Rubber mat layer for anti-slip carpet

A carpet and anti-slip technology, applied in the carpet field of the textile industry, can solve the problems such as the inability of the rubber cushion to curl and fold, the carpet surface is easy to shift, warp, and affect the use effect, etc., to achieve moderate bonding strength, convenient transportation, and improved use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

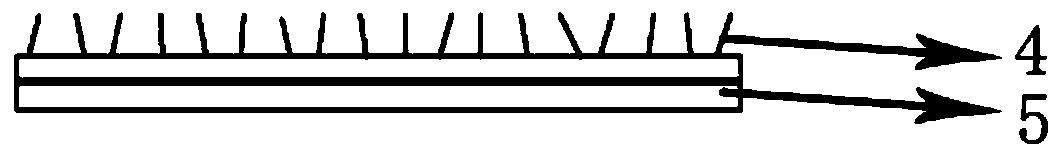

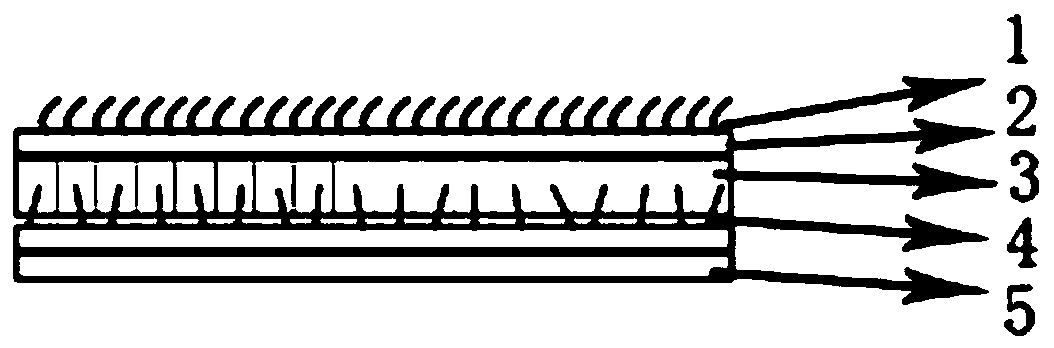

[0028] This embodiment relates to a kind of non-slip carpet rubber pad, such as figure 1 shown, including:

[0029] The anti-slip water-repellent layer 5 (foamed latex layer) of bottom layer;

[0030] The bonding layer 4 of the upper layer is a warp-knitted mesh cloth with several polyester monofilament protrusions.

[0031] The bonding layer is a single-sided structure layer formed by cutting the middle of a three-dimensional interlayer mesh cloth composed of upper and lower layers of warp-knitted mesh cloth and a number of polyester monofilaments that are vertically arranged in the middle to connect the upper and lower layers of warp-knitted mesh cloth; The three-dimensional interlayer mesh fabric is specifically woven with 80D polyester monofilament yarn.

[0032] The included angle between the polyester monofilament protrusions and the warp-knitted mesh fabric is between 40° and 60°; the height of the polyester monofilament protrusions is 5mm. The size of a single mesh ...

Embodiment 2

[0035] This embodiment relates to a kind of non-slip carpet rubber pad, such as figure 1 shown, including:

[0036] The anti-slip water-repellent layer 5 (thermoplastic elastomer material layer) of the bottom layer;

[0037] The bonding layer 4 of the upper layer is a warp-knitted mesh cloth with several polyester monofilament protrusions.

[0038] The bonding layer is a three-dimensional mesh structure layer formed by cutting the upper and lower layers of warp-knitted mesh cloth and the middle vertically arranged several polyester monofilaments connecting the upper and lower layers of warp-knitted mesh cloth to form a single-sided structure layer; The three-dimensional mesh structure layer is specifically woven with 20D polyester monofilament yarns.

[0039] The included angle between the polyester monofilament protrusion and the warp-knitted mesh fabric is between 50° and 70°; the height of the polyester monofilament protrusion is 1.5mm. The area of a single mesh on the...

Embodiment 3

[0042] This embodiment relates to a kind of non-slip carpet rubber pad, such as figure 1 shown, including:

[0043] The anti-slip water-repellent layer 5 (acrylic fiber resin layer) of bottom layer;

[0044] The bonding layer 4 of the upper layer is a warp-knitted mesh cloth with several polyester monofilament protrusions.

[0045] The bonding layer is a three-dimensional mesh structure layer formed by cutting the upper and lower layers of warp-knitted mesh cloth and the middle vertically arranged several polyester monofilaments connecting the upper and lower layers of warp-knitted mesh cloth to form a single-sided structure layer; The three-dimensional mesh structure layer is specifically woven with 120D polyester monofilament yarns.

[0046]The included angle between the polyester monofilament protrusions and the warp-knitted mesh fabric is between 40° and 60°; the height of the polyester monofilament protrusions is 10mm. The area of a single mesh on the warp-knitted me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com