Bearing fault classification method and system based on deep learning network

A technology of deep learning network and fault classification, applied in neural learning methods, biological neural network models, testing of mechanical components, etc., can solve problems such as gradient disappearance, performance degradation, and poor classification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0091] Select normal bearings, roller faults, inner ring faults, outer ring faults, outer ring roller compound faults and inner ring roller compound faults. Point faults for bearings in 11 states.

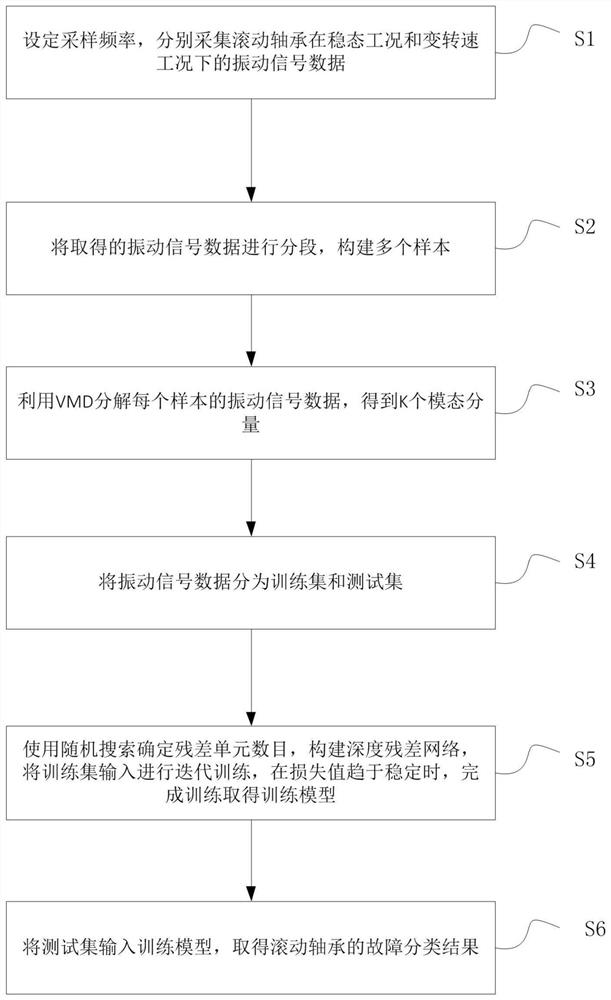

[0092] S1, the collection frequency is set to 20480Hz, (that is, the sampling point data is 20480 points per second), and 8 working conditions are set for rolling bearings (as shown in Table 1), which are 6 steady-state working conditions and 2 For variable speed conditions, F in Table 1 represents the load on the rolling bearing, n represents the speed of the rolling bearing, and n=2000-4000-2000rpm indicates that the speed of the rolling bearing changes from 2000rpm-4000rpm-2000rpm in turn. Collect corresponding vibration signal data for each working condition.

[0093] Table 1

[0094]

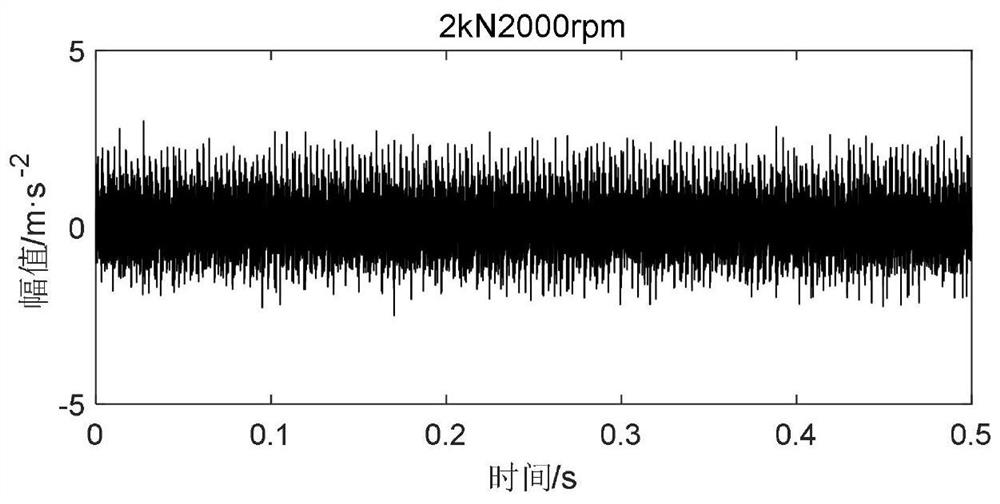

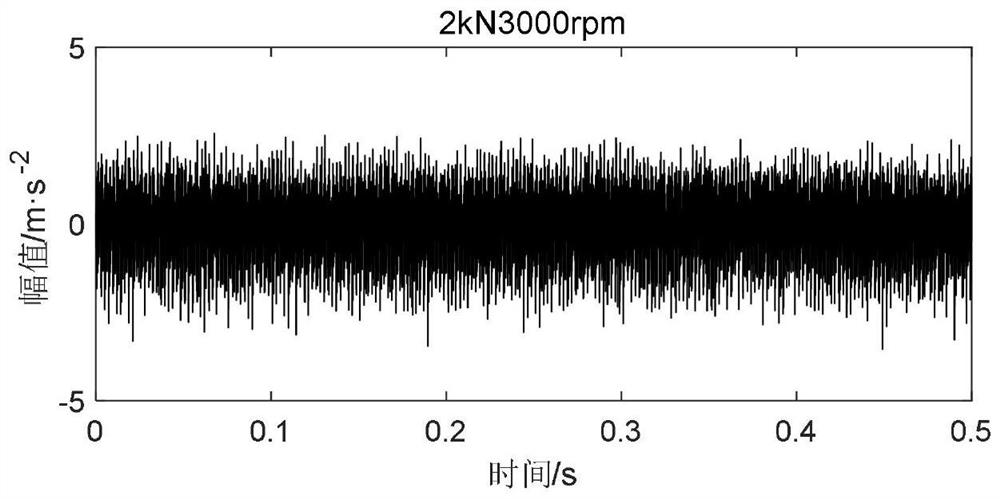

[0095] Among them, the change of the rotational speed has an impact on the vibration signal data. For example, a rolling bearing with a single-point fault on the outer ring, such as Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com