Low-fat mayonnaise

A technology of fat egg yolk and egg yolk, which is applied in the field of low-fat mayonnaise to achieve the effects of enhancing stability, delicate and refreshing taste, and slowing down movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

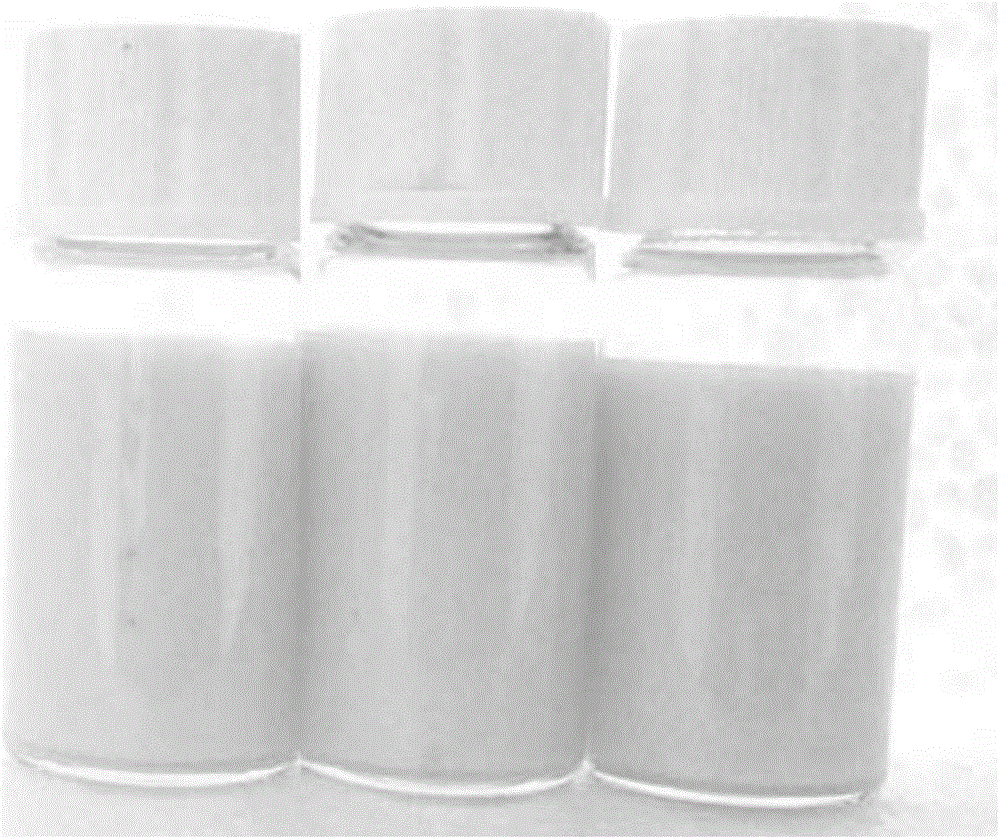

Embodiment 1

[0027] In this example, 1kg of low-fat mayonnaise with a fat content of 40% was prepared, and the mixed raw materials and proportions were as follows: 150g egg yolk, 400g vegetable oil, 5g xanthan gum, 20g white vinegar, 20g white sugar, 1g salt, 5g mustard oil, 2g Citric acid, 3 g potassium sorbate, and 380 g micro-nano wheat bran cellulose suspension, suspension solids 2%.

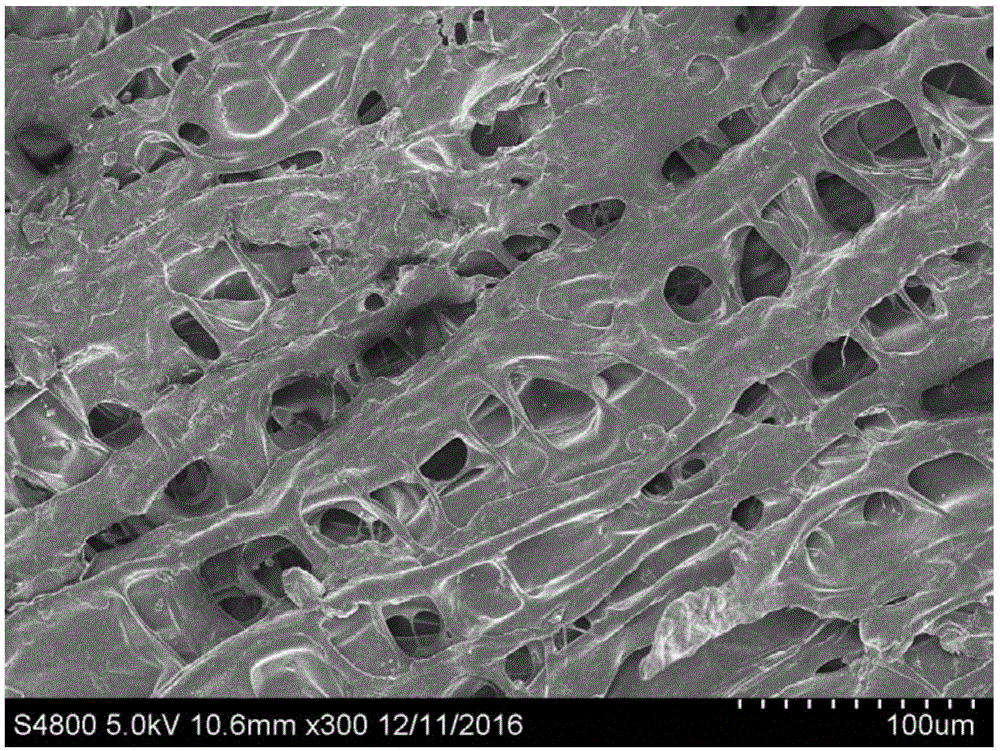

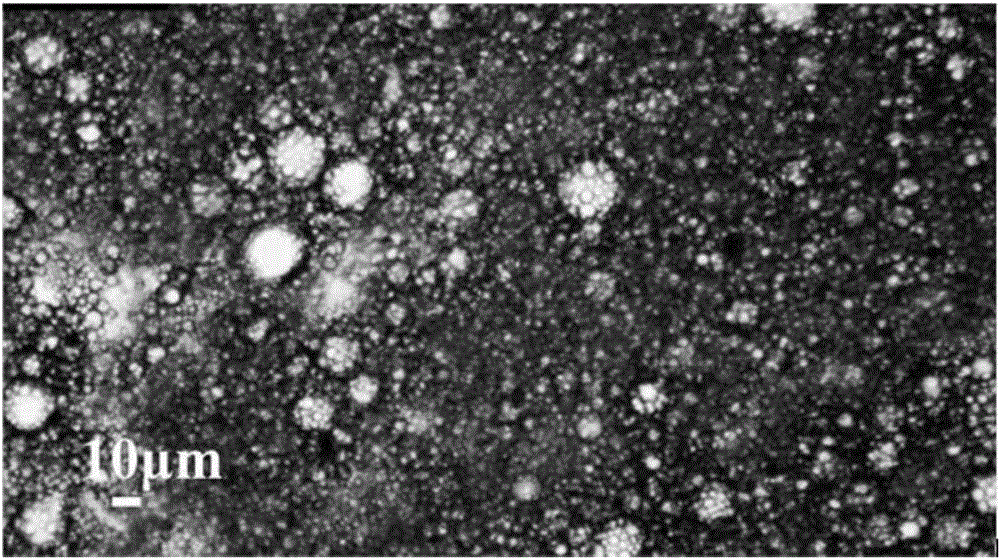

[0028] The preparation method of the above-mentioned micro-nano wheat bran cellulose suspension is as follows: (1) drying: heating and drying the raw wheat bran in an oven at 105° C. for at least 3 hours; (2) pulverizing and sieving: drying the dried wheat bran The bran is processed with a pulverizer, and the obtained wheat bran powder is then sieved through a 200-mesh sieve; (3) alkaline cooking and cleaning: the wheat bran powder and 5% NaOH solution are mixed at a ratio of 1:30 (g / mL) Evenly, cook for 30min, centrifuge the alkali-cooked product at 1000rpm for 5min, wash with deionized water at least 3...

Embodiment 2

[0032] In this example, 1kg of low-fat mayonnaise with a fat content of 50% was prepared, and the mixed raw materials and proportions were as follows: 150g egg yolk, 500g vegetable oil, 5g xanthan gum, 20g white vinegar, 20g white sugar, 10g salt, 5g mustard oil, 2g Citric acid, 3 g potassium sorbate and 285 g micro-nano wheat bran cellulose suspension, suspension solids 3%. The specific preparation method is the same as that in Example 1.

Embodiment 3

[0034] In this example, 1kg of low-fat mayonnaise with a fat content of 60% was prepared, and the mixed raw materials and proportions were as follows: 150g egg yolk, 600g vegetable oil, 4g xanthan gum, 20g white vinegar, 20g white sugar, 10g salt, 5g mustard oil, 2g Citric acid, 3 g potassium sorbate, and 186 g micro-nano wheat bran cellulose suspension, suspension solids 5%. The specific preparation method is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com