Waterborne polyurethane adhesive with high thermal activation temperature and preparation method thereof

A water-based polyurethane, activation temperature technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of poor high temperature resistance, low initial adhesion, etc., to improve mechanical properties, high thermal activation temperature , the effect of low organic solvent content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046]

[0047]

[0048] The water in the last two aqueous solutions can be added to the deionized water.

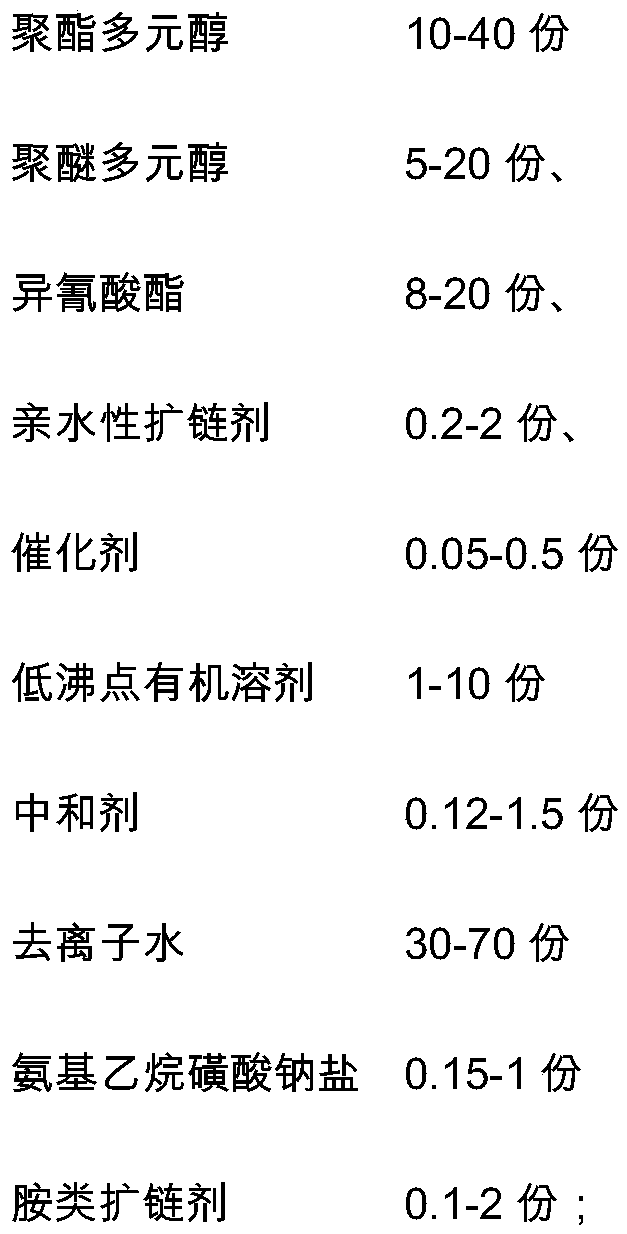

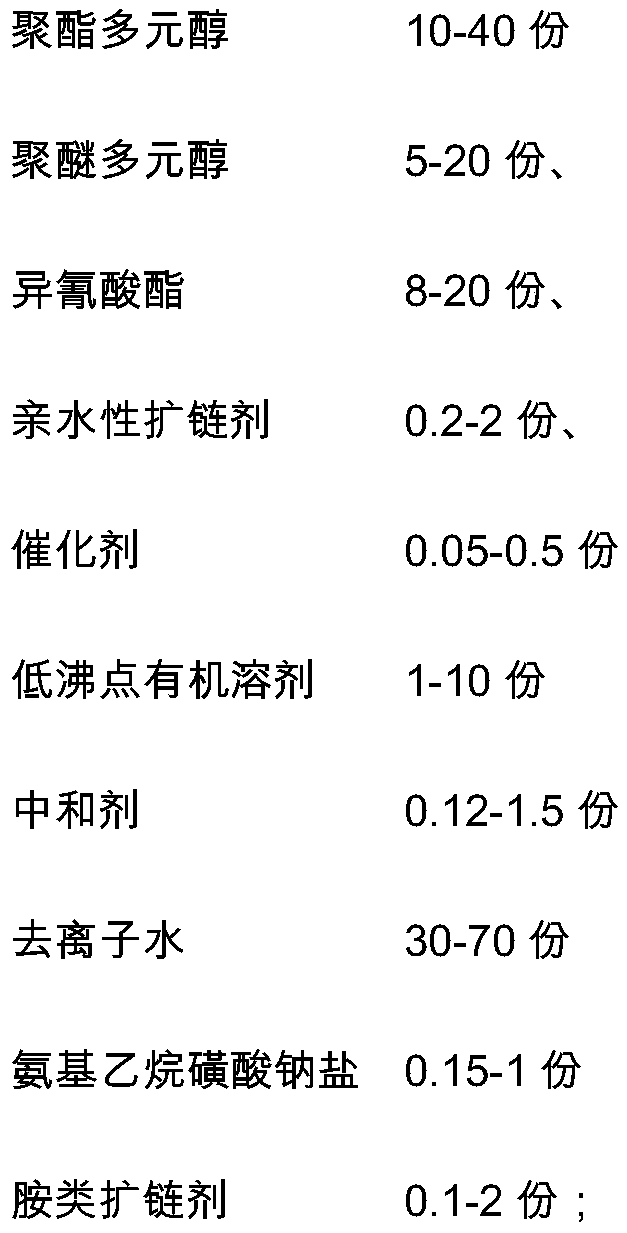

[0049] Mix ethylene terephthalate-based polyester polyol and polypropylene oxide diol, and vacuum dehydrate at 120°C for 3 hours; (2) Cool down to 50°C, add HDI, IPDI, dimethylol Propionic acid and dibutyltin dilaurate were reacted at 80°C for 2.0h to obtain a polyurethane prepolymer; (3) cooling down to 40°C, adding acetone to adjust the viscosity of the system, and adding triethylamine to neutralize the reaction for 10min; (4 ) adding deionized water and aminoethanesulfonic acid sodium salt into the reaction vessel, stirring rapidly until the system is evenly dispersed, then adding ethylenediamine diluted with deionized water, and emulsifying and extending the chain for 1.0 h at a rotational speed of 1500r / min; (5) At 50°C, acetone was removed by vacuum distillation to obtain a water-based polyurethane adhesive.

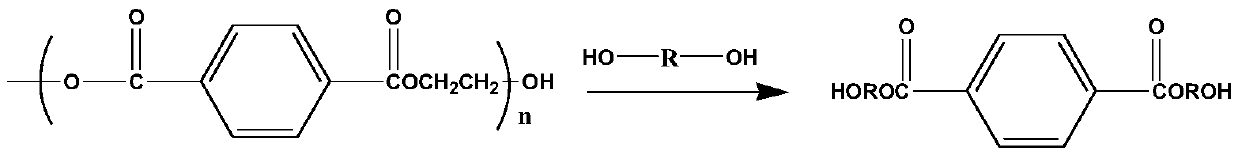

[0050] Wherein, the above-mentioned ethylene terep...

Embodiment 2

[0054]

[0055] The water in the last two aqueous solutions can be added to the deionized water.

[0056] Mix diethylene glycol terephthalate-based polyester polyol and polyoxypropylene glycol, and vacuum dehydrate at 125°C for 3 hours; (2) Cool down to 50°C, add HDI, IPDI, dimethylol Propionic acid and dibutyltin dilaurate were reacted at 80°C for 2.0h to obtain a polyurethane prepolymer; (3) cooling down to 40°C, adding acetone to adjust the viscosity of the system, and adding triethylamine to neutralize the reaction for 10min; (4 ) adding deionized water and aminoethanesulfonic acid sodium salt into the reaction vessel, stirring rapidly until the system is evenly dispersed, then adding ethylenediamine diluted with deionized water, and emulsifying and extending the chain for 1.0 h at a rotational speed of 1600r / min; (5) At 50°C, acetone was removed by vacuum distillation to obtain a water-based polyurethane adhesive.

[0057] Wherein, above-mentioned diethylene glycol te...

Embodiment 3

[0061]

[0062]

[0063] The water in the last two aqueous solutions can be added to the deionized water.

[0064] Mix propylene terephthalate-based polyester polyol, polypropylene oxide diol and polytetrahydrofuran diol, and dehydrate under vacuum for 3 hours at 130°C; (2) cool down to 50°C, add HDI, IPDI, dimethylolpropionic acid and dibutyltin dilaurate were reacted at 85°C for 2.0h to obtain a polyurethane prepolymer; (3) Cool down to 40°C, add acetone to adjust the viscosity of the system, and add triethylamine and react for 10 minutes; (4) add deionized water and aminoethanesulfonate sodium salt to the reaction vessel, stir rapidly until the system is uniformly dispersed, then add ethylenediamine diluted with deionized water, and under the condition of rotating speed 1800r / min Emulsification and chain extension for 1.0 h; (5) At 50°C, acetone was removed by vacuum distillation to obtain a water-based polyurethane adhesive.

[0065] Wherein, the above-mentioned pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com