Thermal-insulation extra-high voltage flame-retardant coating and preparation method thereof

A flame retardant coating and ultra-high voltage technology, applied in anti-corrosion coatings, fire-retardant coatings, coatings and other directions, can solve the problems of insufficient overall performance of insulating coatings, uneven performance of insulating coatings, hidden dangers in long-term use, etc., to shorten the grinding time. effect of time, enhanced pressure resistance, and low mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

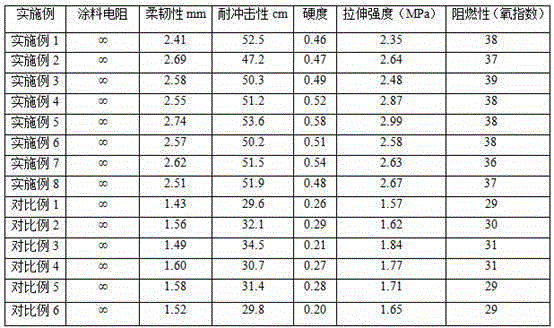

Examples

Embodiment 1

[0036] A heat-insulating UHV flame-retardant coating, comprising: 50 parts of resin, 10 parts of borax, 5 parts of boric acid, 0.5 parts of natural camphor, 0.2 parts of coupling agent, and 12 parts of nano fillers in parts by weight , solvent: 30 parts, chloromethyl ester plasticizer: 1 part, polyolefin wax anti-settling agent: 1 part, anionic polyacrylic acid sodium salt solution HDFSJ-01 dispersant: 2 parts and NXZ defoamer: 0.2 parts .

[0037] Wherein, the resin includes polystyrene resin and silicone resin, and the weight ratio of polystyrene resin and silicone resin is 2:1.

[0038] Wherein, the mixing weight ratio of nano chromium oxide powder, nano magnesium hydroxide powder and nano aluminum hydroxide powder in the nano filler is 1:2:1.

[0039] Its preparation method comprises the following steps:

[0040] 1) Dissolve 0.2 parts by weight of silane coupling agent in 3 parts by weight of a solvent mixed with acetone and xylene at a volume ratio of 1:2, ultrasonicate...

Embodiment 2

[0044] A heat-insulating ultra-high voltage flame-retardant coating, comprising: 65 parts of resin, 20 parts of borax, 8 parts of boric acid, 3.5 parts of natural camphor, 0.2 parts of coupling agent, and 18 parts of nano filler in parts by weight , solvent: 40 parts, chloromethyl ester plasticizer: 3 parts, polyolefin wax anti-settling agent: 3 parts, anionic polyacrylic acid sodium salt solution HDFSJ-01 dispersant: 4 parts and NXZ defoamer: 0.4 parts .

[0045] Wherein, the resin includes polystyrene resin and silicone resin, and the weight ratio of polystyrene resin and silicone resin is 2:1.

[0046] Wherein, the mixing weight ratio of nano chromium oxide powder, nano magnesium hydroxide powder and nano aluminum hydroxide powder in the nano filler is 1:2:2.

[0047] Its preparation method is:

[0048] 1) Dissolve 0.2 parts by weight of silane coupling agent in 4 parts by weight of a solvent mixed with acetone and xylene at a volume ratio of 1:2.5, ultrasonicate for 50 m...

Embodiment 3

[0052] A heat-insulating ultra-high voltage flame-retardant coating, in parts by weight, comprising: resin: 55 parts, borax: 15 parts, boric acid: 6 parts, natural camphor: 2.5 parts, coupling agent: 0.4 parts, nano filler: 16 parts , solvent: 35 parts, chloromethyl ester plasticizer: 2 parts, polyolefin wax anti-settling agent: 2 parts, anionic polyacrylic acid sodium salt solution HDFSJ-01 dispersant: 3 parts and NXZ defoamer: 0.3 parts .

[0053] Wherein, the resin includes polystyrene resin and silicone resin, and the weight ratio of polystyrene resin and silicone resin is 2:1.

[0054] Wherein, the mixing weight ratio of nano chromium oxide powder, nano magnesium hydroxide powder and nano aluminum hydroxide powder in the nano filler is 1:3:1.

[0055] Its preparation method is:

[0056] 1) Dissolve 0.4 parts by weight of silane coupling agent in 7 parts by weight of a solvent mixed with acetone and xylene at a volume ratio of 1:2, ultrasonicate for 40 minutes, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com