Patents

Literature

61results about How to "Low organic solvent content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature self-crosslinked water-based acrylate resin, and preparation method and application thereof

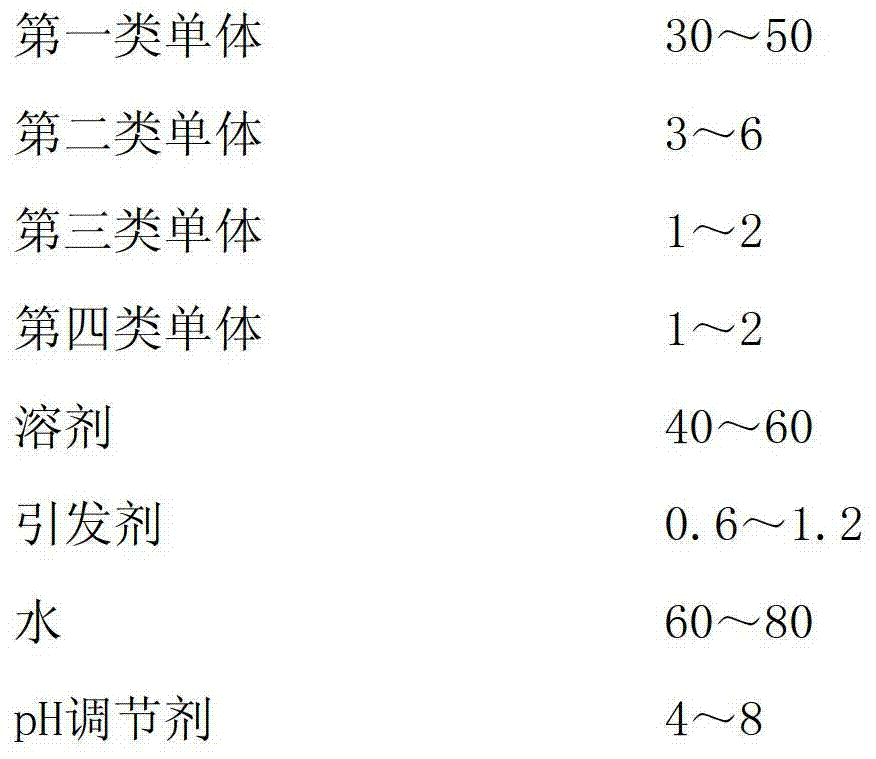

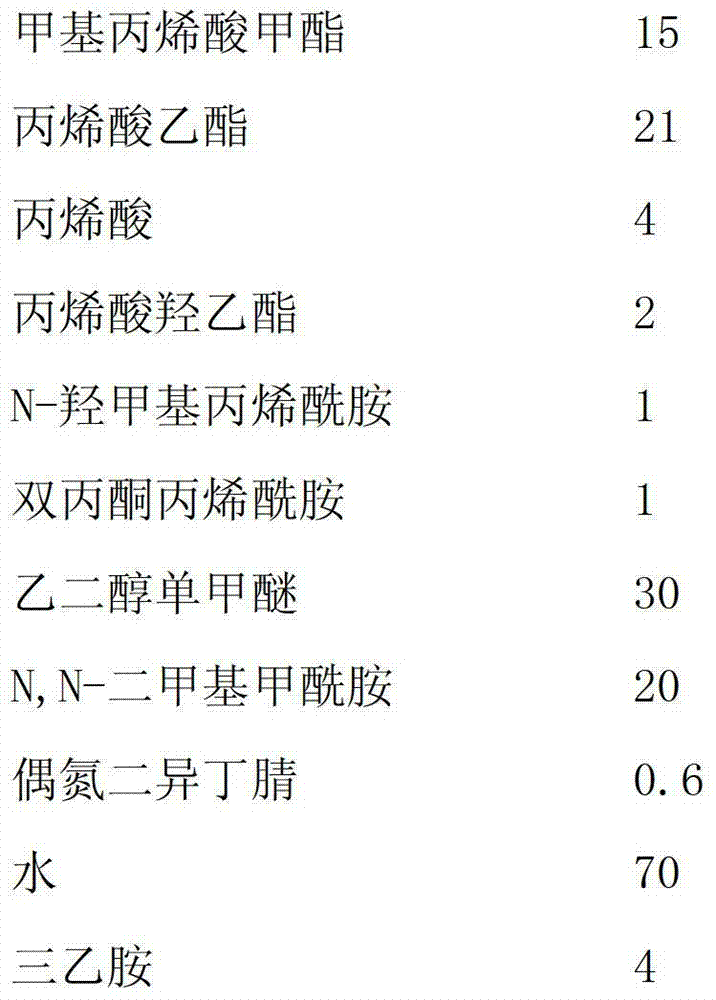

The invention discloses a low-temperature self-crosslinked water-based acrylate resin, and a preparation method and application thereof. The low-temperature self-crosslinked water-based acrylate resin is prepared from the following components in percentage by weight: 30-50% of first monomer, 3-6% of second monomer, 1-2% of third monomer, 1-25 of fourth monomer, 40-60% of solvent, 0.6-1.2% of initiator, 60-80% of water and 4-8% of pH regulator. According to the invention, the prepared water-based acrylate resin and a water-based color paste can be compounded to finally obtain a water-based ink for printing on a low-polarity plastic film. The organic solvent content of the product is lower than 3%, and thus, the product is a safe environment-friendly water-based ink. The coated film on the plastic film has the characteristics of low-temperature self-crosslinking property (<60 DEG C), favorable staining power, high adhesive force, high glossiness and favorable adhesion resistance.

Owner:广州魁科机电科技有限公司

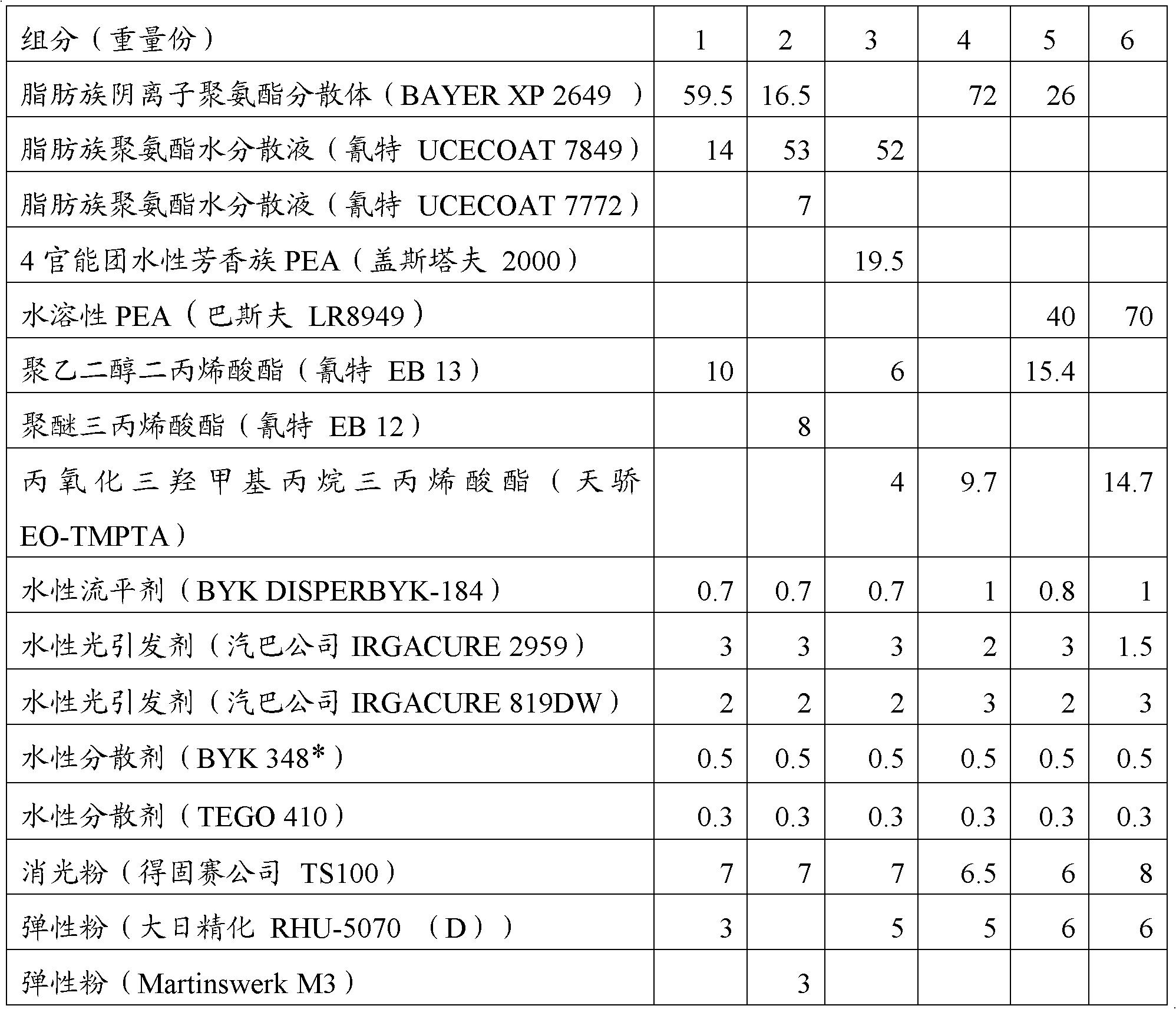

Water-based photo-cured elastomeric paint

InactiveCN102127362AImprove coating efficiencyReduce environmental pollutionPolyurea/polyurethane coatingsPolyether coatingsMonomerUltraviolet

The invention discloses a water-based photo-cured elastomeric paint, which consists of the following components in percentage by weight: 60-80 percent of water-based UV (Ultra Violet) elastic resin, 5-20 percent of water-based UV curing monomer, 1-8 percent of water-based initiator, 0.2-1 percent of water-based flatting agent, 0.2-1 percent of water-based dispersant, 3-9 percent of flatting silica and 1-10 percent of elastic powder. A coating is a water-based UV photo-cured elastomeric paint. Compared with a bi-component coating in the conventional elastic hand paint, the water-based photo-cured elastomeric paint has the advantages of fast curing, high coating efficiency and low environmental pollution.

Owner:ZHEJIANG UVCHEM SPECIAL COATINGS CO LTD

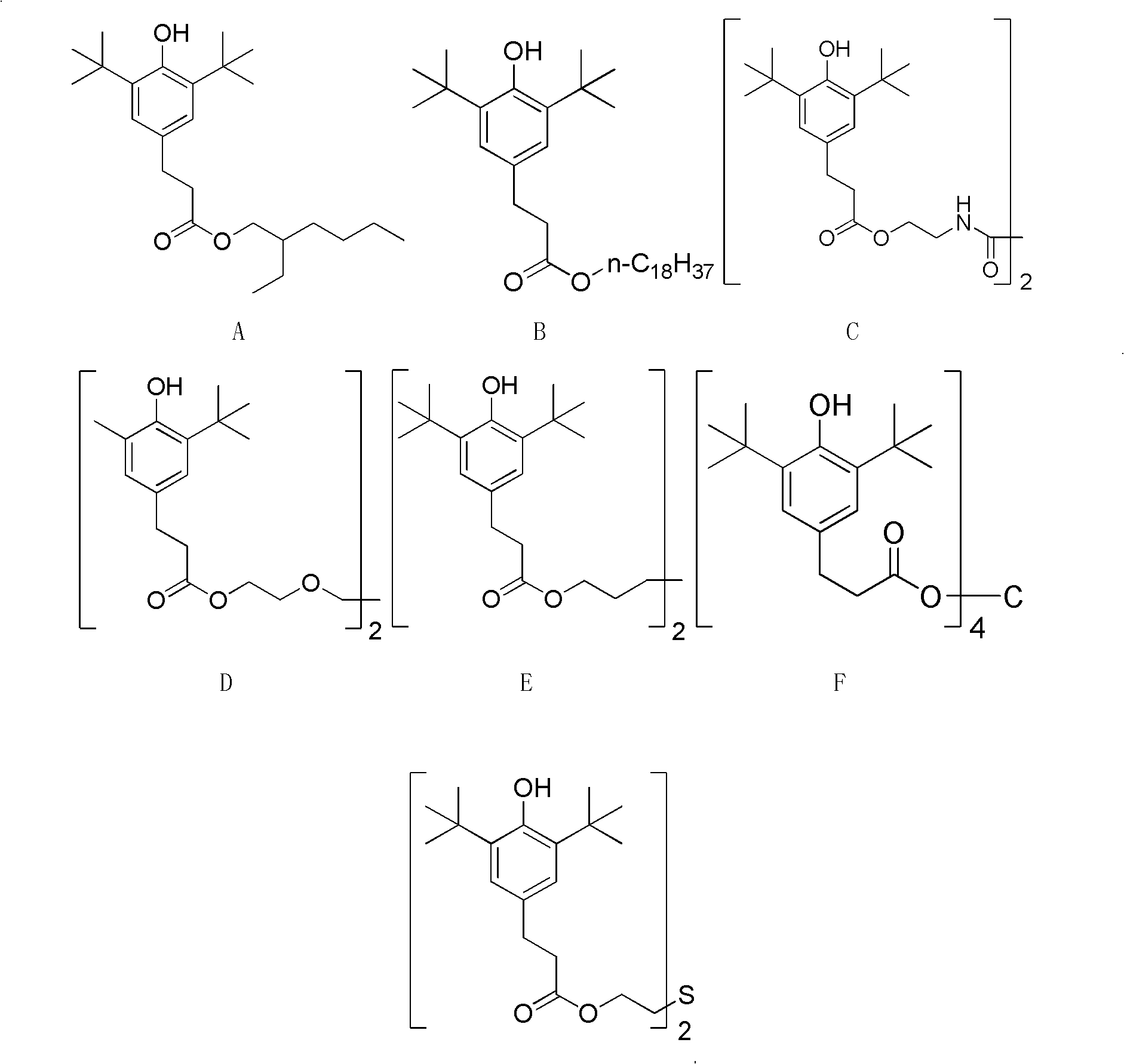

Method for preparing hindered phenol antioxygens by ester exchange process

ActiveCN102020555AReduced tightness requirementsLess investmentOrganic compound preparationPreparation by ester-hydroxy reactionLower limitBoiling point

The invention discloses a method for preparing hindered phenol antioxygens by an ester exchange process, comprising the following steps of: adding reaction raw materials and toluene or mixed xylenes to a reaction kettle, and introducing N2 for protection; heating the reaction kettle to 130-150 DEG C; removing light components until the tower top temperature reaches the boiling point of the toluene or the boiling range lower limit of the mixed xylenes; adding an ester exchange reaction catalyst; when the temperature in the reaction kettle is 140-190 DEG C, starting regulating a reflux ratio controller to be in a total reflux state; when the tower top temperature reaches 63-635 DEG C, regulating the reflux ratio (quantity of reflux: recovery) to be 15-50:25 to recover carbinol; with the reaction, when the tower top temperature reaches 75-90 DEG C, regulating the reflux ratio (quantity of reflux: recovery) to be 5-50:5; and when the tower top temperature reaches the boiling point of the toluene or the boiling range lower limit of the mixed xylenes and is constant at the boiling point for 0.5-2h, finishing the reaction. The method has the advantages of small equipment investment, low cost and small pollution and is suitable for industrially producing the hindered phenol antioxygens.

Owner:RIANLON

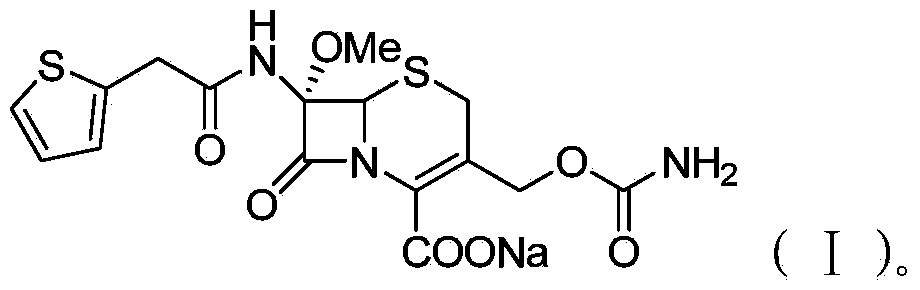

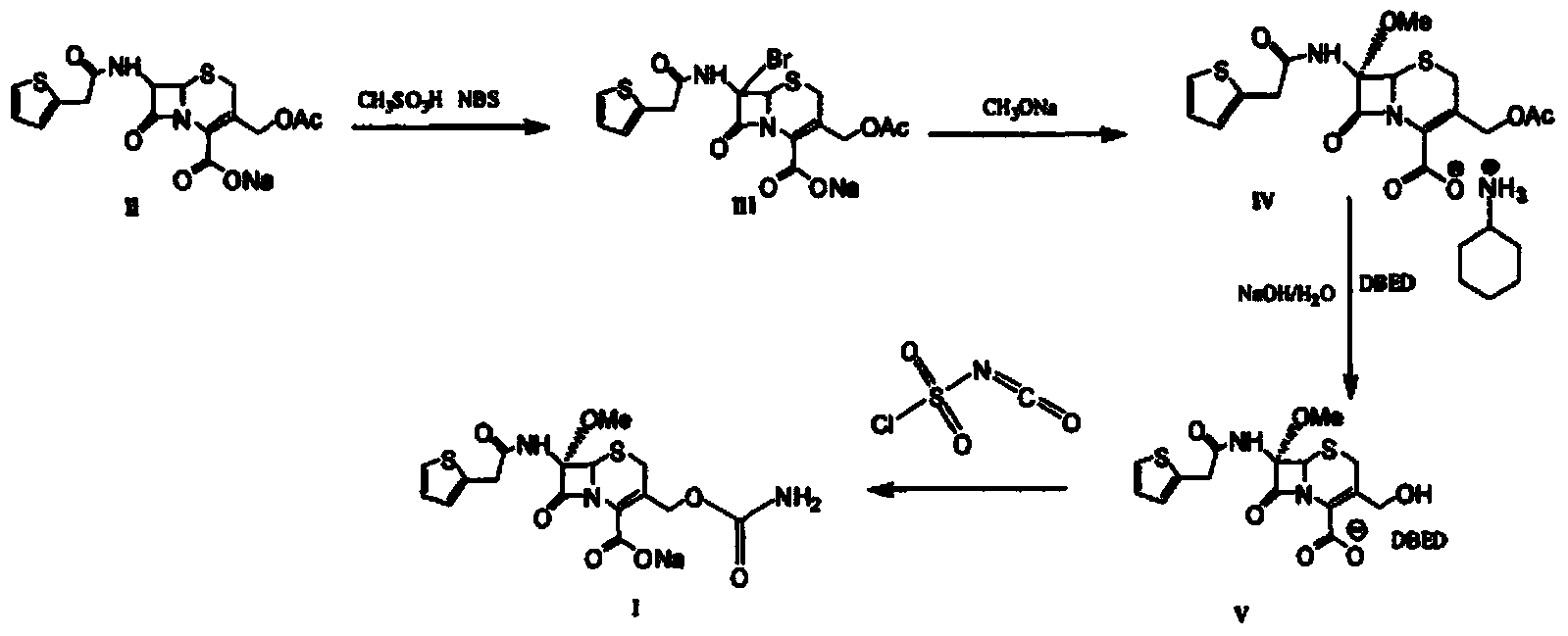

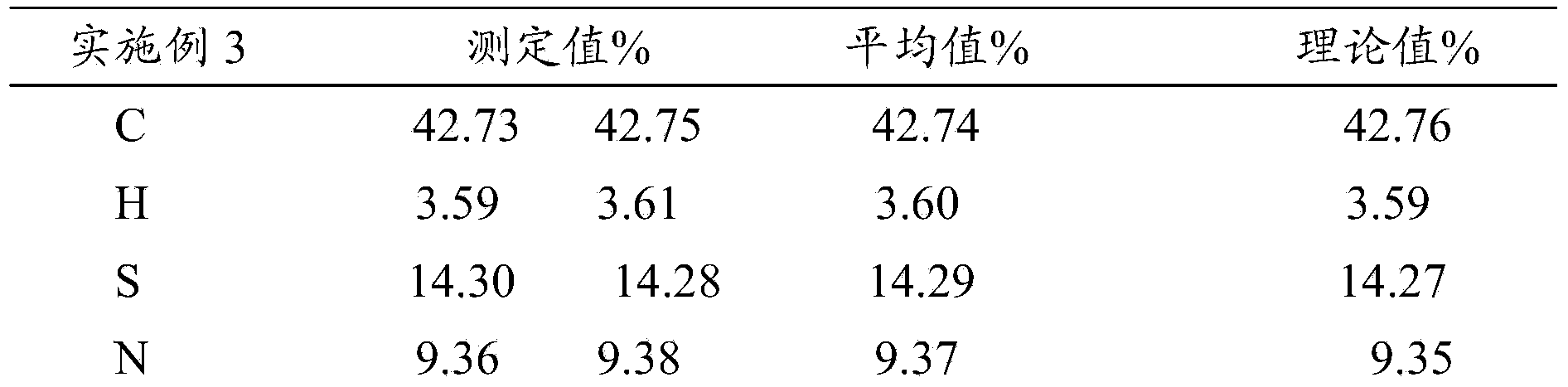

Preparation method of cefoxitin sodium

The invention discloses a preparation method of cefoxitin sodium. The preparation method comprises the following steps: (1) bromizing, for example, the site 7 of a main nucleus of cefalotin by using an NBS (N-bromosuccinimide) reagent to form a bromination compound; performing nucleophilic substitution at the site 5 by using a methoxyl group to generate an intermediate IV; (2) performing acyl group hydrolysis on the site 3 of the intermediate IV to obtain an intermediate V; (3) substituting hydrogen atoms on the hydroxyl group by using chloriosulfonyl isocyanate, and then hydrolyzing to obtain the cefoxitin sodium. The method has the advantages of simple process, high product yield, high purity and high reaction selectivity; no special equipment is used in the production; the preparation method is suitable for industrial production.

Owner:HAINAN HULUWA PHARMA GRP CO LTD

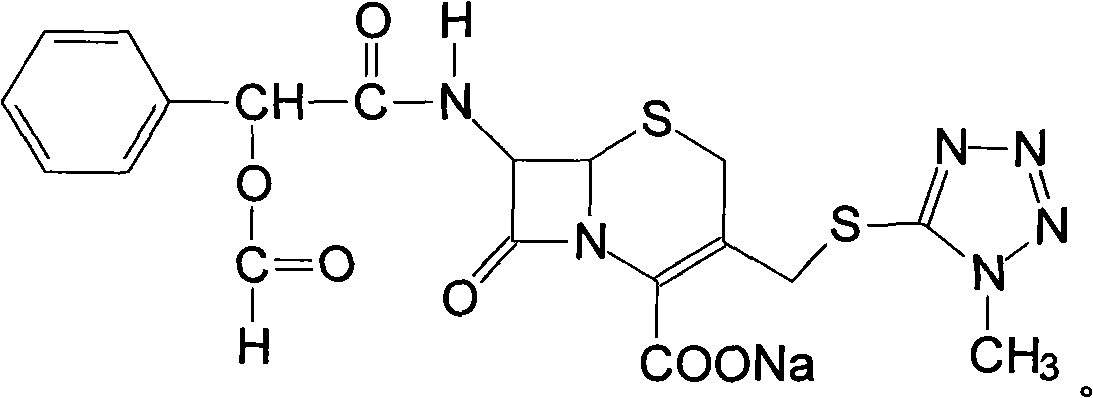

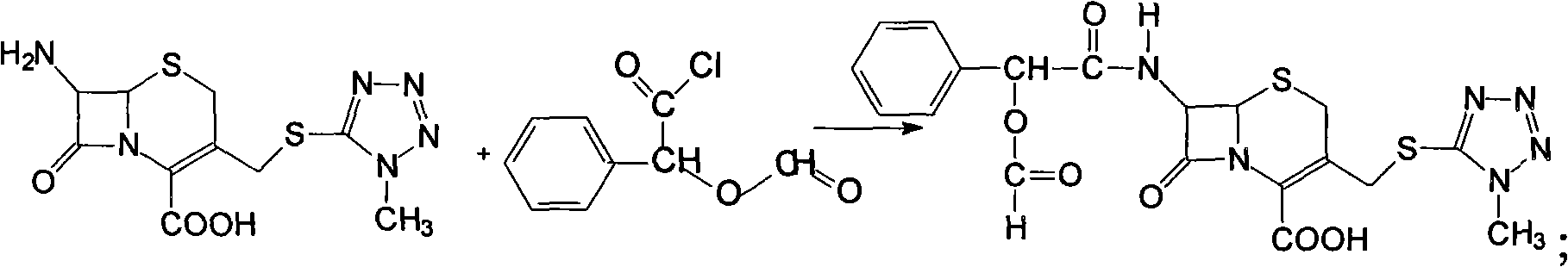

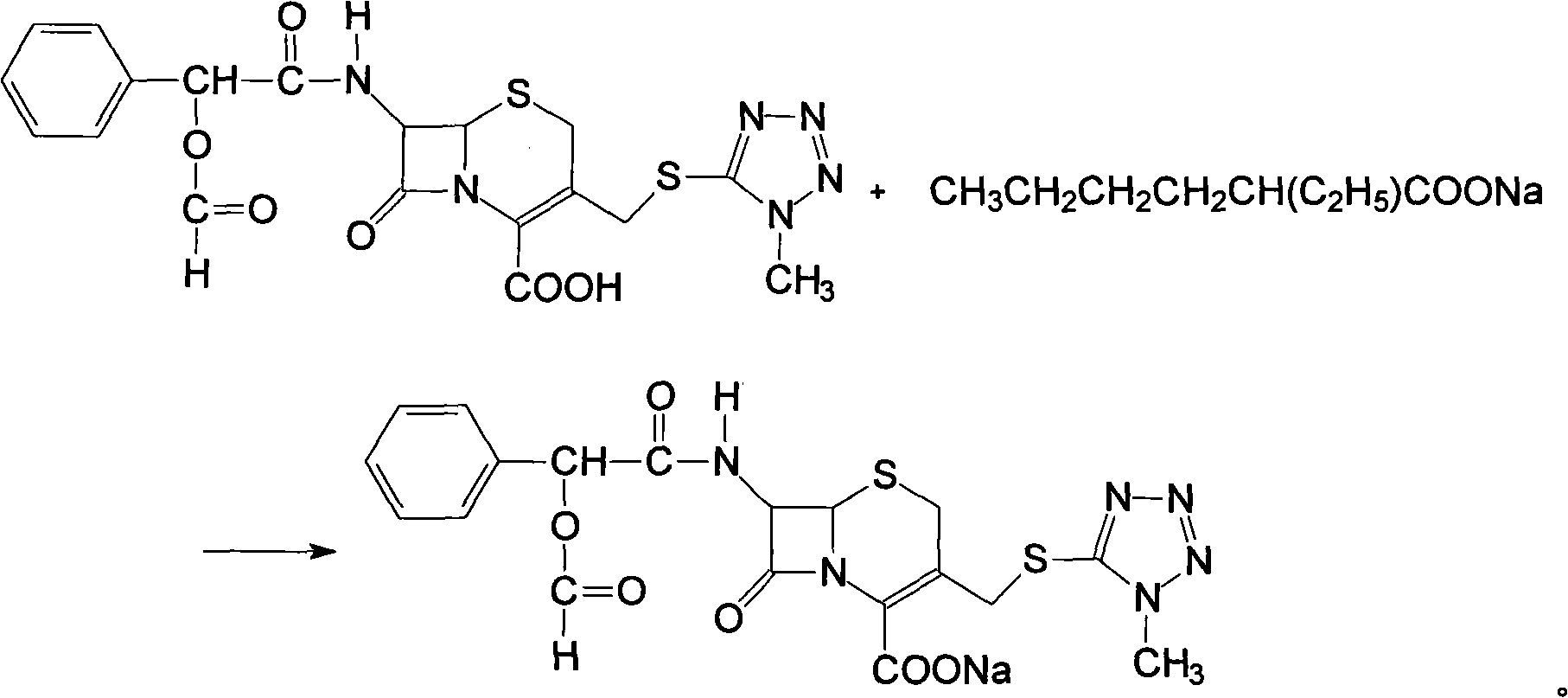

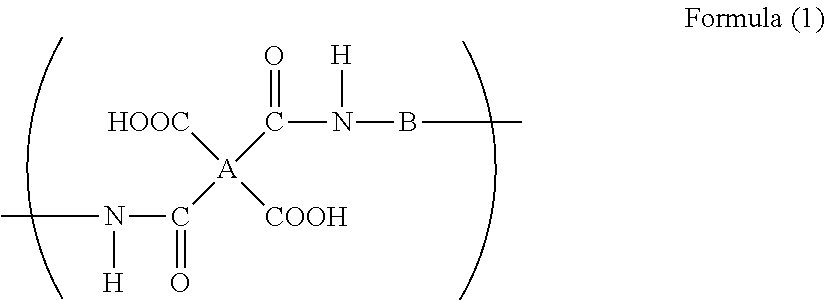

Preparation method of cefamandole nafate

ActiveCN101880290AReduce generationImprove conversion rateOrganic chemistrySodium bicarbonateOrganic acid

The invention discloses a preparation method of cefamandole nafate, which comprises the following steps: (1) suspending 7-amino-3-[(1-methyl-1H-tetrazol-5-yl) S-methyl] -3-cephem-4-carboxylic acid and sodium bicarbonate in an acetone water solution, adding the acetone solution of alpha-formylmandeloyl chloride to carry out a condensation reaction, and preparing 7-D-(2-formyloxy phenylacetamide)-3- [(1-methyl-1H-tetrazol-5-yl) S-methyl]-3-cephem-4-carboxylic acid; and (2) dissolving the 7-D-(2-formyloxy phenylacetamide)-3- [(1-methyl-1H-tetrazol-5-yl) S-methyl]-3-cephem-4-carboxylic acid in acetone to carry out a salification reaction with the acetone solution of organic acid sodium to prepare the cefamandole nafate. The method has the advantages of simple technology, high product yield, high purity, high reaction selectivity and use of no special equipment in production, and is suitable for industrialized production.

Owner:HAINAN HULUWA PHARMA GRP CO LTD

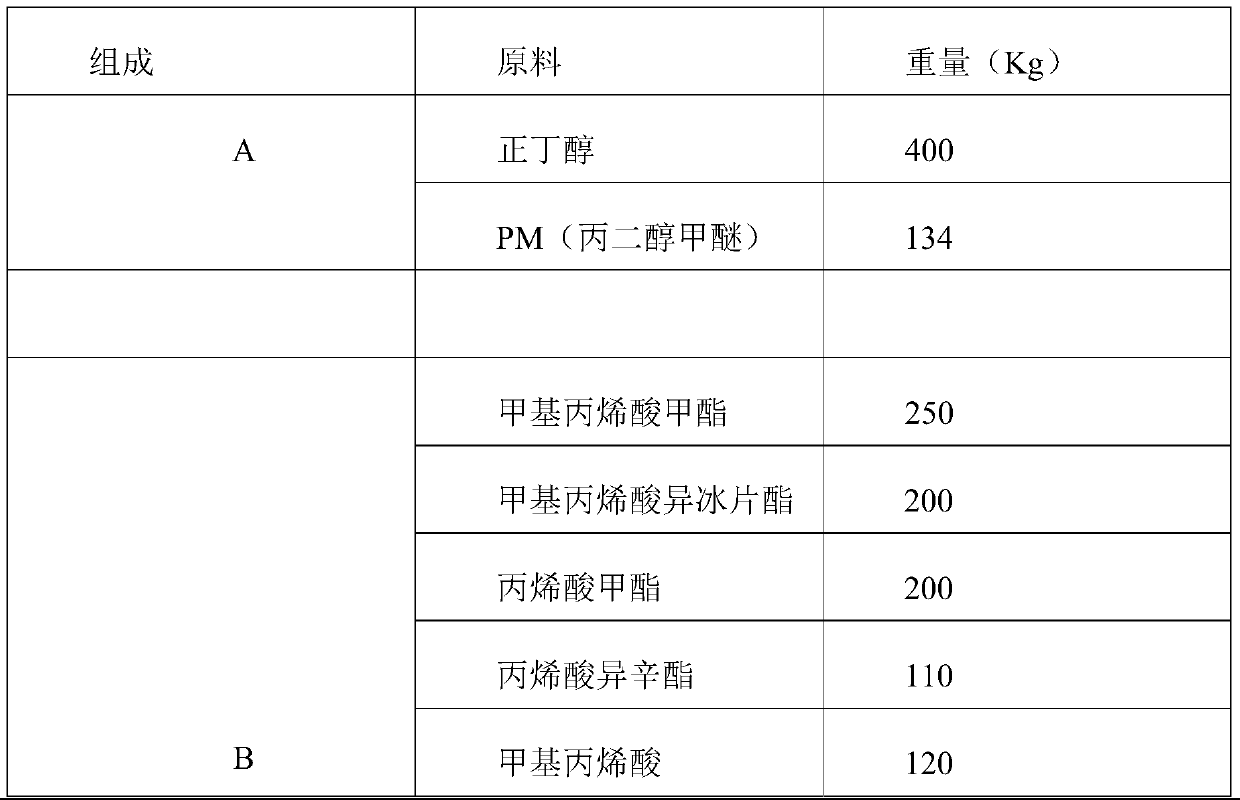

Heat and cold resisting water-soluble air-drying acrylic resin and preparing method thereof

ActiveCN105504137AImprove toughnessGood cold and heat resistanceCoatingsFunctional monomerAcrylic resin

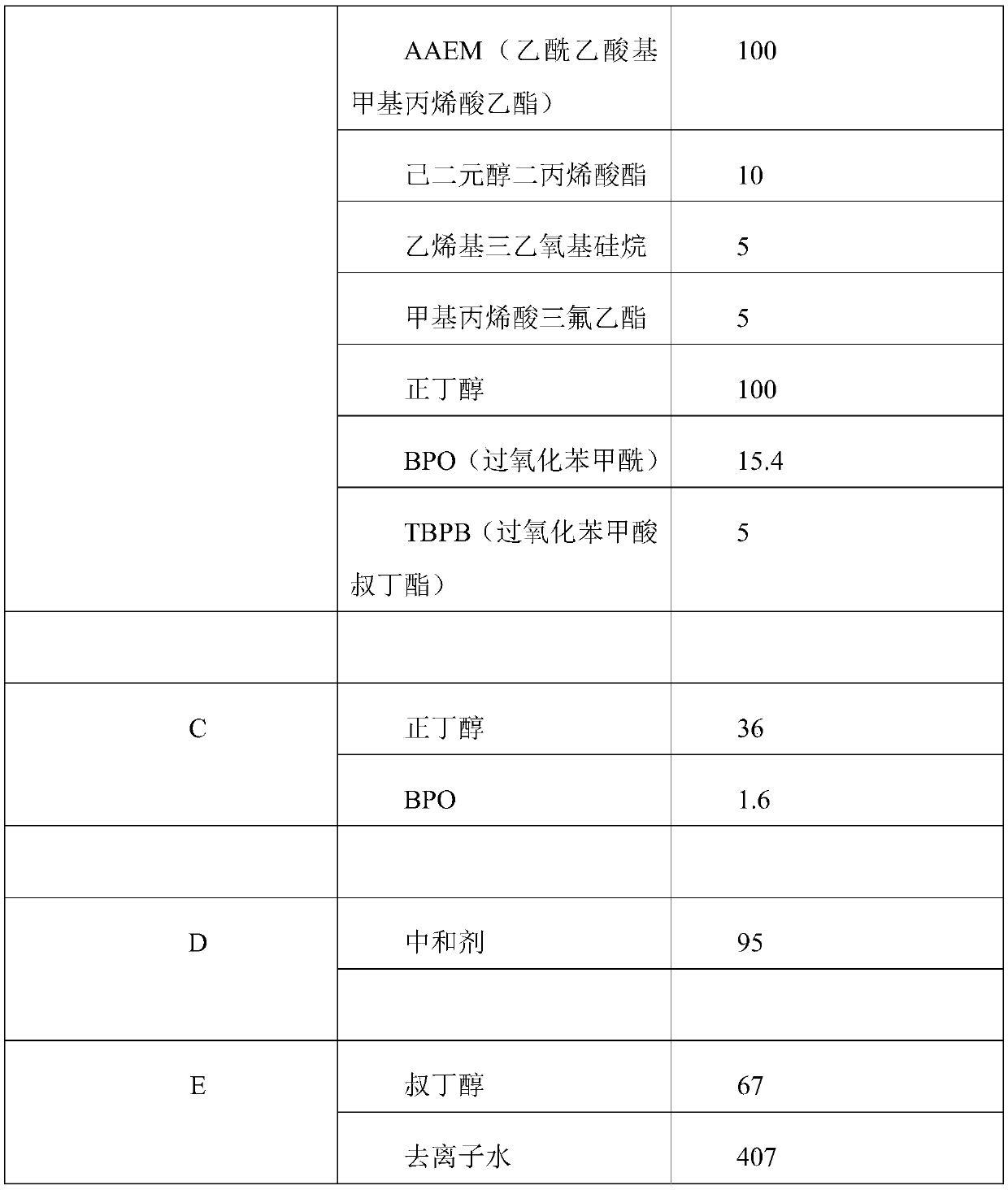

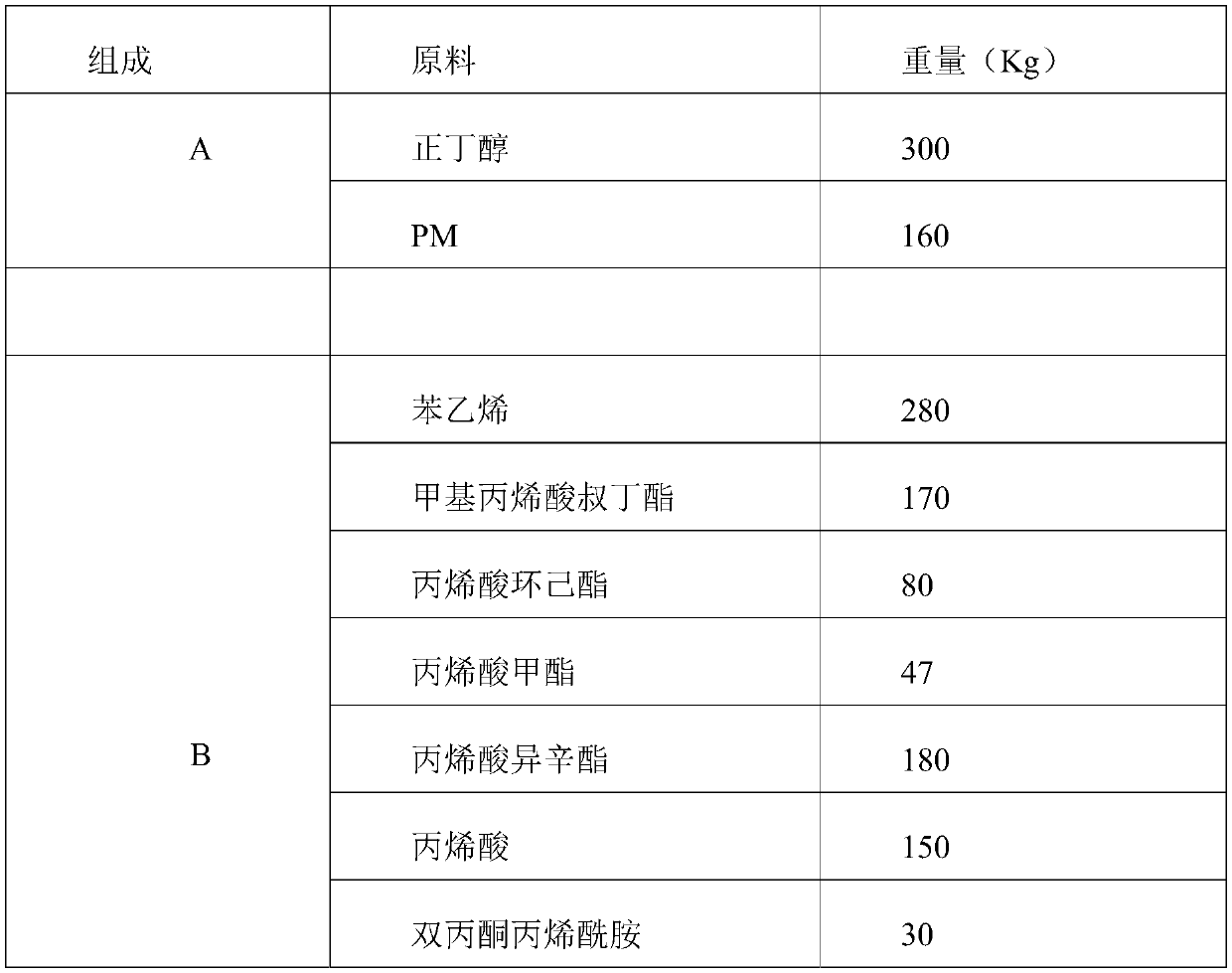

The invention discloses a method for preparing heat and cold resisting water-soluble air-drying acrylic resin. A monometer-phase solution B is prepared from 5-15 wt% of functional monomer, 7-15 wt% of acrylic acid or methacrylic acid, 20-45 wt% of hard monomer, 8-20 wt% of hard tenacity monomer, 15-45 wt% of soft monomer, 0.3-2 wt% of organic siloxane organosilicone monomer, 0.3-2 wt% of fluorine acrylic acid monomer, and 0.5-3 wt% of double-ethylenic-bond monomer, and the total percentage of the monomers is 100%. By the adoption of the method, the heat and cold resisting water-soluble air-drying acrylic resin is provided, and the problems that existing single-component water-soluble acrylic resin paint becomes crispy under the refrigeration condition and becomes tacky and liable to contamination under heating to cause poor membrane surface scratch resistance, dryness is insufficient, and water resistance is low are solved.

Owner:YINGDE BOTE CHEM INDAL

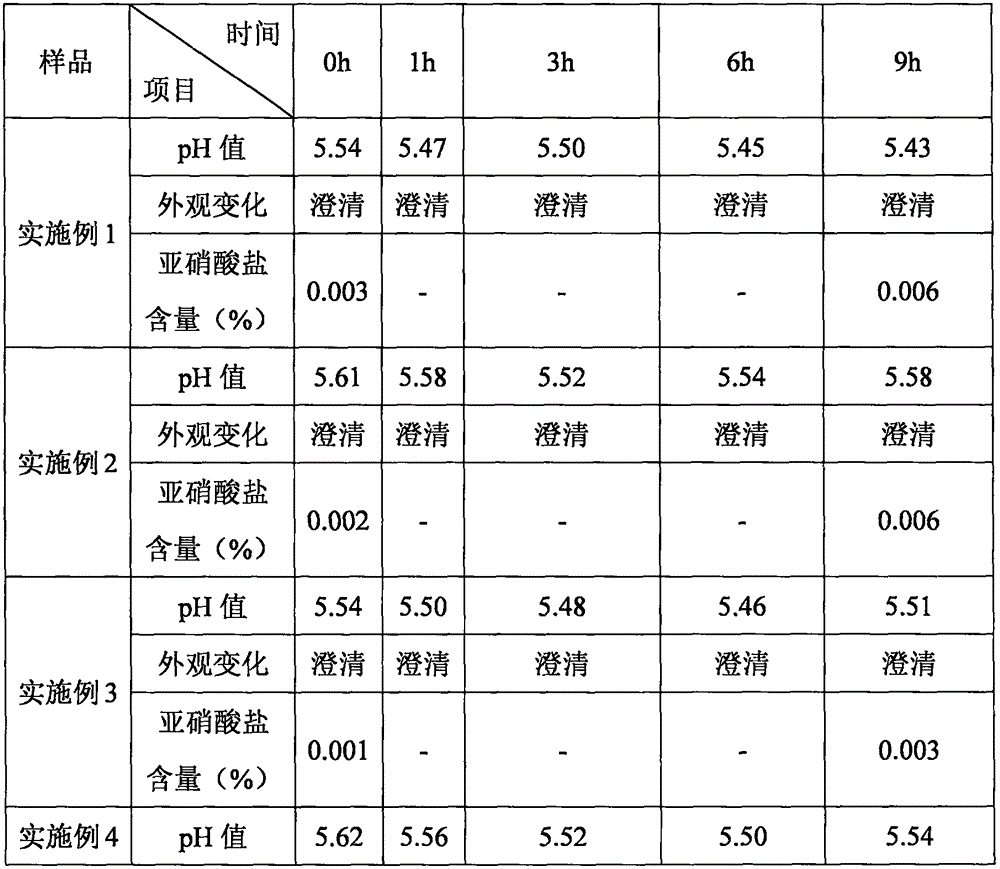

Omidazole injection

InactiveCN106309359ALow organic solvent contentCompatibility is goodAntibacterial agentsOrganic active ingredientsNitriteAlcohol

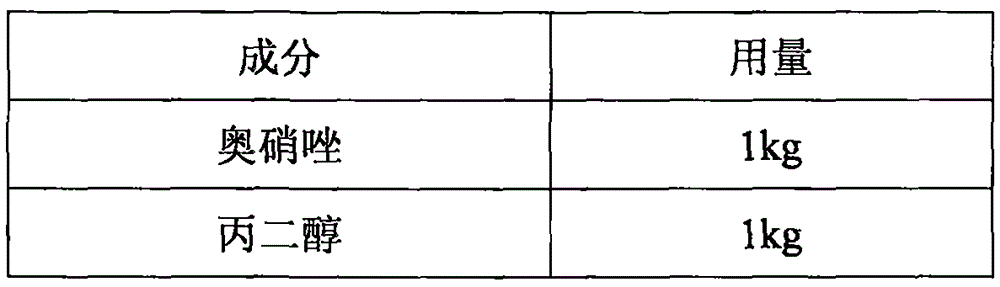

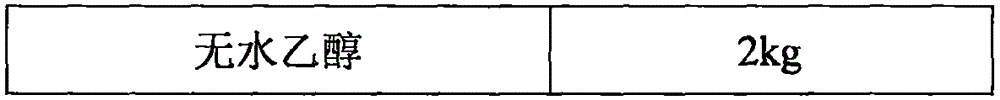

The invention provides an over-saturated omidazole injection which comprises 1 g of omidazole, 0.7-1.1 g of propylene glycol and alcohol added to 4ml. Content of propylene glycol is 0.7-1.02g preferably, 0.78-0.91g further preferably and 0.78g optimally. The over-saturated omidazole injection is high in combining stability and low in content of nitrite in the process of storage.

Owner:BEIJING JINGKE TAILAI TECH

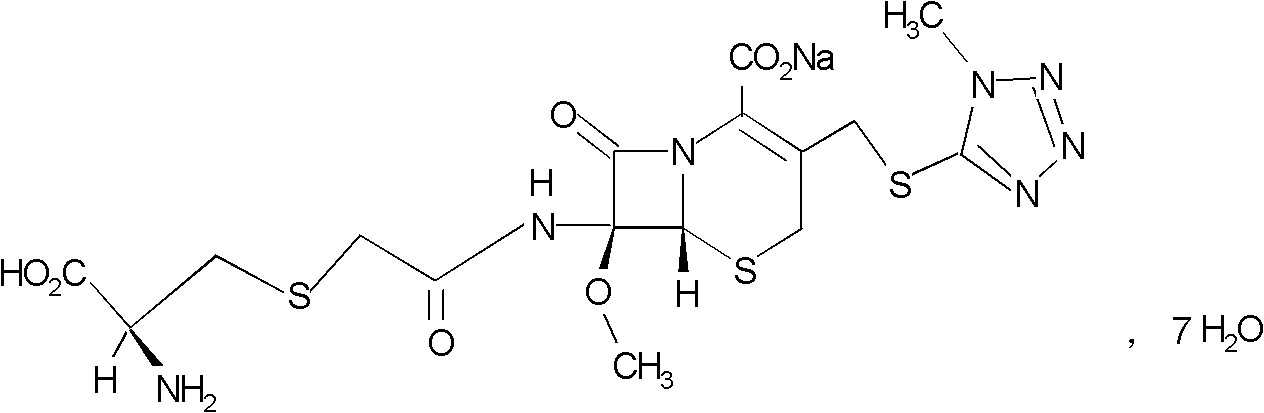

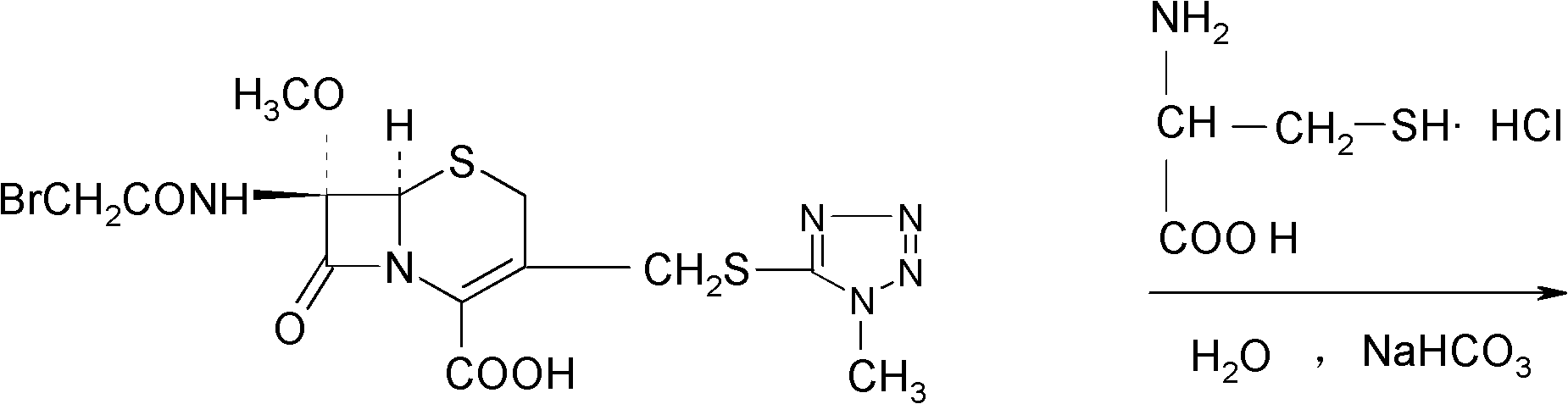

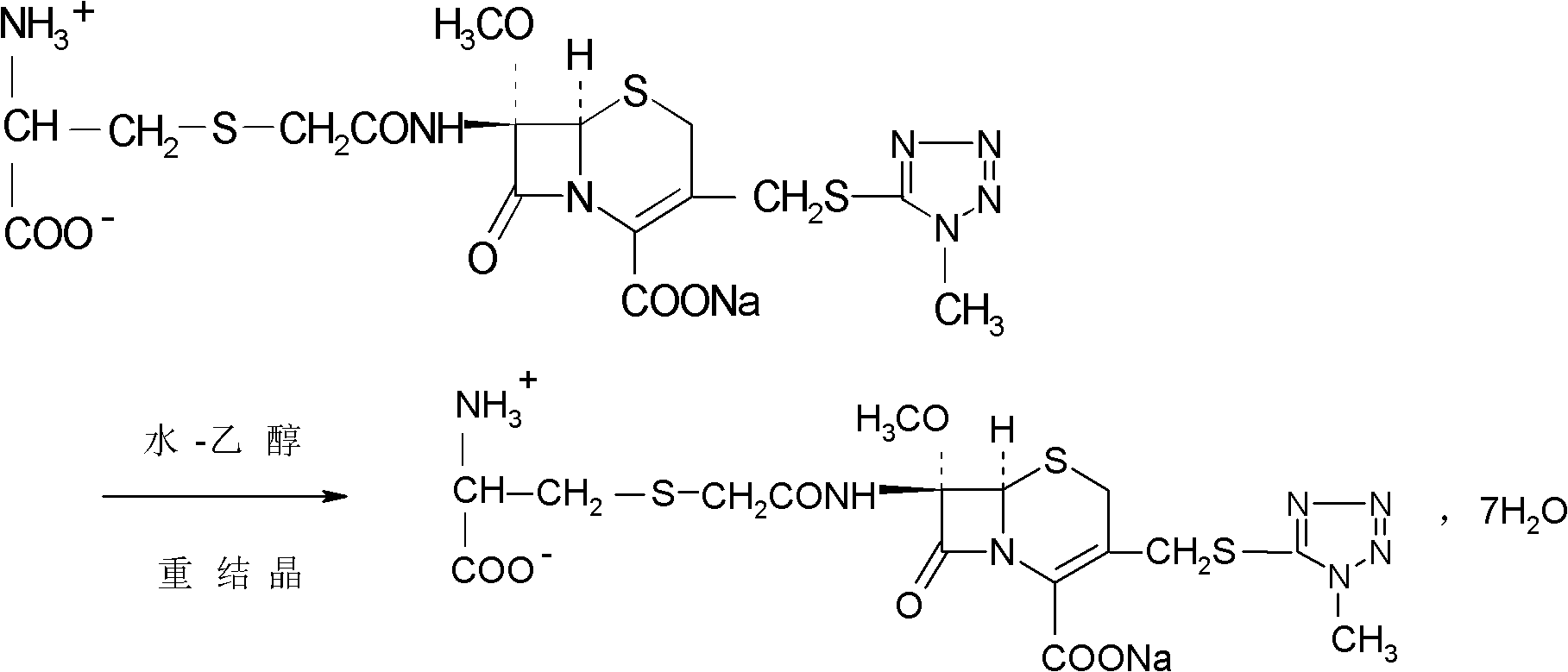

Preparation method of cefminox sodium

The invention discloses a preparation method of cefminox sodium, which comprises the following steps: 7 beta-bromoacetamide-7 alpha-methoxy-3-(1-methyl-1H-5-tetrazyl)sulfur methyl-3- cephem-4-carboxylic acid and D-cysteine hydrochloride are dissolved in water, the pH value is regulated to 6.0-7.0 by sodium bicarbonate, condensation reaction is carried out, and reaction products are post-treated to obtain the cefminox sodium. In the method, cefminox sodium raw material can be prepared through low-temperature reaction, a nonpolar macroporous resin X5 chromatography column is used for purification, ethanol-aqueous solution or anhydrous alcohol recrystallization and other simple operations are adopted to obtain target products, the yield and the purity of the target products are high, the products have uniform crystal forms and good fluidity, no special equipment is needed for the production, and the method is suitable for industrial production.

Owner:HAINAN HULUWA PHARMA GRP CO LTD

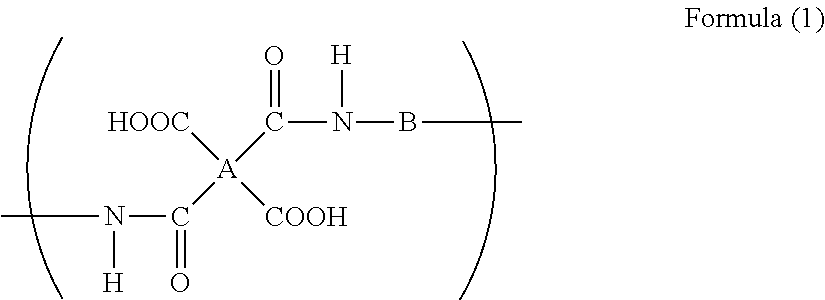

Aqueous polyimide precursor solution composition and method for producing aqueous polyimide precursor solution

InactiveUS20140363687A1High transparencyMaintain good propertiesSynthetic resin layered productsCeramic shaping apparatusPolyamic acidCarboxylic acid

An aqueous polyimide precursor solution composition in which a polyamic acid which is obtained by reacting a tetracarboxylic acid component and a diamine component is dissolved in an aqueous solvent together with an imidazole in an amount of 1.6 moles or more per mole of the tetracarboxylic acid component of the polyamic acid.

Owner:UBE IND LTD

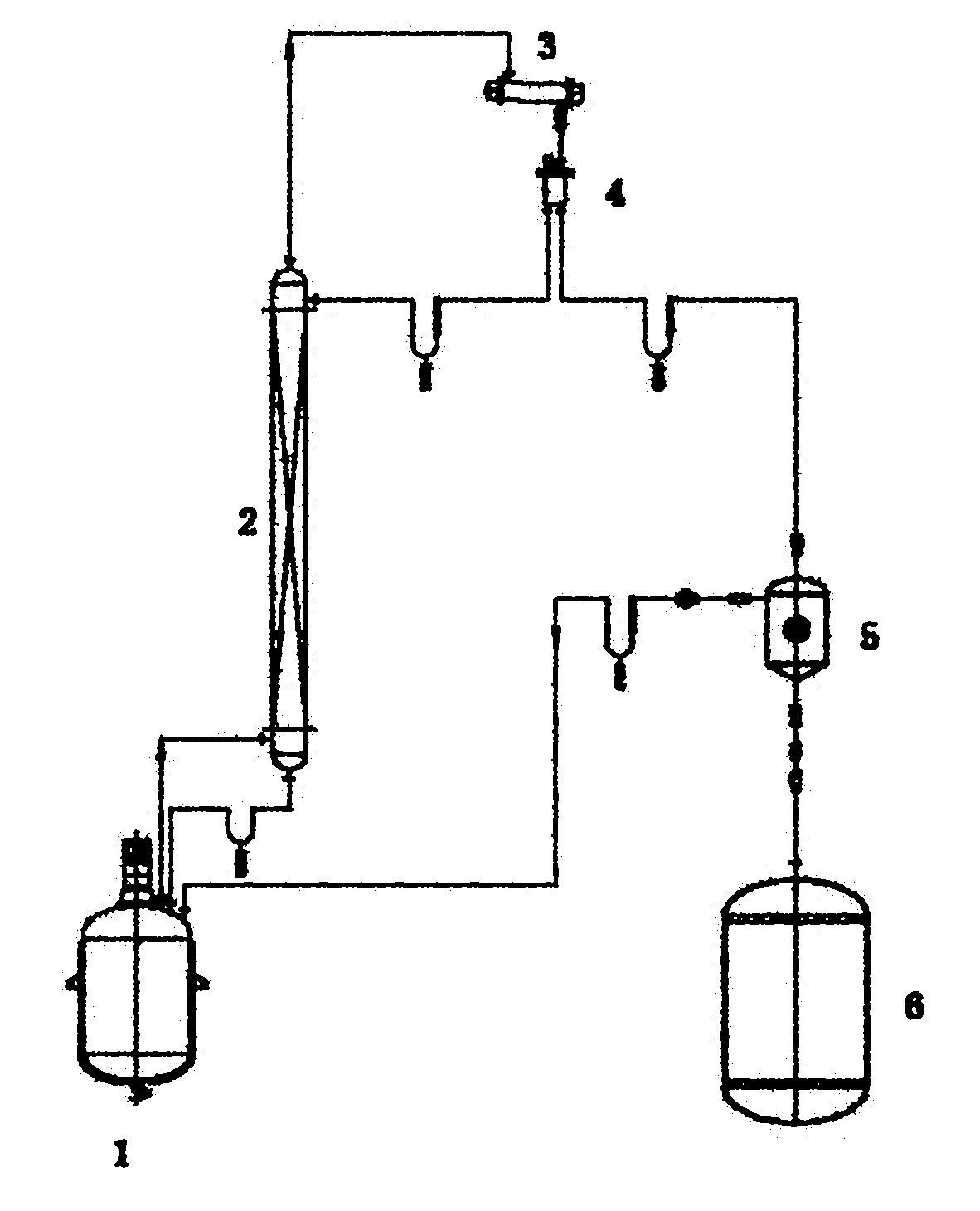

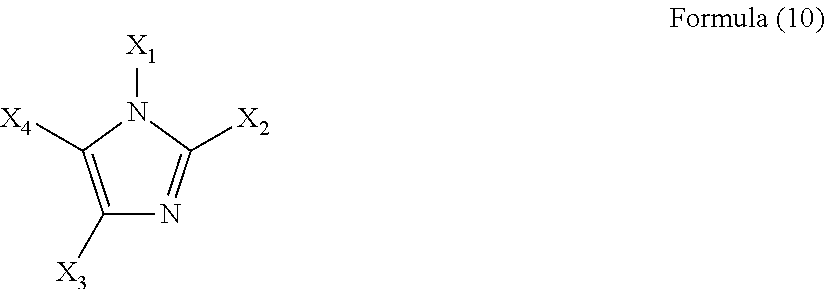

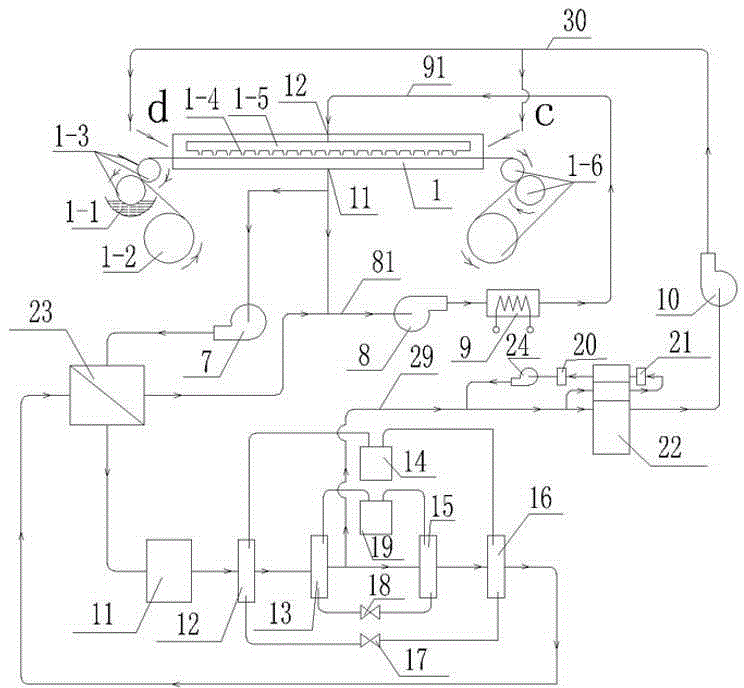

Heat pump and molecular sieve adsorption turning wheel combined cycle organic solvent recycling device

InactiveCN104084357AZero processing costLow organic solvent contentLiquid surface applicatorsHeat recovery systemsGas heaterHeat pump

The invention relates to a heat pump and molecular sieve adsorption turning wheel combined cycle organic solvent recycling device. The heat pump and molecular sieve adsorption turning wheel combined cycle organic solvent recycling device comprises an internal cycle pipeline, a sub pipeline and a branch pipeline, wherein the internal cycle pipeline comprises a gas inlet, an internal cycle fan, a gas heater and a gas outlet; the gas inlet is communicated with a gas outlet of a coating machine; the gas outlet is communicated with a gas inlet of the coating machine; the sub pipeline comprises the gas outlet of the coating machine, an exhaust fan, a hot gas introducing and discharging opening of a gas-gas heat exchanger, an air cooler, an evaporator of the high-temperature heat pump, an evaporator of a low-temperature heat pump, a condenser of the low-temperature heat pump, a condenser of the high-temperature heat pump, a cold gas introducing and discharging opening of the gas-gas heat exchanger and a gas inlet; the branch pipeline comprises a branch pipeline gas inlet, an adsorption area of a molecular sieve concentration turning wheel, a processing fan and a branch pipeline gas outlet; the branch pipeline gas inlet is connected with a gas outlet of the evaporator of the low-temperature heat pump, and the branch pipeline gas outlet is communicated with a machine head and a machine tail of the coating machine. According to the device, a heat pump is used for recycling an organic solvent, and meanwhile the gas temperature is increased, so that energy sources are saved; meanwhile, zero emission under the condition of saving the coating energy sources is realized.

Owner:马军

Composition for aqueous coating material and process for its production, and two-component curable aqueous coating material kit

InactiveUS20090048391A1Reduce contentBig burden to solveNon-macromolecular adhesive additivesFibre treatmentVinyl etherPolymer science

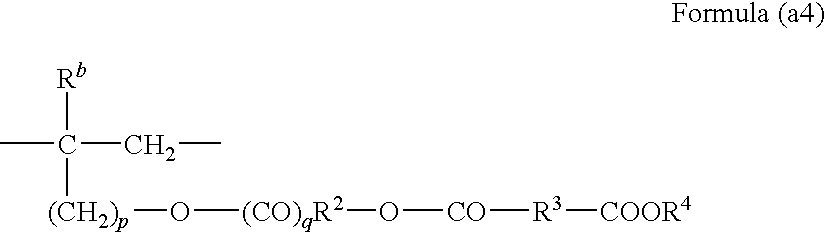

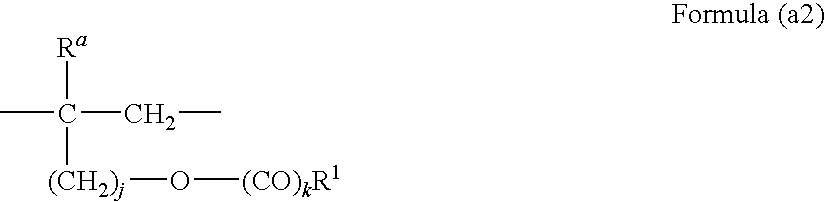

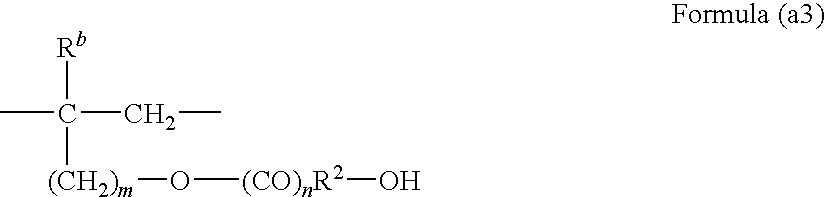

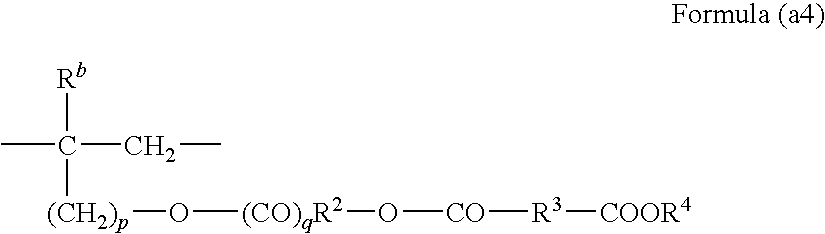

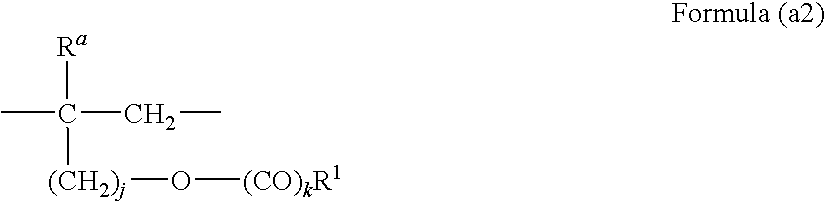

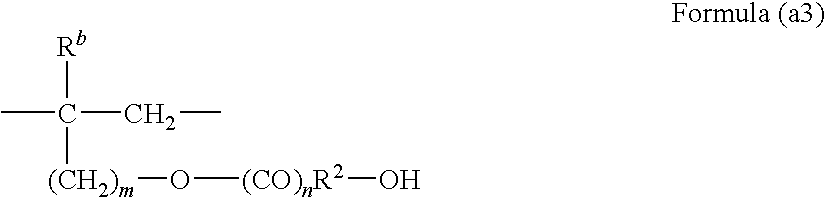

A composition for aqueous coating material which has a low content of an organic solvent and presents little burden on the environment and which is excellent in storage stability.A composition for aqueous coating material, which comprises a synthetic resin containing a fluorinated copolymer (A) comprising from 40 to 60 mol % of a fluoro-olefin unit, from 3 to 50 mol % of an alkyl vinyl ether or alkyl vinyl ester unit, from 4 to 30 mol % of a hydroxyl group-containing vinyl ether unit and 0.4 to 7 mol % of a structural unit of the following formula (a4):

Owner:ASAHI GLASS CO LTD

Composition for aqueous coating material and process for its production, and two-component curable aqueous coating material kit

InactiveUS20100120971A1Reduce contentBig burden to solveFibre treatmentPolyurea/polyurethane coatingsVinyl etherOrganic solvent

A composition for aqueous coating material which has a low content of an organic solvent and presents little burden on the environment and which is excellent in storage stability. A composition for aqueous coating material, which comprises a synthetic resin containing a fluorinated copolymer (A) comprising from 40 to 60 mol % of a fluoroolefin unit, from 3 to 50 mol % of an alkyl vinyl ether or alkyl vinyl ester unit, from 4 to 30 mol % of a hydroxyl group-containing vinyl ether unit and 0.4 to 7 mol % of a structural unit of the following formula (a4):

Owner:ASAHI GLASS CO LTD

Preparation method of environment-friendly printing ink cleaner

InactiveCN106479258ALow organic solvent contentEasy to cleanChemical paints/ink removersEnvironmental resistanceSide effect

The invention discloses a preparation method of an environment-friendly printing ink cleaner and belongs to the technical field of printing ink cleaners. Potato starch, ethylene glycol, n-dodecanol and the like are used as raw materials and subjected to a heating reaction, then the pH of a mixed solution is adjusted, reduced pressure distillation is performed, starch-based dodecyl glycoside is prepared, a mixed microemulsion is prepared from starch-based dodecyl glycoside, sodium dodecyl sulfate, n-butyl alcohol, deionized water and the like, D-limonene, ethanolamine, the mixed microemulsion and the like are placed in a high-shear dispersion emulsifying machine for stirring emulsification, the mixture is left to stand and cooled, and the environment-friendly printing ink cleaner is prepared. The raw materials of the printing ink detergent are environment-friendly, the toxic and side effects of the detergent are effectively reduced, damage to human health and the environment is avoided, and the printing ink detergent is high in deterging speed, high in detergency efficiency and better in stability, can effectively protect base materials and prolong the service life of equipment and has broad application prospect.

Owner:TRUSYN CHEM TECH

Aqueous oracle bone line paint and preparation method thereof

ActiveCN103396727ANo pollution in the processNon-toxicLiquid surface applicatorsPolyester coatingsOrganic solventFilm-coated tablet

The invention relates to a paint, provides an aqueous oracle bone line paint, and the aqueous oracle bone line paint has the advantages of extremely low organic solvent content, basic no pollution to the environment, no toxicity to operating personnel, excellent film coating performance, no heavy metal material and low cost. The aqueous oracle bone line paint comprises a priming paint and a surface paint, the priming paint is a colored oracle bone line priming paint or a colourless oracle bone line priming paint, and surface paint is an aqueous oracle bone line surface paint. The invention also provides a preparation method of the aqueous oracle bone line paint, and the preparation method comprises the preparation of the priming paint and the surface paint. The invention also provides a construction method of the aqueous oracle bone line paint, and the construction method has the advantages of convenient construction and short construction period.

Owner:XINHE NEW MATERIALS CO LTD

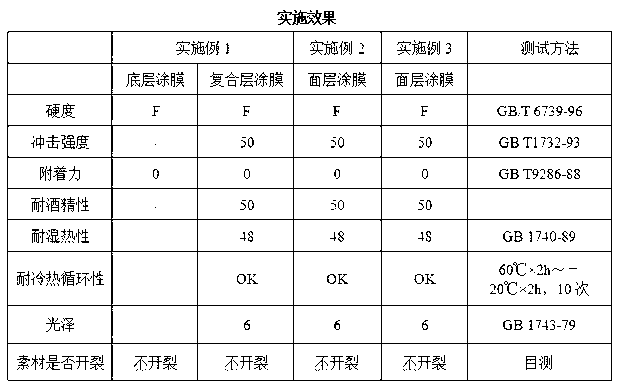

Plastic anti-cracking coating process for domestic appliance

InactiveCN102974515AGood lookingGood decorative effectPretreated surfacesSpecial surfacesAcrylonitrile butadiene styreneHome appliance

The invention discloses a plastic anti-cracking coating process for a domestic appliance. The plastic anti-cracking coating process for the domestic appliance is characterized in that water-based plastic coating of various colors replaces solvent type plastic coating to be used for plastic coating of the domestic appliance, the water-based plastic coating is enabled to be correctly used for the plastic coating of the domestic appliance, not only is the quality problem of cracking occurring in poly carbonate (PC), polymethyl methacrylate (PMMA), acrylonitrile butadiene styrene (ABS)+PMMA and other plastic coating solved, but also the needs of decorative appearance of plastic of the domestic appliance are met.

Owner:GUANGZHOU QINGTIAN INDAL +1

Algae-proof coating composition and preparing process thereof

ActiveCN102559015ALow organic solvent contentGood environmental performanceAntifouling/underwater paintsPaints with biocidesPhenolic amineChemistry

The invention provides an algae-proof coating composition and a preparing process thereof. The algae-proof coating composition includes 20 to 50 parts by weight of epoxy resin, 5 to 15 parts by weight of active diluents, 5 to 15 parts by weight of microcapsulation phenolic amine modified curing agents, 3 to 5 parts by weight of dispersing agents, 4 to 6 parts by weight of thickening agents, 10 to 15 parts by weight of extender pigment, 10 to 20 parts by weight of algae-removing pigment and 30 to 40 parts by weight of water absorption pigment. Compared with the existing single-component algae-proof coating, the algae-proof coating is low in content of organic solvents and good in environmental protection, and can achieve the standard of direct contact with drinking water; compared with the existing double-component algae-proof coating, the algae-proof coating only need stir and then coat without blending before using, and is capable of being performed in underwater operation and applicable for being used in drinking water pipes.

Owner:珠海展辰新材料股份有限公司

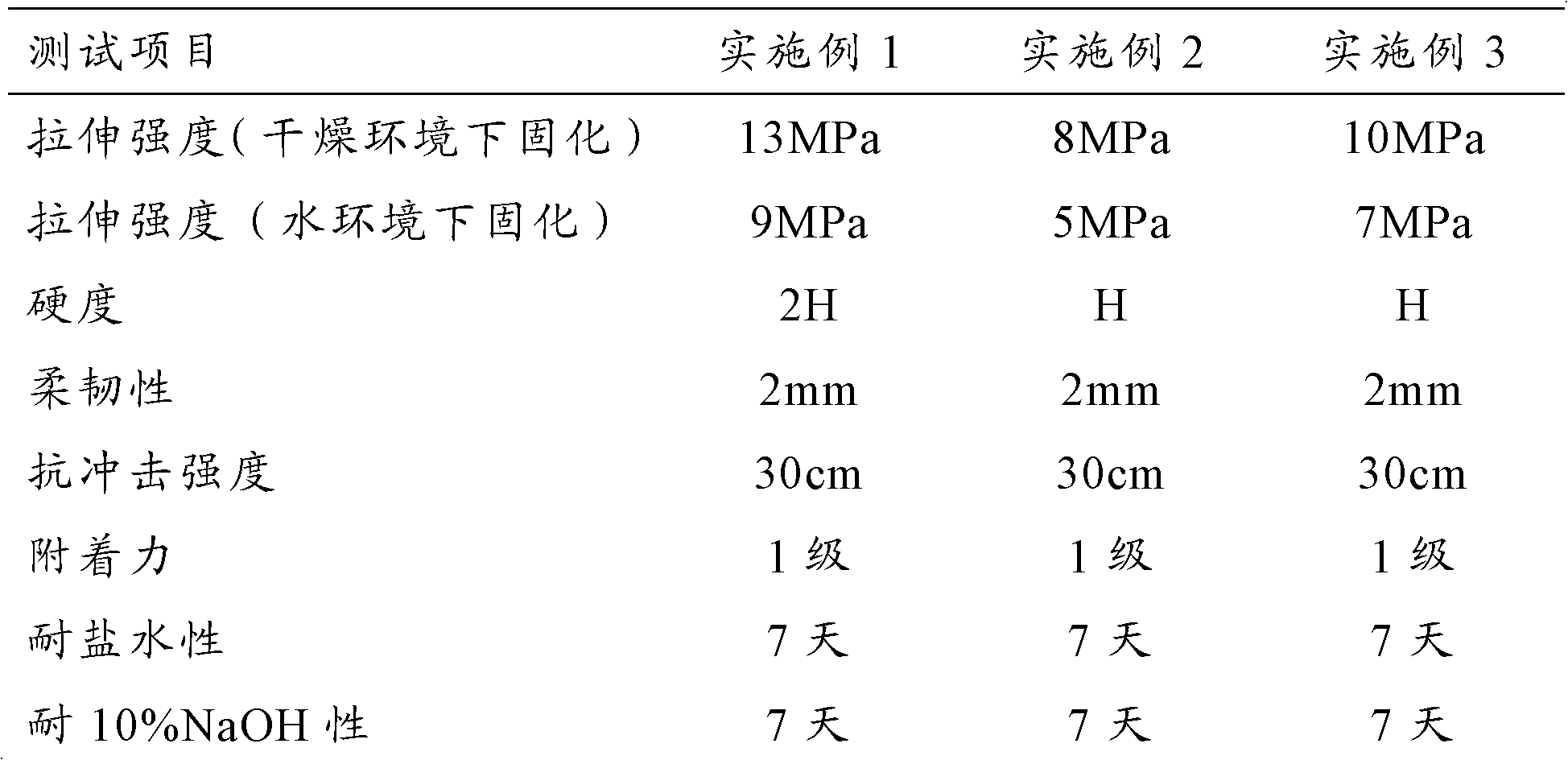

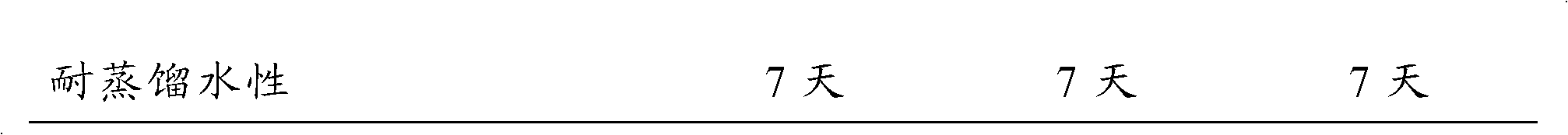

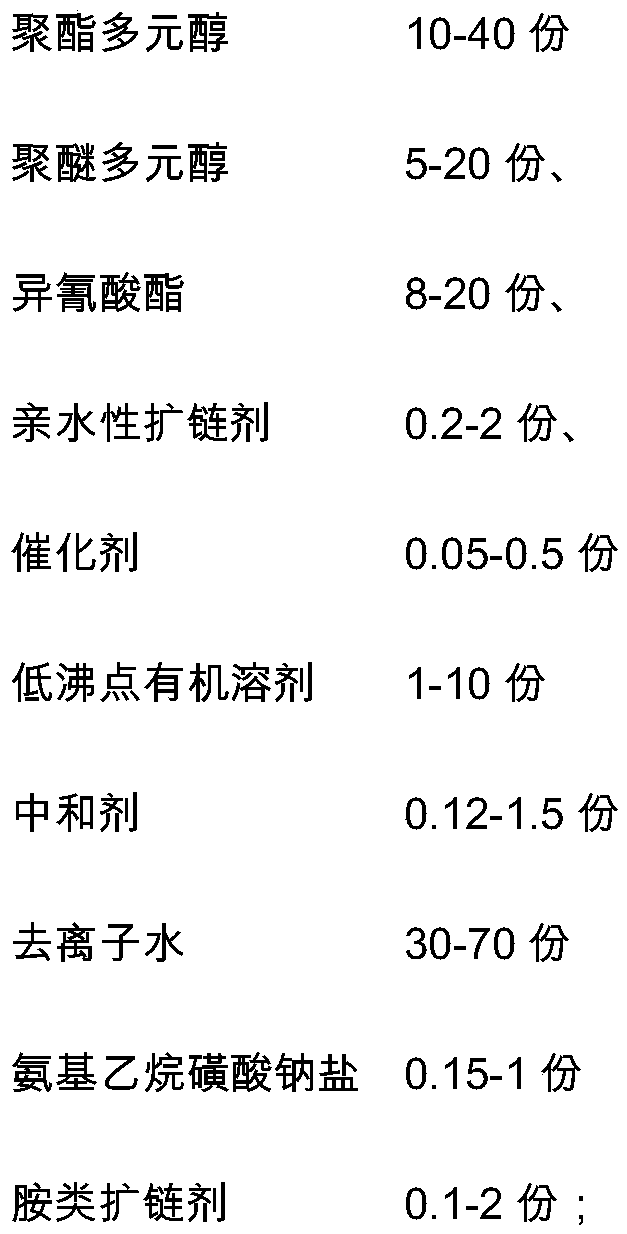

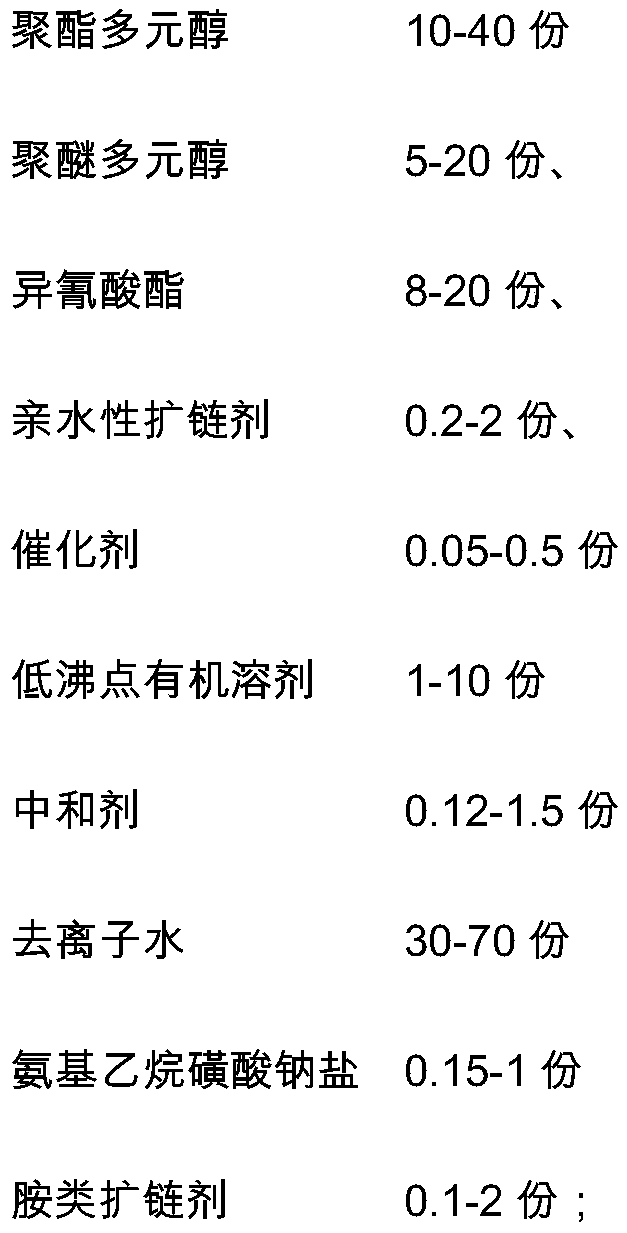

Waterborne polyurethane adhesive with high thermal activation temperature and preparation method thereof

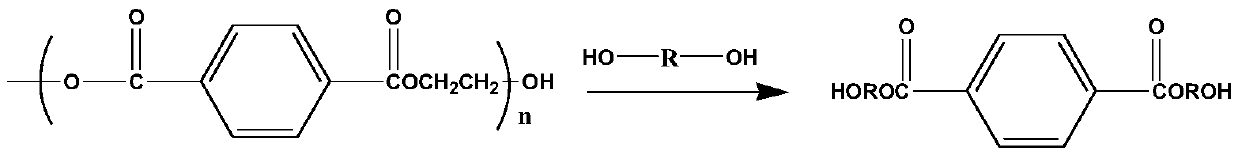

InactiveCN111334238AEnable recyclingSimple structurePolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses a waterborne polyurethane adhesive with high thermal activation temperature and a preparation method thereof, and belongs to the technical field of adhesives. The preparation method comprises the following steps: firstly, preparing an isocyanate-terminated polyurethane prepolymer by taking diisocyanate, polyester polyol, polyether polyol and a hydrophilic chain extender asraw materials; adding acetone to reduce viscosity, adjusting the pH value by using a neutralizer, slowly adding a proper amount of deionized water and sodium aminoethanesulfonate under high-speed shearing and stirring, slowly adding a chain extender diluted by water, and distilling off acetone under reduced pressure to obtain the waterborne polyurethane adhesive. The polyester polyol used in the method contains a chain structure of the aromatic polyester polyol prepared by recycling the waste PET packaging material, so that the production cost of the polyester polyol is reduced, and the waterborne polyurethane adhesive has relatively high thermal activation temperature, bonding strength and high-temperature resistance.

Owner:BEIJING HUATENG NEW MATERIAL CO LTD +1

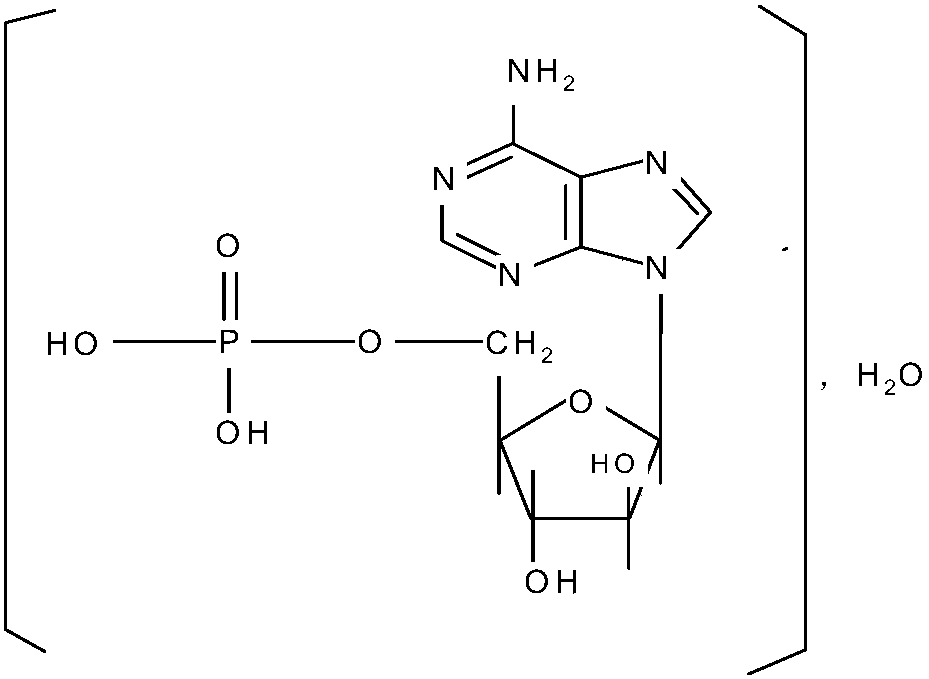

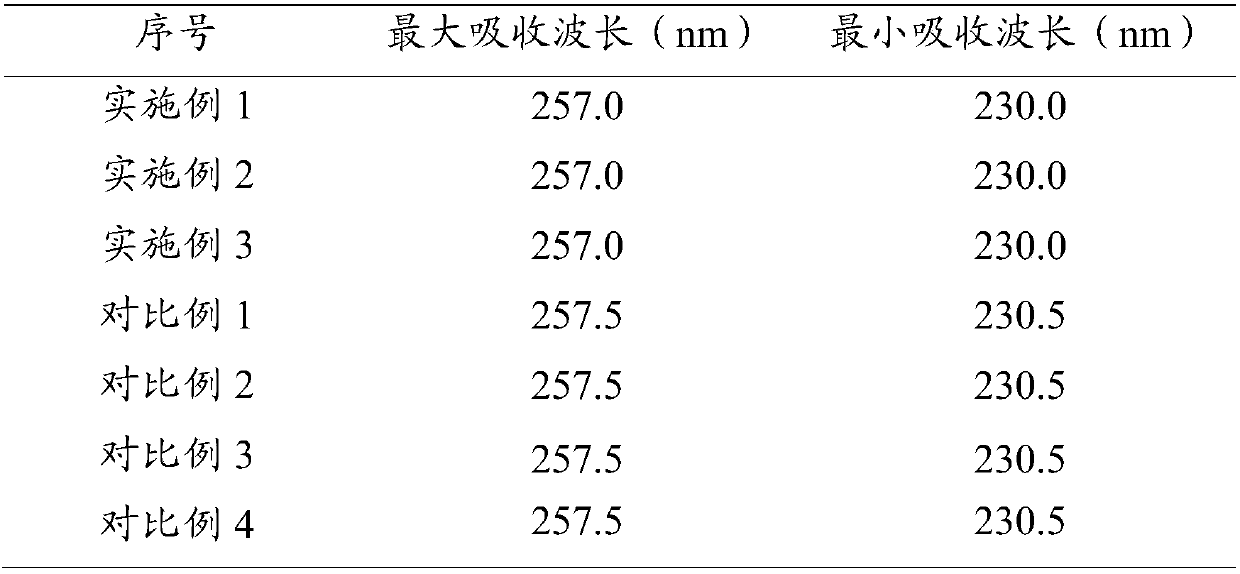

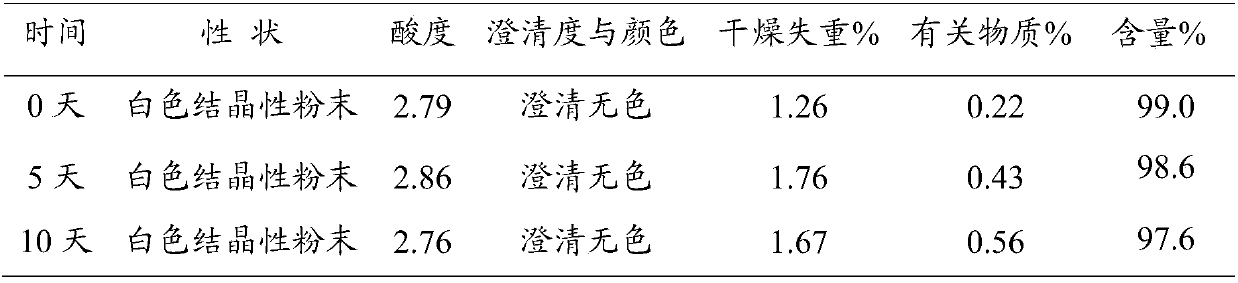

Preparation method of vidarabine monophasphate

ActiveCN107793458AReduce generationReduce production processSugar derivativesSugar derivatives preparationTwo stepSide reaction

The invention discloses a preparation method of vidarabine monophosphate. The preparation method comprises the following two steps: crude product synthesis and crude product refining. In a crude product synthesis stage, reaction conditions are controlled severely, side reaction and production of related substances are reduced effectively, and high percent conversion of a target product is ensured.Meanwhile, because most of side products of reaction are dissolved in the reaction system and the target product is not dissolved in the reaction system basically, aftertreatment is facilitated to improve the purity of the product. The method is simple in process, high in product yield, high in purity and high in reaction selectivity; any special equipment is not used during production; and the preparation method is suitable for industrial production.

Owner:HAINAN HULUWA PHARMA GRP CO LTD

Multilayer water-based coating and spraying method thereof

InactiveCN113234378AImprove interlayer bonding performanceImprove adhesionLiquid surface applicatorsPolyurea/polyurethane coatingsEpoxyPolymer science

The invention discloses a multilayer water-based coating and a spraying method thereof. The multilayer water-based coating comprises a primer, an intermediate paint and a finish paint; the component A of the primer takes water-based epoxy resin as matrix resin, the component B of the primer takes water-based polyamide resin as matrix resin, and the two components are subjected to a chemical reaction on the surface of a workpiece to form a primer layer; the intermediate paint takes waterborne polyurethane as matrix resin and is used for being sprayed and attached to the primer layer to form a connecting layer; and the component C of the finish paint takes water-based hydroxyl polyurethane as matrix resin, the component D of the finish paint takes water-based isocyanate as matrix resin, and the two components are subjected to chemical reaction on the connecting layer to form a protective layer. In the system, the primer has good adhesive force to both the metal material and the plastic material, and the intermediate paint has good interlayer binding force; and the finish paint increases the smoothness, wear resistance and elasticity of the surface, and in the whole spraying process, the drying temperature can be controlled to be not more than 80 DEG C and is below the temperature which can be borne by the plastic material.

Owner:万辉(广州)高新材料有限公司

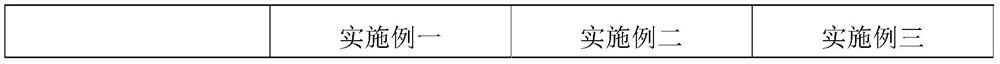

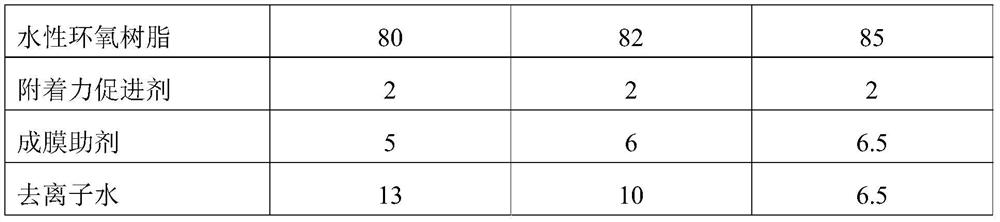

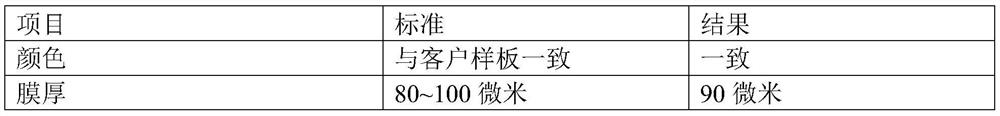

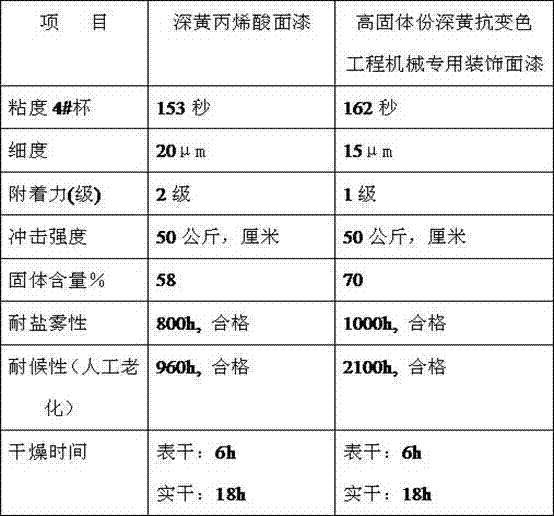

Environment-friendly waterborne epoxy resin emulsion and preparation method thereof

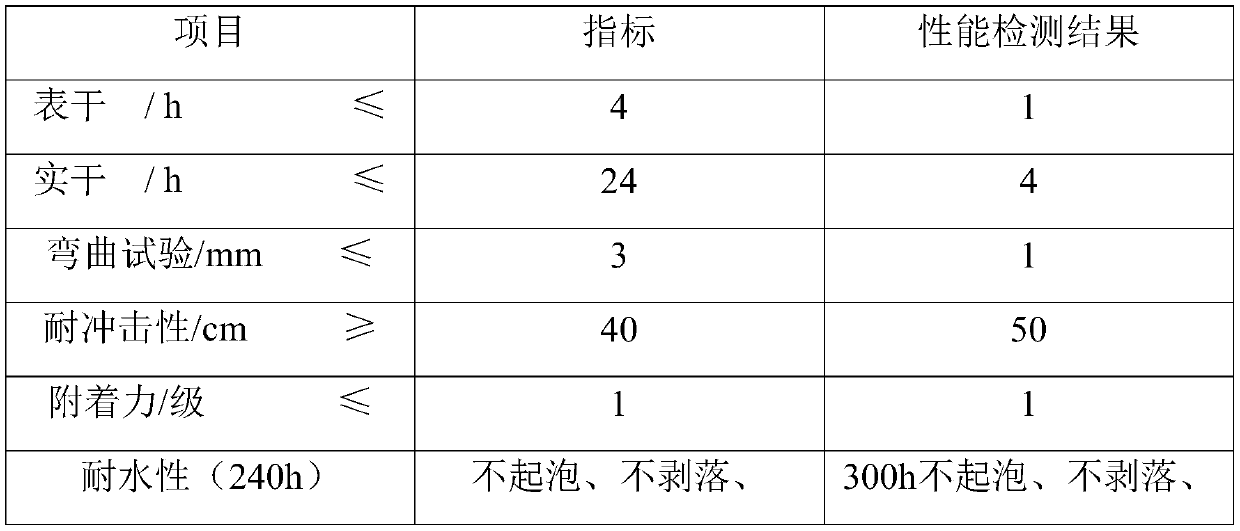

InactiveCN111040191ALow organic solvent contentConducive to friendly developmentEpoxy resin coatingsEpoxyPolymer science

The invention discloses a waterborne epoxy resin emulsion and a preparation method thereof. The preparation method comprises the following steps: heating and dispersing 50-55 wt% of epoxy resin, adding 0.5-1.6 wt% of an alcohol ether solvent and 5.5-6.5 wt% of a composite emulsifier, continuously dispersing, controlling the rotating speed, keeping the temperature, cooling, adding 38-42 wt% of water for phase inversion, and keeping the temperature; and cooling the product, and filtering to obtain the waterborne epoxy emulsion. The two-component room-temperature cured iron oxide red epoxy primerprepared from the waterborne epoxy resin emulsion is an environment-friendly waterborne epoxy anticorrosive coating, the impact resistance of the primer reaches 50 cm, the adhesive force of the primer reaches the first level, and the primer is resistant to water for 300 h and does not blister, peel off, rust or crack; salt fog resistance lasts for 400 h, and foaming, peeling, rusting and crackingare avoided; VOC content is less than or equal to 60 g / L. The waterborne epoxy resin emulsion prepared by the invention is a material with excellent performance.

Owner:陕西宝塔山油漆股份有限公司

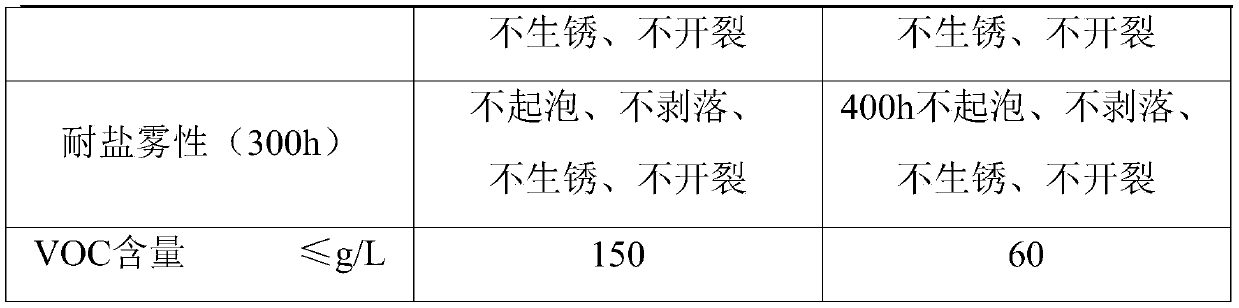

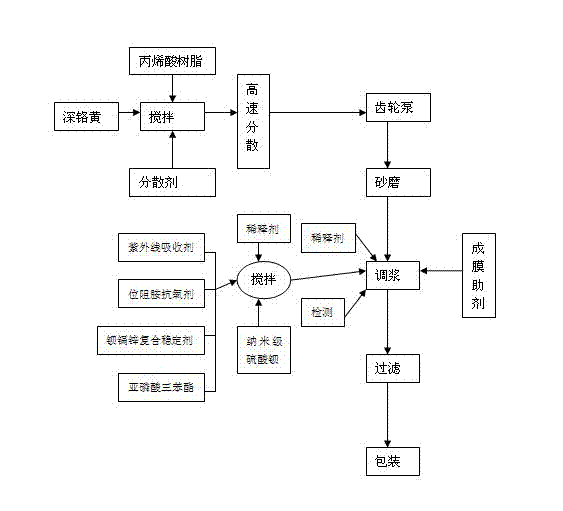

High-solid dark-yellow fastness decoration finish paint special for engineering machinery and preparation method thereof

InactiveCN102766381AThixotropicSolve the problems of easy discoloration and aging performanceCoatingsPolymer scienceZinc compounds

A high-solid dark-yellow fastness decoration finish paint special for engineering machinery is prepared from the raw materials by weight: 30-32% of dark chrome yellow, 0.8-1% of nanometer barium sulfate, 57-61.6% of 70% acrylic resin, 0.1-0.2% of ultraviolet absorber, 0.5-0.8% of hindered amine antioxidant, 1-1.5% of barium cadmium zinc compound stabilizer, 1-1.5% of triphenyl phosphite, 4-5% of diluent, 0.5% of dispersing agent and 0.5% of film formation auxiliary agent. The raw materials are stirred, dispersed and the like, and then filtered and packaged when viscosity achieves a standard. The high-solid dark-yellow fastness decoration finish paint has the following advantages that the technique of drying thermoplastic acrylic resin by volatilization to form a film is adopted, the ultraviolet absorber and the hindered amine antioxidant are used, the barium cadmium zinc compound stabilizer and the triphenyl phosphite antioxidant are matched for the first time in the paint industry, and simultaneously, a certain amount of nanometer barium sulfate is added, so that the problems that bright colors such as dark yellow are apt to change, aging performance exists and the like when the decoration finish paint is used outdoors are solved, and simultaneously the cost is substantially lowered.

Owner:湖南中汉高分子材料科技有限公司

Preparation technology of water-based PU (Polyurethane) glue substituting solvent type printing ink TPU (Thermoplastic Polyurethane)

The invention relates to a preparation technology of water-based PU (Polyurethane) glue substituting solvent type printing ink TPU (Thermoplastic Polyurethane). The technology is characterized by comprising the following steps: slowly stirring 24-30% of acrylic resin in a dispersion tank at normal temperature and pressure state, adding ammonium hydroxide for regulating the pH value to 7-8; sequentially feeding a polyurethane aqueous dispersion, propylene glycol monomethyl acetate, ethylene glycol butyl ether and the like into the dispersion tank, and continuously dispersing for one hour; after the dispersion is over, heating, continuously vacuumizing the tank through a vacuum pump, injecting cooling circulation water to the outer wall of the dispersion tank under the condition that the pressure in the tank is maintained at the negative pressure state of 0.8-1Pa, cooling the temperature to 50DEG C below, releasing the negative pressure in the tank to be normal pressure, filtering through a vacuum filtering machine, to obtain the printing ink TPU water-based PU glue. The product can be used as a printing ink in the ink printing technology of a TPU shoe material. Furthermore, no pollutant solvent is volatized in the process of drying shoe shell fabric using the water-based PU glue, and patterns are colorful.

Owner:SHISHI DECAI CHEM TECH

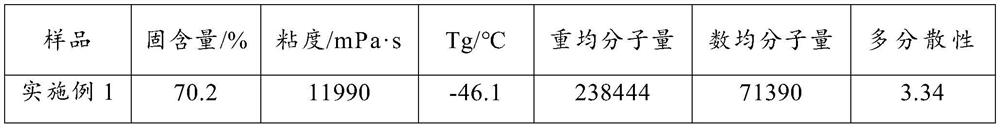

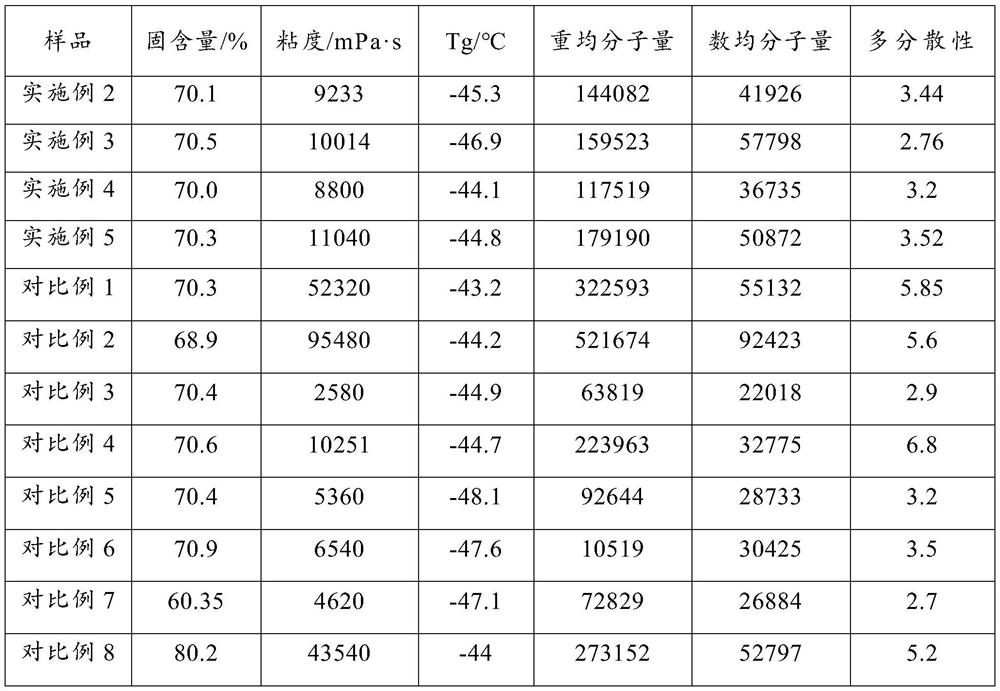

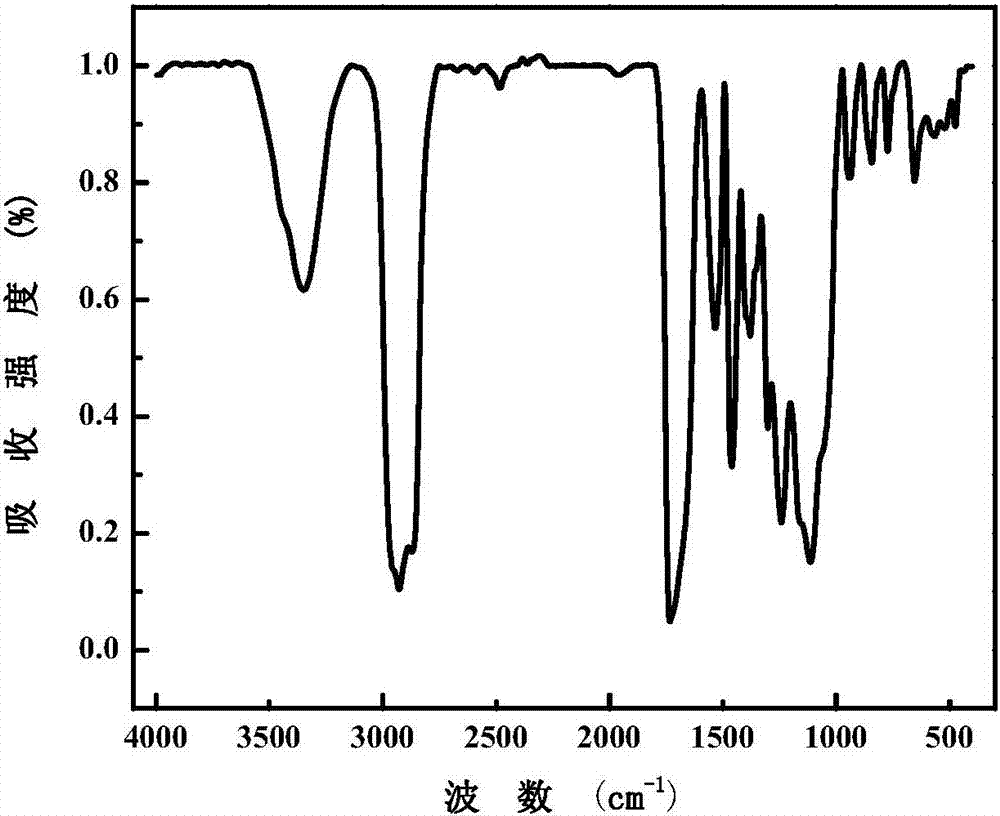

Acrylic acid adhesive with high solid content and low viscosity and preparation method thereof

ActiveCN114316854AImprove wettabilityImprove adhesionEster polymer adhesivesPolymer scienceFunctional monomer

The invention discloses an acrylic acid adhesive with high solid content and low viscosity and a preparation method thereof. The adhesive comprises the following components in parts by weight: 80-90 parts of a soft monomer, 1-10 parts of a hard monomer, 1-10 parts of a first functional monomer, 1-10 parts of a second functional monomer, 0.01-0.2 part of a free radical initiator, 0.01-0.5 part of a chain transfer agent and 25-35 parts of a solvent, the preparation method comprises the following steps: (1) adding a solvent into a dry container, heating and stirring the solvent, and introducing nitrogen until air in the container is exhausted; (2) in a nitrogen atmosphere, uniformly mixing a soft monomer, a hard monomer, a first functional monomer, a chain transfer agent and a first free radical initiator, and continuously dropwise adding the mixture into the container for reaction; and (3) adding a second functional monomer and a second free radical initiator into the container, and reacting to obtain the adhesive. According to the formula and the preparation method, the acrylic acid adhesive which is high in solid content, relatively low in viscosity, low in polydispersity and good in mechanical property is prepared.

Owner:CYBRID TECHNOLOGIES INC

Method for preparing water soluble epoxy insulated resin in alkaline medium

The invention provides a method for preparing water soluble epoxy insulated resin in alkaline medium, which is characterized in comprising the following steps: weighing the following materials by weight parts: epoxy resin 10-25, carboxy 7-15, acid anhydrides 2-8, polyhydric alcohol 10-25, organic amine 2-7, ether solvent 0-15, and deionized water 30-60; stirring and mixing the materials under protection of inert gas. The invention synthesizes water soluble epoxy insulated resin by chemical modification method, has the advantages of simple process, convenient operation, and no poisonous gases discharged in the synthesis process; the prepared water soluble resin is intermiscible with water in alkaline medium, has the advantages of homogeneous, transparent, high storage stability and high solidification speed cooperated with aqueous curing agent; and the condensate has the advantages of good insulating property, low shrinkage, good toughness, high mechanical strength and high heat resistance grade to F. The invention is suitable for the insulation treatment for all kinds of motors and coils, also can be used as base resin of metal baking vanish.

Owner:上海电动工具研究所(集团)有限公司

Water-dispersible light stabilizer and preparation method thereof

The invention discloses a water-dispersible light stabilizer and a preparation method thereof. According to the preparation method, monomers, solvents, catalysts, additives and neutralizers firstly react for 2-8h under the rotating speed of 80-300r / min at the temperature ranging from 50 DEG C to 150 DEG C to prepare waterborne resin pre-polymers, the prepared waterborne resin pre-polymers, light stabilizers, additives and water are uniformly stirred and mixed at the temperature ranging from 20 DEG C to 120 DEG C to prepare water-dispersible light stabilizer, the percentage of the weight of the light stabilizer to total weight is 50%-90%, samples are hermetically placed into a baking oven with the temperature ranging from 50 DEG C to 70 DEG C to store for 4-8 weeks in an accelerated manner and cannot layer, and the samples are dispersed into water to obtain milk-white uniform stable dispersion liquid. The preparation method is simple and easy to control, and the prepared samples are good in stability, wide in application range and easily dispersed into the water and have quite important values in application of waterborne product additives.

Owner:SOUTH CHINA UNIV OF TECH

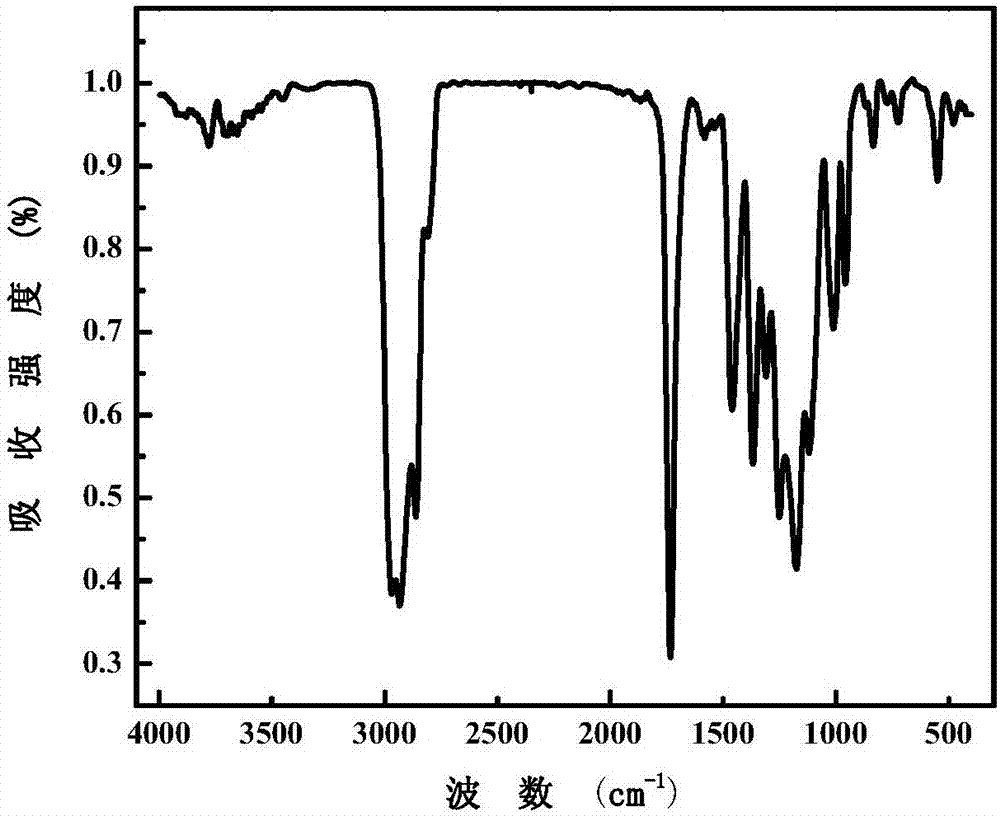

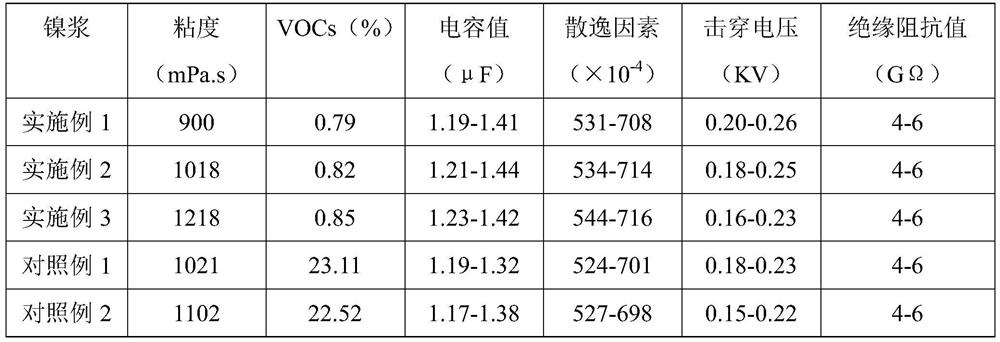

Water-based roll printing nickel paste special for MLCC and preparation method of water-based roll printing nickel paste

InactiveCN113436886ALow organic solvent contentFixed capacitor electrodesFixed capacitor dielectricAdhesiveFirming agent

The invention discloses water-based roller printing nickel paste special for an MLCC. The special roller printing nickel paste comprises the following raw materials in parts by weight: 5-18 parts of a water-soluble adhesive, 60-90 parts of a nickel dispersion liquid, 1-15 parts of an inorganic filler dispersion liquid, 1-5 parts of an auxiliary agent and 1-15 parts of a curing agent, the water-soluble adhesive is prepared from water-soluble resin and purified water in a ratio of 2:90 98; the nickel dispersion liquid is prepared from nickel powder and purified water according to the ratio of 80:15 20; and the inorganic filler dispersion liquid is prepared from inorganic filler and purified water in the ratio of 74:20 30. Compared with traditional MLCC nickel paste, the VOCs content is greatly reduced, other performance is equivalent to the performance of an MLCC prepared from the traditional nickel paste, and the capacitance value of the MLCC is increased through the prepared nickel paste.

Owner:佛山市顺德区百锐新电子材料有限公司

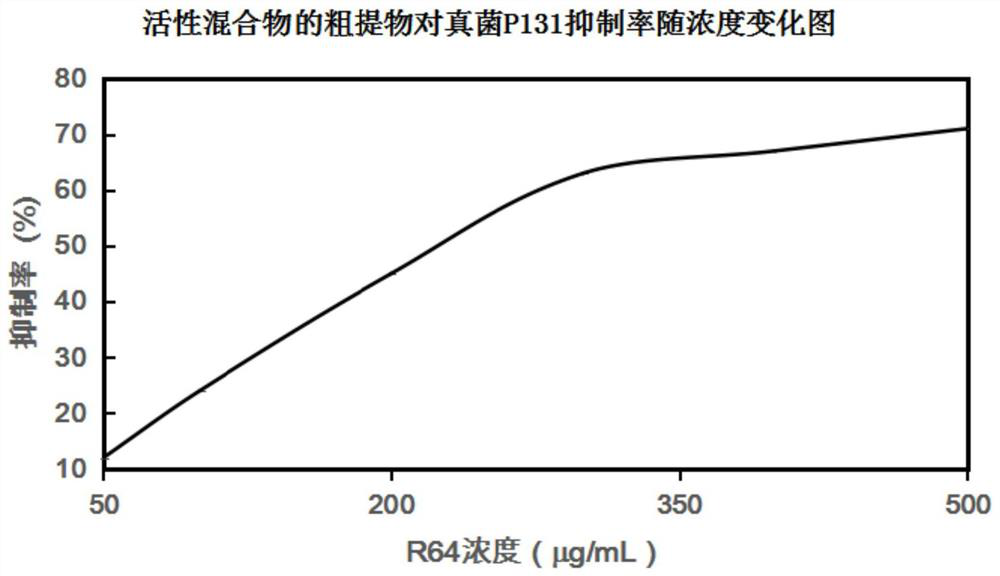

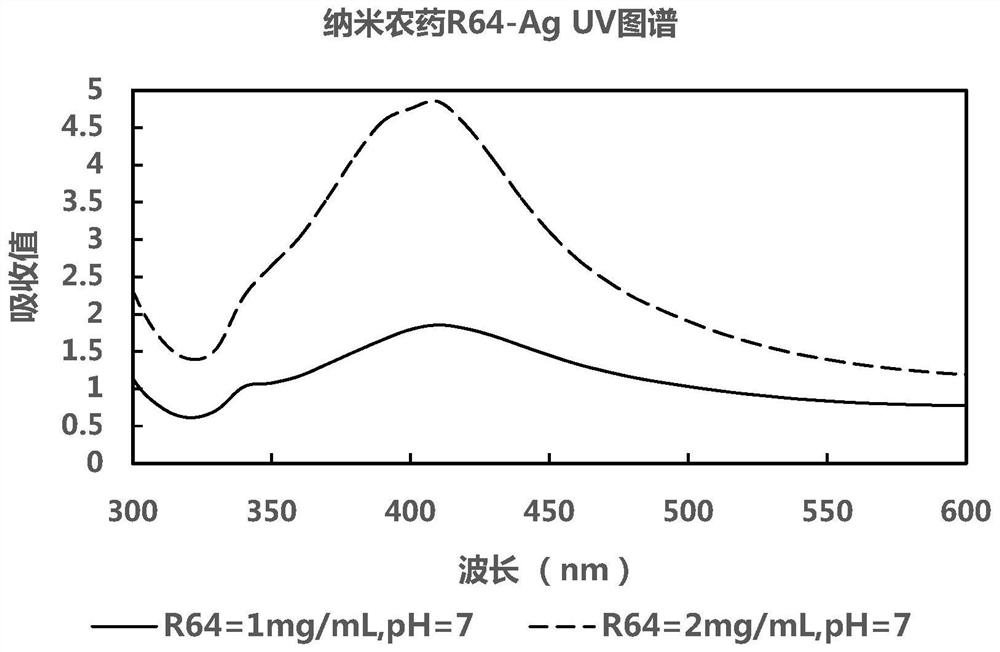

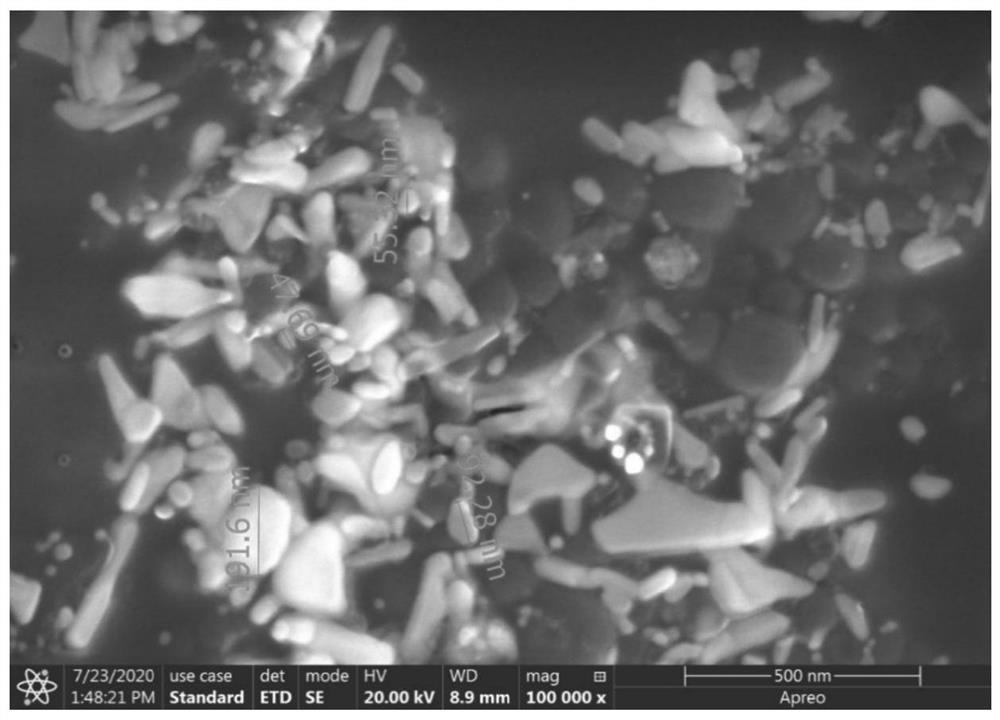

Bacterial strain, extract, nano-pesticide and application and preparation method of nano-pesticide

The invention discloses a bacterial strain, an extract, a nano-pesticide and application and a preparation method of the nano-pesticide. The bacterial strain is a bacterial strain R64 from mangrove forest, the bacterial strain R64 is classified and named as Pseudomonasaeruginosa, and the preservation number of the bacterial strain R64 is CGMCC No. 21803. The extract of the bacterial strain R64 extracted from the bacterial strain R64 and the nano pesticide synthesized by using the extract of the bacterial strain R64 have high antibacterial activity and high efficiency, and have low toxicity to environmental microorganisms. Meanwhile, the biological preparation method disclosed by the invention is low in cost, simple to operate and relatively environment-friendly. The invention provides a novel natural product pesticide, and meanwhile, the environmental toxicity of the natural product pesticide is reduced and the antibacterial activity and high efficiency of the natural product pesticide are improved through a method for preparing the nano pesticide.

Owner:SHENZHEN UNIV

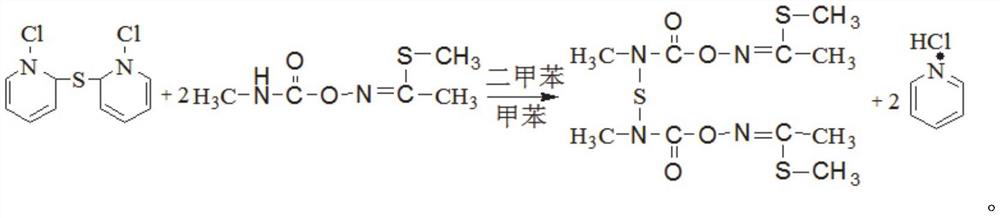

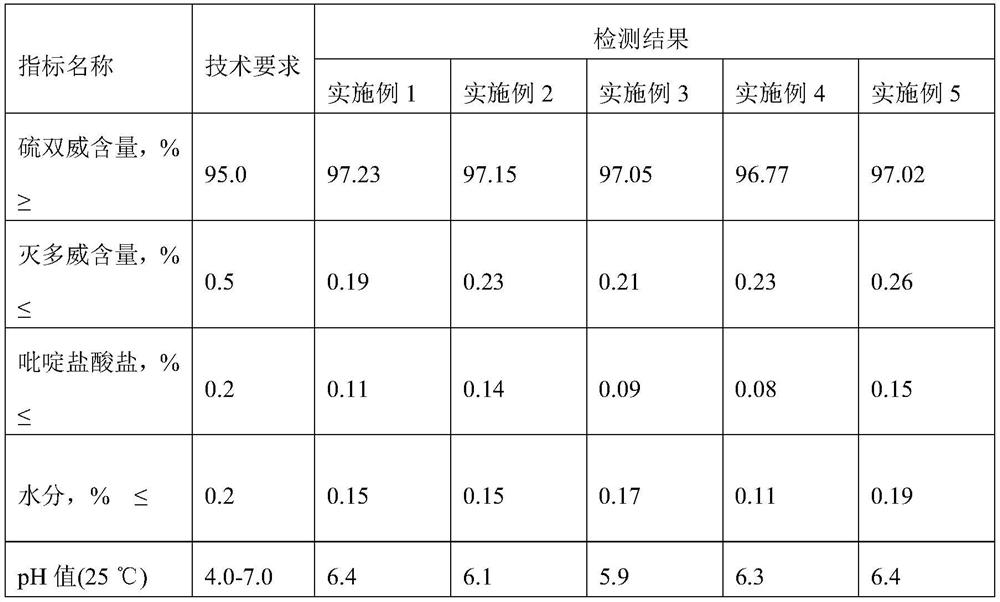

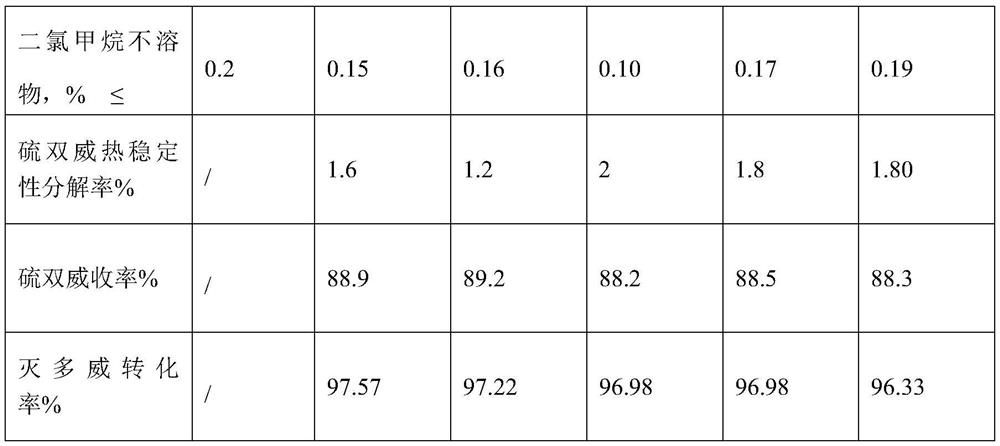

Method for synthesizing thiodicarb with high methomyl conversion rate

The invention relates to a thiodicarb synthesis method with high methomyl conversion rate. The method comprises the following steps: adopting xylene and toluene as solvents; reaction: when the temperature in the synthesis kettle is reduced to be lower than 0 DEG C, starting to dropwise add SCl2, after the SCl2 is dropwise added, adding methomyl into the synthesis kettle, introducing nitrogen into the kettle, heating, and reacting; after the reaction is finished, centrifuging to obtain centrifugate and a centrifugal filter cake; primary water washing and filter pressing; carrying out secondary washing and centrifugation; washing with methanol, and centrifuging; and carrying out vacuum drying on a filter cake obtained by centrifuging the methanol washing material to obtain a thiodicarb finished product. According to the synthesis method provided by the invention, when the intermediate thiobipyridine hydrochloride is synthesized, a toluene and xylene double-component solvent is adopted, pyridine is used as a raw material and a solvent, and the reasonable material ratio avoids the influence on the reaction process of pyridine and sulfur dichloride due to overhigh solid material concentration in a reaction system; the yield of the thiobipyridine hydrochloride and the conversion rate of methomyl in the subsequent reaction between the thiobipyridine hydrochloride and methomyl are improved.

Owner:SHANDONG FIRST MEDICAL UNIV & SHANDONG ACADEMY OF MEDICAL SCI

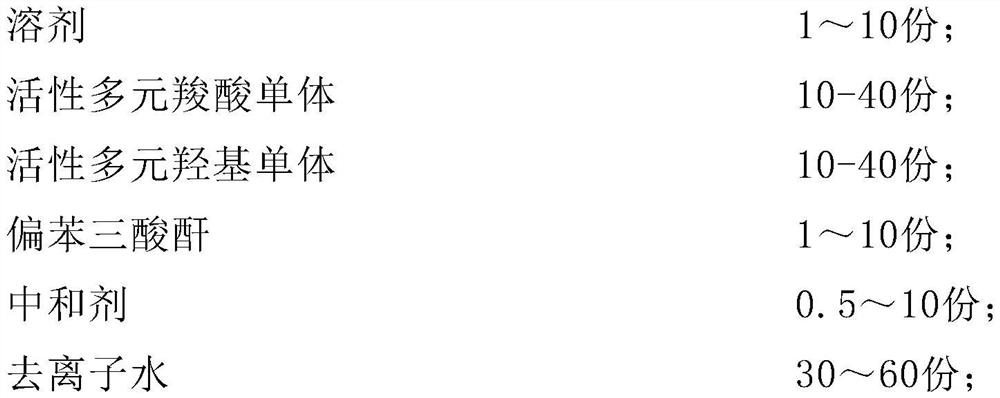

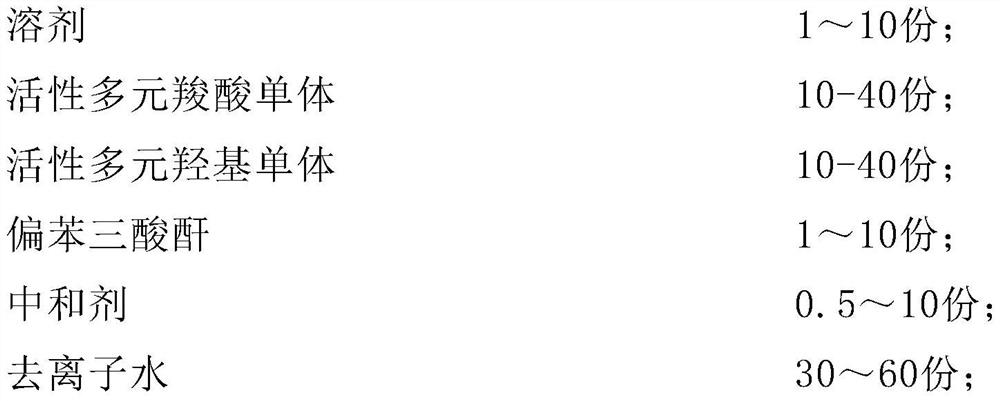

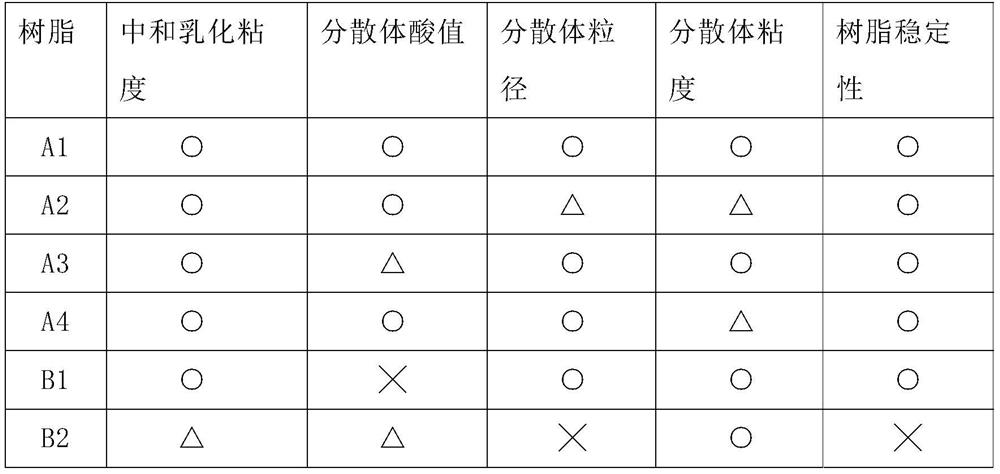

Water-based hydroxyl-containing polyester dispersion for automobile paint and preparation method thereof

The invention discloses water-based hydroxyl-containing polyester dispersion resin for top coating in automobile paint, which is characterized by being prepared from the following six parts: 1 to 10 parts of a solvent, 10 to 40 parts of active polybasic carboxylic acid monomer, 10 to 40 parts of an active polybasic hydroxyl monomer, 1 to 10 parts of trimellitic anhydride, 0.5 to 10 parts of a neutralizer and 30 to 60 parts of deionized water. The invention also discloses a preparation method of the water-based hydroxyl-containing polyester dispersion resin. The preparation method comprises thefollowing steps: reacting polycarboxylic acid with polyol to synthesize polyester resin with hydroxyl, adding trimellitic anhydride to provide hydrophilicity, adding a neutralizer to neutralize, andemulsifying and dispersing with water to obtain the water-based hydroxyl-containing polyester dispersion resin. The water-based hydroxyl-containing polyester dispersion provided by the invention is good in resin stability, low in organic solvent content and very suitable for matrix resin of water-based automobile paint, and the prepared water-based automobile paint is good in appearance and excellent in storage stability.

Owner:上海金力泰化工股份有限公司

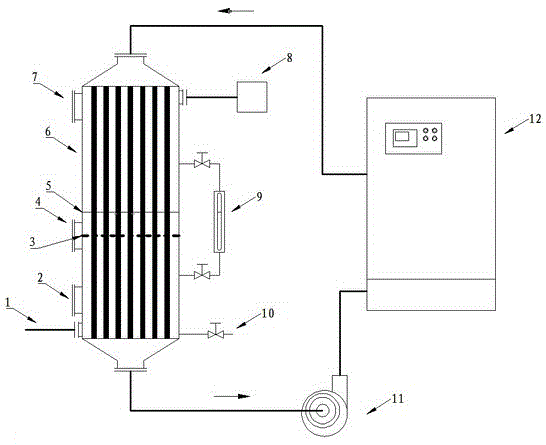

Exhaust gas freezing recovery treatment device

ActiveCN103463832BLow organic solvent contentIncrease heat transfer areaVapor condensationOrganic solventEvaporation

The invention discloses a tail gas refrigeration recycling processing device which comprises a heat exchanger. A heat preservation layer covers the surface of the heat exchanger, a plurality of heat exchange nest tubes are arranged in the heat exchanger, the heat exchange nest tubes, a cold water machine and a cold water pump form a circulation system, the temperature of liquid in a tube pass of the heat exchange nest tubes can be set from minus 10 DEG C to plus 10 DEG C, a shell pass of the heat exchange nest tubes is filled with a padding ring with the certain height and an organic solvent, the padding ring is used for dispersing gas, and the liquid level of the organic solvent is slightly higher than the height of the padding ring. A tail gas inlet tube and a valve for discharging the organic solvent are arranged on the circumference of the bottom of the heat exchanger, and the circumference of the top of the heat exchanger is connected with a vacuum pump. The tail gas refrigeration recycling processing device is simple in structure, high in practicability, capable of recycling more than 90% of the organic solvent in the tail gas and wide in application prospect. Evaporation energy consumption of the organic solvent is saved by more than 30%.

Owner:铜陵市海林管理咨询有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com