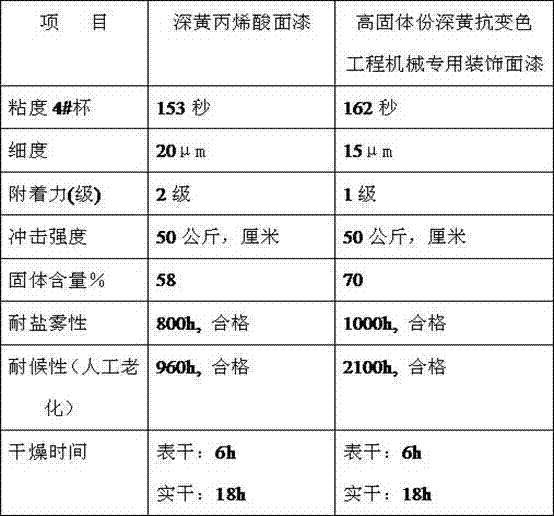

High-solid dark-yellow fastness decoration finish paint special for engineering machinery and preparation method thereof

A kind of construction machinery and anti-tarnish technology, applied in the direction of coating, etc., can solve the problems of impermanence, easy to change color, loss of light, etc., and achieve the effects of reducing cost, enhancing adhesion, and reducing organic solvent content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

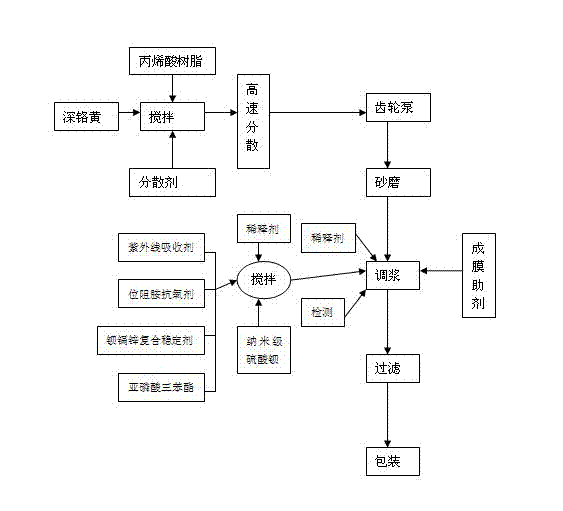

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1: (1), by weight percentage of raw materials: dark chrome yellow 30-32%, nano barium sulfate 0.8-1%, 70% acrylic resin 57-61.6%, ultraviolet absorber 0.1-0.2%, hindered amine resistance Oxygen agent 0.5-0.8%, barium cadmium zinc composite stabilizer 1-1.5%, triphenyl phosphite 1-1.5%, diluent 4-5%, dispersant 0.5%, film-forming aid 0.5%; Add the agent into the mixing tank, under high-speed stirring, add nano barium sulfate, stir for 10-20 minutes to make it into a gel, and then gradually add ultraviolet absorber, barium cadmium zinc composite stabilizer, hindered amine antioxidant, sub Triphenyl phosphate, after stirring evenly, store for later use;

[0013] (2) According to the weight percentage of raw materials, add 70% acrylic resin, a film-forming material, into the batching barrel, add dark chrome yellow and dispersant under stirring, and after stirring evenly and thoroughly, discharge the material and disperse it to the scraper through a sander After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com