Polyionic liquid adhesive and preparation method thereof

A polyionic liquid, ionic liquid technology, applied in the direction of adhesives, etc., can solve the problems of glass transition temperature, bonding strength and waterproof performance, difficult to prepare special adhesives, non-structural adhesives, single structure of ionic liquid monomers, etc. To achieve the effect of convenient adjustment, strong operability, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] In addition, the present invention also provides a kind of preparation method of polyionic liquid adhesive, it comprises steps:

[0066] S1: Carry out quaternization reaction with alkoxy-containing halogenated hydrocarbons to N-containing heterocyclic small molecules with polymerizable groups to obtain polymerizable alkoxy-functionalized ionic liquid monomers;

[0067] S2: the ionic liquid monomer is subjected to a free radical polymerization reaction under the condition of an initiator to obtain an alkoxy-functionalized polyionic liquid whose anion is a halogen;

[0068] S3: Perform anion exchange reaction on the polyionic liquid to obtain an alkoxy-functionalized polyionic liquid with target anions, which can be directly used as an adhesive or formulated with other polymer groups to form an adhesive.

[0069] In step S1, halogenated hydrocarbons containing alkoxy groups can be selected or prepared according to needs, and the quaternization reaction is carried out in a...

Embodiment 1

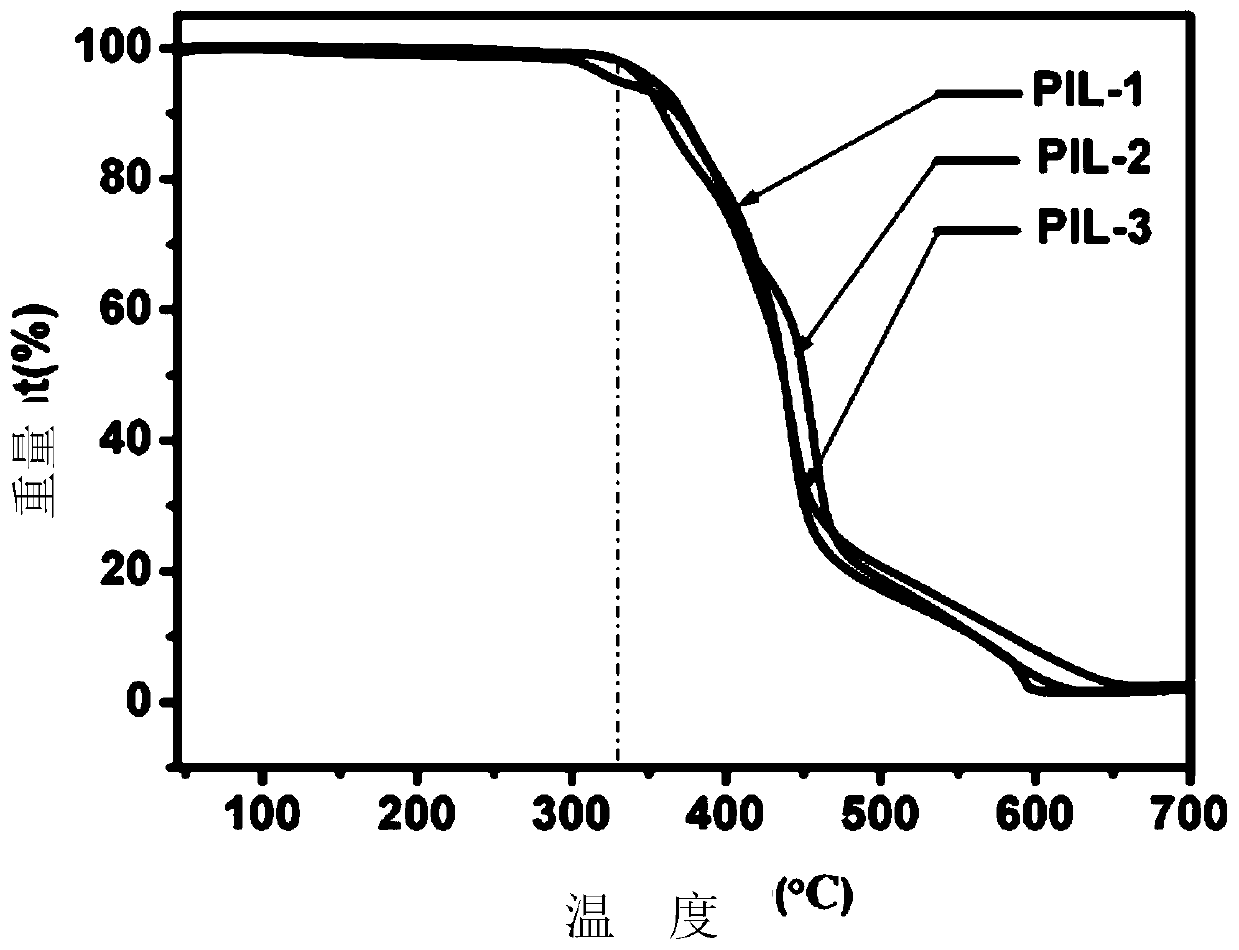

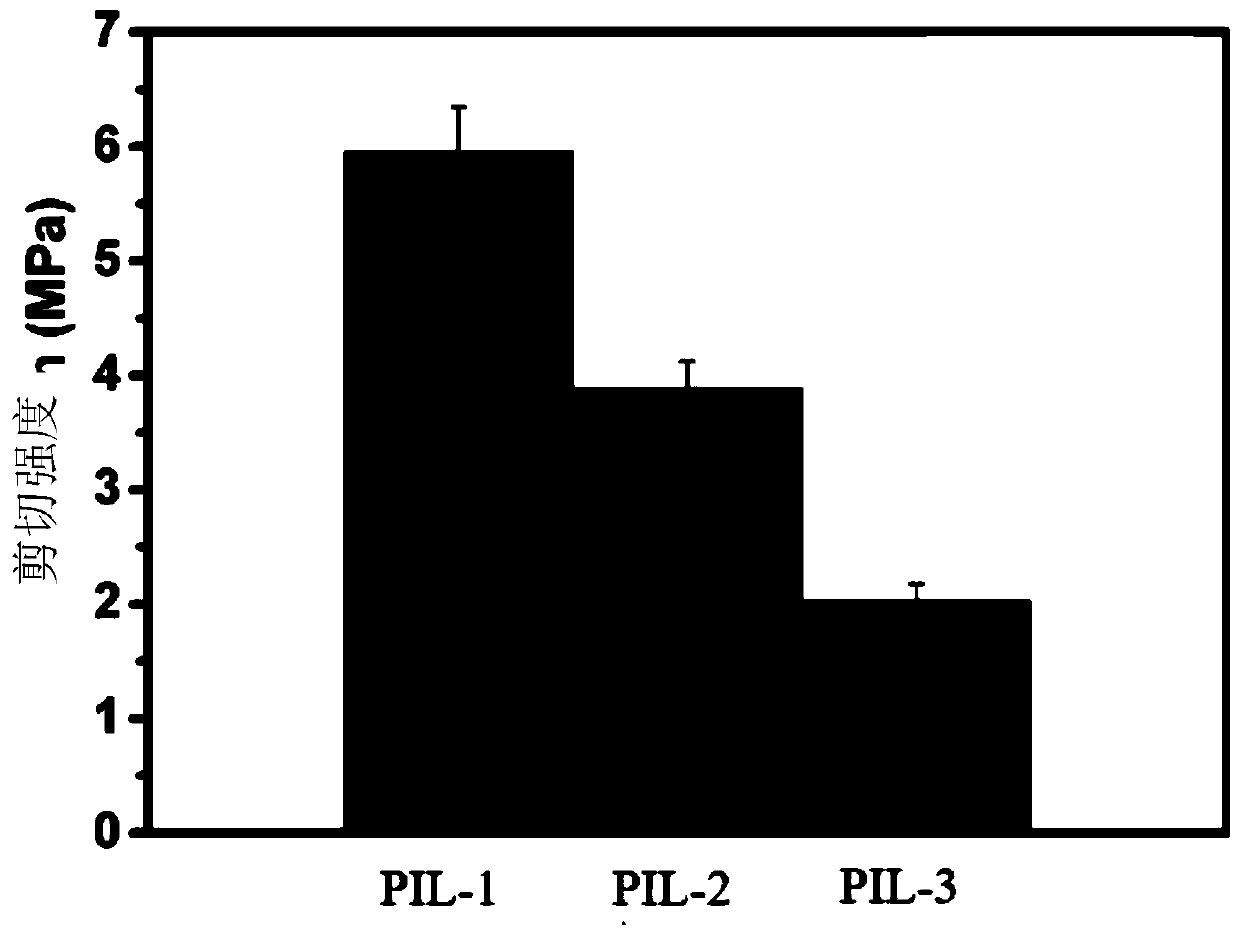

[0080] This embodiment provides a method for preparing an imidazole-type bistrifluoromethylsulfonimide salt polyionic liquid adhesive, which includes the following three steps:

[0081] (1) Quaternization reaction: Weigh 0.1mol 2-chloroethyl ether and 0.1mol N-vinylimidazole and dissolve them in 30mL of DMSO, and continuously stir the reaction at 90°C under the condition of continuously feeding inert gas into the flask 48h. After the reaction was completed and cooled, the mixed solution was precipitated in ethyl acetate and the product was collected, and dried in vacuum to obtain an alkoxy-functionalized ionic liquid monomer with a yield of 72%.

[0082] (2) Radical polymerization reaction: Weigh 0.05 mol of the alkoxy-functionalized ionic liquid monomer obtained above and dissolve it in 50 ml of DMSO, add 0.5 mmol of azobisisobutyronitrile as an initiator, and stir to dissolve. Under the condition of continuously feeding inert gas into the flask, the reaction was continuousl...

Embodiment 2

[0085] This example provides a preparation method of an imidazole-type bistrifluoromethylsulfonimide salt polyionic liquid adhesive, which is based on Example 1 by adding the alkoxy-containing halogenated hydrocarbon in step (1) " 2-Chloroethyl ethyl ether" was replaced by "2-(2-ethoxyethoxy)ethyl chloride". Refer to Example 1 for other operations and conditions, and the product is named PIL-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com