Organosilicone composition, reflecting coating, preparation method therefor and photovoltaic module comprising reflecting coating

A composition and silicone technology, applied in coatings, photovoltaic power generation, reflective/signal coatings, etc., can solve problems affecting coating performance, difficult construction, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

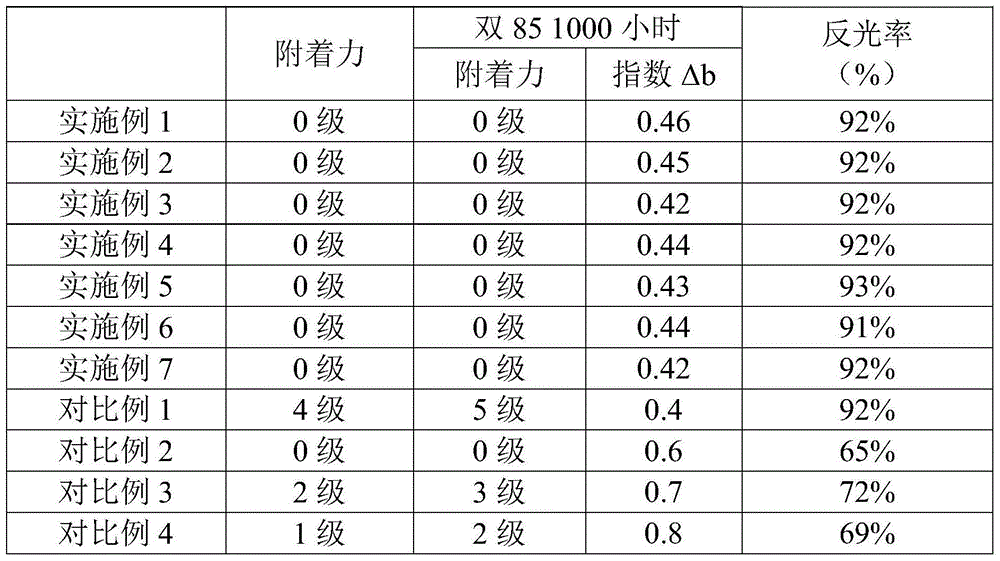

Examples

preparation example Construction

[0022] The hydrogenated epoxy resin or alicyclic epoxy resin-modified hydroxyl-terminated polymethylvinylsiloxane that can be used in the present invention can be selected from commercially available products, or can be synthesized according to conventional synthesis methods. In a preferred embodiment of the present invention, the synthesis method of the above-mentioned hydrogenated epoxy resin or alicyclic epoxy resin modified hydroxyl-terminated polymethyl vinyl siloxane comprises: hydrogenated epoxy resin or alicyclic epoxy resin The epoxy resin and the hydroxyl-terminated methyl vinyl polysiloxane are reacted at 100-150° C. for 6-12 hours under the catalysis of a catalyst (such as triphenylphosphine) to obtain a reaction product.

[0023]In the synthesis of the above-mentioned hydrogenated epoxy resin or cycloaliphatic epoxy resin-modified hydroxyl-terminated polymethylvinylsiloxane, hydrogenated epoxy resins that can be used include but are not limited to hydrogenated bisp...

Embodiment 1

[0047] (1) Preparation of Hydroxyl-terminated Polymethylvinylsiloxane Modified by Hydrogenated Epoxy Resin

[0048]With 100 parts of hydrogenated bisphenol A epoxy resin (commercially purchased from CVC company model is the product of EPALLOY 5000, epoxy equivalent is 230), and 70 parts of methyl vinyl polysiloxane (commercially purchased from Anbi Subcompany model is the product of DA30, wherein the vinyl content is 0.6%), under the catalysis of triphenylphosphine, react at 120 ℃ for 9 hours to obtain the reaction product.

[0049] (2) Mixing of Component A and Component B in the organosilicon composition

[0050] Mixing of component A: with 100 parts of α, ω-divinyl polydimethylsiloxane (commercially purchased from Ambia company model VS5000 product, the content of vinyl is 0.16%, viscosity (25 ℃) is 5000CP), 10 parts of hydroxyl-terminated polymethylvinyl siloxane modified by the aforementioned hydrogenated epoxy resin, 10 parts of MQ silicone resin (commercially purchased...

Embodiment 2

[0055] (1) Preparation of hydroxyl-terminated polymethylvinylsiloxane modified by hydrogenated epoxy resin:

[0056] With 100 parts of hydrogenated bisphenol A epoxy resin (commercially purchased from CVC company model is EPALLOY 5000 product, epoxy equivalent is 230), and 200 parts of methyl vinyl polysiloxane (commercially purchased from Ambia The company model is the product of DA30, wherein the vinyl content is 0.6%), under the catalysis of triphenylphosphine, react at 120 ℃ for 9 hours to obtain the reaction product.

[0057] (2) Mixing of Component A and Component B in the organosilicon composition

[0058] Mixing of component A: 81 parts of vinyl dimethyl siloxy end-capped polydimethylsiloxane (commercially purchased from Runhe company model is RH301 product, vinyl content is 0.04%, viscosity (25 ℃) is 100000CP) and 19 parts of vinyl dimethyl siloxy end-capped polydimethylsiloxane (commercially purchased from Ambia company model is VS200 product, the content of vinyl i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com