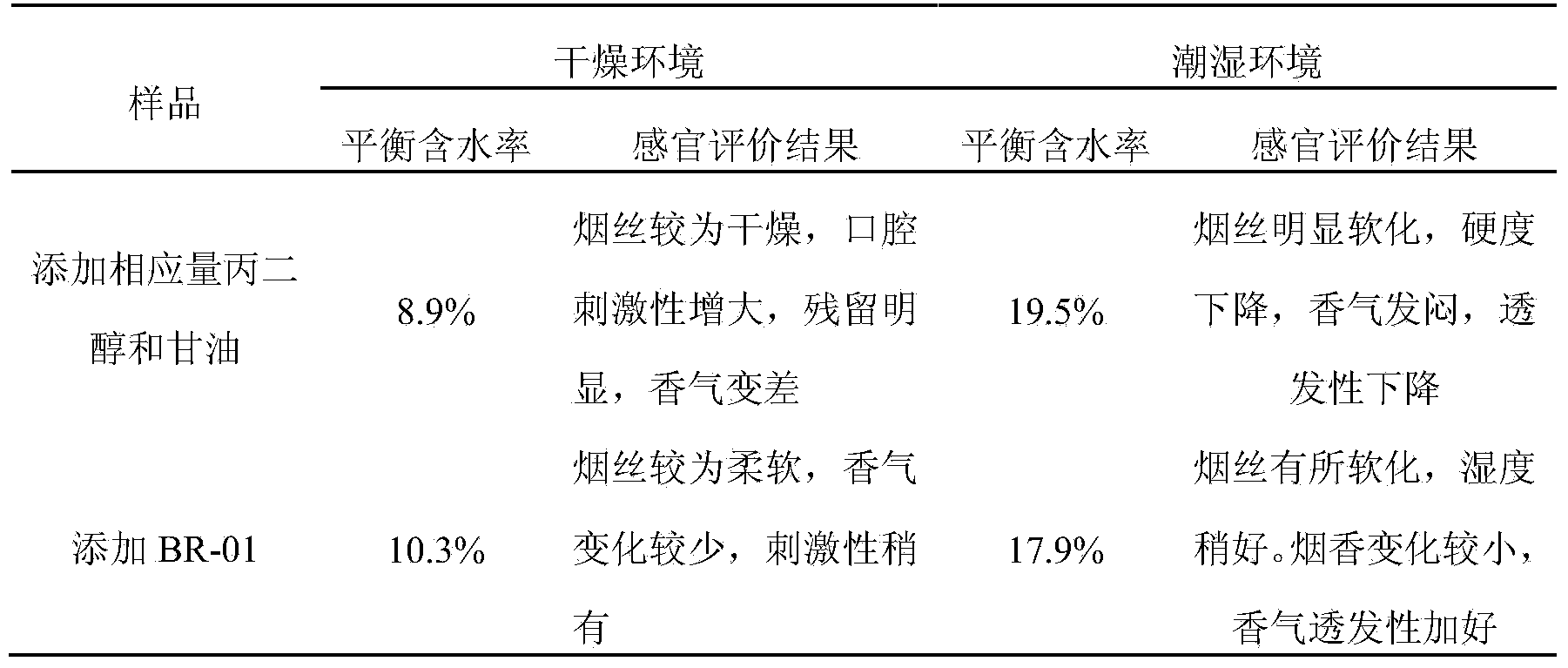

[0020] Add BR-01 to the cigarette material liquid at a ratio of 50%, and add it to the cigarette according to the method of addition to make a cigarette sample. The results are shown in Table 1 under different conditions compared with the cigarette products added with normal feed liquid and supplemented with corresponding amounts of propylene g...

Embodiment 2

[0025] The tobacco humectant with molecular weight gradient distribution in this embodiment, its formula is calculated by weight percentage, and includes the following substances: 20 wt% of propylene glycol with a molecular weight range of 100-1000, 10% of glycerin, 0.2 wt% of starch with a molecular weight range of 1000-100000, molecular weight in the range of 10 5 ~10 6 Potassium alginate is 0.005wt%, and the balance is water, accounting for 69.795wt%.

[0026] Dissolve potassium alginate and starch in water in turn, add propylene glycol and glycerin, stir and dissolve until homogeneous, and obtain humectant BR-02.

[0027] Add BR-02 to the cigarette material liquid at a ratio of 50%, and add it to the cigarette according to the method of addition to make a cigarette sample. The results are shown in Table 2 for comparison under different conditions with the cigarette products added with normal feed liquid and supplemented with corresponding amounts of propylene glycol and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com