Patents

Literature

64results about How to "Moderate bond strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

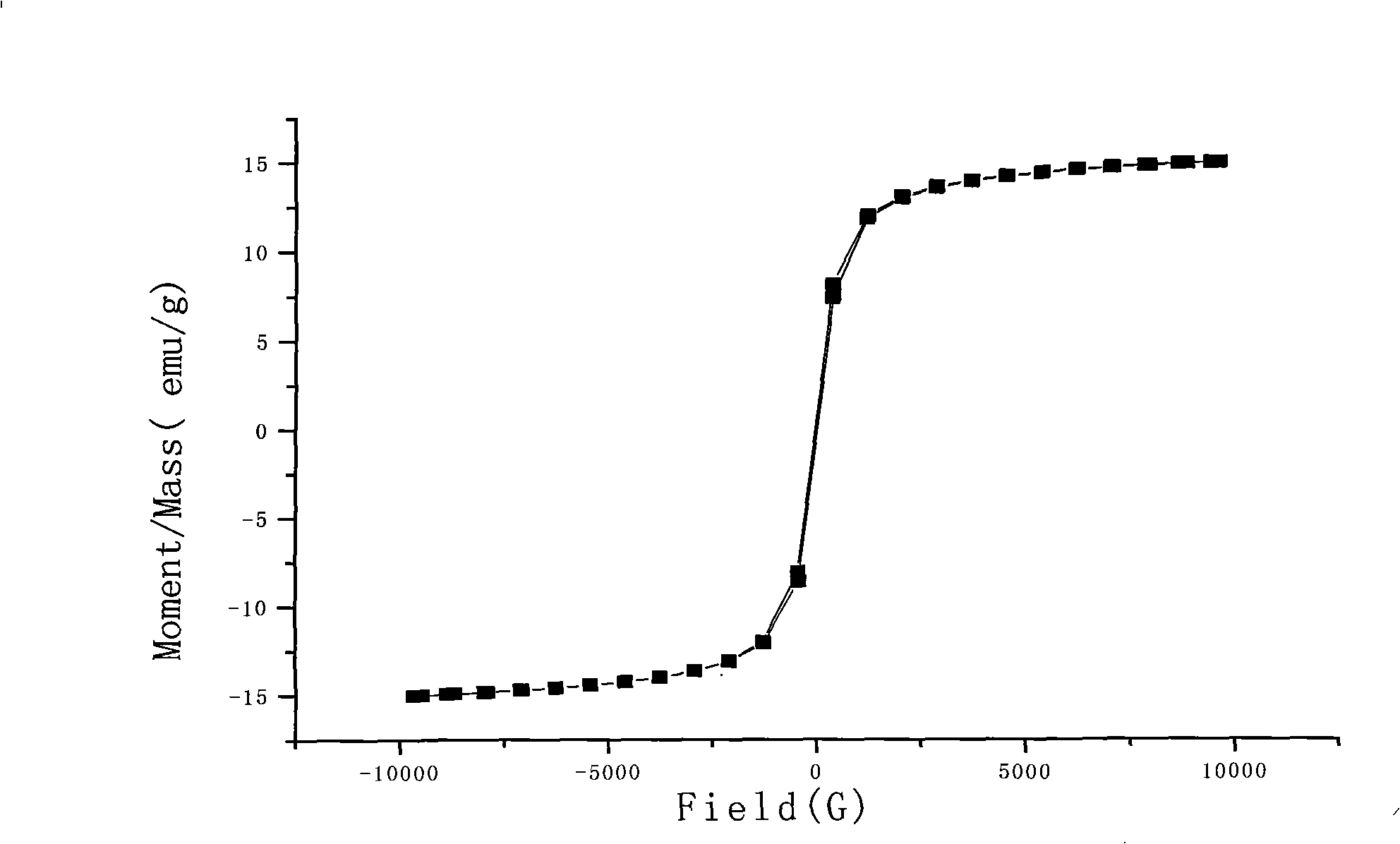

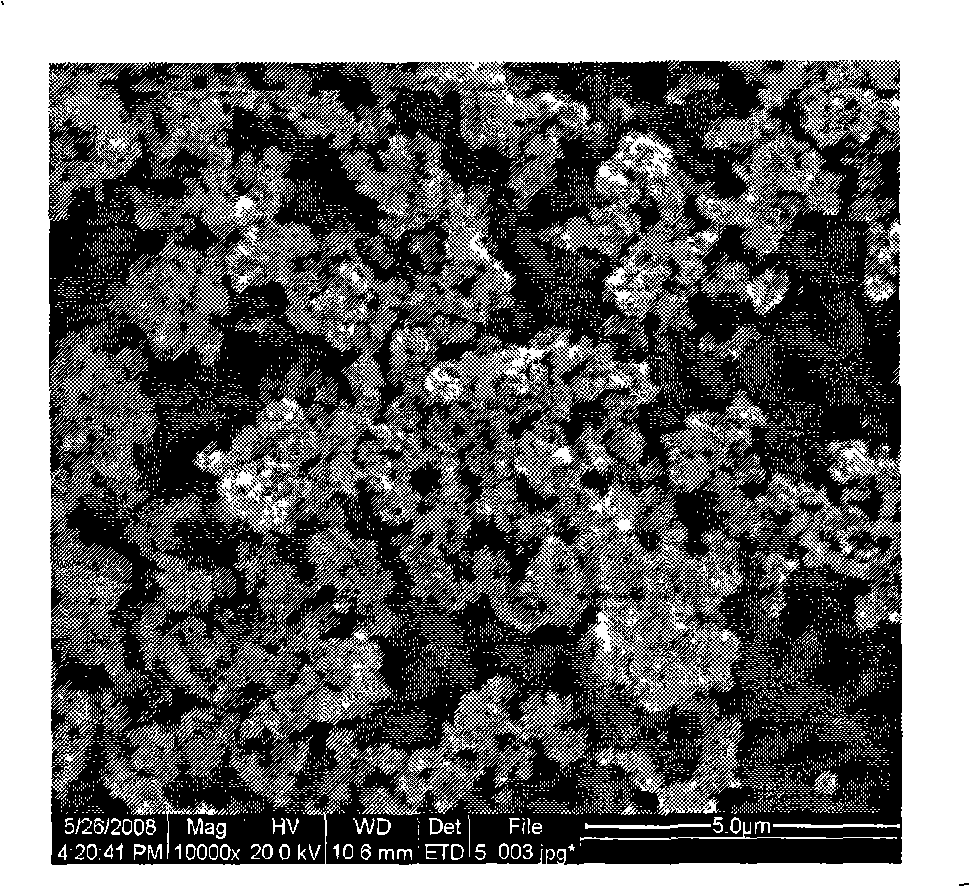

Preparation of magnetic silicon dioxide microsphere with metallic ion chelated surface and use thereof

InactiveCN101323454APrevent leakageStrong forceSilicaPeptide preparation methodsProtein targetMicrosphere

The invention relates to a method for preparing magnetic silicon dioxide microspheres with the surfaces chelated with metal ions; the method of the inventioncomprises the following steps of preparation of the magnetic silicon dioxide microspheres, epoxidation of the magnetic silicon dioxide microspheres, carboxylation of the magnetic silicon dioxide microspheres and chelation technique of metal ions. Compared with the existing preparing method, the method of the invention has the advantages of reasonable design, simple operation and large amount of chelation of metal, etc. The magnetic silicon dioxide microspheres with the surfaces chelated with the metal ions, which are prepared by adopting the method, contain cobalt ions, have stronger bonding force with the modified microspheres so as to lead the cobalt ions to be not easy to leak out, and have higher selectivity and proper bonding strength with histidine on the protein, thus leading the magnetic silicon dioxide microspheres with the surfaces chelated with the metal ions to have high selectivity to hexameric histidine tag protein, and being easy to realize the separation and the purification of the target protein; the magnetic silicon dioxide microspheres with the surfaces chelated with the metal ions, which are prepared by adopting the method, can be used for separating the hexameric histidine tag protein.

Owner:SHAANXI NORMAL UNIV

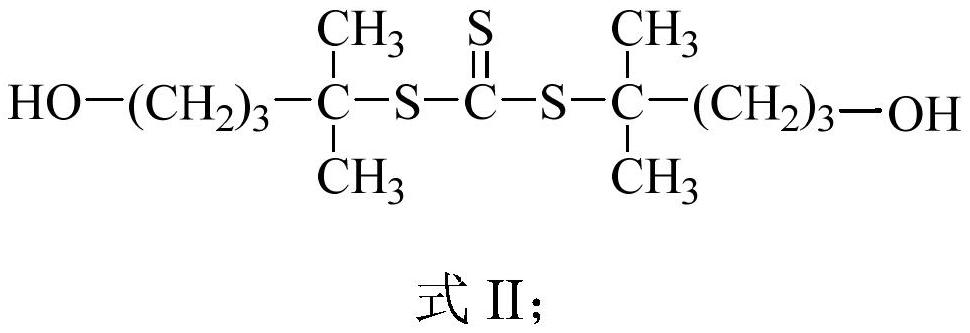

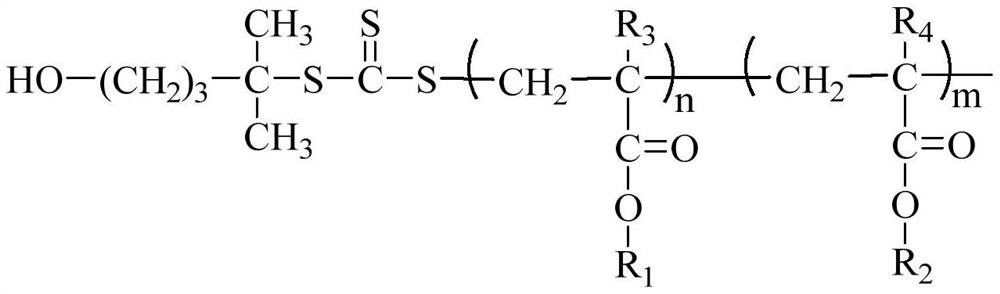

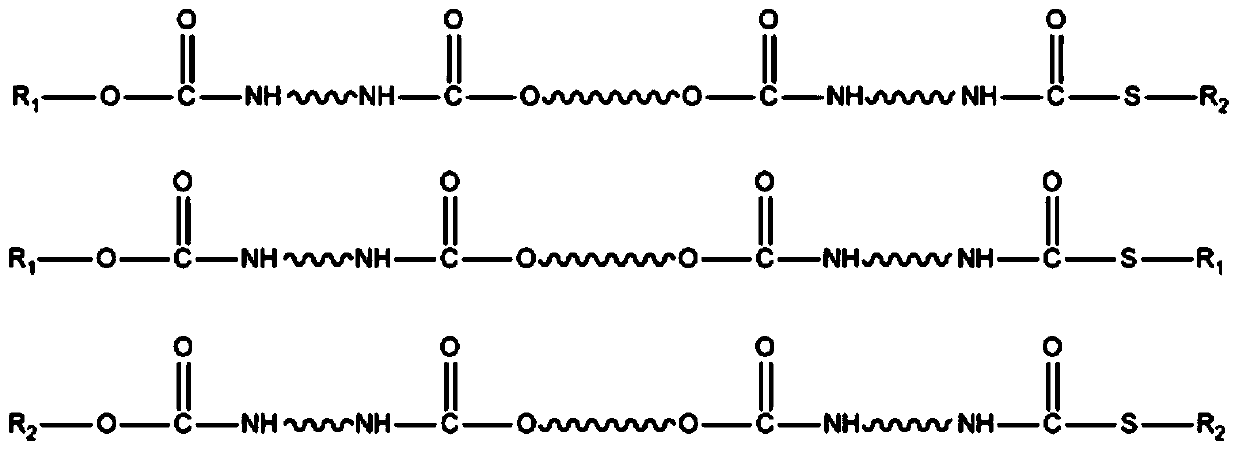

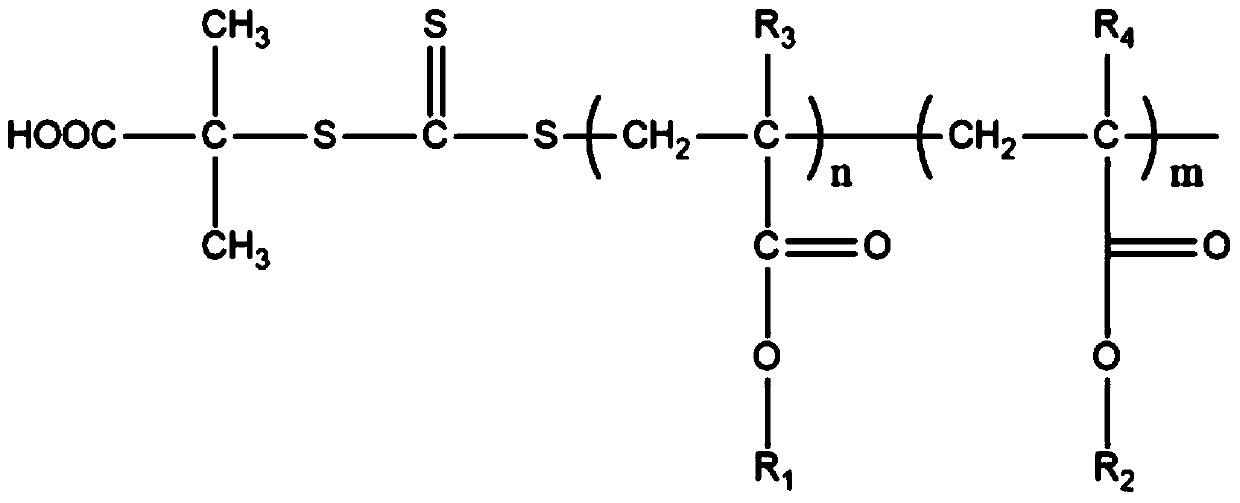

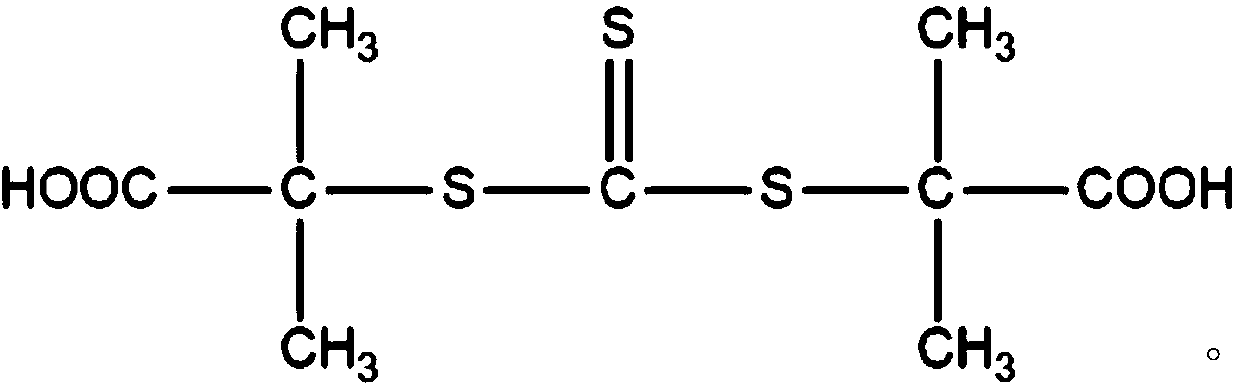

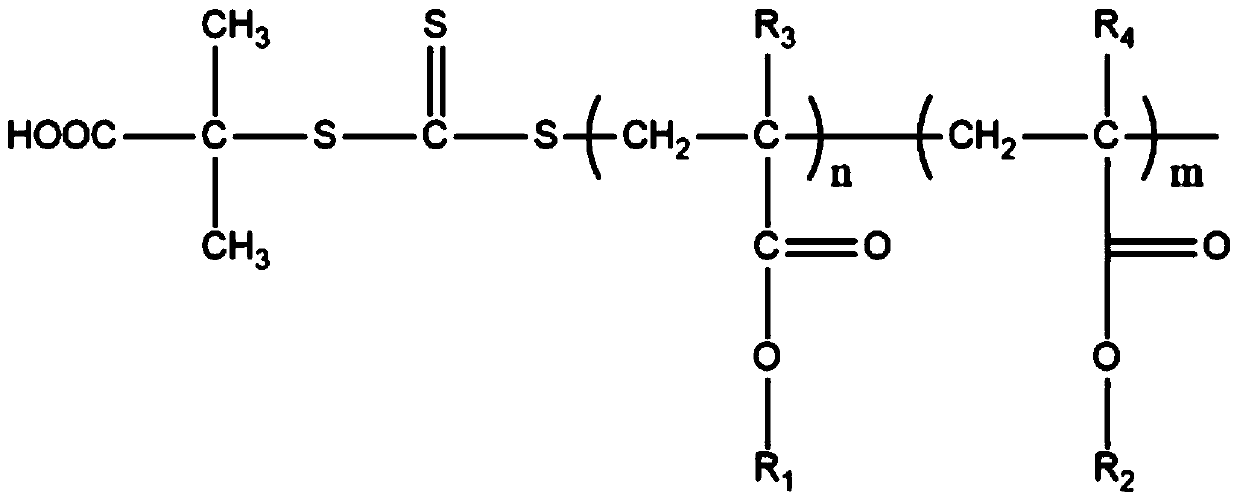

UV curing liquid optical cement and preparation method and application thereof

ActiveCN105985749AThere will be no glue overflow problemModerate bond strengthPolyureas/polyurethane adhesivesEster polymer adhesivesUV curingOligomer

The invention discloses UV curing liquid optical cement. The UV curing liquid optical cement is prepared from, by weight, 20-70 parts of active oligomer, 10-50 parts of tackifying resin, 10-40 parts of reactive diluent, 0.3-5 parts of photoinitiator and 1-5 parts of additive. The tackifying resin has a unique molecular structural formula. A preparation method of the UV curing liquid optical cement comprises the steps that the active oligomer, the tackifying resin, the reactive diluent, the photoinitiator and the additive are placed in a planetary vacuum mixer and are stirred and mixed to be uniform, and a finished product is obtained through filtering and defoaming. The problem of cement overflow that common liquid optical cement cannot overcome and the problem that the common liquid optical cement is not suitable for the special lamination process of UV precuring, lamination and UV curing for cement overflow prevention are solved, a cement film formed by the UV curing liquid optical cement has moderate bonding strength and a good locating effect, the bonding strength is greatly improved after UV curing is carried out again, the surface of the cement film is very smooth, a certain edge shape is kept, and no edge collapse phenomenon occurs; the UV curing liquid optical cement is suitable for automatic equipment coating and especially suitable for full lamination of modules.

Owner:DONGGUAN POWERBOND NEW MATERIALS TECH DEV

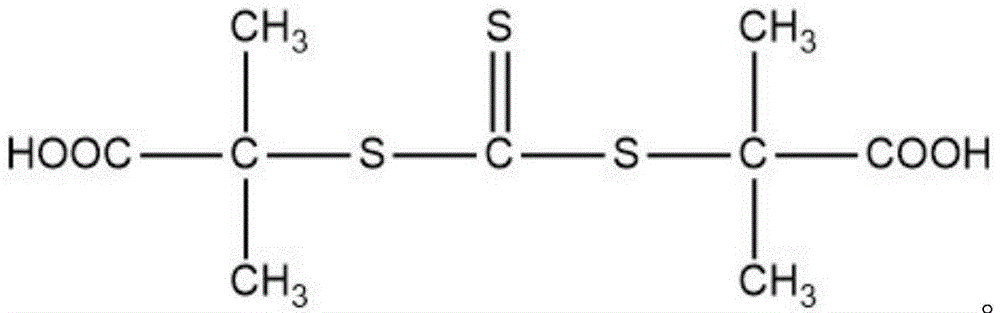

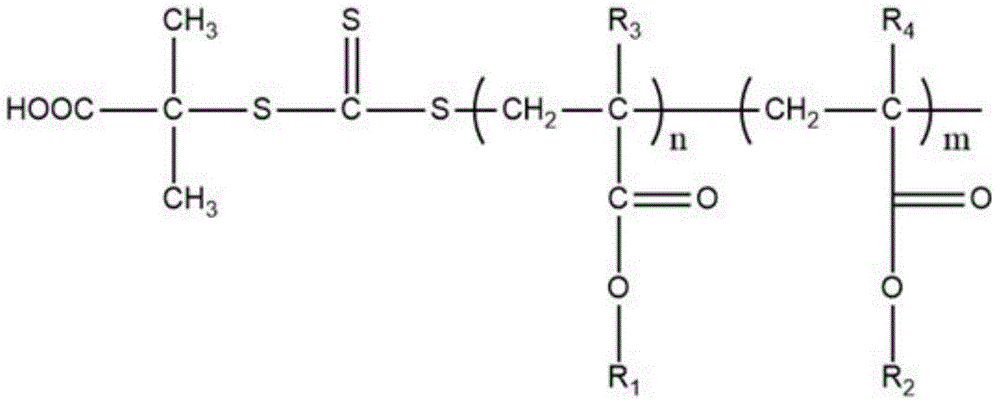

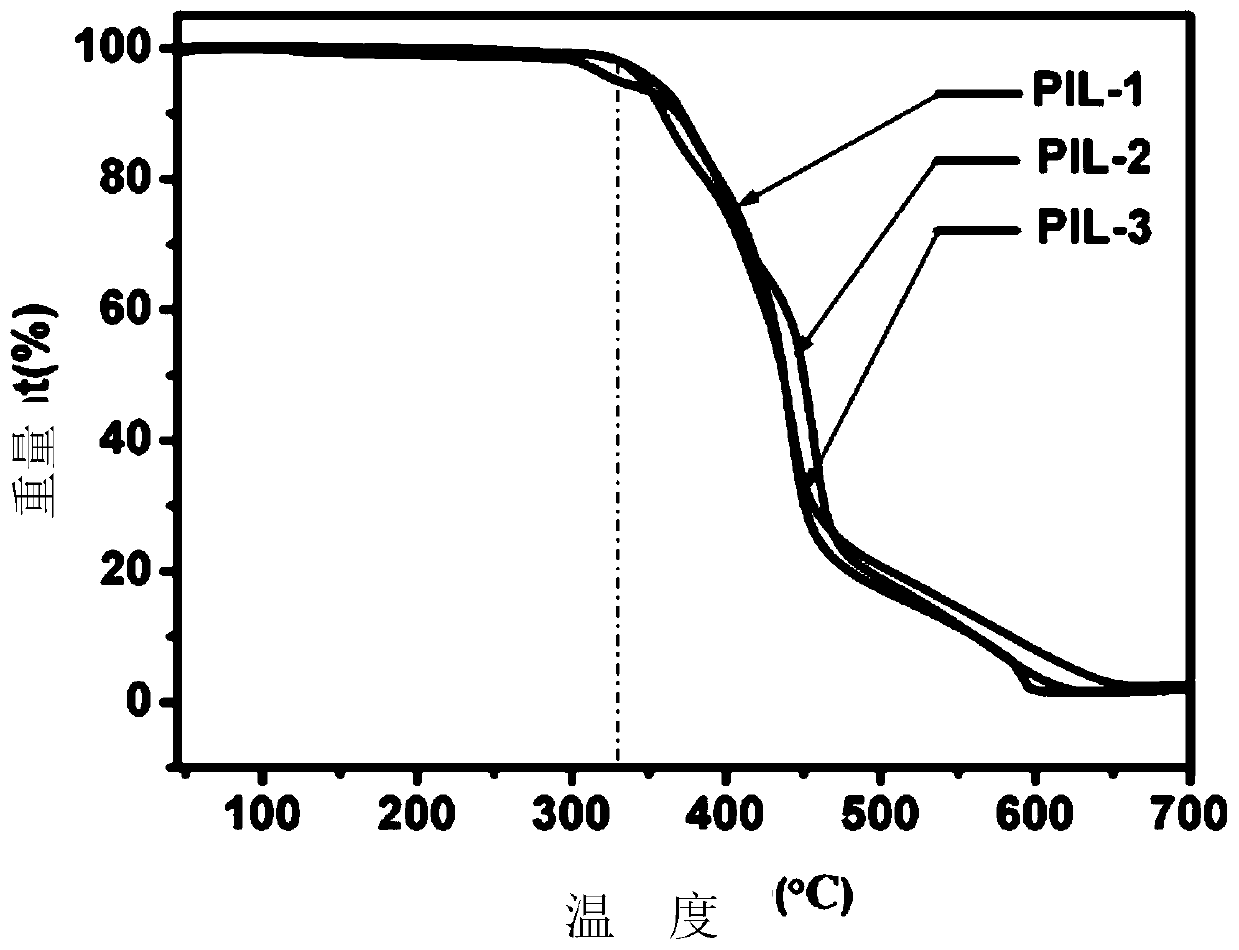

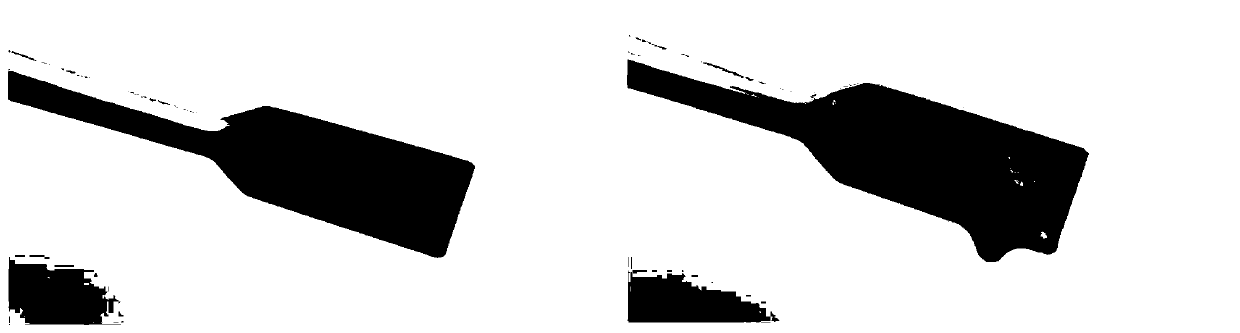

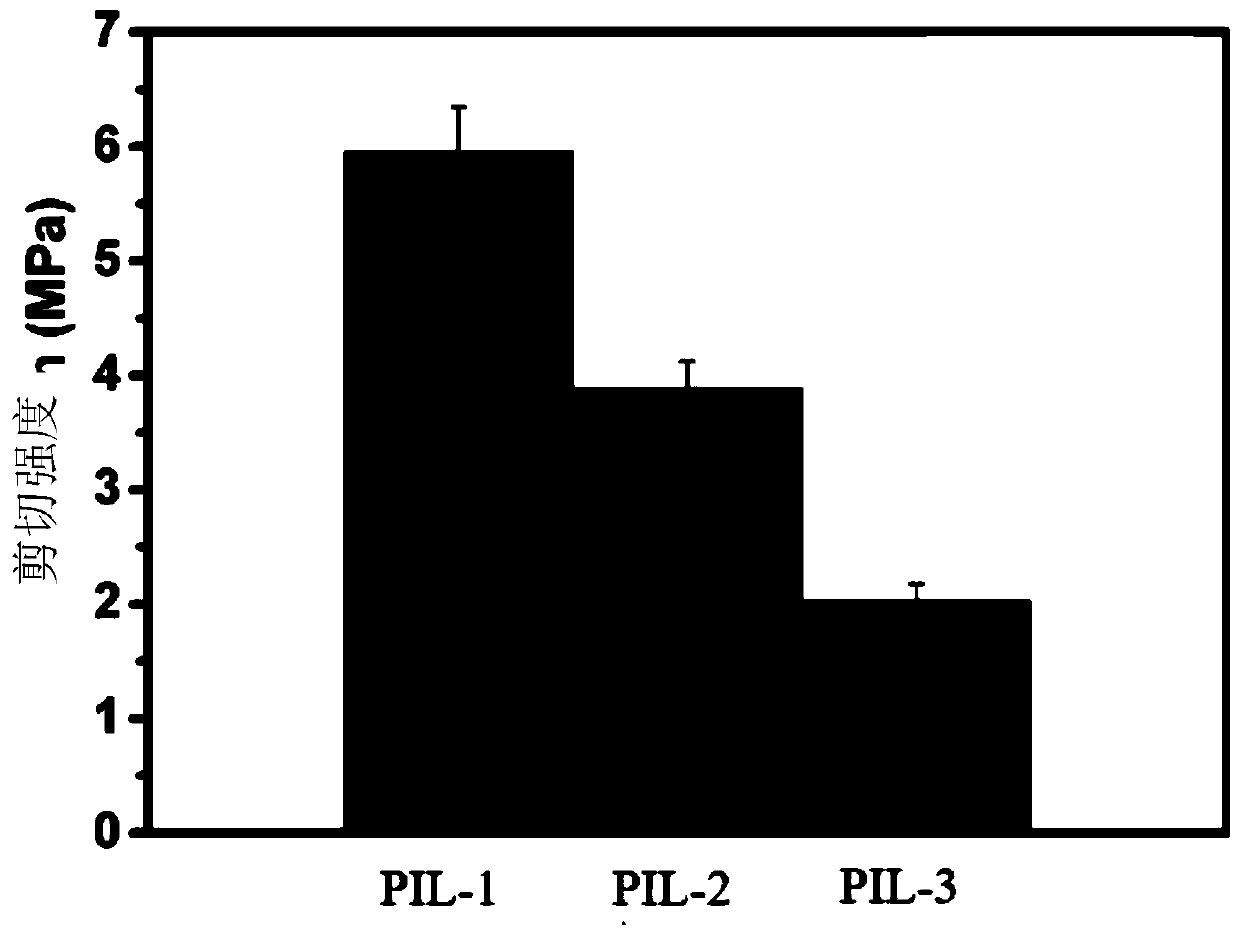

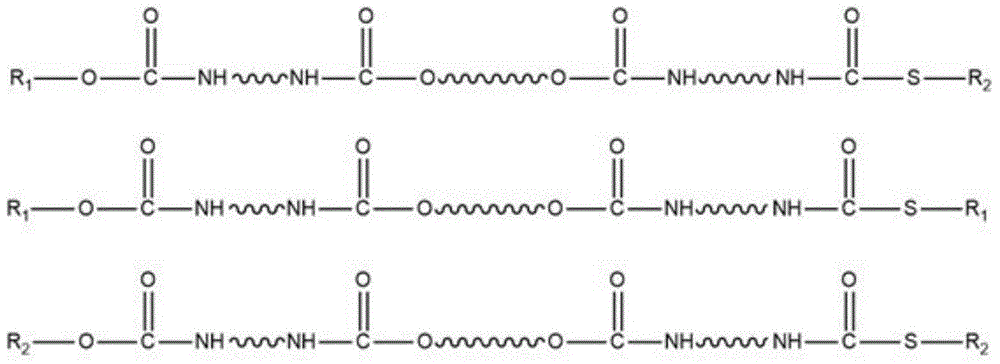

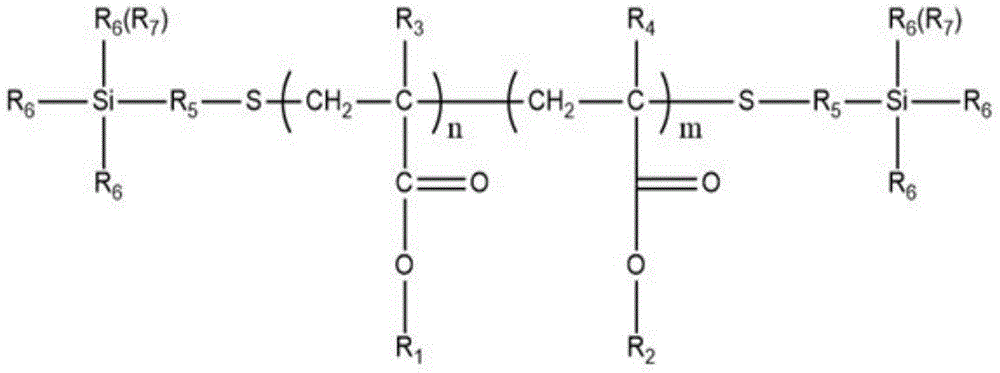

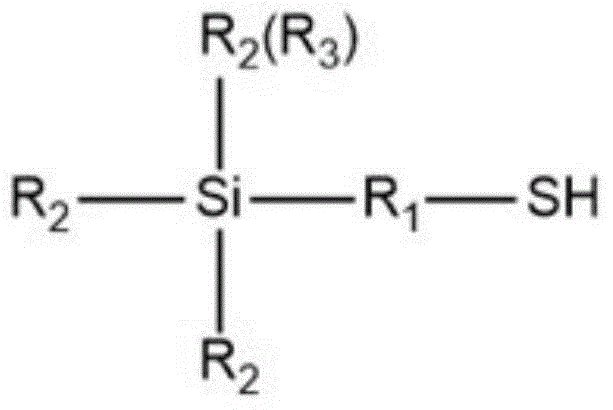

Polyionic liquid adhesive and preparation method thereof

The invention relates to a polyionic liquid adhesive which comprises cations and anions, the cations are formed by polymerizing ionic liquid monomers, and alkoxy side groups are contained on structural chains of the cations. Polyionic liquid formed by polymerizing alkoxy functionalized ionic liquid monomers can form very strong hydrogen bonds with the surfaces of most of adhered substrate materials, so that relatively strong adhesive force is brought; meanwhile, hydrogen-bond interaction between the alkoxy side groups and active protons on an imidazole ring or a pyridine heterocyclic ring possibly exists in the polyion liquid adhesive to form a physical crosslinking structure with certain strength, so that the cohesion of the adhesive is improved to a certain extent. Under the combined action of the two aspects, the polyionic liquid adhesive provided by the invention shows excellent adhesive property.

Owner:HUNAN UNIV

Conductive adhesive

InactiveCN101081969AFlexibleModerate bond strengthNon-macromolecular adhesive additivesConjugated diene hydrocarbon adhesivesEnd-groupElectromagnetic shielding

The present invention relates to conductive adhesive, and is especially one kind of conductive adhesive for adhering electromagnetic shielding material. The conductive adhesive has polybutadiene liquid rubber containing active end group as the base material, silver coated powder as the conductive stuffing and other assistants. Having low resistivity, moderate adhesion strength, certain elasticity and cold resistance, and low cost, the conductive adhesive may be applied widely in adhering electromagnetic shielding material, especially of great adhered area.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

High-toughness 3D printing paraffin forming material and preparation method thereof

ActiveCN106118082AImprove impact toughnessImproves strength and hardnessAdditive manufacturing apparatusParaffin waxBonding strength

The invention discloses a high-toughness 3D printing paraffin forming material. The high-toughness 3D printing paraffin forming material is prepared from components of raw materials in percentage by mass as follows: 30%-50% of paraffin, 2%-5% of bee wax, 5%-10% of epoxy resin, 2%-3% of a curing agent, 2%-20% of a viscosity modifier, 20%-30% of a toughening polymer, 6%-25% of a high-hardness polymer, 2%-4% of a filling material, 0.1%-0.3% of dyes and 2%-4% of a phase transferring agent. The bee wax is added to physically modify a paraffin support material, and the impact toughness of the paraffin support material is effectively improved; meanwhile, epoxy resin and the corresponding curing agent are added, and the adding quantity of the epoxy resin and the adding quantity of the corresponding curing agent are adjusted, so that the bonding strength of the paraffin support material and a 3D printing product interface is moderate while the hardness and the strength of the paraffin support material are improved and the shrinkage is reduced, and the paraffin support material is easy to peel off, doesn't deform and doesn't affect the support function on the 3D printing product in the printing process when removed in the later period. The toughening polymer and the high-hardness polymer are added to the paraffin support material, the needle penetration of the material can be effectively reduced, the toughness of the material is improved, and the high-toughness 3D printing paraffin forming material has excellent overall properties.

Owner:佛山市晗宇科技有限公司

UV-moisture dual-curing liquid optical cement and preparation method and application thereof

ActiveCN105985750ARealize the function of dual curingReduce consumptionPolyureas/polyurethane adhesivesEster polymer adhesivesUV curingReactive diluent

The invention discloses UV-moisture dual-curing liquid optical cement. The UV-moisture dual-curing liquid optical cement is prepared from, by weight, 45-80 parts of UV moisture curing matrix resin, 10-50 parts of tackifying resin, 10-35 parts of reactive diluents, 0.3-5 parts of photoinitiator and 1-5 parts of additive. The matrix resin and the tackifying resin have unique molecular structures. The invention further provides a preparation method of the UV-moisture dual-curing liquid optical cement. The preparation method comprises the following steps that the matrix resin and the tackfying resin are prepared; then all the materials are placed in a planetary vacuum mixer and are stirred and mixed to be uniform, and the finished product is obtained through filtering and defoaming. The problem of cement overflow that common liquid optical cement cannot overcome and the problem that the common liquid optical cement is not suitable for the special lamination process of UV precuring, lamination and moisture curing for cement overflow prevention are solved, a cement film formed by the UV-moisture dual-curing liquid optical cement after primary UV curing has moderate bonding strength and a good locating effect, the bonding strength is greatly improved after moisture curing, the surface of the cement film is very smooth, a certain edge shape is kept, no edge collapse phenomenon occurs, and the UV-moisture dual-curing liquid optical cement is suitable for automatic equipment coating.

Owner:DONGGUAN POWERBOND NEW MATERIALS TECH DEV

Microcapsule guar gum and preparation method thereof

ActiveCN103045212AMicroencapsulationIncrease the use concentrationDrilling compositionHigh concentrationPetroleum resin

The invention provides microcapsule guar gum which comprises guar gum and C5 petroleum resin coating the guar gum. The invention further provides a preparation method of the microcapsule guar gum. According to the embodiment of the application, the guar gum is coated with the C5 petroleum resin, so that the microencapsulation of the guar gum is achieved, a use concentration of the guar gum is increased under the condition that the guarant viscosity is not increased, the microcapsule guar gum with a very high concentration can be pumped over, the gum strength of the guar gum can be improved greatly, and cracks and solution caves of strata can be blocked off well.

Owner:CHINA NAT OFFSHORE OIL CORP +1

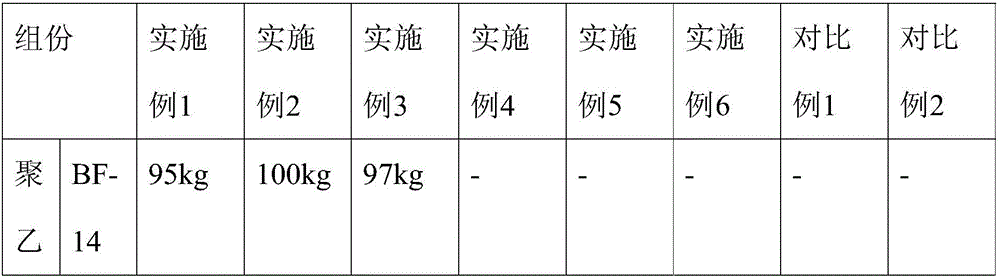

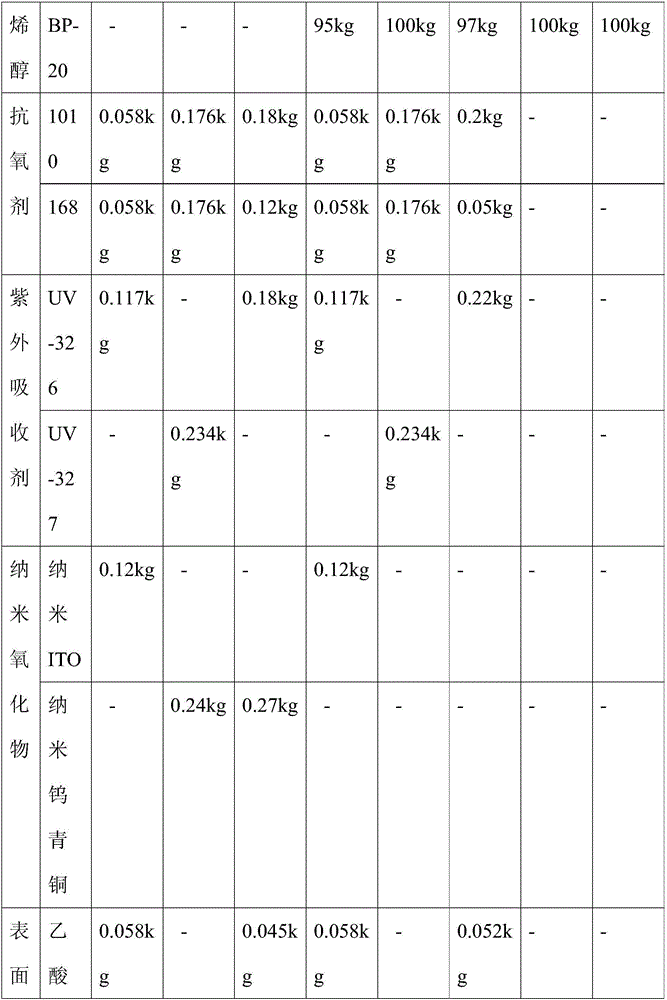

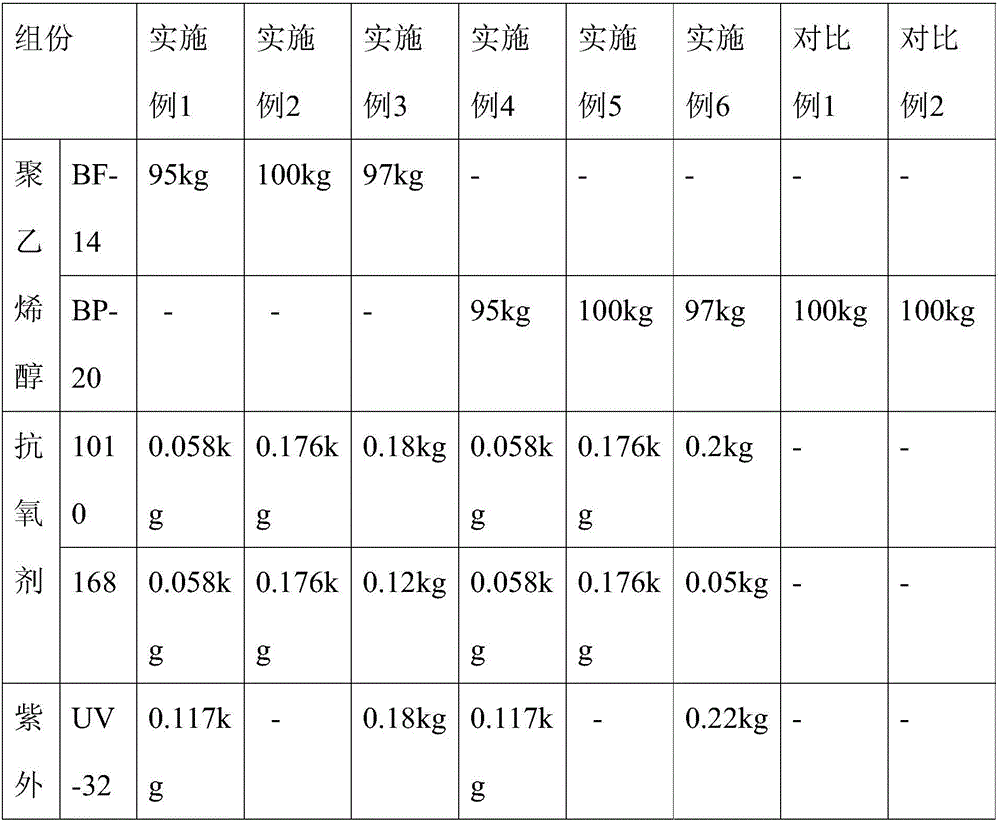

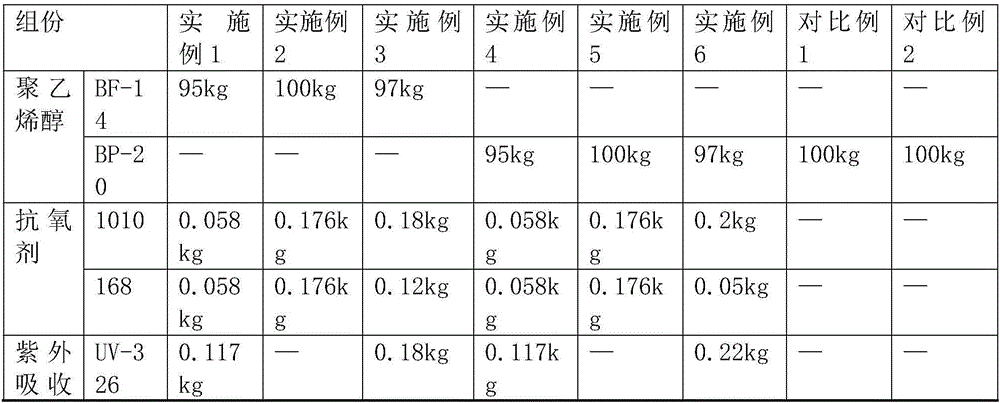

Modified PVB resin powder and preparation method thereof

ActiveCN106543927AEvenly dispersedIncrease productivityNon-macromolecular adhesive additivesFilm/foil adhesivesAntioxidantNanoparticle

The invention relates to modified PVB resin powder and a preparation method thereof. The modified PVB resin powder is prepared by adding an antioxidant, an ultraviolet absorber, a surface tension regulator and nano oxide which can be uniformly dispersed in resin powder in the synthesis process of PVB resin powder which is a raw material, so that the problem of non-uniform dispersion of nanoparticles and auxiliaries in the resin powder is solved, and production efficiency of extrusion and casting of PVB films is improved; blending and premixing links are omitted, so that powder pollution is avoided. The modified PVB resin powder prepared by the method has excellent temperature resistance, heat insulativity and infrared rejection rate and moderate bonding strength.

Owner:ZHEJIANG DECENT PLASTIC

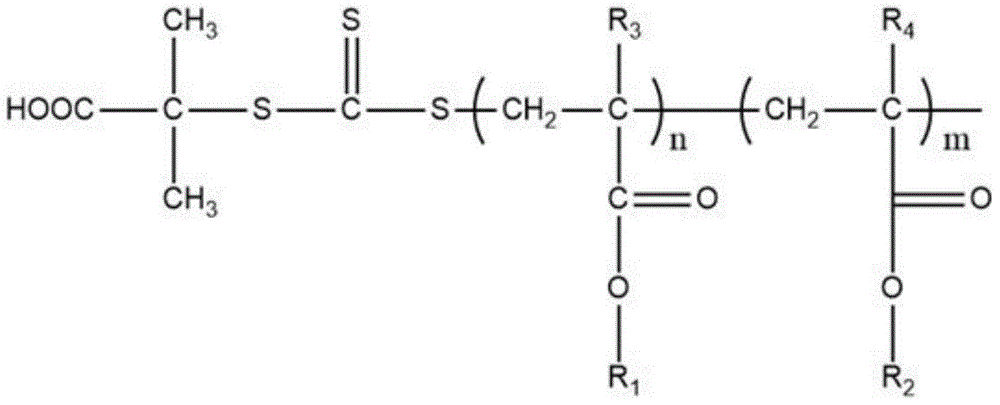

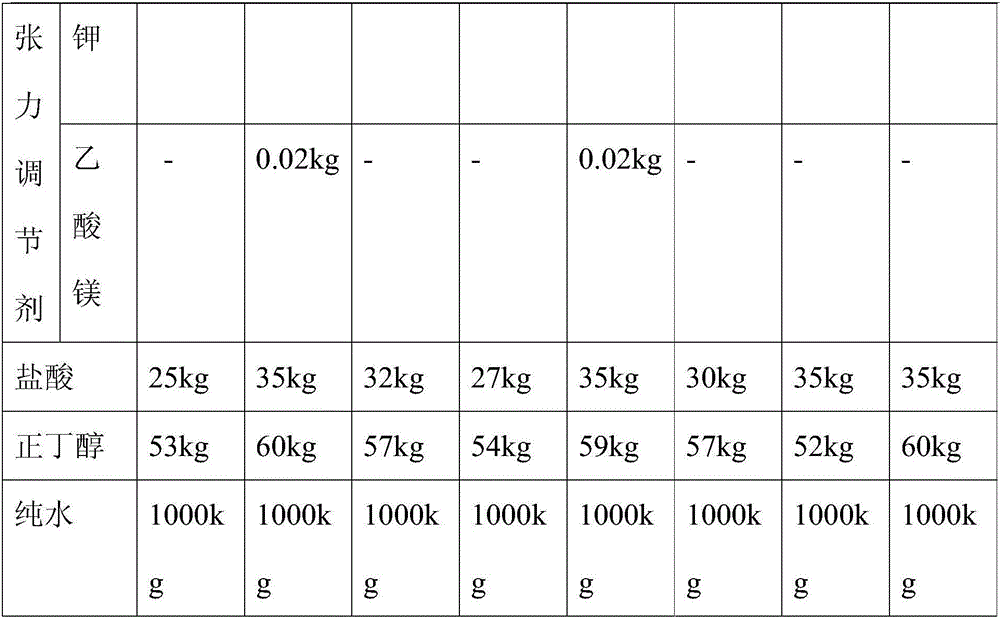

Ultraviolet-cured liquid optical adhesive as well as preparation method and application thereof

ActiveCN111808534AThere will be no glue overflow problemModerate bond strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesOligomerUltraviolet

The invention provides an ultraviolet curing liquid optical adhesive as well as a preparation method and application thereof. The intrinsic solid shrinkage rate of the ultraviolet curing liquid optical adhesive is 0.6% or below. The ultraviolet curing liquid optical adhesive comprises tackifying resin, an active oligomer, an active diluent and a photoinitiator, wherein the tackifying resin has a structure as shown in a formula I which is described in the specification. The ultraviolet curing liquid optical adhesive can reduce curing shrinkage and reduce the mura risk of yellow spots in a liquid crystal touch screen attaching process.

Owner:DONGGUAN POWERBOND NEW MATERIALS TECH DEV

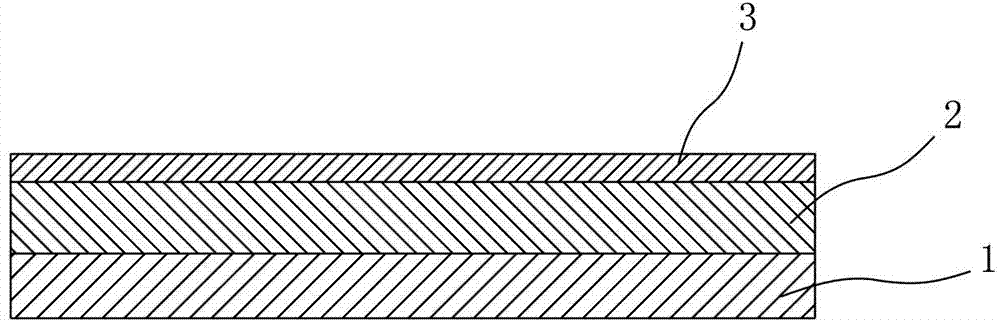

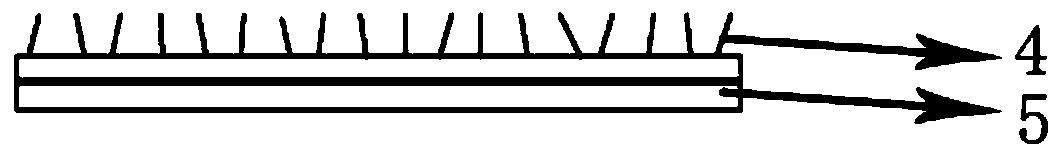

Thermal composite light polyurethane film and preparation method thereof

InactiveCN102963049AImprove breathabilityReduce labor costsSynthetic resin layered productsLaminationMelting temperatureHot-melt adhesive

The invention provides a thermal composite light polyurethane film which comprises a hot melt adhesive layer, a wet-process polyurethane layer and a dry-process polyurethane cover layer which are composited in sequence from bottom to top. The melting temperature of the hot melt adhesive layer is lower than that of the wet-process polyurethane layer and the dry-process polyurethane cover layer. The polyurethane film provided by the invention can be composited with various substrates by hot press welding, and has the advantages of simple structure, convenience in use, flexible application, light weight, high softness, easiness for processing and the like.

Owner:QUANZHOU WANHUA SEWANG MICRO FIBER CO LTD

Aqueous polyurethane adhesive for bead planting and preparation method thereof

InactiveCN102391821ALow curing temperatureReduce energy consumptionPolyureas/polyurethane adhesivesEpoxyPolyurethane adhesive

The invention discloses an aqueous polyurethane adhesive for bead planting and a preparation method thereof, which belong to the field of adhesive preparation. After polyether polyol and isocyanic acid react for a certain period of time, epoxy resin, hydrophilic chain extender and diglycol are added, prepolymer is produced after a certain period of reaction, solvent is added to decrease the viscosity of the prepolymer, neutralization for salification, emulsification and secondary chain extension are then carried out, the solvent is removed by vacuum, and thereby main agent is prepared; the main agent is mixed with curing agent according to a certain proportion by weight, and thereby the aqueous polyurethane adhesive for the bead planting is prepared. By choosing the hydrolysis-resistant polyether polyol, the method enhances the hydrolysis resistance of the aqueous polyurethane adhesive by means of epoxy modification, moreover, the produced adhesive film is not sticky, the bonding strength is moderate, and the properties of the aqueous polyurethane adhesive for the bead planting are excellent.

Owner:BEIJING COMENS NEW MATERIALS

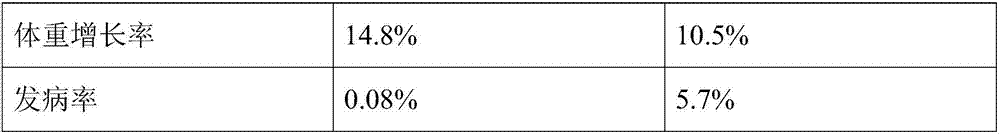

Feed for promoting intestinal development of meat chickens in fattening period

InactiveCN106509471AImprove developmentPromote peristalsisFood processingAnimal feeding stuffBiotechnologyRapeseed

The present invention discloses a feed for promoting intestinal development of meat chickens in a fattening period. The feed comprises the following raw materials in parts by weight: 3-7 parts of microcrystalline cellulose, 3-5 parts of modified soybean proteins, 4-6 parts of salted duck egg yolk, 3-7 parts of puffed soybeans, 4-10 parts of soybean cake, 12-20 parts of rapeseed meal, 12-18 parts of rapeseed cake, 4-8 parts of lard, 25-55 parts of corn, 10-16 parts of wheat, 3-9 parts of malt powder, 4-12 parts of corn stalks, 1.5-2.5 parts of vital gluten, 1.5-2.5 parts of coix chinensis, 1.5-2.5 parts of haw powder, 0.5-1.5 parts of unprocessed rehmannia roots, 1.5-2.5 parts of grape leaves, 0.6-1 part of barley malt, 0.4-1 part of red date, 1.5-2.5 parts of honey, 1.5-3.5 parts of spirulina platensis powder, 1.5-2.5 parts of soybean lecithin, 1-3 parts of malt selenium, 0.2-0.8 part of red chili powder, 0.4-0.8 part of vitamin, 1.5-2.5 parts of calcium hydrogen phosphate and 2-4 parts of stone powder.

Owner:岳从军

Cold-pressurized adhesive paper tape

The cold-pressurized adhesive paper tape consists of paper substrate and adhesive layer painted onto the surface of the paper substrate. The adhesive consists of natural latex of a 60% solid content, copolymer of vinyl acetate and acrylate and with a 45% solid content, soft water or distilled water and marketable rubber antiager. The cold-pressurized adhesive paper tape is mainly used in producing braid for film capacitor, resistor and other small electronic elements. It has proper adhering strength and will not produce residual on electronic elements and pollutant to other article.

Owner:GUANGDONG PAPER IND RES INST

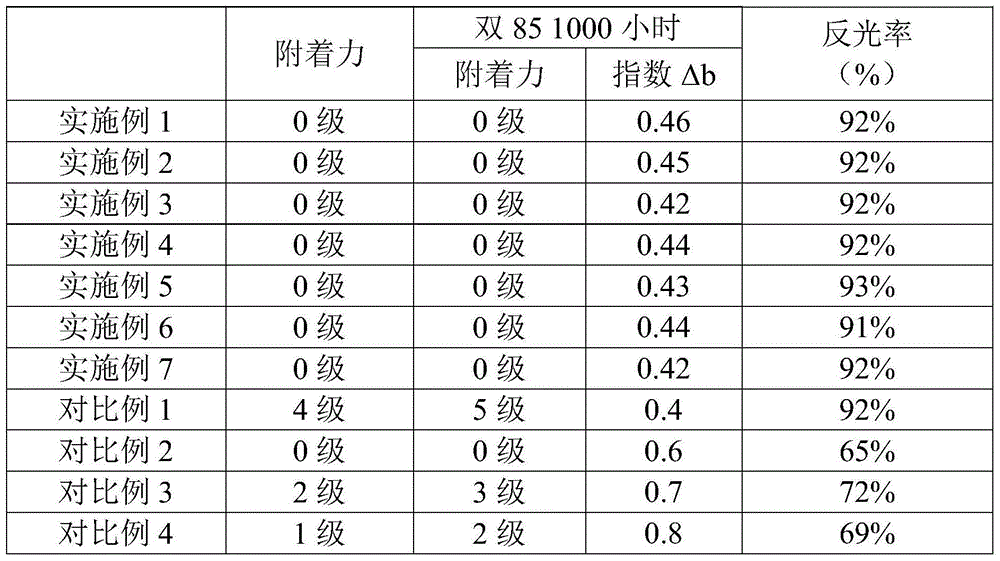

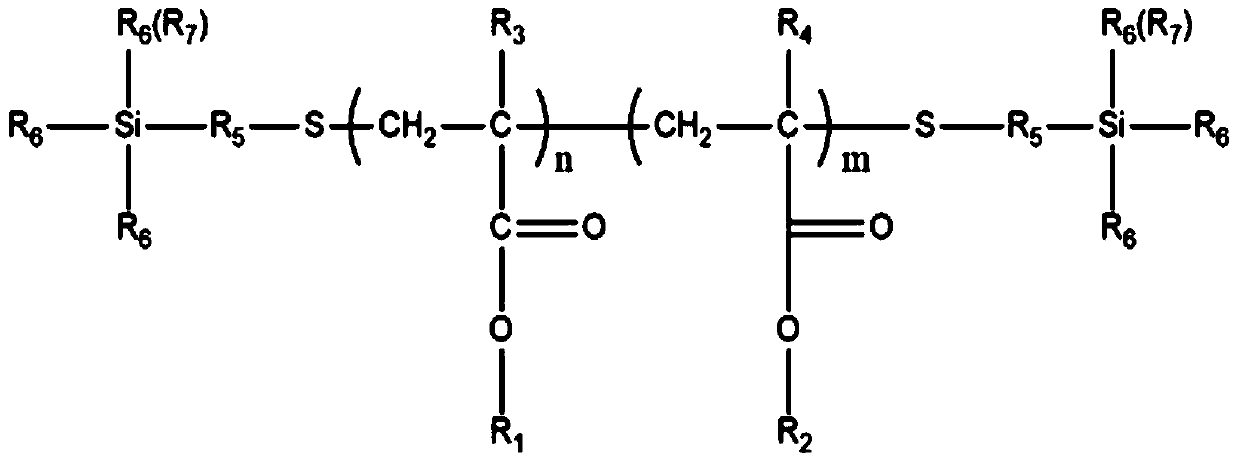

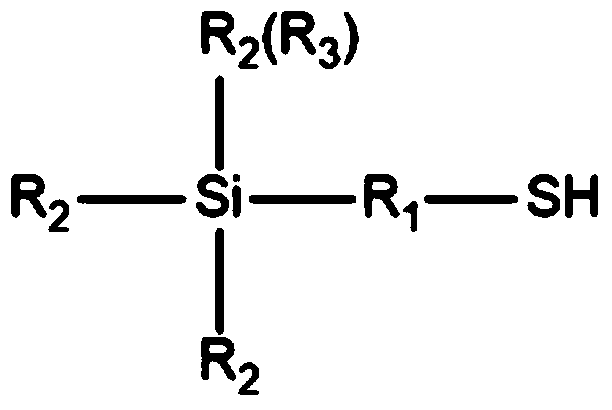

Organosilicone composition, reflecting coating, preparation method therefor and photovoltaic module comprising reflecting coating

ActiveCN106317894AImprove adhesionModerate bond strengthPhotovoltaic energy generationEpoxy resin coatingsCross linkerSilorane Resins

The invention relates to the field of preparation of photovoltaic cells and discloses an organosilicone composition, a reflecting coating, a preparation method therefor and a photovoltaic module comprising the reflecting coating. The organosilicone composition contains basic polymerization ingredients, a catalyst, a cross-linker and reflecting particles, wherein the basic polymerization ingredients, the catalyst and the cross-linker are not simultaneously mixed before use, the basic polymerization ingredients contain the ingredients in parts by weight: 100 parts of polymethyl siloxane, of which each molecule contains at least two Si-Vi bonds, 5-15 parts of hydrogenated epoxy resin or alicyclic epoxy resin modified hydroxyl-terminated polymethylvinylsiloxane and 10-20 parts of siloxane resin containing at least two Si-Vi bonds, and the cross-linker is polyorganosiloxane containing at least two Si-H bonds. According to the organosilicone composition, the adhesion of the reflecting coating can be improved while the curing time of the reflecting coating prepared from the organosilicone composition is shortened.

Owner:BYD CO LTD

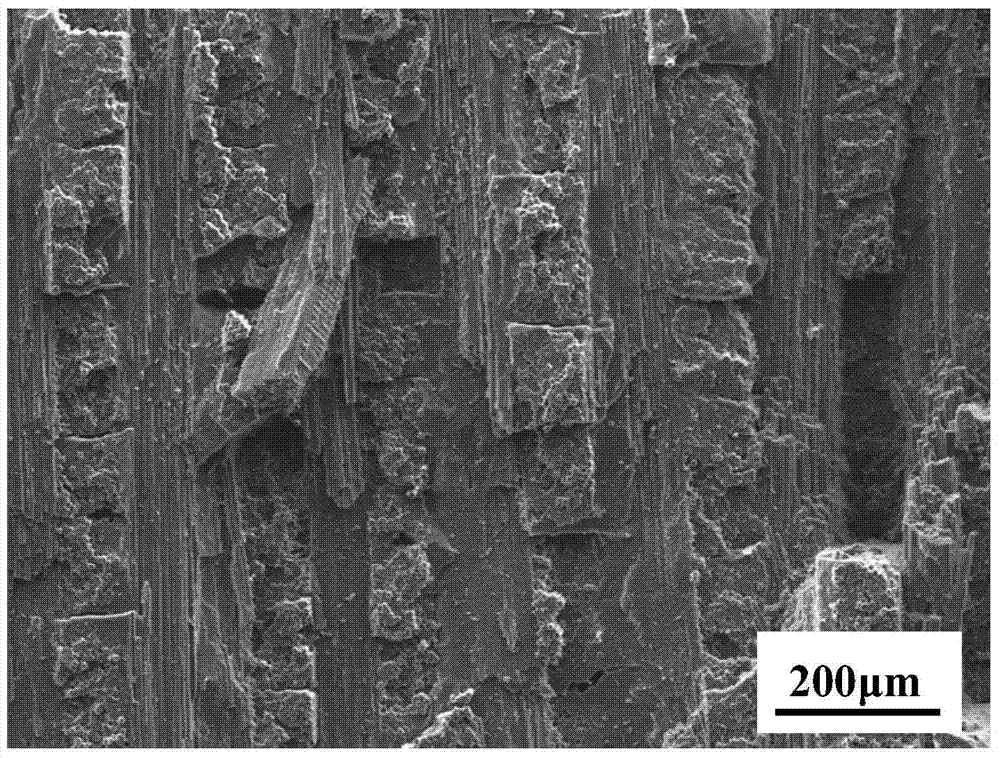

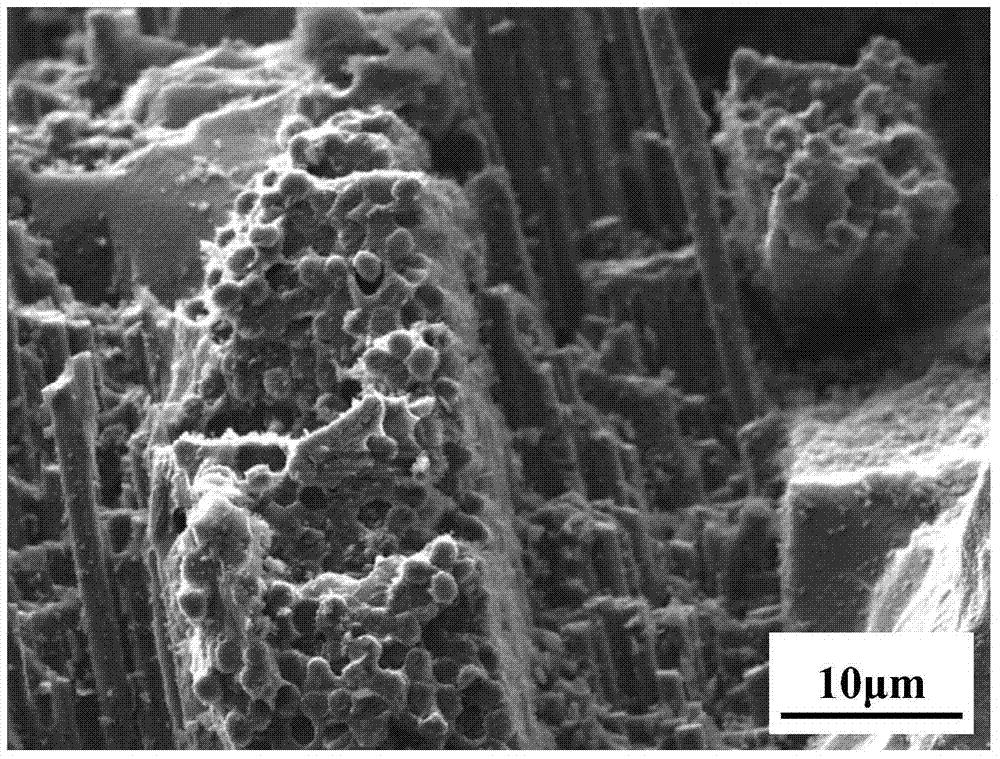

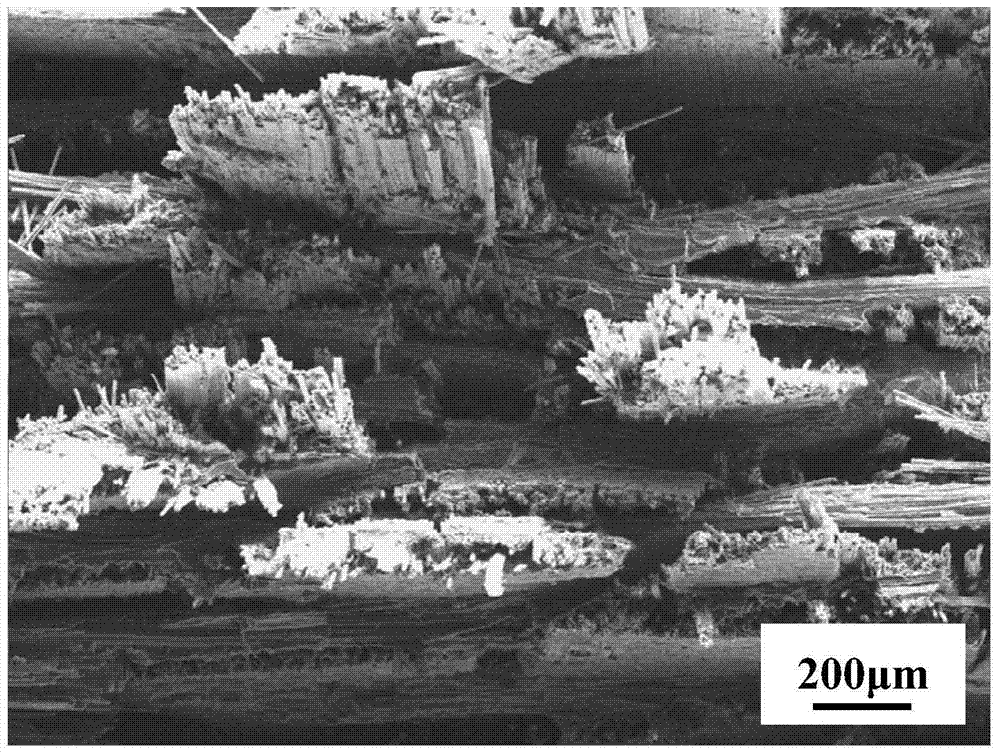

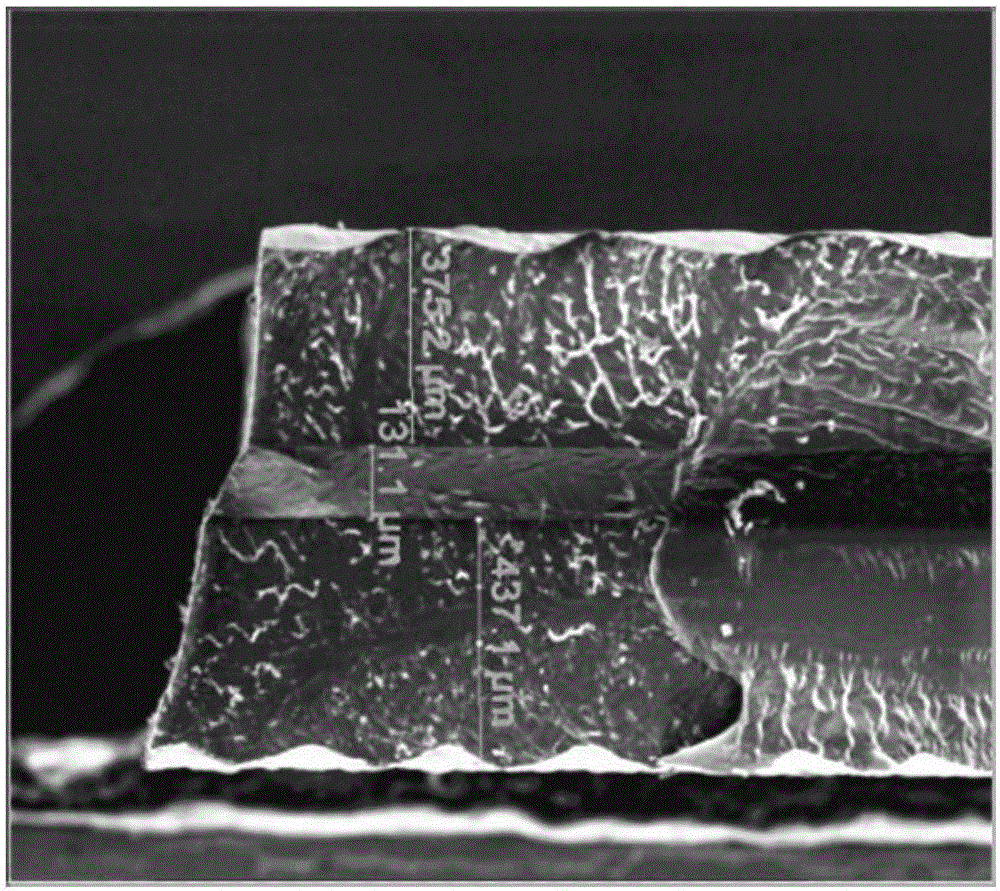

Method for improving binding strength of two-dimensional carbon/carbon composite material

The invention relates to a method for improving the binding strength of a two-dimensional carbon / carbon composite material so as to improve the tensile strength of the material in the horizontal direction, belonging to the technical field of heatproof bearing integrated carbon / carbon composite materials. The two-dimensional carbon / carbon composite material prepared by the method is moderate in binding strength of fibers and matrix interfaces, the fracture appearance is rough, multi-layered and multi-size fibers can be pulled out, the bearing and the force conduction effect of the fibers are brought into good play, the tensile property of the material is greatly improved, and the tensile strength is 137-301MPa, that is, the tensile strength is improved by more than 50% when being compared with the original tensile strength of 92MPa.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

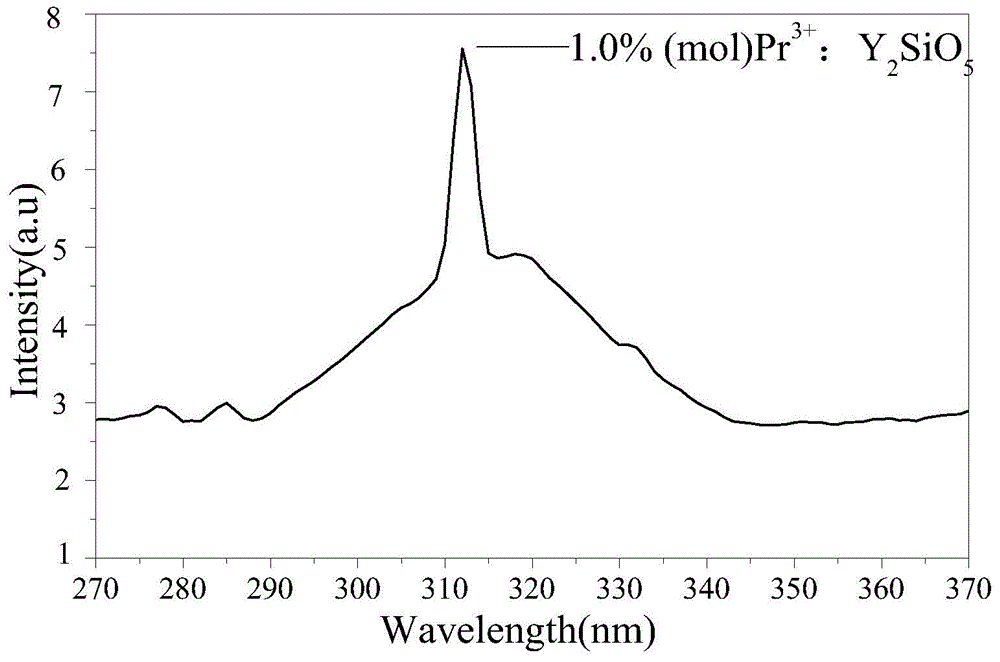

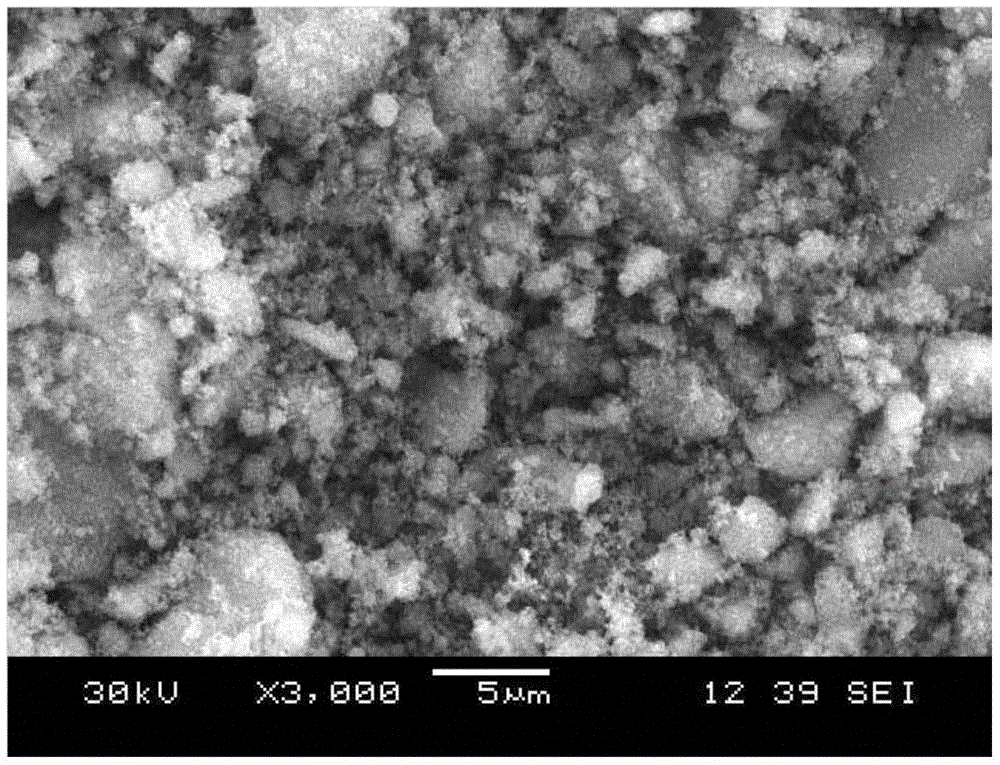

PR<3+>:Y2SiO5/TiO2 photocatalytic composite film based on glass fiber filter film carrier, preparation method and application thereof

InactiveCN104923210AImprove photocatalytic performanceGood chemical stabilityWater/sewage treatment by irradiationEnergy based wastewater treatmentGlass fiberComposite film

The invention discloses a Pr<3+>:Y2SiO5 / TiO2 photocatalytic composite film based on a glass fiber filter film carrier, a preparation method and an application thereof. The composite film is formed by loading 1% (mol) Pr<3+>:Y2SiO5 / nano TiO2 on the surface of a glass fiber film, so that the photocatalytic performance of the material is improved by utilizing the synergistic effect of the glass fiber and the Pr<3+>:Y2SiO5. The composite film has good chemical stability, the advantages of Pr<3+>:Y2SiO5 and nano TiO2 photocatalyst can be effectively utilized, the pohotocatalytic degradation under the visible light can be carried out, and the energy is saved.

Owner:NANJING UNIV OF SCI & TECH

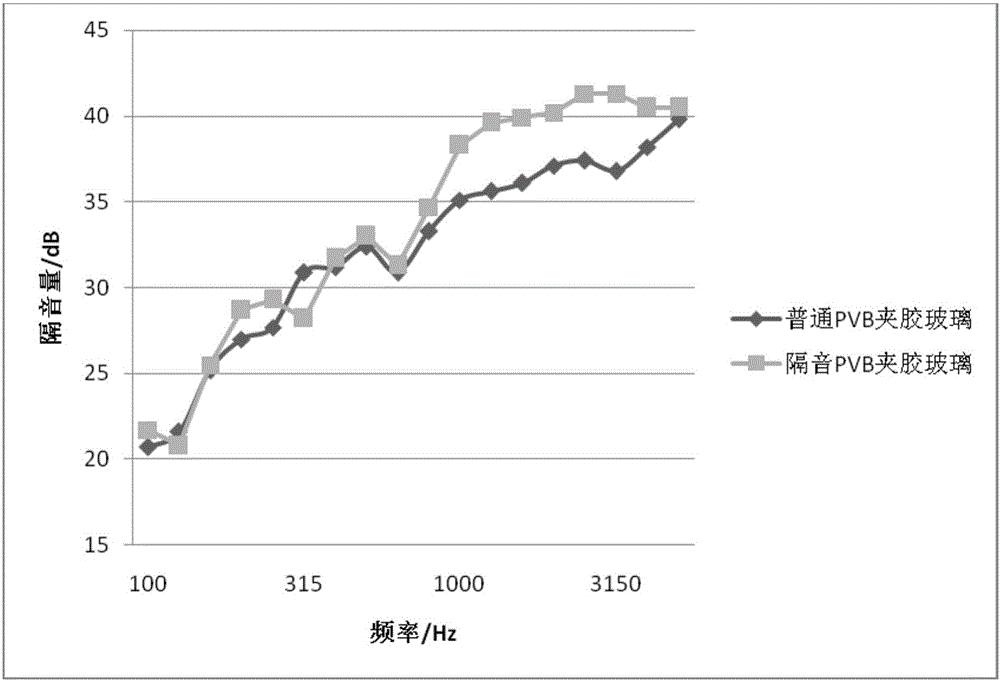

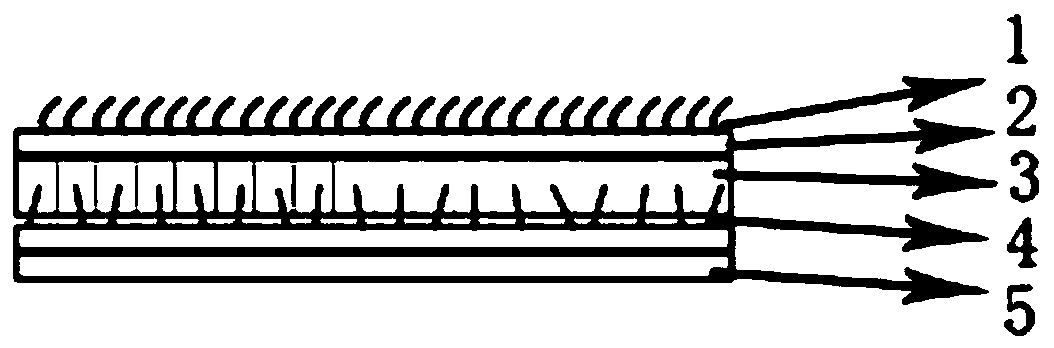

Sound-insulation PVB photographic film and preparation method thereof

ActiveCN106543612AEvenly dispersedIncrease productivitySynthetic resin layered productsGlass/slag layered productsMaterials scienceFilm (photographic)

The invention relates to a sound-insulation PVB photographic film and a preparation method thereof. The sound-insulation PVB photographic film is formed by compounding three layers of films A, B and C, wherein the thickness of the middle-layer film B is 100-200 microns, the thickness of the film A outside the film B is 300-500 microns, and the thickness of the film C outside the film B is 300-500 microns; and the middle-layer film B is prepared from modified PVB resin powder with a fusion index of 6g / 10min-10g / 10min, and the film A and the film C are prepared from modified PVB resin powder with a fusion index of 4g / min-5g / 10min. The prepared three-layer sound-insulation PVB photographic film is capable of effectively blocking noise within in a human ear-sensitive range of 1000Hz-4000Hz, and compared with PVB with a conventional thickness, the sound-insulation effect can be increased by 3dB-5dB.

Owner:ZHEJIANG DECENT PLASTIC

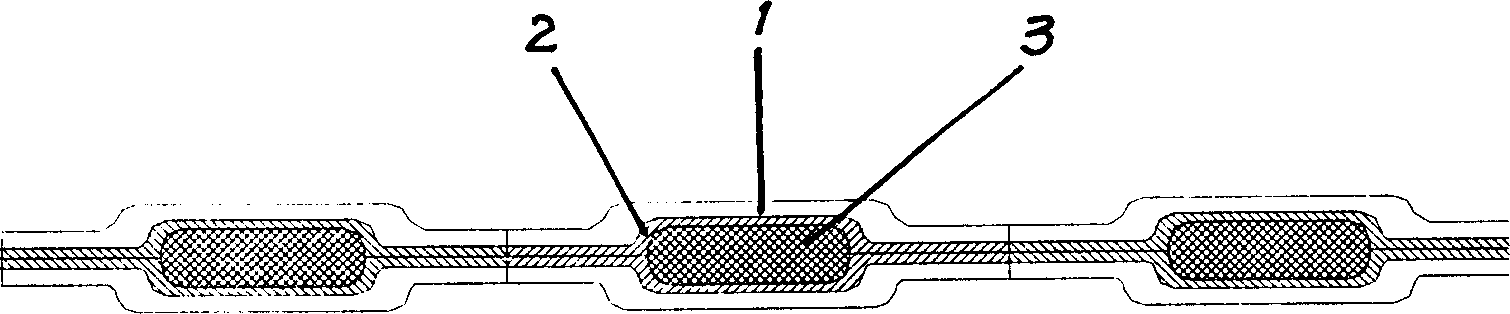

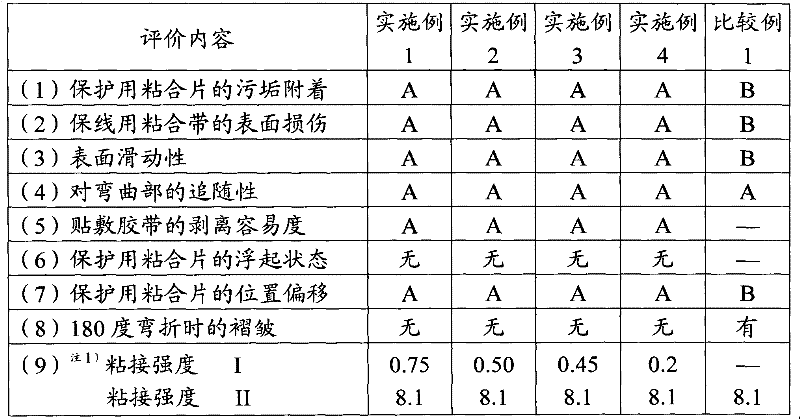

Application tape and protective pressure-sensitive adhesive sheet equipped with application tape

InactiveCN102373021AModerate surface slipperyModerate softnessEster polymer adhesivesThin material handlingStatic friction coefficientPlasticizer

The present invention relates to an application tape, which has a function of improving an application workability when a protective pressure-sensitive adhesive sheet is applied to an adherend, in which the application tape has a surface that has a coefficient of static friction for a PET film of 0.05-1.0 in the case where the PET film is slid on the application tape having a size of 30 mm 30 mm under a condition of a load of 100 g and a rate of 100 mm / min, and the application tape has a Young's modulus of 300 MPa or lower. In a preferred embodiment the base layer of the tape comprises a soft polyvinyl chloride which contains a plasticizer and the adhesive layer comprises an acrylic pressure-sensitive adhesive.

Owner:NITTO DENKO CORP

Rubber mat layer for anti-slip carpet

PendingCN110421913ANot easy to fall offExtended service lifeSynthetic resin layered productsCarpet fastenersPolyesterCombined use

The invention discloses a rubber mat layer for an anti-slip carpet. The rubber mat layer for the anti-slip carpet comprises a bottom non-slip water-repellent layer and an upper bonding layer, whereinthe bonding layer is a single-sided fabric which is provided with a plurality of monofilament protrusions. The bonding layer is the single-sided fabric prepared from monofilaments with a fineness of 20 D or above and having protrusions or is a single-sided structure layer formed by cutting a three-dimensional mesh structure layer from the middle; and the three-dimensional mesh structure layer is composed of an upper warp-knitted eyelet fabric layer, a lower warp-knitted eyelet fabric layer and a plurality of polyester fibers, polypropylene fibers or nylon monofilaments which are vertically arranged in the middle and connect the upper and lower warp-knitted mesh fabric layers. The rubber mat layer for the anti-slip carpet in the invention can be bonded with a plurality of carpet surfaces for use; the rubber mat layer has moderate bonding strength, and is free of the phenomenon of damage to carpet surfaces during dismounting due to too high bonding force or the phenomena of easy shiftingand warpage of the carpet surfaces due to too low bonding force; and the rubber mat layer has the advantages of rollability, foldability, machine-washability, easiness in laying, convenience in transporting, etc.

Owner:KUNSHAN YIJIAJU TEXTILE CO LTD

Wave-absorbing ceramic-based composite material with multi-scale toughening and layering structure and preparation method thereof

ActiveCN113754455AAchieve uniformityAvoid the problem of uneven distribution inside and outsideNanostructureBinding force

The invention discloses a wave-absorbing ceramic-based composite material with a multi-scale toughening and layering structure and a preparation method thereof. The preparation method comprises the following steps: deposition of an interface layer, introduction of a one-dimensional nano toughening phase, design of a layering structure preform, suction filtration and impregnation of a precursor, and cracking. A one-dimensional reinforcing phase is introduced into the continuous fiber reinforced ceramic-based composite material in situ, and multi-stage toughening of the ceramic-based composite material is achieved. The one-dimensional nano reinforced phase is introduced through in-situ growth before the fiber preform is formed, so that the nano reinforced phase is uniformly distributed in the ceramic-based composite material while relatively strong binding force between the one-dimensional nano structure and the fiber is ensured, the designability of the microstructure of the composite material is improved, and the preparation period is shortened. The nano wave-absorbing agent is in gradient distribution in the composite material by adopting a suction filtration and impregnation process, the excellent wave-absorbing performance of the material can be ensured, meanwhile, a preform is prepared by adopting a layering process, a special-shaped component can be designed and prepared, and the design requirements of aerospace hot-end components can be met.

Owner:湖北瑞宇空天高新技术有限公司

UV-moisture dual-cure liquid optical adhesive and its preparation method and application

ActiveCN105985750BRealize the function of dual curingReduce consumptionPolyureas/polyurethane adhesivesEster polymer adhesivesUV curingReactive diluent

The invention discloses UV-moisture dual-curing liquid optical cement. The UV-moisture dual-curing liquid optical cement is prepared from, by weight, 45-80 parts of UV moisture curing matrix resin, 10-50 parts of tackifying resin, 10-35 parts of reactive diluents, 0.3-5 parts of photoinitiator and 1-5 parts of additive. The matrix resin and the tackifying resin have unique molecular structures. The invention further provides a preparation method of the UV-moisture dual-curing liquid optical cement. The preparation method comprises the following steps that the matrix resin and the tackfying resin are prepared; then all the materials are placed in a planetary vacuum mixer and are stirred and mixed to be uniform, and the finished product is obtained through filtering and defoaming. The problem of cement overflow that common liquid optical cement cannot overcome and the problem that the common liquid optical cement is not suitable for the special lamination process of UV precuring, lamination and moisture curing for cement overflow prevention are solved, a cement film formed by the UV-moisture dual-curing liquid optical cement after primary UV curing has moderate bonding strength and a good locating effect, the bonding strength is greatly improved after moisture curing, the surface of the cement film is very smooth, a certain edge shape is kept, no edge collapse phenomenon occurs, and the UV-moisture dual-curing liquid optical cement is suitable for automatic equipment coating.

Owner:DONGGUAN POWERBOND NEW MATERIALS TECH DEV

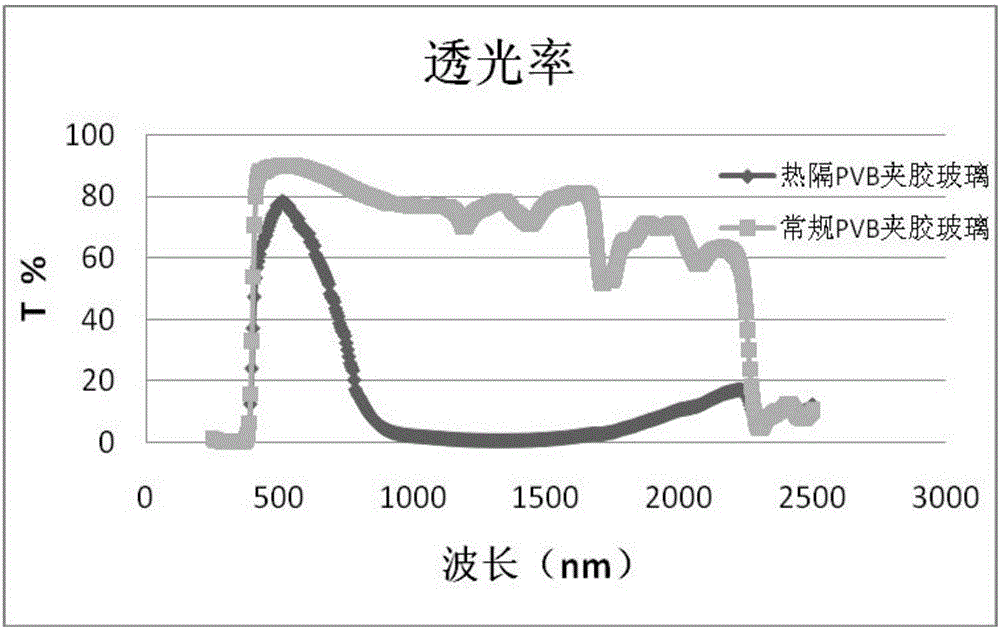

PVB film capable of blocking ultraviolet rays and infrared rays simultaneously and preparation method thereof

InactiveCN106752996AModerate bond strengthFully playNon-macromolecular adhesive additivesFilm/foil adhesivesInfraredUltraviolet

The invention relates to a PVB (polyvinyl butyral) film capable of blocking ultraviolet rays and infrared rays simultaneously and a preparation method thereof. The PVB film capable of blocking ultraviolet rays and infrared rays simultaneously is formed by compounding an upper layer film, a middle layer film and a lower layer film sequentially, wherein the thickness of the middle layer film is 110-150 microns, and the thicknesses of the upper layer and lower layer films are 150-450 microns; the material of the middle layer film is prepared from modified PVB resin powder of which the melt index is 5-8g / 10min, and the materials of the upper layer and lower layer films are prepared from modified PVB resin powder of which the melt index is 3-4g / 10min; and a preparation method of the modified PVB resin powder comprises the steps of performing a condensation reaction on selected raw materials, and then performing neutralization treatment, dehydration and drying preparation to prepare the modified PVB resin powder. A prepared three-layer PVB film is applied to laminated glass and can effectively block infrared rays of which the wavelength is 780-2500nm and ultraviolet rays of which the wavelength is 200-380nm.

Owner:ZHEJIANG DECENT PLASTIC

UV curing liquid optical glue and its preparation method and application

ActiveCN105985749BThere will be no glue overflow problemModerate bond strengthPolyureas/polyurethane adhesivesEster polymer adhesivesOligomerUV curing

The invention discloses UV curing liquid optical cement. The UV curing liquid optical cement is prepared from, by weight, 20-70 parts of active oligomer, 10-50 parts of tackifying resin, 10-40 parts of reactive diluent, 0.3-5 parts of photoinitiator and 1-5 parts of additive. The tackifying resin has a unique molecular structural formula. A preparation method of the UV curing liquid optical cement comprises the steps that the active oligomer, the tackifying resin, the reactive diluent, the photoinitiator and the additive are placed in a planetary vacuum mixer and are stirred and mixed to be uniform, and a finished product is obtained through filtering and defoaming. The problem of cement overflow that common liquid optical cement cannot overcome and the problem that the common liquid optical cement is not suitable for the special lamination process of UV precuring, lamination and UV curing for cement overflow prevention are solved, a cement film formed by the UV curing liquid optical cement has moderate bonding strength and a good locating effect, the bonding strength is greatly improved after UV curing is carried out again, the surface of the cement film is very smooth, a certain edge shape is kept, and no edge collapse phenomenon occurs; the UV curing liquid optical cement is suitable for automatic equipment coating and especially suitable for full lamination of modules.

Owner:DONGGUAN POWERBOND NEW MATERIALS TECH DEV

Complexing agent for preparing tungsten carbide granule reinforced steel matrix skin layer composite material

The invention discloses a preparation method for complexing agent to WCp reinforcing steel-base surface composite material, which comprises 15-30% thermosetting water-soluble phenolic resin and borax, 1-7% mixture of 300 item aluminum powder, 300 item high carbon ferro-chrome and 270 item ferro-molybdenum powder, and water. The product has well wettability with WC particle, proper binding strength, low foam quantity, little bad residue, and strong function to eliminate defect between metal body and particle, and sets base for casting-osmosis method to prepare the said composite material.

Owner:XI AN JIAOTONG UNIV

Exterior wall surface dry powder coating and preparation method thereof

The invention belongs to the technical field of coating, and particularly relates to exterior wall surface dry powder coating and a preparation method thereof. The exterior wall surface dry powder coating is mainly prepared from the following raw materials in parts by weight: 45-50 parts of heave calcium, 10-20 parts of grey calcium, 10-20 parts of quartz sand, 5-12 parts of porous quartz powder,1-15 parts of cellulose ether and 1-5 parts of a moisturizing lubricant HS-2. The exterior wall surface dry powder coating has the advantages that the comprehensive use performance is good, and the raw materials are easy to obtain.

Owner:河南方众环保科技有限公司

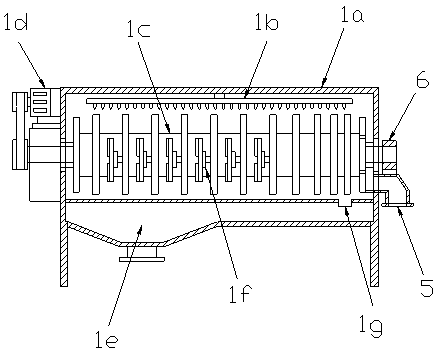

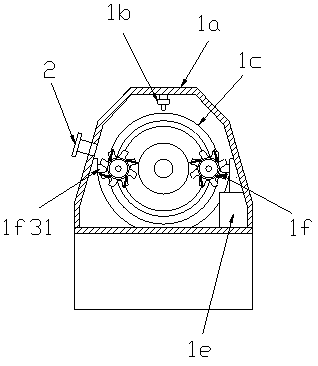

Novel slurry refining and concentrating system

InactiveCN110755914AFast processingIncrease bonding densityGrain treatmentsMoving filtering element filtersFluff pulpProcess engineering

The invention discloses a novel slurry refining and concentrating system. The novel slurry refining and concentrating system structurally comprises a slurry concentrator, a feeding pipe, a supportingframe, a discharging pipe, a slag discharging pipe and a bearing seat, the slurry concentrator is composed of a machine body, a spraying device, a concentrating mechanism, a driving motor set, a slurry transferring cavity, a stirring mechanism and a slurry guide hole. The slurry concentrator utilizes the spraying device to clean and blend raw materials; the stirring mechanism is used for stirringthe raw materials into fluff pulp; the concentrating mechanism is used for refining and concentrating the fluff pulp; the bonding density of the fluff pulp is improved; so that the fluff pulp is not easy to fall off, a hollow shaft uses a filter disc to filter and discharge the fluff pulp, the fluff pulp product prepared through the technology has the advantages of being high in dry bulkiness, good in absorptivity and moderate in fiber bonding strength, the performance requirement of subsequent fluff pulp for producing disposable hygienic products is met, and the quality defect of the fluff pulp product is overcome.

Owner:卢亚丹

Surface protection material for engine containment ring

ActiveCN112375468AModerate bond strengthImprove water resistanceChloropene polymer coatingsAnti-corrosive paintsFiberSilanes

The invention discloses a surface protection material for an engine containment ring. The surface protection material is a putty-like material composed of a component A and a component B, wherein thecomponent A is prepared from 70-80 wt.% of bisphenol A epoxy resin, 10-20 wt.% of nitrile butadiene rubber, 5-15 wt.% of milled asbestos fiber, 0-5 wt.% of fumed silica and 0.5-2 wt.% of silane coupling agent; and the component B is prepared from 90-99 wt% of polyamide resin and 1-10 wt% of aliphatic amine, wherein the component A and the component B are proportioned according to a mass ratio of 1:1-2:1. When in use, the component A and the component B are uniformly mixed, are applied to the surface of a part by adopting a blade coating method, and are cured to form a protective coating. The protective material has proper bonding strength and good water resistance, does not corrode four metals of TC4, GH232, 2A70 and 0Cr18Ni9Ti, and can be appllied to the inner surface of the engine containment ring.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Feed specially for goslings of 0-12 days old

InactiveCN106376729AGuaranteed proteinEasy to eatFood processingAnimal feeding stuffBiotechnologyPhytase

The invention discloses feed specially for goslings of 0-12 days old. The feed comprises, by weight, 25-35 parts of corn, 18-24 parts of wheat, 12-18 parts of rice bran, 20-25 parts of soybean meal, 1-5 parts of a yeast protein, 5-10 parts of corn bran, 10-20 parts of fish meal, 5-15 parts of poplar leaves, 1-6 parts of alfalfa, 1-5 parts of modified casein, 1-2 parts of stone flour, 0.5-1.2 parts of calcium hydrogen phosphate, 0.5-1.2 parts of a composite premix for goslings, 0.01-0.05 parts of a compound enzyme and 0.001-0.008 parts of phytase. The feed is rich in nutrients, effectively improves gosling immunity, has a high feed digestion rate, has high gosling feed intake, has good aggregativity and is convenient for gosling eating.

Owner:ANHUI BAIXIN FEED CO LTD

Chinese herbal medicine-containing feed used for beef cattle and having good palatability

InactiveCN107242362AGood palatabilityIncrease appetiteFood processingAnimal feeding stuffGizzardMultivitamin

The invention discloses a Chinese herbal medicine-containing feed used for beef cattle and having good palatability. Raw materials of the feed comprise northeast Leymus Chinensis, millet flour, corn flour, red bean powder, wheat bran, lotus root starch, white radish powder, fish meal, shell powder, modified soybean protein isolate, composite Chinese herbal medicines, composite vitamins, sodium hydroxymethyl cellulose, galactooligosaccharides, sucrose, frankincense essence, chicken's gizzard membrane, oregano oil, inositol, calcium dihydrogen phosphate, sodium bicarbonate, vegetable oil and edible salt. The Chinese herbal medicine-containing feed used for beef cattle and having good palatability has the advantages of reasonable formula, high utilization rate, good palatability, long storage period, stable performances, effective prevention of diseases, improvement of the physique of the beef cattle, promotion of the growth of the beef cattle, improvement of the beef quality, and increase of the economic and social benefits of beef cattle breeding.

Owner:天长市金农农业发展有限公司

Compound feed for improving mutton quality

The invention discloses a compound feed for improving mutton quality. The compound feed comprises the following raw materials in parts by weight: 90-100 parts of a plant main material, 10-20 parts of meat and bone meal, 2-8 parts of molasses, 2-5 parts of a sodium alginate compound, 1-3 parts of zeolite powder, 0.5-1.5 parts of sepiolite powder, 2-6 parts of corn oil, 0.25-0.45 part of vitamins, and 0.04-0.09 part of trace elements. The sodium alginate compound is prepared through the following technology: drying turf, adding anhydrous calcium carbonate, performing stirring to obtain a mixture, sending the mixture to an anaerobic Muffle furnace, performing heating, performing heat insulation, performing natural cooling to normal temperature, performing grinding, adding carboxymethyl cellulose, sodium alginate and water, performing stirring, adding calcium chloride and aluminium chloride, performing stirring, adding divinyl sulfone, performing stirring, performing filtering, performing washing, and performing drying so as to obtain the sodium alginate compound. The compound feed is low in cost, reasonable in formula and rich in nutrition, and can stimulate the appetite and the absorption function of the sheep at a fattening period, effectively strengthen the constitutions of the sheep and improve the mutton quality.

Owner:丁永胜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com