Patents

Literature

177results about How to "Thixotropic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Clean carbon dioxide foam fracturing fluid and preparation method thereof

ActiveCN104531129AFine foamImprove foam stabilityDrilling compositionPotassium persulfatePolymer science

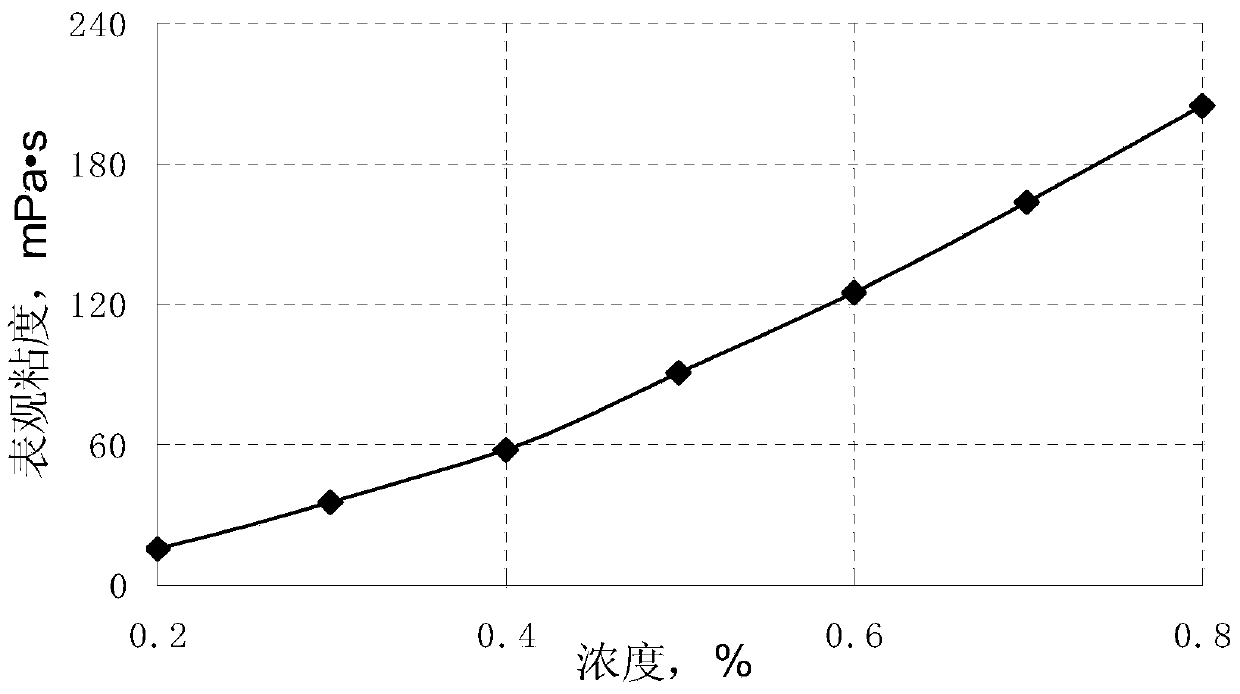

The invention discloses clean carbon dioxide foam fracturing fluid and a preparation method thereof, and relates to the technical field of oilfield chemistry and fracturing production increase. The carbon dioxide foam fracturing fluid is mainly composed of a base solution, a foaming agent, a gel breaker and liquid carbon dioxide with the mass ratio being 100 to 0.15-0.45 to 0.02-0.08 to 100-900. The base solution is formed by 0.2%-0.55% of a thickening agent and water. The thickening agent is mainly formed by bisacrylamide, vinyl pyrrolidone, kation unsaturated monomer, anion unsaturated monomer, an initiator, sodium carbonate, an emulsifying agent and a hydrotropy agent. The foaming agent is mainly formed by hexadecyl dimethyl tertiary amine, dimethyl sulfate, caustic soda flakes, potassium persulfate and solvent. The clean carbon dioxide foam fracturing fluid has the advantages of being high in foam stability, high in temperature resistance and shear resistance, high in sand-carrying performance, wide in applicable temperature range, extremely low in residue content, high in backflow performance, and small in secondary damage to a reservoir after fracturing, thereby improving the fracturing effect and increasing the reservoir productivity.

Owner:CHENGDU BAICHUN PETROLEUM TECH

Geopolymer composite material for 3D printing and preparation method and application thereof

ActiveCN106082898ASave energyEnvironmentally friendlyAdditive manufacturing apparatusSolid waste managementAdditive ingredientSlag

A geopolymer composite material for 3D printing and a preparation method and application thereof are disclosed. The geopolymer composite material comprises the following ingredients (by weight): 20-25% of water-quenched granulated blast furnace slag powder, 10-15% of ground steel slag, 0-5% of fly ash, 33-45% of tailings machine-made sand, 3-5% of a composite activator, 2.5-3% of a high-molecular polymer, 1-3% of a volume stabilizer, 1-2% of a thixotropic agent, 0.05-0.1% of an antifoaming agent and 13.9-12.45% of mixing water. The above ingredients are fully and uniformly stirred and then the mixture is subsequently pumped into a 3D printer for construction. The geopolymer composite material has good caking property, strong stability and has good pump-out morphology maintaining capability and bond property. Printed buildings have good morphology and volume stability, and houses and buildings have good overall stability and use security.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Environment-friendly and decorative nail-free glue and preparation method thereof

ActiveCN103484043AReduce contentNo pollution in the processMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesElastomerPolymer science

The invention belongs to environment-friendly and decorative glue, particularly relates to environment-friendly and decorative nail-free glue and a preparation method thereof. The environment-friendly and decorative nail-free glue comprises the following components: 5.0 to 20.0 percent of rubber elastomers, 10.0 to 30.0 percent of tackifying resin, 15.0 to 35.0 percent of reinforcing fillers, 2.0 to 8.0 percent of a thixotropic agent, 10.0 to 40.0 percent of a solvent and 0.1 to 1.0 percent of anti-oxidant; the preparation method of the environment-friendly and decorative nail-free glue comprises the following steps: putting the solvent into a high-speed stirrer, sequentially adding the rubber elastomers and the tackifying resin after a stirrer is started, stirring for 2 to 8 hours until all materials are dissolved to be a uniform liquid, then slowly adding the enhancing fillers and stirring uniformly so as to prepare a flowable slurry mixture, then adding the thixotropic agent and the anti-oxidant, and stirring uniformly so as to prepare the environment-friendly and decorative nail-free glue. The environment-friendly and decorative glue provided by the invention is environmental-friendly, is convenient to use, has high product bonding intensity and is excellent in durability.

Owner:GLEIHOW NEW MATERIALS CO LTD

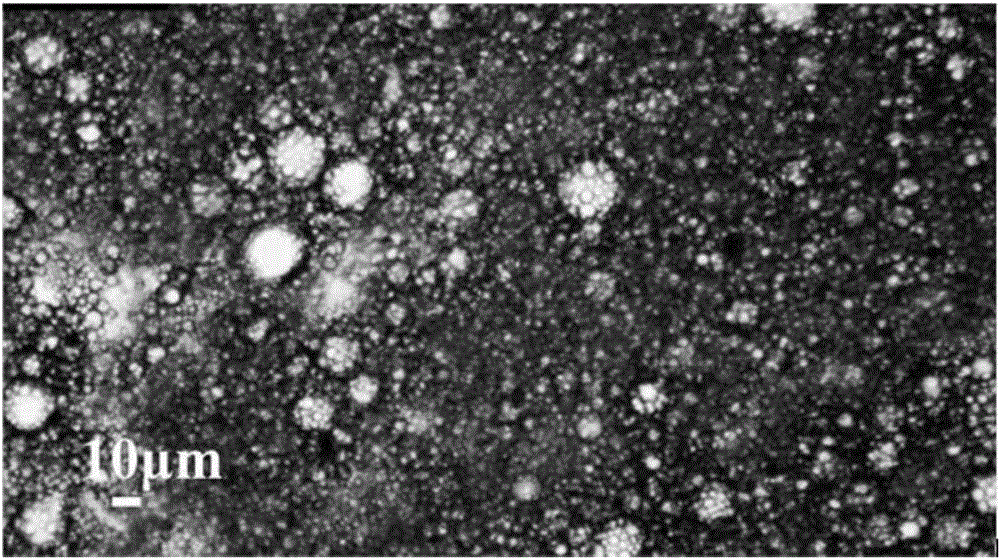

Precursor suspension of lyotropic liquid crystal and preparation method thereof

ActiveCN103040741AHigh viscosityHigh strengthSolution deliveryEmulsion deliveryOrganic solventUltimate tensile strength

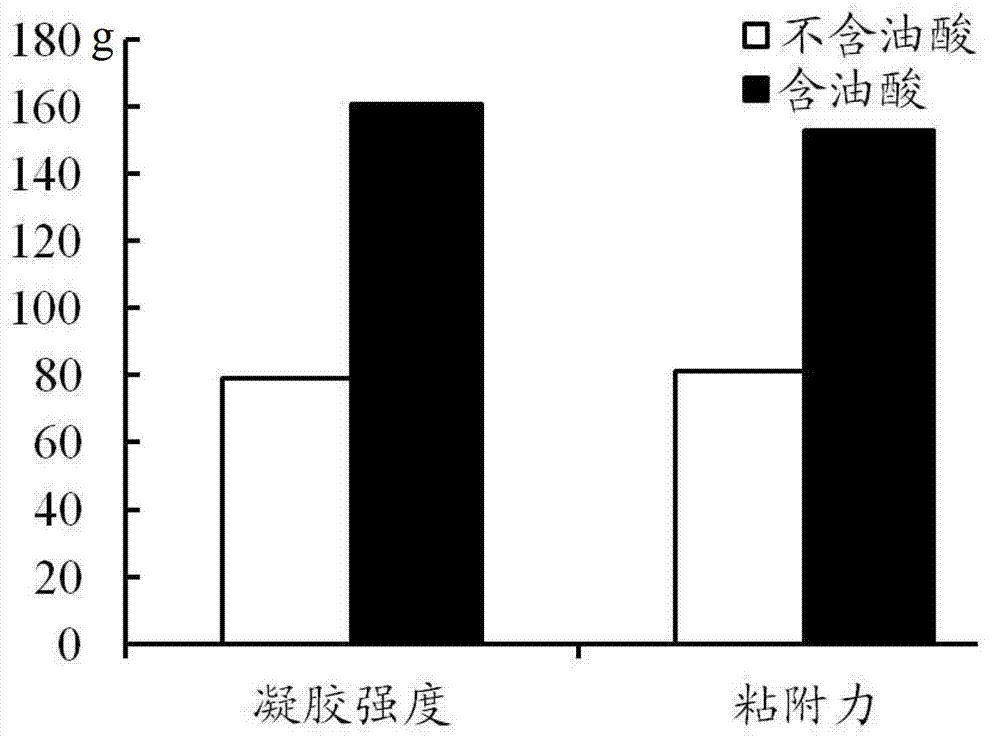

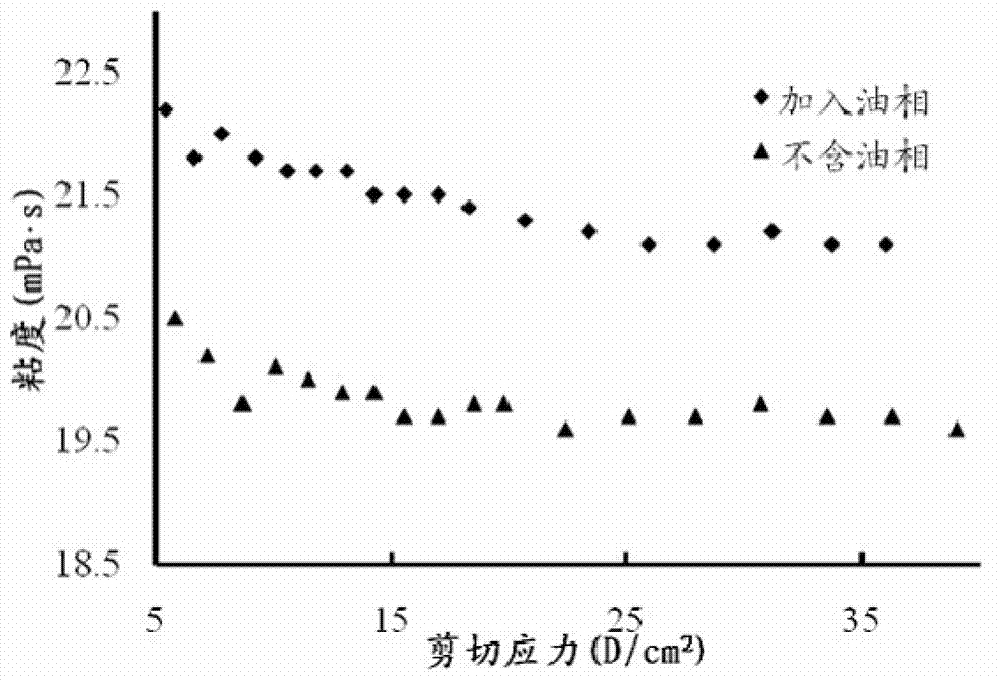

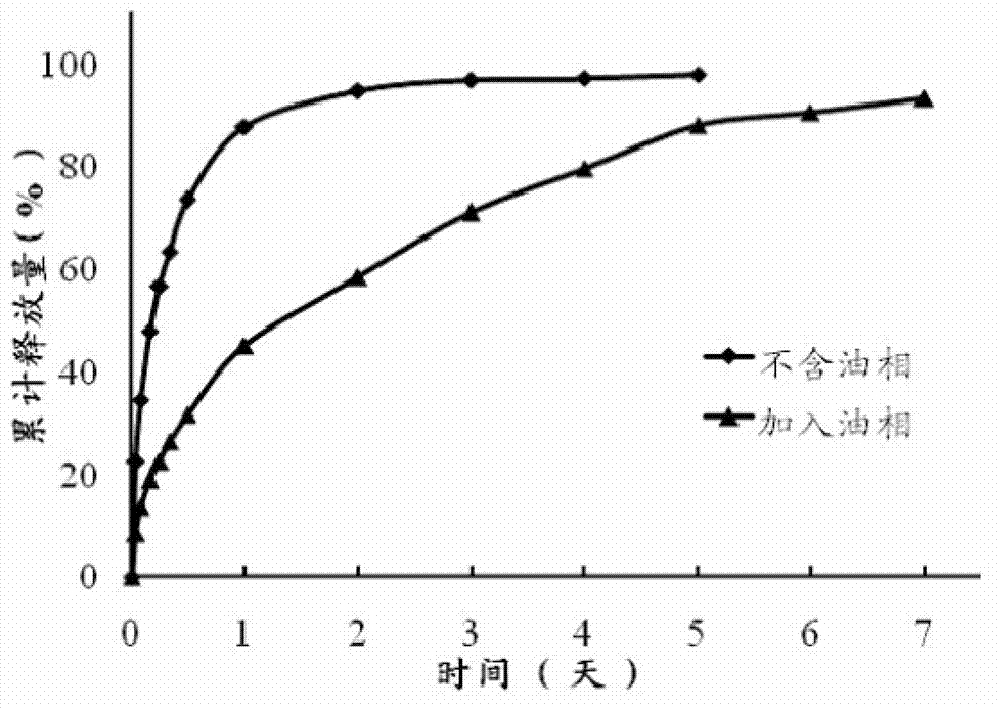

The invention discloses a precursor suspension of a lyotropic liquid crystal. The precursor suspension comprises lyotropic liquid crystal material, organic solvent, oil phase and a drug, wherein the weight percentage of the oil phase in the precursor suspension is 2-50 percent, the weight percentage of the drug in the precursor suspension is 1-30 percent, and the weight ratio of the lyotropic liquid crystal material and the organic solvent in the precursor suspension is 2-9:1. According to the invention, through the adding of the oil phase into the precursor suspension, the stability of the suspension is improved, the sedimentation rate is reduced, and the strength and the adhesive force of the gel formed are enhanced at the same time; the gel formed in the body is more liable to stay at a lesion location and less liable to be relocated and the shape is less liable to be damaged by the mechanical motion of the body, so that the drug therapy can be located effectively; and the preparation technology is simple and the precursor suspension of the lyotropic liquid crystal is a partial slow-release drug delivering system provided with a favorable perspective.

Owner:GUANGZHOU NEWORLD PHARMA CO LTD

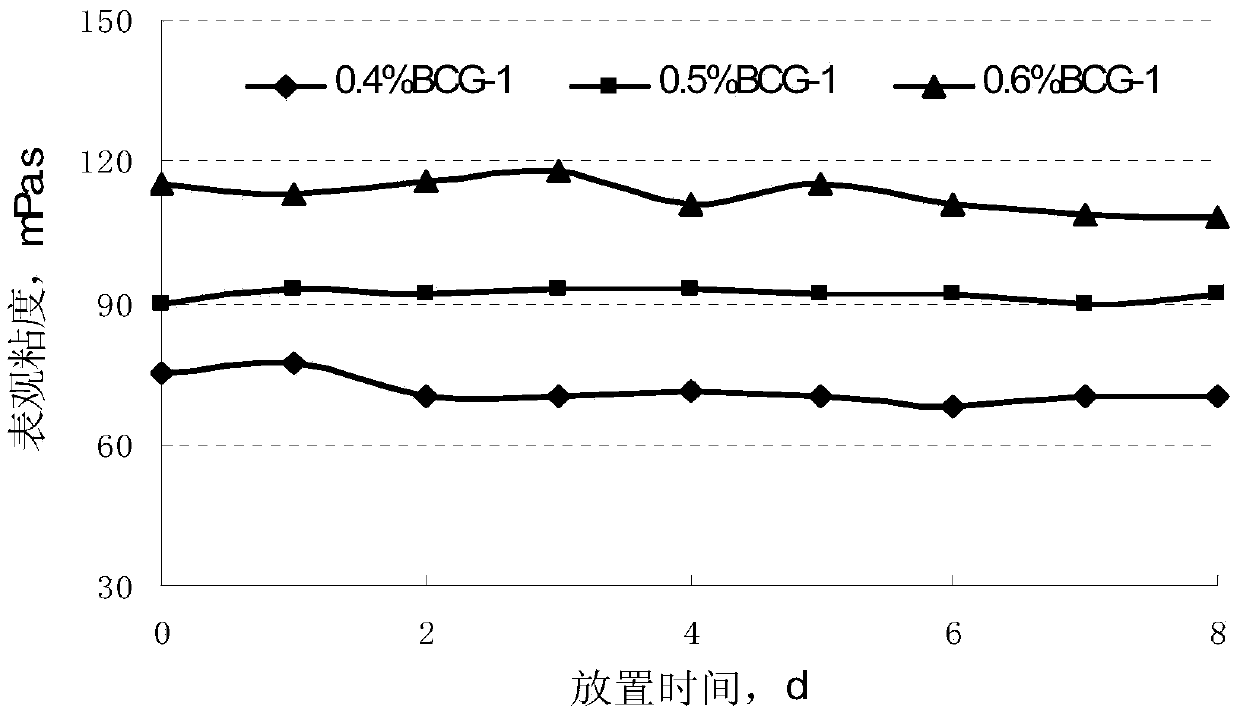

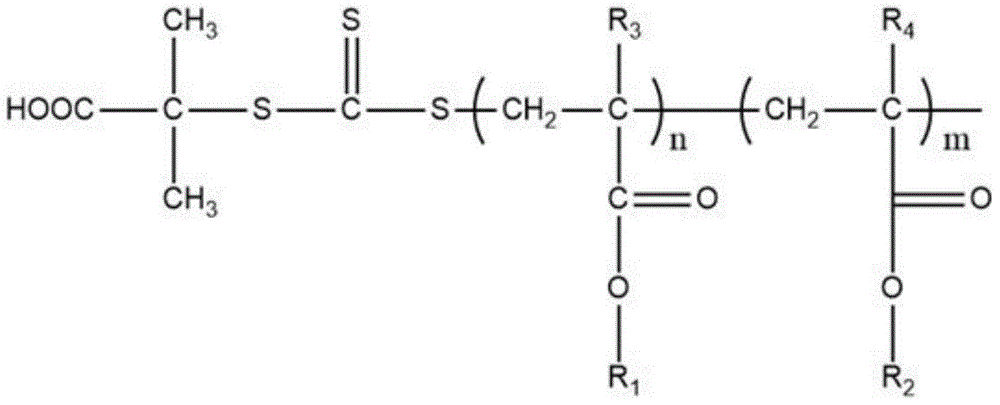

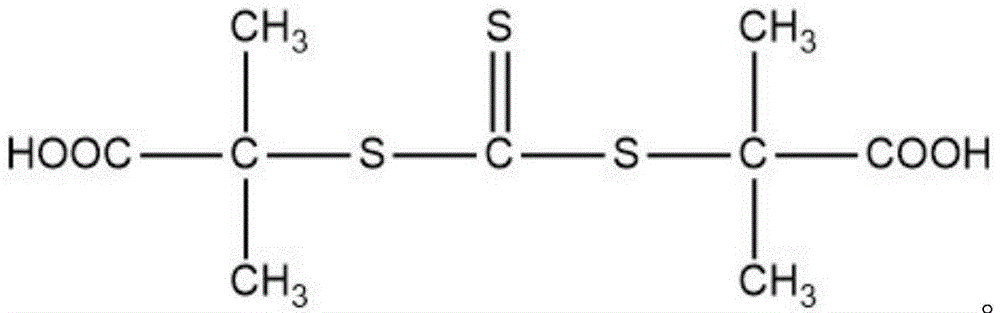

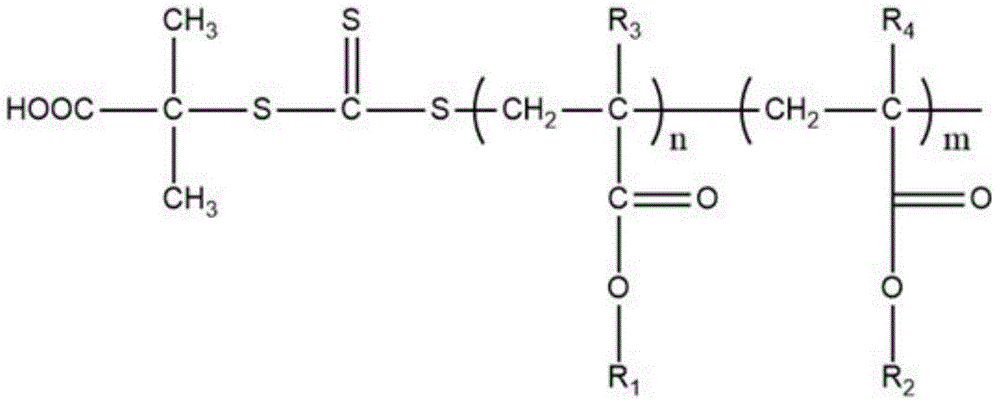

Cross-linkable high-temperature-resistant residue-free polybasic copolymerizable fracturing fluid and preparation method thereof

ActiveCN104178102AHigh apparent viscosityImprove structural strengthDrilling compositionCross-linkPolymer science

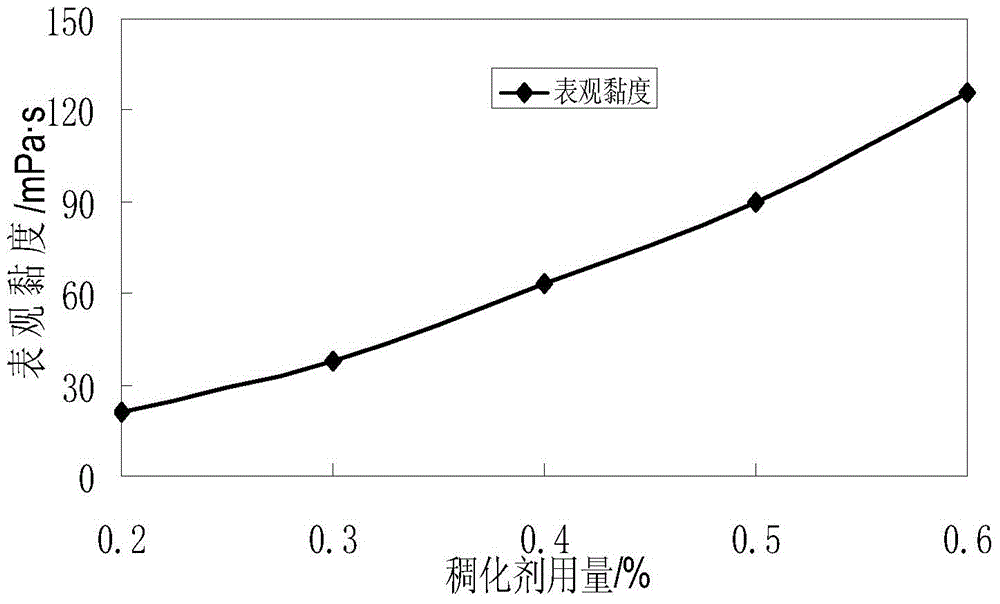

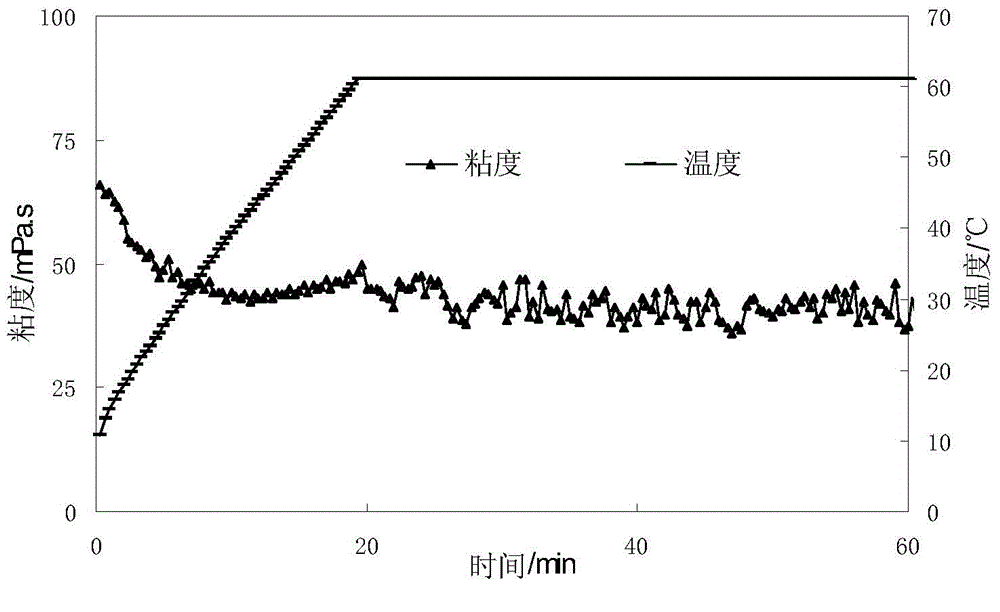

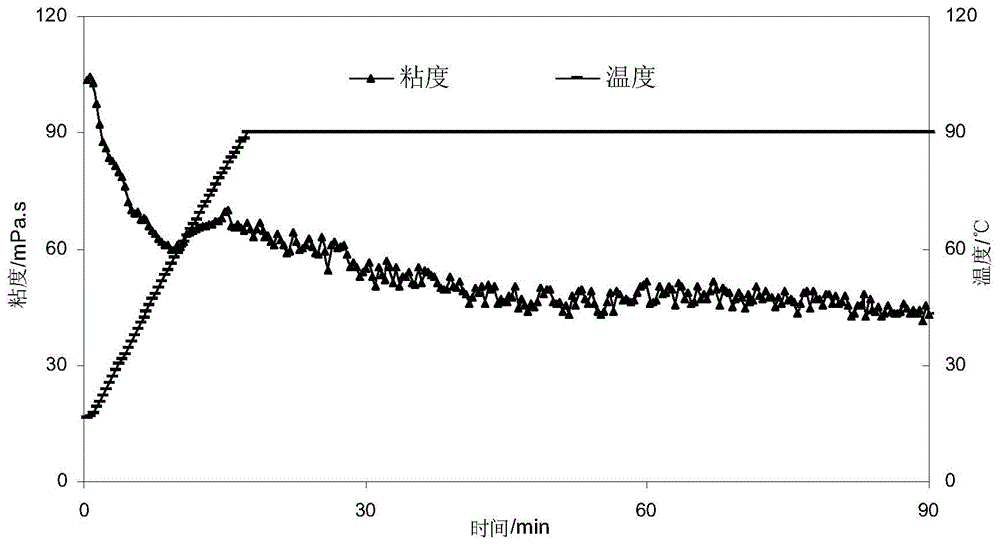

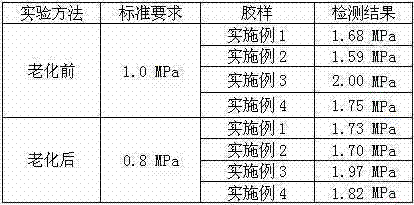

The invention discloses a cross-linkable high-temperature-resistant residue-free polybasic copolymerizable fracturing fluid and a preparation method thereof. The preparation method comprises the following steps of (1) preparing a thickener for the fracturing fluid; (2) preparing a cross-linking agent for the fracturing fluid; (3) preparing a gel breaker for the fracturing fluid and (4) preparing the cross-linkable high-temperature-resistant residue-free polybasic copolymerizable fracturing fluid. The fracturing fluid prepared by adopting the preparation method has the characteristics of excellent viscoelasticity, temperature resistance and shear resistance, sand-carrying performance and wide applicable temperature range; the fracturing fluid can well meet the requirement on the fracturing construction, and the content of the residue is very low; after the fracturing, the secondary harm to a reservoir is small and thus the fracturing effect is improved and the production capacity of the reservoir is increased.

Owner:CHENGDU BAICHUN PETROLEUM TECH

Low-fat health-care chicken meat balls prepared from complex hydrophilic gel and chicken skin instead of fat and method thereof

The invention provides a method for preparing low-fat health-care chicken meat balls prepared from combinational hydrophilic gel and chicken skin instead of fats, which belongs to the technical field of poultry deep processing. The method takes chicken meat and mixed fat as main raw materials, and MTGase, the complex hydrophilic gel, compound phosphate, and soy isolated protein as auxiliary materials. The preparation procedure comprises: pickling, enzyme liquid pretreatment, hydrophilic gel pretreatment, chopping and mixing, forming, reaction, and boiling. The method has simple production process, wide raw materials and low cost, and solves the problem of quality reduction caused by low fat. Meanwhile, based on the low-fat chicken meat balls, the method can also develop series of low-fat health-care chicken meat ball products with various tastes and nutritions.

Owner:FUZHOU UNIV

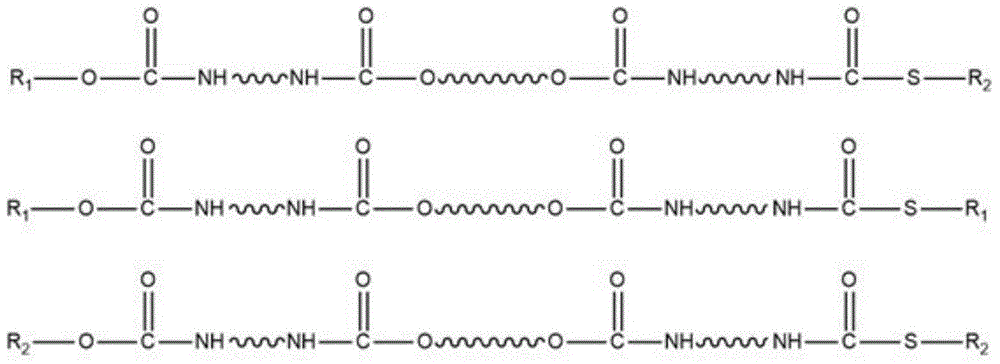

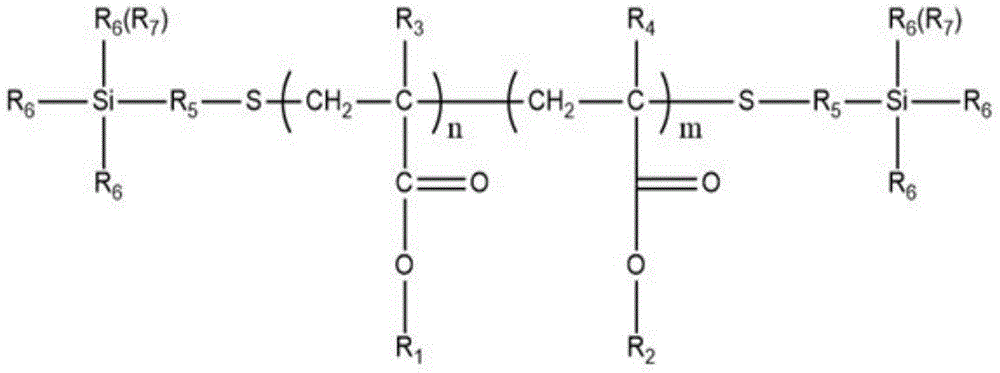

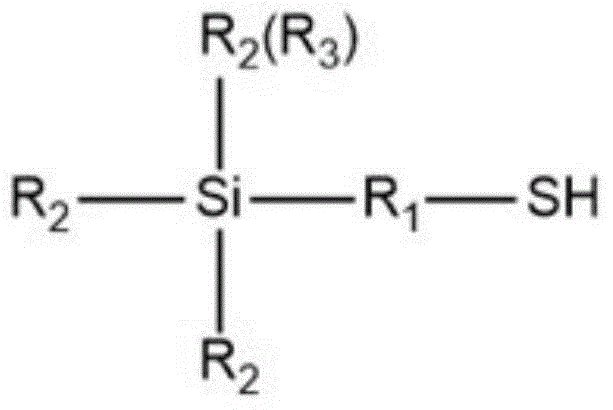

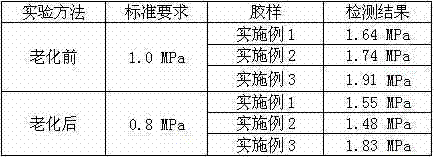

UV curing liquid optical cement and preparation method and application thereof

ActiveCN105985749AThere will be no glue overflow problemModerate bond strengthPolyureas/polyurethane adhesivesEster polymer adhesivesUV curingOligomer

The invention discloses UV curing liquid optical cement. The UV curing liquid optical cement is prepared from, by weight, 20-70 parts of active oligomer, 10-50 parts of tackifying resin, 10-40 parts of reactive diluent, 0.3-5 parts of photoinitiator and 1-5 parts of additive. The tackifying resin has a unique molecular structural formula. A preparation method of the UV curing liquid optical cement comprises the steps that the active oligomer, the tackifying resin, the reactive diluent, the photoinitiator and the additive are placed in a planetary vacuum mixer and are stirred and mixed to be uniform, and a finished product is obtained through filtering and defoaming. The problem of cement overflow that common liquid optical cement cannot overcome and the problem that the common liquid optical cement is not suitable for the special lamination process of UV precuring, lamination and UV curing for cement overflow prevention are solved, a cement film formed by the UV curing liquid optical cement has moderate bonding strength and a good locating effect, the bonding strength is greatly improved after UV curing is carried out again, the surface of the cement film is very smooth, a certain edge shape is kept, and no edge collapse phenomenon occurs; the UV curing liquid optical cement is suitable for automatic equipment coating and especially suitable for full lamination of modules.

Owner:DONGGUAN POWERBOND NEW MATERIALS TECH DEV

Novel chicken block taking hydrophilic compound gel and soybean protein as functional auxiliary materials and preparation method thereof

The invention provides a novel chicken block taking hydrophilic compound gel and soybean protein as functional auxiliary materials, which belongs to the technical field of deep processing of poultry. The novel chicken block taking the hydrophilic compound gel and the soybean protein as the functional auxiliary materials takes chicken and chicken skin as main raw materials; and the auxiliary materials comprise transglutaminase, hydrophilic compound gel, composite phosphate and soybean protein isolate. Preparation working procedures comprise pickling, the pre-treatment of enzyme solution, the pretreatment of hydrophilic gel, cutting and mixing, molding, reaction, rebaking, tabletting, battering and breading, and frying. The novel chicken block has the advantages of simple production technology, broad raw materials and low cost, and overcomes the disadvantage of the quality of products produced by chicken raw materials. At the same time, serial chicken block products with various tastes and various nutritions can also be developed based on the novel chicken block.

Owner:FUZHOU UNIV

Low-fat health care chicken sausage prepared by utilizing compound hydrophilic gel and chicken skin to substitute fat and method thereof

The invention provides a low-fat health care chicken sausage prepared by utilizing compound hydrophilic gel and chicken skin to substitute fat and a method thereof, which belong to the technical field of deep processing of poultry. The low-fat health care chicken sausage prepared by utilizing the compound hydrophilic gel and the chicken skin to substitute the fat is characterized in that the chicken sausage takes chicken and the chicken skin as main raw materials; and auxiliary materials comprise transglutaminase, hydrophilic compound gel, composite phosphate and soybean protein isolate. Preparation working procedures comprise pickling, the pre-treatment of enzyme solution, the pretreatment of hydrophilic gel, cutting and mixing, enema exhaust, reaction, drying and boiling. The chicken sausage has the advantages of simple production technology, broad raw materials and low cost, and overcomes the disadvantage of the decrease of the quality caused by low fat. At the same time, serial low-fat health care chicken sausage products with various tastes and various nutritions can also be developed based on the low-fat chicken sausage.

Owner:FUZHOU UNIV

Low-fat mayonnaise

The invention discloses a preparation method of low-fat mayonnaise. The low-fat mayonnaise is prepared from following mixed raw materials: egg yolk, vegetable oil, a food thickening agent, a flavoring agent and a preservative, and is characterized in that the mixed raw materials also comprise micro-nano wheat bran cellulose suspension liquid with a solid content of 1-5%, wherein the adding amount of the micro-nano wheat bran cellulose suspension liquid is 9-40% of the total mass of the mixed raw materials; the adding amount of the vegetable oil is 39-70% of the total mass of the mixed raw materials. The low-fat mayonnaise is more suitable for people with hyperlipidemia or obesity; a gel network structure formed by the combined action of the micro-nano wheat bran cellulose and the thickening agent in the components can slow down the movement of oil droplets so as to enable the whole system to be more stable; the micro-nano wheat bran cellulose also can further improve the stability of the system by means of weak flocculation thereof and a filling effect for an oil-water interface, thus being more beneficial to long-term storage and flavor maintenance. The low-fat mayonnaise has a weak gel structure, has thixotropy and is better in viscoelasticity, thus being finer and smoother as well as tastier and more refreshing when being eaten.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

UV-moisture dual-curing liquid optical cement and preparation method and application thereof

ActiveCN105985750ARealize the function of dual curingReduce consumptionPolyureas/polyurethane adhesivesEster polymer adhesivesUV curingReactive diluent

The invention discloses UV-moisture dual-curing liquid optical cement. The UV-moisture dual-curing liquid optical cement is prepared from, by weight, 45-80 parts of UV moisture curing matrix resin, 10-50 parts of tackifying resin, 10-35 parts of reactive diluents, 0.3-5 parts of photoinitiator and 1-5 parts of additive. The matrix resin and the tackifying resin have unique molecular structures. The invention further provides a preparation method of the UV-moisture dual-curing liquid optical cement. The preparation method comprises the following steps that the matrix resin and the tackfying resin are prepared; then all the materials are placed in a planetary vacuum mixer and are stirred and mixed to be uniform, and the finished product is obtained through filtering and defoaming. The problem of cement overflow that common liquid optical cement cannot overcome and the problem that the common liquid optical cement is not suitable for the special lamination process of UV precuring, lamination and moisture curing for cement overflow prevention are solved, a cement film formed by the UV-moisture dual-curing liquid optical cement after primary UV curing has moderate bonding strength and a good locating effect, the bonding strength is greatly improved after moisture curing, the surface of the cement film is very smooth, a certain edge shape is kept, no edge collapse phenomenon occurs, and the UV-moisture dual-curing liquid optical cement is suitable for automatic equipment coating.

Owner:DONGGUAN POWERBOND NEW MATERIALS TECH DEV

Double-component epoxy structural adhesive and preparation method thereof

InactiveCN102408861AThixotropicImpact resistantNon-macromolecular adhesive additivesEpoxy resin adhesivesGlass fiberPolymer science

The invention provides a double-component epoxy structural adhesive and a preparation method thereof. The structural adhesive is prepared from a component A and a component B in a weight ratio of 1:1, wherein the component A comprises 100 parts by weight of modified bisphenol A epoxy resin and 40-100 parts by weight of active filler; and the component B comprises 30-40 parts by weight of modified fatty amine, 10-25 parts by weight of toughener, 1.5-5 parts by weight of coupling agent and 75-140 parts by weight of thixotropic filler. The double-component epoxy structural adhesive is curable at normal temperature, can be cured quickly at moderate temperature, and can be completely cured at 80 DEG C within 1 hour or at 100 DEG C within half an hour. The adhesive has thixotropy, and the adhesive liquid does not flow when being cured at normal temperature and raised temperature; and the double-component epoxy structural adhesive has the advantages of shock resistance, vibration resistance and high bonding strength, and has favorable effects on bonding glass fiber reinforced plastics, steel, aluminum and other metal profiles.

Owner:BEIJING QINGDA SUNKIST NEW MATERIAL TECH

Environment-friendly nail-free glue for construction and preparation method thereof

ActiveCN103484040AReduce contentNo pollution in the processMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPolymer sciencePolyvinyl acetate

The invention belongs to environment-friendly glue for construction, and particularly relates to environment-friendly nail-free glue for construction and a preparation method thereof. The nail-free glue comprises the following compositions: 12.0-40.0% of polyvinyl acetate resin, 18.0-40.0% of reinforcing filler, 15.0-40.0% of a solvent, 0.5-8.0% of a thixotropic agent, 0.1-3.5% of a coupling agent, 0.1-5.0% of a plasticizer, and 0.1-0.5% of a dispersing agent. The preparation method comprises the following steps: adding the solvent into a homogenizer, starting the homogenizer, then adding the polyvinyl acetate resin, stirring for 1-3 hours until all the materials are dissolved into a transparent and uniform liquid, further, adding the plasticizer, the coupling agent and the dispersing agent, uniformly stirring, then slowly adding the reinforcing filler, uniformly stirring to prepare a flowing pulpy mixture, then adding the thixotropic agent, and uniformly stirring to prepare the environment-friendly nail-free glue for construction. According to the invention, the environment is protected, the construction is convenient, no nail-holes are bonded, the bonding strength is high, and the ageing resistance is excellent.

Owner:GLEIHOW NEW MATERIALS CO LTD

Preparation method for special precipitated calcium carbonate for PVC (polyvinyl chloride) stone chip resistant coating

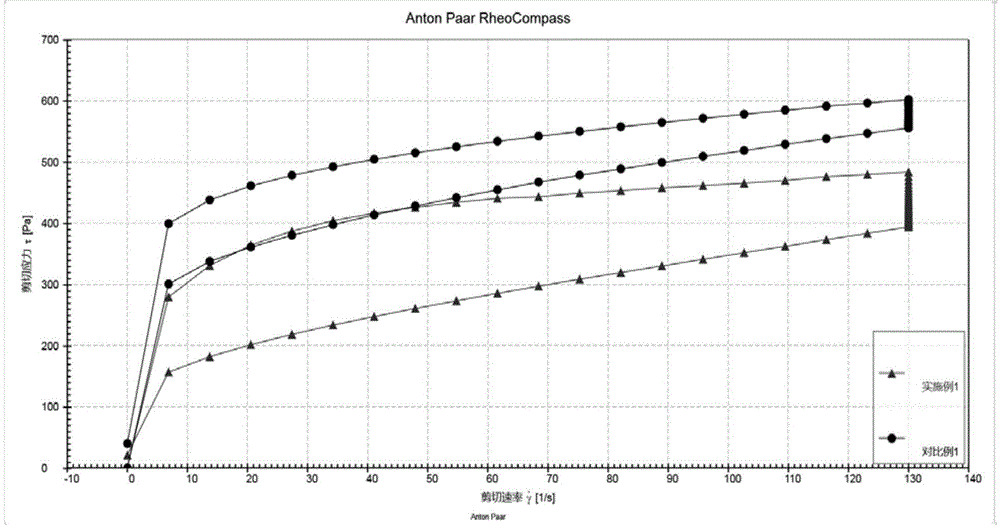

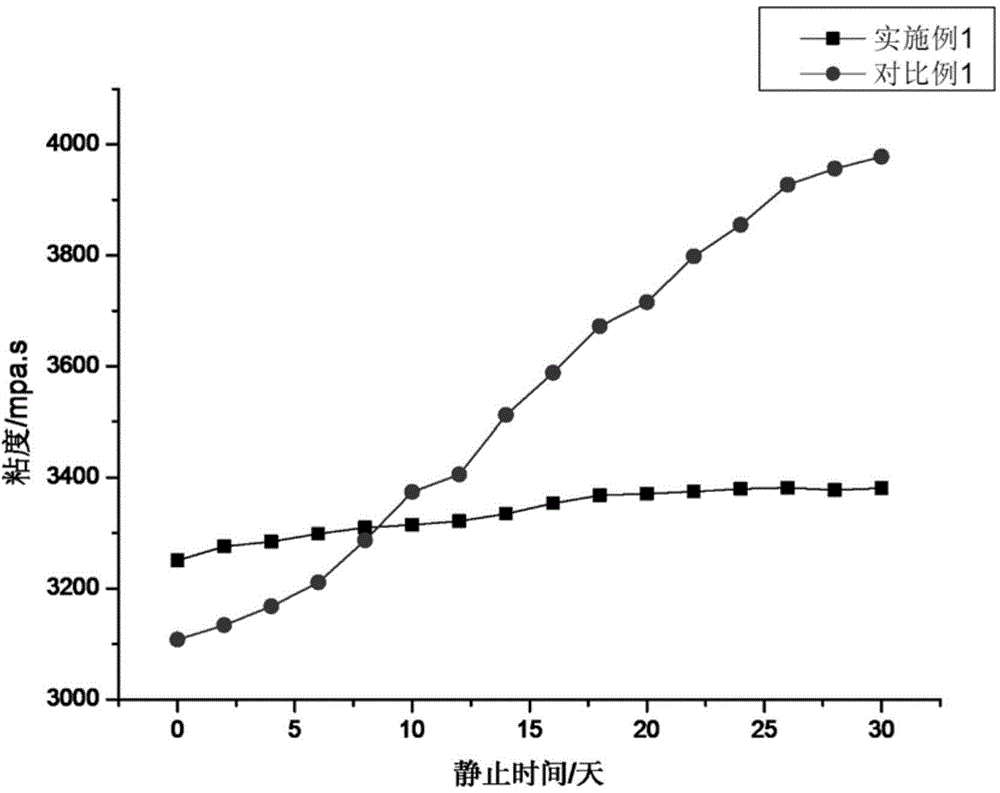

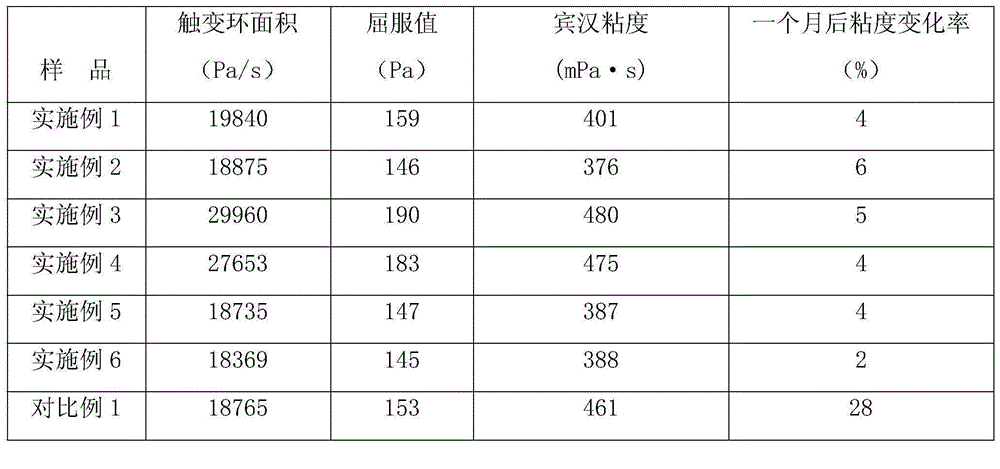

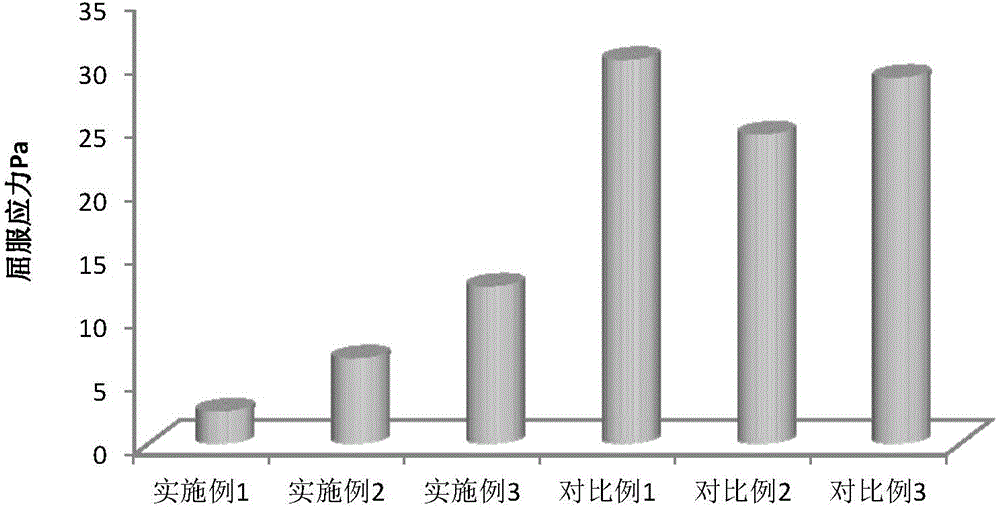

ActiveCN104403433AGood dispersionThixotropicCalcium/strontium/barium carbonatesCoatingsFiltrationPolyvinyl chloride

The invention discloses a preparation method for special precipitated calcium carbonate for a PVC (polyvinyl chloride) stone chip resistant coating. The preparation method comprises the technical operation as follows: adjusting the ratio of lime milk to be 1.040-1.080, feeding kiln gas with the flow of 6-10m<3> / h, controlling the specific surface area of matured slurry to be 16-40m<2> / g when the pH value of reaction liquid is reduced to be below 7.0, and adding a composite surface treatment agent at the temperature of 50-90 DEG C for wrapping, wherein the total adding amount of the surface treatment agent is 1.5-5.0 percent of dry calcium carbonate base; performing pressure filtration dewatering, drying, smashing and packaging on the slurry to obtain a precipitated calcium carbonate product for the PVC stone chip resistant coating. The precipitated calcium carbonate prepared by the preparation method disclosed by the invention is lower in hygroscopicity, so that the thixotropy, yield value and viscosity of filling of PVC plastipaste are effectively controlled, and the rheology stability of the PVC plastipaste is improved. The method disclosed by the invention is simple, feasible and low in production cost, and has higher economical and social benefits.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

Preparation method of self crosslinking type acrylateresin high-temperature sintering electronic silver paste

InactiveCN101834008AThixotropicAnti-sinkingNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteSolution polymerization

The invention discloses a preparation method of self crosslinking type acrylateresin high-temperature sintering electronic silver paste. The method comprises the following steps of: firstly, selecting acrylate monomers to prepare self crosslinking type acrylateresin through solution polymerization; then mixing and dispersing superfine silver powder, low-melting-point lead-free glass powder, a surface modifier, an auxiliary agent and a defoaming agent into the prepared self crosslinking type acrylateresin; and repeatedly grinding to prepare electronic silver paste. The method for preparing the high-temperature sintering electronic silver paste has the characteristics of simple process, convenience, easy application, no need of special equipment, low investment, convenient control of product properties, and the like.

Owner:ZHEJIANG UNIV

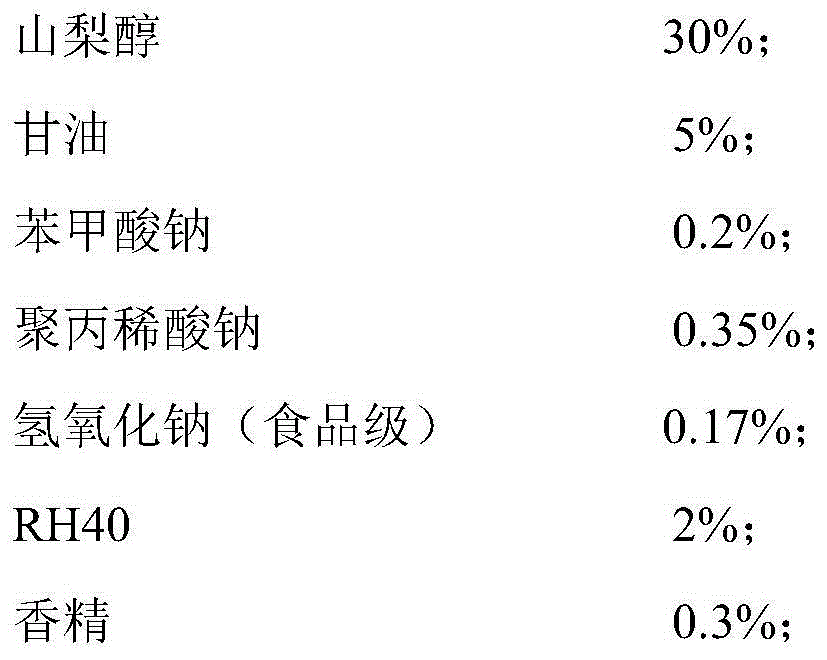

Child toothpaste composition

ActiveCN104905987APseudoplasticThixotropicCosmetic preparationsToilet preparationsToothpasteVeterinary medicine

The invention discloses child toothpaste composition. The child toothpaste composition comprises, by weight, 0.1-5 percent of thickener, 0.5-4 percent of solubilizer, 1-60 percent of humectant, 10-90 percent of water, 0.1-2 percent of essence and the balance other components. Abrasives are not added into the child toothpaste composition, and toothpaste body is transparent, generates a little or nearly no foam, is easy to extrude and brush, so that friction to the surfaces of teeth is reduced. The child toothpaste composition is high in safety with the pH range being 5.5-7.5, and can be used as training toothpaste for children at the age of 2-6.

Owner:GUANGZHOU LIBY

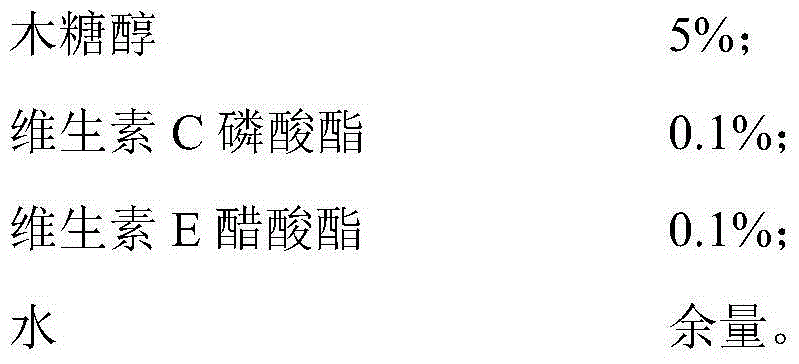

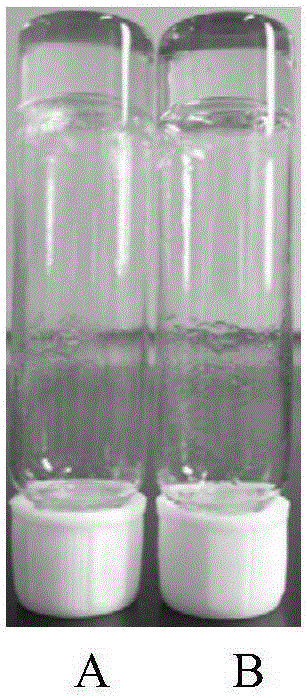

N-amino alkyl substituted glucosamide as well as preparation method and application thereof

InactiveCN105175388AThermoreversibleThixotropicOrganic chemistryThixotropic paintsSolventGel forming

The invention discloses N-amino alkyl substituted glucosamide as well as a preparation method and an application thereof. The N-amino alkyl substituted glucosamide is shown in formula (I), wherein n=2, 4, 6, 8 or 12. Supra-molecular gel formed by the N-amino alkyl substituted glucosamide in a solvent has thermal reversibility and thixotropy. Two-component gel formed by the N-amino alkyl substituted glucosamide in a solvent also has thermal reversibility and thixotropy. The instantaneous response rate after thixotropy is high, full response can be realized, and the thixotropy process is reversible and can be repeated. Gel with thixotropy is expected to be used in fields of coating, paint, pigment and the like.

Owner:TIANJIN UNIV

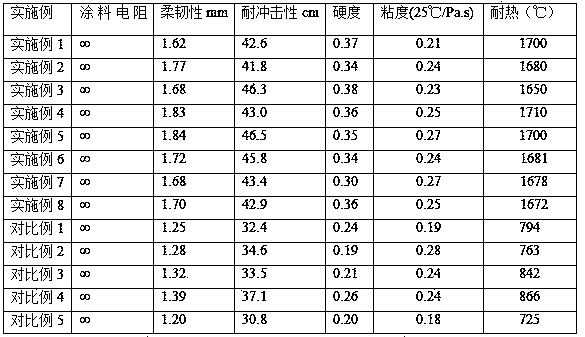

High temperature resistant and wear resistant ultrahigh voltage insulation coating and preparation method thereof

The invention provides a high temperature resistant and wear resistant ultrahigh voltage insulation coating and a preparation method thereof. The coating includes the following components by weight: 35-50 parts of silicone resin, 0.1-0.8 part of a coupling agent, 3-6 parts of titanium dioxide, 7-10 parts of quartz sand, 1-5 parts of natural camphor, 18-23 parts of a nano inorganic filler, 40-55 parts of a solvent, 0.3-0.7 part of a curing agent, 1-3 parts of a leveling agent, 2-4 parts of an anti-settling agent, 0.2-2 parts of a dispersion agent, 0.1-0.5 part of a preservative and 0.2-0.5 part of an antifoaming agent. The high temperature resistant and wear resistant ultrahigh voltage insulation coating has the advantages of high temperature resistance, high mechanical properties, good electrical insulation, corrosion resistance, strong wear resistance, simple preparation process, and easily available raw materials.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY +1

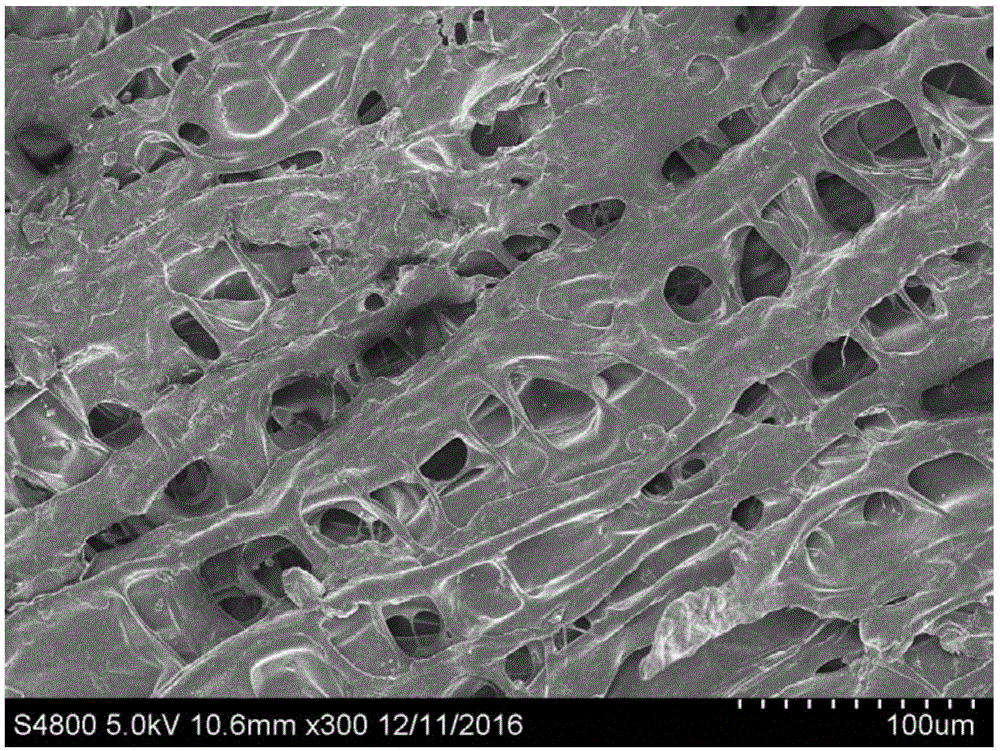

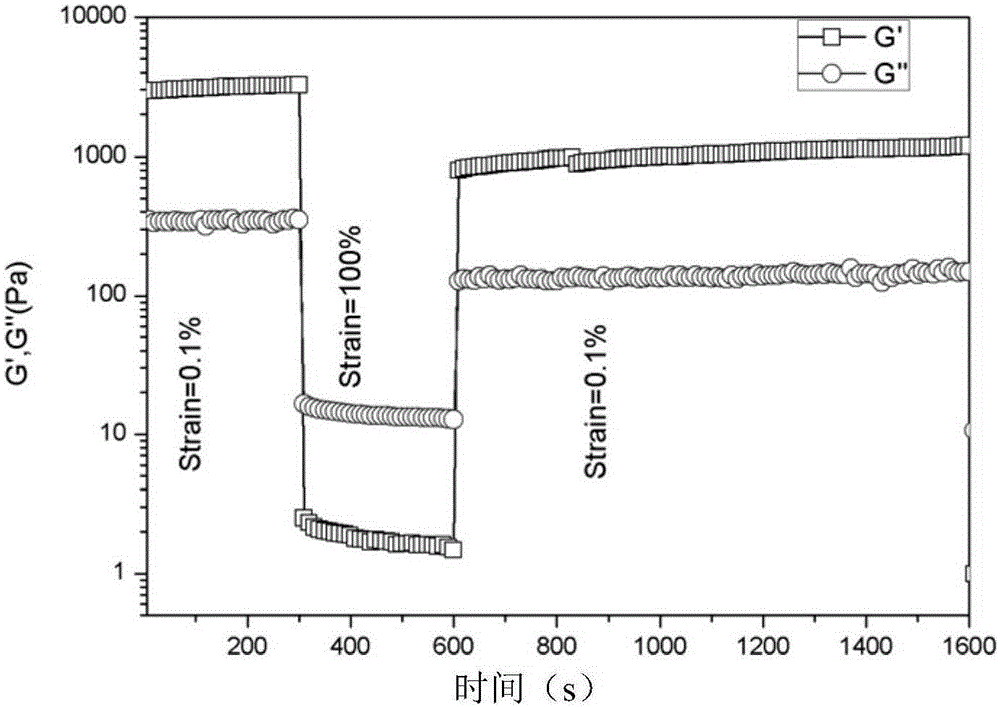

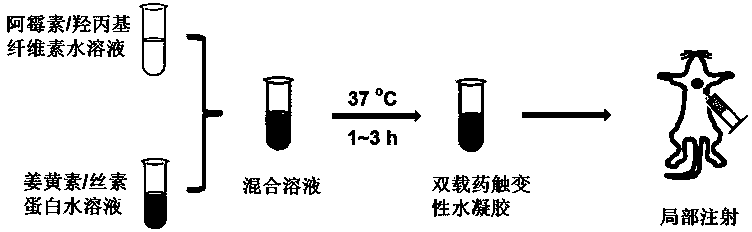

Double-drug loaded thixotropic hydrogel for tumor local treatment and preparation method thereof

ActiveCN104069120AGood biocompatibilityPromote degradationKetone active ingredientsSolution deliveryCelluloseMedicine

The invention belongs to the technical field of biomedicines, and particularly relates to a double-drug loaded thixotropic hydrogel for tumor local treatment and a preparation method thereof. The thixotropic hydrogel can be used for treating tumors by local injection including but not limited to intratumor injection, peritumoral injection and the like), and comprises the following components in percentage by mass: 1.2-18 percent of silk fibroin and 0.2-8 percent of hydroxy propyl cellulose, wherein the mass ratio of silk fibroin to hydroxy propyl cellulose is 1.5-9; and the anti-cancer medicament comprises 60-1900 mu g / mL curcumin and 10-3200 mu g / mL of doxorubicin hydrochloride. The drug loaded hydrogel has thixotropic syringeability and long-time drug sustained-release effect.

Owner:FUDAN UNIV

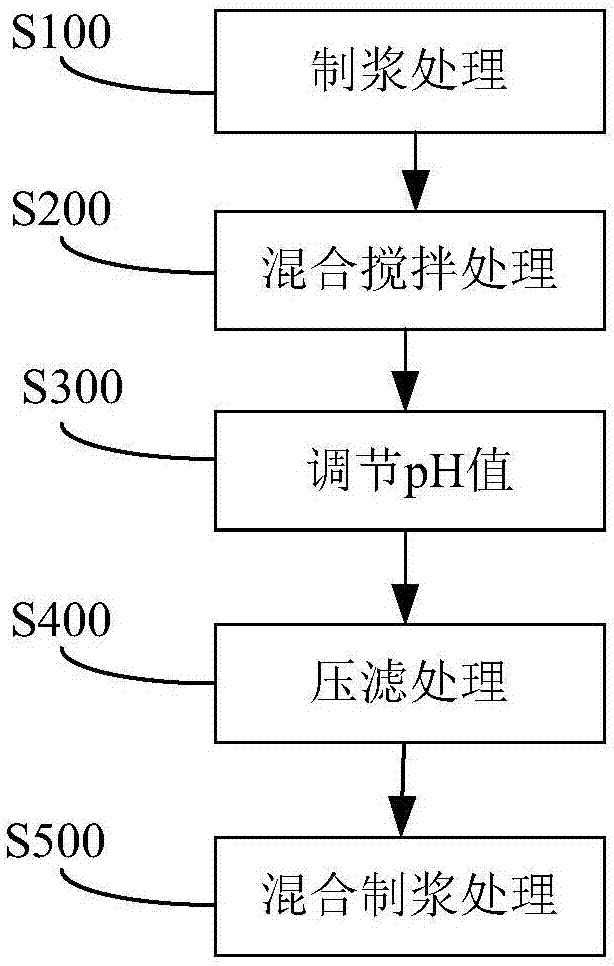

Method for preparing titanium dioxide slurry

InactiveCN106947295AReduce viscosityReduce or shield hydrogen bondsInorganic pigment treatmentHydrogenPulp treatment

The invention discloses a method for preparing a titanium dioxide slurry. The method comprises the following steps: pulping a titanium dioxide base material to obtain a titanium dioxide protoplasm; mixing and stirring the titanium dioxide protoplasm and an aluminum-containing compound to make the surfaces of titanium dioxide base material particles of the titanium dioxide protoplasm coated with an aluminum film in order to obtain aluminum coated titanium dioxide particles; adjusting the pH value of the slurry for coating the aluminum film to be less than 7 in order to obtain a pH value adjusted slurry; carrying out press filtration treatment on the pH value adjusted slurry to obtain a filter cake; and carrying out mixing and pulping treatment on the filter cake and a dispersant to obtain the titanium dioxide slurry. The method reduces or shields hydrogen bonds on the surfaces of the titanium dioxide base material particles through coating the surfaces of the titanium dioxide base material particles, so the titanium dioxide base material particles easily undergo solid-liquid separation to form the filter cake, sodium chloride is effectively removed, and the viscosity of the titanium dioxide slurry is reduced.

Owner:YUNNAN METALLURGICAL XINLI TITANIUM IND CO LTD

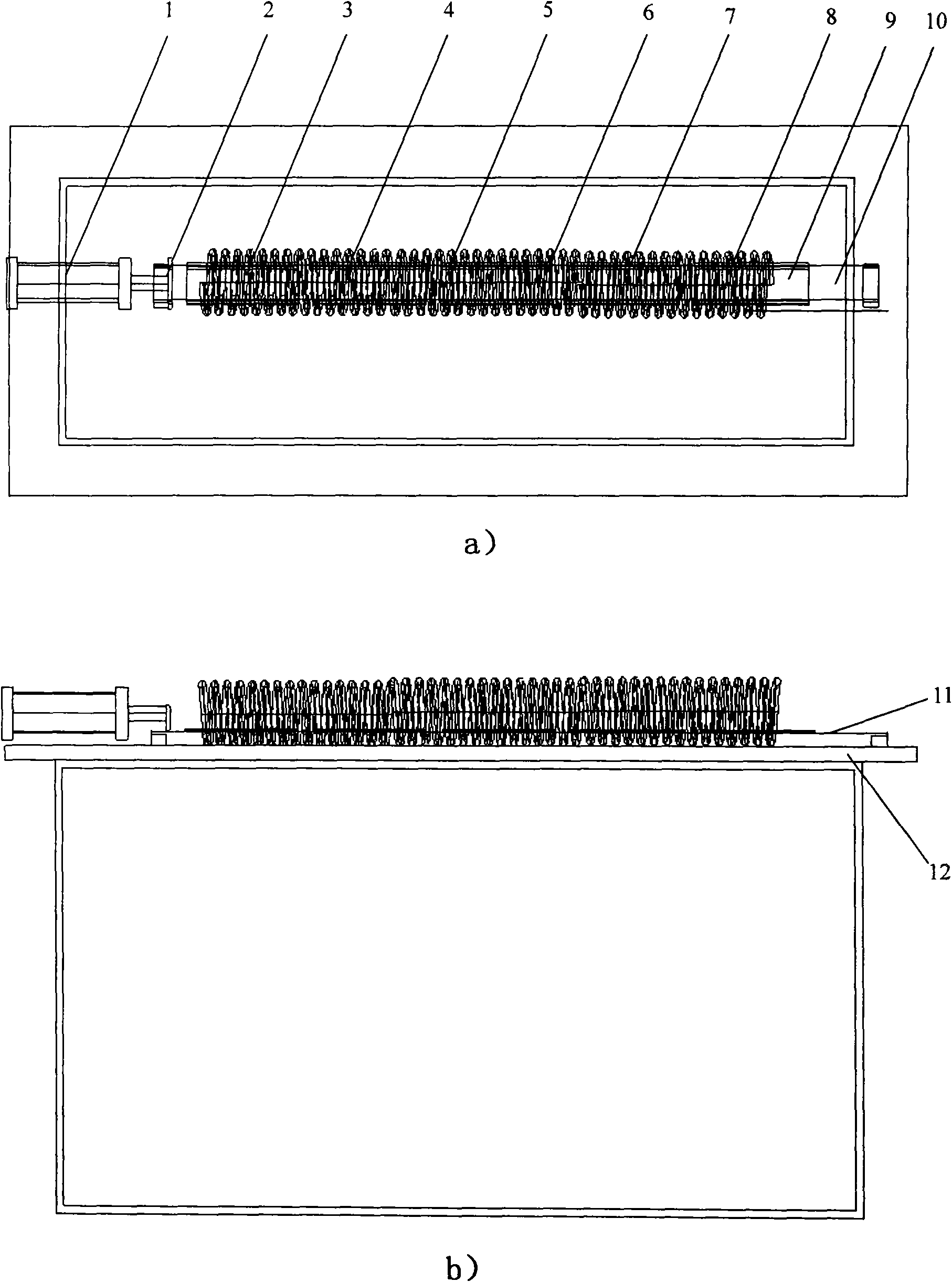

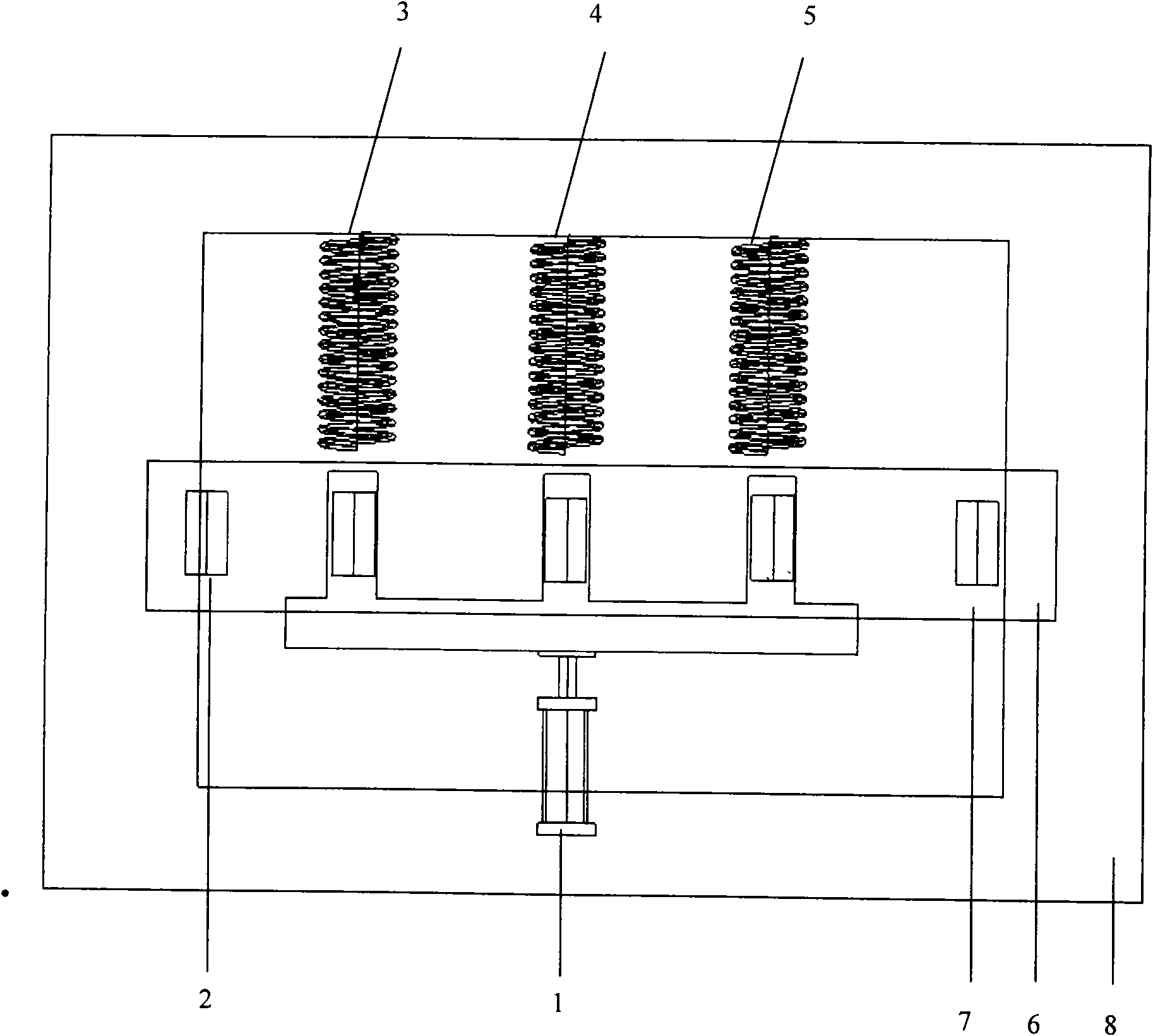

Horizontal type device for reheating semi-solid metal blank material

The invention relates to a horizontal type device for reheating a semi-solid metal blank material, which comprises an induction heating power supply, an induction heating mechanism, and a blank material carrying mechanism, and is provided with five stations, such as at least three material heating stations, a material placing station and a material discharging station, wherein the induction heating mechanism adopts three sections of induction heating coils which are separately and horizontally arranged, and all the induction heating coils are mutually electrically communicated and arranged on the three material heating stations respectively; the blank material carrying mechanism comprises a feed mechanism and a blank material transporting device; the blank material transporting device is a delivering device processing in front of each station; and the feed mechanism is positioned in front of each induction heating coil. The induction heating three-section heating mode is selected to make the heating of the blank material and the distribution of the temperature field more even and reasonable. The horizontal structure is adopted, the blank material cannot collapse or discharge fluid, and the blank material transportation is simple and convenient because of a large contact surface between the blank material and a supporting part. The blank material is allowed to have a higher liquid phase fraction, which is convenient for the thixotropic forming of more complicated parts.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Novel coal ash grouting material

The invention discloses a novel coal ash grouting material, which is composed of specific components by mass: 1 part of coal ash, 2 parts of water, liquid water glass occupying 5% to 10% of the coal ash and sepiolite occupying 2%. to 5%.of the coal ash. Improved coal ash grout has strong adhesion performance on firing articles, can evenly and effectively cover the surfaces of the firing articles, is strong in water-retaining performance and good in fire resistance, can effectively block leakage insulate oxygen to prevent grout from losing, and is low in price, environmental-friendly, good in stability and suitable for pipeline transportation.

Owner:CHINA COAL RES INST

Makeup removing stick and preparation method thereof

InactiveCN109248105AStrong emulsifying abilityImprove cleaning powerCosmetic preparationsMake-upIrritationTocopherol

The invention discloses a makeup removing stick and a preparation method thereof. The makeup removing stick comprises the following components of a compound of PEG-20 glyceryl triisostearate and tocopherol and sorbitol-30 tetraisostearate, and the weight ratio of the compound of the PEG-20 glyceryl triisostearate and the tocopherol to the sorbitol-30 tetraisostearate is (2-4):(1-3). The makeup removing stick has excellent emulsifying ability and high cleaning strength, can effectively remove cosmetics on the skin, is gentle to the skin without irritation, does not damage the skin keratin, hasskin repairing and moisturizing effects, provides various nutrition ingredients for the skin, has good spreadability, is fresh and not sticky in skin feeling, can further effectively alleviate skin allergies and inflammation, tightens skin pores, and has dual effects of makeup removing and skin care. The makeup removing stick is in a solid stick shape, has thixotropic properties, can spread quickly when the makeup removing stick contacts the skin, can fully dissolves makeup, convenient to use, easy to carry, and good in makeup removing effect.

Owner:I&B GUANGZHOU BIOLOGICAL TECH CO LTD

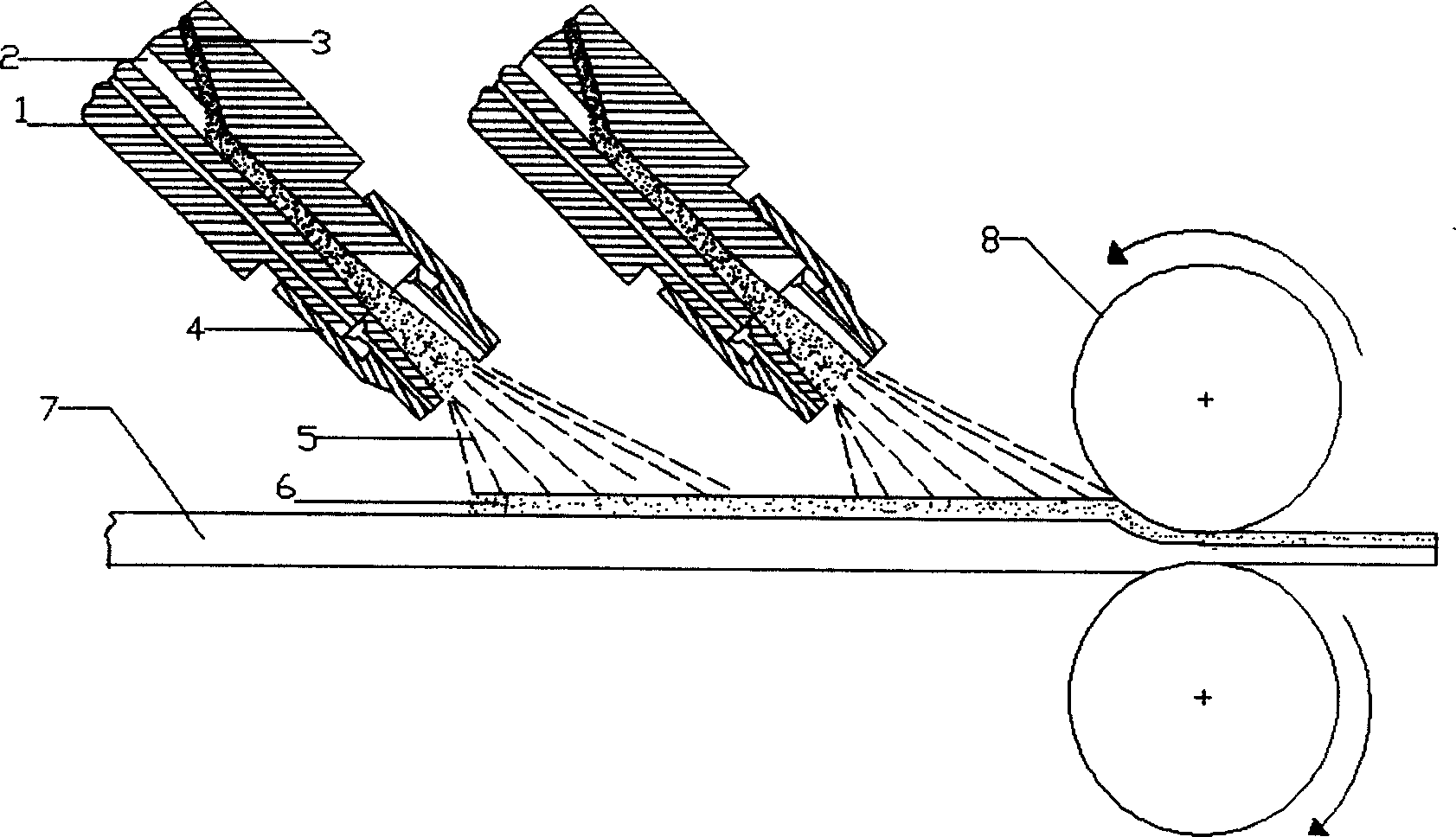

Method for preparing metal ceramic gradient coated steel plate by self-stretching continuous mill

InactiveCN1743089AFully meltedLight in massMolten spray coatingMetal rolling arrangementsProduction lineSelf-propagating high-temperature synthesis

On the hot-rolling production line, before the steel sheet to be hot-rolled is fed into hot-rolling rolls a self-spreading metal-ceramic gradient coating layer can be hot-sprayed on the surface of said steel sheet to be hot-rolled, after the hot-spraying process is completed, said steel sheet can be promptly hot-rolled, so that on the surface of steel sheet a Ti-C-Ni gradiet coating layer with excellent comprehensive performance can be formed. Said invention also provides the concrete steps of said hot-spraying process and the composition of said coating layer.

Owner:JIANGSU FASTEN TECH DEV CENT

Preparation method of nano-composite ultrafine heavy calcium carbonate

ActiveCN107697940ASolve the problem of high oil absorptionSolve liquidity problemsCalcium/strontium/barium carbonatesMaterial nanotechnologyNanoparticleWet grinding

The invention relates to a preparation method of nano-composite ultrafine heavy calcium carbonate. The problems that the oil absorbing quantity is high, the water-absorbing property is high, the flowability is low and the extrudability is low when nanometer calcium carbonate is applied in other fields are solved. According to the process, ultrafine wet-grinding calcium triple superphosphate servesas a basic core, the advantages of a tandem supergravity reactor are utilized, and the nano-composite ultrafine heavy calcium carbonate is prepared; meanwhile, supercritical CO2 fluid low-temperaturedrying is adopted, so nanoparticles adsorbed on the surface of the ultrafine heavy calcium carbonate are not agglomerated or coagulated. The ultrafine heavy calcium carbonate prepared with the methodis small in particle size, large in BET, high in viscosity, high in thixotropy, little in agglomeration, uniform in particle size distribution and easy to disperse, and has small hydrophilic oil-absorbing amount, high flowability and high extrudability during application.

Owner:SHANXI XINTAI HENGXIN NANO MATERIALS TECH CO LTD

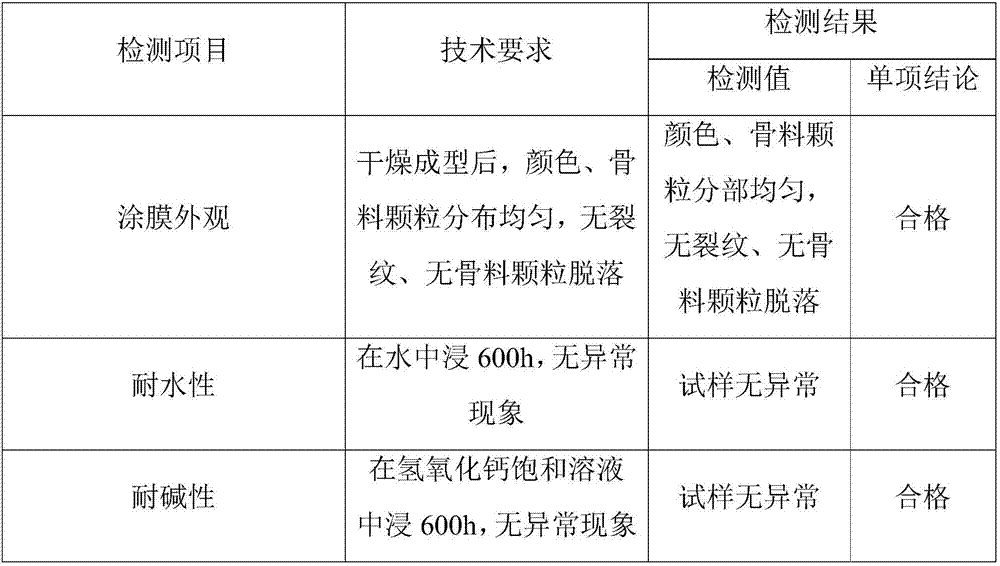

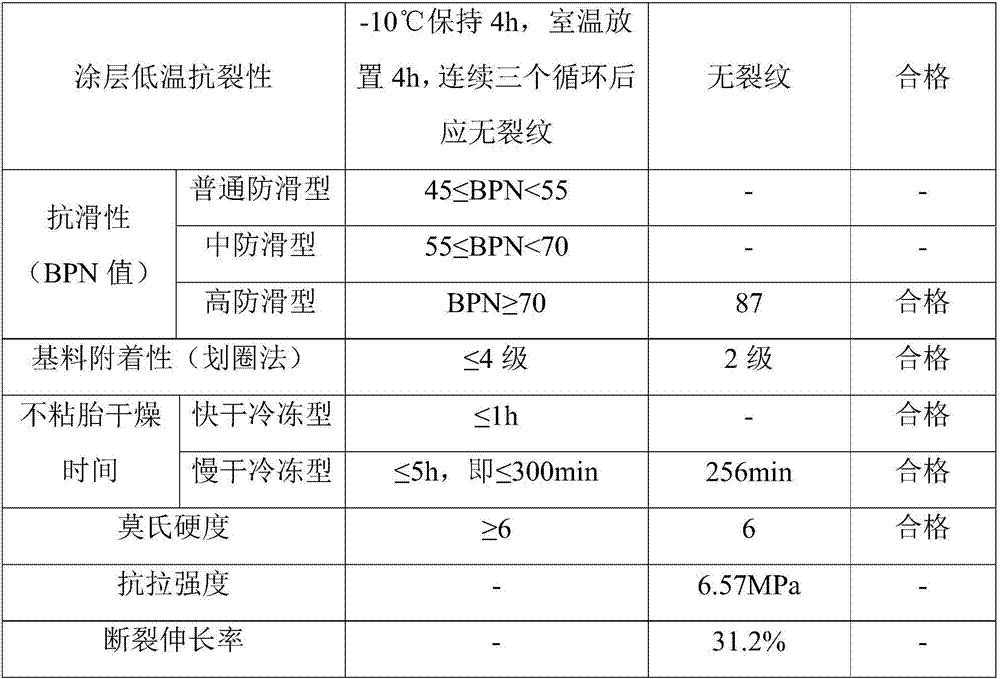

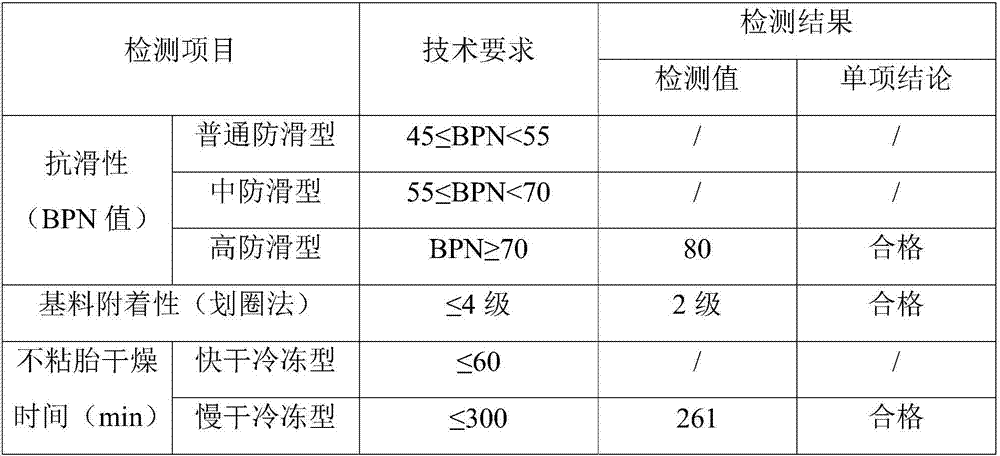

Outdoor weather-resistant wear-resistant stain-proofing colorful anti-skid water-borne environment-friendly coating and preparation method thereof

InactiveCN107513335AWith thickeningThixotropicAntifouling/underwater paintsPaints with biocidesEpoxyEnvironmental resistance

The invention relates to an outdoor weather-resistant wear-resistant stain-proofing colorful anti-skid water-borne environment-friendly coating and a preparation method thereof. The water-borne environment-friendly coating comprises a first composition and a second composition, wherein the first composition is prepared from the following raw materials in parts by weight: 20-30 parts of a water-borne curing agent, 0.5-3 parts of nano-materials, 2-5 parts of mica, 30-60 parts of packing and 20-30 parts of water; and the second composition is prepared from the following raw materials in parts by weight: 70-80 parts of epoxy resin, 20-30 parts of hyperbranched polymer, 0.2-0.6 part of an ultraviolet absorbent and 0.2-0.6 part of an antioxidant; and the first composition and the second composition are packaged independently. The water-borne environment-friendly coating has excellent performance of good coating toughness, high strength, good adhesion, good weather resistance, good water resistance, good abrasion resistance, pollution resistance, no toxicity, environmental friendliness and the like; and the preparation method is simple, and is low in production cost.

Owner:重庆东吴道路工程有限公司

Health-care activating water purifying agent

InactiveCN101954269AImprove adsorption capacityHigh speedOther chemical processesAluminium silicatesWater qualityImpurity

The invention discloses a health-care activating water purifying agent, which comprises the following raw materials in parts by weight: 30-50 parts of kaolin, 18-32 parts of medical stone, 16-30 parts of tourmaline and 25-40 parts of bentonite. The health-care activating water purifying agent can be health-care and activate water quality and efficiency, more importantly has the characteristics of high purifying efficiency, less use amount and low cost and can rapidly absorb adhesive impurities.

Owner:嘉兴实业环保有限公司

Wear-resistant coating for aluminum alloy doors and windows, and preparation method thereof

InactiveCN107163645AGood acid and alkali resistanceImprove aging resistanceCoatingsEpoxyWear resistant

The invention discloses a wear-resistant coating for aluminum alloy doors and windows, and belongs to the technical field of door and window coatings. The coating comprises, by weight, 20-30 parts of hexafluorobutyl acrylate, 40-50 parts of epoxy resin, 1-2 parts of styrene-butadiene rubber, 23-26 parts of kaolin, 2-4 parts of cast stone powder, 0.5-1.5 parts of silicon nitride, 1-2 parts of alumina, 0.4-0.8 parts of carboxymethylcellulose, 2-3 parts of paraffin, 6-9 parts of carbon black, 1-4 parts of an antifoaming agent, 0.6-1 pars of a coupling agent, 0.4-0.8 parts of an anti-settling agent and 1-2 parts of a diluent. The invention also discloses a preparation method of the wear-resistant coating for aluminum alloy doors and windows. The coating disclosed in the invention has the advantages of simplicity in preparation, excellent wear resistance, excellent resistance to high temperature, excellent corrosion resistance, excellent aging resistance and difficulty in breakage.

Owner:合肥市旺友门窗有限公司

Concrete anti-segregation water reducing agent and preparation method thereof

The invention relates to the technical field of concrete water reducing agents, in particular to a concrete anti-segregation water reducing agent and a preparation method thereof. The concrete anti-segregation water reducing agent at least comprises the following components in parts by weight: 20-40 parts of a water reducing agent; 5-20 parts of an air entraining agent; 1-5 parts of a thickening agent; 0.1-2 parts of a retarder; and 0.1-3 parts of a defoaming agent. The concrete anti-segregation water reducing agent of the invention provides the anti-segregation water reducing agent for concrete so as to enhance the stability of a fresh concrete multiphase system and improve the workability of concrete. With the concrete anti-segregation water reducing agent and the preparation method thereof of the invention adopted, the problem that concrete using a polycarboxylate superplasticizer or a sulfamate superplasticizer is easy to bleed and harden is solved, the defect that the strength ofthe concrete is greatly reduced by a common air entraining agent is avoided, and the problem that the water reducing rate of the superplasticizer is influenced by a common thickening agent can be avoided.

Owner:JIANGSU WANBANG BUILDING MATERIALS CO LTD

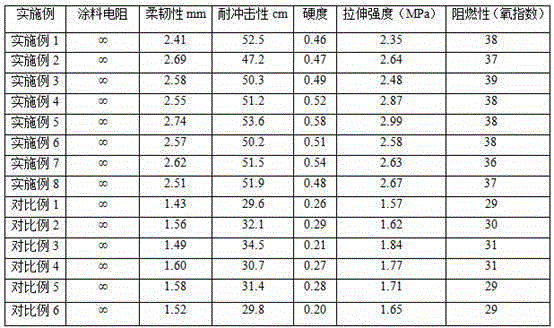

Thermal-insulation extra-high voltage flame-retardant coating and preparation method thereof

ActiveCN105331207AImprove performanceLow heat resistanceFireproof paintsAnti-corrosive paintsThermal insulationPlasticizer

The invention provides a thermal-insulation extra-high voltage flame-retardant coating and a preparation method thereof. The coating comprises, in parts by weight, 50-65 parts of resin, 10-20 parts of borax, 5-8 parts of boric acid, 0.5-3.5 parts of natural camphor, 0.1-0.5 parts of a coupling agent, 12-18 parts of nanofiller, 30-40 parts of a solvent, 1-3 parts of a plasticizer, 1-3 parts of an anti-settling agent, 2-4 parts of a dispersing agent and 0.2-0.4 parts of a defoaming agent. The thermal-insulation extra-high voltage flame-retardant coating has the good flame retardance, the high mechanical properties and the good electrical insulating property, the preparation technology is simple, and raw materials are easy to obtain.

Owner:STATE GRID CORP OF CHINA +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com