Non-ionic self-emulsification solid epoxy resin and preparation method for emulsion thereof

A solid epoxy resin, non-ionic technology, used in epoxy resin coatings, coatings and other directions, can solve the problems of volatile organic compounds environmental pollution, harm to human health and other problems, achieve delicate appearance, energy saving, convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

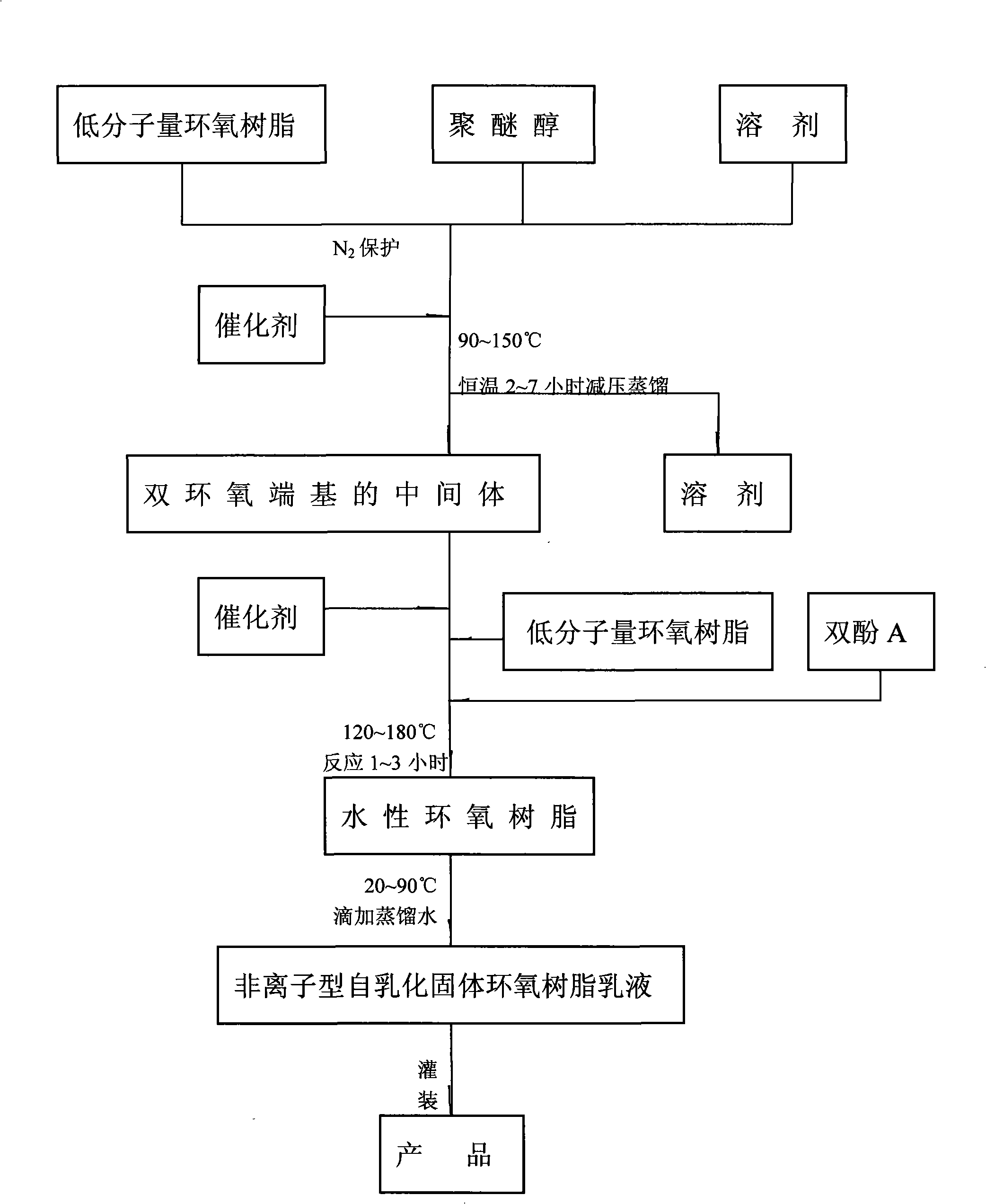

Method used

Image

Examples

Embodiment 1

[0096] in N 2 Under protection, weigh 15.0g epoxy resin E-51 (epoxy equivalent 190), add 100.0g PEG-8000 and MIBK20.0g, heat and stir, slowly raise the temperature to about 90°C, stir vigorously until clear, add catalyst A0.1 ~0.2g, slowly heat up to about 120°C, keep warm for 2~3h, stop N 2 , vacuum distilled until no fraction flows out. Add 150.0g of bisphenol A and 565.0g of E-51, stir evenly, then react at a constant temperature of about 160°C for 2-3 hours, cool down to about 80°C, and gradually add 830g of deionized water dropwise under high-speed stirring, and the dropwise addition is completed Afterwards, continue to stir for about 1 hour to discharge, and milky white water-based epoxy resin can be obtained, and its solid content is above 50%.

Embodiment 2

[0098] in N 2 Under protection, weigh 35.0g epoxy resin E-44 (epoxy equivalent 225) and add 100.0g PEG-4000 and MIBK20.0g, heat and stir, slowly raise the temperature to about 90°C, stir vigorously until clear, add catalyst A0.2 ~0.4g, slowly heat up to about 120°C, keep warm for 2~3h, stop N 2 , vacuum distilled until no fraction flows out. Add 300g of bisphenol A and 50.0g of E-5110, stir evenly, add 1.0g of catalyst B, then react at a constant temperature of about 160°C for 2-3 hours, cool down to about 80°C, gradually add 1400g of deionized water dropwise under high-speed stirring, drop After the addition is completed, continue to stir for about 1 hour to discharge, and then milky white water-based epoxy resin can be obtained, with a solid content of more than 50%.

Embodiment 3

[0100] in N 2 Under protection, weigh 5.2g of epoxy resin shell 828 (epoxy equivalent 195), add 54.8g of PEG-8000 and MIBK4g, heat and stir, slowly raise the temperature to about 90°C, stir vigorously until clear, add catalyst A0.1~0.2g , slowly raise the temperature to about 120°C, keep it warm for 2-3 hours, stop N 2 , vacuum distilled until no fraction flows out. Add 72.5g of bisphenol A and 267.7g of Shell 828, stir evenly, add 0.6g of catalyst B, then react at a constant temperature of about 160°C for 2-3 hours, cool down to about 80°C, and gradually add 400.0g of deionized under high-speed stirring Water, after the dropwise addition is completed, continue to stir for about 1 hour to discharge the material, and a milky white water-based epoxy resin can be obtained with a solid content of more than 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com