Compound feed for improving mutton quality

A compound feed and meat quality technology, applied in the field of compound feed to improve mutton meat quality, can solve the problems of restricting the development of sheep breeding industry, unsatisfactory income of farmers, unsatisfactory mutton meat quality, etc. The effect of biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

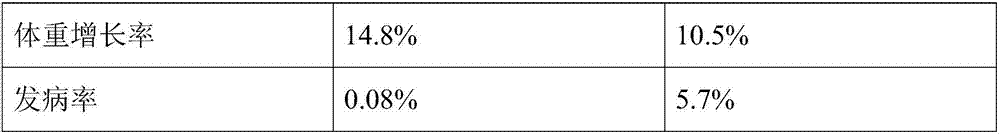

Examples

Embodiment 1

[0016] A compound feed for improving mutton meat quality proposed by the present invention, its raw materials include by weight: 90 parts of vegetable main ingredients, 20 parts of meat and bone meal, 2 parts of molasses, 2 parts of sodium alginate compound, 3 parts of zeolite powder, sea 0.5 parts of pumice powder, 6 parts of corn oil, 0.25 parts of vitamins, and 0.09 parts of trace elements.

Embodiment 2

[0018] A compound feed for improving mutton meat quality proposed by the present invention, its raw materials include by weight: 100 parts of vegetable main ingredients, 10 parts of meat and bone meal, 8 parts of molasses, 5 parts of sodium alginate compound, 1 part of zeolite powder, sea 1.5 parts of pumice powder, 2 parts of corn oil, 0.45 parts of vitamins, and 0.04 parts of trace elements.

[0019] The sodium alginate compound is prepared by the following process: dry the peat, add anhydrous calcium carbonate and stir, send it into an oxygen-free muffle furnace, heat up, keep warm, naturally cool to room temperature, grind, add carboxymethyl cellulose and alginic acid Sodium and water were stirred, calcium chloride and aluminum chloride were added to stir, divinyl sulfone was added to stir, filtered, washed and dried to obtain sodium alginate complex.

Embodiment 3

[0021] A compound feed for improving mutton meat quality proposed by the present invention, its raw materials include by weight: 92 parts of vegetable main ingredients, 18 parts of meat and bone meal, 4 parts of molasses, 3 parts of sodium alginate compound, 2.3 parts of zeolite powder, sea 0.8 parts of pumice powder, 5 parts of corn oil, 0.3 parts of vitamins, and 0.07 parts of trace elements.

[0022] The sodium alginate compound is prepared by the following process: dry 8 parts of peat by weight, add 4 parts of anhydrous calcium carbonate and stir, send it into an anaerobic muffle furnace, heat up, keep warm, naturally cool to room temperature, grind, add 3 1 part of carboxymethyl cellulose, 4 parts of sodium alginate, 70 parts of water, stir, add 1.5 parts of calcium chloride, 0.35 parts of aluminum chloride, stir, add 1 part of divinyl sulfone, stir, filter, wash, and dry to obtain sodium alginate Complex.

[0023] The plant main ingredients include by weight: 10 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com